Comparative Evaluation for Tracking the Capability of Solar Cell Malfunction Caused by Soil Debris between UAV Video versus Photo-Mosaic

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Data Collection

2.3. Thermal Video Frame Mosaic

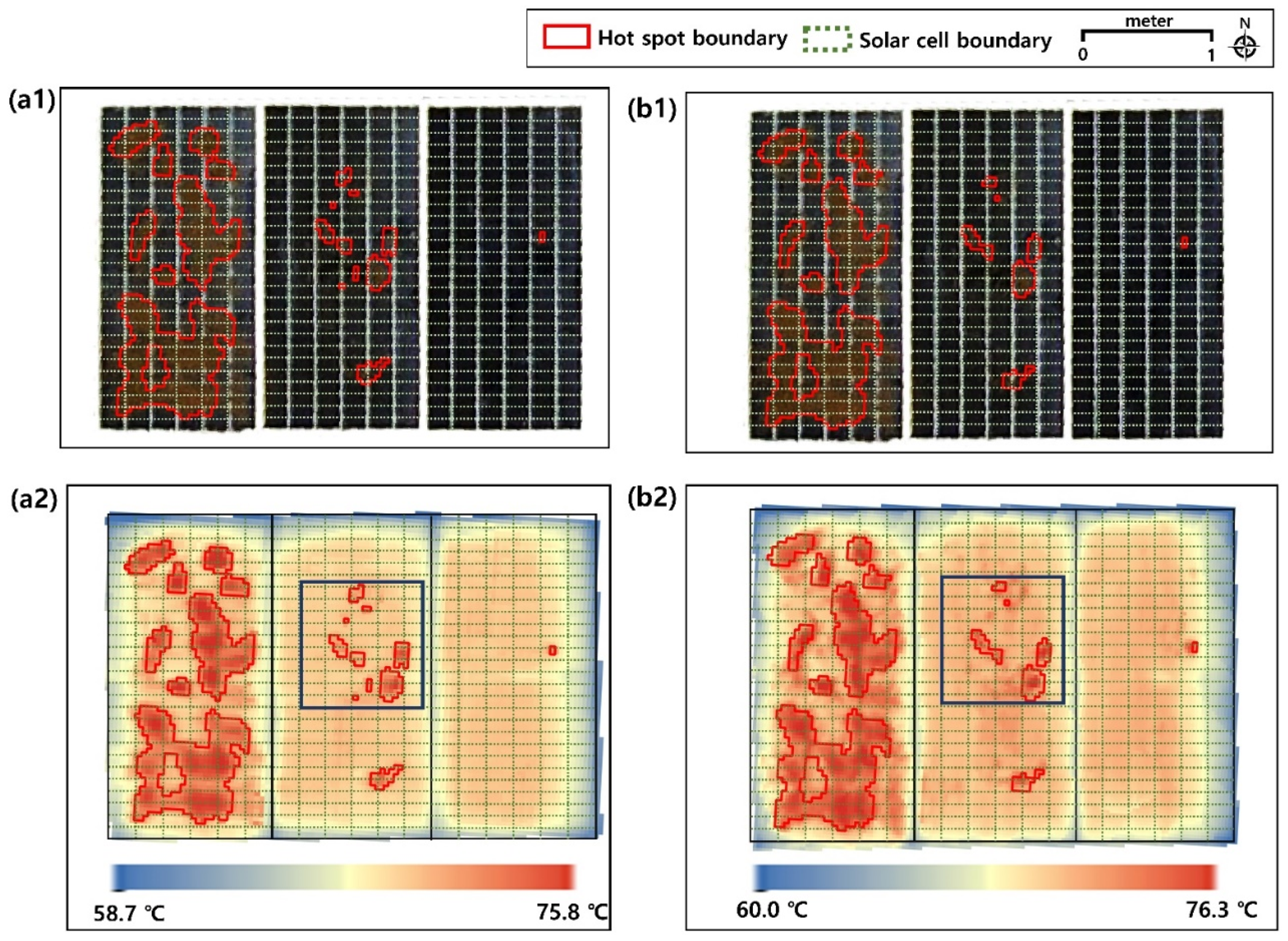

