Assessment of the Possibility of Implementing a Circular Economy by Environmental Evaluating the Life Cycle of Products Derived from Bulky Municipal Waste

Abstract

1. Introduction

- What are the environmental hotspots in the (from cradle to market) life cycle of the secondary wooden blocks? (Q1);

- Are the results sensitive to a choice of allocation procedure? (Q2);

- Are the secondary wooden blocks an environmentally better or worse option in comparison to similar products? (Q3).

2. Materials and Methods

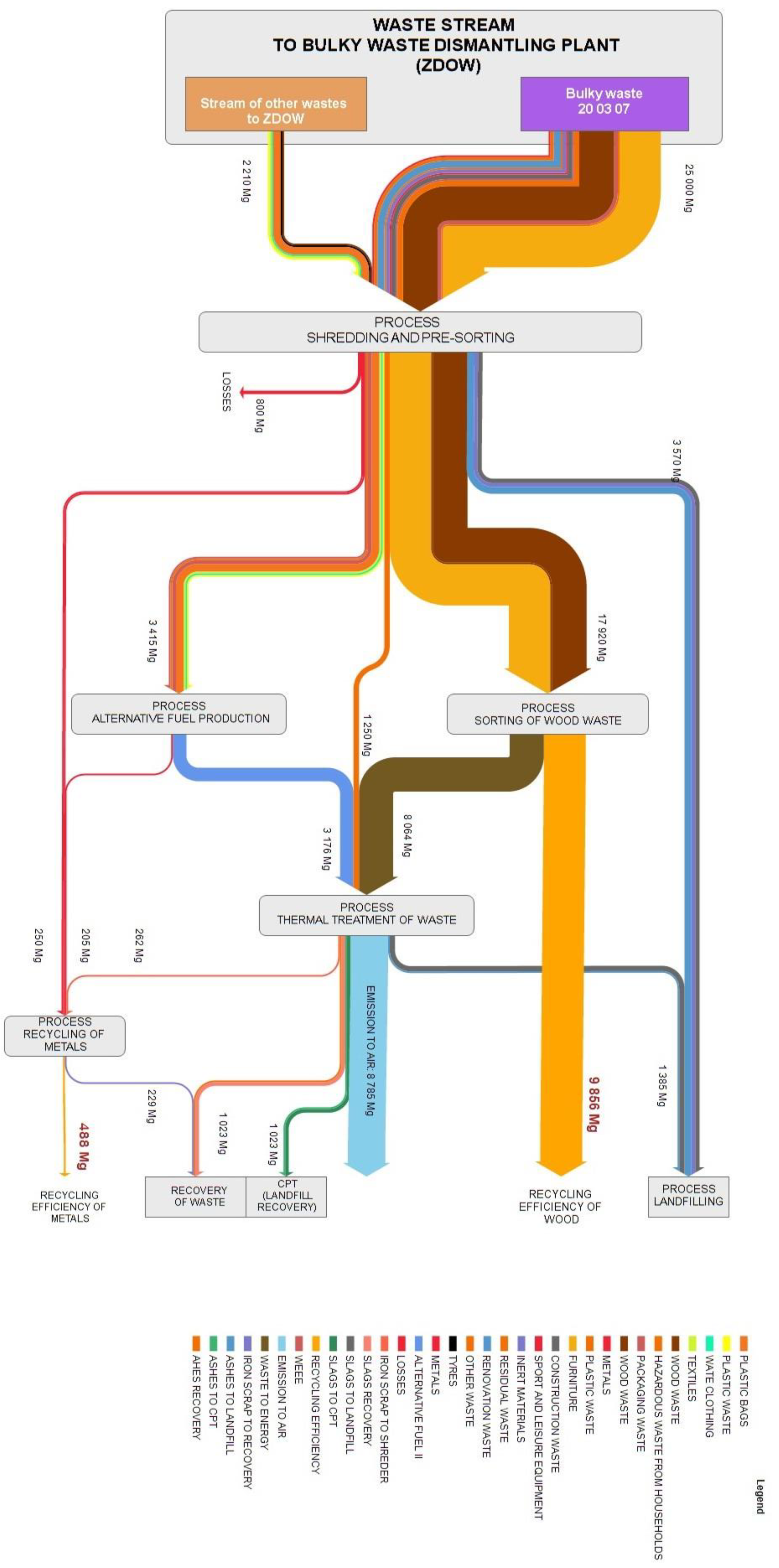

2.1. Material Flow Analysis

2.2. Life Cycle Assessment (LCA)

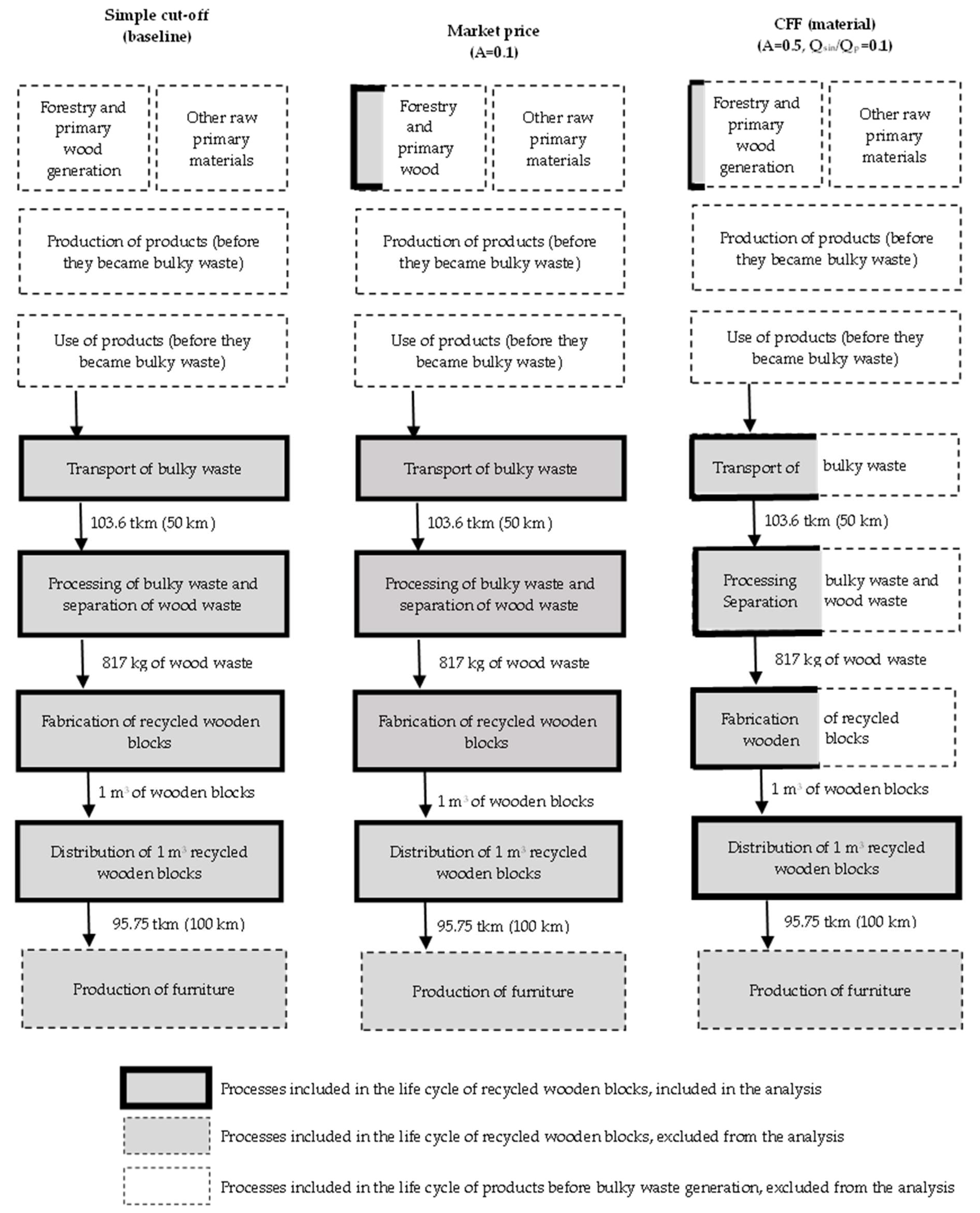

2.2.1. Goal and Scope Definition

- Transport of bulky waste (transport to the processing site, 50 km),

- Recovery—processing of bulky waste and separation of the wooden fraction with shredding, magnetic separation, ballistic separation, cutting, stirring, pressing,

- Recycling—fabrication of secondary wooden blocks with shredding, homogenization of the structure of the materials, stirring and pressing together with additives,

- Distribution of secondary wooden blocks (transport to the market, 100 km).

- 100:0 (cut-off), baseline—0% of the burdens for forestry and 100% of the burdens from recovery and recycling are allocated to the secondary wooden blocks;

- The market price-based allocation—the virgin material production (forestry) needs to be partitioned between the product where the virgin material is used and the product where the material is lost [64]. The allocation factor A is defined as the ratio between the market value of scrap or recycled material to the market value of virgin material [64]. In our case study, prices representative of Polish market have been used. Based on yearly reports of the Central Statistical Office [66,67,68,69,70], an average 5-year price for primary wood has been calculated (58 euro/m3). Because of lack of market data on waste wood, a price of wood waste for 2024 year [71] has been used (6 euro/m3). The allocation factor A is 0.1 (6/58), which means that 10% of the burdens from forestry and 100% of the burdens from recovery and recycling are allocated to the recycled wooden blocks;

- The Circular Footprint Formula—as our case study has been scoped from the cradle to the market, only a part of the CFF formula (for Material) has been applied. The formula has been sourced from the Commission Recommendation (EU) 2021/2279 [62] and presented in an Equation (1):

