1. Introduction

One of the priority goals of the contemporary world is to promote a circular economy, which is an idea minimizing environmental burdens by introducing rational economic solutions [

1,

2]. The construction industry has long been one of the most environmentally impactful sectors of the economy [

3]. In order to reduce the destructive impact of civil engineering on ecosystems, efforts are being made to reduce material consumption, especially natural resources, and minimize waste generation [

4,

5]. Waste generated by the construction sector includes, among others: concrete, asphalt, ceramics, steel, tires, polyethylene terephthalate (PET), slag, and ashes. Storing these wastes in landfills leads to contamination of adjacent soils, air, and water, and the limitation of available space for local communities [

6].

The introduction of the circular economy concept in the construction industry primarily occurs through the use of recycling in the production of building materials. It is becoming increasingly common to utilize recycled aggregates in concrete, particularly in concrete pavements but also in other civil engineering structures [

7]. According to estimates [

8,

9], the concrete industry annually requires 1.5 billion tons of cement, 10–20 billion tons of aggregates, and approximately 1 billion tons of water for concrete production. This means that introducing alternative solutions in concrete technology opens the door to efficient recycling of construction and industrial waste [

10].

Green concretes are most often produced by incorporating recycled aggregate or modified cements into the mix. The use of eco-friendly cements containing waste substances allows for the production of materials with similar or sometimes even better mechanical properties compared to traditional cements [

11,

12].

Aggregates occupy a large portion of the volume in concrete, approximately 80%, and are a fundamental factor in shaping the compressive strength of the hardened material [

13]. The most commonly used recycled aggregates in concrete are from demolished concrete and ceramics [

14].

Recycled ceramic aggregate consists of finely crushed roof tiles and bricks made of red ceramics, along with ceramic tiles and sanitary ceramics, which are the focus of research studies [

15,

16]. Waste from sanitary ceramics includes chipped and cracked sanitary ware, rejected during quality control, such as: toilet bowls, sinks, bidets, bathtubs, and urinals [

17]. The manufacturing of sanitary products includes shaping, drying, and glazing semi-finished items, followed by firing at approximately 1200 °C [

18].

The utilization of finely crushed recycled sanitary ceramic aggregate (ceramic cullet) in concrete technology requires experimental analysis of the properties of mixtures containing ceramics. Concrete must absolutely meet durability requirements during its service life [

19]. The lack of standards and guidelines for designing mixtures based on ceramic aggregate means that concrete production relies on experimental analysis of the relationship between secondary aggregates, cement, natural aggregates, and other mixture components [

20].

According to a few studies addressing the incorporation of sanitary ceramics into concrete mixtures, partial replacement of coarse aggregate with ceramic aggregate positively affects the strength characteristics of the hardened material [

17,

21,

22]. Research [

21] has shown an improvement in compressive strength after the application of recycled ceramics in the mixture, a reduction in the porosity of the concrete structure, and an increase in the bond between the cement matrix and the aggregate [

23]. Furthermore, this concrete exhibited higher resistance to freeze-thaw cycles [

24] and elevated temperatures [

25]. This results from the ceramic aggregate’s low thermal expansion coefficient [

18,

24,

26].

Important factors in waste management are financial considerations and the costs associated with implementing a particular solution on a larger scale. Introducing sanitary ceramic aggregate into concrete enables the production of inexpensive and durable material, which contributes to solving environmental problems [

17]. This direction should be promoted due to the high durability of sanitary ceramics, which undergo biodegradation over more than 4000 years [

27].

This article describes the author’s research results on compressive strength, compressive strength after roasting, and shear modulus of elasticity under compression. The preparation and curing of samples were conducted using commonly used procedures, following construction standards. The concrete production conditions aimed to demonstrate the possibility of achieving a high-quality material containing recycled ceramic aggregate without additional financial outlay associated with the use of complex and hard-to-access technologies, equipment, and materials.

2. Materials and Methods

To determine the composition of the concrete mix, the density and absorption of the coarse aggregates were analyzed. Samples for testing comprised weighed portions of granite and recycled ceramic aggregate. The determinations were conducted in accordance with the recommendations of European standard [

28], using the pycnometer method for aggregates with particle sizes ranging from 4 mm to 31.5 mm.