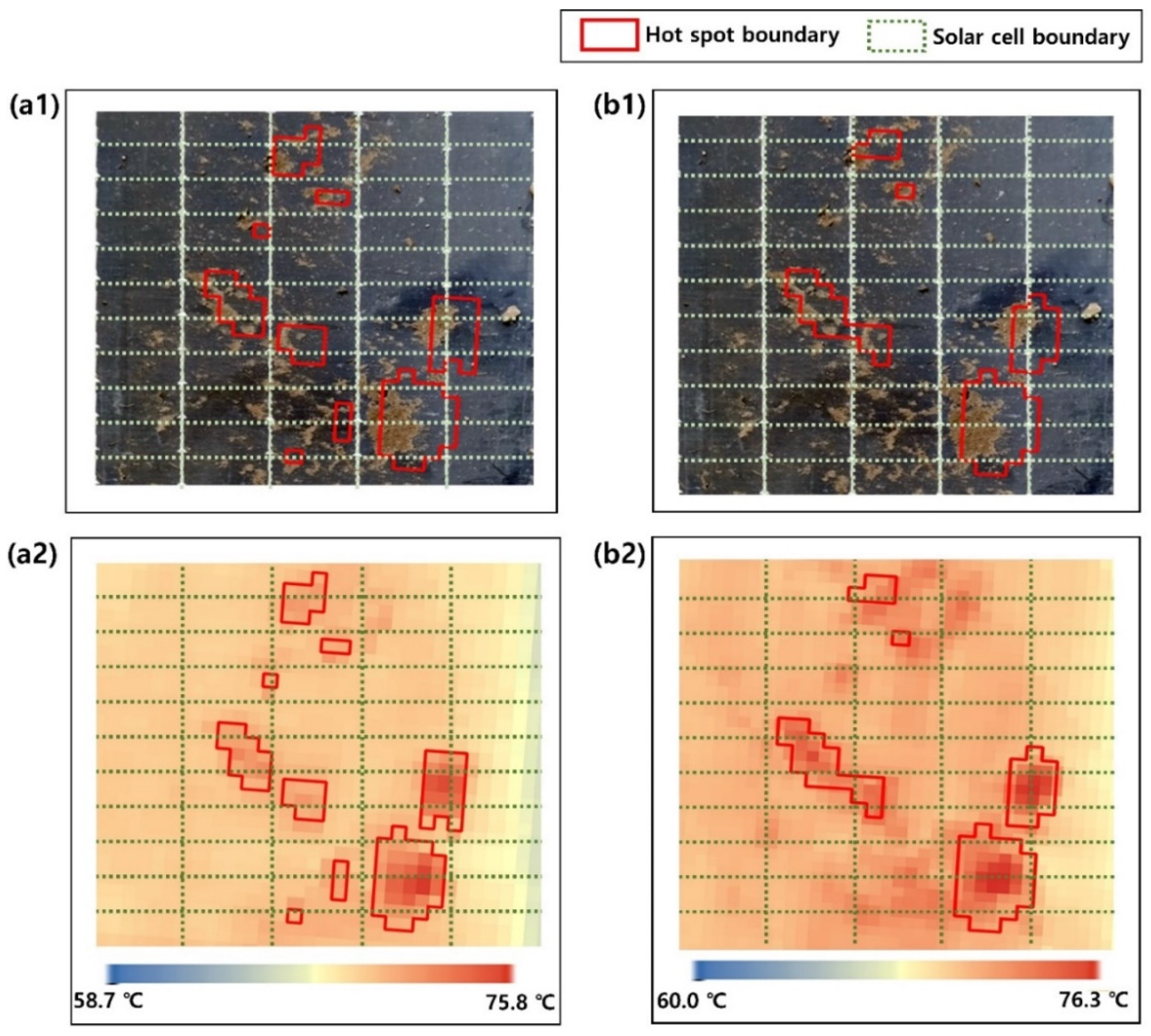

2.4. Hot Spot Analysis (Getis-Ord Gi*)

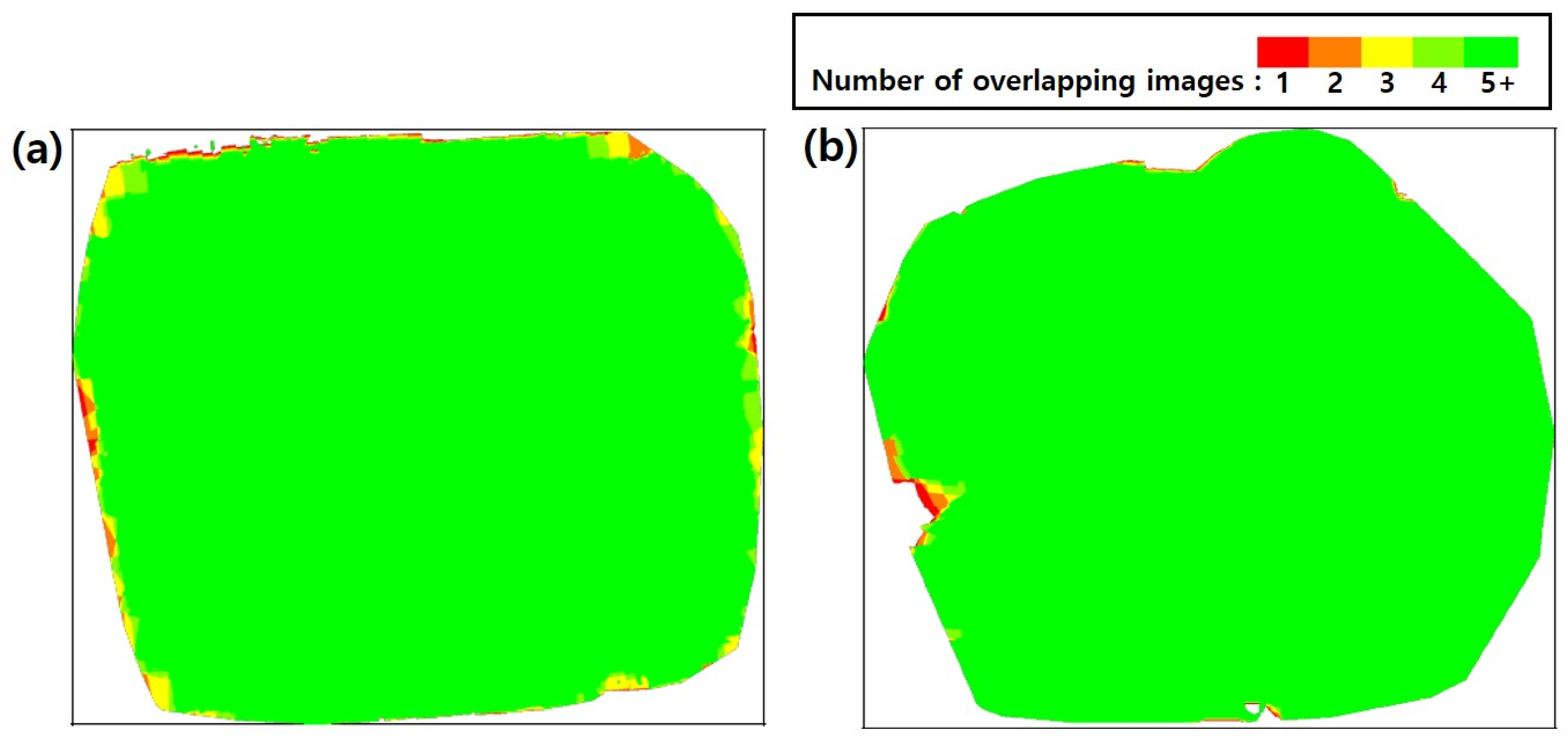

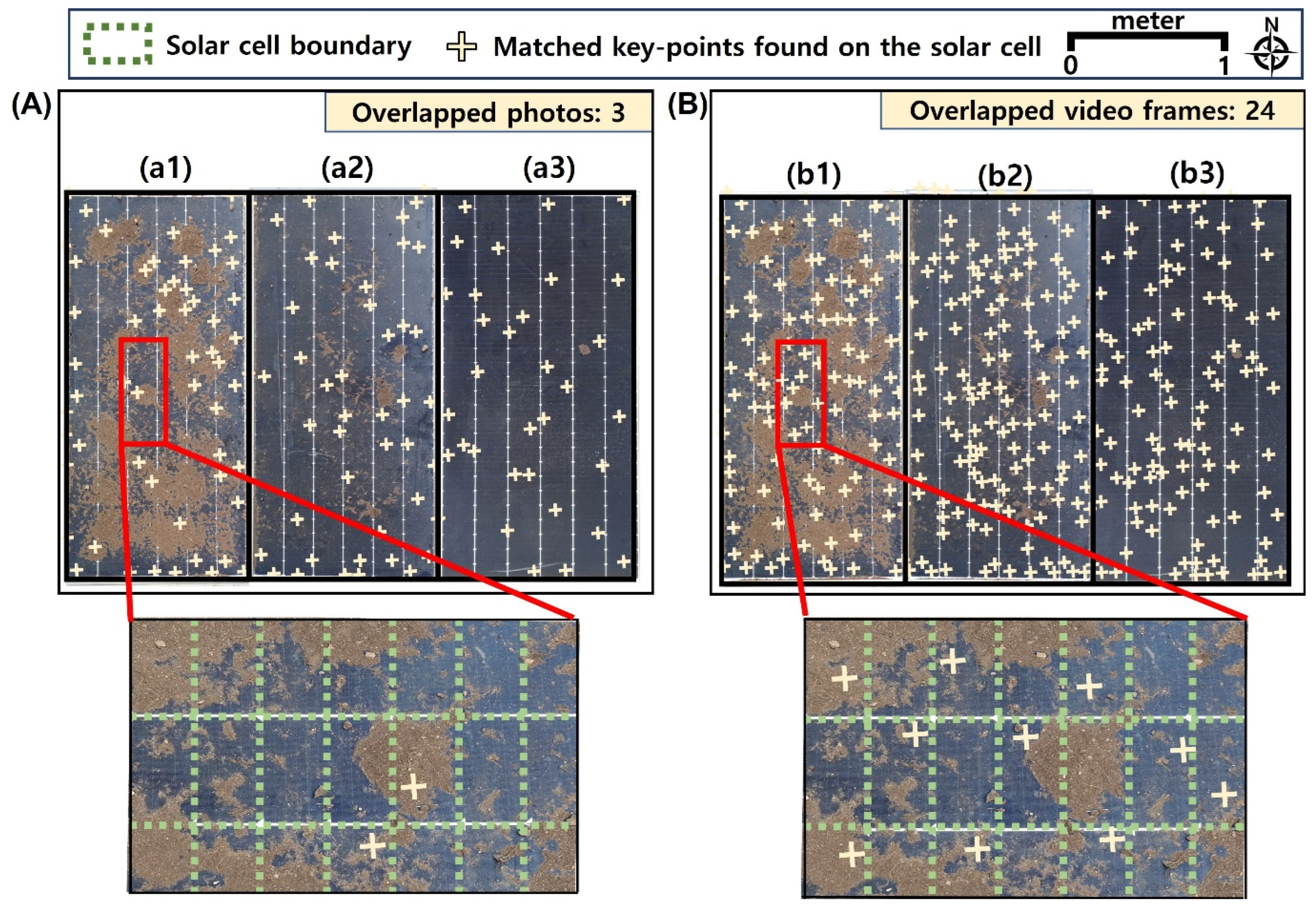

2.5. Evaluating the Performance of Video-Mosaic

2.5.1. Ordinary Least Squares (OLS) Linear Regression

2.5.2. Histogram-Based Correlation

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussain, A.; Batra, A.; Pachauri, R. An experimental study on effect of dust on power loss in solar photovoltaic module. Renew. Wind. Water Sol. 2017, 4, 9. [Google Scholar] [CrossRef]