2.2.2. Life Cycle Inventory (LCI)

3. Results—Life Cycle Impact Assessment (LCIA)

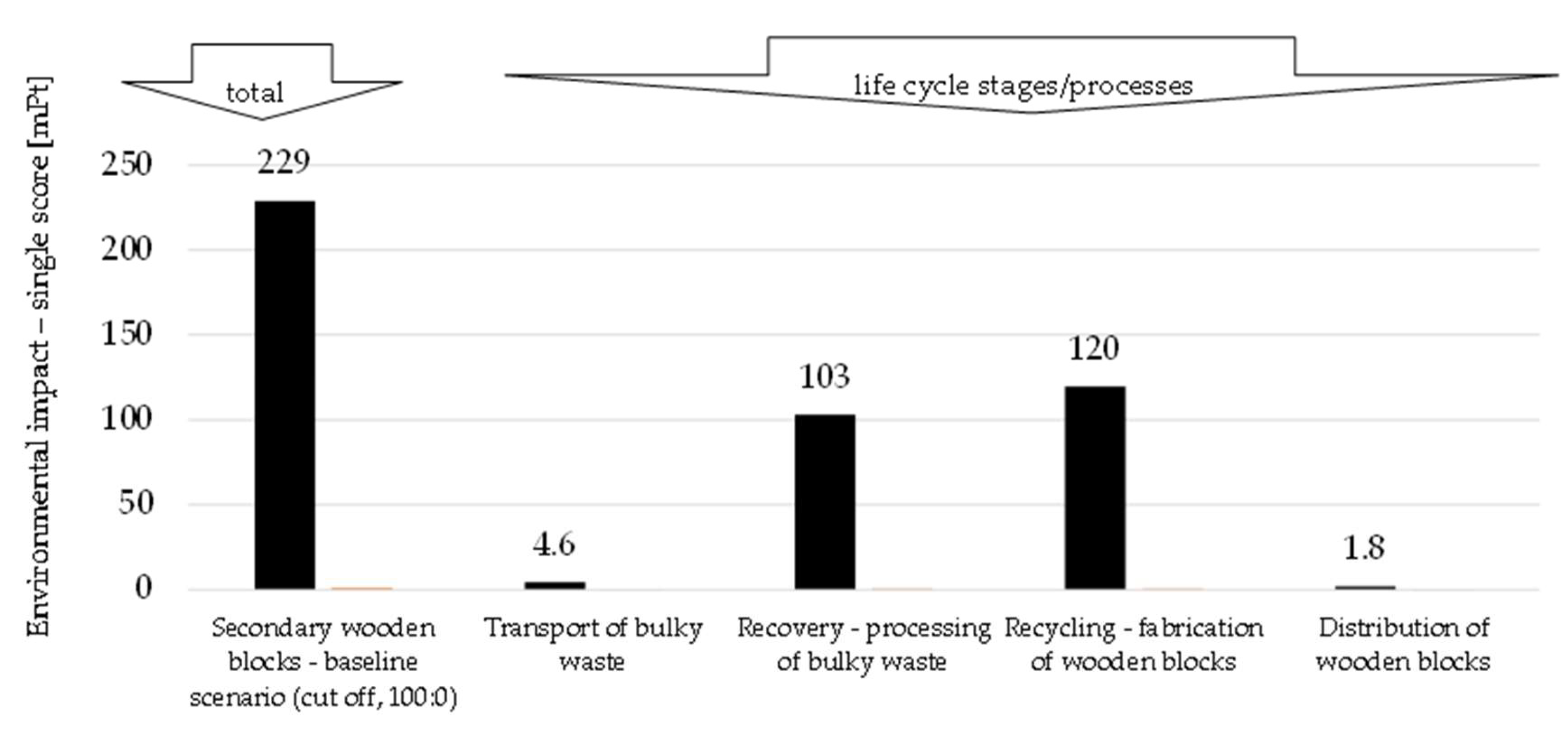

3.1. What Are the Environmental Hotspots in the Life Cycle of Secondary Wooden Blocks?

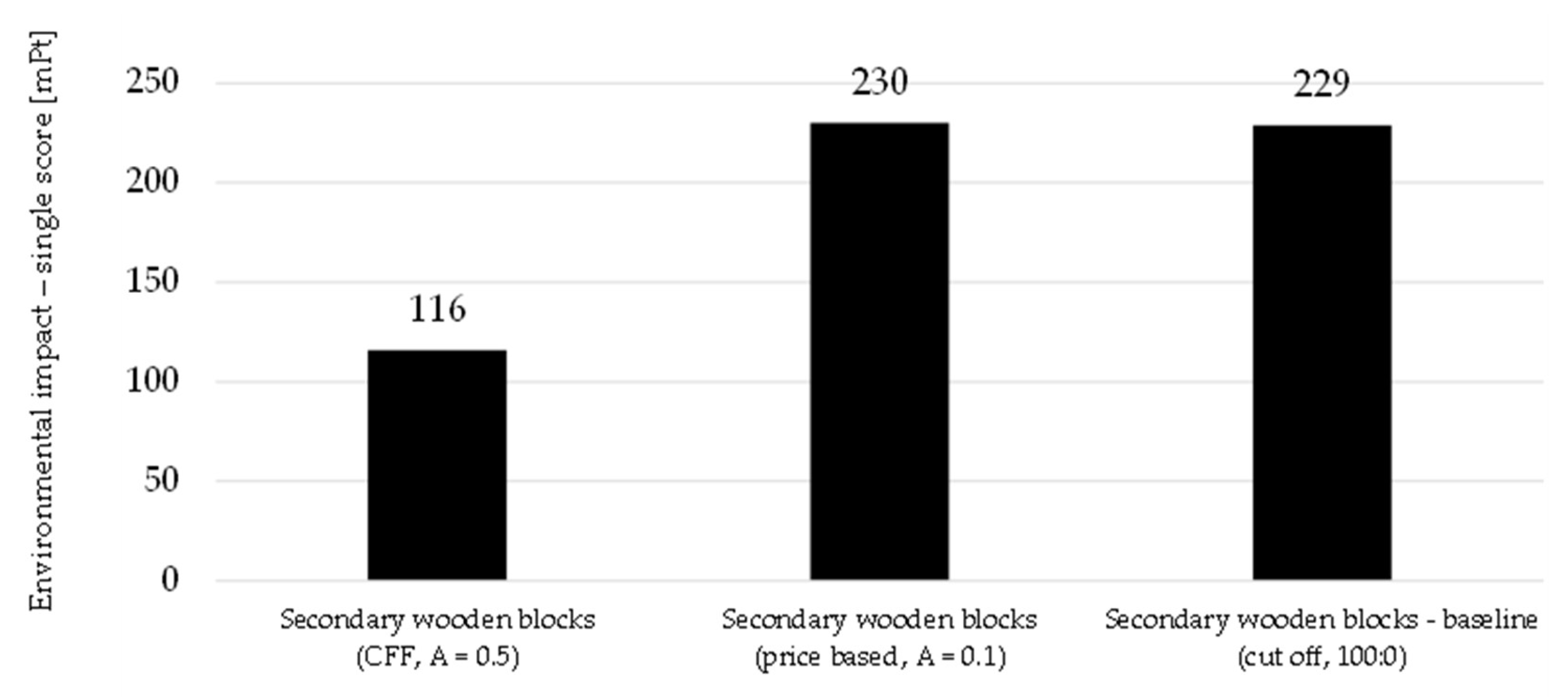

3.2. Are the Results Sensitive to the Choice of Allocation Procedure?

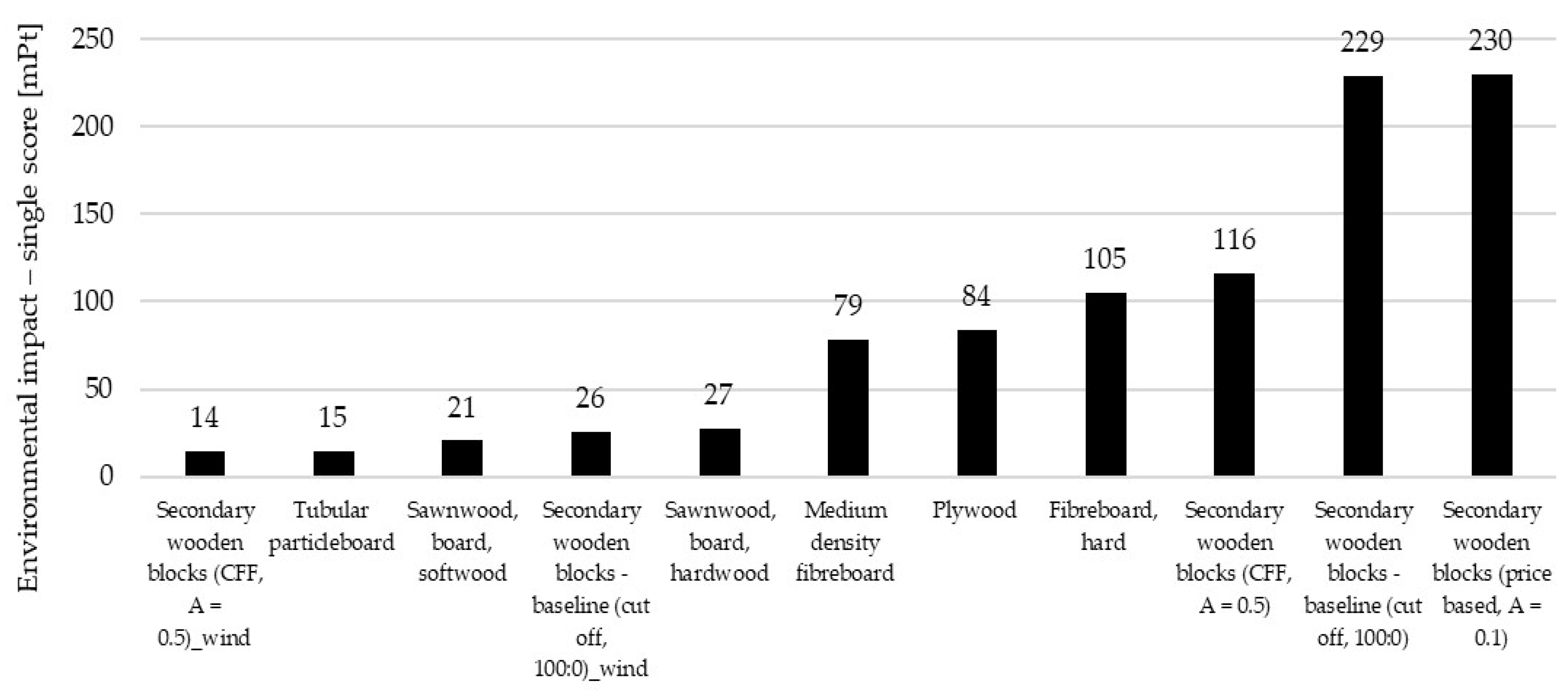

3.3. Are the Secondary Wooden Blocks an Environmentally Better or Worse Option in Comparison to the Market Alternatives?

4. Discussion

5. Conclusions

- The objective of the article was to propose and attempt to evaluate, using LCA, a management system for bulky waste, in particular wood and wood-based wastes coming from the selective collection of municipal waste.

- The largest impact is exerted by the electricity used. Yet, it should be noted that the demand for electricity was calculated on a laboratory scale. Reducing electricity consumption and using renewable electricity are the most evident recommendations for further improving the process.

- A choice of electricity type impacted the results strongly. If the European electricity mix was assumed, the results for secondary blocks were very high. If renewable sources are used (in our calculations wind power has been assumed), the environmental score for secondary wooden blocks decreases to a level similar to or even lower than for other alternatives. Reduction of electricity consumption (as a result of switching from laboratory to commercial scale) through the use of renewable energy sources will allow the development of a technology for the production of new material with a limited impact on the environment in relation to the current solution. The use of the LCA method ensures that the result of the environmental impact assessment is measurable and objective.

