Automated BIM Reconstruction of Full-Scale Complex Tubular Engineering Structures Using Terrestrial Laser Scanning

Abstract

:1. Introduction

2. Related Work

3. Methodology

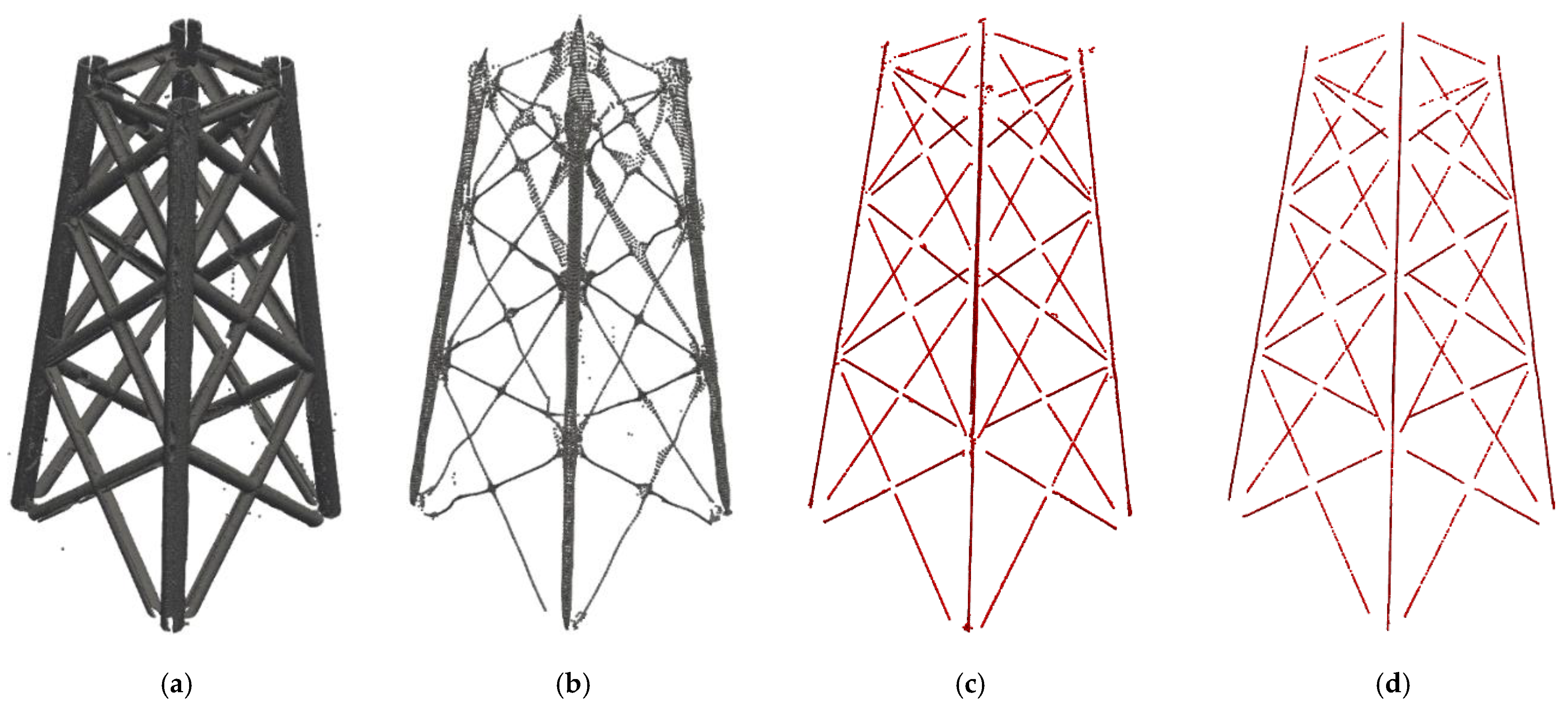

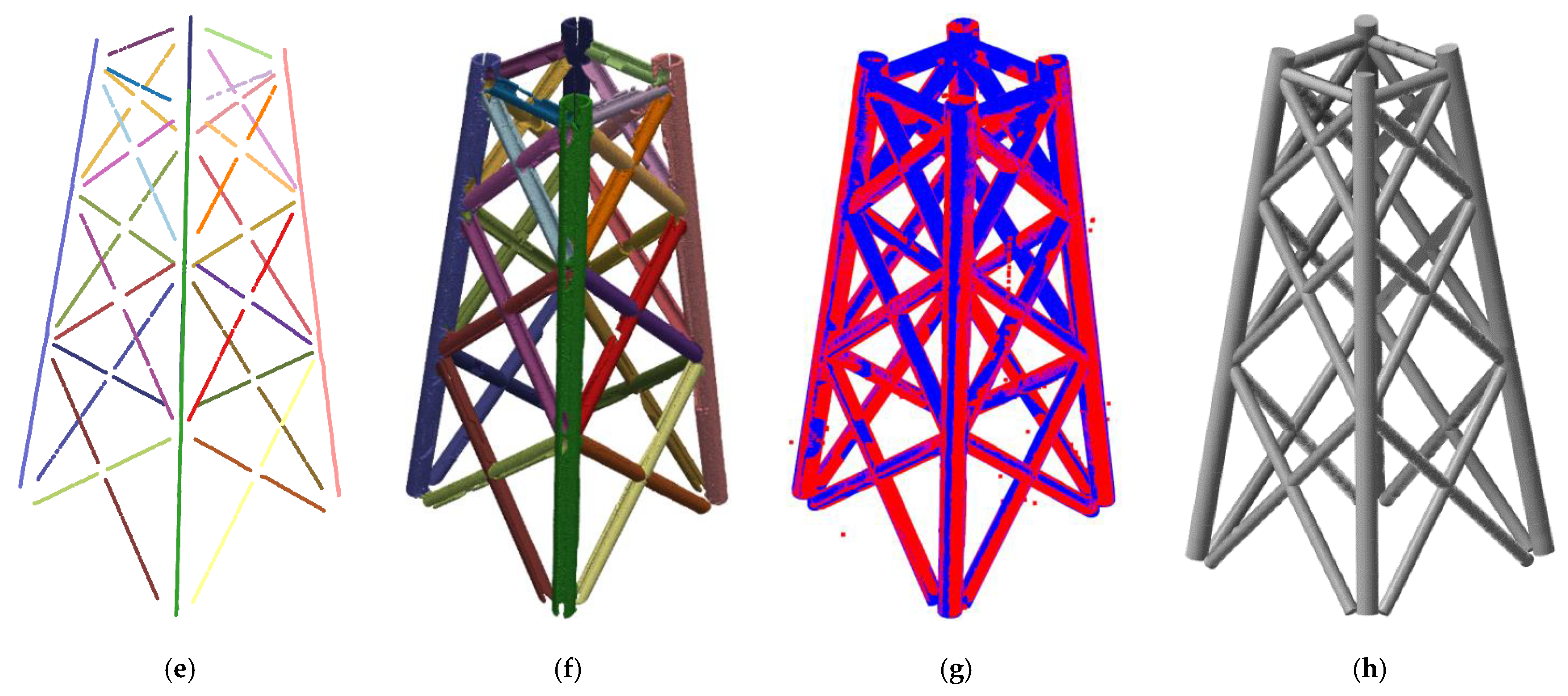

3.1. Central Axis Extraction

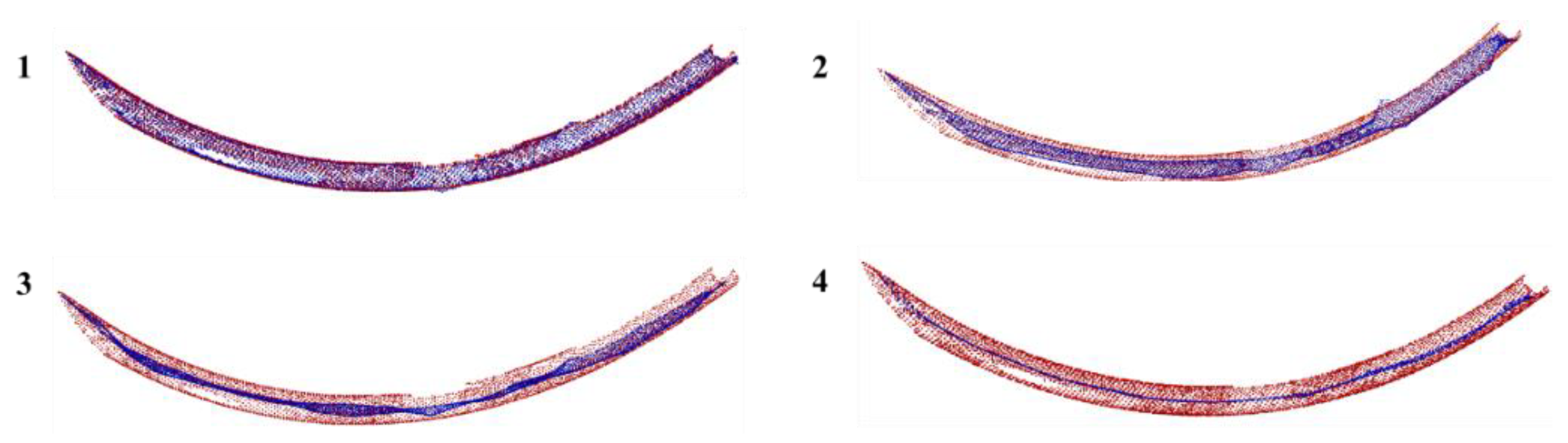

3.1.1. Central Skeleton Contraction Algorithm

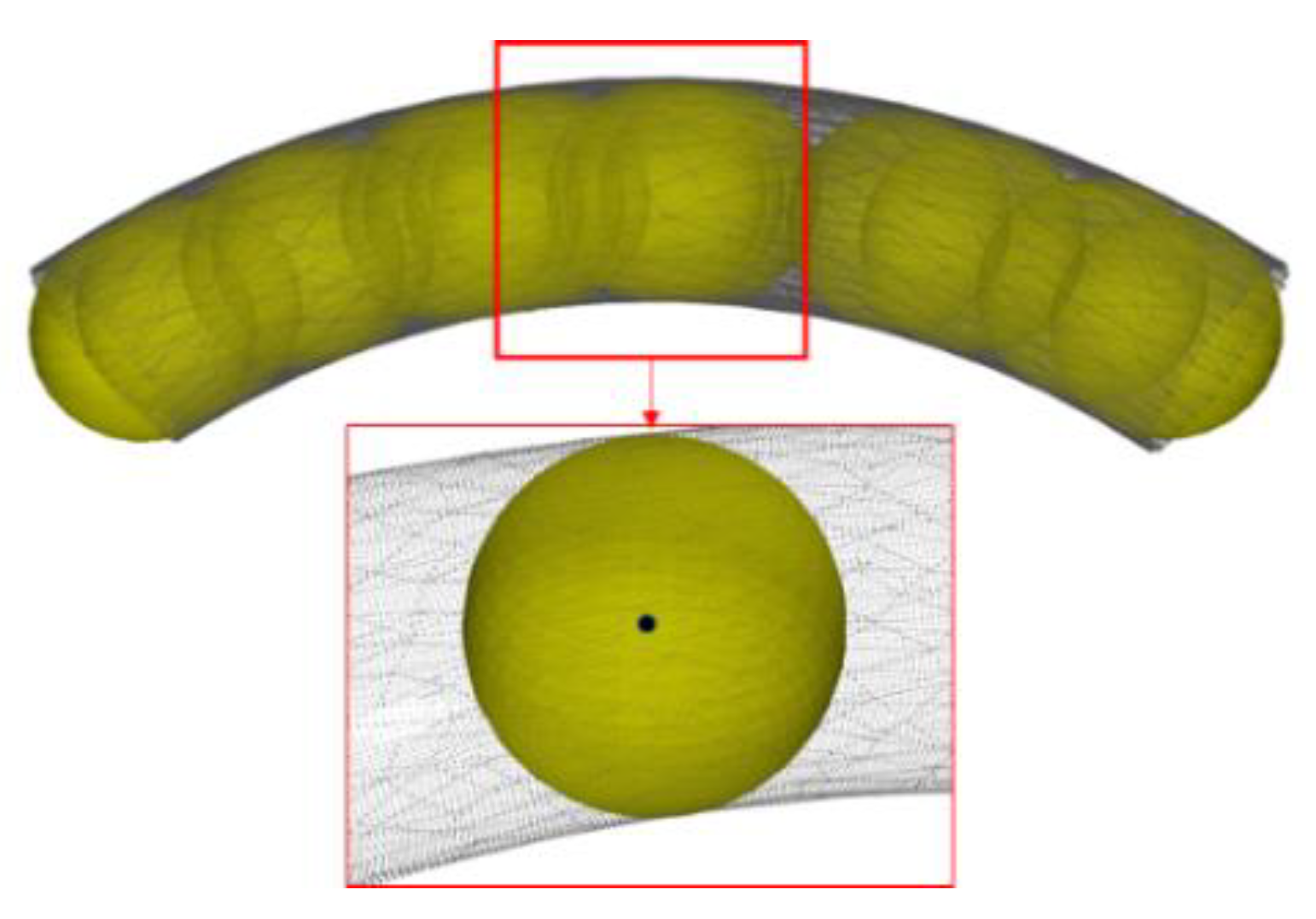

3.1.2. Rolling Sphere Algorithm

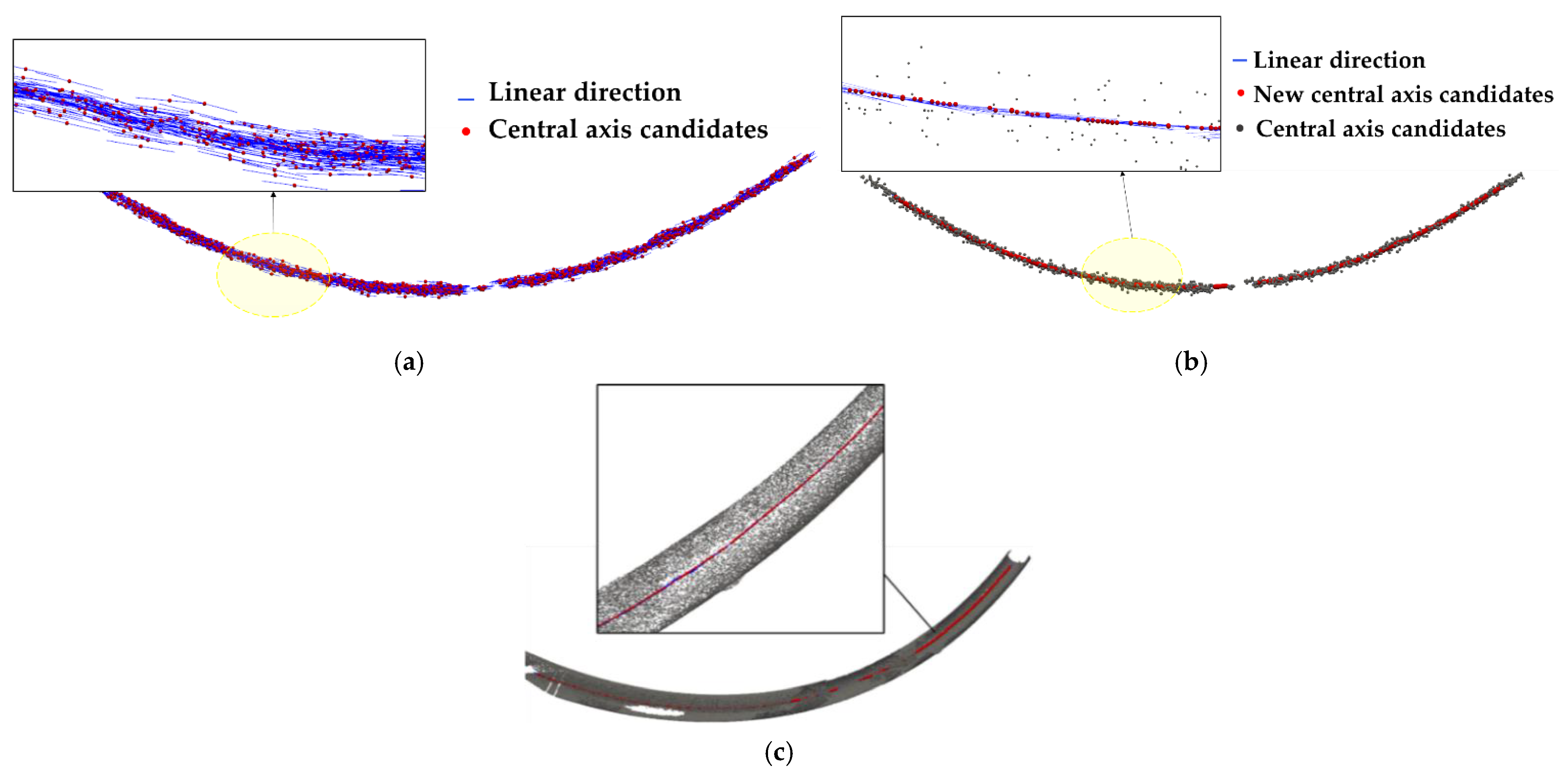

