Sensory Characteristics and Nutritional Quality of Food Products Made with a Biofortified and Lectin Free Common Bean (Phaseolus vulgaris L.) Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

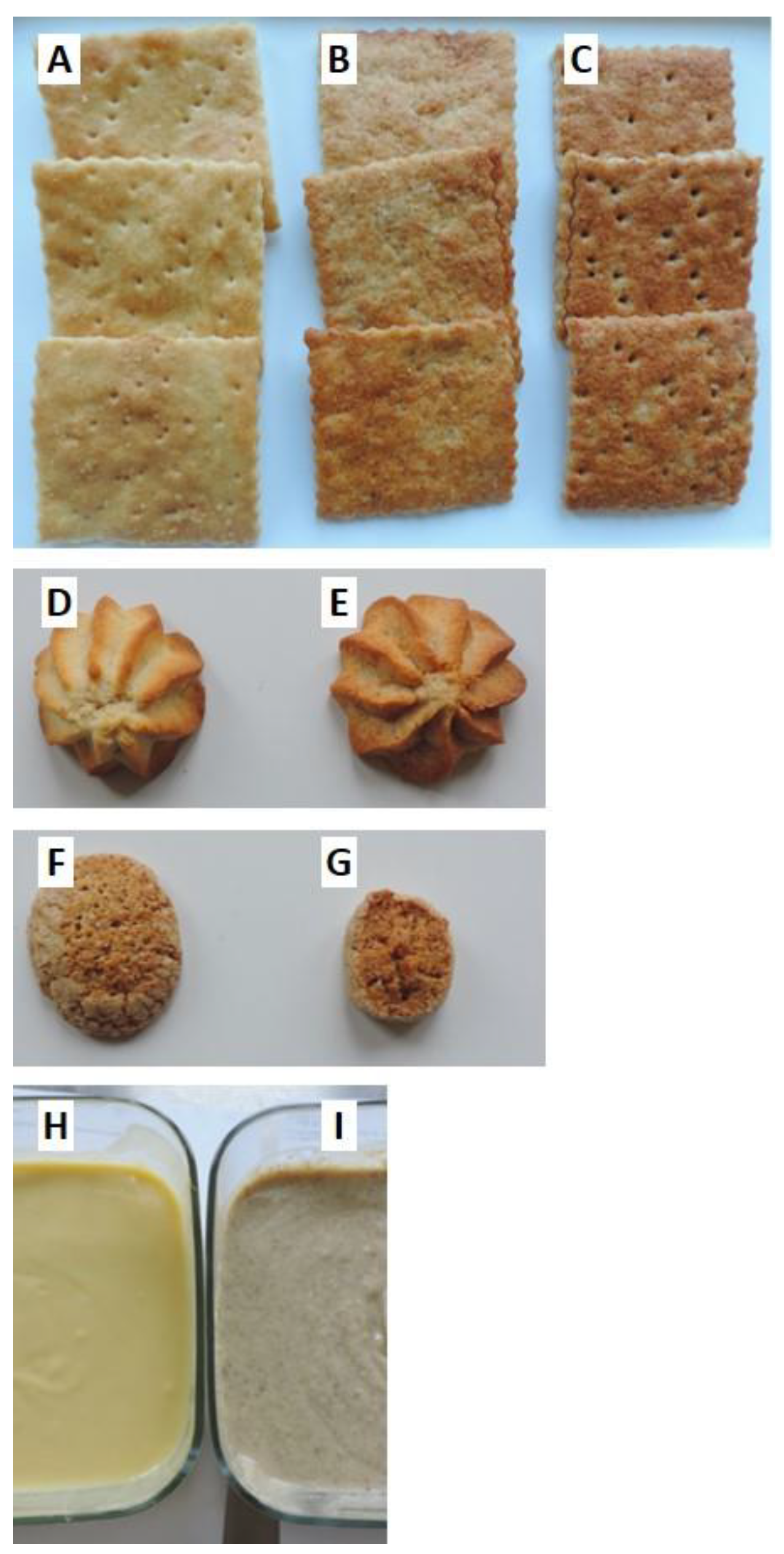

2.2. Products Preparation

2.3. Proximate Composition Analyses

2.4. Hemagglutination Test

2.5. Assay of α-Amylase Inhibitor Activity

2.6. Preparation of the Pepsin, Pancreatin and Bile Extract Digests

2.7. In Vitro Analysis of Iron Bioavailability and Iron Content Evaluation

2.8. Sensorial Evaluation

2.8.1. Descriptive Analysis

2.8.2. Temporal Dominance of Sensations

3. Results

3.1. Proximate Composition

3.2. Evaluation of Hemagglutinating Activity

3.3. Evaluation of α-Amylase Inhibitor Activity

3.4. In Vitro Predicted Glycemic Index

3.5. Assessment of Fe Bioavailability of Bean Biofortified Biscuit 1 in Caco-2 Cells

3.6. Sensory Analyses of Bean-Based Products

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bielefeld, D.; Grafenauer, S.; Rangan, A. The Effects of Legume Consumption on Markers of Glycaemic Control in Individuals with and without Diabetes Mellitus: A Systematic Literature Review of Randomised Controlled Trials. Nutrients 2020, 12, 2123. [Google Scholar] [CrossRef]

