An Environmental Life-Cycle Assessment of End-of-Life Vehicles Management in Romania

Abstract

1. Introduction

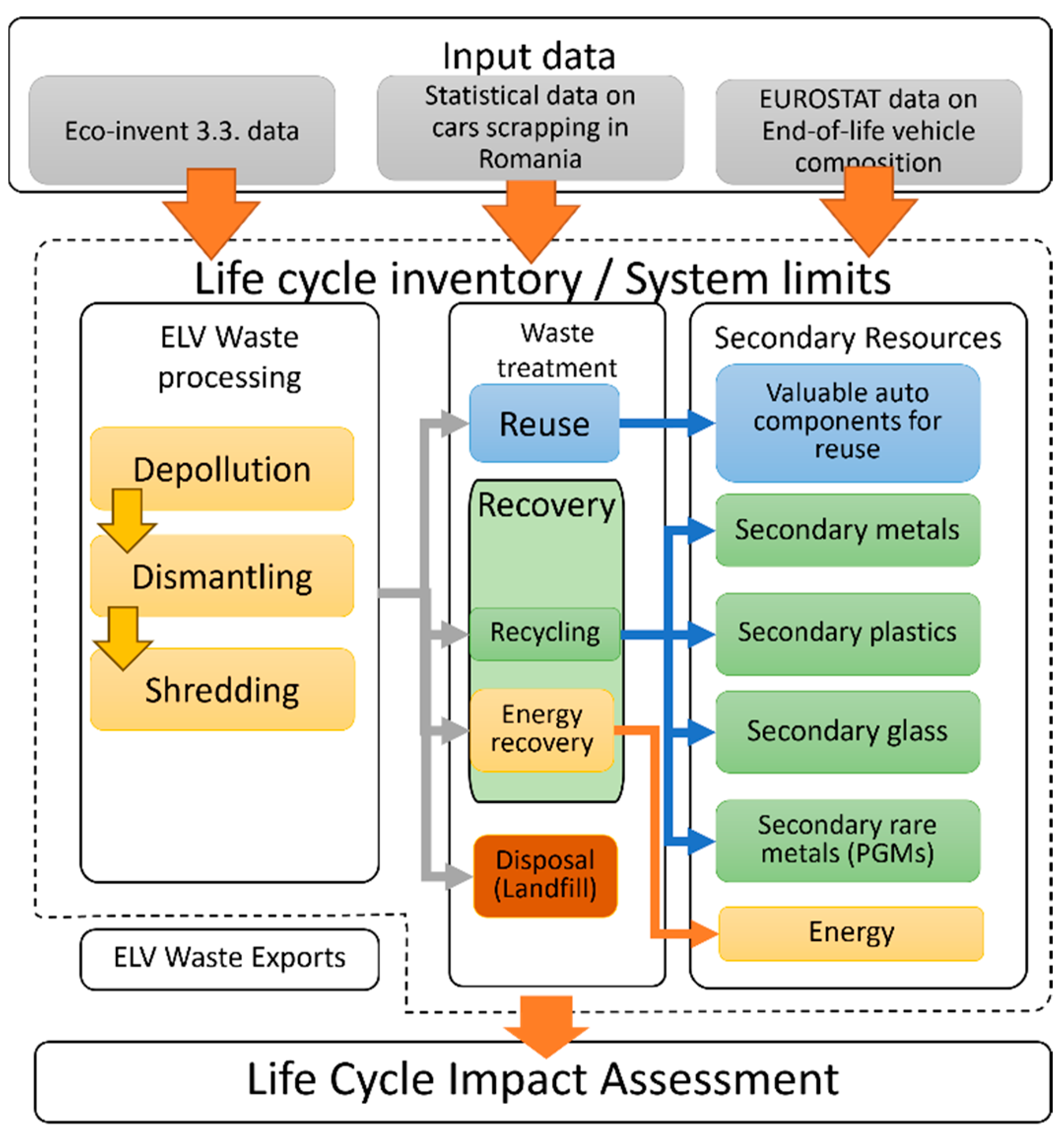

2. Materials and Methods

2.1. Research Methodology

2.2. Data Sources

2.3. Life-Cycle Assessment Methodology

3. Results and Discussion

3.1. Life-Cycle Inventory

3.2. Environmental Profiles

3.2.1. Landfilling

3.2.2. Energy Recovery

3.2.3. ELV Recycling

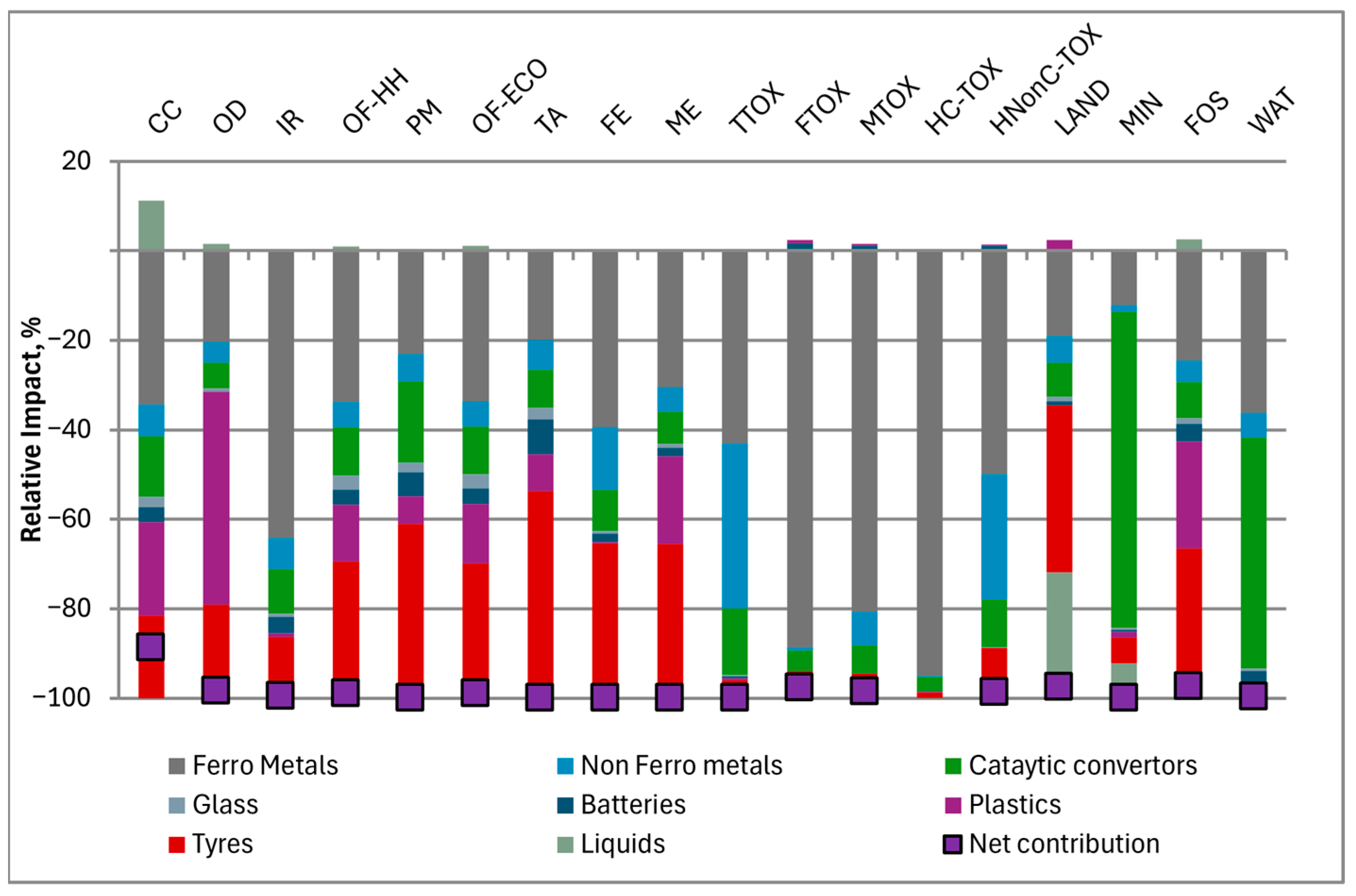

3.2.4. ELV Components Reuse

3.3. Profiles Comparison

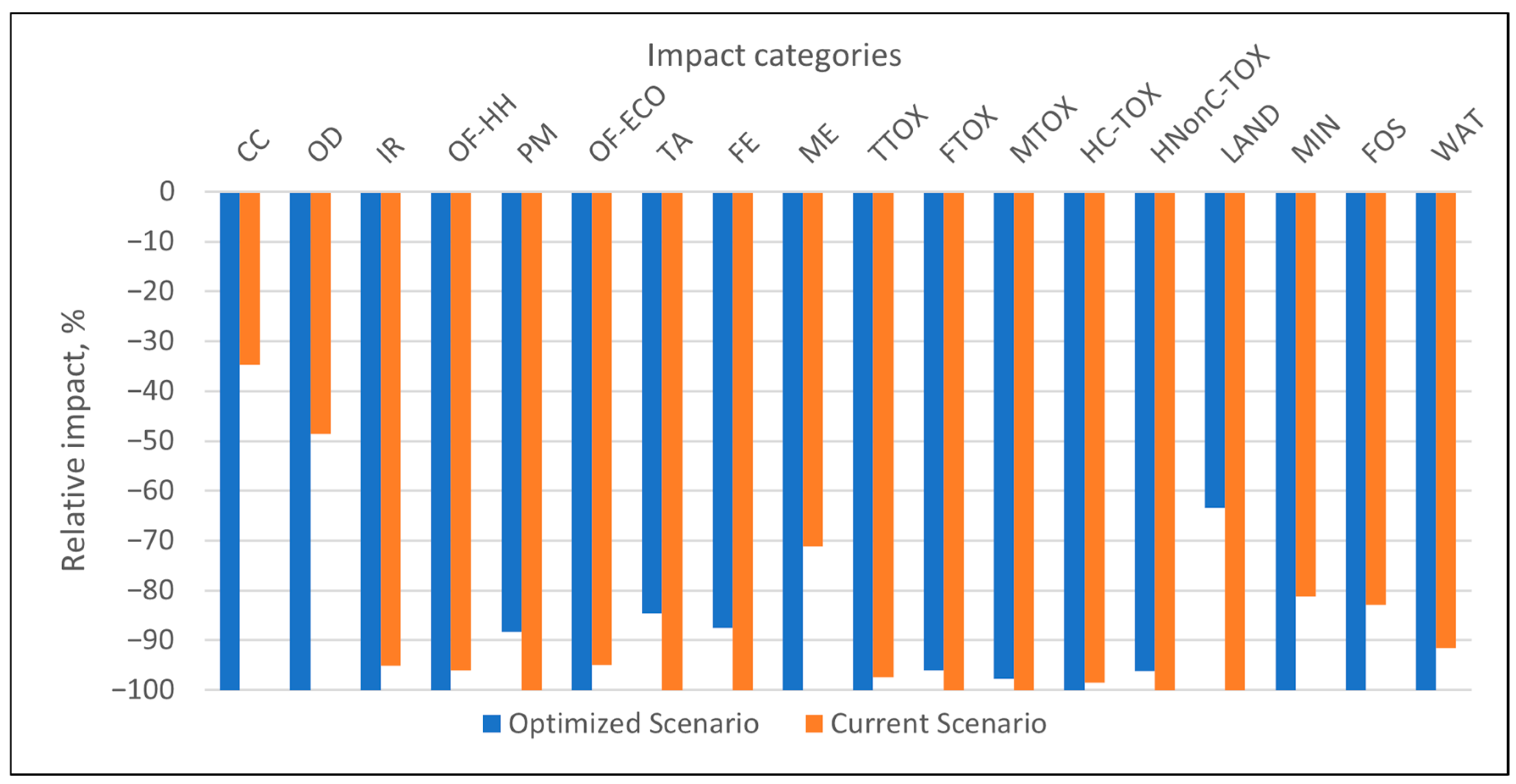

3.4. Environmental Assessment of Future ELV Scenario

