An Innovative Sensor Integrated with GNSS and Accelerometer for Bridge Health Monitoring

Abstract

1. Introduction

- (1)

- Static differential positioning model: This model refers to technology based on the difference method between stations to eliminate atmospheric and other related errors after accumulating a certain amount of GNSS observation data for a certain period;

- (2)

- Real-time kinematic (RTK) positioning model: The RTK model is a positioning technology that involves a monitoring station continuously receiving corrections of satellite signals and other related errors from a reference station based on their known positions and then obtains a high-precision location in real time;

- (3)

- Network RTK (NRTK) positioning model: The NRTK model is based on RTK technology and utilizes multiple GNSS reference stations around the monitoring station to model satellite signals and other related errors to obtain accurate positioning results;

- (4)

- Precision point positioning (PPP) positioning model: The PPP model is a method used to directly obtain high-precision absolute coordinates of monitoring points based on extra positioning data such as precision orbit and clock deviation, which means that this method does not require reference stations;

- (5)

- PPP–RTK positioning model: The PPP–RTK model combines PPP and RTK technologies, using a small amount of reference station data on the server to model distance-related errors and broadcast them. The user can determine locations in the PPP model within a large area around the reference station.

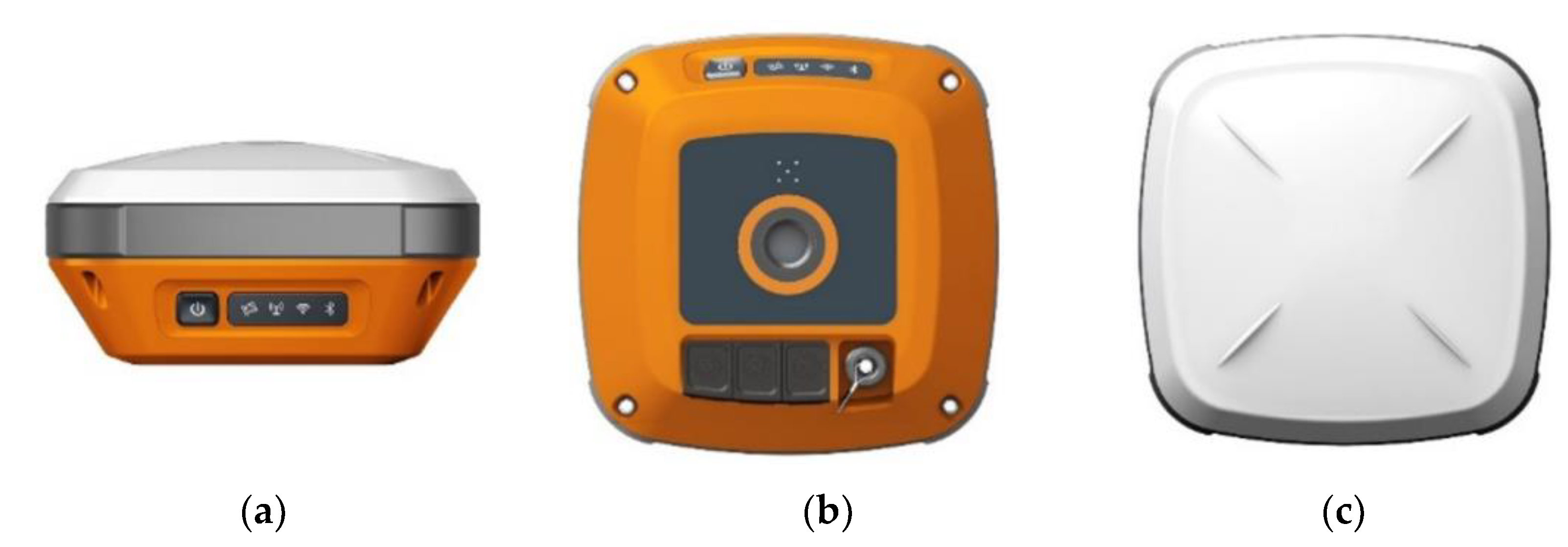

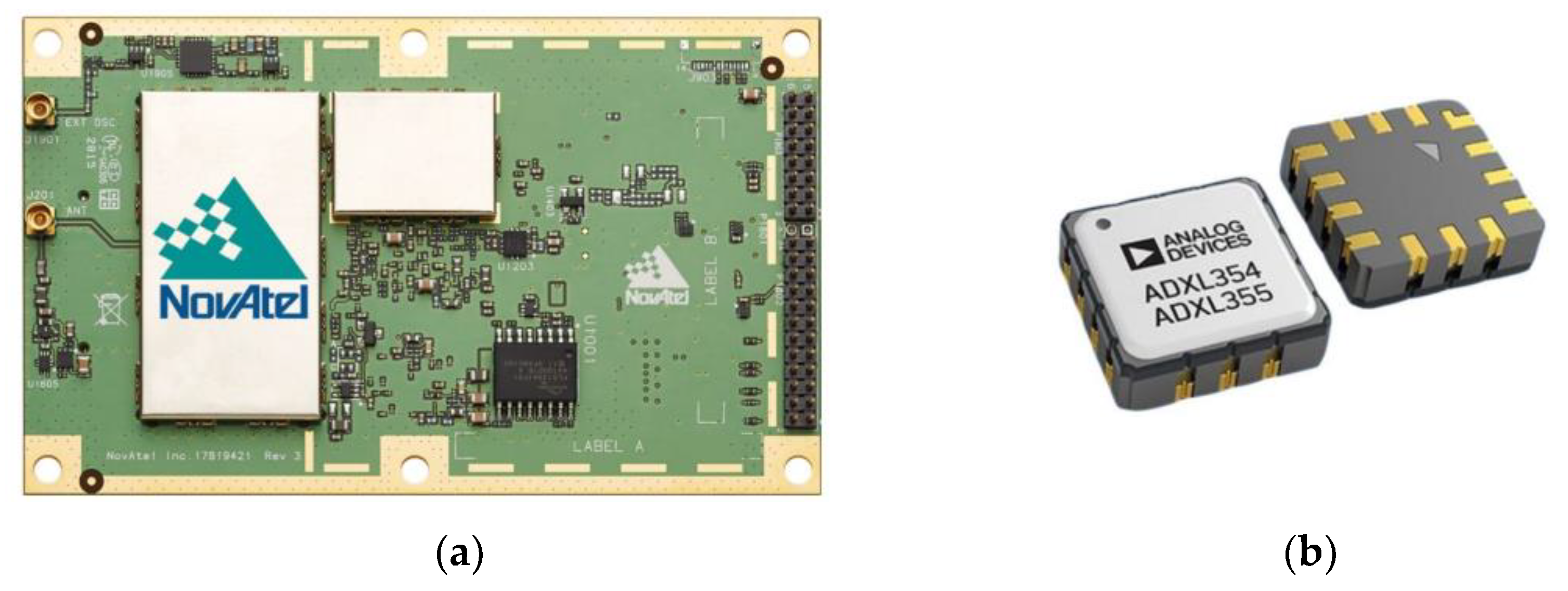

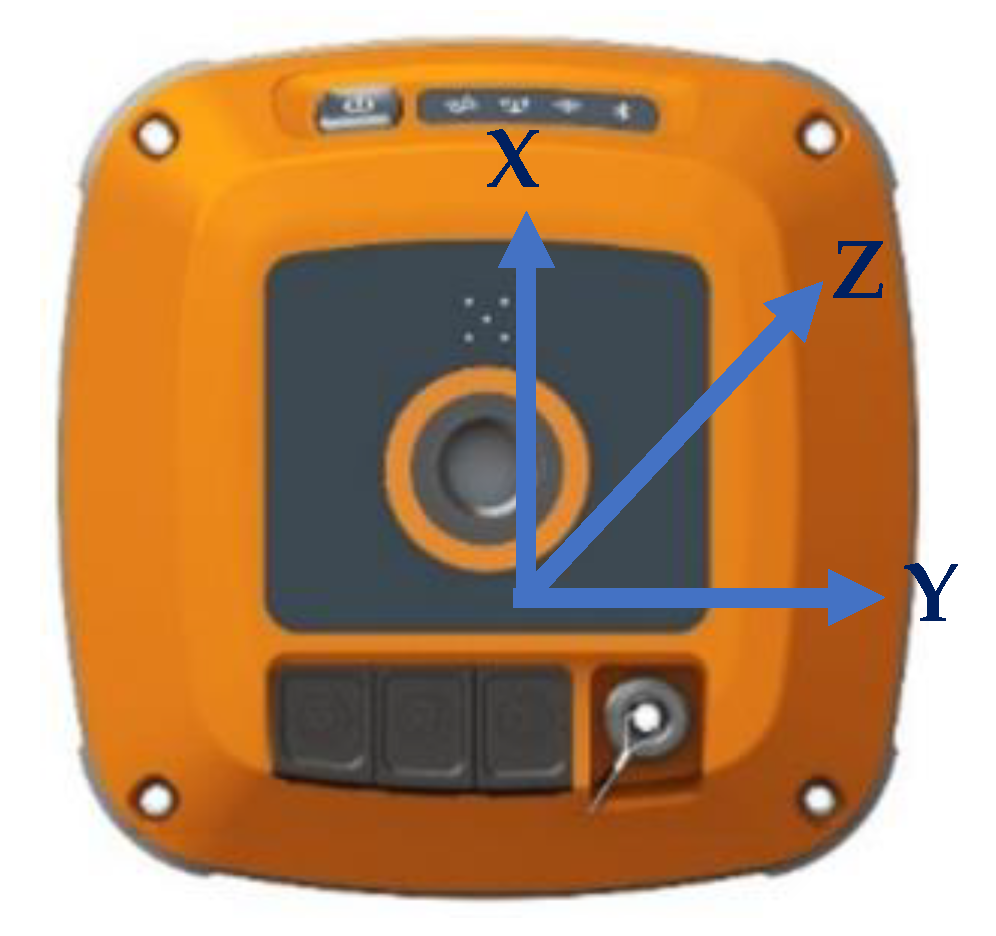

2. Innovative Sensor Introduction

3. Sensor Experiment and Assessment

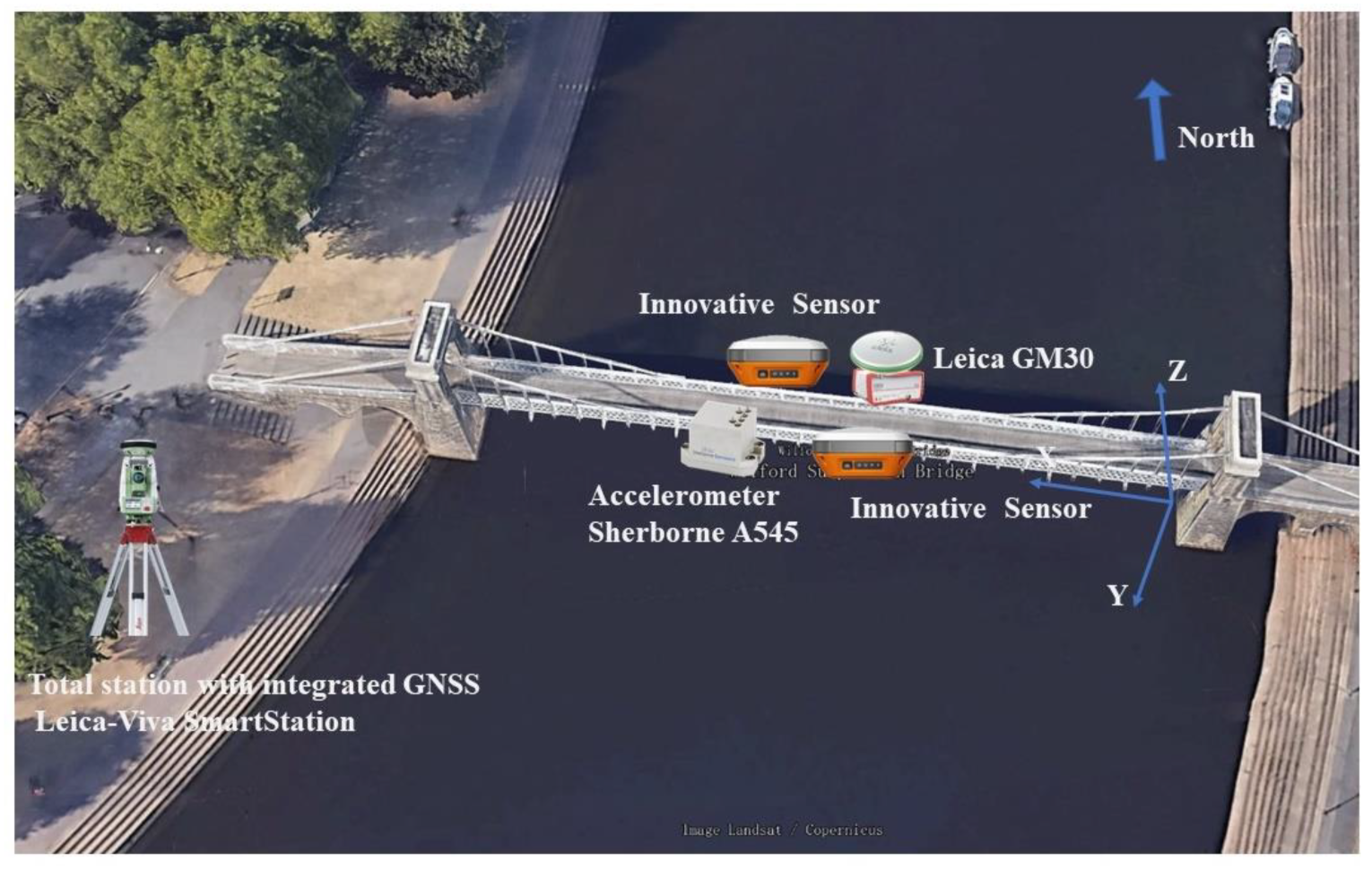

