An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges

Abstract

1. Introduction

2. Causes and Consequences of Damage to Reinforced Concrete Bridge Structures

2.1. Mechanical and Dynamic Loads Impacts on RC Bridges

2.2. Impact of Aggressive Environments on Bridge Structures

2.3. Research on the Behavior and Strengthening of Reinforced Concrete Bridge Structures

2.4. Conclusions for Section 2

3. The Use of Modern Materials for Strengthening Reinforced Concrete Bridges

3.1. Determining the Actual Stressed-Deformed State in Case of Damage

3.2. Reinforcement Using Various Methods with the Help of Composite Materials

3.3. Conclusion for Section 3

4. Innovative Approaches to the Ecological Restoration of RC Bridges

4.1. Environmental Challenges of Demolishing Reinforced Concrete Bridges

4.2. Sustainable Restoration Strategies for Reinforced Concrete Bridges

4.3. Conclusions for Section 4

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- American Association of State Highway and Transportation Officials (AASHTO). The Manual for Bridge Evaluation, 3rd ed.; AASHTO: Washington, DC, USA, 2018. Available online: https://www.regulations.gov/document/FHWA-2017-0047-0274 (accessed on 9 March 2025).

- American Association of State Highway and Transportation Officials (AASHTO). Manual for Bridge Element Inspection, 2nd ed.; AASHTO: Washington, DC, USA, 2019. Available online: https://www.regulations.gov/document/FHWA-2017-0047-0273 (accessed on 9 March 2025).

- Ministero delle Infrastrutture e dei Trasporti. Linee Guida per la Classificazione e Gestione del Rischio, la Valutazione della Sicurezza ed il Monitoraggio dei Ponti Esistenti. 2020. Available online: https://cslp.mit.gov.it/circolari-e-linee-guida/linee-guida-la-classificazione-e-gestione-del-rischio-la-valutazione-della (accessed on 9 March 2025).

- Ibrahim, A.; Abdelkhalek, S.; Zayed, T.; Qureshi, A.H.; Mohammed Abdelkader, E. A Comprehensive Review of the Key Deterioration Factors of Concrete Bridge Decks. Buildings 2024, 14, 3425. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M. Strengthening of reinforced concrete beams by using fiber-reinforced polymer composites: A review. J. Build. Eng. 2019, 25, 100798. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Chen, G. Flexural strengthening of reinforced concrete beams or slabs using ultra-high performance concrete (UHPC): A state of the art review. Eng. Struct. 2020, 205, 110035. [Google Scholar] [CrossRef]

- Calò, M.; Ruggieri, S.; Buitrago, M.; Nettis, A.; Adam, J.M.; Uva, G. An ML-based framework for predicting prestressing force reduction in reinforced concrete box-girder bridges with unbonded tendons. Eng. Struct. 2025, 325, 119400. [Google Scholar] [CrossRef]

- Bobalo, T.; Blikharskyy, Y.; Kopiika, N.; Volynets, M. Serviceability of RC Beams Reinforced with High Strength Rebar’s and Steel Plate. Lect. Notes Civ. Eng. 2019, 47, 25–33. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Shear Strengthening of Reinforced Concrete Beams Using Epoxy-Bonded FRP Composites. ACI Struct. J. 1998, 95, 107–115. [Google Scholar]

- Koteš, P.; Zahuranec, M.; Prokop, J.; Strauss, A.; Matos, J. Measurement of corrosion rates on reinforcement using the field test. Ce/Papers 2023, 6, 1053–1058. [Google Scholar] [CrossRef]

- Koteš, P.; Vavruš, M.; Jošt, J.; Prokop, J. Strengthening of concrete column by using the wrapper layer of fibre reinforced concrete. Materials 2020, 13, 5432. [Google Scholar] [CrossRef]

- Fatemi, A.; Yang, L. Cumulative fatigue damage and life prediction theories: A survey of the state of the art for homogeneous materials. Int. J. Fatigue 1998, 20, 9–34. [Google Scholar] [CrossRef]