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ELV | End-of-life vehicles |

| ICEV | Internal combustion engine vehicle |

| LCA | Life-cycle assessment |

| CC | Climate Change (global warming) |

| OD | Stratospheric ozone depletion |

| IR | Ionizing radiation |

| OF-HH | Ozone formation, Human health |

| PM | Fine particulate matter formation |

| OF-ECO | Ozone formation, Terrestrial ecosystems |

| TA | Terrestrial acidification |

| FE | Freshwater eutrophication |

| ME | Marine eutrophication |

| TTOX | Terrestrial ecotoxicity |

| FTOX | Freshwater ecotoxicity |

| MTOX | Marine ecotoxicity |

| HC-TO | Human carcinogenic toxicity |

| HNonC-TOX | Human non-carcinogenic toxicity |

| LAND | Land use |

| MIN | Mineral resource scarcity |

| FOS | Fossil resource scarcity |

| WAT | Water consumption |

| ABS | Acrylonitrile butadiene styrene |

| PMMA | Polymethyl methacrylate |

| POM | Polyoxymethylene |

| PVC | Polyvinyl chloride |

| PS | Polystyrene |

| PC | Polycarbonate |

References

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of End-of-Life Vehicles: Assessing Trends and Performances in Europe. Technol. Forecast. Soc. Chang. 2020, 152, 119887. [Google Scholar] [CrossRef]