- Clark, S.; Duncan, A.M. The role of pulses in satiety, food intake and body weight management. J. Funct. Foods 2017, 38, 612–623. [Google Scholar] [CrossRef]

- Ferreira, H.; Vasconcelos, M.; Gil, A.M.; Pinto, E. Benefits of pulse consumption on metabolism and health: A systematic review of randomized controlled trials. Crit. Rev. Food Sci. Nutr. 2021, 61, 85–96. [Google Scholar] [CrossRef] [PubMed]

- Padhi, E.M.T.; Ramdath, D.D. A review of the relationship between pulse consumption and reduction of cardiovascular disease risk factors. J. Funct. Foods 2017, 38, 635–643. [Google Scholar] [CrossRef]

- Sievenpiper, J.L.; Kendall, C.W.C.; Esfahani, A.; Wong, J.M.W.; Carleton, A.J.; Jiang, H.Y.R.; Bazinet, P.; Vidgen, E.; Jenkins, D.J.A. Effect of non-oil-seed pulses on glycaemic control: A systematic review and meta-analysis of randomised controlled experimental trials in people with and without diabetes. Diabetologia 2009, 52, 1479. [Google Scholar] [CrossRef] [PubMed]

- Rawal, V.; Navarro, D.K. The Global Economy of Pulses; Food and Agriculture Organization: Rome, Italy, 2019. [Google Scholar]

- Escobedo, A.; Mojica, L. Pulse-based snacks as functional foods: Processing challenges and biological potential. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4678–4702. [Google Scholar] [CrossRef]

- Dhurandhar, E.J.; Dawson, J.; Alcorn, A.; Larsen, L.H.; Thomas, E.A.; Cardel, M.; Bourland, A.C.; Astrup, A.; St-Onge, M.P.; Hill, J.O.; et al. The effectiveness of Breakfast recommendations on weight loss: A randomized controlled trial. Am. J. Clin. Nutr. 2014, 100, 507–513. [Google Scholar] [CrossRef] [PubMed]

- Popkin, B.M.; Adair, L.S.; Ng, S.W. Global nutrition transition and the pandemic of obesity in developing countries. Nutr. Rev. 2012, 70, 3–21. [Google Scholar] [CrossRef]

- Kerr, M.A.; Rennie, K.L.; Mccaffrey, T.A.; Wallace, J.M.W.; Hannon-Fletcher, M.P.; Livingstone, M.B.E. Snacking patterns among adolescents: A comparison of type, frequency and portion size between Britain in 1997 and Northern Ireland in 2005. Br. J. Nutr. 2009, 101, 122–131. [Google Scholar] [CrossRef]

- World Health Organization. Obesity and Overweight. Available online: https://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight (accessed on 3 November 2021).

- Sparvoli, F.; Laureati, M.; Pilu, R.; Pagliarini, E.; Toschi, I.; Giuberti, G.; Fortunati, P.; Daminati, M.G.; Cominelli, E.; Bollini, R. Exploitation of common bean flours with low antinutrient content for making nutritionally enhanced biscuits. Front. Plant Sci. 2016, 7, 928. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Bioactive compounds, antioxidant activity, and sensory analysis of rice-based extruded snacks-like fortified with bean and carob fruit flours. Foods 2019, 8, 381. [Google Scholar] [CrossRef] [PubMed]

- Maia, L.C.; Nano, R.M.W.; dos Santos, W.P.C.; de Oliveira, F.S.; Barros, C.O.; de Souza Miranda, K.E. Evaluation of the nutritional quality of cereal bars made with pulse flours using desirability functions. Food Sci. Technol. Int. 2021, 27, 702–711. [Google Scholar] [CrossRef] [PubMed]

- Mecha, E.; Correia, V.; da Silva, A.B.; Ferreira, A.; Sepodes, B.; Figueira, M.E.; Patto, M.C.V.; Rosário Bronze, M. Improvement of wheat cookies’ nutritional quality, by partial substitution with common bean and maize flours, sustained human glycemia and enhanced satiety perception. Cereal Chem. 2021, 98, 1123–1134. [Google Scholar] [CrossRef]

- Anton, A.A.; Fulcher, R.G.; Arntfield, S.D. Physical and nutritional impact of fortification of corn starch-based extruded snacks with common bean (Phaseolus vulgaris L.) flour: Effects of bean addition and extrusion cooking. Food Chem. 2009, 113, 989–996. [Google Scholar] [CrossRef]

