Framework for Development of Best Practices for Low-Volume Road Asphalt Pavements—A Roadmap to Increase Recycling

Abstract

1. Introduction

2. Goals and Objectives

- Review the available literature pertaining to asphalt mix design specifications for state highway agencies (SHAs). This review focuses on asphalt mix design requirements and acceptance criteria for different bituminous materials, such as HMA for LVRs. Composition, gradation, performance tests, sampling frequency, and effects of significant parameters for different SHAs are examples of data collected and contrasted.

- Interview subject matter experts across the United States to discuss procedures for designing asphalt mixtures for LVRs and determine differences in the mixes for LVRs and other types. The topics covered by these interviews include current practices for LVR mix design methods, field-testing acceptance criteria for LVRs, quality assurance and quality control requirements, and overall observations for LVRs.

- Compare and evaluate important parameters to identify the best practices of mix design approaches, such as traffic volume, material selection, and the use of recycled materials, mix design methods, and quality control testing for LVR requirements.

3. Comparison of State Highway Agencies’ LVRS Specifications

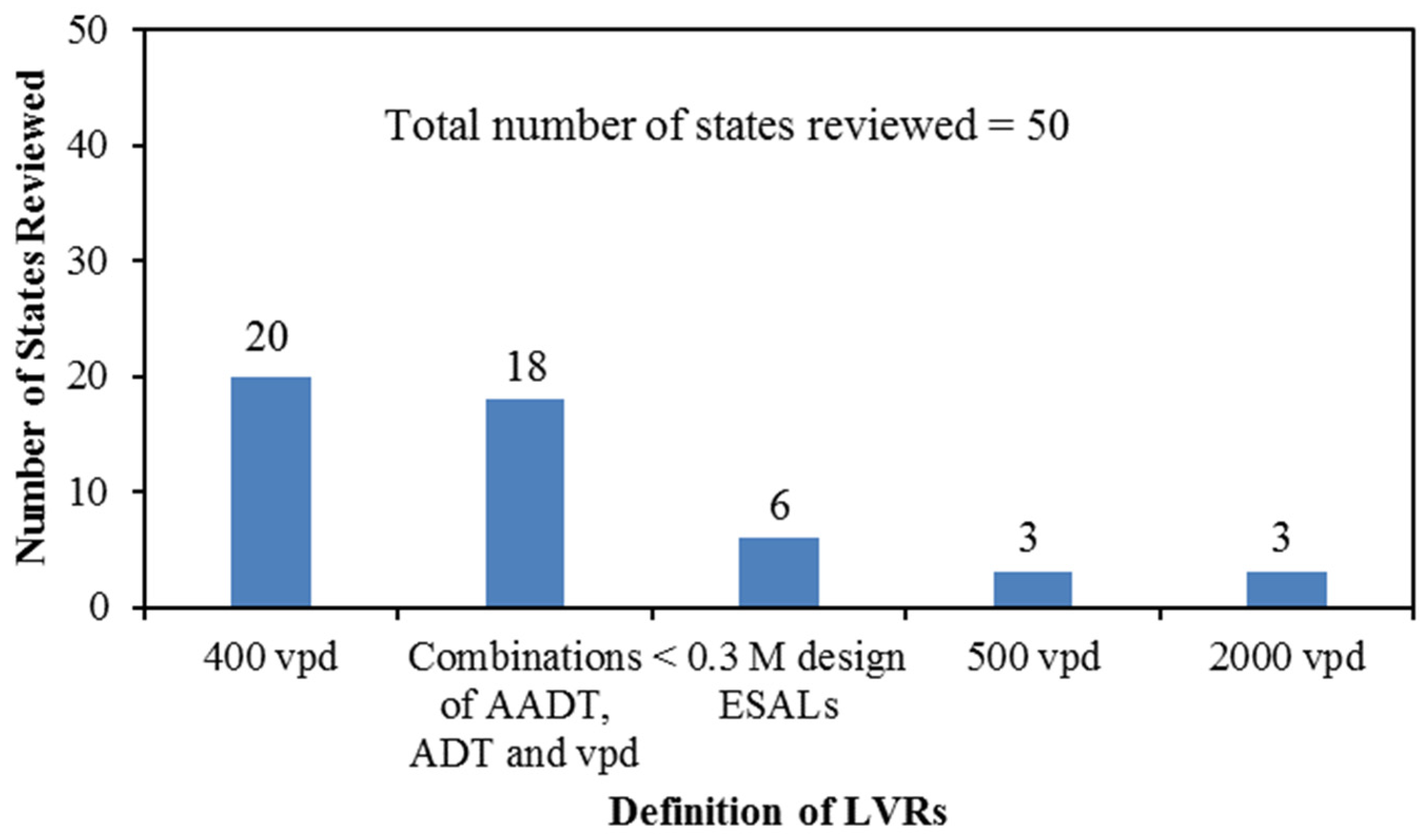

3.1. Definition of LVRs

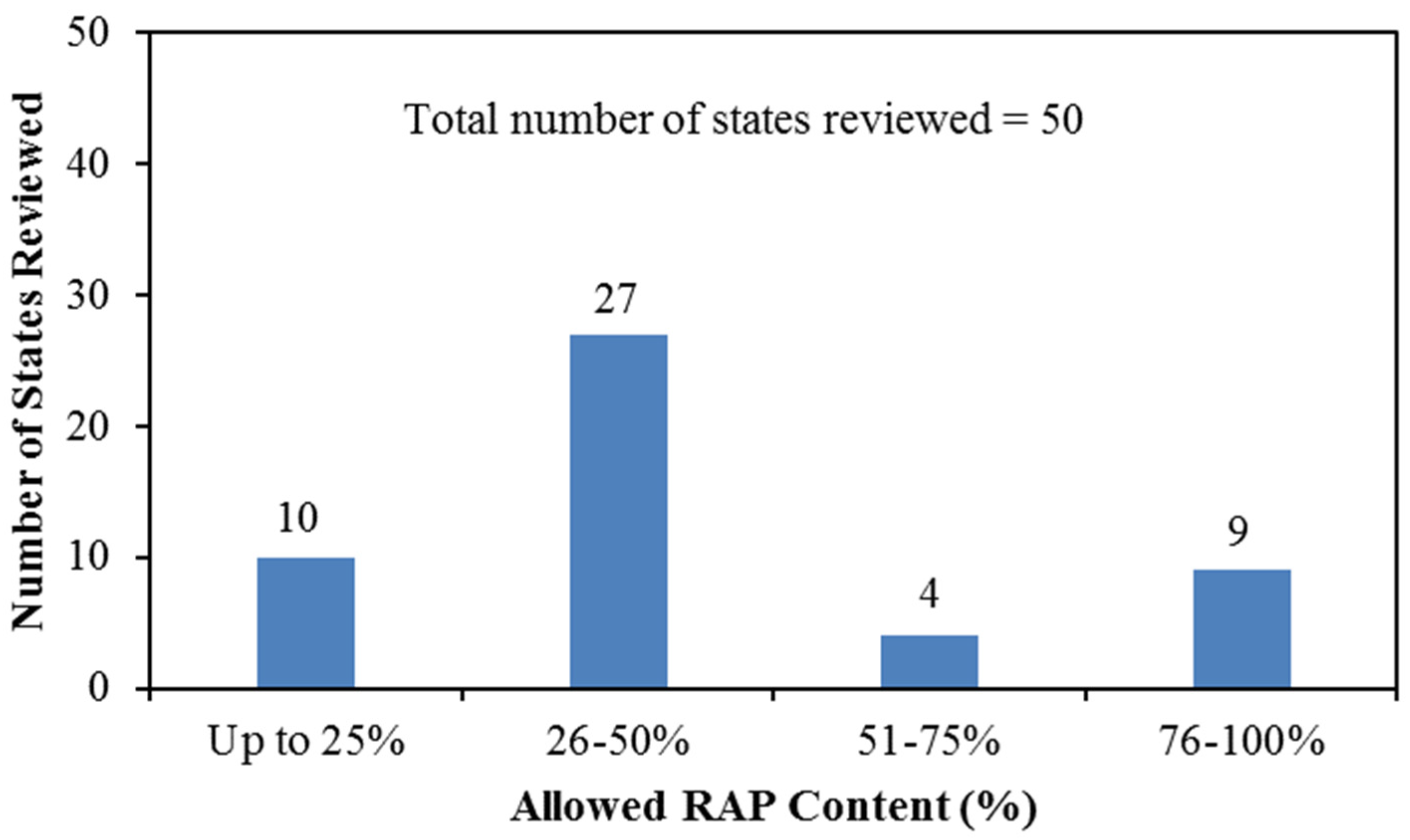

3.2. Recycled Materials and RAP Content

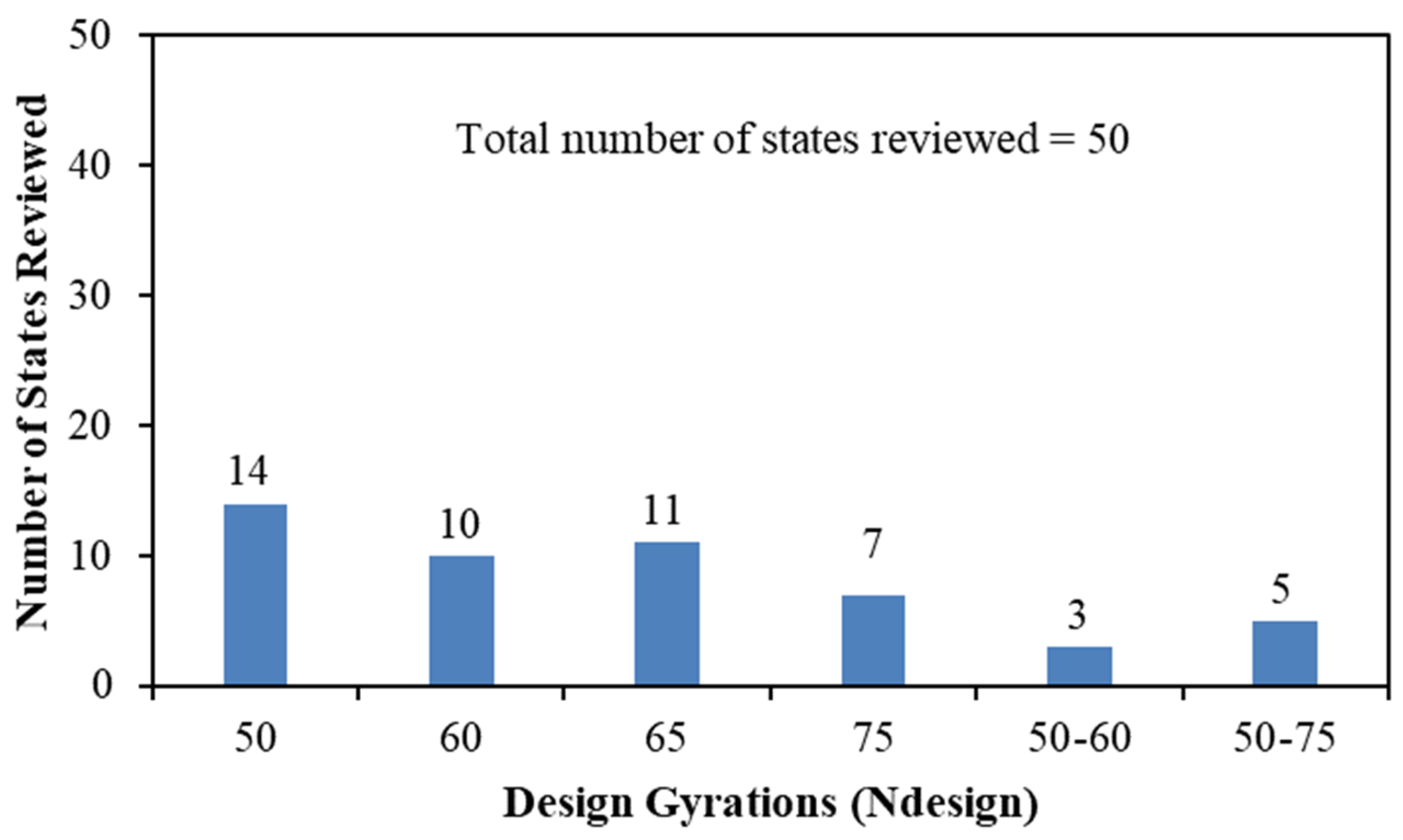

3.3. Design Gyrations (NDesign)

3.4. Gradation Limits

3.5. Design Methodologies

3.6. Volumetrics

3.6.1. Voids Filled with Asphalt (VFAs)

3.6.2. Voids in Mineral Aggregates (VMAs)

3.7. Laboratory Tests for Performance Evaluation

3.7.1. Asphalt Pavement Analyzer (APA)

3.7.2. Hamburg Wheel Tracking Test (HWTT)

3.7.3. Indirect Tension Asphalt Cracking Test (IDEAL-CT)

3.7.4. Indirect Tension Asphalt Rutting Test (IDEAL-RT)

4. Interviews with Subject Matter Experts (SMEs)

- The ESAL thresholds for LVRs range from 10,000 to 50,000 ESALs per year, but these figures vary and can go up to 100,000 ESALs to 300,000 ESALs per year. The classification of a road as low-volume depends on various factors, including local standards, the purpose of the road, and the available infrastructure.