- Løvik, A.N.; Marmy, C.; Kushnir, D.; Huisman, J.; Maury, T.; Ciuta, T.; Mathieux, F.; Wäger, P. Material Composition Trends in Vehicles: Critical Raw Materials and Other Relevant Metals; European Commission: Brussels, Belgium, 2021; ISBN 9789276452133. [Google Scholar]

- Ravina, M.; Bianco, I.; Ruffino, B.; Minardi, M.; Panepinto, D.; Zanetti, M. Hard-to-Recycle Plastics in the Automotive Sector: Economic, Environmental and Technical Analyses of Possible Actions. J. Clean. Prod. 2023, 394, 136227. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, L.; Zheng, J.; Ding, R.; Li, K.; Zhao, H.; Baqar, M.; Zhu, H.; Cheng, Z.; Sun, H. End-of-Life Vehicle Dismantling Activity Emits Large Quantities of Phthalates and Their Alternatives: New Insights on Environmental Sources and Co-Exposure Risks. Environ. Int. 2024, 190, 108933. [Google Scholar] [CrossRef]

- Hu, S.; Wen, Z. Monetary Evaluation of End-of-Life Vehicle Treatment from a Social Perspective for Different Scenarios in China. J. Clean. Prod. 2017, 159, 257–270. [Google Scholar] [CrossRef]

- European Commission. Impact Assessment Report for the ELV Regulation (Executive Summary); European Commission: Brussels, Belgium, 2023. [Google Scholar]

- European Commission. Porposal for a Regulation of the European Parliament and of the Council on Circularity Requirements for Vehicle Design and on Management of End-of-Life Vehicles, Amending Regulations (EU) 2018/858 and 2019/1020 and Repealing Directives 2000/53/EC and 2005; European Commission: Brussels, Belgium, 2023; Volume 0284. [Google Scholar]

- Chong, J.Y.; Mat Saman, M.Z.; Ngadiman, N.H.A. End-of-Life Vehicles Research Development in Malaysia: A Comprehensive Review with the Integrated Conceptual Model of Innovative Sustainable Manufacturing Elements. J. Mater. Cycles Waste Manag. 2023, 25, 698–716. [Google Scholar] [CrossRef]

- Karagoz, S.; Aydin, N.; Simic, V. End-of-Life Vehicle Management: A Comprehensive Review. J. Mater. Cycles Waste Manag. 2020, 22, 416–442. [Google Scholar] [CrossRef]

- European Parliament. Council of the European Union Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End-of Life Vehicles—Commission Statements. Off. J. Eur. Union 2000, 269, 34. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32000L0053 (accessed on 21 February 2025).

- Baron, Y.; Kosińska-Terrade, I.; Loew, C.; Köhler, A.; Moch, K.; Sutter, J.; Graulich, K.; Adjei, F.; Mehlhart, G. Study to Support the Impact Assessment for the Review of Directive 2000/53/EC on End-of-Life Vehicles—Final Report; Publications Office of the European Union: Brussels, Belgium, 2023. [Google Scholar]

- European Parliament, Council of the European Union. Directive 2005/64/EC of the European Parliament and of the Council of 26 October 2005 on the type-approval of motor vehicles with regard to their reusability, recyclability and recoverability and amending Council Directive 70/156/EEC. Off. J. Eur. Union 2005, 56, 10–27. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:2005:310:TOC (accessed on 21 February 2025).

- Tazi, N.; Orefice, M.; Marmy, C.; Baron, Y.; Ljunggren, M.; Wäger, P.; Mathieux, F. Initial Analysis of Selected Measures to Improve the Circularity of Critical Raw Materials and Other Materials in Passenger Cars; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar]

- Zhou, F.; Lim, M.K.; He, Y.; Lin, Y.; Chen, S. End-of-Life Vehicle (ELV) Recycling Management: Improving Performance Using an ISM Approach. J. Clean. Prod. 2019, 228, 231–243. [Google Scholar] [CrossRef]

- Staniszewska, E.; Klimecka-Tatar, D.; Obrecht, M. Eco-Design Processes in the Automotive Industry. Prod. Eng. Arch. 2020, 26, 131–137. [Google Scholar] [CrossRef]