- The results are highly sensitive to the choice of allocation procedure. It should be noted that the secondary blocks have been ranked differently depending on the type of approach used to model multifunctionality. In this context, agreeing on a single common approach to model multifunctionality would be desirable. The Circular Footprint Formula [69] is a good example of looking for this kind of consensus.

- The proposed methodology may serve as an element of quality assessment of new products in the circular economy and in environmental management in the waste management sector.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFF | Circular Footprint Formula |

| EU | European Union |

| FRO | Furniture Reuse Organizations |

| FW | Furniture Waste |

| ISO | International Organization for Standardization |

| LCA | Multidisciplinary Digital Publishing Institute |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LDF | Low Density Fiberboard |

| HDF | High Density Fiberboard |

| MDF | Medium Density Fiberboard |

| MFA | Material Flow Analysis |

| RDF | Refuse-Derived Fuel |

| SFA | Substance Flow Analysis |

| WPP | Wood Waste Particles |

| WSARC | Water-Soluble Acrylic Resin Coatings |

| WWP | Wood Waste Particles |

References

- Gronba-Chyła, A.; Generowicz, A. Municipal waste fraction below 10 mm and possibility of its use in ceramic building materials. Przem. Chem. 2020, 99, 1318–1321. (In Polish) [Google Scholar] [CrossRef]

- Höglmeier, K.; Weber-Blaschke, G.; Richtera, K. Utilization of recovered wood in cascades versus utilization of primary wood—A comparison with life cycle assessment using system expansion. Int. J. Life Cycle Assess. 2014, 19, 1755–1766. [Google Scholar] [CrossRef]

- Vis, M.; Mantau, U.; Allen, B. (Eds.) Cascades. Study on the Optimized Cascading Use of Wood. No 394/PP/ENT/RCH/14/7689. Final Report. Available online: https://op.europa.eu/en/publication-detail/-/publication/04c3a181-4e3d-11e6-89bd-01aa75ed71a1 (accessed on 26 January 2025).