- A typical LVR has about 12 to 15% of trucks of various sizes (e.g., semi-tractors, dump trucks, agricultural vehicles, or trucks carrying agricultural equipment and other heavier/larger vehicles). By analyzing the current traffic patterns and characteristics, the experts suggested developing effective strategies for the design, maintenance, and management of LVRs to ensure that these roads meet the needs of their users while promoting safety and efficiency.

- A few states (e.g., New York, Ohio) have already started to use more cold mixes compared to hot mixes as the cold mixes have a “little” richer asphalt binder, which might be useful in the growth of mixture design for LVRs. The life of low-volume pavements is relatively short, at around 15–20 years. Several local agencies mostly consider about 10 years of service life for LVRs.

- The gradation and mix design requirements for LVRs involve careful consideration of local materials, aggregate gradation, binder selection, mix design methods, thickness design, and adequate drainage considerations (or coefficient).

- The selection of binder grade is closely tied to the desired performance characteristics of the pavement, including rutting resistance, fatigue resistance, and cracking resistance. The experts stressed the importance of considering the local climate when selecting the binder grade for low-volume mixes.

- The use of rejuvenators in the mix design of LVRs is seen as a valuable strategy to address aging issues, enhance binder properties, and improve the overall performance and sustainability of asphalt pavements. Careful consideration of rejuvenator selection, dosage, and compatibility within the mix design process is crucial for achieving optimal results in LVR construction.

- The experts recommended field testing, such as density tests (e.g., nuclear density gauge testing or sand cone testing), at regular intervals across the project site to identify areas of inadequate compaction and verify the in-place density is meeting the specified requirements for LVRs. Field testing and acceptance criteria for the mix designs of LVRs encompass a comprehensive range of assessments, including compaction, smoothness (e.g., accepted IRI-160 inch/mile, baseline IRI-280 inch/mile), density, distress evaluation, skid resistance, moisture susceptibility, and long-term performance monitoring.