- Golos, K.; Ellyin, F. Generalization of cumulative damage criterion to multilevel cyclic loading. Theor. Appl. Fract. Mech. 1987, 7, 169–176. [Google Scholar] [CrossRef]

- Schäfer, N.; Gudžulić, V.; Breitenbücher, R.; Meschke, G. Experimental and Numerical Investigations on High Performance SFRC: Cyclic Tensile Loading and Fatigue. Materials 2021, 14, 7593. [Google Scholar] [CrossRef] [PubMed]

- Kopiika, N.; Vegera, P.; Vashkevych, R.; Blikharskyy, Z. Stress-strain state of damaged reinforced concrete bended elements at operational load level. Prod. Eng. Arch. 2021, 27, 242–247. [Google Scholar] [CrossRef]

- Shymanovskyi, O.V.; Kolesnichenko, S.V. Determining the procedure and composition of the inspection for residual resource calculation. Ind. Constr. Eng. Struct. 2018, 3, 2–6. [Google Scholar]

- Klymenko, Y.V.; Polyanskyi, K.V. Experimental studies of the stress-strain state of damaged reinforced concrete beams. Bull. Odessa State Acad. Civ. Eng. Archit. 2019, 76, 24–30. [Google Scholar]

- Herrera, D.; Tolentino, D. Fragility Assessment of RC Bridges Exposed to Seismic Loads and Corrosion over Time. Materials 2023, 16, 1100. [Google Scholar] [CrossRef]

- Kalashemi, S.H.; Bidgoli, M.R.; Mazaheri, H. Seismic analysis and optimization of concrete bridge under the moving train utilizing numerical methods and adaptive improved harmony search algorithm. J. Comput. Des. Eng. 2022, 9, 919–932. [Google Scholar] [CrossRef]

- Hakimian, R. Dresden Bridge Failure Caused by Hydrogen-Induced Stress Corrosion, Report Confirms. 2024. Available online: https://www.newcivilengineer.com/latest/dresden-bridge-failure-caused-by-hydrogen-induced-stress-corrosion-report-confirms-19-12-2024/ (accessed on 3 March 2025).

- Aggarwal, V.; Parameswaran, L. Effect of Overweight Trucks on Fatigue Damage of a Bridge. In Advances in Structural Engineering; Matsagar, V., Ed.; Springer: New Delhi, India, 2015. [Google Scholar] [CrossRef]

- Nowak, A.S.; Nassif, H.; DeFrain, L. Effect of truck loads on bridges. J. Transp. Eng. 1993, 119, 853–867. [Google Scholar] [CrossRef]

- Alliche, A. Damage model for fatigue loading of concrete. Int. J. Fatigue 2004, 26, 915–921. [Google Scholar] [CrossRef]

- Do, T.V.; Pham, T.M.; Hao, H. Impact force profile and failure classification of reinforced concrete bridge columns against vehicle impact. Eng. Struct. 2019, 183, 443–458. [Google Scholar] [CrossRef]

- Zhang, C.; Gholipour, G.; Mousavi, A.A. State-of-the-Art Review on Responses of RC Structures Subjected to Lateral Impact Loads. Arch. Comput. Methods Eng. 2021, 28, 2477–2507. [Google Scholar] [CrossRef]

- Savytskyi, M.V.; Titiuk, A.O.; Lytvynenko, D.A. Strength and energy characteristics of concrete under the conditions of corrosion process development. In Proceedings of the 2nd International Symposium “Mechanics and Physics of Destruction of Building Materials and Structures”; Lviv Polytechnic National University: Lviv, Ukraine, 1996; pp. 383–386. [Google Scholar]

- Mahmoodian, M. Structural reliability assessment of corroded offshore pipelines. Aust. J. Civ. Eng. 2020, 19, 123–133. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Bressolette, P.; Chateauneuf, A.; Sánchez-Silva, M. Probabilistic lifetime assessment of RC structures under coupled corrosion–fatigue deterioration processes. Struct. Saf. 2009, 31, 84–96. [Google Scholar] [CrossRef]