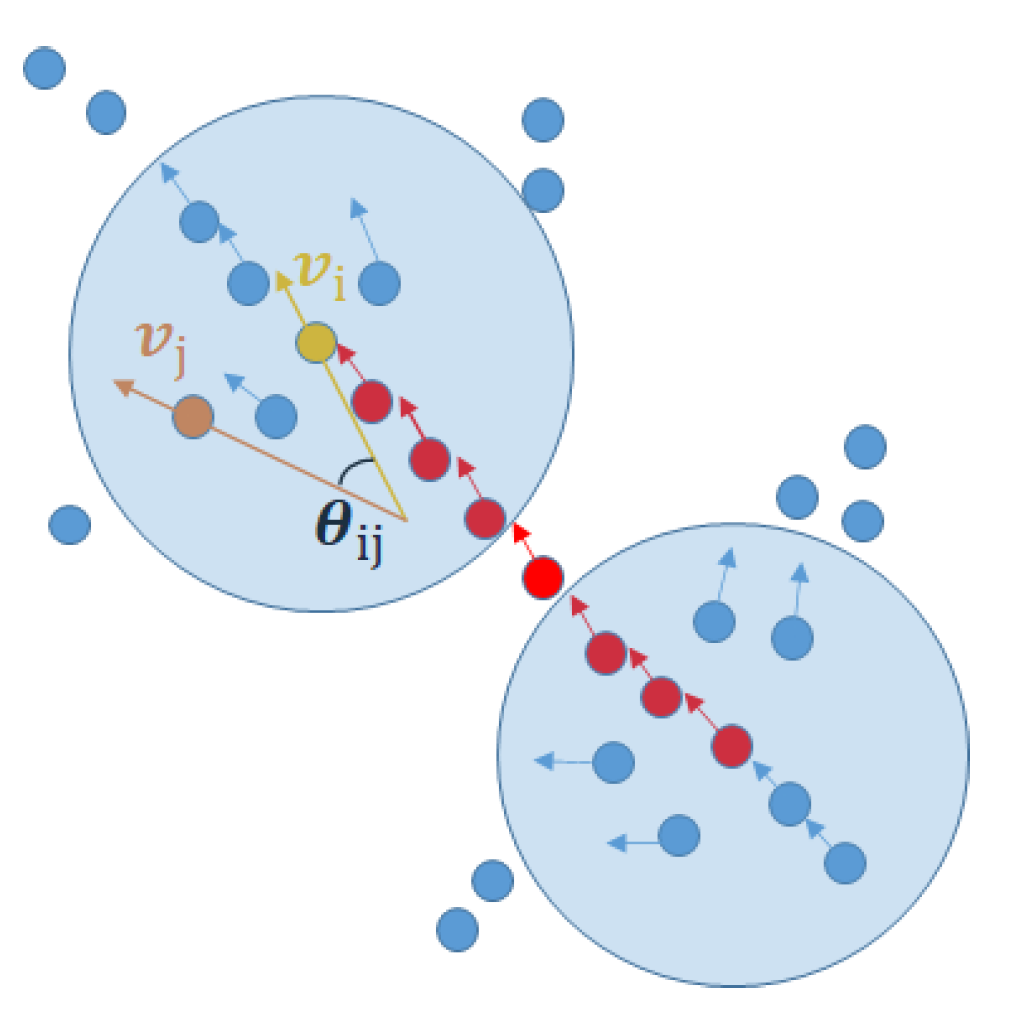

3.1.3. Central Axis Refinement

| Algorithm 1: The pseudocode of the central axis refinement algorithm. | |

| input: | central axis candidates ; angle threshold ; k |

| output: | refined central axis |

| 1 | initialize refined central axis set |

| 2 | compute the neighborhood candidates and |

| 3 | compute the linear direction vectors based on |

| 4 | for |

| 5 | initialize |

| 6 | for |

| 7 | compute the vector angle between and |

