Evaluation of Field Applicability of High-Speed 3D Digital Image Correlation for Shock Vibration Measurement in Underground Mining

Abstract

:1. Introduction

2. Methodology

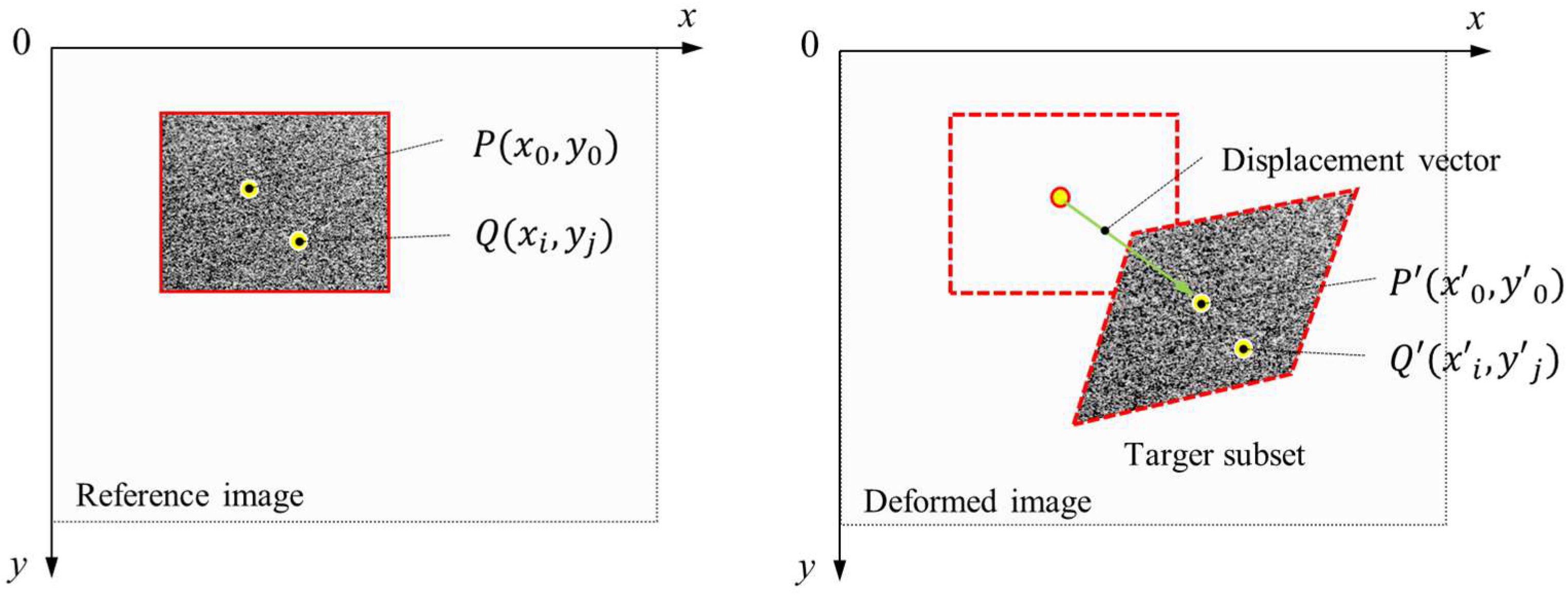

2.1. Overview of DIC Technique

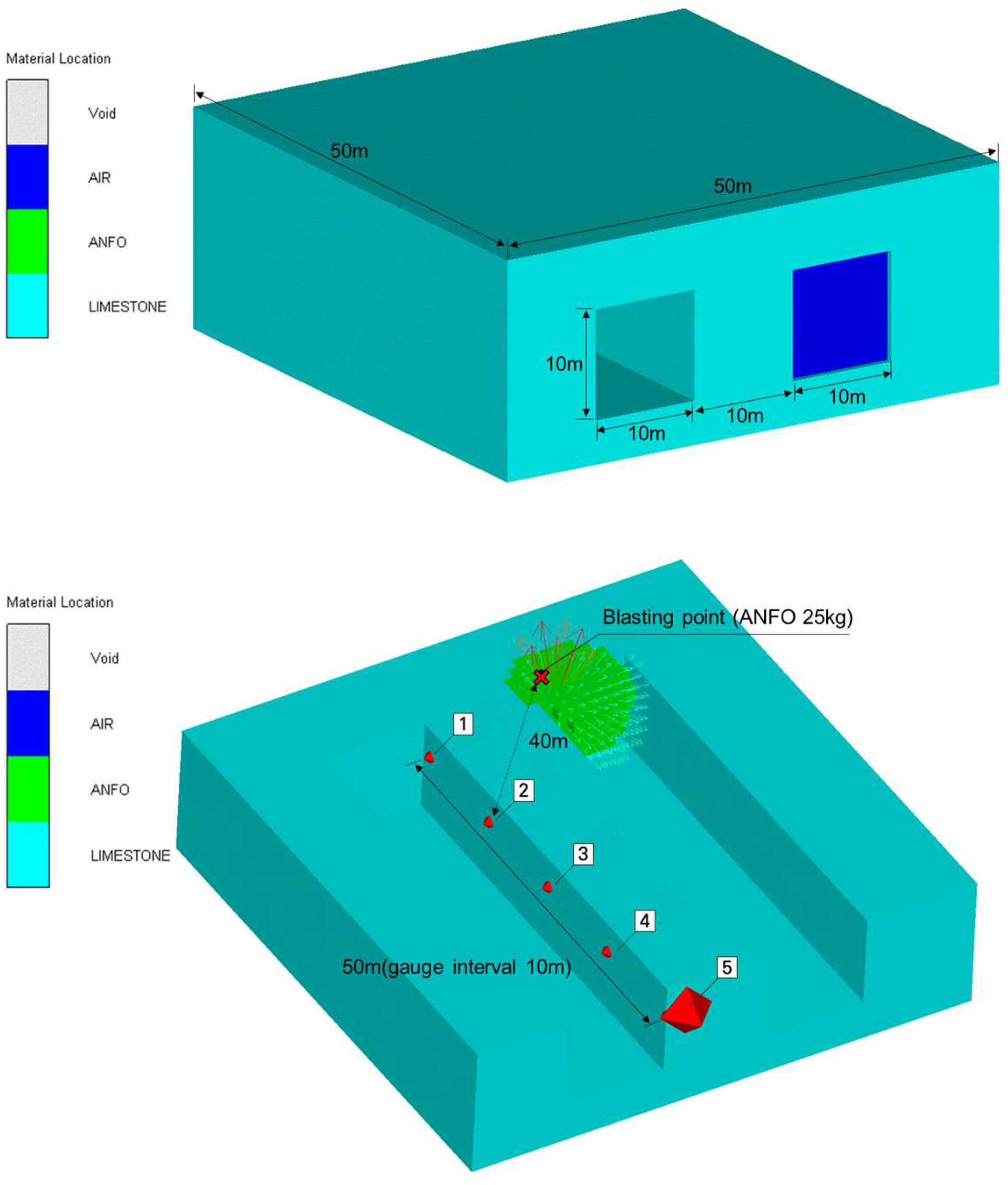

2.2. Numerical Simulation

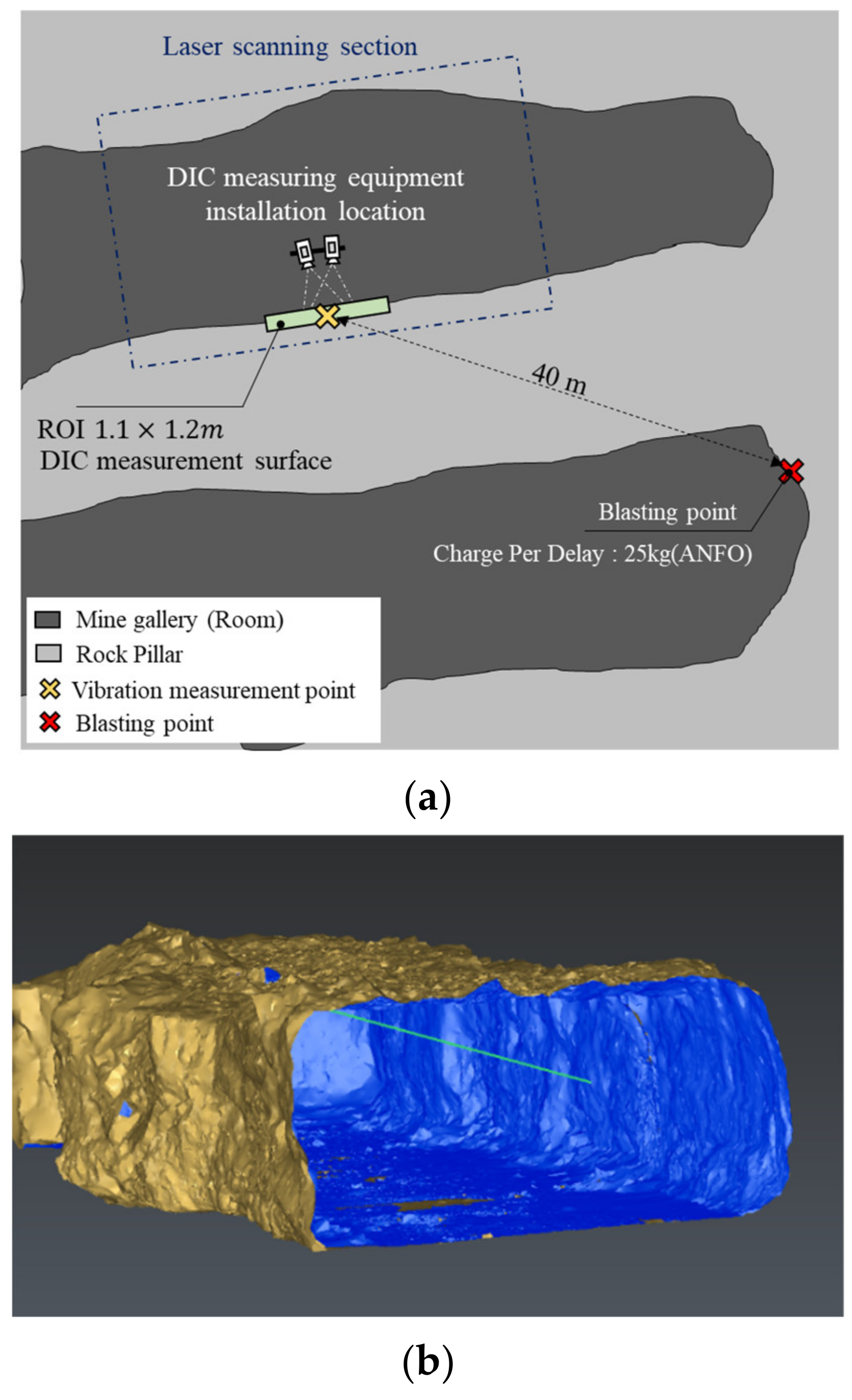

3. Experiment Setup

4. Test Results

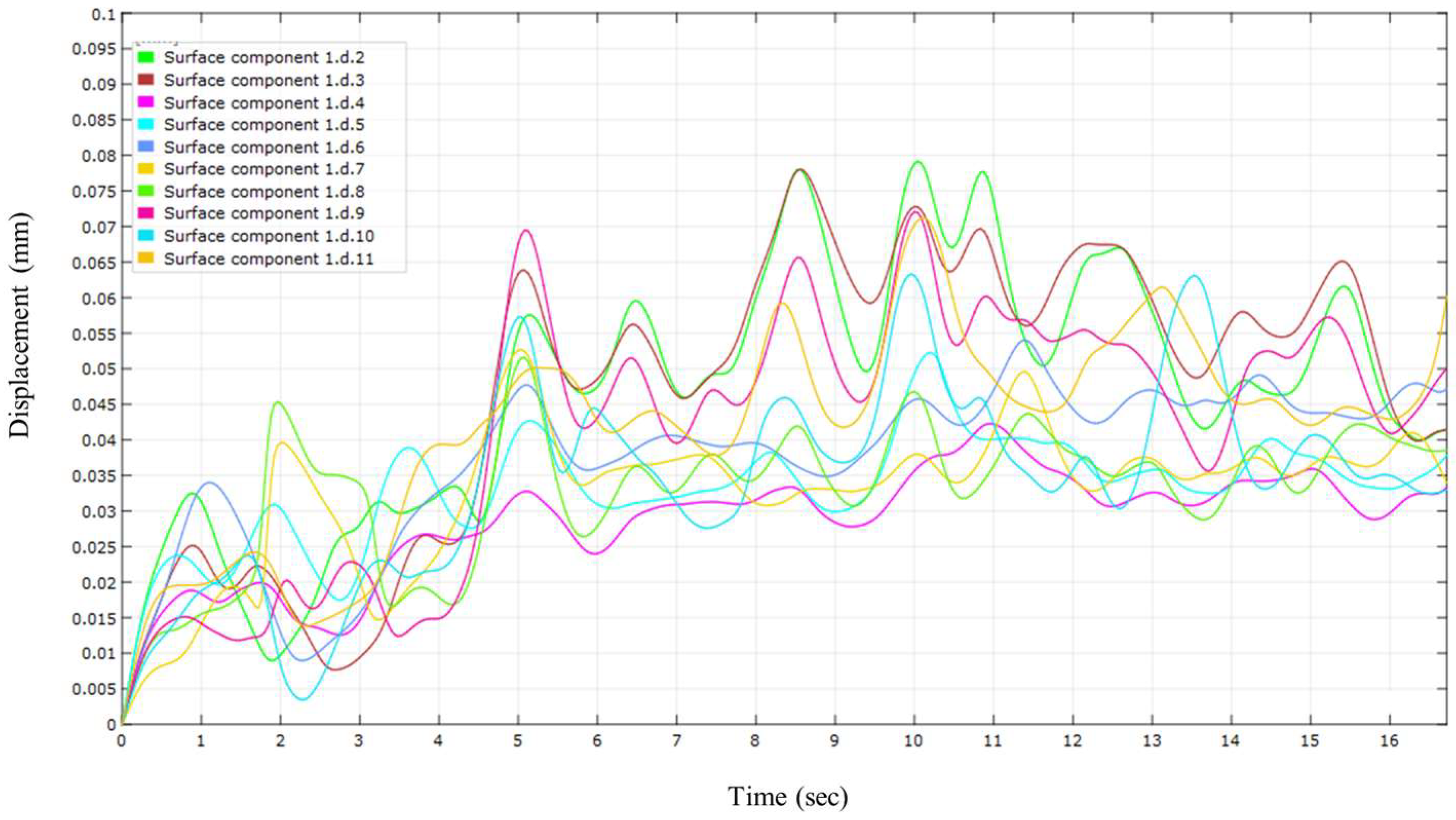