5. Recommendations

5.1. Design Gyrations

5.2. RAP Content

5.3. Design Methodology

5.4. Gradation Limits

5.5. Performance Testing

5.6. Volumetrics

5.7. Binder Grade

6. Conclusions

- The incorporation of reclaimed asphalt pavement (RAP) material should be prioritized in the mix design of low-volume roads, resulting in enhanced sustainability and cost efficiency.

- The durability and cracking resistance of asphalt mixtures can be enhanced by optimizing asphalt content and adjusting the gyrations between 50 and 65 by preventing over-compaction.

- The mix design for low-volume roads should integrate performance-based specifications that prioritize durability, flexibility, and cost-effectiveness. Performance tests like IDEAL-CT and IDEAL-RT can be employed to define general specifications for low-volume roads.

- Long-Term Impacts on Sustainable Practices in Pavements: The current study presents a comprehensive literature review concerning existing specifications of different state highway agencies regarding low-volume roads. The synthesis of research on low-volume roads holds vast potential in future studies for improving durability, sustainability, and cost-effectiveness. This study will serve as a catalyst to use higher percentages of RAP in materials and hence take a big step towards achieving sustainable practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Purvis, J. Sensitivity Analysis of Pavement Thickness Design Software for Local Roads in Iowa. Ph.D. Thesis, University of Iowa, Iowa City, IA, USA, 2013. [Google Scholar]

- Hafez, M.; Ksaibati, K.; Atadero, R. Developing a methodology to evaluate the effectiveness of pavement treatments applied to low-volume paved roads. Int. J. Pavement Eng. 2019, 20, 894–904. [Google Scholar] [CrossRef]

- Leiva-Villacorta, F.; West, R.; Brown, E. A Synthesis of Technical Needs of Asphalt Pavements for Local Roads; National Center for Asphalt Technology: Auburn, AL, USA, 2019. [Google Scholar]

- Hand, A.J.T.; Ragavan, P.; Elias, N.G.; Hajj, E.Y.; Sebaaly, P.E. Evaluation of Low Volume Roads Surfaced with 100% RAP Millings. Materials 2022, 15, 7462. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, A.E.; Ovalles, E.; Reyes-Ortiz, O.J. Mixture design and performance characterization of asphalt mixtures prepared using paving-heavy crude oils for low-traffic volume roads. Constr. Build. Mater. 2022, 329, 127141. [Google Scholar] [CrossRef]

- Prasad, A.N.; Saboo, N.; Pani, A. Material and mix design aspects of hot recycled asphalt mixes: A review. Environ. Sci. Pollut. Res. 2023, 30, 108411–108447. [Google Scholar] [CrossRef] [PubMed]

- Harshita, H.; Mamatha, K.H.; Dinesh, S.V. RAP as an improved layer for low volume roads. Mater. Today Proc. 2022, 61, 552–557. [Google Scholar] [CrossRef]

- Al-Qadi, I.; Aurangzeb, Q.; Carpenter, S.; Pine, W.; Trepanier, J. Impact of High RAP Contents on Structural and Performance Properties of Asphalt Mixtures. 2012. Available online: http://hdl.handle.net/2142/45810 (accessed on 15 January 2025).

- Arámbula-Mercado, E.; Chavarro-Muñoz, S.J.; Hu, S.; Moseley, H. Performance of Hot and Cold Recycled Mixtures with High Reclaimed Asphalt Pavement Content. Transp. Res. Rec. J. Transp. Res. Board. 2020, 2674, 714–726. [Google Scholar] [CrossRef]

- Li, N.; Hao, P.; Yao, Y.; Zhang, C. The implementation of balanced mix design in asphalt materials: A review. Constr. Build. Mater. 2023, 402, 132919. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The Challenges of Using Reclaimed Asphalt Pavement for New Asphalt Mixtures: A Review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef] [PubMed]

- McDaniel, R.; Shah, A. Use of Reclaimed Asphalt Pavement (RAP) Under Superpave Specifications; Purdue University: West Lafayette, IN, USA, 2003. [Google Scholar]

- Al-Qadi, I.; Carpenter, S.; Roberts, G.; Ozer, H.; Aurangzeb, Q.; Elseifi, M.; Trepanier, J. Determination of Usable Residual Asphalt Binder in RAP, FHWA-ICT-09-031. 2009. Available online: http://hdl.handle.net/2142/13714 (accessed on 15 January 2025).