- Report of Polish Chamber of Commerce of Furniture Manufacturers. Available online: http://www.oigpm.org.pl/865/raport-polskie-meble-outlook-2022 (accessed on 26 January 2025).

- Polskie Meble Outlook. Sectoral Report Prepared by B+R Studio Tomasz Wiktorski. Available online: www.brstudio.eu (accessed on 26 January 2025).

- Mantau, U. Wood Flow Analysis: Quantification of Resource Potentials, Cascades and Carbon Effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Nowaczek, A.; Kowalski, Z.; Kulczycka, J.; Makara, A. Determinants of the Implementation of a Circular Economy Model in the Tire Sector in Poland. Sustainability 2024, 16, 11167. [Google Scholar] [CrossRef]

- Kajda-Szcześniak, M.; Czop, M. Comparison of pyrolysis and combustion processes of vinyl floor panels using thermogravimetric analysis (TG-FTIR) in terms of the circular economy. Energies 2022, 15, 1516. [Google Scholar] [CrossRef]

- Cooper, T.; Kaner, J.; Furmston, K.; Cutts, A. Furniture lifetimes in a circular economy: A state of the art review. In Proceedings of the 4th PLATE 2021 Virtual Conference, Virtual, 26–28 May 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Yousef, F.; Truijens, J. Efficient Logistics for Circular Furniture Flows. Master’s Thesis, University of Gothenburg, Gothenburg, Sweden, 2016. Available online: https://gupea.ub.gu.se/bitstream/handle/2077/44892/gupea_2077_44892_1.pdf?sequence=1&isAllowed=y (accessed on 26 January 2025).

- Xiong, N.; Lu, H.; Yang, X.; Wang, J.; Yue, D. Spatial characteristics and multifactorial driving analysis of fly-tipping bulky waste in Beijing based on the random forest model. J. Clean. Prod. 2022, 363, 132534. [Google Scholar] [CrossRef]

- Top, Y. Waste generation and utilization in micro-sized furniture-manufacturing enterprises in Turkey. Waste Manag. 2015, 35, 3–11. [Google Scholar] [CrossRef]

- Report of the European Environmental Bureau on the Circular Economy in the Furniture Sector. Available online: https://eeb.org/wp-content/uploads/2019/05/Report-on-the-Circular-Economy-in-the-Furniture-Sector.pdf (accessed on 26 January 2025).

- Final Report of MSW Consultants and Center for Ecotechnology on Statewide Bulky Waste Characterization Study. Available online: https://www.mass.gov/doc/statewide-bulky-waste-characterization-study-june-2022/download (accessed on 26 January 2025).

- Balcerzak, W.; Generowicz, A.; Mucha, Z. Application of multi-criteria analysis for selection of a reclamation method for a hazardous waste landfill. Pol. J. Environ. Stud. 2014, 23, 983–987. [Google Scholar]

- Minelgaitė, A.; Liobikienė, G. Waste problem in European Union and its influence on waste management behaviours. Sci. Total Environ. 2019, 667, 86–93. [Google Scholar] [CrossRef]

- Gotowska, M. New challenges for business of waste management in Poland on the example of REMONDIS Bydgoszcz sp. z o.o. Manag. Theory Pract. 2019, 2, 29–36. (In Polish) [Google Scholar]

- Demirarslan, K.; Demirarslan, D. Furniture Wastes and Their Environmental Impacts as Being a Different Problem of Our Time. Int. J. Adv. Eng. Pure Sci. 2021, 33, 97–105. [Google Scholar] [CrossRef]

- Salthammer, T.; Schwarz, A.; Fuhrmann, F. Emission of reactive compounds and secondary products from wood-based furniture coatings. Atmos. Environ. 1998, 33, 75–84. [Google Scholar] [CrossRef]

- Christensen, T.H.; Fruergaard, T.; Matsufuji, Y. Residential Waste. In Solid Waste Technology and Management; Christensen, T.H., Ed.; Wiley: Chichester, UK, 2011; pp. 85–96. [Google Scholar]

- Ramusch, R.; Pertl, A.; Scherhaufer, S.; Schmied, E.; Obersteiner, G. Modelling informally collected quantities of bulky waste and reusable items in Austria. Waste Manag. 2015, 44, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Przydatek, G.; Kochanek, A.; Basta, M. Analysis of changes in municipal waste management at the county level. J. Ecol. Eng. 2017, 18, 72–80. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Zhang, C.; Dong, Z.; Yue, Y.; Xu, Q. Effects of water-soluble acrylic resin coatings on the pyrolysis behavior of wooden bulky waste. Fuel Process. Technol. 2022, 228, 107170. [Google Scholar] [CrossRef]

- Hanandeh, A.E. Carbon abatement via treating the solid waste from the Australian olive industry in mobile pyrolysis units: LCA with uncertainty analysis. Waste Manag. Res. 2013, 31, 341–352. [Google Scholar] [CrossRef]

- Larsen, A.W.; Petersen, C.; Christensen, T.H. Bulky waste quantities and treatment methods in Denmark. Waste Manag. Res. 2012, 30, 147–154. [Google Scholar] [CrossRef]

- Poluszyńska, J. The content of heavy metal ions in ash from waste incinerated in domestic furnaces. Arch. Environ. Prot. 2020, 46, 68–73. [Google Scholar] [CrossRef]