- Lipiński, T. Investigation of corrosion rate of X55CrMo14 stainless steel at 65% nitrate acid at 348 K. Prod. Eng. Arch. 2021, 27, 108–111. [Google Scholar] [CrossRef]

- Irassar, E.F. Sulfate resistance of blended cement: Prediction and relation with flexural strength. Cem. Concr. Res. 1990, 20, 209–218. [Google Scholar] [CrossRef]

- Gollop, R.S.; Taylor, H.F.W. Microstructural and microanalytical studies of sulfate attack. I. Ordinary Portland cement paste. Cem. Concr. Res. 1992, 22, 1027–1038. [Google Scholar] [CrossRef]

- Meyer, C. The Coming of Age of Concrete Construction. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Fagerlund, G. The significance of critical degrees of saturation at freezing of porous and brittle materials. Durab. Build. Mater. 1977, 2, 217–225. [Google Scholar]

- Golewski, G.L. The Phenomenon of Cracking in Cement Concretes and Reinforced Concrete Structures: The Mechanism of Cracks Formation, Causes of Their Initiation, Types and Places of Occurrence, and Methods of Detection—A Review. Buildings 2023, 13, 765. [Google Scholar] [CrossRef]

- Rezaie, A.; Achanta, R.; Godio, M.; Beyer, K. Comparison of crack segmentation using digital image correlation measurements and deep learning. Constr. Build. Mater. 2020, 261, 120474. [Google Scholar] [CrossRef]

- Smith, P.; Garcia, R.; Johnson, T. History and Future of Reinforced Concrete. Eng. Struct. 1999, 21, 1009–1020. [Google Scholar]

- Czajkowska, A.; Raczkiewicz, W.; Bacharz, M.; Bacharz, K. Influence of maturing conditions of steel-fiber reinforced concrete on its selected parameters. Constr. Optim Energy Potential (CoOEP) 2020, 9, 47–54. [Google Scholar] [CrossRef]

- Meier, U. Strengthening of Structures Using Carbon Fibre/Epoxy Composites. Constr. Build. Mater. 1995, 9, 341–351. [Google Scholar] [CrossRef]

- Zhuravskyi, O.D.; Zhuravska, N.E.; Bambura, A.M. Features of calculation of prefabricated steel fiber concrete airfield slabs. Int. J. Tech. Phys. Probl. Eng. 2022, 14, 103–107. [Google Scholar]

- Dorofeev, V.S.; Karpyuk, V.M.; Karpyuk, F.R.; Yaroshevych, N.M. Deformation method for calculating the strength of bearing areas of reinforced concrete structures. Bull. Odessa State Acad. Civ. Eng. Archit. 2008, 31, 141–150. [Google Scholar]

- Dorofeev, V.S.; Karpyuk, V.M.; Petrov, N.N. Strength of bearing areas of eccentrically compressed or tensioned span elements. Bull. Natl. Univ. Lviv Polytech. 2010, 17, 391–398. [Google Scholar]

- Dorofeev, V.S.; Karpyuk, V.M.; Krantovska, O.M. Strength calculation of continuous beams using a deformation model. In Proceedings of the Scientific Papers “Mechanics and Physics of Destruction of Building Materials and Structures”; Luchka, J.J., Ed.; Kameniar: Lviv, Ukraine, 2007; Volume 7, pp. 223–237. [Google Scholar]

- Dorofeev, V.S.; Karpyuk, V.M.; Neutov, S.F. Experimental studies of crack resistance in bearing areas of bent reinforced concrete elements under prolonged load. Bull. Odessa State Acad. Civ. Eng. Archit. 2009, 34, 19–22. [Google Scholar]

- Leonhardt, F.; Walter, R. Beitrage zur Behandlung der Schubprobleme. Beton Und Stahlbetonban 1962, 9, 13–28. [Google Scholar]