| 8 | if |

| 9 | |

| 10 | end if |

| 11 | end for |

| 12 | if |

| 13 | compute the average of |

| 14 | |

| 15 | end if |

| 16 | end for |

| 17 | return |

3.2. PCD Segmentation

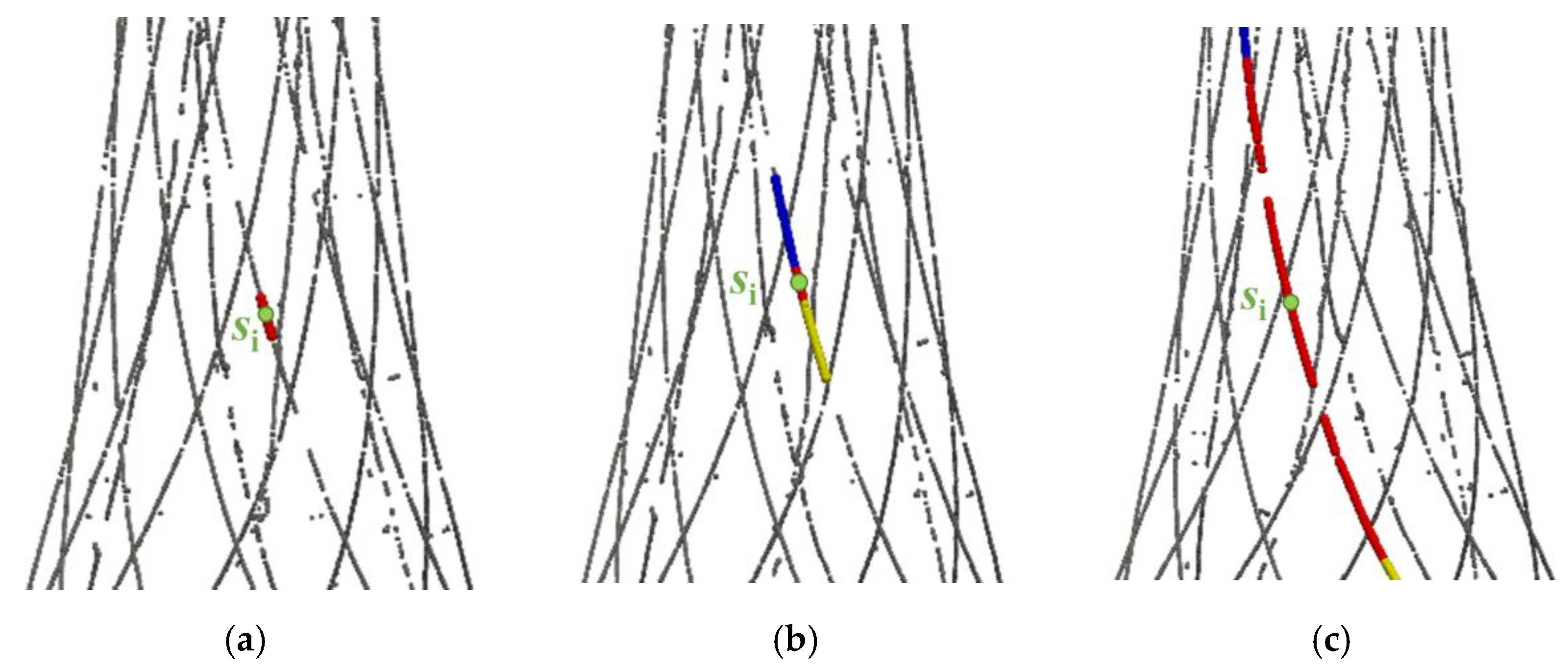

3.2.1. Central Axis Segmentation

| Algorithm 2: The pseudocode for the extended axis searching algorithm. | |

| input: | central axis , angle threshold criterion , the search radius rs |

| output: | segmented central axis Sg |

| 1 | initialize segmented central axis set Sg |

| 2 | compute the neighborhood points of each point on the central axis |

| 3 | compute the linear direction vectors based on |

| 4 | |

| 5 | while S |

| 6 | select a random point si and |

| 7 | remove si from |

| 8 | initialize , , t = 1 |

| 9 | while |

| 10 | extract two ends si1, si2 of |

| 11 | compute the extended points E(si1), E(si2) based on rs |

| 12 | compute the angle from each point in E(si1) to si1 and from each point in E(si2) to si2 |