- Anselma, P.G.; Belingardi, G. Comparing Battery Electric Vehicle Powertrains through Rapid Component Sizing. Int. J. Electr. Hybrid Veh. 2019, 11, 36–58. [Google Scholar] [CrossRef]

- Jung, H. Fuel Economy of Plug-In Hybrid Electric and Hybrid Electric Vehicles: Effects of Vehicle Weight, Hybridization Ratio and Ambient Temperature. World Electr. Veh. J. 2020, 11, 31. [Google Scholar] [CrossRef]

- Mierlo, J. Van Special Issue “Plug-In Hybrid Electric Vehicle (PHEV)”. Appl. Sci. 2019, 9, 2829. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, B.; Jiao, K. Life Cycle Assessment of Fuel Cell, Electric and Internal Combustion Engine Vehicles under Different Fuel Scenarios and Driving Mileages in China. Energy 2020, 198, 117365. [Google Scholar] [CrossRef]

- Alvarez-Meaza, I.; Zarrabeitia-Bilbao, E.; Rio-Belver, R.M.; Garechana-Anacabe, G. Fuel-Cell Electric Vehicles: Plotting a Scientific and Technological Knowledge Map. Sustainability 2020, 12, 2334. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, K.; Liu, W.; Cui, X.; Liu, Y.; Cui, Z. Collaborative Approach for Environmental and Economic Optimization Based on Life Cycle Assessment of End-of-Life Vehicles’ Dismantling in China. J. Clean. Prod. 2020, 276, 124288. [Google Scholar] [CrossRef]

- Purwani, A.; Sutopo, W.; Hisjam, M.; Widiyanto, A. Approach For Determining Cut-off Values For Electric Motorcycle Swap Battery Before The End-of-Life In The Recycling Classification. J. Appl. Sci. Eng. 2025, 28, 811–820. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J. Life Cycle Assessment for Spent Lithium-Ion Batteries’ Recycling Process: Environmental Impact, Energy Consumption, and Sensitivity Analysis. ACS Sustain. Chem. Eng. 2024, 12, 12966–12975. [Google Scholar] [CrossRef]

- Chayutthanabun, A.; Chinda, T.; Papong, S. End-of-Life Management of Electric Vehicle Batteries Utilizing the Life Cycle Assessment. J. Air Waste Manag. Assoc. 2025, 75, 131–143. [Google Scholar] [CrossRef]

- Liu, C.; Ren, J.; Hu, Y.; Song, J.; Yang, W. Future Projections and Life Cycle Assessment of End-of-Life Tires to Energy Conversion in Hong Kong: Environmental, Climate and Energy Benefits for Regional Sustainability. Sustain. Prod. Consum. 2025, 55, 328–339. [Google Scholar] [CrossRef]

- Mügge, J.; Seegrün, A.; Faßbender, L.; Riedelsheimer, T.; Staufenbiel, P.; Lindow, K. Integrated Consideration of Data Flows and Life Cycle Assessment in Vehicle Dismantling Processes. Procedia CIRP 2024, 122, 1018–1023. [Google Scholar] [CrossRef]

- Ahmed, S.; Ahmed, S.; Shumon, M.R.H.; Falatoonitoosi, E.; Quader, M.A. A Comparative Decision-Making Model for Sustainable End-of-Life Vehicle Management Alternative Selection Using AHP and Extent Analysis Method on Fuzzy AHP. Int. J. Sustain. Dev. World Ecol. 2016, 23, 83–97. [Google Scholar] [CrossRef]

- dos Santos Soares, T.; Silva, M.M.; Santos, S.M. A Hybrid Grey-DEMATEL Approach to Identify Barriers to the Implementation of an End-of-Life Vehicle Management System in Brazil. J. Clean. Prod. 2023, 386, 135791. [Google Scholar] [CrossRef]

- Rosa, P.; Terzi, S. Improving End of Life Vehicle’s Management Practices: An Economic Assessment through System Dynamics. J. Clean. Prod. 2018, 184, 520–536. [Google Scholar] [CrossRef]

- Anthony, C.; Cheung, W.M. Cost Evaluation in Design for End-of-Life of Automotive Components. J. Remanuf. 2017, 7, 97–111. [Google Scholar] [CrossRef]

- DGPCI – General Directorate for Driving Licenses and Registrations of Ministry of Internal Affairs (Directia Generala Permise de Conducere si Inmatriculari a Ministerului Afacerilor Interne). National Automotive Park Statistics at 31 December 2014. Available online: https://dgpci.mai.gov.ro/news-details/statistica/6790c7e978b3ca04620e1e29 (accessed on 20 March 2025).