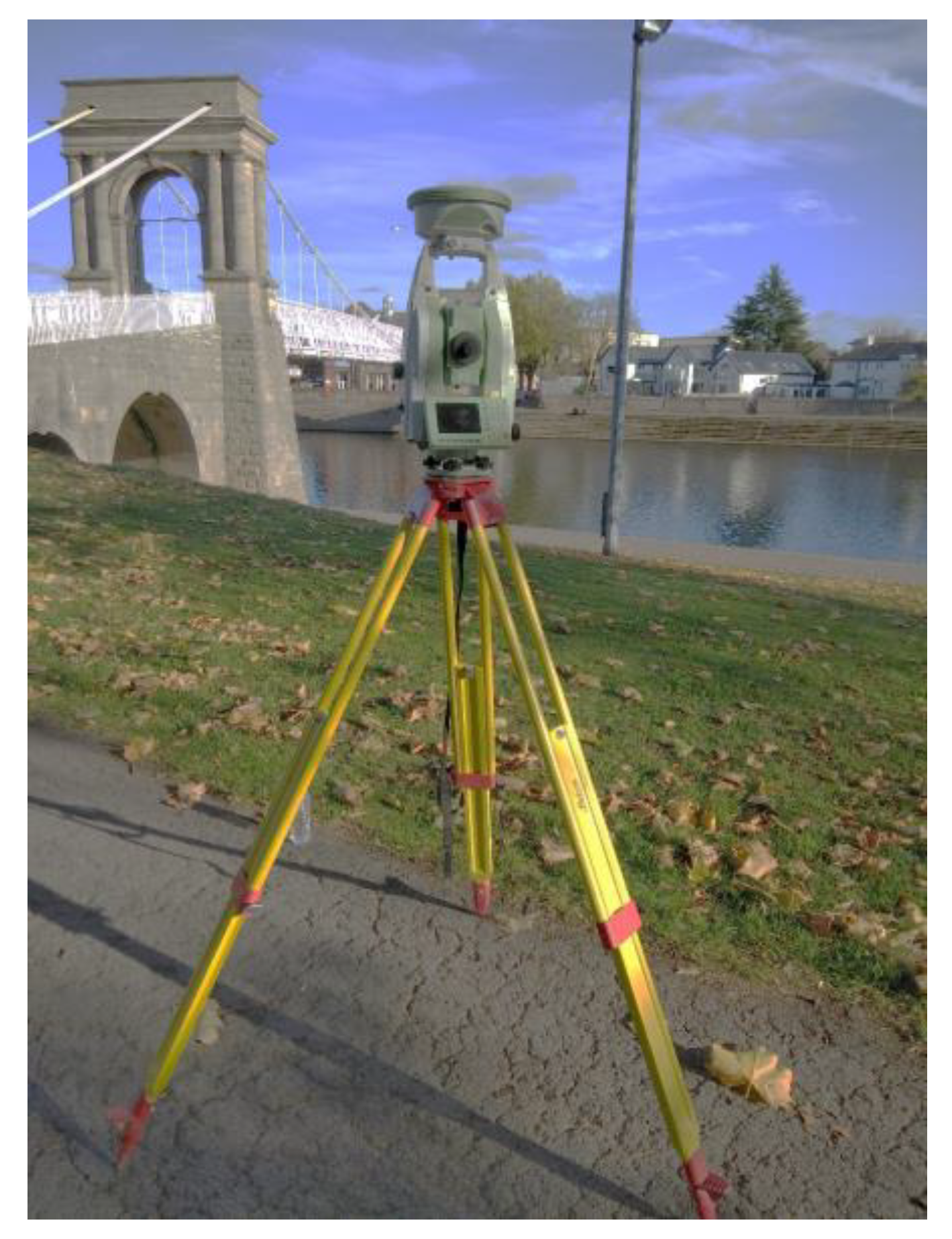

3.1. Experiment Introduction

3.2. Time Synchronization and Geospatial Reference of Accelerometer

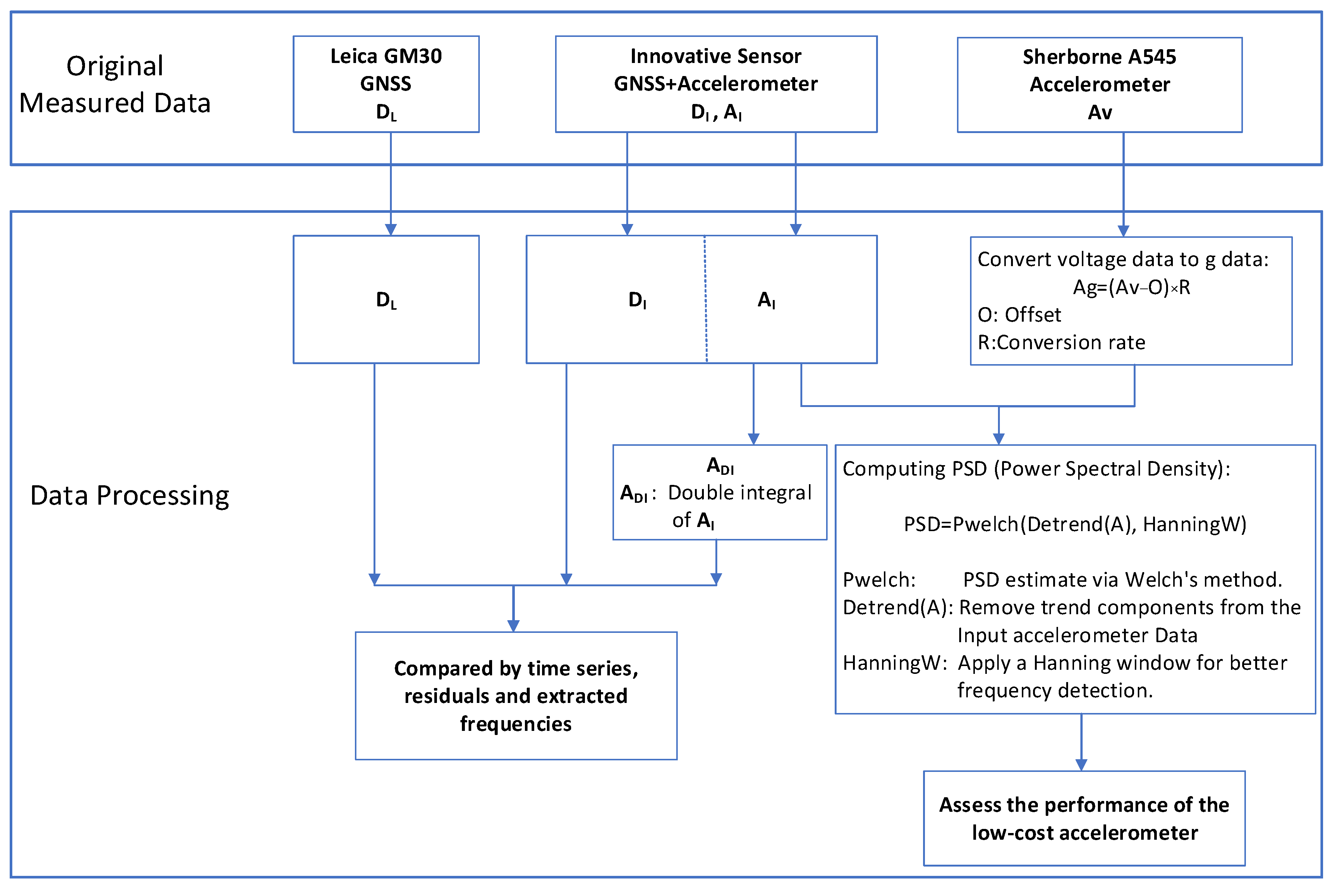

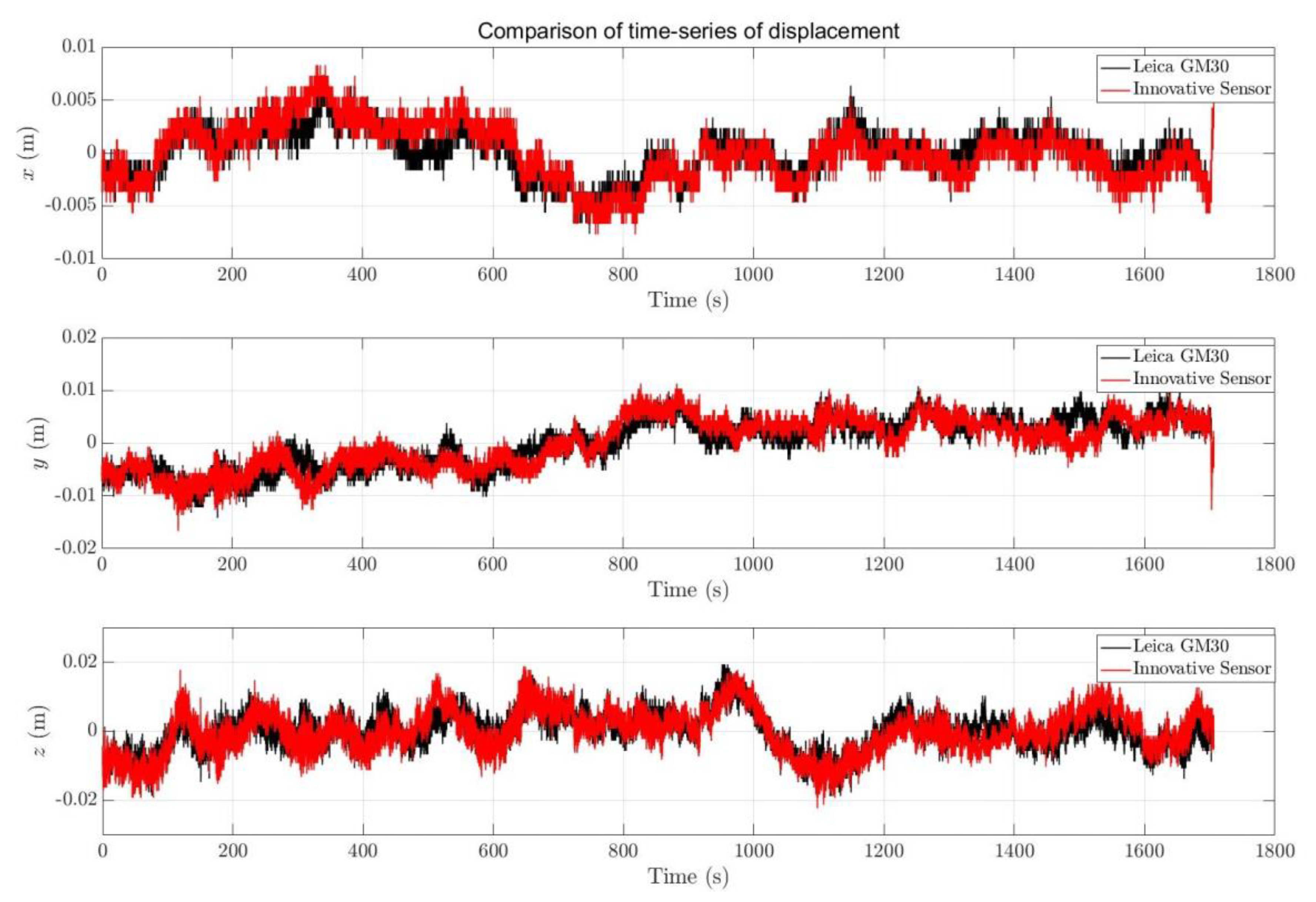

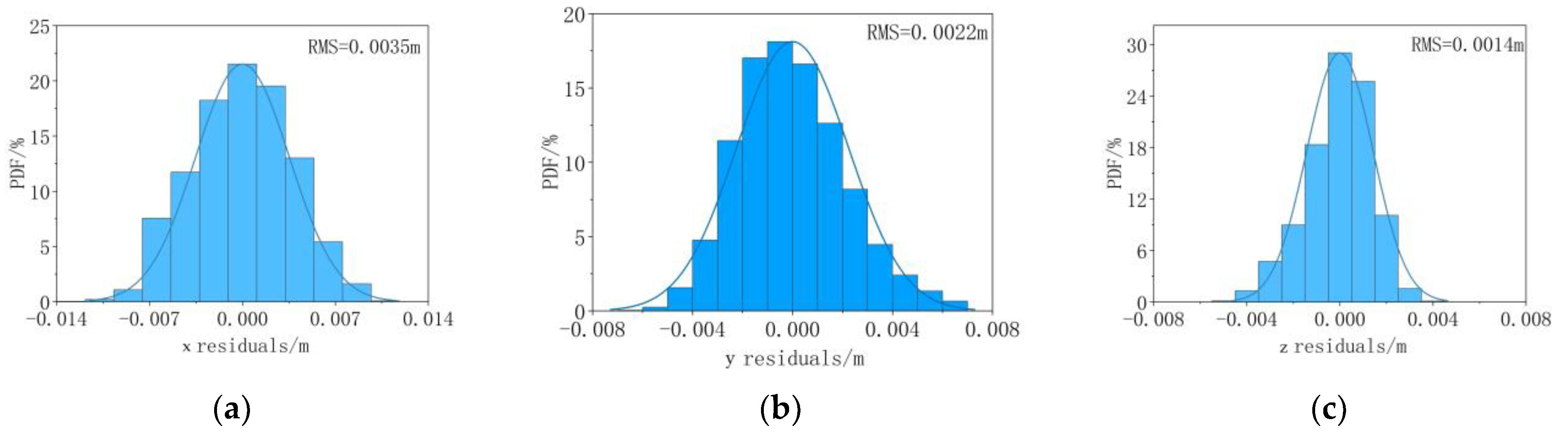

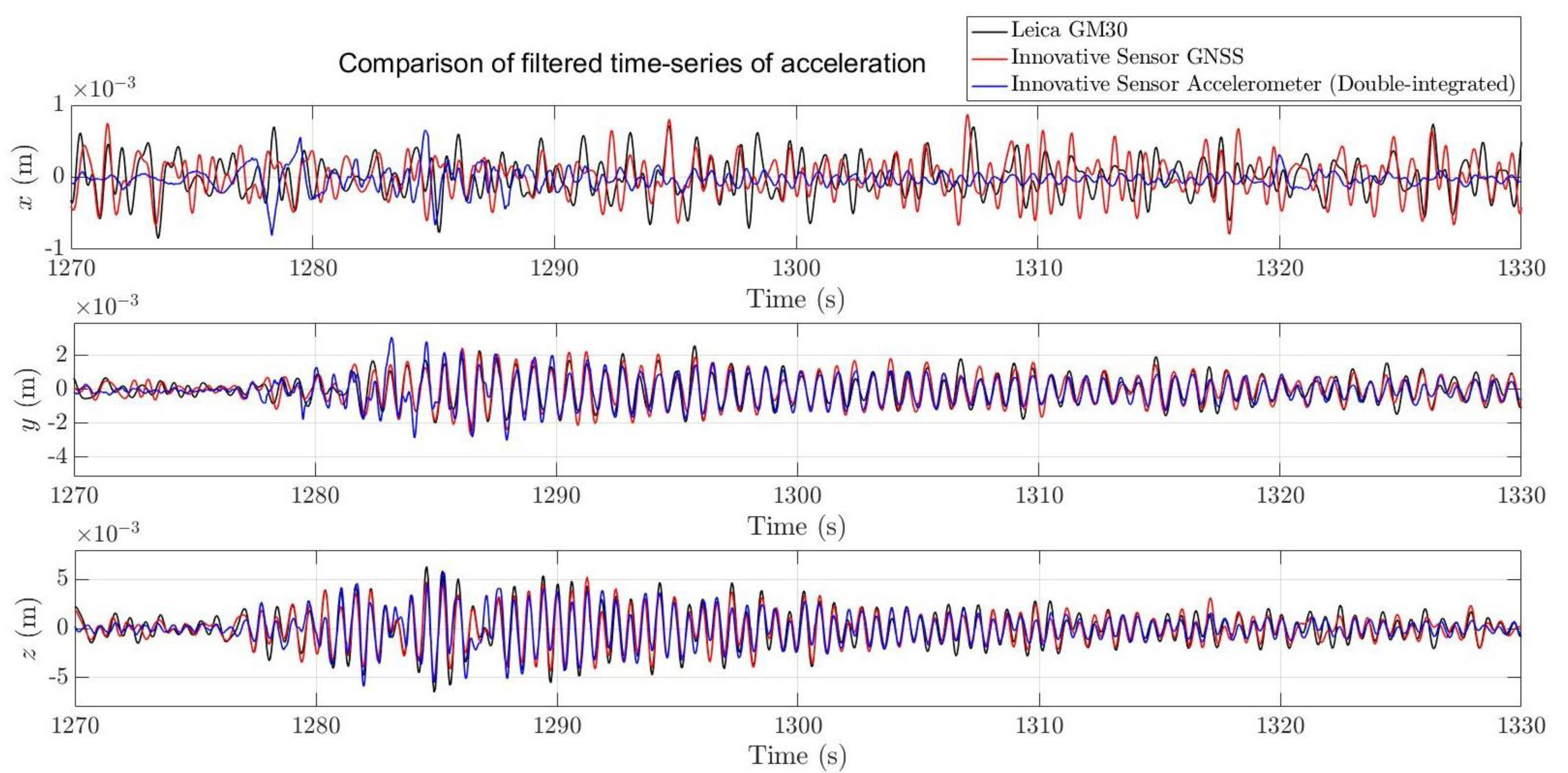

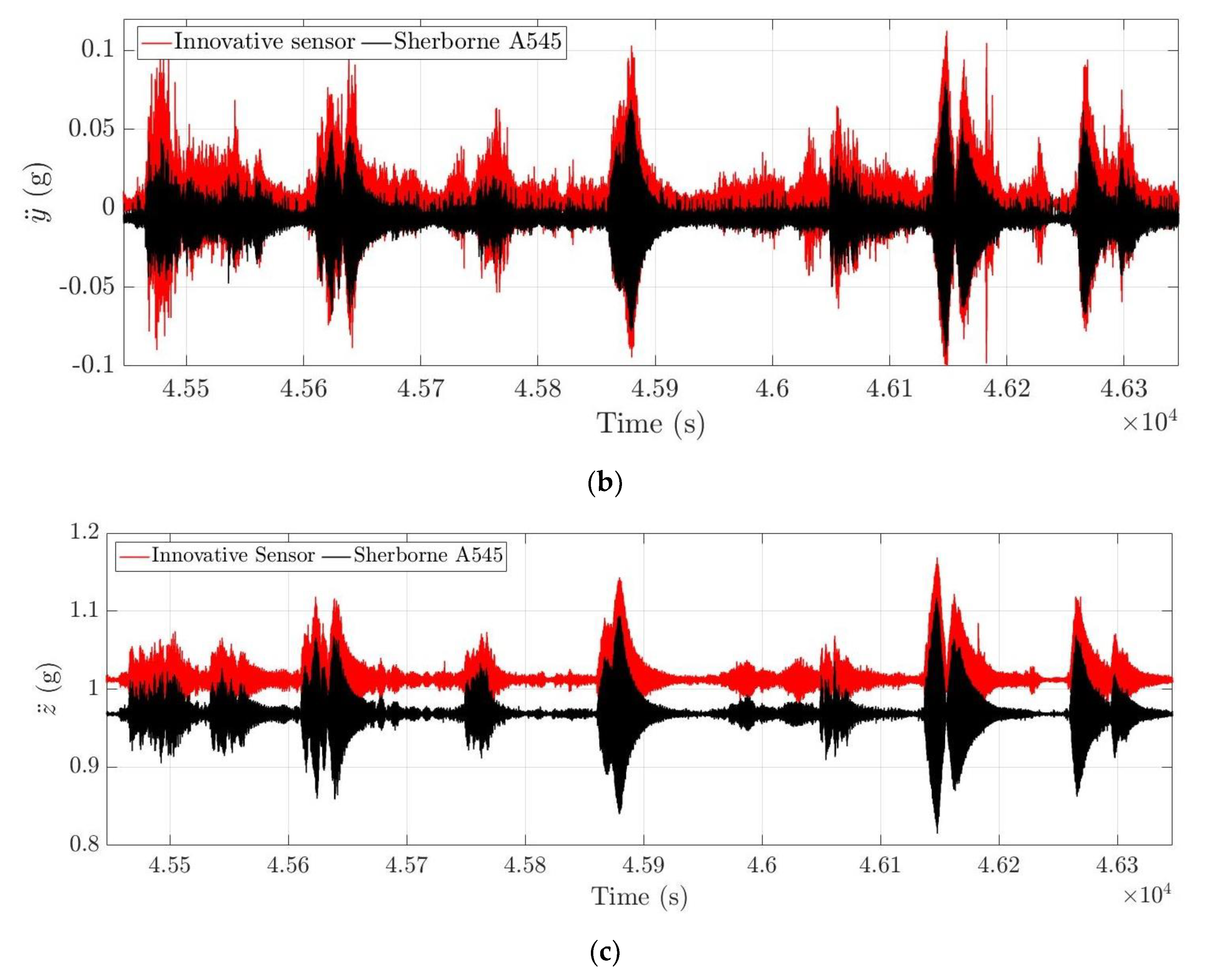

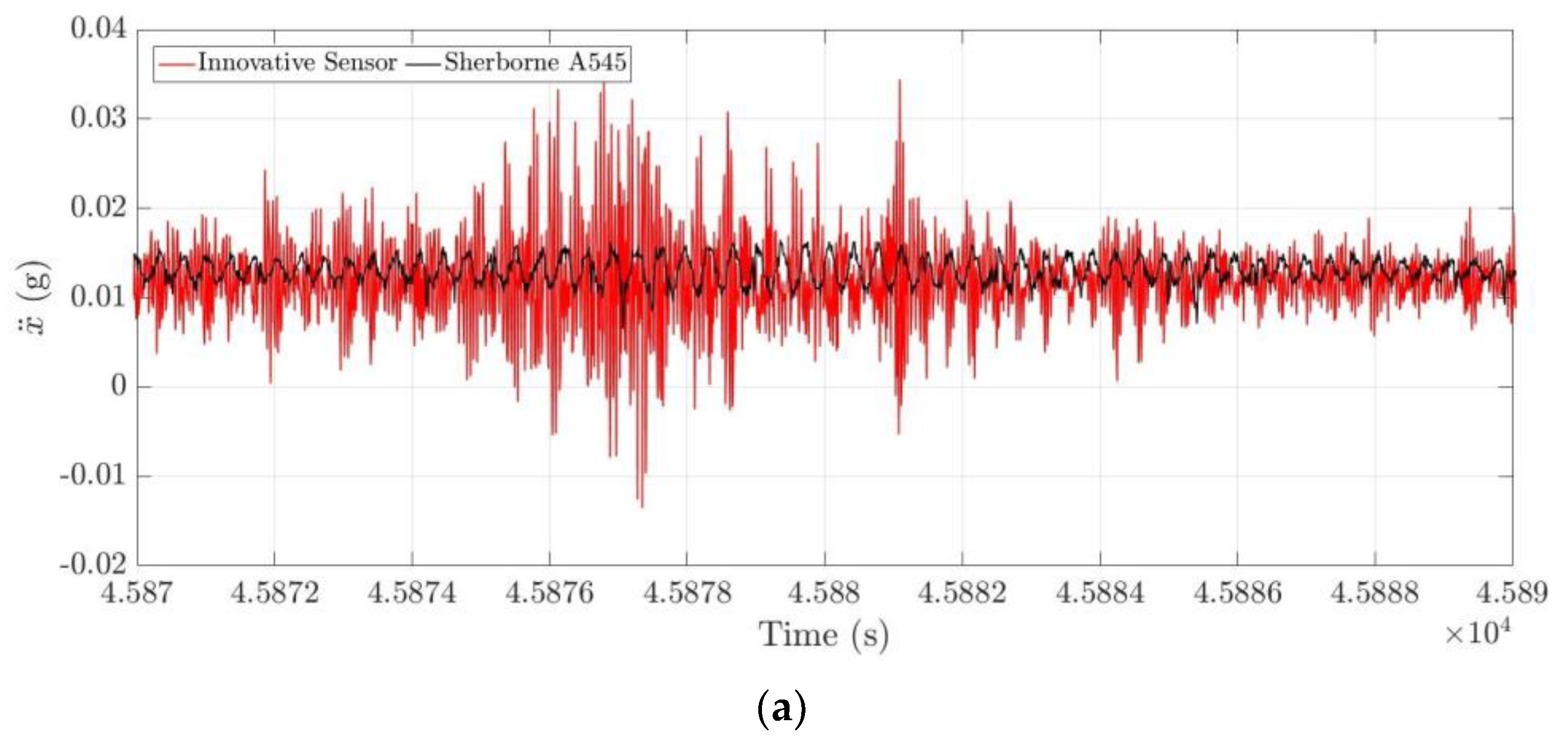

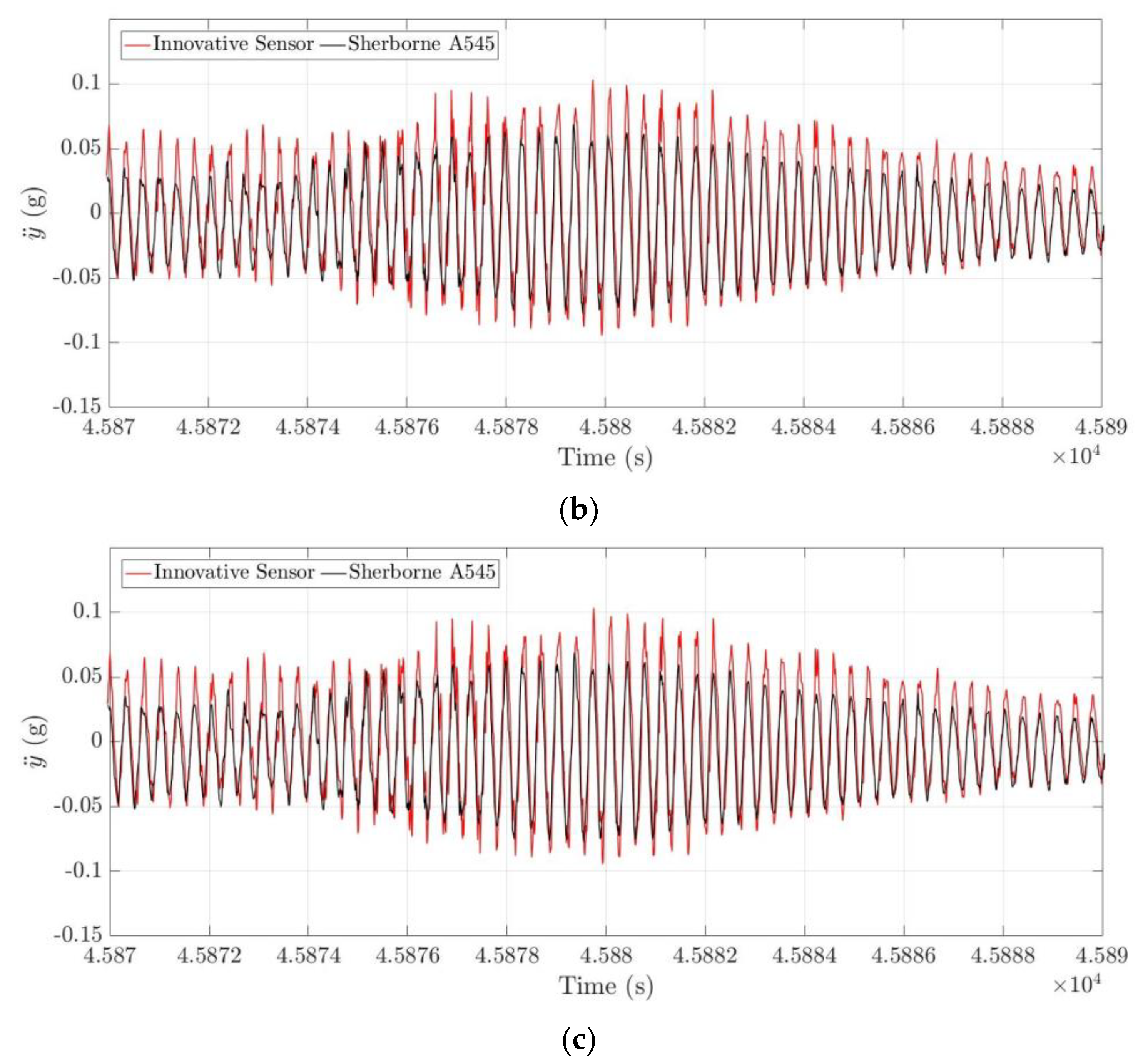

3.3. Data Processing and Analysis

4. Discussion and Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, X.; Roberts, G.; Dodson, A.; Brown, C. GNSS for bridge deformation: Limitations and solutions. In Proceedings of the Third International Conference on Bridge Maintenance, Safety and Management, Porto, Portugal, 16–19 July 2006. [Google Scholar]

- Yu, D.; Yang, Q.; University, C.A. The identification of structural loading response for long-span bridge by using GNSS time series. Technol. Econ. Areas Commun. 2013, 15. [Google Scholar] [CrossRef]

- Davarpanah, S.M.; Sharifzadeh, M.; Sattarvand, J.; Narimani, S. Evaluation of building displacement induced by epb tunneling through GPS-GNSS monitoring system and back analysis technique (tabriz subway twin tunnels). Civ. Eng. J. 2016, 2, 270–285. [Google Scholar] [CrossRef]

- Barzaghi, R.; Cazzaniga, N.; Pinto, L.; Tornatore, V. GNSS methods in dam monitoring: Case studies and future perspectives. In Proceedings of the 3rd Joint International Symposium on Deformation Monitoring (JISDM), Vienna, Austria, 30 March–1 April 2016; AUT: Vienna, Austria, 2016. [Google Scholar]

- Shen, N.; Chen, L.; Liu, J.B.; Wang, L.; Tao, T.Y.; Wu, D.W.; Chen, R.Z. A review of Global Navigation Satellite System (GNSS)-based dynamic monitoring technologies for structural health monitoring. Remote Sens. 2019, 11, 1001. [Google Scholar] [CrossRef]