- Mörsch, E. Der Eisenbetonbau: Seine Theorie und Anwendung; Wittwer: Stuttgart, Germany, 1922; 484p. [Google Scholar]

- Talbot, A.N. Tests of Reinforced Concrete Beams: Resistance of web Stresses; Bulletin No29; University of Illinois, Engineering Experiment Station: Champaign, IL, USA, 1909; pp. 17–19. [Google Scholar]

- Regan, P.E. Shear in reinforced concrete beams. Mag. Concr. Res. 1909, 21, 51–55. [Google Scholar] [CrossRef]

- Farneti, E.; Cavalagli, N.; Costantini, M.; Trillo, F.; Minati, F.; Venanzi, I.; Ubertini, F. A method for structural monitoring of multispan bridges using satellite InSAR data with uncertainty quantification and its pre-collapse application to the Albiano-Magra Bridge in Italy. Struct. Health Monit. 2023, 22, 353–371. [Google Scholar] [CrossRef]

- Calò, M.; Ruggieri, S.; Doglioni, A.; Morga, M.; Nettis, A.; Simeone, V.; Uva, G. Probabilistic-based assessment of subsidence phenomena on the existing built heritage by combining MTInSAR data and UAV photogrammetry. Struct. Infrastruct. Eng. 2024, 1–16. [Google Scholar] [CrossRef]

- Bambura, A.M. Analytical description of the mechanical state diagram of reinforcement for reinforced concrete structures. Collect. Sci. Pap. Build. Struct. 2003, 59, 131–136. [Google Scholar]

- Pavlikov, A.M.; Boyko, O.V.; Fedorov, D.F. Application of a nonlinear deformation model in the strength calculations of eccentrically compressed reinforced concrete elements under planar and oblique deformation. Resour. Econ. Mater. Build. Struct. Build. Struct. Collect. Sci. Pap. 2011, 22, 444–451. [Google Scholar]

- Kochkarev, D.; Azizov, T.; Galinska, T. Bending deflection reinforced concrete elements determination. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 230, p. 02012. [Google Scholar] [CrossRef]

- Babich, E.M.; Krus, Y.O. On the construction of the concrete deformation diagram and determination of the stress diagram completeness coefficient. Resour.-Econ. Mater. Struct. Build. Struct. 2001, 6, 94–104. [Google Scholar]

- Ballim, Y.; Reid, J.; Kemp, A. Deflection of RC beams under simultaneous load and steel corrosion. Mag. Concr. Res. 2001, 53, 171–181. [Google Scholar] [CrossRef]

- Klymenko, E.V.; Chernyeva, O.S.; Dovhan, O.D.; Mohamed Ismael, A. The influence of damaged T-beam factors on their destructive load. Interuniv. Collect. Sci. Notes 2013, 43, 94–97. [Google Scholar]

- Sika GCC. The S/A Bridges BR 101/5C Highway. 2019. Available online: https://gcc.sika.com/en/reference-projects/sa-bridges.html (accessed on 3 March 2025).

- Federal Highway Administration (FHWA). Techniques for Bridge Strengthening, U.S. Department of Transportation. 2018. Available online: https://www.fhwa.dot.gov/bridge/pubs/hif18041.pdf (accessed on 3 March 2025).

- Qureshi, J. A Review of Fibre Reinforced Polymer Bridges. Fibers 2023, 11, 40. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology (NIST). Use of Fiber-Reinforced Polymer (FRP) Composites in Infrastructure Applications. NIST Special Publication 1244; 2020. Available online: https://nvlpubs.nist.gov/nistpubs/SpecialPublications/NIST.SP.1244.pdf (accessed on 3 March 2025).

- Oregon Department of Transportation (ODOT). Strengthening Bridges Using Composite Materials. 2015. Available online: https://www.oregon.gov/odot/Programs/ResearchDocuments/StrenghtingBridgesUsingCompMat.pdf (accessed on 3 March 2025).