- Di Cairano, M.; Condelli, N.; Galgano, F.; Caruso, M.C. Experimental gluten-free biscuits with underexploited flours versus commercial products: Preference pattern and sensory characterisation by Check All That Apply Questionnaire. Int. J. Food Sci. Technol. 2021, 1–9. [Google Scholar] [CrossRef]

- Simons, C.W.; Hall, C. Consumer acceptability of gluten-free cookies containing raw cooked and germinated pinto bean flours. Food Sci. Nutr. 2018, 6, 77–84. [Google Scholar] [CrossRef]

- Saeed, S.M.G.; Ali, S.A.; Ali, R.; Naz, S.; Sayeed, S.A.; Mobin, L.; Ahmed, R. Utilization of Vigna mungo flour as fat mimetic in biscuits: Its impact on antioxidant profile, polyphenolic content, storage stability, and quality attributes. Legum. Sci. 2020, 2, e58. [Google Scholar] [CrossRef]

- Granito, M.; Valero, Y.; Zambrano, R. Baked product development based fermented legumes and cereals for school children snack. Arch. Latinoam. Nutr. 2010, 60, 85–92. [Google Scholar]

- Bogue, J.; Collins, O.; Troy, A.J. Market analysis and concept development of functional foods. In Developing New Functional Food and Nutraceutical Products, 1st ed.; Bagch, D., Nair, S., Eds.; Academic Press: San Diego, CA, USA, 2017; pp. 29–45. [Google Scholar] [CrossRef]

- Hayat, I.; Ahmad, A.; Masud, T.; Ahmed, A.; Bashir, S. Nutritional and Health Perspectives of Beans (Phaseolus vulgaris L.): An Overview. Crit. Rev. Food Sci. Nutr. 2014, 54, 580–592. [Google Scholar] [CrossRef]

- Petry, N.; Boy, E.; Wirth, J.P.; Hurrell, R.F. Review: The potential of the common bean (Phaseolus vulgaris) as a vehicle for iron biofortification. Nutrients 2015, 7, 1144–1173. [Google Scholar] [CrossRef]

- Cominelli, E.; Rodiño, A.P.; De Ron, A.M.; Sparvoli, F. Genetic approaches to improve common bean nutritional quality: Current knowledge and future perspectives. In Quality Breeding in Field Crops; Qureshi, A.M.I., Dar, Z.A., Wani, S.H., Eds.; Springer: Cham, Switzerland, 2019; ISBN 978-3-030-04608-8. [Google Scholar]

- Noah, N.D.; Bender, A.E.; Reaidi, G.B.; Gilbert, R.J. Food poisoning from raw red kidney beans. Br. Med. J. 1980, 281, 236–237. [Google Scholar] [PubMed]

- Rodhouse, J.C.; Haugh, C.A.; Roberts, D.; Gilbert, R.J. Red kidney bean poisoning in the UK: An analysis of 50 suspected incidents between 1976 and 1989. Epidemiol. Infect. 1990, 105, 485–491. [Google Scholar] [CrossRef] [PubMed]

- Petry, N.; Rohner, F.; Gahutu, J.B.; Campion, B.; Boy, E.; Tugirimana, P.L.; Zimmerman, M.B.; Zwahlen, C.; Wirth, J.P.; Moretti, D. In rwandese women with low iron status, iron absorption from low-phytic acid beans and biofortified beans is comparable, but low-phytic acid beans cause adverse gastrointestinal symptoms. J. Nutr. 2016, 146, 970–975. [Google Scholar] [CrossRef]

- Kumar, S.; Verma, A.K.; Das, M.; Jain, S.K.; Dwivedi, P.D. Clinical complications of kidney bean (Phaseolus vulgaris L.) consumption. Nutrition 2013, 29, 821–827. [Google Scholar] [CrossRef] [PubMed]

- Schlemmer, U.; Frølich, W.; Prieto, R.M.; Grases, F. Phytate in foods and significance for humans: Food sources, intake, processing, bioavailability, protective role and analysis. Mol. Nutr. Food Res. 2009, 53, S330–S375. [Google Scholar] [CrossRef]

- Alonso, R.; Aguirre, A.; Marzo, F. Effects of extrusion and traditional processing methods on antinutrients and in vitro digestibility of protein and starch in faba and kidney beans. Food Chem. 2000, 68, 159–165. [Google Scholar] [CrossRef]

- El-Adawy, T.A. Nutritional composition and antinutritional factors of chickpeas (Cicer arietinum L.) undergoing different cooking methods and germination. Plant Foods Hum. Nutr. 2002, 57, 83–97. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. The effect of extrusion on the bioactive compounds and antioxidant capacity of novel gluten-free expanded products based on carob fruit, pea and rice blends. Innov. Food Sci. Emerg. Technol. 2019, 52, 100–107. [Google Scholar] [CrossRef]