- Paggi, M.; Corrado, M.; Berardone, I. A global/local approach for the prediction of the electric response of cracked solar cells in photovoltaic modules under the action of mechanical loads. Eng. Fract. Mech. 2016, 168, 40–57. [Google Scholar] [CrossRef]

- IEA. Review of Failures of Photovoltaic Modules; IEA: Paris, France, 2014. [Google Scholar]

- Zefri, Y.; ElKettani, A.; Sebari, I.; Ait Lamallam, S. Thermal Infrared and Visual Inspection of Photovoltaic Installations by UAV Photogrammetry—Application Case: Morocco. Drones 2018, 2, 41. [Google Scholar] [CrossRef]

- Lopez-Garcia, J.; Pozza, A.; Sample, T. Long-term soiling of silicon PV modules in a moderate subtropical climate. Sol. Energy 2016, 130, 174–183. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Xu, R.; Ni, K.; Hu, Y.; Si, J.; Wen, H.; Yu, D. Analysis of the optimum tilt angle for a soiled PV panel. Energy Convers. Manag. 2017, 148, 100–109. [Google Scholar] [CrossRef]

- Anana, W.; Chaouki, F.; Laarabi, B.; Dahlioui, D.; Sebbar, M.A.; Barhdadi, A.; Gilioli, V.; Verdilio, D. Soiling impact on energy generation of high concentration Photovoltaic power plant in Morocco. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakesh, Morocco, 14–17 November 2016; pp. 234–238. [Google Scholar]

- Lee, D.H.; Park, J.H. Developing Inspection Methodology of Solar Energy Plants by Thermal Infrared Sensor on Board Unmanned Aerial Vehicles. Energies 2019, 12, 2928. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wu, T.; Zhang, H.; Sun, X. Detection and location of fouling on photovoltaic panels using a drone-mounted infrared thermography system. J. Appl. Remote Sens. 2017, 11, 016026. [Google Scholar] [CrossRef]

- Yao, Y.; Hu, Y. Recognition and location of solar panels based on machine vision. In Proceedings of the 2017 2nd Asia-Pacific Conference on Intelligent Robot Systems (ACIRS), Wuhan, China, 16–18 June 2017; pp. 7–12. [Google Scholar]

- Jurca, T.; Tulcan-Paulescu, E.; Dughir, C.; Lascu, M.; Gravila, P.; Sabata, A.D.; Luminosu, I.; Sabata, C.D.; Paulescu, M. Global Solar Irradiation Modeling and Measurements in Timisoara. Am. Inst. Phys. 2011, 1387, 253–258. [Google Scholar] [CrossRef]

- Um, J.-S.; Wright, R. ‘Video Strip Mapping (VSM)’ for Time-sequential Monitoring of Revegetation of a Pipeline Route. Geocarto Int. 1999, 14, 24–35. [Google Scholar] [CrossRef]

- Um, J.S.; Wright, R. A comparative evaluation of video remote sensing and field survey for revegetation monitoring of a pipeline route. Sci. Total Environ. 1998, 215, 189–207. [Google Scholar] [CrossRef]

- Um, J.S.; Wright, R. Video strip mosaicking: A two-dimensional approach by convergent image bridging. Int. J. Remote Sens. 1999, 20, 2015–2032. [Google Scholar] [CrossRef]

- Nguyen, H.V.; Tran, L.H. Application of graph segmentation method in thermal camera object detection. In Proceedings of the 2015 20th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 24–27 August 2015; pp. 829–833. [Google Scholar]

- Leira, F.S.; Johansen, T.A.; Fossen, T.I. Automatic detection, classification and tracking of objects in the ocean surface from UAVs using a thermal camera. In Proceedings of the 2015 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–10. [Google Scholar]

- Gómez-Candón, D.; Virlet, N.; Labbé, S.; Jolivot, A.; Regnard, J.-L. Field phenotyping of water stress at tree scale by UAV-sensed imagery: New insights for thermal acquisition and calibration. Precis. Agric. 2016, 17, 786–800. [Google Scholar] [CrossRef]

- Wu, J.; Dong, Z.; Zhou, G. Geo-registration and mosaic of UAV video for quick-response to forest fire disaster. In Proceedings of the MIPPR 2007: Pattern Recognition and Computer Vision, Wuhan, China, 15–17 November 2007; p. 678810. [Google Scholar]

- Lafkih, S.; Zaz, Y. Video Solar Plant Monitoring. In Proceedings of the 2017 International Renewable and Sustainable Energy Conference (IRSEC), Tangier, Morocco, 4–7 December 2017; pp. 1–4. [Google Scholar]