Specimens for strength testing were prepared in accordance with European standard [

29]. For compressive strength and compressive strength after roasting tests, cubic samples with dimensions of 100 × 100 × 100 mm were used. For the determination of modulus of elasticity, cylindrical samples with a diameter of 150 mm and a height of 300 mm were employed. After molding, the samples were stored in air-dry conditions for 48 h. Subsequently, they were removed from the molds and submerged in a water tank to reach full saturation. The tests were conducted 28 days after the samples were made, ensuring the standard concrete curing period.

The determination of compressive strength was carried out based on the guidelines outlined in European standard [

30]. After removing the samples from the tank to ensure full saturation of the concrete, they were dried to remove excess moisture. Subsequently, three measurements were taken for each side of the sample using a caliper to determine the cross-sectional area subjected to compressive force. The samples were positioned in the testing machine (ToniTechnik PACT II, ToniTechnik GmbH, Schrobenhausen, Germany) so that the load was applied perpendicular to the direction of the cube formation during concrete casting. To obtain values for analysis, the test results were converted using an appropriate scaling factor of 0.90 for cubic samples with a side length of 100 mm compared to samples with a side length of 150 mm [

31].

After 28 days from the preparation of the samples intended for compressive strength testing after roasting at elevated temperatures, the samples were transferred from the tank to a rack for drying. After 7 days, the concrete was roasted in a muffle furnace type FCF 12SP (LAC, Židlochovice, Czech Republic). The investigation of the impact of elevated temperatures on the strength of the concrete was conducted in four temperature variants—150, 300, 550, and 750 °C. The furnace temperature was increased following guidelines from the Fire Academy (Warsaw, Poland): 150 °C was reached in 30 min and maintained for an hour. Subsequently, reaching 300 °C took another 30 min, and it was maintained for another hour. Reaching 550 °C took an additional 40 min, and it was maintained for an hour, while reaching 750 °C took 50 min, and it was maintained for 30 min. After heating, the samples were left in the furnace until completely cooled. The roasted cubes were subjected to compressive strength testing.