- Lee, S. Evaluation of Asphalt Binder and Mixture Properties That Incorporate Reclaimed Asphalt Pavement. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2018. [Google Scholar]

- Imaninasab, R.; Loria-Salazar, L.; Carter, A. Integrated performance evaluation of asphalt mixtures with very high reclaimed asphalt pavement (RAP) content. Constr. Build. Mater. 2022, 347, 128607. [Google Scholar] [CrossRef]

- Habib, A.; Hossain, M.; Kaldate, R.; Fager, G. Comparison of Superpave and Marshall Mixtures for Low-Volume Roads and Shoulders. Transp. Res. Rec. J. Transp. Res. Board. 1998, 1609, 44–50. [Google Scholar] [CrossRef]

- Arámbula-Mercado, E.; Chavarro-Munoz, S.; Hu, S.; Epps, J.; Park, E.; Martin, A.E. High Reclaimed Asphalt Pavement (RAP) Asphalt Mixes for Low Volume Roads; Texas A&M Transportation Institute: College Station, TX, USA, 2018. [Google Scholar]

- Li, M.; Yuan, J.; Jin, T.; Wang, W.; Sun, Y.; Cheng, H. Investigation of performance evolution in recycled asphalt mixtures: The impact of virgin and RAP binder blending. Constr. Build. Mater. 2025, 469, 140519. [Google Scholar] [CrossRef]

- Costa, D.B.; Neto, O.d.M.M.; Luz, P.M.S.G.; Lucena, L.C.d.F.L.; Lucena, A.E.d.F.L. Influence of aging, RAP content, and recycling agent on the performance of asphalt mixtures. Environ. Sci. Pollut. Res. 2023, 31, 1419–1441. [Google Scholar] [CrossRef] [PubMed]

- Tong, B.; Habbouche, J.; Diefenderfer, S.D.; Flintsch, G.W. Multi-level performance evaluation of BMD surface mixtures with conventional and high RAP contents: A case study in Virginia. Int. J. Pavement Eng. 2024, 25, 2325609. [Google Scholar] [CrossRef]

- Min, Z.; Shi, Z.; Huang, W.; Kong, L. Effect of the Degree of Blending on the Performance of Epoxy Component–Modified Recycled Asphalt and Epoxy Component–Modified Recycled Asphalt Mixture. J. Mater. Civ. Eng. 2025, 37, 04024506. [Google Scholar] [CrossRef]

- Cai, F.; Xiao, T.; She, H.; Zhao, Y.; Feng, Z.; Zhang, J.; Li, Y. Performance optimization of asphalt blending behavior considering the effect of RAP agglomerates in hot in-place recycled asphalt mixture. Constr. Build. Mater. 2025, 470, 140633. [Google Scholar] [CrossRef]

- Hassan, R. Feasibility of using high RAP contents in hot mix asphalt. In Proceedings of the 13th International Flexible Pavements Conference, Surfers Paradise, Australia, 11–14 October 2009. [Google Scholar]

- Kennedy, T.; Huber, G.; Harrigan, E.; Cominsky, R.; Hughes, C.; Von Quintus, H.; Moulthrop, J. Superior Performing Asphalt Pavements (Superpave): The Product of the SHRP Asphalt Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Mate, A. Evaluation of Balanced Mix Design Gyrations (Ndesign) for North Dakota’s Lower Class HMA Pavement; The University of North Dakota: Grand Forks, ND, USA, 2020. [Google Scholar]

- Abbas, A.; Nazzal, M.; Kim, S.; Zhou, F.; Quasem, T.; Hudaib, A.; Manasreh, D. Asphalt Mix Overlay Alternative for Low Volume Roads on the Local Transportation System. n.d. Available online: https://rosap.ntl.bts.gov/view/dot/58716 (accessed on 15 January 2025).