- Barjoveanu, G.; Dinita, F.; Teodosiu, C. Aging Passenger Car Fleet Structure, Dynamics, and Environmental Performance Evaluation at the Regional Level by Life Cycle Assessment. Sustainability 2022, 14, 8443. [Google Scholar] [CrossRef]

- EUROSTAT. Manual for the Implementation of Regulation (EC) No 2150/2002 on Waste Statistics, 2024 Edition; EUROSTAT: Luxemburg, 2024. [Google Scholar]

- European Commission. Annex V. Waste subject to the export prohibition in article 36 introductory notes. Off. J. Eur. Union 2006, C 272E, 49, 123–170. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:C:2006:272E:TOC (accessed on 21 February 2025).

- Sander, K.; Schilling, S.; Lüskow, H.; Gonser, J.; Schwedtje, A.; Küchen, V. Review of the European List of Waste; European Commission: Brussels, Belgium, 2008; p. 532. [Google Scholar]

- Nis, R. TRN103C—Registered Road Vehicles (End of the Year), by Groups of Age Data Set. Available online: http://statistici.insse.ro:8077/tempo-online/#/pages/tables/insse-table (accessed on 21 February 2025).

- ISO 14040; Environmental Management—Life Cycle Assessment—Part 1: Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006; Volume 3.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1.1; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2017. [Google Scholar]

- Greer, E.L.; Brunet, A. Different Dietary Restriction Regimens Extend Lifespan by Both Independent and Overlapping Genetic Pathways in C. Elegans. Aging Cell 2009, 8, 113–127. [Google Scholar] [CrossRef]

- ERTMA. New End-of-Life Tyres Statistics for 2020 and 2021. ERTMA—European Tyre & Rubber Manufacturers Association. Available online: https://www.etrma.org/news/new-end-of-life-tyre-statistics-2020-2021/ (accessed on 20 February 2025).

- ERTMA. ERTMA Consolidated Data Report on the Management of End of Life Tyres ( ELTs ) in Europe; ERTMA—European Tyre & Rubber Manufacturers Association: Brussels, Belgium, 2021. [Google Scholar]

- UBA. End-of-Life Vehicle Reuse/Recycling/Recovery Rates in Germany for 2008 Pursuant to Art. 7 (2) of the End-of-Life Vehicles Directive 2000/53/EC Country: Germany; UBA—Umwelt Bundesamt: Dessau-Roßlau, Germany, 2015. [Google Scholar]

- Maga, D.; Aryan, V.; Blömer, J. A Comparative Life Cycle Assessment of Tyre Recycling Using Pyrolysis Compared to Conventional End-of-Life Pathways. Resour. Conserv. Recycl. 2023, 199, 107255. [Google Scholar] [CrossRef]

- Bianco, I.; Panepinto, D.; Zanetti, M. End-of-life Tyres: Comparative Life Cycle Assessment of Treatment. Appl. Sci. 2021, 11, 3599. [Google Scholar] [CrossRef]

- Betke, U.; Lieb, A. Micro-Macroporous Composite Materials—Preparation Techniques and Selected Applications: A Review. Adv. Eng. Mater. 2018, 20, 1–28. [Google Scholar] [CrossRef]

- Amatayakul, W.; Ramnäs, O. Life Cycle Assessment of a Catalytic Converter for Passenger Cars. J. Clean. Prod. 2001, 9, 395–403. [Google Scholar] [CrossRef]

- Ghodrat, M.; Rhamdhani, M.A.; Sharafi, P.; Samali, B. A Comparative Life Cycle Assessment of Recycling the Platinum Group Metals from Automobile Catalytic Converter: An Australian Perspective. Metall. Mater. Trans. E 2017, 4, 77–88. [Google Scholar] [CrossRef]

- Unterreiner, L.; Jülch, V.; Reith, S. Recycling of Battery Technologies—Ecological Impact Analysis Using Life Cycle Assessment (LCA). Energy Procedia 2016, 99, 229–234. [Google Scholar] [CrossRef]

- Sebola, M.R.; Mativenga, P.T.; Pretorius, J. A Benchmark Study of Waste Tyre Recycling in South Africa to European Union Practice. Procedia CIRP 2018, 69, 950–955. [Google Scholar] [CrossRef]

- Handbook of Environmental Engineering Calculations, 2nd ed.; Lee, C.C., Lin, S.D., Eds.; McGraw-Hill Education: New York, NY, USA, 2007; ISBN 9780071475839. [Google Scholar]