- Vaz Patto, M.C.; Amarowicz, R.; Aryee, A.N.A.; Boye, J.I.; Chung, H.J.; Martín-Cabrejas, M.A.; Domoney, C. Achievements and Challenges in Improving the Nutritional Quality of Food Legumes. CRC Crit. Rev. Plant Sci. 2015, 34, 105–143. [Google Scholar] [CrossRef]

- Wołosiak, R.; Drużyńska, B.; Piecyk, M.; Majewska, E.; Worobiej, E. Effect of Sterilization Process and Storage on the Antioxidative Properties of Runner Bean. Molecules 2018, 23, 1409. [Google Scholar] [CrossRef] [PubMed]

- Confalonieri, M.; Bollini, R.; Berardo, N.; Vitale, A.; Allavena, A. Influence of Phytohemagglutinin on the Agronomic Performance of Beans (Phaseolus vulgaris L.). Plant Breed. 1992, 109, 329–334. [Google Scholar] [CrossRef]

- Bollini, R.; Carnovale, E.; Campion, B. Removal of antinutritional factors from bean (Phaseolus vulgaris L.) seeds. Biotechnol. Agron. Soc. Environ. 1999, 3, 217–219. [Google Scholar]

- Campion, B.; Sparvoli, F.; Doria, E.; Tagliabue, G.; Galasso, I.; Fileppi, M.; Bollini, R.; Nielsen, E. Isolation and characterisation of an lpa (low phytic acid) mutant in common bean (Phaseolus vulgaris L.). Theor. Appl. Genet. 2009, 118, 1211–1221. [Google Scholar] [CrossRef]

- Cominelli, E.; Confalonieri, M.; Carlessi, M.; Cortinovis, G.; Daminati, M.G.; Porch, T.G.; Losa, A.; Sparvoli, F. Phytic acid transport in Phaseolus vulgaris: A new low phytic acid mutant in the PvMRP1 gene and study of the PvMRPs promoters in two different plant systems. Plant Sci. 2018, 270, 1–12. [Google Scholar] [CrossRef]

- Lioi, L.; Sparvoli, F.; Galasso, I.; Lanave, C.; Bollini, R. Lectin-related resistance factors against bruchids evolved through a number of duplication events. Theor. Appl. Genet. 2003, 107, 814–822. [Google Scholar] [CrossRef]

- Santimone, M.; Koukiekolo, R.; Moreau, Y.; Le Berre, V.; Rougé, P.; Marchis-Mouren, G.; Desseaux, V. Porcine pancreatic α-amylase inhibition by the kidney bean (Phaseolus vulgaris) inhibitor (α-AI1) and structural changes in the α-amylase inhibitor complex. Biochim. Biophys. Acta-Proteins Proteom. 2004, 1696, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Barrett, M.L.; Udani, J.K. A proprietary alpha-amylase inhibitor from white bean (Phaseolus vulgaris): A review of clinical studies on weight loss and glycemic control. Nutr. J. 2011, 10, 24. [Google Scholar] [CrossRef] [PubMed]

- Layer, P.; Carlson, G.L.; DiMagno, E.P. Partially purified white bean amylase inhibitor reduces starch digestion in vitro and inactivates intraduodenal amylase in humans. Gastroenterology 1985, 88, 1895–1902. [Google Scholar] [CrossRef]

- Layer, P.; Zinsmeister, A.R.; DiMagno, E.P. Effects of decreasing intraluminal amylase activity on starch digestion and postprandial gastrointestinal function in humans. Gastroenterology 1986, 91, 41–48. [Google Scholar] [CrossRef]

- Petry, N.; Egli, I.; Campion, B.; Nielsen, E.; Hurrell, R. Genetic reduction of phytate in common bean (Phaseolus vulgaris L.) seeds increases iron absorption in young women. J. Nutr. 2013, 143, 1219–1224. [Google Scholar] [CrossRef]

- Cominelli, E.; Galimberti, M.; Pongrac, P.; Landoni, M.; Losa, A.; Paolo, D.; Daminati, M.G.; Bollini, R.; Cichy, K.A.; Vogel-Mikuš, K.; et al. Calcium redistribution contributes to the hard-to-cook phenotype and increases PHA-L lectin thermal stability in common bean low phytic acid 1 mutant seeds. Food Chem. 2020, 321, 126680. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Fortunati, P.; Masoero, F. Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chem. 2015, 175, 43–49. [Google Scholar] [CrossRef]

- Granfeldt, Y. Foods Factors Affecting Metabolic Responses to Cereal Products. Ph.D. Thesis, University of Lund, Lund, Sweden, 1994. [Google Scholar]