- Abbas, A.; Nazzal, M.; Farash, M.; Matouq, Y.; Quasem, T.; Mansour, M. Optimizing the Performance of Item 404-Low Volume Traffic Mixes [Fact Sheet] (No. 114248); Ohio Department of Transportation. Office of Research and Development: Columbus, OH, USA, 2023.

- Skok, E.; Timm, D.; Brown, M.; Clyne, T. Best Practices for the Design and Construction of Low Volume Roads (No. MN/RC-2002-17); Minnesota Department of Transportation: Saint Paul, MN, USA, 2002.

- Prowell, B.; Haddock, J. Superpave for low volume roads and base mixtures (with discussion). J. Assoc. Asph. Paving Technol. 2002, 71, 417–443. [Google Scholar]

- Cross, S.A. Determination of Superpave Gyratory Compactor Design Compactive Effort for Cold In-Place Recycled Mixtures. Transp. Res. Rec. J. Transp. Res. Board. 2003, 1819, 152–160. [Google Scholar] [CrossRef]

- Vitillo, N.P.; Bennert, T.; Smith, J.; Maher, A. Evaluation of Superpave Mix Design for Low-Volume Roads in New Jersey. Transp. Res. Rec. J. Transp. Res. Board. 2006, 1946, 139–146. [Google Scholar] [CrossRef]

- Barman, M.; Dhasmana, H.; Manickavasagan, V.; Marasteanu, M. Optimizing Asphalt Mixtures for Low-volume Roads in Minnesota; Minnesota Department of Transportation. Office of Research & Innovation: St. Paul, MN, USA, 2023.

- Mogawer, W.; Mallick, R. Design of Superpave HMA for Low Volume Roads (No. NETCR 51, NETC 01-03); New England Transportation Consortium: Lowell, MA, USA, 2004. [Google Scholar]

- Witzcak, M. Simple Performance Test for Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2002. [Google Scholar]

- Zhou, F.; Hu, S.; Newcomb, D. Development of a performance-related framework for production quality control with ideal cracking and rutting tests. Constr. Build. Mater. 2020, 261, 120549. [Google Scholar] [CrossRef]

| Parameter | Recommendation |

|---|---|

| Design gyrations | 50–65 |

| RAP content | 26% to 50% |

| Design methodology | Superpave mix design |

| Gradation limits | 4.75 to 37.5 NMAS |

| Performance criteria | IDEAL-CT and IDEAL-RT |

| Volumetrics | VFAa 70–80% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaudhary, M.; Ali, A.; Mehta, Y. Framework for Development of Best Practices for Low-Volume Road Asphalt Pavements—A Roadmap to Increase Recycling. Sustainability 2025, 17, 3519. https://doi.org/10.3390/su17083519

Chaudhary M, Ali A, Mehta Y. Framework for Development of Best Practices for Low-Volume Road Asphalt Pavements—A Roadmap to Increase Recycling. Sustainability. 2025; 17(8):3519. https://doi.org/10.3390/su17083519

Chicago/Turabian StyleChaudhary, Mohit, Ayman Ali, and Yusuf Mehta. 2025. "Framework for Development of Best Practices for Low-Volume Road Asphalt Pavements—A Roadmap to Increase Recycling" Sustainability 17, no. 8: 3519. https://doi.org/10.3390/su17083519

APA StyleChaudhary, M., Ali, A., & Mehta, Y. (2025). Framework for Development of Best Practices for Low-Volume Road Asphalt Pavements—A Roadmap to Increase Recycling. Sustainability, 17(8), 3519. https://doi.org/10.3390/su17083519