- Rybiński, P.; Syrek, B.; Szwed, M.; Bradło, D.; Żukowski, W.; Marzec, A.; Śliwka-Kaszyńska, M. Influence of Thermal Decomposition of Wood and Wood-Based Materials on the State of the Atmospheric Air. Emiss. Toxic. Compd. Greenh. Gases. Energ. 2021, 14, 3247. [Google Scholar] [CrossRef]

- Ciuła, J.; Generowicz, A.; Mitryasova, O.; Jasińska, A.; Jurkowski, S.; Kwaśnicki, P. The Analysis of Geospatial Factors Necessary for the Planning, Design, and Construction of Agricultural Biogas Plants in the Context of Sustainable Development. Energies 2024, 17, 5619. [Google Scholar] [CrossRef]

- Regulation of EU Parliment and EU Council 2020/852 of 18 June 2020 Establishing a Framework to Facilitate Sustainable Investments, and Amending EU Regulation 2019/2088. Available online: https://eur-lex.europa.eu/eli/reg/2020/852/oj/eng (accessed on 26 January 2025).

- Lubis, M.A.R.; Hong, M.-K.; Park, B.-D.; Lee, S.-M. Effects of Recycled Fiber Content on the Properties of Medium Density Fiberboard. Eur. J. Wood Prod. 2018, 76, 1515–1526. [Google Scholar] [CrossRef]

- Ihnát, V.; Lübke, H.; Russ, A.; Borůvka, V. Waste Agglomerated Wood Materials as a Secondary Raw Material for Chipboards and Fibreboards Part I. Prep. Charact. Wood Chips Terms Their Reuse. Wood Res. 2017, 62, 45–56. [Google Scholar]

- Hong, M.-K.; Lubis, M.A.R.; Park, B.-D.; Sohn, C.H.; Roh, J. Effects of Surface Laminate Type and Recycled Fiber Content on Properties of Three-Layer Medium Density Fiberboard. Wood Mater. Sci. Eng. 2020, 15, 163–171. [Google Scholar] [CrossRef]

- Hartini, S.; Wicaksono, P.A.; Rizal, A.M.D.; Hamdi, M. Integration lean manufacturing and 6R to reduce wood waste in furniture company toward circular economy. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1072, 012067. [Google Scholar] [CrossRef]

- Valizadeh, S.; Jang, S.-H.; Rhee, G.H.; Lee, J.; Show, P.L.; Khan, M.A.; Jeon, B.-H.; Lin, K.-Y.A.; Ko, C.H.; Chen, W.-H.; et al. Biohydrogen production from furniture waste via catalytic gasification in air over Ni-loaded Ultra-stable Y-type zeolite. J. Chem. Eng. 2022, 433, 133793. [Google Scholar] [CrossRef]

- Maier, D.A. Review of the Environmental Benefits of Using Wood Waste and Magnesium Oxychloride Cement as a Composite Building Material. Materials 2023, 16, 1944. [Google Scholar] [CrossRef]

- Azambuja, R.d.R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling Wood Waste from Construction and Demolition to Produce Particleboards. Maderas. Cienc. Tecnol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Okonkwo, C.E.; Alhassan, E.A.; Ajiboye, M. Durability and Strength Properties of Particle Boards from Polystyrene–Wood Wastes. J. Mater. Cycles Waste Manag. 2019, 21, 1541–1549. [Google Scholar] [CrossRef]

- Mrówka, M.; Szymiczek, M.; Skonieczna, M. The Impact of Wood Waste on the Properties of Silicone-Based Composites. Polymers 2020, 13, 7. [Google Scholar] [CrossRef]

- Kaho, S.P.; Kouadio, K.C.; Kouakou, C.H.; Eméruwa, E. Development of a Composite Material Based on Wood Waste Stabilized with Recycled Expanded Polystyrene. Open J. Compos. Mater. 2020, 10, 66–76. [Google Scholar] [CrossRef]

- De Souza Pinho, G.C.; Calmon, J.L. LCA of Wood Waste Management Systems: Guiding Proposal for the Standardization of Studies Based on a Critical Review. Sustainability 2023, 15, 1854. [Google Scholar] [CrossRef]

- Van den Auwelant, E.; Nimmegeers, P.; Van Passel, S. Life cycle assessment and circular practices in the woodworking sector: A systematic review. Clean. Technol. Environ. Policy. 2024, 1–20. [Google Scholar] [CrossRef]

- Sari, D.P.; Mahdiyah, A.S.; Purwaningsih, R. Assessing environmental impact and eco-efficiency of wood waste gallon holders using life cycle assessment. J. Ecol. Eng. 2025, 26, 336–349. [Google Scholar] [CrossRef] [PubMed]

- Rivela, B.; Moreira, M.T.; Munoz, I.; Rieradevall, J.; Feijoo, G. Life cycle assessment of wood wastes: A case study of ephemeral architecture. Sci. Total Environ. 2005, 357, 1–11. [Google Scholar] [CrossRef]

- Jungmeier, G.; Merl, A.; Mcdarby, F.; Gallis, C.; Hohenthal, C.; Petersen, A.K.; Spanos, S. End of Use and End of Life Aspects in LCA of Wood Products—Selection of Waste Management Options and LCA Integration. Available online: https://www.researchgate.net/publication/237678691_End_of_Use_and_End_of_Life_Aspects_in_LCA_of_Wood_Products_-_Selection_of_Waste_Management_Options_and_LCA_Integration/link/53d37c5e0cf220632f3cd045/download?_tp=eyJjb250ZXh0Ijp7InBhZ2UiOiJwdWJsaWNhdGlvbiIsInByZXZpb3VzUGFnZSI6Il9kaXJlY3QiLCJzdWJQYWdlIjpudWxsfX0 (accessed on 26 March 2025).

- Nordic Council of Ministers. LCA for Treatment of Wood Waste in the Nordics. Available online: https://www.norden.org/en/publication/lca-treatment-wood-waste-nordics (accessed on 26 March 2025).