- Altabella, T.; Chrispeels, M.J. Tobacco plants transformed with the bean αAI gene express an inhibitor of insect α-amylase in their seeds. Plant Physiol. 1990, 93, 805–810. [Google Scholar] [CrossRef]

- Varner, J.E.; Mense, R.M. Characteristics of the Process of Enzyme Release from Secretory Plant Cells. Plant Physiol. 1972, 49, 187–189. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Marshall, J.J.; Lauda, C.M. Purification and properties of phaseolamin, an inhibitor of α amylase, from the kidney bean, Phaseolus vulgaris. J. Biol. Chem. 1975, 250, 8030–8037. [Google Scholar] [CrossRef]

- Glahn, R.P.; Lee, O.A.; Yeung, A.; Goldman, M.I.; Miller, D.D. Caco-2 cell ferritin formation predicts nonradiolabeled food iron availability in an in vitro digestion/Caco-2 cell culture model. J. Nutr. 1998, 128, 1555–1561. [Google Scholar] [CrossRef]

- Pineau, N.; de Bouillé, A.G.; Lepage, M.; Lenfant, F.; Schlich, P.; Martin, N.; Rytz, A. Temporal Dominance of Sensations: What is a good attribute list? Food Qual. Prefer. 2012, 26, 159–165. [Google Scholar] [CrossRef]

- Le Calvé, B.; Saint-Léger, C.; Gaudreau, N.; Cayeux, I. Capturing key sensory moments during biscuit consumption: Using TDS to evaluate several concurrent sensory modalities. J. Sens. Stud. 2019, 34, e12529. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Carr, B.T.; Carr, B.T. Sensory Evaluation Techniques, 4th ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- International Organization for Standardization. UNI EN ISO 8589 Sensory Analysis-General Guidance for the Design of Test Rooms; International Organization for Standardization: Paris, France, 2014. [Google Scholar]

- Peryam, D.R.; Pilgrim, F.J. Hedonic scale method of measuring food preferences. Food Technol. 1957, 11, 9–14. [Google Scholar]

- Jaworska, D.; Królak, M.; Jezewska-Zychowicz, M. Reformulation of bread rolls using oat fibre: An acceptable way of dietary fibre enrichment? Nutr. Bull. 2020, 45, 189–198. [Google Scholar] [CrossRef]

- Obiro, W.C.; Zhang, T.; Jiang, B. The nutraceutical role of the Phaseolus vulgaris α-amylase inhibitor. Br. J. Nutr. 2008, 100, 1–12. [Google Scholar] [CrossRef]

- Campion, B.; Glahn, R.P.; Tava, A.; Perrone, D.; Doria, E.; Sparvoli, F.; Cecotti, R.; Dani, V.; Nielsen, E. Genetic reduction of antinutrients in common bean (Phaseolus vulgaris L.) seed, increases nutrients and in vitro iron bioavailability without depressing main agronomic traits. Field Crops Res. 2013, 141, 27–37. [Google Scholar] [CrossRef]

- Bellisle, F. Meals and snacking, diet quality and energy balance. Physiol. Behav. 2014, 134, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Ciurzyńska, A.; Cieśluk, P.; Barwińska, M.; Marczak, W.; Ordyniak, A.; Lenart, A.; Janowicz, M. Eating habits and sustainable food production in the development of innovative “healthy” snacks (running title: Innovative and “healthy” snacks). Sustainability 2019, 11, 2800. [Google Scholar] [CrossRef]

- Yadav, A.; Sharma, L.; Singh, P.; Batra, P. Nutritional composition and sensory attributes of gluten-free brownie enriched with kidney beans and functional ingredients. Ann. Biol. 2021, 37, 262–266. [Google Scholar]

- Binou, P.; Yanni, A.E.; Karathanos, V.T. Physical properties, sensory acceptance, postprandial glycemic response, and satiety of cereal based foods enriched with legume flours: A review. Crit. Rev. Food Sci. Nutr. 2020, 1–19. [Google Scholar] [CrossRef]

- Lynch, S.R. Why nutritional iron deficiency persists as a worldwide problem. J. Nutr. 2011, 141, 763S–768S. [Google Scholar] [CrossRef]

- Harvest Plus. Available online: https://www.harvestplus.org (accessed on 3 November 2021).