- López-Fernández, L.; Lagüela, S.; Fernández, J.; González-Aguilera, D. Automatic Evaluation of Photovoltaic Power Stations from High-Density RGB-T 3D Point Clouds. Remote Sens. 2017, 9, 631. [Google Scholar] [CrossRef]

- Hwang, Y.-S.; Schlüter, S.; Park, S.-I.; Um, J.-S. Comparative Evaluation of Mapping Accuracy between UAV Video versus Photo Mosaic for the Scattered Urban Photovoltaic Panel. Remote Sens. 2021, 13, 2745. [Google Scholar] [CrossRef]

- Hwang, Y.-S.; Schlüter, S.; Lee, J.-J.; Um, J.-S. Evaluating the Correlation between Thermal Signatures of UAV Video Stream versus Photomosaic for Urban Rooftop Solar Panels. Remote Sens. 2021, 13, 4770. [Google Scholar] [CrossRef]

- Robertson, S. Campus, City, Networks and Nation: Student-Migrant Activism as Socio-spatial Experience in Melbourne, Australia. Int. J. Urban Reg. Res. 2013, 37, 972–988. [Google Scholar] [CrossRef]

- Srivanit, M.; Hokao, K. Evaluating the cooling effects of greening for improving the outdoor thermal environment at an institutional campus in the summer. Build. Environ. 2013, 66, 158–172. [Google Scholar] [CrossRef]

- Hwang, Y.-S.; Um, J.-S. Comparative Evaluation of Cool Surface Ratio in University Campus: A Case Study of KNU and UC Davis. KIEAE J. 2015, 15, 117–127. [Google Scholar] [CrossRef][Green Version]

- Park, S.-I.; Um, J.-S. Differentiating carbon sinks versus sources on a university campus using synergistic UAV NIR and visible signatures. Environ. Monit. Assess. 2018, 190, 652. [Google Scholar] [CrossRef] [PubMed]

- Klasen, N.; Mondon, A.; Kraft, A.; Eitner, U. Shingled cell interconnection: A new generation of bifacial PV-modules. In Proceedings of the 7th Workshop on Metallization and Interconnection for Crystalline Silicon Solar Cells, Konstanz, Germany, 23–24 October 2017. [Google Scholar]

- Chaichan, M.T.; Kazem, H.A. Experimental evaluation of dust composition impact on photovoltaic performance in Iraq. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–22. [Google Scholar] [CrossRef]

- Verhoeven, G. Taking computer vision aloft—Archaeological three-dimensional reconstructions from aerial photographs with photoscan. Archaeol. Prospect. 2011, 18, 67–73. [Google Scholar] [CrossRef]

- Lee, J.-J.; Hwang, Y.-S.; Park, S.-I.; Um, J.-S. Comparative Evaluation of UAV NIR Imagery versus in-situ Point Photo in Surveying Urban Tributary Vegetation. J. Environ. Impact Assess. 2018, 27, 475–488. [Google Scholar] [CrossRef]

- Um, J.-S. Valuing current drone CPS in terms of bi-directional bridging intensity: Embracing the future of spatial information. Spat. Inf. Res. 2017, 25, 585–591. [Google Scholar] [CrossRef]

- Park, S.-I.; Hwang, Y.-S.; Lee, J.-J.; Um, J.-S. Evaluating Operational Potential of UAV Transect Mapping for Wetland Vegetation Survey. J. Coast. Res. 2021, 114, 474–478. [Google Scholar] [CrossRef]

- Um, J.-S. Evaluating patent tendency for UAV related to spatial information in South Korea. Spat. Inf. Res. 2018, 26, 143–150. [Google Scholar] [CrossRef]

- Um, J.-S. Embracing cyber-physical system as cross-platform to enhance fusion-application value of spatial information. Spat. Inf. Res. 2017, 25, 439–447. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, X.; Ai, G.; Zhang, Y.; Zuo, Y. Generating a High-Precision True Digital Orthophoto Map Based on UAV Images. ISPRS Int. J. Geo-Inf. 2018, 7, 333. [Google Scholar] [CrossRef]

- Park, S.-I.; Hwang, Y.-S.; Um, J.-S. Estimating blue carbon accumulated in a halophyte community using UAV imagery: A case study of the southern coastal wetlands in South Korea. J. Coast. Conserv. 2021, 25, 38. [Google Scholar] [CrossRef]

- Khan, G.; Qin, X.; Noyce, D.A. Spatial Analysis of Weather Crash Patterns. J. Transp. Eng. 2008, 134, 191–202. [Google Scholar] [CrossRef]

- Getis, A.; Ord, K. The Analysis of Spatial Association by Use of Distance Statistics. Geogr. Anal. 1992, 24, 189–206. [Google Scholar] [CrossRef]

- Hwang, Y.; Um, J.-S.; Hwang, J.; Schlüter, S. Evaluating the Causal Relations between the Kaya Identity Index and ODIAC-Based Fossil Fuel CO2 Flux. Energies 2020, 13, 6009. [Google Scholar] [CrossRef]