- Gronba-Chyła, A.; Generowicz, A.; Alwaeli, M.; Mannheim, V.; Grąz, K.; Kwaśnicki, P.; Kramek, A. Municipal waste utilization as a substitute for natural aggregate in the light of the circular economy. J. Clean. Prod. 2024, 440, 140907. [Google Scholar] [CrossRef]

- Markic, D.N.; Carapina, H.S.; Bjelic, D.; Bjelic, L.S.; Ilic, P.; Pesic, Z.S.; Kikanovicz, O. Using Material Flow Analysis for Waste Management Planning. Pol. J. Environ. Stud. 2019, 28, 255–265. [Google Scholar] [CrossRef]

- Kleinhans, K.; Hallemans, M.; Huysveld, S.; Thomassen, G.; Ragaert, K.; Van Geem, K.M.; Roosen, M.; Mys, N.; Dewulf, J.; De Meester, S. Development and application of a predictive modelling approach for household packaging waste flows in sorting facilities. Waste Manag. 2021, 120, 290–302. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kleinhans, K.; Lase, I.S.; Huysveld, S.; Brouwer, M.; Thoden van Velzen, E.U.; Van Geem, K.M.; Dewulf, J.; Ragaert, K.; et al. Expanding the collection portfolio of plastic packaging: Impact on quantity and quality of sorted plastic waste fractions. Resour. Conserv. Recycl. 2022, 178, 106025. [Google Scholar] [CrossRef]

- Demets, R.; Van Kets, K.; Huysveld, S.; Dewulf, J.; De Meester, S.; Ragaert, K. Addressing the complex challenge of understanding and quantifying substitutability for recycled plastics. Resour. Conserv. Recycl. 2021, 174, 105826. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. The International Organization for Standardization: Brussels, Belgium, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. The International Organization for Standardization: Brussels, Belgium, 2006.

- De la Rúa Lope, C.; Lechón, Y. Life Cycle Assessment of Biofuel Production. In Biofuels Production and Processing Technology, 1st ed.; Riazi, M.R., Chiaramonti, D., Eds.; Taylor & Francis Group CRC Press: Boca Raton, FL, USA, 2017; Chapter 21; pp. 587–605. [Google Scholar] [CrossRef]

- Mandegari, M.A.; Farzad, S.; Görgens, J.F. Economic and environmental assessment of cellulosic ethanol production scenarios annexed to a typical sugar mill. Bioresour. Technol. 2017, 224, 314–326. [Google Scholar] [CrossRef]

- Meyer, D.E.; Upadhyayula, V.K. The use of life cycle tools to support decision making for sustainable nanotechnologies. Clean. Technol. Environ. Policy 2014, 16, 757–772. [Google Scholar] [CrossRef]

- Yay, A.S.E. Application of life cycle assessment (LCA) for municipal solid waste management: A case study of Sakarya. J. Clean. Prod. 2015, 94, 284–293. [Google Scholar] [CrossRef]

- Farzad, S.; Mandegari, M.A.; Görgens, J.F. Integrated techno-economic and environmental analysis of butadiene production from biomass. Bioresour. Technol. 2017, 239, 37–48. [Google Scholar] [CrossRef]

- Beylot, A.; Muller, S.; Descat, M.; Ménard, Y.; Villeneuve, J. Life cycle assessment of the French municipal solid waste incineration sector. Waste Manag. 2018, 80, 144–153. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A. Life cycle assessment on the treatment of organic waste streams by anaerobic digestion, hydrothermal carbonization and incineration. Waste Manag. 2021, 130, 93–106. [Google Scholar] [CrossRef]

- Pérez, L.; Ziegler-Rodríguez, K.; Pérez, A.; Vásquez, Ó.; Vázquez-Rowe, I. Closing the gap in the municipal solid waste management between metropolitan and regional cities from developing countries: A life cycle assessment approach. Waste Manag. 2021, 124, 314–324. [Google Scholar] [CrossRef]

- Generowicz, A.; Gronba-Chyła, A.; Kulczycka, J.; Harazin, P.; Gaska, K.; Ciuła, J.; Ocłoń, P. Life Cycle Assessment for the environmental impact assessment of a city’ cleaning system. The case of Cracow (Poland). J. Clean. Prod. 2023, 382, 135184. [Google Scholar] [CrossRef]

- Recommendation 2021/2279 of 15 December 2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32021H2279 (accessed on 26 January 2025).

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Ekvall, T.; Björklund, A.; Sandin, G.; Jelse, K. Modeling Recycling in Life Cycle Assessment. Swedish Life Cycle Centre. Report number: 2020:05. Available online: https://www.lifecyclecenter.se/wp-content/uploads/2020_05_Modeling-recyling-in-life-cycle-assessment-1.pdf (accessed on 26 January 2025).

- ISO 14067; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. The International Organization for Standardization: Brussels, Belgium, 2018.

- Announcement of the Central Statistical Office on the Average Price of Wood in 2021 Year. Available online: https://stat.gov.pl/sygnalne/komunikaty-i-obwieszczenia/lista-komunikatow-i-obwieszczen/komunikat-w-sprawie-sredniej-ceny-sprzedazy-drewna-obliczonej-wedlug-sredniej-ceny-drewna-uzyskanej-przez-nadlesnictwa-za-pierwsze-trzy-kwartaly-2021-roku,268,8.html (accessed on 26 January 2025).

- Announcement of the Central Statistical Office on the Average Price of Wood in 2019 Year. Available online: https://stat.gov.pl/sygnalne/komunikaty-i-obwieszczenia/lista-komunikatow-i-obwieszczen/komunikat-w-sprawie-sredniej-ceny-sprzedazy-drewna-obliczonej-wedlug-sredniej-ceny-drewna-uzyskanej-przez-nadlesnictwa-za-pierwsze-trzy-kwartaly-2019-roku,268,6.html (accessed on 26 January 2025).