- Hummel, M.; Talsma, E.F.; Taleon, V.; Londoño, L.; Brychkova, G.; Gallego, S.; Raatz, B.; Spillane, C. Iron, zinc and phytic acid retention of biofortified, low phytic acid, and conventional bean varieties when preparing common household recipes. Nutrients 2020, 12, 658. [Google Scholar] [CrossRef] [PubMed]

- Skalkos, S.; Moschonis, G.; Thomas, C.J.; McMillan, J.; Kouris-Blazos, A. Effect of Lupin-Enriched Biscuits as Substitute Mid-Meal Snacks on Post-Prandial Interstitial Glucose Excursions in Post-Surgical Hospital Patients with Type 2 Diabetes. Nutrients 2020, 12, 1239. [Google Scholar] [CrossRef]

- Foster-Powell, K.; Holt, S.H.A.; Brand-Miller, J.C. International table of glycemic index and glycemic load values: 2002. Am. J. Clin. Nutr. 2002, 76, 5–56. [Google Scholar] [CrossRef]

- Di Cairano, M.; Condelli, N.; Caruso, M.C.; Cela, N.; Tolve, R.; Galgano, F. Use of Underexploited Flours for the Reduction of Glycaemic Index of Gluten-Free Biscuits: Physicochemical and Sensory Characterization. Food Bioprocess Technol. 2021, 14, 1490–1502. [Google Scholar] [CrossRef]

- Natabirwa, H.; Nakimbugwe, D.; Lung’aho, M.; Tumwesigye, K.S.; Muyonga, J.H. Bean-based nutrient-enriched puffed snacks: Formulation design, functional evaluation, and optimization. Food Sci. Nutr. 2020, 8, 4763–4772. [Google Scholar] [CrossRef] [PubMed]

- Nyombaire, G.; Siddiq, M.; Dolan, K.D. Physico-chemical and sensory quality of extruded light red kidney bean (Phaseolus vulgaris L.) porridge. LWT-Food Sci. Technol. 2011, 44, 1597–1602. [Google Scholar] [CrossRef]

- Siddiq, M.; Uebersax, M.A. (Eds.) Dry Beans and Pulses Production, Processing and Nutrition; Wiley: Hoboken, NJ, USA, 2013; ISBN 9780813823874. [Google Scholar]

- Wang, W.; Zhou, X.; Liu, Y. Characterization and evaluation of umami taste: A review. TrAC Trends Anal. Chem. 2020, 127, 115876. [Google Scholar] [CrossRef]

- Sasano, T.; Satoh-Kuriwada, S.; Shoji, N.; Iikubo, M.; Kawai, M.; Uneyama, H.; Sakamoto, M. Important Role of Umami Taste Sensitivity in Oral and Overall Health. Curr. Pharm. Des. 2014, 20, 2750–2754. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.; Son, H.J.; Kim, Y.; Kim, K.H.; Kim, J.T.; Moon, H.; Kim, M.J.; Misaka, T.; Rhyu, M.R. Modulation of sweet taste by umami compounds via sweet taste receptor. PLoS ONE 2015, 10, e0124030. [Google Scholar] [CrossRef]

- Gabriele, M.; Sparvoli, F.; Bollini, R.; Lubrano, V.; Longo, V.; Pucci, L. The Impact of Sourdough Fermentation on Non-Nutritive Compounds and Antioxidant Activities of Flours from Different Phaseolus vulgaris L. Genotypes. J. Food Sci. 2019, 84, 1929–1936. [Google Scholar] [CrossRef] [PubMed]

- David Wesley, S.; André, B.H.M.; Clerici, M. Gluten-free rice & bean biscuit: Characterization of a new food product. Heliyon 2021, 7, e05956. [Google Scholar] [CrossRef]

- Roland, W.S.U.; Pouvreau, L.; Curran, J.; van de Velde, F.; de Kok, P.M.T. Flavor Aspects of Pulse Ingredients. Cereal Chem. 2017, 94, 58–65. [Google Scholar] [CrossRef]

- Siegrist, M.; Hartmann, C.; Keller, C. Antecedents of food neophobia and its association with eating behavior and food choices. Food Qual. Prefer. 2013, 30, 293–298. [Google Scholar] [CrossRef]

- Bech-Larsen, T.; Jensen, B.B. Food quality assessment in parent–child dyads–A hall-test of healthier in-between meals for adolescents. Food Qual. Prefer. 2011, 22, 614–619. [Google Scholar] [CrossRef]

- Flores-Silva, P.C.; Tovar, J.; Reynoso-Camacho, R.; Bello-Pérez, L.A. Impact of Chickpea- and Raw Planta in-Based Gluten-Free Snacks on Weight Gain, Serum Lipid Profile, and Insulin Resistance of Rats Fed with a High-Fructose Diet. Cereal Chem. 2017, 94, 124–127. [Google Scholar] [CrossRef]