- Hwang, Y.; Um, J.-S. Performance evaluation of OCO-2 XCO2 signatures in exploring casual relationship between CO2 emission and land cover. Spat. Inf. Res. 2016, 24, 451–461. [Google Scholar] [CrossRef]

- Hwang, Y.; Um, J.-S. Evaluating co-relationship between OCO-2 XCO2 and in situ CO2 measured with portable equipment in Seoul. Spat. Inf. Res. 2016, 24, 565–575. [Google Scholar] [CrossRef]

- Hao, D.; Li, Q.; Li, C. Histogram-based image segmentation using variational mode decomposition and correlation coefficients. Signal Image Video Process. 2017, 11, 1411–1418. [Google Scholar] [CrossRef]

- Abdollahnejad, A.; Panagiotidis, D.; Surový, P. Estimation and Extrapolation of Tree Parameters Using Spectral Correlation between UAV and Pléiades Data. Forests 2018, 9, 85. [Google Scholar] [CrossRef]

- Liao, K.-C.; Lu, J.-H. Using UAV to Detect Solar Module Fault Conditions of a Solar Power Farm with IR and Visual Image Analysis. Appl. Sci. 2021, 11, 1835. [Google Scholar] [CrossRef]

- Bian, J.; Zhang, Z.; Chen, J.; Chen, H.; Cui, C.; Li, X.; Chen, S.; Fu, Q. Simplified Evaluation of Cotton Water Stress Using High Resolution Unmanned Aerial Vehicle Thermal Imagery. Remote Sens. 2019, 11, 267. [Google Scholar] [CrossRef]

- Um, J.-S. Drones as Cyber-Physical Systems; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Gadag, R.V.; Shetty, A.N. Engineering Chemistry, 3rd ed.; IK International Pvt Ltd.: New Delhi, India, 2014. [Google Scholar]

- Hwang, Y.; Um, J.-S.; Schlüter, S. Evaluating the Mutual Relationship between IPAT/Kaya Identity Index and ODIAC-Based GOSAT Fossil-Fuel CO2 Flux: Potential and Constraints in Utilizing Decomposed Variables. Int. J. Environ. Res. Public Health 2020, 17, 5976. [Google Scholar] [CrossRef] [PubMed]

- Troy, A.; Morgan Grove, J.; O’Neil-Dunne, J. The relationship between tree canopy and crime rates across an urban–rural gradient in the greater Baltimore region. Landsc. Urban Plan. 2012, 106, 262–270. [Google Scholar] [CrossRef]

- Mudholkar, G.S.; Natarajan, R. The inverse Gaussian models: Analogues of symmetry, skewness and kurtosis. Ann. Inst. Stat. Math. 2002, 54, 138–154. [Google Scholar] [CrossRef]

| UAV (DJI Matrice 200 V2) | Camera (DJI Zenmuse XT2) | |||

|---|---|---|---|---|

| Weight | 4.69 kg | Pixel numbers (width × height) | 640 × 512 | |

| Maximum flight altitude | 3000 m (flight altitude used in this experiment: 80 m) | Sensor size (width × height) | 10.88 mm × 8.7 mm | |

| Focal length * | 19 mm | |||

| FOV/IFOV | 32° × 26°/0.895 mr | |||

| Hovering accuracy | z (height) | Vertical, ±0.1 m Horizontal, ±0.3 m | Spectral band | 7.5–13.5 μm |

| ISO | 128 | |||

| x, y (location) | Horizontal, ±1.5 m or ±0.3 m (Downward Vision System) | Full frame rates | 30 Hz | |

| Exposure value | 4.55 | |||

| Maximum flight speed | 61.2 km/h (P-mode) | Sensitivity [NEDT]/Aperture | <0.05 °C, f/1.0 | |

| Category | Photo-Mosaic | Video-Mosaic | |

|---|---|---|---|

| SCSTs of solar cells detected in testbeds (°C) | Min | 58.7 | 60.0 |

| Max | 75.8 | 76.3 | |

| Mean | 68.0 | 68.6 | |

| Standard deviation | 2.00 | 2.15 | |

| Numbers of detected solar cells | 8316 | 8316 | |

| Overlapping rates (%) | 95 | 97 | |

| Category | Matched Key-Points per m3 | Matched Key-Points per Solar Module | ||||

|---|---|---|---|---|---|---|

| Testbed 1 | Testbed 2 | Testbed 3 | Testbed 1 | Testbed 2 | Testbed 3 | |

| Photo-mosaic | 26.2 | 21.8 | 14.1 | 54 | 45 | 29 |

| Video-mosaic | 52.4 | 53.4 | 48.5 | 108 | 110 | 100 |

| Category | Photo-Mosaic | Video-Mosaic | |||||

|---|---|---|---|---|---|---|---|

| Testbed 1 | Testbed 2 | Testbed 3 | Testbed 1 | Testbed 2 | Testbed 3 | ||

| Numbers of pixels | 809 | 106 | 2 | 767 | 88 | 2 | |

| z-score of Getis-Ord Gi * | Min | 1.962 | 1.963 | 2.112 | 1.961 | 1.962 | 2.041 |

| Max | 6.199 | 5.958 | 2.218 | 5.292 | 5.766 | 2.046 | |

| Mean | 3.139 | 2.905 | 2.215 | 3.027 | 2.881 | 2.044 | |

| SCSTs in hot spots (°C) | Min | 69.6 | 68.7 | 70.0 | 70.4 | 69.7 | 70.4 |

| Max | 75.8 | 73.3 | 70.4 | 76.3 | 74.1 | 70.9 | |

| Mean | 71.8 | 70.3 | 70.2 | 72.4 | 71.1 | 70.6 | |

| Standard deviation | 1.03 | 0.95 | 0.21 | 0.98 | 0.97 | 0.26 | |

| The similarity of spatial patterns of hotspots between photo-mosaic vs. video-mosaic (%) | 94 | 81 | 100 | 99 | 97 | 100 | |