- Announcement of the Central Statistical Office on the Average Price of Wood in 2020 Year. Available online: https://stat.gov.pl/sygnalne/komunikaty-i-obwieszczenia/lista-komunikatow-i-obwieszczen/komunikat-w-sprawie-sredniej-ceny-sprzedazy-drewna-obliczonej-wedlug-sredniej-ceny-drewna-uzyskanej-przez-nadlesnictwa-za-pierwsze-trzy-kwartaly-2020-roku,268,7.html (accessed on 26 January 2025).

- Announcement of the Central Statistical Office on the Average Price of Wood in 2022 Year. Available online: https://stat.gov.pl/sygnalne/komunikaty-i-obwieszczenia/lista-komunikatow-i-obwieszczen/komunikat-w-sprawie-sredniej-ceny-sprzedazy-drewna-obliczonej-wedlug-sredniej-ceny-drewna-uzyskanej-przez-nadlesnictwa-za-pierwsze-trzy-kwartaly-2022-roku,268,9.html (accessed on 26 January 2025).

- Announcement of the Central Statistical Office on the Average Price of Wood in 2023 Year. Available online: https://stat.gov.pl/sygnalne/komunikaty-i-obwieszczenia/lista-komunikatow-i-obwieszczen/komunikat-w-sprawie-sredniej-ceny-sprzedazy-drewna-obliczonej-wedlug-sredniej-ceny-drewna-uzyskanej-przez-nadlesnictwa-za-pierwsze-trzy-kwartaly-2023-roku,268,10.html (accessed on 26 January 2025).

- WasteMaster. Price List of Waste Wood. Available online: https://mamodpad.wastemaster.pl/cennik/odpady-drewniane (accessed on 26 January 2025).

- Allesch, A.; Brunner, P.H. Material Flow Analysis as a Tool to improve Waste Management Systems: The Case of Austria. Environ. Sci. Technol. 2017, 51, 540–551. [Google Scholar] [CrossRef]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef]

| TRANSPORT OF BULKY WASTE | ||

| Transport, freight, lorry 3.5–7.5 metric tons | 103.6 (2.07 Mg × 50 km) | tkm |

| RECOVERY—PROCESSING OF BULKY WASTE AND SEPARATION OF THE WOOD FRACTION (shredding, magnetic separation, ballistic separation, cutting, stirring, pressing) | ||

| Electricity, low voltage (electricity mix for Europe) | 2455.5 | kWh |

| RECYCLING—FABRICATION OF SECONDARY WOODEN BLOCKS (shredding, homogenization of the structure of the material, stirring and pressing together with additives) | ||

| Secondary wood, separated from bulky waste (burden free) | 817.0 | kg |

| Maize starch | 44.9 | kg |

| Tap water | 95.6 | kg |

| Electricity, low voltage (electricity mix for Europe) | 2663.3 | kWh |

| DISTRIBUTION OF SECONDARY WOODEN BLOCKS | ||

| Transport, freight, lorry 7.5–16 metric tons | 95.8 (0.958 Mg × 100 km) | tkm |

| Life Cycle of the Secondary Wooden Blocks –Baseline Scenario (Cut Off) (% Vertically) | The Most Relevant Impact Categories | Life Cycle Stages (% Horizontally) | |||

|---|---|---|---|---|---|

| Transport of Bulky Waste | Recovery—Processing of Bulky Waste | Recycling—Fabrication of Wooden Blocks | Distribution of Wooden Blocks | ||

| 24.0% | Resource use, fossils | 22.6% | 24.6% | 23.6% | 22.6% |

| 23.9% | Climate change | 35.1% | 23.7% | 23.5% | 35.0% |

| 13.3% | Eutrophication, freshwater | 1.9% | 13.9% | 13.3% | 1.5% |

| 11.8% | Resource use, minerals, and metals | 6.5% | 12.1% | 11.9% | 4.7% |

| 6.0% | Ionizing radiation | 0.4% | 6.4% | 6.0% | 0.3% |

| 5.4% | Acidification | 4.3% | 5.4% | 5.5% | 4.4% |

| 3.1% | Particulate matter | 11.0% | 2.7% | 3.1% | 12.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Generowicz, A.; Gronba-Chyła, A.; Godula, P.; Kulczycka, J.; Lewandowska, A.; Dorosz, A.; Ciuła, J.; Kwaśnicki, P. Assessment of the Possibility of Implementing a Circular Economy by Environmental Evaluating the Life Cycle of Products Derived from Bulky Municipal Waste. Sustainability 2025, 17, 3377. https://doi.org/10.3390/su17083377

Generowicz A, Gronba-Chyła A, Godula P, Kulczycka J, Lewandowska A, Dorosz A, Ciuła J, Kwaśnicki P. Assessment of the Possibility of Implementing a Circular Economy by Environmental Evaluating the Life Cycle of Products Derived from Bulky Municipal Waste. Sustainability. 2025; 17(8):3377. https://doi.org/10.3390/su17083377

Chicago/Turabian StyleGenerowicz, Agnieszka, Anna Gronba-Chyła, Piotr Godula, Joanna Kulczycka, Anna Lewandowska, Aneta Dorosz, Józef Ciuła, and Paweł Kwaśnicki. 2025. "Assessment of the Possibility of Implementing a Circular Economy by Environmental Evaluating the Life Cycle of Products Derived from Bulky Municipal Waste" Sustainability 17, no. 8: 3377. https://doi.org/10.3390/su17083377

APA StyleGenerowicz, A., Gronba-Chyła, A., Godula, P., Kulczycka, J., Lewandowska, A., Dorosz, A., Ciuła, J., & Kwaśnicki, P. (2025). Assessment of the Possibility of Implementing a Circular Economy by Environmental Evaluating the Life Cycle of Products Derived from Bulky Municipal Waste. Sustainability, 17(8), 3377. https://doi.org/10.3390/su17083377