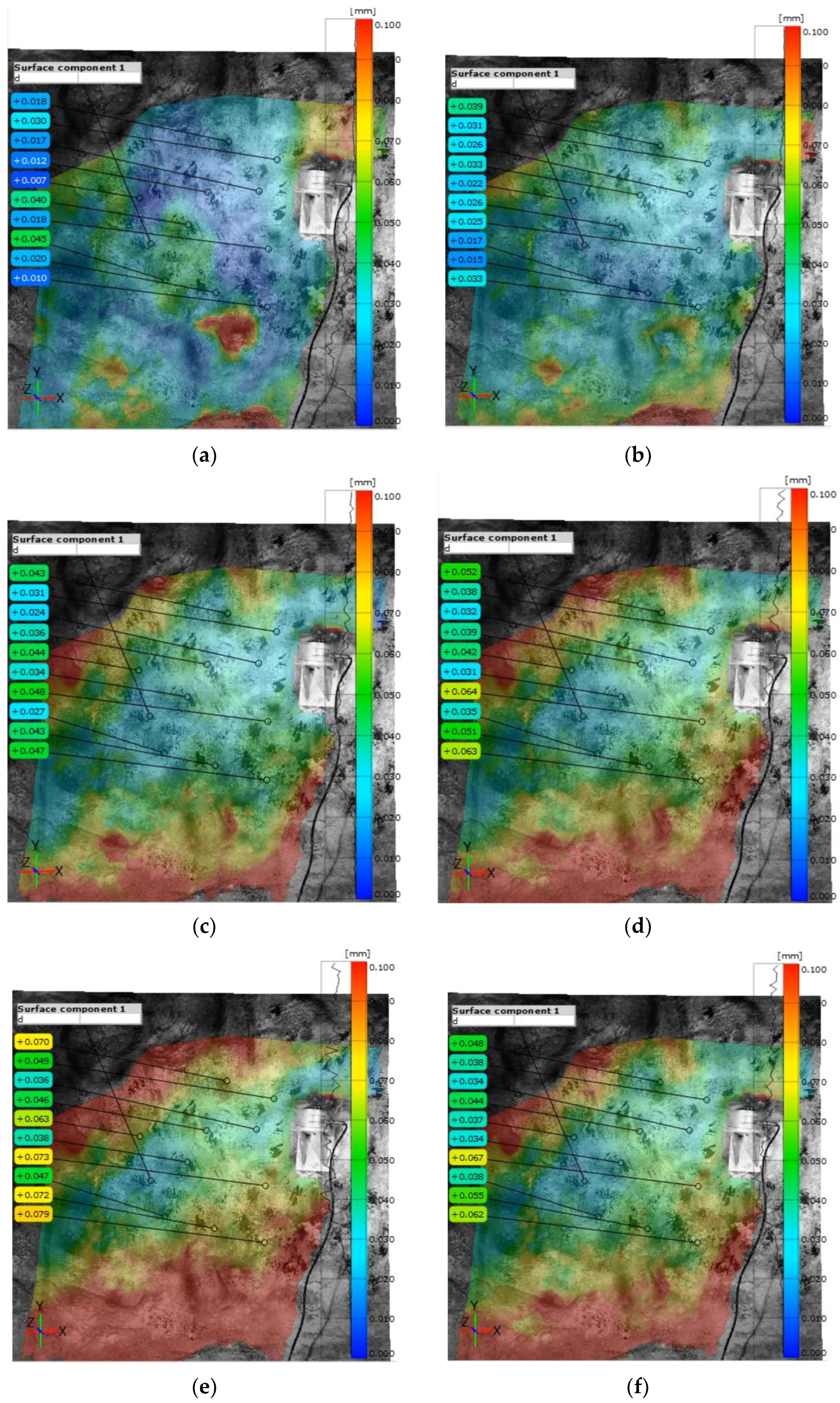

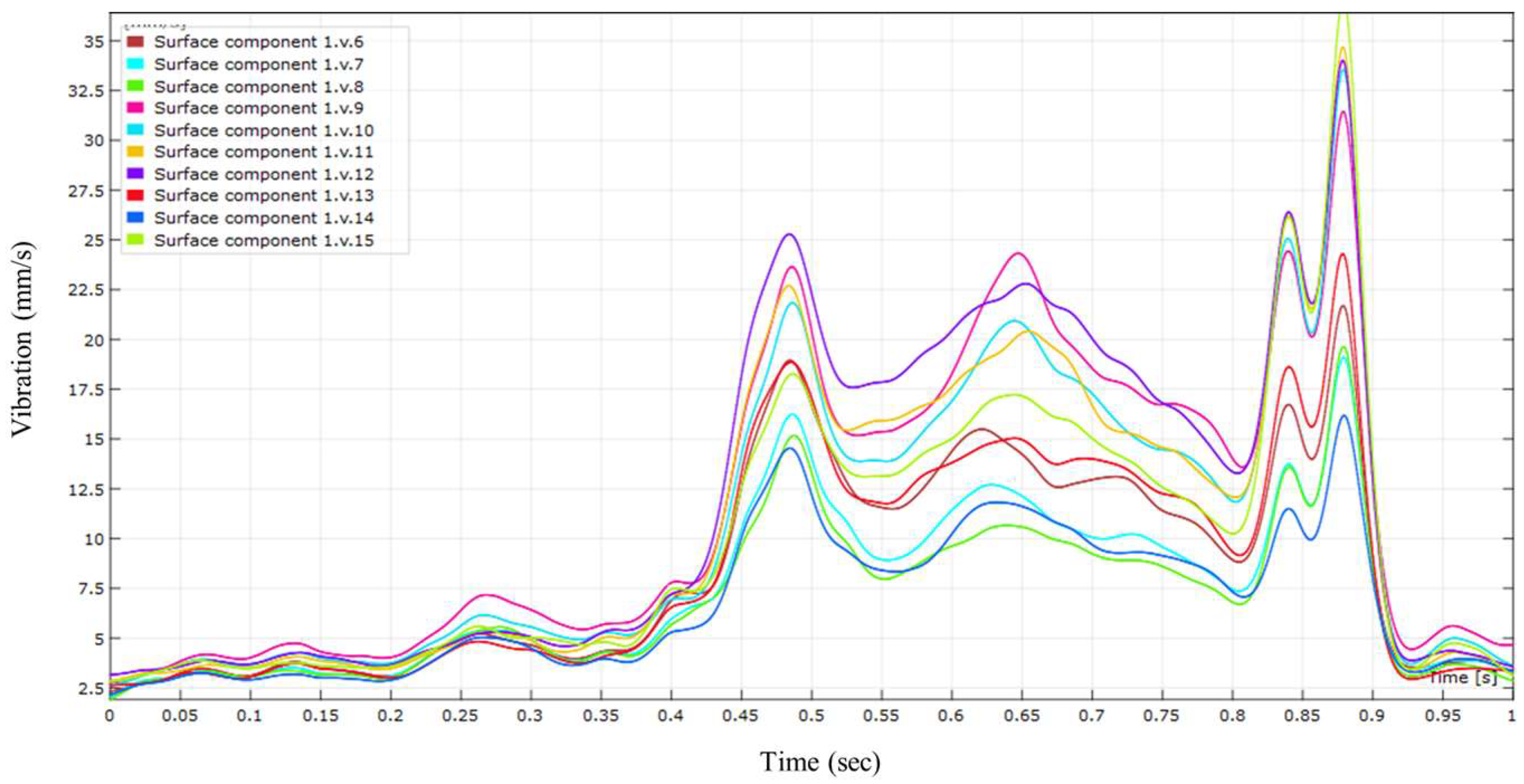

4.1. Measurement Results Using DIC

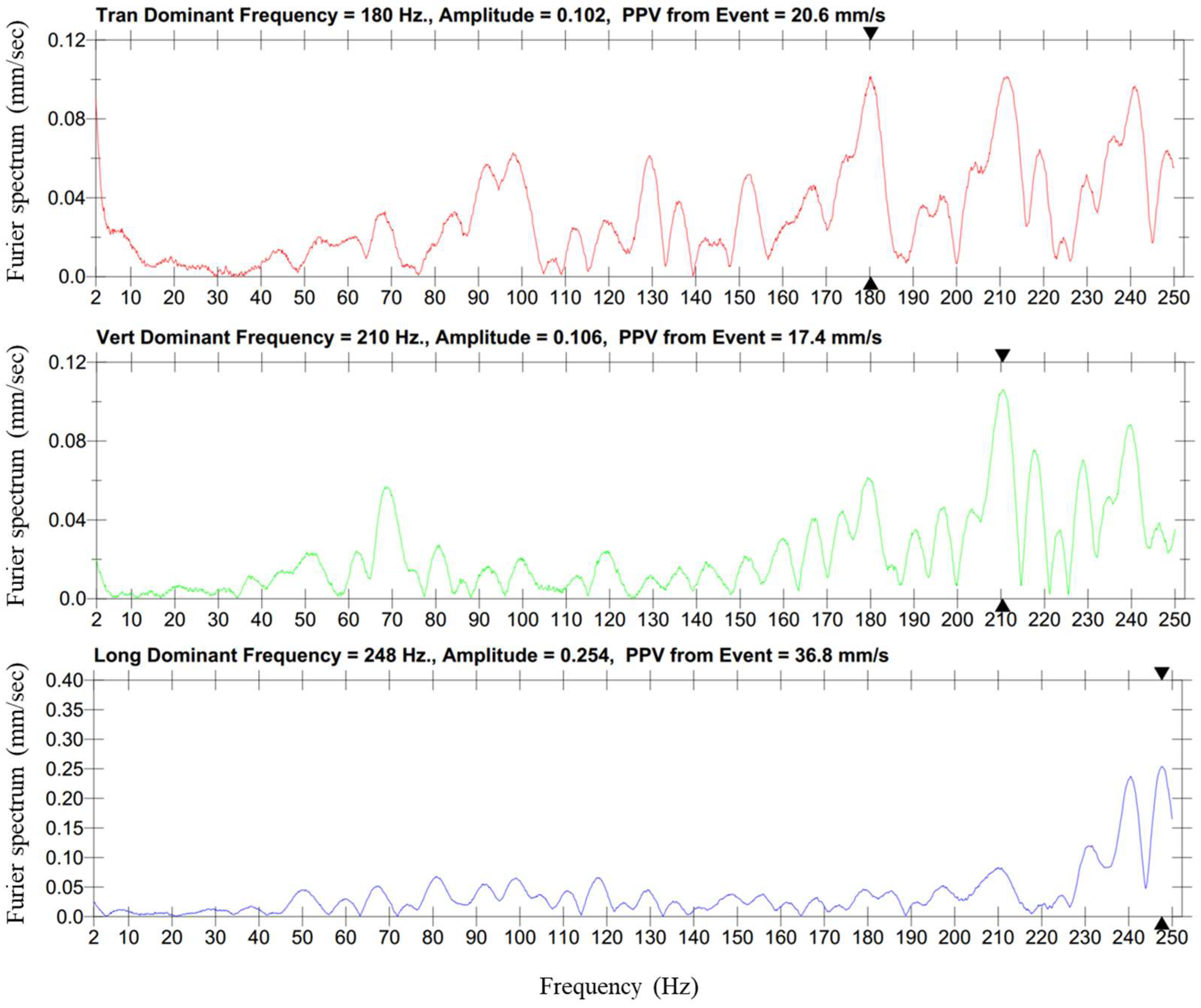

4.2. Measurement Results Using Vibration Measurement Instruments

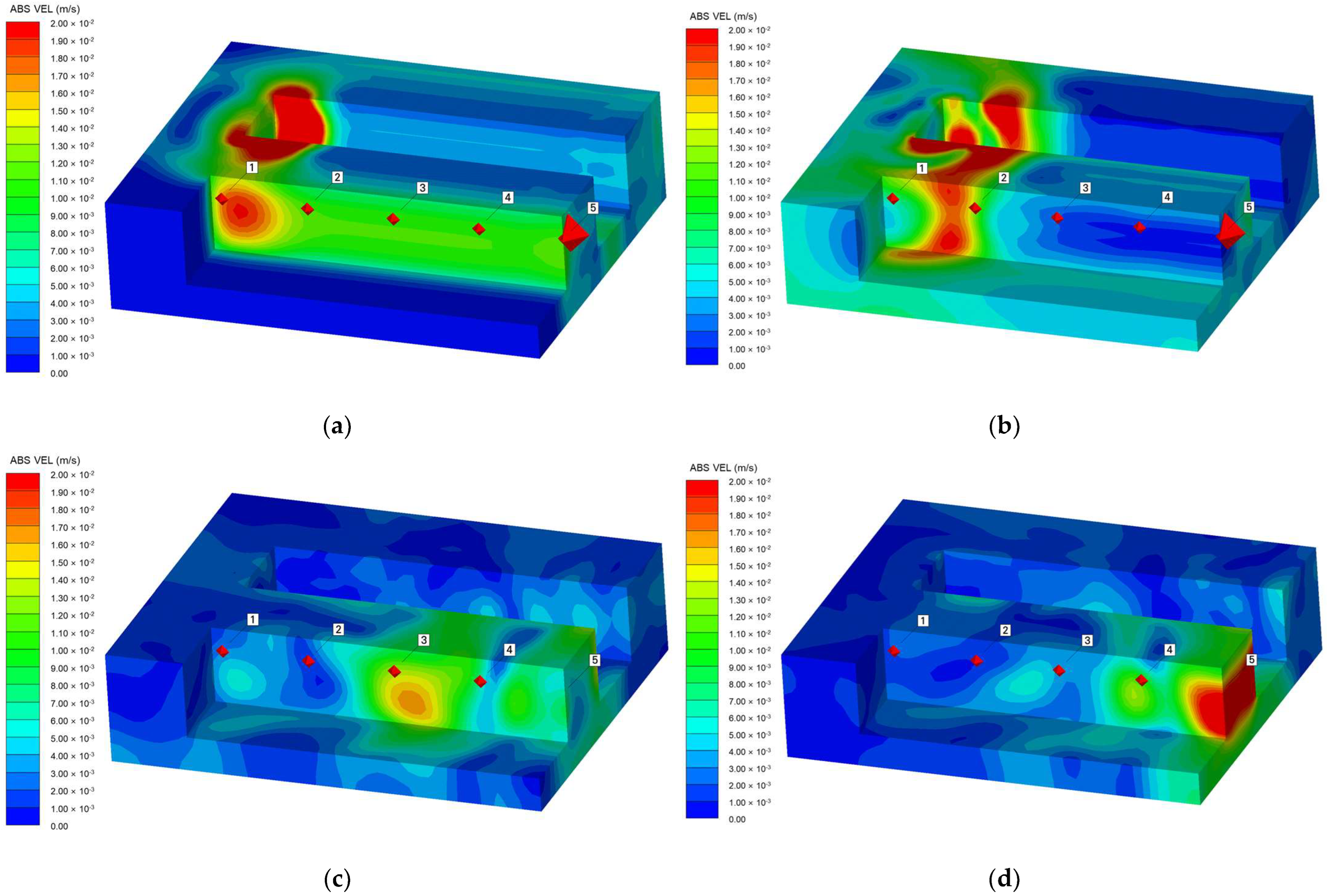

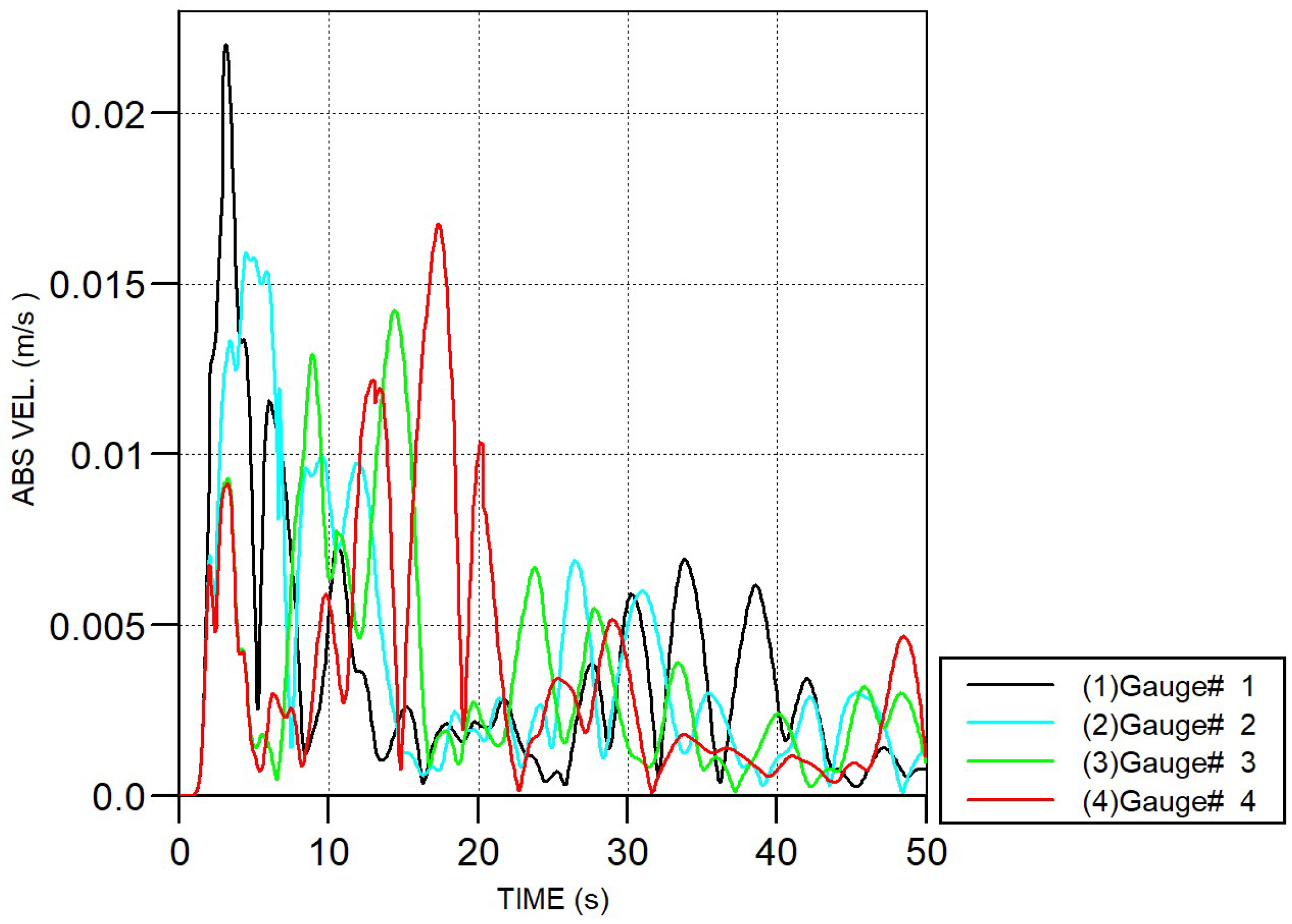

4.3. Numerical Simulation Results

5. Discussion

6. Conclusions