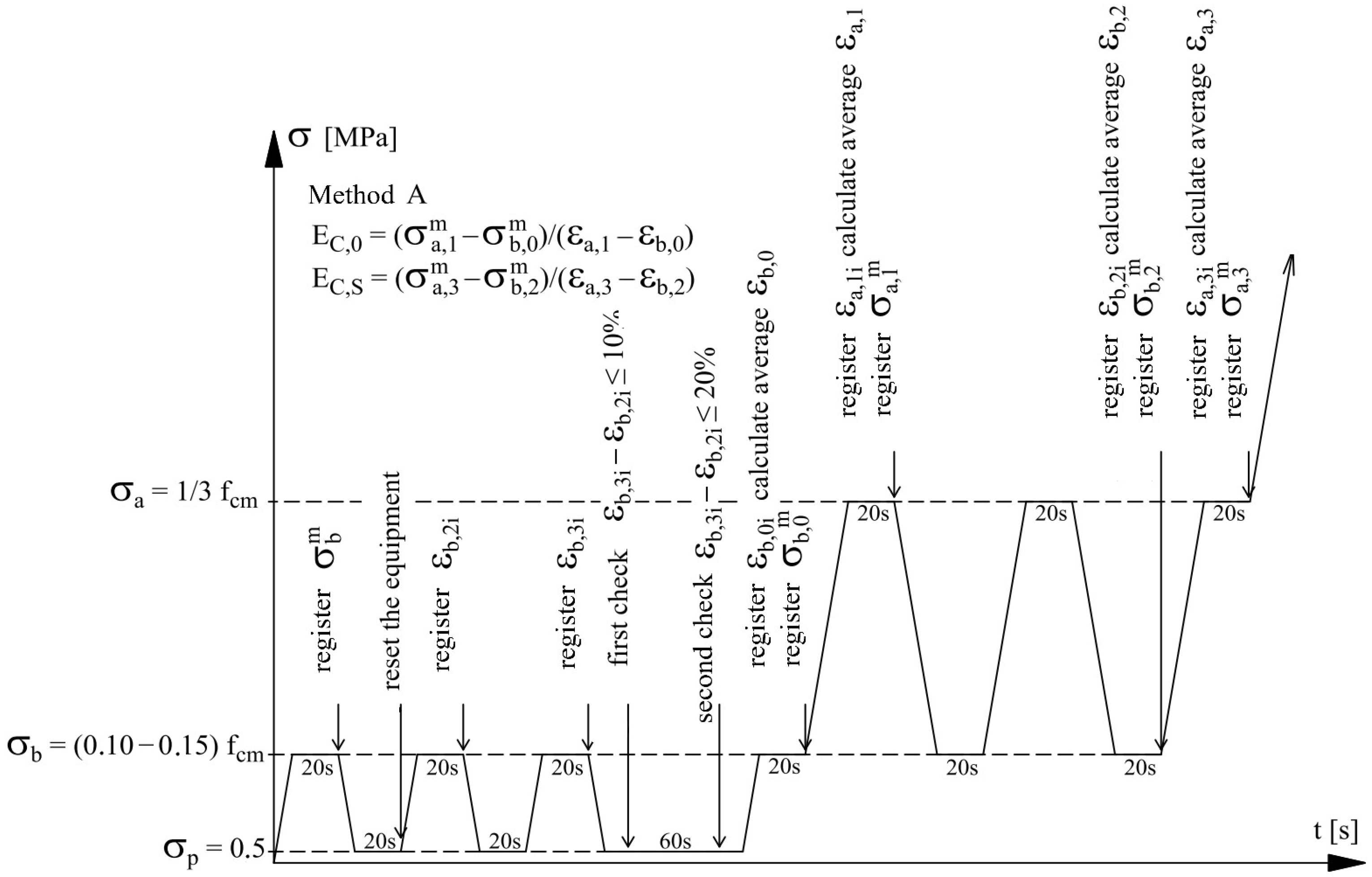

The determination of modulus of elasticity was conducted according to European standard [

32] in press C088-11N (Matest, Arcore, Italy). Method A enables the determination of both the initial and stabilized modulus of elasticity. The loading and unloading cycles followed the pattern shown in

Figure 1. The compressive strength, tested on cylindrical samples and required for calculating stresses σa and σb, was obtained by converting the strength from cubic samples (15 × 15 × 15 cm) using a scaling factor of 0.80 [

22,

31].

The binder used for sample preparation was CEM I 42.5R cement (from Górażdże Cement S.A., Chorula, Poland), known for its high early strength and significant heat of hydration. This type of cement is commonly used for ordinary concrete classes but can also be suitable for high-strength concrete applications.

This study utilized two types of coarse aggregates: granite base aggregate and recycled ceramic aggregate (ceramic cullet), derived from finely crushed sanitary ware. The recycled aggregate was obtained from the Sanitec Koło factory (Włocławek, Poland). Before determining the composition of the concrete mixtures, properties of aggregates such as grain density and water absorption were examined. Both properties were necessary to consider in determining the proportions between the mixture components. The water absorption values were WA24 0.73% for granite and WA24 3.92% for recycled ceramic aggregate. The grain density of ceramic cullet was 2.38 g/cm

3 in its dried state and 2.59 g/cm

3 after saturation followed by initial surface drying. In comparison, the density of dried granite grains reached 2.56 g/cm

3, increasing to 2.61 g/cm

3 after saturation and initial drying. Aggregate absorption directly affects the consistency of the concrete mixture. Since absorbed water is excluded from the water/cement ratio calculations, pre-wetting of the aggregates was necessary to achieve the desired

w/

c ratio. For this purpose, the amount of water absorbed by granite and ceramic cullet was experimentally determined. After wetting the aggregates to full saturation, they were spread out and air-dried under laboratory conditions for one hour to remove surface water. This method was experimentally determined by monitoring the water content in the aggregates at various drying intervals, with the optimal drying time found to be 60 min [

22].

It was assumed that aggregates with particle size fractions of 4–8 mm and 8–16 mm (

Figure 2) would be used. Each fraction ultimately comprised 50% of the total coarse aggregate content in the concrete mix. Eight batches were prepared in total, differing in water/cement ratio and the level of ceramic aggregate recycling in the mixture. The reference concrete, used as the benchmark for all tests, contained only natural granite aggregate. Sanitary ceramics were introduced as a substitute for coarse aggregate, replacing 15%, 30%, and 45% of the granite base aggregate.