| 13 | find the points on the central axis that their angles are less than |

| 14 | upgrade , , t = t+ 1 |

| 15 | end while |

| 16 | if |

| 17 | record the category of current segmented central axis as c |

| 18 | add the labelled to Sg |

| 19 | remove from S |

| 20 | c = c + 1 |

| 21 | end if |

| 22 | end while |

| 23 | Return Sg |

3.2.2. Component Data Segmentation

3.3. Geometric Parameter Estimation

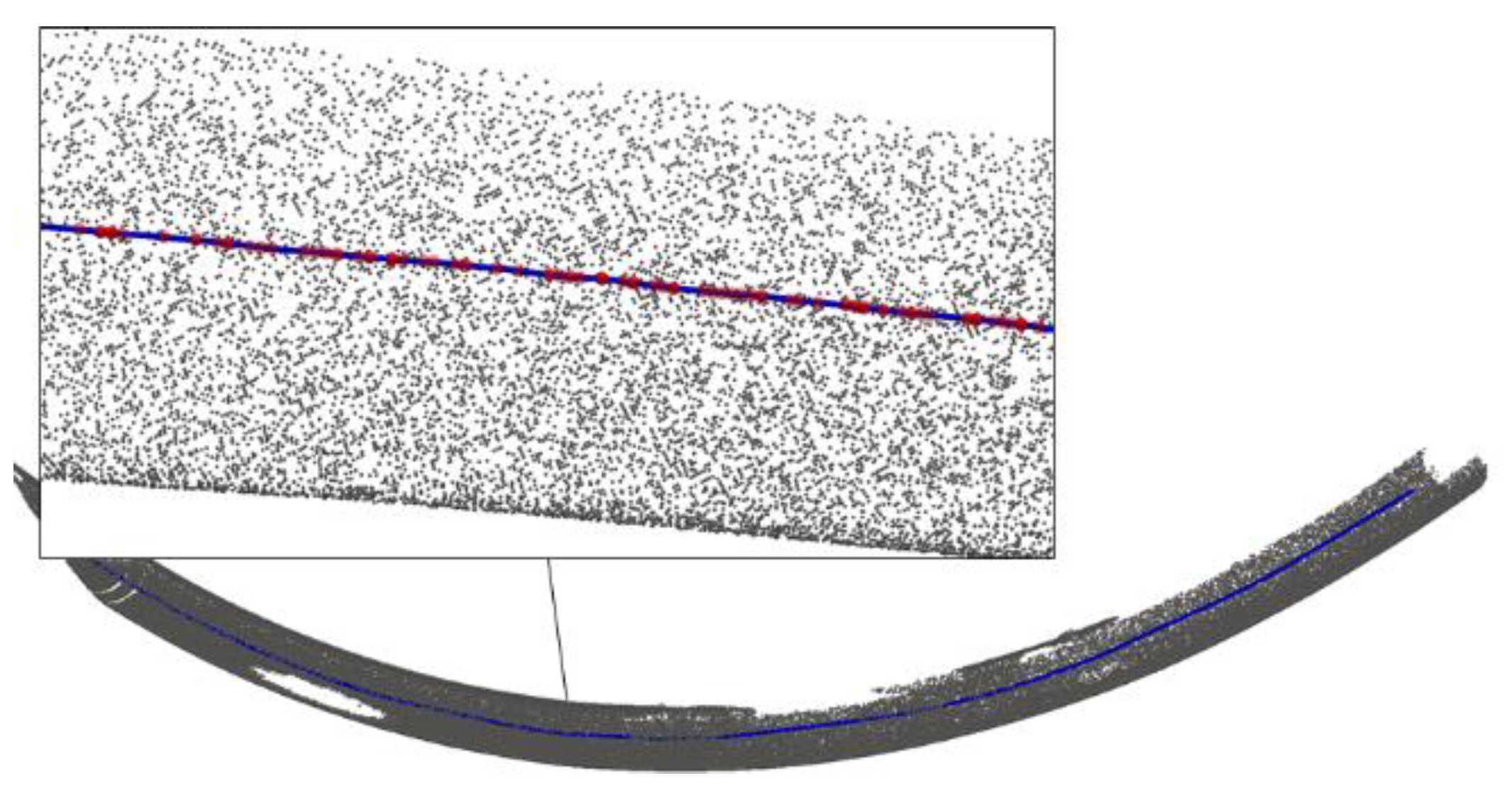

3.3.1. Central Axis Curve Estimation

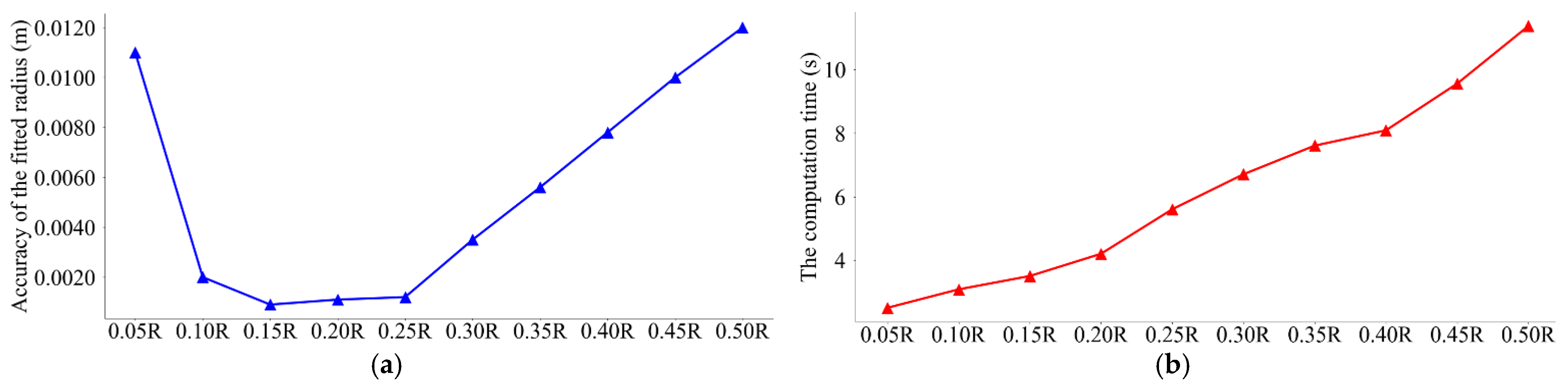

3.3.2. Cross-Sectional Radius Fitting

3.4. Model Generation