- The conventionally measured data and data obtained using DIC were compared, and the results showed that both the peak displacement and the peak particle velocity were very similar to the actual measured values.

- The above results confirmed the feasibility of using a blasting displacement and vibration measurement system in conjunction with the DIC technique and a stereo camera system and high-speed camera.

- A camera with a capture speed that is 10–20 times faster than the vibration frequency is commonly required to precisely measure vibrations with DIC. Although the range of blast-induced natural frequencies varies depending on the site, an HD ultrahigh-speed camera of at least 3000 fps is required to analyze blasting vibration waveforms more precisely.

- As a result of comparing the DIC results for blast vibration with the measured values of the contact sensor through field tests, the maximum displacement and vibration speeds were found to be 86 and 93% accurate, respectively. In addition, as a result of numerical analysis through blast modeling, the vibration velocity caused by the explosion and the contour pattern generated on the tunnel wall were similar to the DIC results. Accordingly, it is judged that high-speed cameras and DICs can be used to measure blast vibration in underground mines.

- The experiments in this study were conducted within a limited ROI. However, it is expected that the configuration of a stereo DIC system capable of measuring a wider ROI can ensure applicability and utilization in various blast engineering fields, such as the evaluation of the stability of advanced length during nearby tunnel excavations, real-time stability of adjacent rock pillars, and monitoring of multiple blast displacements on the object of interest at remote distances.