To evaluate the impact of ceramic cullet on concrete properties, tests were conducted on mixtures with two water/cement ratio variants:

w/

c = 0.30 and

w/

c = 0.40. The following designations were used: A0, A15, A30, and A45 for

w/

c = 0.40, and B0, B15, B30, and B45 for

w/

c = 0.30. Here, 0, 15, 30, and 45 represent the percentage substitutions of granite aggregate with recycled ceramic aggregate. The selection of replacement levels was made experimentally, assuming a gradual and uniform increase while ensuring a clear distinction between the tested variants. Each series was designed to achieve the S3 consistency class, determined using the slump cone method because it ensures a plastic consistency, which facilitates easy handling and placement of the mix without workability issues. A water-reducing admixture was incorporated to achieve this target. A polycarboxylate-based superplasticizer was employed to significantly reduce mixing water requirements while ensuring proper workability and minimizing segregation and drying shrinkage. The compositions of the prepared concrete mixtures are detailed in

Table 1 and

Table 2. The research cycle included testing the compressive strength of hardened concrete, the modulus of elasticity, and the compressive strength after subjecting the samples to thermal loads.

3. Results

The compressive strength and compressive strength after heating were determined using six samples from each analyzed series. Additionally, the secant modulus of elasticity under compression was calculated based on the results from three cylindrical samples. The results of these tests are summarized in

Table 3.

Measurement uncertainty was determined exclusively for the compressive strength test results. The determination of the secant modulus of elasticity was conducted with the minimum number of samples, and therefore, statistical analysis was not included. Measurement uncertainties were determined using the t-Student distribution, with a 95% confidence interval [

22].

4. Discussion

The compressive strength tests revealed that for concretes with a water/cement ratio of 0.40, the strength changes slightly with varying percentages of ceramic aggregate. For concretes with a w/c ratio of 0.30, the addition of ceramic aggregate resulted in a decrease in strength (over 20%). However, no significant differences (up to 2%) were observed between samples containing 15%, 30%, or 45% recycled aggregate.