| Product | Ingredients | Quantity (g) | % Total | % Bean Flour in | |

|---|---|---|---|---|---|

| Total Flour | Whole Product | ||||

| Cracker 1 | Wheat flour type 2 * | 600 | 38.10 | 40 | 26 |

| Bean flour | 400 | 25.40 | |||

| Water | 550 | 34.92 | |||

| Yeast | 10 | 0.63 | |||

| Salt | 15 | 0.95 | |||

| Cracker 2 | Wheat flour type 2 * | 400 | 24.62 | 60 | 38 |

| Bean flour | 600 | 36.92 | |||

| Water | 600 | 36.92 | |||

| Salt | 15 | 0.92 | |||

| Yeast | 10 | 0.62 | |||

| Biscuit 1 (shortbread) | Butter | 500 | 30.30 | 50 | 20 |

| Milk | 350 | 21.21 | |||

| Wheat flour type 2 * | 325 | 19.70 | |||

| Bean flour | 325 | 19.70 | |||

| Vanilla icing sugar | 150 | 9.09 | |||

| Biscuit 2 (buckwheat biscuit) | Sugar | 350 | 27.08 | 33 | 12 |

| Eggs | 250 | 19.34 | |||

| Butter | 200 | 15.47 | |||

| Whole wheat flour * | 160 | 12.38 | |||

| Buckwheat flour | 160 | 12.38 | |||

| Bean flour | 160 | 12.38 | |||

| Backing | 12.5 | 0.97 | |||

| Cream | Almond milk | 1000 | 28.41 | 100 | 9 |

| Sugar | 300 | 8.52 | |||

| Eggs yolks | 300 | 8.52 | |||

| Bean flour * | 150 | 4.26 | |||

| Lemon peel | 10 | 10 | |||

| Cracker | Biscuit 1 | Biscuit 2 | Cream | |

|---|---|---|---|---|

| Flavor of legumes | DA + TDS | DA + TDS | DA + TDS | DA + TDS |

| Flavor of wholemeal/bran | DA + TDS | DA + TDS | DA + TDS | |

| Flavor of wheat | DA + TDS | |||

| Flavor of butter | DA + TDS | DA + TDS | ||

| Flavor of shortcrust pastry | DA + TDS | |||

| Flavor of biscuit | DA + TDS | |||

| Flavor of almond | DA + TDS | |||

| Flavor of lemon | DA + TDS | |||

| Flavor of cream | DA + TDS | |||

| Flavor of eggs | DA + TDS | |||

| Flavor of biscuit | DA | |||

| Odor of legumes | DA | DA | DA | DA |

| Odor of wholemeal/bran | DA | DA | DA | |

| Odor of butter | DA | |||

| Odor of shortcrust pastry | DA | |||

| Odor of crackers | DA | |||

| Odor of biscuit | DA | |||

| Odor of eggs | DA | |||

| Odor of cream | DA | |||

| Odor of lemon | DA | |||

| Snapping | DA | |||

| Consistency | DA | DA | DA | |

| Crunchiness | DA | DA | DA | |

| Friability | DA | DA | DA | |

| Graininess | DA | DA | DA | DA |

| Viscosity | DA | |||

| Creaminess | DA | |||

| Adhesiveness | DA | DA | DA | |

| Humidity | DA | DA | ||

| Chewiness | DA | |||

| Flouriness | DA | |||

| Astringency | DA | DA | DA | DA |

| Umami | DA + TDS | DA + TDS | DA + TDS | DA + TDS |

| Bitterness | DA | DA | DA | DA |

| Salty | DA + TDS | DA | DA | DA |

| Sweetness | DA + TDS | DA + TDS | DA + TDS |

| Sample | Water | Crude Protein | Crude Lipid | Total Carbohydrates | Ash | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Starch | Saccharose | Glucose | Fructose | Total Dietary Fiber | ||||||

| Cracker 1 | lpa lec− | 7.3 | 19.1 | 3.3 | 44.6 | <LOQ | 0.9 | <LOQ | 16.7 | 6.3 |

| wt | 6.3 | 17.0 | 3.1 | 46.3 | <LOQ | 0.9 | <LOQ | 17.9 | 6.7 | |

| Cracker 2 | lpa lec− | 6.5 | 21.7 | 3.4 | 36.6 | <LOQ | <LOQ | 1.0 | 21.7 | 7.5 |

| wt | 6.9 | 18.5 | 2.2 | 38.5 | <LOQ | 1.1 | 0.5 | 22.8 | 7.8 | |

| Biscuit 1 | lpa lec− | 4.6 | 11.7 | 32.0 | 19.3 | 11.3 | 0.0 | <LOQ | 18.4 | 1.3 |

| wt | 5.0 | 11.0 | 32.9 | 21.2 | 12.7 | 0.0 | 0.0 | 14.8 | 1.5 | |

| Biscuit 2 | lpa lec− | 4.6 | 11.6 | 15.4 | 14.8 | 32.3 | 0.1 | <LOQ | 18.2 | 1.8 |