4. Validation Experiment

4.1. Comparison Test

4.2. Experimental Results for the BIM Reconstruction

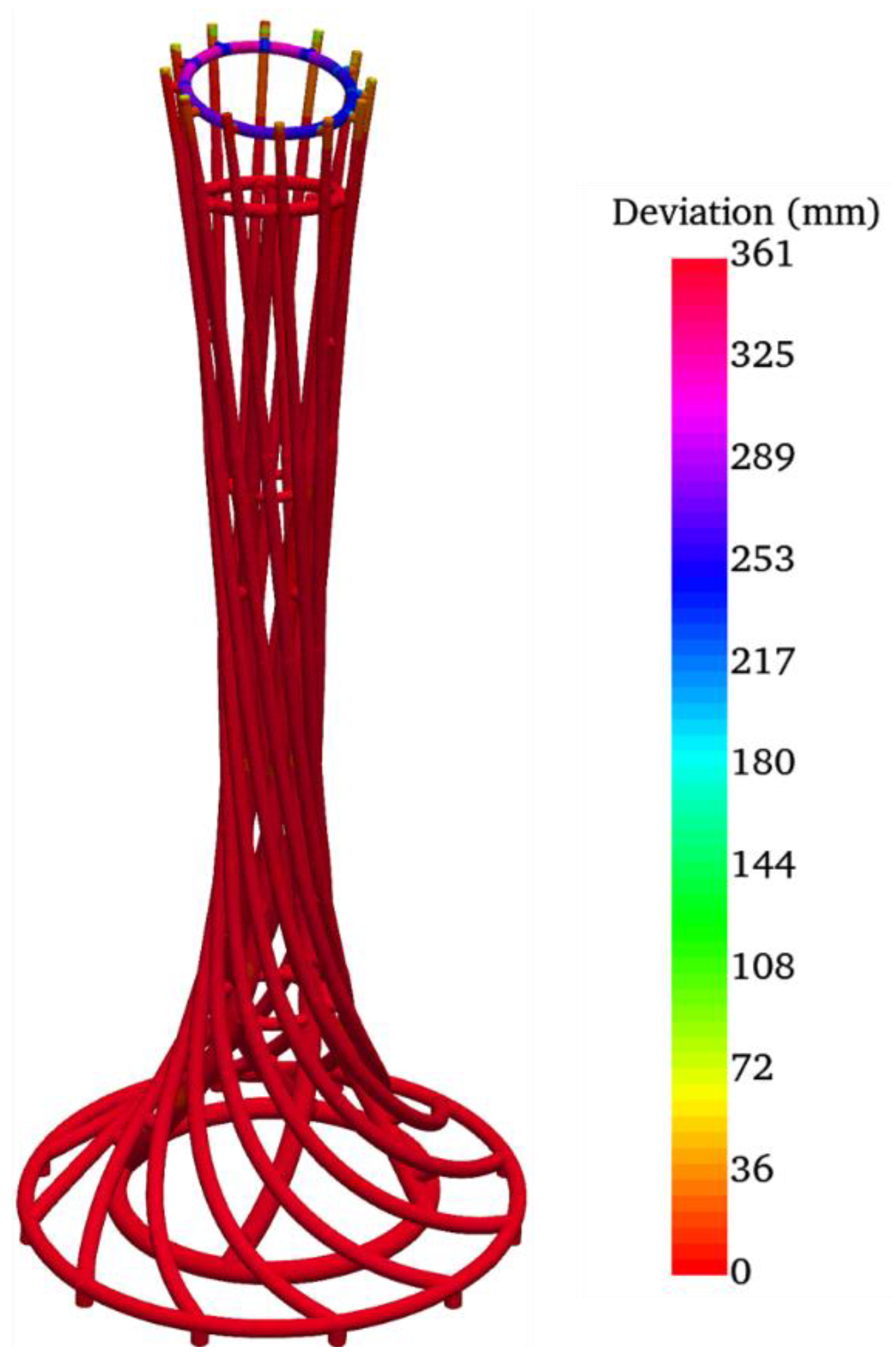

4.3. Accuracy of Reconstructed BIM

4.4. Construction Quality Assessment Using the As-Built Model

4.5. Expanded Experiment

5. Conclusions

- (1)

- A novel central axis extraction method for tubular components is developed and demonstrated to be effective.

- (2)

- An extended axis searching algorithm based on the concept of region growing is proposed, which is suitable for the segmentation of PCD of CETS with missing and noisy data.