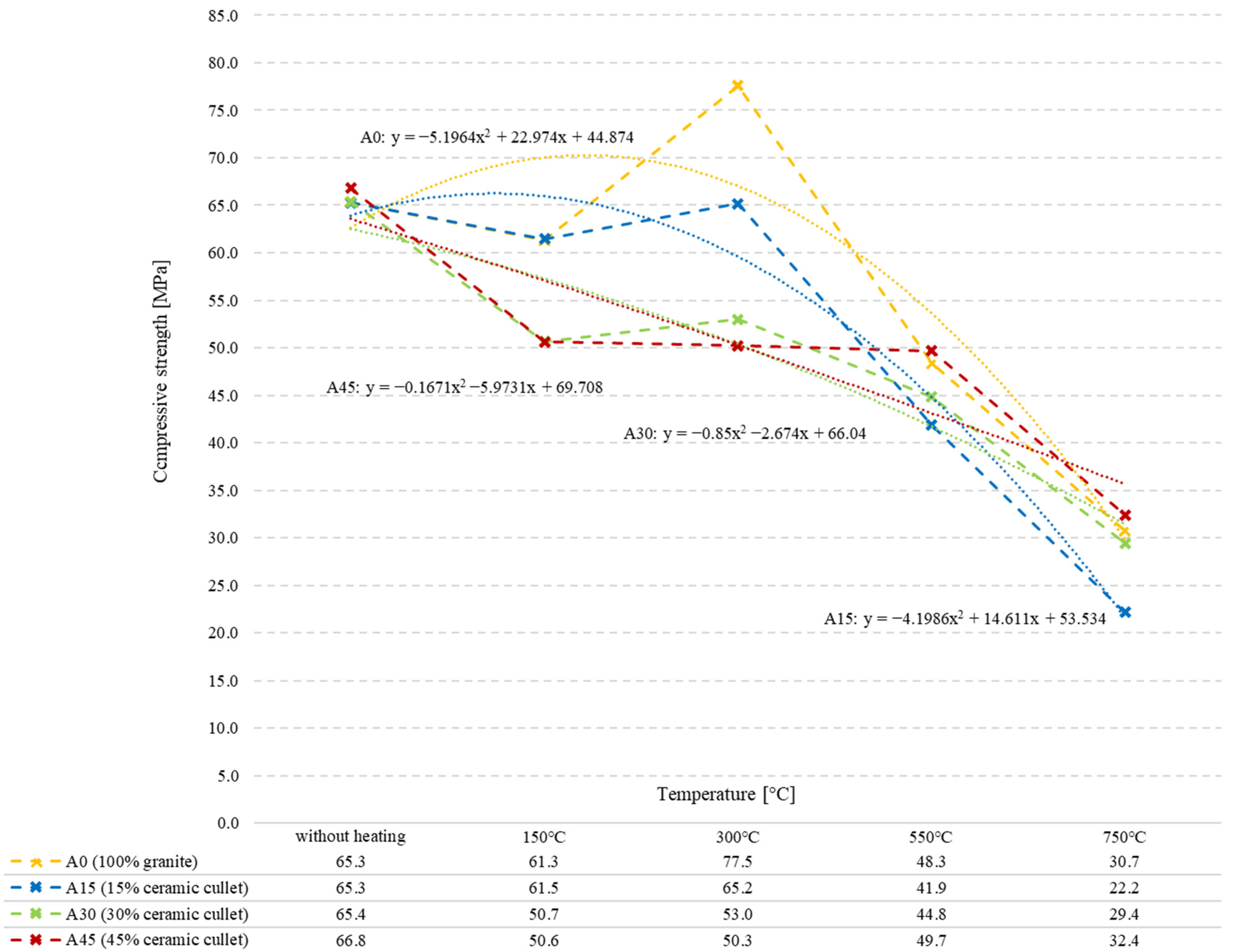

For concretes with a water/cement ratio of 0.40 subjected to heating at 150 °C, 300 °C, 550 °C, and 750 °C (

Figure 3), the presence of ceramic cullet improved the material’s resistance to elevated temperatures (550 °C and 750 °C). The compressive strength of unheated samples varied slightly (up to ~2.5%) regardless of the concrete composition. After heating at 150 °C, there was a decrease (about 20%) in strength between concrete without cullet and concrete containing ceramics at 15% of the mass of coarse aggregate, and between concrete with ceramic cullet at 30% and 45%, respectively. At 300 °C, there was an increase in compressive strength for A0 (~25%), A15 (~5%), and A30 (~5%) compared to their respective strengths at 150 °C, while A45 showed a slight decrease. At 550 °C, the strength increased as the proportion of ceramic cullet in the concrete rose. The highest strength was achieved by the recycled concrete containing 45% ceramic aggregate (A45). This strength was approximately 3% higher than the base concrete (A0, 100% granite), 17% higher than A15, and 10% higher than A30. After heating at 750 °C, the highest strength was achieved by concrete A45, which was about 5% higher than A0, 45% higher than A15, and 10% higher than A30.