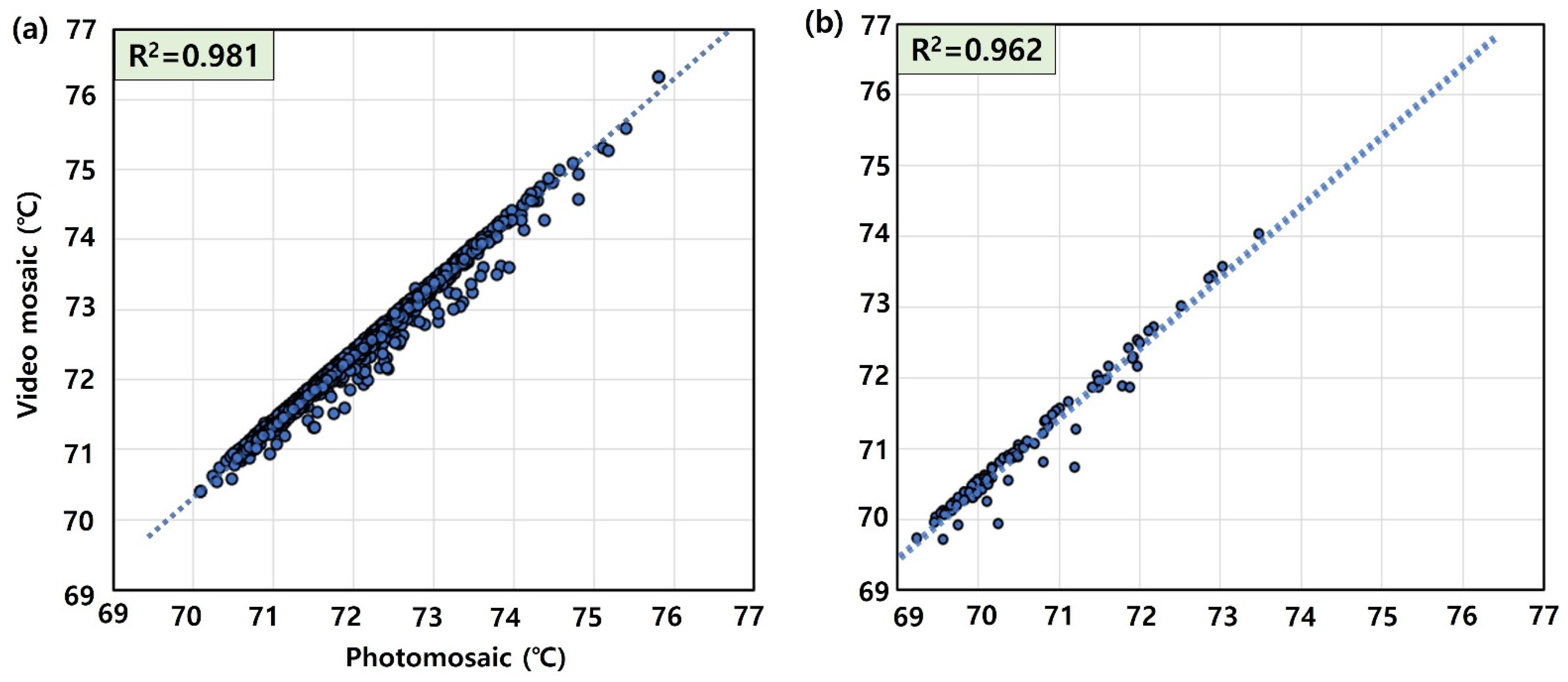

| Frame Intervals | Testbed 1 | Testbed 2 & Testbed 3 |

|---|---|---|

| Numbers of pixels | 762 | 88 |

| Unstandardized coefficient (°C) | 1.003 * | 0.973 * |

| t-statistic | 199.847 * | 46.949 * |

| VIF | 1.000 | 1.000 |

| Pearson correlation | 0.991 | 0.981 |

| R2 | 0.981 | 0.962 |

| RMSE (°C) | 0.136 | 0.183 |

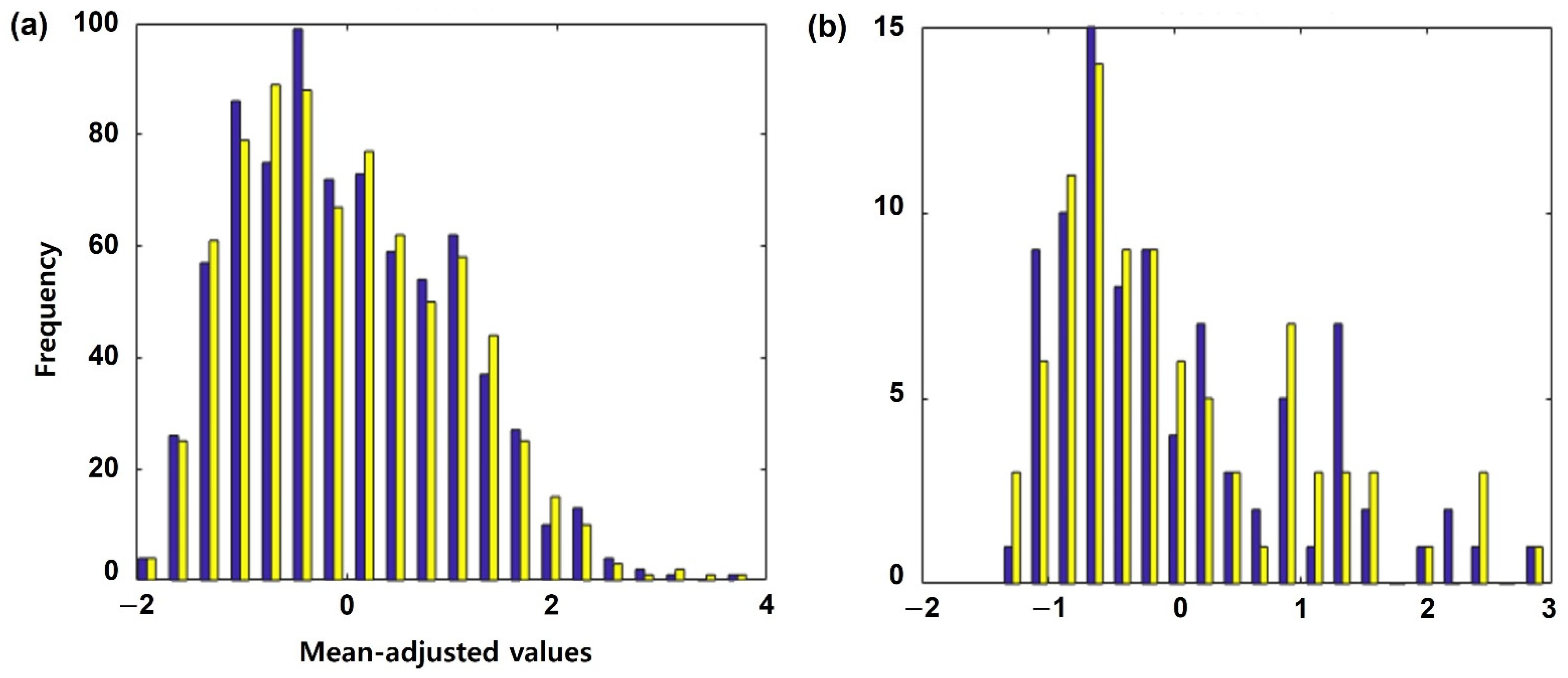

| Testbed | Min | Max | Mean | Standard Deviation | Skewness | Kurtosis | (%) | |

|---|---|---|---|---|---|---|---|---|

| 1 | Photo-mosaic | 70.1 | 75.8 | 72.1 | 0.99 | 0.48 | 2.72 | 98.95 |

| Video-mosaic | 70.4 | 76.3 | 72.5 | 0.98 | 0.50 | 2.74 | ||

| 2 & 3 | Photo-mosaic | 69.2 | 73..5 | 70.6 | 0.95 | 0.96 | 3.18 | 90.52 |

| Video-mosaic | 69.7 | 74.0 | 71.0 | 0.96 | 1.04 | 3.49 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, Y.-S.; Schlüter, S.; Park, S.-I.; Um, J.-S. Comparative Evaluation for Tracking the Capability of Solar Cell Malfunction Caused by Soil Debris between UAV Video versus Photo-Mosaic. Remote Sens. 2022, 14, 1220. https://doi.org/10.3390/rs14051220

Hwang Y-S, Schlüter S, Park S-I, Um J-S. Comparative Evaluation for Tracking the Capability of Solar Cell Malfunction Caused by Soil Debris between UAV Video versus Photo-Mosaic. Remote Sensing. 2022; 14(5):1220. https://doi.org/10.3390/rs14051220

Chicago/Turabian StyleHwang, Young-Seok, Stephan Schlüter, Seong-Il Park, and Jung-Sup Um. 2022. "Comparative Evaluation for Tracking the Capability of Solar Cell Malfunction Caused by Soil Debris between UAV Video versus Photo-Mosaic" Remote Sensing 14, no. 5: 1220. https://doi.org/10.3390/rs14051220

APA StyleHwang, Y.-S., Schlüter, S., Park, S.-I., & Um, J.-S. (2022). Comparative Evaluation for Tracking the Capability of Solar Cell Malfunction Caused by Soil Debris between UAV Video versus Photo-Mosaic. Remote Sensing, 14(5), 1220. https://doi.org/10.3390/rs14051220