- (3)

- The maximum error of the proposed BIM reconstruction method is 0.92 mm, which is acceptable in a real application.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Veldhuis, H.; Vosselman, G. The 3D reconstruction of straight and curved pipes using digital line photogrammetry. ISPRS J. Photogramm. Remote Sens. 1998, 53, 6–16. [Google Scholar] [CrossRef]

- Tserng, H.P.; Yin, Y.L.; Jaselskis, E.J.; Hung, W.-C.; Lin, Y.-C. Modularization and assembly algorithm for efficient MEP construction. Autom. Constr. 2011, 20, 837–863. [Google Scholar] [CrossRef]

- Son, H.; Kim, C.; Kim, C. Automatic 3D Reconstruction of As-built Pipeline Based on Curvature Computations from Laser-Scanned Data. Constr. Res. Congress. 2014, 925–934. [Google Scholar]

- Son, H.; Kim, C.; Kim, C. Fully Automated As-Built 3D Pipeline Segmentation Based on Curvature Computation from Laser-Scanned Data. Comput. Civ. Eng. 2013, 765–772. [Google Scholar]

- Son, H.; Kim, C.; Kim, C. Fully automated as-built 3D pipeline extraction method from laser-scanned data based on curvature computation. J. Comput. Civ. Eng. 2015, 29, 765–772. [Google Scholar] [CrossRef]

- Kim, M.-K.; Wang, Q.; Li, H. Non-contact sensing based geometric quality assessment of buildings and civil structures: A review. Autom. Constr. 2019, 100, 163–179. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, S. A review of 3D reconstruction techniques in civil engineering and their applications. Adv. Eng. Inform. 2018, 37, 163–174. [Google Scholar] [CrossRef]

- Wang, Q.; Tan, Y.; Mei, Z. Computational Methods of Acquisition and Processing of 3D Point Cloud Data for Construction Applications. Arch. Comput. Methods Eng. 2020, 27, 479–499. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, M.-K. Applications of 3D point cloud data in the construction industry: A fifteen-year review from 2004 to 2018. Adv. Eng. Inform. 2019, 39, 306–319. [Google Scholar] [CrossRef]

- Adams, R.; Bischof, L. Seeded region growing. IEEE Trans. Pattern Anal. Mach. Intell. 1994, 16, 641–647. [Google Scholar] [CrossRef] [Green Version]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for point-cloud shape detection. Comput. Graph. Forum 2007, 26, 214–226. [Google Scholar] [CrossRef]

- Cabaleiro, M.; Riveiro, B.; Arias, P.; Caamaño, J.C.; Vilán, J.A. Automatic 3D modelling of metal frame connections from LiDAR data for structural engineering purposes. ISPRS J. Photogramm. Remote Sens. 2014, 96, 47–56. [Google Scholar] [CrossRef]

- Laefer, D.F.; Truong-Hong, L. Toward automatic generation of 3D steel structures for building information modelling. Autom. Constr. 2017, 74, 66–77. [Google Scholar] [CrossRef]

- Li, M.; Rottensteiner, F.; Heipke, C. Modelling of buildings from aerial LiDAR point clouds using TINs and label maps. ISPRS J. Photogramm. Remote Sens. 2019, 154, 127–138. [Google Scholar] [CrossRef]

- Kawashima, K.; Kanai, S.; Date, H. As-built modeling of piping system from terrestrial laser-scanned point clouds using normal-based region growing. J. Comput. Des. Eng. 2014, 1, 13–26. [Google Scholar] [CrossRef]

- Jin, Y.-H.; Lee, W.-H. Fast Cylinder Shape Matching Using Random Sample Consensus in Large Scale Point Cloud. Appl. Sci. 2019, 9, 974. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Son, H.; Kim, C.; Kim, C. Skeleton-based 3D reconstruction of as-built pipelines from laser-scan data. Autom. Constr. 2013, 35, 199–207. [Google Scholar] [CrossRef]

- Trimble. Trimble RealWorks. Available online: https://geospatial.trimble.com/products-and-solutions/trimble-realworks (accessed on 26 February 2022).

- Geomagic. Geomagic Wrap. Available online: https://www.3dsystems.com/software/geomagic-wrap (accessed on 26 February 2022).

- ClearEdge3D. EdgeWise. Available online: https://www.clearedge3d.com/products/edgewise (accessed on 26 February 2022).

- Mukhopadhyay, P.; Chaudhuri, B.B. A survey of Hough Transform. Pattern Recognit. 2015, 48, 993–1010. [Google Scholar] [CrossRef]

- Vo, A.-V.; Truong-Hong, L.; Laefer, D.F.; Bertolotto, M. Octree-based region growing for point cloud segmentation. ISPRS J. Photogramm. Remote Sens. 2015, 104, 88–100. [Google Scholar] [CrossRef]

- Liu, Y.J.; Zhang, J.B.; Hou, J.C.; Ren, J.C.; Tang, W.Q. Cylinder Detection in Large-Scale Point Cloud of Pipeline Plant. IEEE Trans. Vis. Comput. Graph. 2013, 19, 1700–1707. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Haas, C.T.; Caldas, C.; Ergen, E.; Akinci, B. Automating the task of tracking the delivery and receipt of fabricated pipe spools in industrial projects. Autom. Constr. 2006, 15, 166–177. [Google Scholar] [CrossRef]

- Qiu, R.; Zhou, Q.-Y.; Neumann, U. Pipe-Run Extraction and Reconstruction from Point Clouds. In Proceedings of the European Conference on Computer Vision, Zurich, Switzerland, 6–12 September 2014; pp. 17–30. [Google Scholar]

- Patil, A.K.; Holi, P.; Lee, S.K.; Chai, Y.H. An adaptive approach for the reconstruction and modeling of as-built 3D pipelines from point clouds. Autom. Constr. 2017, 75, 65–78. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Q.; Park, J.-H. Geometric quality inspection of prefabricated MEP modules with 3D laser scanning. Autom. Constr. 2020, 111, 103053. [Google Scholar] [CrossRef]