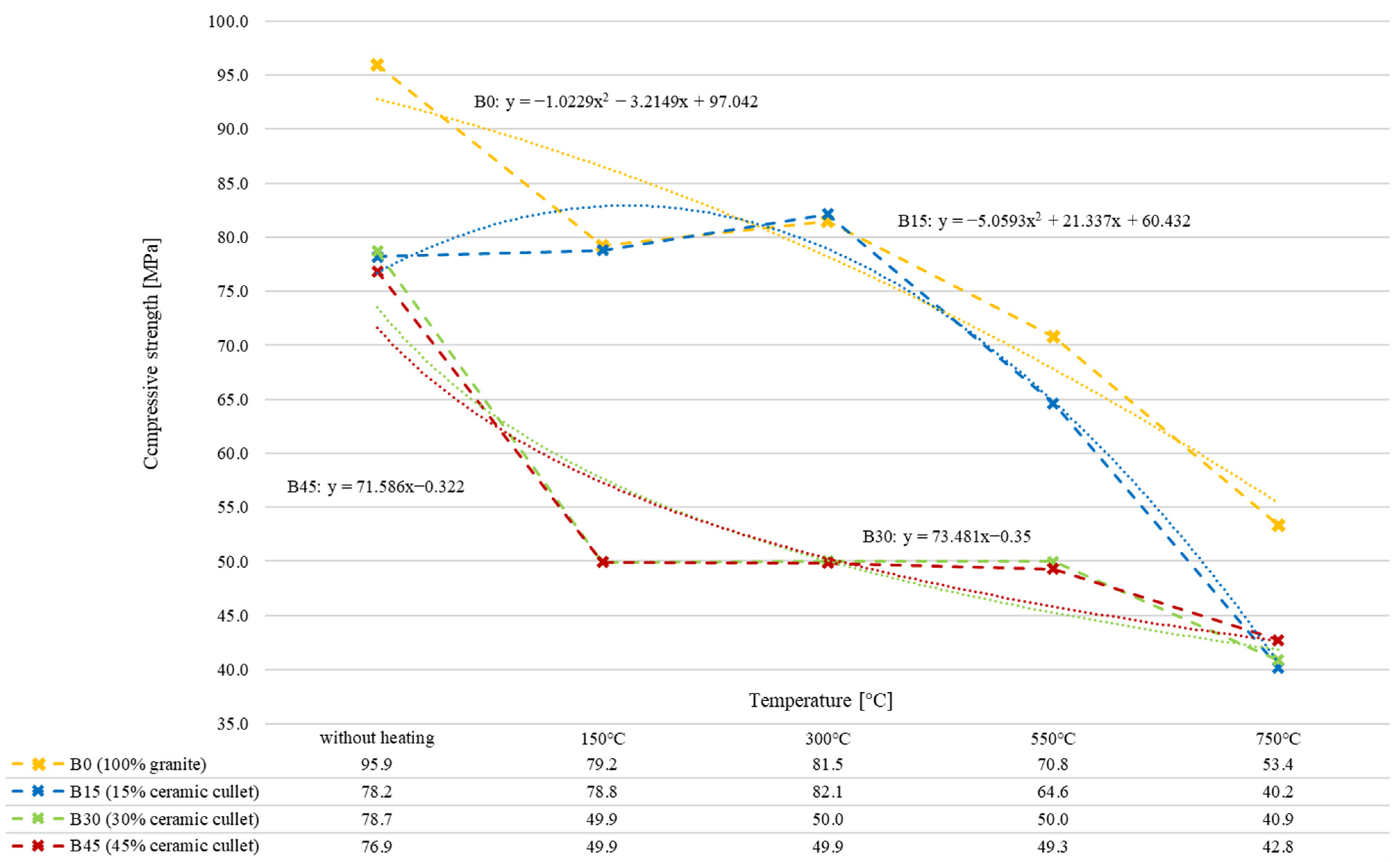

The compressive strength test on concrete samples with a water/cement ratio of 0.30 revealed that the inclusion of ceramic cullet aggregate in the concrete mix does not enhance this property (

Figure 4). Among the unheated samples, the highest compressive strength was achieved by the reference concrete (B0), which was over 20% higher than the strength of concretes with cullet. Regardless of the percentage of granite replacement, the concretes containing cullet displayed similar strength values. After heating at 150 °C, a significant strength reduction (over 55%) was observed in samples with ceramic cullet (B30 and B45) compared to B0 and B15. At 300 °C, a slight increase in compressive strength was noted relative to 150 °C. The strength of B0 rose by approximately 3%, B15 by 4%, while the strengths of B30 and B45 remained unchanged. At 550 °C, B0 continued to exhibit the highest compressive strength, surpassing B15 by about 10%, B30 by 40%, and B45 by 45%. Following heating at 750 °C, B0 retained the highest strength, though a trend emerged where the strength increased with the proportion of cullet in the concrete. Specifically, B0 demonstrated a strength 30% higher than B15, 31% higher than B30, and 25% higher than B45.