- In this study, we focused on evaluating the applicability of high-speed cameras and DICs to actual blasting sites. The accuracy compared to the measured value of the existing contact sensor may be insufficient; however, it is judged that an experiment to establish the stereo system conditions optimized for the field is necessary, which can be achieved by adjusting the distance to the baseline of the stereo camera and the target plane in the tunnel. In addition, in order to reduce the measurement cost due to the use of two or more high-speed cameras, it will be necessary to maximize cost-effectiveness by applying stereo DIC with a single camera.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sutton, M.; Orteu, J.; Schreier, H. Image, Correlation for Shape, Motion, and Deformation Measurements: Basic Concepts, Theory and Application; Springer Science Business Media LLC: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A Review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Sutton, M.A.; Hild, F. Recent Advances and Perspectives in Digital Image Correlation. Exp. Mech. 2015, 55, 1–8. [Google Scholar] [CrossRef]

- Pan, B. Digital image correlation for surface deformation measurement: Historical developments, recent advances and future goals. Meas. Sci. Technol. 2018, 29, 082001. [Google Scholar] [CrossRef]

- Maccioni, L.; Concli, F. Fracture locus of a CORTEN steel: Finite Element calibration based on experimental results. Procedia Struct. Integr. 2019, 24, 738–745. [Google Scholar] [CrossRef]

- Farahani, B.V.; de Melo, F.Q.; Tavares, P.J.; Moreira, P.M.G.P. New approaches on the stress intensity factor characterization—Review. Procedia Struct. Integr. 2020, 28, 226–233. [Google Scholar] [CrossRef]

- Lecompte, D.; Vantomme, J.; Sol, H. Crack Detection in a Concrete Beam using Two Different Camera Techniques. Struct. Health Monit. 2006, 5, 59–68. [Google Scholar] [CrossRef]

- Jolin, M.; Küntz, M.; Bastien, J.; Perez, F.; Hild, F. Digital image correlation analysis of crack behaviour in a reinforced concrete beam during a load test. Can. J. Civ. Eng. 2006, 33, 1418–1425. [Google Scholar]

- Destrebecq, J.-F.; Toussaint, E.; Ferrier, E. Analysis of Cracks and Deformations in a Full Scale Reinforce Concrete Beam using a Digital Image Correlation Technique. Exp. Mech. 2011, 51, 879–890. [Google Scholar] [CrossRef]

- Mojsilović, N.; Salmanpour, A.H. Application of Digital Image Correlation for strain measurements of large masonry walls. In Proceedings of the APCOM & ISCM, Zurich, Switzerland, 11–14 December 2013. [Google Scholar]

- Ghorbani, R.; Matta, F.; Sutton, M. Full-Field Deformation Measurement and Crack Mapping on Confined Masonry Walls Using Digital Image Correlation. Exp. Mech. 2014, 55, 227–243. [Google Scholar] [CrossRef]

- Malesa, M.; Malowany, K.; Tomczak, U.; Siwek, B.; Kujawińska, M.; Siemińska-Lewandowska, A. Application of 3D digital image correlation in maintenance and process control in industry. Comput. Ind. 2013, 64, 1301–1315. [Google Scholar] [CrossRef]

- Shao, X.X.; Chen, Z.N.; Dai, X.J.; He, X.Y. Camera array-based digital image correlation for high-resolution strain measurement. Rev. Sci. Instrum. 2018, 89, 105110. [Google Scholar] [CrossRef] [PubMed]

- Beberniss, T.J.; Ehrhardt, D.A. High-speed 3D digital image correlation vibration measurement: Recent advancements and noted limitations. Mech. Syst. Signal Process. 2017, 86, 35–48. [Google Scholar] [CrossRef]

- Baqersad, J.; Poozesh, P.; Niezrecki, C.; Avitabile, P. Photogrammetry and optical methods in structural dynamics—A review. Mech. Syst. Signal Process. 2017, 86, 17–34. [Google Scholar] [CrossRef]

- Srivastava, V.; Baqersad, J. A multi-view optical technique to extract the operating deflection shapes of a full vehicle using digital image correlation. Thin-Walled Struct. 2019, 145, 106426. [Google Scholar] [CrossRef]

- Huňady, R.; Hagara, M. A new procedure of modal parameter estimation for high-speed digital image correlation. Mech. Syst. Signal Process. 2017, 93, 66–79. [Google Scholar] [CrossRef]

- Bharadwaj, K.; Sheidaei, A.; Afshar, A.; Baqersad, J. Full field strain prediction using mode shapes measured with digital image correlation. Measurement 2019, 139, 326–333. [Google Scholar] [CrossRef]

- Pan, B.; Yu, L.; Zhang, Q. Review of single-camera stereo-digital image correlation techniques for full-field 3D shape and deformation measurement. Sci. China Technol. Sci. 2018, 61, 2–20. [Google Scholar] [CrossRef] [Green Version]

- Genovese, K.; Casaletto, L.; Rayas, J.; Flores, V.; Martinez, A. Stereo-Digital Image Correlation (DIC) measurements with a single camera using a biprism. Opt. Lasers Eng. 2013, 51, 278–285. [Google Scholar] [CrossRef]

- Pankow, M.; Justusson, B.; Waas, A.M. Three-dimensional digital image correlation technique using single high-speed camera for measuring large out-of-plane displacements at high framing rates. Appl. Opt. 2010, 49, 3418–3427. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Single-camera high-speed stereo-digital image correlation for full-field vibration measurement. Mech. Syst. Signal Process. 2017, 94, 374–383. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Full-frame, high-speed 3D shape and deformation measurements using stereo-digital image correlation and a single color high-speed camera. Opt. Lasers Eng. 2017, 95, 17–25. [Google Scholar] [CrossRef]

- Xu, Z.; Yang, J.; Guo, L. Study of the Splitting Crack Propagation Morphology Using High Speed 3D DIC. Explos. Shock Waves 2016, 3, 38–41. [Google Scholar]

- Zhao, Y.; Gao, Y.; Wu, S.; Chen, L.; Zhang, C. Experimental and numerical study of failure characteristics of brittle rocks with single internal 3D open-type flaw. Acta Geotech. 2021, 16, 3087–3113. [Google Scholar] [CrossRef]

- Lin, Q.; Labuz, J. Fracture of sandstone characterized by digital image correlation. Int. J. Rock Mech. Min. Sci. 2013, 60, 235–245. [Google Scholar] [CrossRef]