- Hagelüken, C. Closing the Loop—Recycling of Automotive Catalysts. Metall 2007, 61, 24–39. [Google Scholar]

| Waste Type | Generated (Tonnes/%) | Disposal (Tonnes/%) | Recovered (Tonnes/%) | Energy Recovery (Tonnes/%) | Recycled (Tonnes/%) | Reused (Tonnes/%) |

|---|---|---|---|---|---|---|

| 2 = 3 + 4 + 7 | 3 | 4 = 5 + 6 | 5 | 6 | 7 | |

| Waste arising only from ELV Vehicles | 83,782 | 7079 | 72,188 | 5198 | 66,991 | 4515 |

| 100% | 8.45% | 86.16% | 6.20% | 79.96% | 5.39% | |

| Waste from dismantling and depollution of ELV, of which: | 74,273 | 5259 | 64,499 | 5198 | 59,301 | 4515 |

| 100% | 7.08% | 86.84% | 7.00% | 79.84% | 6.08% | |

| Liquids (excluding fuel) | 3576 | 499 | 3048 | 746 | 2302 | 28 |

| 100% | 13.97% | 85.24% | 20.86% | 64.38% | 0.80% | |

| ELV tires | 11,561 | 452 | 10,748 | 3885 | 6863 | 361 |

| 100% | 3.91% | 92.97% | 33.60% | 59.36% | 3.12% | |

| ELV oil filters | 300 | 46 | 254 | 4 | 250 | 0 |

| 100% | 15.21% | 84.79% | 1.34% | 83.45% | 0.00% | |

| ELV other materials arising from depollution (excluding fuel) | 1230 | 322 | 908 | 346 | 561 | 0 |

| 100% | 26.17% | 73.80% | 28.17% | 45.63% | 0.03% | |

| ELV metal components | 40,998 | 264 | 37,812 | 2 | 37,810 | 2922 |

| 100% | 0.64% | 92.23% | 0.01% | 92.22% | 7.13% | |

| ELV large plastic parts | 2684 | 747 | 1808 | 57 | 1751 | 128 |

| 100% | 27.83% | 67.38% | 2.12% | 65.26% | 4.78% | |

| ELV glass | 1409 | 103 | 1249 | 3 | 1245 | 57 |

| 100% | 7.33% | 88.60% | 0.23% | 88.37% | 4.07% | |

| ELV other materials arising from dismantling | 6066 | 2491 | 2687 | 138 | 2549 | 887 |

| 100% | 41.07% | 44.30% | 2.27% | 42.03% | 14.63% | |

| Batteries and accumulators | 4816 | 326 | 4416 | 16 | 4400 | 74 |

| 100% | 6.78% | 91.69% | 0.34% | 91.35% | 1.53% | |

| Catalysts | 1634 | 8 | 1569 | 0 | 1569 | 57 |

| 100% | 0.46% | 96.03% | 0.01% | 96.03% | 3.50% | |

| Waste arising from ELV shredding, of which: | 9274 | 1820 | 7454 | 0 | 7454 | |

| 100% | 19.62% | 80.38% | 0% | 80.38% | 0% | |

| Ferrous scrap (steel) from shredding | 7253 | 0 | 7253 | 7253 | ||

| 100% | 0% | 100% | 0% | 100% | 0% | |

| Non-ferrous materials (aluminum, copper, zinc, lead, etc.) from shredding | 200 | 0 | 200 | 200 | ||

| 100% | 0% | 100% | 0% | 100% | 0% | |

| Shredder Light Fraction (SLF) | 0 | 0 | 0 | 0 | 0 | |

| 0% | 0% | 0% | 0% | 0% | ||

| Other materials arising from shredding | 1820 | 1820 | 0 | 0 | 0 | |

| 100% | 100% | 0% | 0% | 0% | 0% | |

| End-of-life vehicles exported | 236 | 0 | 236 | 236 | ||

| 0% | 100% | 0% | 0% | 100% |

| Waste Treatment Operation/Treated Waste Flow | Modeling Details/Recovered Materials (Energy) | References |

|---|---|---|

| Reuse and Recycling | Reuse and recycling consider the recovery of various secondary materials. Reuse (4515 tonnes, 5.38%). Recycling (59,301 tonnes + 7454 tonnes shredded, 79.64%), of which: | - |

| Metal components (63.7%) | Secondary materials recovery: 85% steel, 15% non-ferrous metals, of which 88.3% secondary aluminum, 11.7% secondary copper Non-ferrous metals only consider Al and Cu, other species were not modeled due to lack of data for their fate in recycled materials. | [2,42] |