| wt | 4.5 | 11.0 | 15.0 | 18.6 | 28.5 | 0.0 | <LOQ | 17.7 | 1.8 | |

| Bean flours | lpa lec− | 10.6 | 27.7 | 0.6 | 36.0 | na | na | na | na | 3.5 |

| wt | 10.6 | 23.1 | 1.1 | 44.9 | na | na | na | na | 3.8 | |

| Sample | % Bean Flour in the Total Sample | Expected U α-AI/100 mg Flour | Measured U α-AI/100 mg Flour | % Residual α-AI Activity | |

|---|---|---|---|---|---|

| Control flours | wt | 100 | - | 1552.33 | - |

| lpa lec− | - | 1253.10 | - | ||

| Cracker 1 | wt | 26 | 620.93 | 4.23 | 0.68 |

| lpa lec− | 501.24 | 83.86 | 16.63 | ||

| Cracker 2 | wt | 38 | 931.40 | 2.20 | 0.24 |

| lpa lec− | 640.35 | 207.09 | 32.34 | ||

| Biscuit 1 | wt | 29 a | 494.73 | 101.11 | 20.44 |

| lpa lec− | 399.36 | 204.43 | 51.19 | ||

| Biscuit 2 | wt | 14 a | 232.38 | 87.77 | 37.77 |

| lpa lec− | 187.60 | 157.89 | 84.17 | ||

| Cream | lpa lec− | 24 b | 304.50 | 83.06 | 27.28 |

| Sample | % of Bean Flour in the Total Sample | pGI a | Starch | Saccharose | Dietary Fiber | |

|---|---|---|---|---|---|---|

| Cracker 1 | wt | 26 | 76.6 | 46.3 | <LOQ | 17.9 |

| lpa lec− | 71.4 | 44.6 | <LOQ | 16.7 | ||

| Average | 74.0 | 45.4 | 17.3 | |||

| Cracker 2 | wt | 38 | 61.6 | 38.5 | <LOQ | 22.8 |

| lpa lec− | 55.4 | 36.6 | <LOQ | 21.7 | ||

| Average | 58.5 | 37.5 | 22.2 | |||

| Biscuit 1 | wt | 29 b | 42.9 | 21.2 | 12.7 | 14.8 |

| lpa lec− | 39.8 | 19.3 | 11.3 | 18.4 | ||

| Average | 41.3 | 20.2 | 12.0 | 16.6 | ||

| Biscuit 2 | wt | 14 b | 50.4 | 18.6 | 28.5 | 17.7 |

| lpa lec− | 45.0 | 14.8 | 32.3 | 18.2 | ||

| Average | 47.7 | 16.7 | 30.4 | 17.9 | ||

| Sample | Fe Content (mg/Kg) |

|---|---|

| wt bean flour | 27.03 |

| lpa lec− bean flour | 29.76 |

| wt Biscuit 1 flour | 29.38 |

| lpa lec− Biscuit 1 flour | 30.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sparvoli, F.; Giofré, S.; Cominelli, E.; Avite, E.; Giuberti, G.; Luongo, D.; Gatti, E.; Cianciabella, M.; Daniele, G.M.; Rossi, M.; et al. Sensory Characteristics and Nutritional Quality of Food Products Made with a Biofortified and Lectin Free Common Bean (Phaseolus vulgaris L.) Flour. Nutrients 2021, 13, 4517. https://doi.org/10.3390/nu13124517

Sparvoli F, Giofré S, Cominelli E, Avite E, Giuberti G, Luongo D, Gatti E, Cianciabella M, Daniele GM, Rossi M, et al. Sensory Characteristics and Nutritional Quality of Food Products Made with a Biofortified and Lectin Free Common Bean (Phaseolus vulgaris L.) Flour. Nutrients. 2021; 13(12):4517. https://doi.org/10.3390/nu13124517

Chicago/Turabian StyleSparvoli, Francesca, Silvia Giofré, Eleonora Cominelli, Elena Avite, Gianluca Giuberti, Diomira Luongo, Edoardo Gatti, Marta Cianciabella, Giulia Maria Daniele, Mauro Rossi, and et al. 2021. "Sensory Characteristics and Nutritional Quality of Food Products Made with a Biofortified and Lectin Free Common Bean (Phaseolus vulgaris L.) Flour" Nutrients 13, no. 12: 4517. https://doi.org/10.3390/nu13124517

APA StyleSparvoli, F., Giofré, S., Cominelli, E., Avite, E., Giuberti, G., Luongo, D., Gatti, E., Cianciabella, M., Daniele, G. M., Rossi, M., & Predieri, S. (2021). Sensory Characteristics and Nutritional Quality of Food Products Made with a Biofortified and Lectin Free Common Bean (Phaseolus vulgaris L.) Flour. Nutrients, 13(12), 4517. https://doi.org/10.3390/nu13124517