- Moschas, F.; Stiros, S. Dynamic deflections of a stiff footbridge using 100-Hz GNSS and accelerometer data. J. Surv. Eng. 2015, 141, 04015003. [Google Scholar] [CrossRef]

- Msaewe, H.A.; Psimoulis, P.A.; Hancock, C.M.; Roberts, G.W.; Bonenberg, L. Monitoring the response of Severn Suspension Bridge in the United Kingdom using multi-GNSS measurements. Struct. Control. Health Monit. 2021, 28, e2830. [Google Scholar] [CrossRef]

- Gaxiola-Camacho, J.R.; Bennett, R.; Guzman-Acevedo, G.M.; Gaxiola-Camacho, I.E. Structural evaluation of dynamic and semi-static displacements of the Juarez Bridge using GPS technology. Measurement 2017, 110, 146–153. [Google Scholar]

- Xi, R.J.; Chen, H.; Meng, X.L.; Jiang, W.P.; Chen, Q.S. Reliable dynamic monitoring of bridges with integrated GPS and BeiDou. J. Surv. Eng. 2018, 144, 04018008. [Google Scholar] [CrossRef]

- Yu, L.N.; Xiong, C.B.; Gao, Y.; Zhu, J.S. Combining GNSS and accelerometer measurements for evaluation of dynamic and semi-static characteristics of bridge structures. Meas. Sci. Technol. 2020, 31, 125102. [Google Scholar] [CrossRef]

- Jiang, W.; Liang, Y.; Yu, Z.; Xiao, Y.; Chen, Y.; Chen, Q. Progress and Thoughts on Application of Satellite Positioning Technology in Deformation Monitoring of Water Conservancy Projects. Geomat. Inf. Sci. Wuhan Univ. 2022, 47, 1625–1634. [Google Scholar]

- Mita, A.; Yokoi, I. Fiber Bragg grating accelerometer for structural health monitoring. In Proceedings of the Fifth International Conference on Motion and Vibration Control (MOVIC 2000), Sydney, Australia, 4–8 December 2000. [Google Scholar]

- Kaloop, M.R.; Wan, H.J. Stayed-cable bridge damage detection and localization based on accelerometer health monitoring measurements. Shock Vib. 2015, 2015, 102680. [Google Scholar] [CrossRef]

- Zhu, L.; Fu, Y.; Chow, R.; Spencer, B.F., Jr.; Park, J.W.; Mechitov, K. Development of a high-sensitivity wireless accelerometer for structural health monitoring. Sensors 2018, 18, 262. [Google Scholar] [CrossRef]

- Bedon, C.; Bergamo, E.; Izzi, M.; Noè, S. Prototyping and validation of MEMS accelerometers for structural health monitoring—The case study of the Pietratagliata cable-stayed bridge. J. Sens. Actuator Netw. 2018, 7, 30. [Google Scholar] [CrossRef]

- García, D.; Tcherniak, D. An experimental study on the data-driven structural health monitoring of large wind turbine blades using a single accelerometer and actuator. Mech. Syst. Signal Process. 2019, 127, 102–119. [Google Scholar] [CrossRef]

- Ponzo, F.C.; Ditommaso, R.; Auletta, G.; Ielpo, P. Numerical model calibration of a bridge by using inverse engineering: A case study. In International Conference on Experimental Vibration Analysis for Civil Engineering Structures; Springer: Cham, Switzerland, 2023; pp. 441–450. [Google Scholar]

- Ponzo, F.C.; Auletta, G.; Ielpo, P.; Ditommaso, R. DInSAR–SBAS satellite monitoring of infrastructures: How temperature affects the “Ponte della Musica” case study. J. Civ. Struct. Health Monit. 2024. [CrossRef]

- Murià-Vila, D.; Camargo, J.; Aldama, B.D.; Rodríguez, G.; Aguilar, L.A.; Ayala, M. Structural health monitoring of an instrumented building in Mexico with accelerometers and GPS sensors. In Proceedings of the 6th International Conference on Structural Health Monitoring of Intelligent Infrastructure, Hong Kong, China, 9–11 December 2013. [Google Scholar]

- Kim, K.; Sohn, H. Dynamic displacement estimation by fusing LDV and LiDAR measurements via smoothing based Kalman filtering. Mech. Syst. Signal Process. 2017, 82, 339–355. [Google Scholar] [CrossRef]

- Meng, X.; Dodson, A.H.; Roberts, G.W. Detecting bridge dynamics with GPS and triaxial accelerometers. Eng. Struct. 2007, 29, 3178–3184. [Google Scholar] [CrossRef]

- Bogusz, J.; Figurski, M.; Nykiel, G.; Szolucha, M.; Wrona, M. GNSS-based multi-sensor system for structural monitoring applications. J. Appl. Geod. 2012, 6, 55–64. [Google Scholar] [CrossRef]

- Teunissen, P. Experimental evaluation of smartphone accelerometer and low-cost dual frequency GNSS sensors for deformation monitoring. Sensors 2021, 21, 7946. [Google Scholar]

- Geng, J.; Bock, Y.; Melgar, D.; Crowell, B.W.; Haase, J.S. A new seismogeodetic approach applied to GPS and accelerometer observations of the 2012 brawley seismic swarm: Implications for earthquake early warning. Geochem. Geophys. Geosystems 2013, 14, 2124–2142. [Google Scholar] [CrossRef]

- Xiong, C.; Lu, H.; Zhu, J. Operational modal analysis of bridge structures with data from GNSS/accelerometer measurements. Sensors 2017, 17, 436. [Google Scholar] [CrossRef]

- Xin, S.; Geng, J.; Zeng, R.; Zhang, Q.; Wang, T. In-situ real-time seismogeodesy by integrating multi-GNSS and accelerometers. Measurement 2021, 179, 109453. [Google Scholar] [CrossRef]

- Cina, A.; Manzino, A.M.; Bendea, I.H. Improving GNSS Landslide Monitoring with the Use of Low-Cost MEMS Accelerometers. Appl. Sci. 2019, 9, 5075. [Google Scholar] [CrossRef]

- Hu, L.; Bao, Y.; Sun, Z.; Meng, X.; Tang, C.; Zhang, D. Outlier Detection Based on Nelder-Mead Simplex Robust Kalman Filtering for Trustworthy Bridge Structural Health Monitoring. Remote Sens. 2023, 15, 2385. [Google Scholar] [CrossRef]