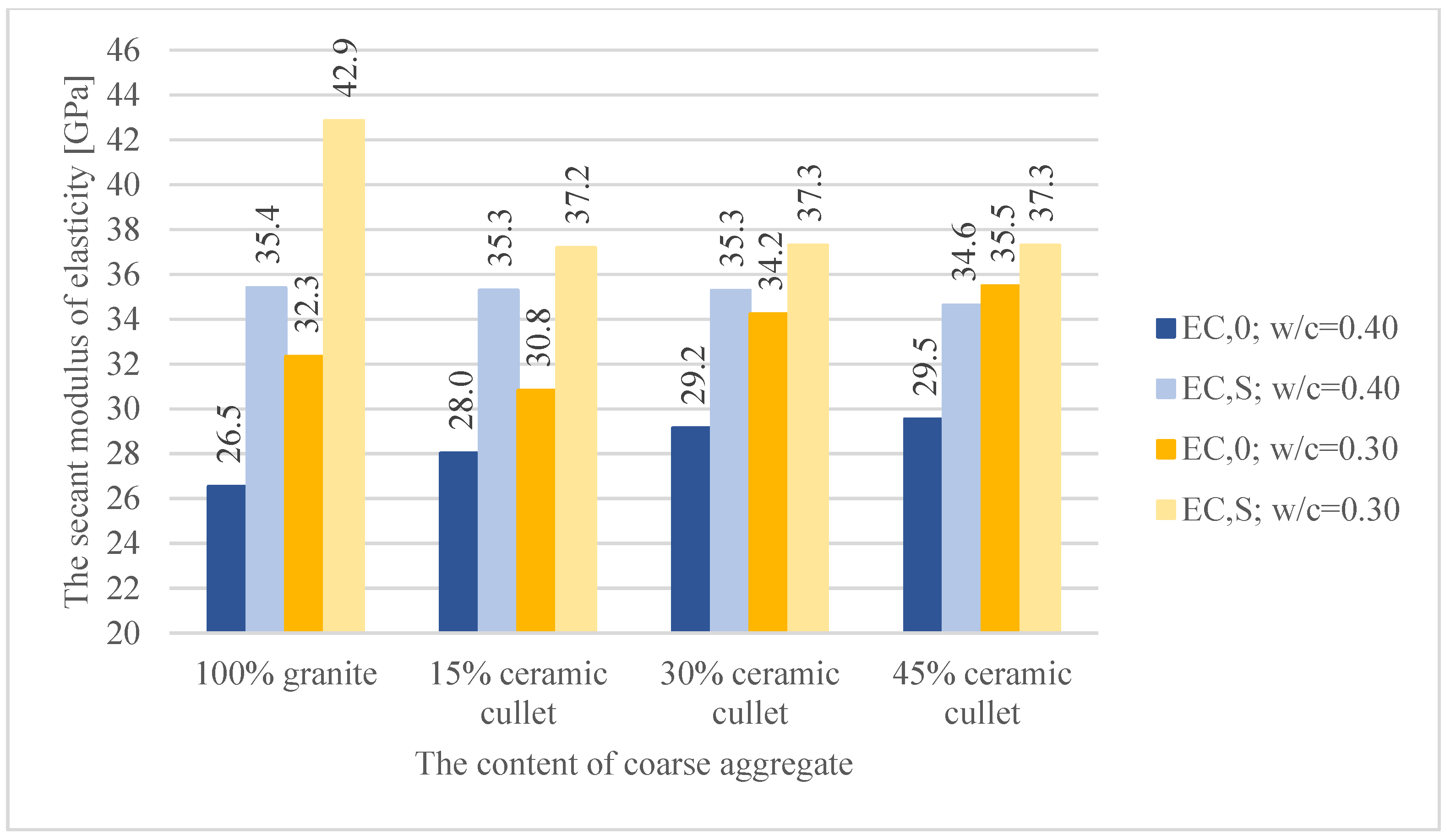

The secant modulus of elasticity was evaluated in two variants (

Figure 5)—initial (

EC,0) and stabilized (

EC,S). For concrete with a water/cement ratio of 0.4, the initial modulus of elasticity gradually increased with the replacement level of granite aggregate by recycled ceramic aggregate. In concrete samples with a water/cement ratio of 0.3, the initial addition of ceramic cullet led to a reduction in the secant modulus compared to samples without ceramic aggregate. As the proportion of cullet in the mix increased, the secant modulus gradually improved.

For samples with a w/c ratio of 0.4, the stabilized secant modulus remained consistent regardless of the amount of granite aggregate replaced by ceramic cullet. In contrast, for samples with a w/c ratio of 0.3, a slight decrease in the stabilized modulus was observed after introducing ceramic cullet. Samples without cullet showed results approximately 15% higher than those with partial aggregate replacement. However, concrete mixes containing 15%, 30%, and 45% recycled ceramic aggregate exhibited almost identical stabilized modulus values.

5. Conclusions

The compressive strength test results indicate that for concrete with a water/cement ratio of 0.30, the introduction of recycled ceramic aggregate into the mix led to a significant reduction in strength (by over 20%). In series where 15%, 30%, and 45% of the granite coarse aggregate was replaced with ceramic aggregate, the compressive strength values were similar, averaging around 78 MPa. For all series with a w/c ratio of 0.40, the results remained consistent, averaging approximately 66 MPa. This suggests that the addition of ceramic aggregate had no notable impact on the compressive strength of the concrete at this w/c ratio.