| Tires | Secondary materials recovered in the reuse track: rubber, steel Energy recovery in the recycling track, modeled as above [41]. | [43,44] |

| Other materials from dismantling | Secondary materials: 50% metals, 50% plastic materials | - |

| Large plastic parts and other plastic materials | Plastic materials composition (wt%): Polypropylene 37%, Polyurethane 15%, polyacetate 12%, Polyethylene 8%, Polyethylene terephthalate 7%, ABS 7%, others (PMMA, POM, PVC, PS, PC, etc.) 16% | [45] |

| Catalytic convertors | Secondary materials recovery: stainless steel, platinum group metals Composition considering: average mass/unit: 7.1 kg, 5 kg stainless steel case, 2 kg ceramic monolith, rare metals composition: Rhodium 0.125 g/ELV unit, Palladium 0.125g/ELV unit, Platinum 1.75 g/ELV unit | [2,46,47] |

| Batteries | Lead acid battery composition modeled for a 60 Ah battery weighing 16.6 kg: 25% lead, 35% lead oxides, 10% sulfuric acid, 16% water, 10% PP, 1% glass, 1% antimony Secondary materials recovered: secondary lead, sulfuric acid, polypropilene | [48] |

| Liquids | Liquids (excluding fuels) composition based on own assumption considering typical liquid volumes in a medium-class vehicle: 46% motor oil, hydraulic oil and brake fluid, 50% coolant, 4% refrigerants. Recovered in reuse: mineral oils. | - |

| Glass | Secondary materials recovery, 100% recovery rate | - |

| Energy recovery: | Energy recovery, 5198 tonnes, 6.20% | - |

| Tires | Tires energetic recovery is modeled as an input in cement production, where they contribute as fuel. Tire composition as described above, net heat production, calorific values, and energy efficiency were accounted for, as well as pollution outputs | [40,49,50] |

| Large plastic parts and other plastic materials | Plastic mix composition as above Energy recovery was modeled based on an existing incineration process with particularized thermal characteristics for calorific values, and energy efficiencies for each plastic stream. Pollutant emissions and incineration waste were accounted for based on default treatment technologies available in Ecoinvent databases | - |

| Catalytic convertors, metals, batteries | These flows were modeled as hazardous material incineration without energy recovery | - |

| Disposal | Disposal, 7079 tonnes, 8.44% ELV waste composition as described above Disposal of materials considers default landfilling processes for materials presented in Table 1. Landfilling is modeled considering Ecoinvent 3.3. default emissions, waste stabilization, and other specific burdens associated with landfilling. | - |

| ELV Treatment Option | Original (2020) Tonnes (%) * | Recycled-Oriented Scenario (Optimized) Tonnes (%) * | Change % |

|---|---|---|---|

| Landfilling | 7079 (8.45%) | 2380 (2.84%) | −66.3% |

| Material recycling | 66,755 (79.96%) | 71,260 (85.45%) | +6.3% |

| Energy recovery | 5198 (6.2%) | 5377 (6.41%) | +3.44% |

| Reuse | 4515 (5.39%) | 4515 (5.38%) | 0% |

| Exported ELV | 236 (0.28%) | 236 (0.28%) | 0% |

| Total | 83,782 | 83,782 | 0% |

| Total recovery (recycling + energy recovery) | 86.16% | 91.86% | +5.7 |

| Total valorization (recycling +energy recovery + reuse) | 91.27% | 97.14% | +5.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinita, F.; Barjoveanu, G.; Teodosiu, C. An Environmental Life-Cycle Assessment of End-of-Life Vehicles Management in Romania. Sustainability 2025, 17, 3691. https://doi.org/10.3390/su17083691

Dinita F, Barjoveanu G, Teodosiu C. An Environmental Life-Cycle Assessment of End-of-Life Vehicles Management in Romania. Sustainability. 2025; 17(8):3691. https://doi.org/10.3390/su17083691

Chicago/Turabian StyleDinita, Florenta, George Barjoveanu, and Carmen Teodosiu. 2025. "An Environmental Life-Cycle Assessment of End-of-Life Vehicles Management in Romania" Sustainability 17, no. 8: 3691. https://doi.org/10.3390/su17083691

APA StyleDinita, F., Barjoveanu, G., & Teodosiu, C. (2025). An Environmental Life-Cycle Assessment of End-of-Life Vehicles Management in Romania. Sustainability, 17(8), 3691. https://doi.org/10.3390/su17083691