- Benedetti, E.; Dermanis, A.; Crespi, M. On the feasibility to integrate low-cost mems accelerometers and GNSS receivers. Adv. Space Res. 2017, 59, 2764–2778. [Google Scholar] [CrossRef]

| Positioning Model | Response Time | Plane Accuracy/mm | Elevation Accuracy/mm |

|---|---|---|---|

| Static differential | Near real time | ||

| RTK | Real time | ||

| NRTK | Real time | ||

| PPP | Real time | ||

| PPP–RTK | Real time |

| Parameter | Item | Comments |

|---|---|---|

| Signal Tracking | GPS | L1 C/A, L1C, L2C, L2P, L5 |

| GLONASS | L1, L2, L3, L5 | |

| Galileo | E1, E5 AltBOC, E5a, E5b, E6 | |

| BeiDou | B1l, B1C, B2a, B2b, B2l, B3l | |

| SBAS/QZSS | L1 C/A, L1C, L2C, L5, LEX | |

| Horizontal Position (Accuracy—RMS) | Single Point L1 | 1.5 m |

| Single Point L1/L2 | 1.2 m | |

| SBAS | 60 cm | |

| DGPS (code) | 40 cm | |

| RTK | 1 cm + 1 ppm |

| Parameter | Test Condition/Comments | Typical Value | Unit |

|---|---|---|---|

| Zero Offset | ±2 g (X, Y, and Z) | ±25 | mg |

| Sensitivity | ±2 g (X, Y, and Z) | 400 | mV/g |

| Sensitivity Change Due to Temperature | −40 °C to +125 °C | ±0.01 | %/°C |

| Nonlinearity | ±2 g | 0.1 | % |

| Noise (Spectral Density) | ±2 g (X, Y, and Z) | 22.5 |

| RTK Positioning Modes | Reference Station (Smoothed) | Monitoring (Instantaneous) | Network RTK (Instantaneous) |

|---|---|---|---|

| Single baseline (<30 km) | Hz: 6 mm + 1 ppm V: 10 mm + 1 ppm | Hz: 8 mm + 1 ppm V: 15 mm + 1 ppm | Hz: 8 mm + 1 ppm V: 15 mm + 1 ppm |

| Network RTK | Hz: 6 mm + 1 ppm V: 10 mm + 1 ppm | Hz: 8 mm + 1 ppm V: 15 mm + 1 ppm | Hz: 8 mm + 1 ppm V: 15 mm + 1 ppm |

| Parameter | Value |

|---|---|

| Zero Offset | ≤±2 mV |

| Nonlinearity | ≤±0.5% FRO |

| Hysteresis | ≤0.02% FRO |

| Resolution | ≤0.0005% FRO |

| Damping Ratio | 0.7 (±0.2) |

| Noise Output | 10 µV (rms) max |

| Axis | Pearson Correlation Coefficients | R-Squared Values | ||

|---|---|---|---|---|

| 20 min Data | 20 s Data | 20 min Data | 20 s Data | |

| X | −0.0098 | −0.19 | 0.000092 | 0.0038 |

| Y | 0.73 | 0.91 | 0.54 | 0.84 |

| Z | 0.92 | 0.98 | 0.84 | 0.95 |

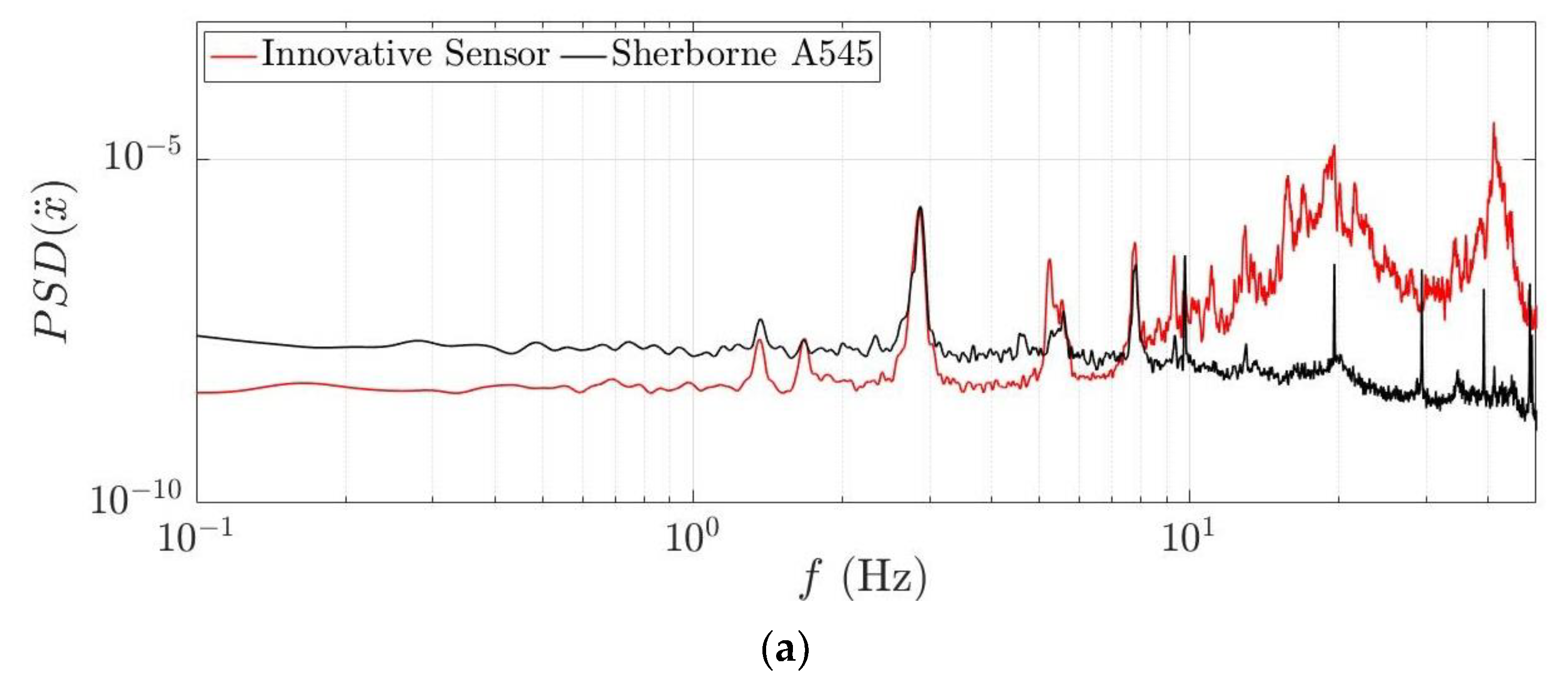

| Sherborne A545 | Innovative Sensor | Difference (%) |

|---|---|---|

| 1.369 | 1.364 | 0.37% |

| 1.675 | 1.680 | 0.30% |

| 2.324 | 2.315 | 0.39% |

| 2.417 | 2.408 | 0.37% |

| 2.873 | 2.861 | 0.42% |

| 4.567 | 4.555 | 0.26% |

| 5.283 | 5.233 | 0.95% |

| 5.583 | 5.542 | 0.73% |

| 7.805 | 7.775 | 0.38% |

| 9.354 | 9.323 | 0.33% |

| 11.14 | 11.1 | 0.36% |

| 11.71 | 11.65 | 0.51% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Zhang, S.; Meng, X.; Nguyen, D.T.; Ye, G.; Li, H. An Innovative Sensor Integrated with GNSS and Accelerometer for Bridge Health Monitoring. Remote Sens. 2024, 16, 607. https://doi.org/10.3390/rs16040607

Xie Y, Zhang S, Meng X, Nguyen DT, Ye G, Li H. An Innovative Sensor Integrated with GNSS and Accelerometer for Bridge Health Monitoring. Remote Sensing. 2024; 16(4):607. https://doi.org/10.3390/rs16040607

Chicago/Turabian StyleXie, Yilin, Song Zhang, Xiaolin Meng, Dinh Tung Nguyen, George Ye, and Haiyang Li. 2024. "An Innovative Sensor Integrated with GNSS and Accelerometer for Bridge Health Monitoring" Remote Sensing 16, no. 4: 607. https://doi.org/10.3390/rs16040607

APA StyleXie, Y., Zhang, S., Meng, X., Nguyen, D. T., Ye, G., & Li, H. (2024). An Innovative Sensor Integrated with GNSS and Accelerometer for Bridge Health Monitoring. Remote Sensing, 16(4), 607. https://doi.org/10.3390/rs16040607

_Sun.png)