- Cao, J.; Tagliasacchi, A.; Olson, M.; Zhang, H.; Su, Z. Point Cloud Skeletons via Laplacian Based Contraction. In Proceedings of the Shape Modeling International Conference, Aix-en-Provence, France, 21–23 June 2010; pp. 187–197. [Google Scholar]

- Au, O.K.-C.; Tai, C.-L.; Chu, H.-K.; Cohen-Or, D.; Lee, T.-Y. Skeleton extraction by mesh contraction. ACM Trans. Graph. (TOG) 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Svensson, S.; Nyström, I.; Sanniti di Baja, G. Curve skeletonization of surface-like objects in 3D images guided by voxel classification. Pattern Recognit. Lett. 2002, 23, 1419–1426. [Google Scholar] [CrossRef]

- Su, Z.; Zhao, Y.; Zhao, C.; Guo, X.; Li, Z. Skeleton extraction for tree models. Math. Comput. Model. 2011, 54, 1115–1120. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X.; Zong, M.; Zhu, X.; Wang, R. Efficient kNN Classification with Different Numbers of Nearest Neighbors. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 1774–1785. [Google Scholar] [CrossRef]

- Smith, L.I. A tutorial on Principal Components Analysis. 2002. Available online: https://faculty.iiit.ac.in/~mkrishna/PrincipalComponents.pdf (accessed on 26 February 2022).

- Meyer, M.; Desbrun, M.; Schröder, P.; Barr, A.H. Discrete differential-geometry operators for triangulated 2-manifolds. In Visualization and Mathematics III; Springer: Berlin/Heidelberg, Germany, 2003; pp. 35–57. [Google Scholar]

- Belkin, M.; Sun, J.; Wang, Y. Constructing Laplace operator from point clouds in ℝd. In Proceedings of the Twentieth Annual ACM-SIAM Symposium on Discrete Algorithms, New York, NY, USA, 4–6 January 2009; pp. 1031–1040. [Google Scholar]

- Tran, T.-T.; Cao, V.-T.; Laurendeau, D. ESphere: Extracting Spheres from Unorganized Point Clouds. Vis. Comput. 2016, 32, 1205–1222. [Google Scholar] [CrossRef]

- Twigg, C.J.C. Catmull-Rom Splines. 2003. Available online: http://www.cs.cmu.edu/~fp/courses/graphics/asst5/catmullRom.pdf (accessed on 26 February 2022).

- Revit API Docs. Available online: https://www.revitapidocs.com/ (accessed on 26 February 2022).

- Faro. Faro Focus Laser Scanner User Manual. 2019. Available online: https://www.faro.com/en/Products/Hardware/Focus-Laser-Scanners (accessed on 26 February 2022).

- Point Cloud Outlier Removal, Open3D. Available online: http://www.open3d.org/docs/0.9.0/tutorial/Advanced/pointcloud_outlier_removal.html (accessed on 26 February 2022).

- Point Cloud Voxel Down Sample, Open3D. Available online: http://www.open3d.org/docs/0.6.0/python_api/open3d.geometry.voxel_down_sample.html (accessed on 26 February 2022).

- GB 50205-2020; Standard for Acceptance of Construction Quality of Steel Structures; Ministry of Housing and Urban-Rural Development of PRC, Beijing, China. 2020. Available online: https://www.chinesestandard.net/China/Chinese.aspx/GB50205-2020 (accessed on 26 February 2022).

- Li, D.; Liu, J.; Feng, L.; Zhou, Y.; Liu, P.; Chen, Y.F. Terrestrial laser scanning assisted flatness quality assessment for two different types of concrete surfaces. Measurement 2020, 154, 107436. [Google Scholar] [CrossRef]

- Case, F.; Beinat, A.; Crosilla, F.; Alba, I.M. Virtual trial assembly of a complex steel structure by Generalized Procrustes Analysis techniques. Autom. Constr. 2014, 37, 155–165. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

| Evaluation Indicators | Rolling Sphere Algorithm | The Proposed Method |

|---|---|---|

| Execution time (s) | 208 | 165.47 |

| Average of the radius for fitted spheres (m) | 0.190 | 0.176 |

| Variance of the radius for fitted spheres | 0.073 | 0.0034 |

| Procedure Steps | Number of Points | Execution Time |

|---|---|---|

| Central skeleton contraction | 91,558 | 18,342.58 s |

| Central axis candidate extraction | 91,558 | 5891.21 s |

| Central axis refinement | 91,558 | 948.7 8s |

| Central axis segmentation | 84,733 | 160.12 s |

| PCD segmentation | 21,213,417 | 356.15 s |

| Central axis curve estimation | 84,733 | 2873.21 s |

| 3D modeling of CTES | 21,213,417 | 359.67 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Fu, L.; Cheng, G.; Li, D.; Zhou, J.; Cui, N.; Chen, Y.F. Automated BIM Reconstruction of Full-Scale Complex Tubular Engineering Structures Using Terrestrial Laser Scanning. Remote Sens. 2022, 14, 1659. https://doi.org/10.3390/rs14071659

Liu J, Fu L, Cheng G, Li D, Zhou J, Cui N, Chen YF. Automated BIM Reconstruction of Full-Scale Complex Tubular Engineering Structures Using Terrestrial Laser Scanning. Remote Sensing. 2022; 14(7):1659. https://doi.org/10.3390/rs14071659

Chicago/Turabian StyleLiu, Jiepeng, Lihua Fu, Guozhong Cheng, Dongsheng Li, Jing Zhou, Na Cui, and Y. Frank Chen. 2022. "Automated BIM Reconstruction of Full-Scale Complex Tubular Engineering Structures Using Terrestrial Laser Scanning" Remote Sensing 14, no. 7: 1659. https://doi.org/10.3390/rs14071659

APA StyleLiu, J., Fu, L., Cheng, G., Li, D., Zhou, J., Cui, N., & Chen, Y. F. (2022). Automated BIM Reconstruction of Full-Scale Complex Tubular Engineering Structures Using Terrestrial Laser Scanning. Remote Sensing, 14(7), 1659. https://doi.org/10.3390/rs14071659