- Zhang, N.; Hedayt, A.; Sosa, H.G.B.; Bernal, R.P.H.; Tupa, N.; Morales, I.Y.; Loza, R.S.C. Fracture Properties of the Gold Mine Tailings-based Geopolymer under Model Loading Condition through Semi-circular Bend Tests with Digital Image Correlation. Theor. Appl. Fract. Mech. 2021, 116, 103116. [Google Scholar] [CrossRef]

- Beberniss, T.; Spottswood, S.; Eason, T. High-Speed Digital Image Correlation Measurements of Random Nonlinear Dynamic Response. In Proceedings of the SEM Annual Conference, Uncasville, CT, USA, 10–13 June 2011. [Google Scholar]

- Beberniss, T.; Spottswood, S.; Eason, T. High-Speed 3D Digital Image Correlation Measurements of Long-duration Random Vibration; Recent Advancements and Noted Limitations. In Proceedings of the ISMA Biennial Conference, Lueven, Belgium, 17–19 September 2012. [Google Scholar]

- Beberniss, T.; Ehrhardt, D. Temporal Aliasing in High-speed 3-Dimmensional Digital Image Correlation Vibration Measurement. In Proceedings of the AIAA SciTech, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Chao, Y.J.; Sutton, M.A. Application of Stereo Vision to Three-dimensional Deformation Analyses in Fracture Experiments. Opt. Eng. 1994, 33, 981–990. [Google Scholar] [CrossRef]

- Lan, I.-F.; Hung, S.-C.; Chen, C.-Y.; Niu, Y.-M.; Shiuan, J.-H. An Improved Simple Method of Deducing JWL Parameters from cylinder expansion test. Propellants Explos. Pyrotech. 1993, 18, 18–24. [Google Scholar] [CrossRef]

- Riedel, W.; Thomaand, K.; Hiermaier, S. Penetration of Reinforced Concrete by BETA-B-500-numerical Analysis Using a New Macroscopic Concrete Model for Hydrocodes. In Proceedings of the 9th International Symposium on Interaction of the Effect of Munitions with Structures, Berlin, Germany, 3–7 May 1999; pp. 315–322. [Google Scholar]

- Nariseti, C. Quantification of Damage in Selected Rocks due to Impact with Tungsten Carbide Bits. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2013. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Reference density | 2.66 | g/cm3 |

| EOS | ||

| Bulk modulus (A1) | 71.2 | GPa |

| Parameter A2 | 49.40 | GPa |

| Parameter A3 | 11.62 | GPa |

| Parameter B0 | 1.22 | - |

| Parameter B1 | 1.22 | - |

| Parameter T1 | 43.87 | GPa |

| Parameter T2 | 0.00 | - |

| Reference temperature | 300.00 | K |

| Specific heat | 654.00 | J/(kg·K) |

| Thermal conductivity | 0.00 | - |

| Strength | ||

| Shear modulus (G) | 24.2 | GPa |

| Compressive strength (fc) | 100 | MPa |

| Tensile strength (ft/fc) | 0.05 | - |

| Shear strength (fs/fc) | 0.07 | - |

| Intact failure surface constant (A) | 0.80 | - |

| Intact failure surface exponent (N) | 0.61 | - |

| Tens/Comp meridian ratio (Q) | 0.72 | - |

| Brittle to ductile transition | 0.01 | - |

| G | 1.10 | - |

| Elastic strength/ft | 0.40 | - |

| Elastic strength/fc | 0.85 | - |

| Fractured strength constant (B) | 2.67 | - |

| Fractured strength constant (M) | 0.61 | - |

| Compressive strain rate | 0.025 | - |

| Tensile strain rate | 0.045 | - |

| Failure | ||

| Damage constant D1 | 0.005 | - |

| Damage constant D2 | 0.7 | - |

| Minimum strain to failure | 0.06 | - |

| Residual shear modulus fraction | 0.250 | - |

| Tensile failure | Hydro | - |

| Charge Per Delay (kg/Delay) | Charge Hole Diameter (mm) | Charge Density (kg/m3) | Charge Hole Length (m) | Charge Length (m) | Total Charge Explosives (kg) |

|---|---|---|---|---|---|

| 25 | 51 | 0.8 (ANFO) | 3.8 | 2.5 | 95.8 |

| No. | Tran (T) | Vert (V) | Long (L) |

|---|---|---|---|

| 1 | 0.066 | 0.007 | 0.015 |

| 2 | 0.073 | 0.008 | 0.017 |

| 3 | 0.065 | 0.029 | 0.011 |

| Peak vector sum (PPV) (mm/s) | 20.6 | 17.4 | 36.8 |

| Type | Vibration Measurement | DIC | Similarity (%) |

|---|---|---|---|

| Mean of the peak displacement (T) (mm) | 0.068 | 0.078 | 86 |

| Mean of the peak particle velocity (mm/s) | 32.6 | 35 | 93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, S.; Ko, Y.; Chung, M. Evaluation of Field Applicability of High-Speed 3D Digital Image Correlation for Shock Vibration Measurement in Underground Mining. Remote Sens. 2022, 14, 3133. https://doi.org/10.3390/rs14133133

Seo S, Ko Y, Chung M. Evaluation of Field Applicability of High-Speed 3D Digital Image Correlation for Shock Vibration Measurement in Underground Mining. Remote Sensing. 2022; 14(13):3133. https://doi.org/10.3390/rs14133133

Chicago/Turabian StyleSeo, Seunghwan, Younghun Ko, and Moonkyung Chung. 2022. "Evaluation of Field Applicability of High-Speed 3D Digital Image Correlation for Shock Vibration Measurement in Underground Mining" Remote Sensing 14, no. 13: 3133. https://doi.org/10.3390/rs14133133

APA StyleSeo, S., Ko, Y., & Chung, M. (2022). Evaluation of Field Applicability of High-Speed 3D Digital Image Correlation for Shock Vibration Measurement in Underground Mining. Remote Sensing, 14(13), 3133. https://doi.org/10.3390/rs14133133