The compressive strength test results after heating reveal that higher ceramic aggregate content enhances the thermal resistance of concrete, particularly at temperatures of 550 °C and 750 °C. This effect was more pronounced in concrete with a water/cement ratio of 0.40, where replacing 45% of granite with ceramic aggregate yielded the highest compressive strengths at elevated temperatures.

In contrast, concrete with a water/cement ratio of 0.30 achieved its highest compressive strengths in the series made exclusively with granite aggregate. However, it is plausible that at replacement levels exceeding 50%, the compressive strength could surpass that of lower replacement ratios. Additionally, for all tested series, an increase in strength was observed after heating to 300 °C compared to 150 °C. This behavior suggests that the evaporation of free water contributed to strengthening the concrete, followed by a gradual decline in strength as dehydration progressed. The observed strength increase may also be linked to the presence of a superplasticizer, which optimizes water distribution within the concrete matrix. To comprehensively understand these phenomena, further research focusing on the rheological characteristics of concrete is recommended.

By incorporating crushed ceramic aggregate in appropriate proportions, it is possible to produce concrete with enhanced resistance to elevated temperatures compared to conventional granite aggregate-based concrete. The results of the conducted research confirm the validity of the proposed theses, indicating that the addition of ceramic waste significantly enhances the thermal resistance of concrete. The obtained findings are consistent with previous reports [

33,

34], while also expanding the understanding of the mechanisms by which ceramics influence the properties of concrete under high-temperature conditions.

The replacement of natural granite aggregate with ceramic aggregate also resulted in an increase in the initial secant modulus of elasticity. When 45% of the granite aggregate was substituted, this increase reached approximately 10%. This trend was consistent for mixtures with both water/cement ratios of 0.30 and 0.40. The initial secant modulus of elasticity under compression is particularly relevant in prestressed concrete structures, as it affects calculations of instantaneous prestress loss and initial deflection [

35]. The observed increase in the initial modulus of elasticity highlights the potential for using recycled ceramic aggregate in prestressed concrete applications. The prospect of using the material in such complex implementations requires a broad analysis of the durability, shrinkage, and corrosion resistance of concrete.

The stabilized secant modulus of elasticity for concrete with a w/c ratio of 0.40 showed minimal variation, regardless of the proportion of recycled ceramic aggregate. For mixtures with a w/c ratio of 0.30, the introduction of sanitary ceramics led to a slight decrease in modulus values. However, across all tested proportions of crushed ceramic aggregate (15%, 30%, 45%), the results were relatively consistent.

The modulus of elasticity of concrete reflects the elasticity of its aggregate and the bond between the aggregate and the cementitious matrix. The results demonstrate that recycled ceramic aggregate can maintain the stress–strain relationship in concrete at levels comparable to granite aggregate [

20].

These findings confirm that sanitary ceramics can serve as a viable substitute for coarse aggregate in concretes subjected to thermal loads. Designing concrete mixtures with recycled ceramic aggregate requires careful experimental evaluation of both fresh and hardened concrete properties, particularly concerning durability under anticipated service conditions.

Additionally, we agree that a detailed analysis of the interfacial transition zone (ITZ) between ceramic aggregates and the cement matrix would provide important insights into the microscopic mechanisms affecting strength variations. To address this, future research will focus on conducting SEM and XRD analyses to investigate the microstructure of the concrete more thoroughly, helping to deepen our understanding of the material’s performance under various conditions.

In summary, replacing granite aggregate with ceramic aggregate helps reduce the extraction of natural resources. Utilizing recycled ceramic waste can also decrease expenses related to disposal and the transportation of natural aggregates. Additionally, producing recycled ceramic aggregates may require less energy than extracting and transporting natural aggregates. The improved thermal resistance of concrete containing ceramics can result in benefits, particularly in demanding environments such as tunnels or power plants. Furthermore, the advancement of recycled concrete technology can drive innovation in the construction industry and create new job opportunities in the waste processing sector.

The use of recycled ceramic aggregates offers numerous economic, social, and environmental benefits. However, their widespread adoption requires further research and technological optimization. Large-scale implementation necessitates a comprehensive microstructural analysis, long-term durability assessments (including shrinkage and corrosion resistance), and an evaluation of practical cost implications. While ceramic recycling can lower raw material costs, the need to adapt production technology and construction standards may increase overall implementation expenses.