- Peng, H.; Chen, Z.; Liu, M.; Zhao, Y.; Fu, W.; Liu, J.; Tan, X. Study on the Effect of Additives on the Performance of Cement-Based Composite Anti-Corrosion Coatings for Steel Bars in Prefabricated Construction. Materials 2024, 17, 1996. [Google Scholar] [CrossRef]

- Nuguzhinov, Z.; Vatin, N.; Bakirov, Z.; Khabidolda, O.; Zholmagambetov, S.; Kurokhtina, I. Stress-strain state of bending reinforced beams with cracks. Mag. Civ. Eng. 2020, 5, 9701. [Google Scholar]

- Barashikov, A.Y.; Sumak, O.P.; Boyarchuk, B.A. Experimental Studies of Reinforced Concrete Bending Elements Strengthened by Various Methods; RDTU: Rivne, Ukraine, 2000; pp. 294–297. [Google Scholar]

- Kryvosheev, P.I. Scientific and technical problems of building and facility reconstruction. Building Structures. Building and Facility Reconstruction. Exp. Probl. 2001, 54, 3–10. [Google Scholar]

- Valovy, O.I.; Popruha, D.V. Strength of normal and inclined cross-sections of beams strengthened in the compression zone. Bull. Kryvyi Rih Tech. Univ. Collect. Sci. Pap. 2009, 24, 1–4. [Google Scholar]

- Roberts, T.M. Approximate analysis of shear and normal stress concentrations in the adhesive layer of plated RC beam. Struct. Eng. 1989, 67, 229–233. [Google Scholar]

- Irwin, C.F. The Strengthening of Concrete Beams by Bonded Steel Plates; Transport and Road Research Laboratory: Berkshire, UK, 1975; pp. 5–9. [Google Scholar]

- Bambura, A.M.; Gurkivskyi, O.; Dorohova, O.; Sazanova, I.; Miroshnyk, T.; Panchenko, O.; Sobko, Y. Recommendations for the Use of Sika Composite Materials for Strengthening Reinforced Concrete Structures; State Scientific Research Institute of Building Constructions: Kyiv, Ukraine, 2014; p. 45. [Google Scholar]

- Borysyuk, O.P.; Melnyk, S.V. Strengthening of reinforced concrete structures with modern materials. Resour. Econ. Mater. Struct. Build. Facil. Collect. Sci. Pap. 2010, 20, 459–465. [Google Scholar]

- Campbell, F.C. Structural Composite Materials; ASM International: Novelty, OH, USA, 2010; 500p. [Google Scholar]

- Amadio, C.; Macorini, L.; Sorgon, S.; Suraci, G. A novel hybrid system with RC-encased steel joints. Eur. J. Environ. Civ. Eng. 2011, 15, 1433–1463. [Google Scholar] [CrossRef]

- Ekenel, M.; Rizzo, A.; Myers, J.J.; Nanni, A. Flexural fatigue behavior of reinforced concrete beams strengthened with FRP fabric procured laminate systems. J. Compos. Constr. 2006, 1, 433–442. [Google Scholar] [CrossRef]

- Alzate, A. Shear strengthening of reinforced concrete members with CFRP sheets. Mater. Construcción 2013, 251–265. Available online: http://digital.casalini.it/an/2627840 (accessed on 9 March 2025). [CrossRef]

- Visbud. C-MESH 42/42. 2020. Available online: https://www.visbud.com/produkt/c-mesh-42-42/ (accessed on 3 March 2025).

- Yefimenko, V.I.; Savchenko, A.A.; Sukhan, O.P. Experimental studies of the load-bearing capacity of reinforced concrete beams restored with polymer concrete repair mixtures. Min. Bull. 2014, 98, 44–48. [Google Scholar]

- Valovoy, O.I.; Vozian, I.O.; Valovoy, M.O. Methodology of manufacturing and experimental study of reinforced concrete beams with subsequent strengthening using adhesive mixtures. Sci. Pap. Natl. Univ. Lviv Polytech. Constr. 2017, 871, 27–32. [Google Scholar]

- Bentura, A.; Ming, W. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

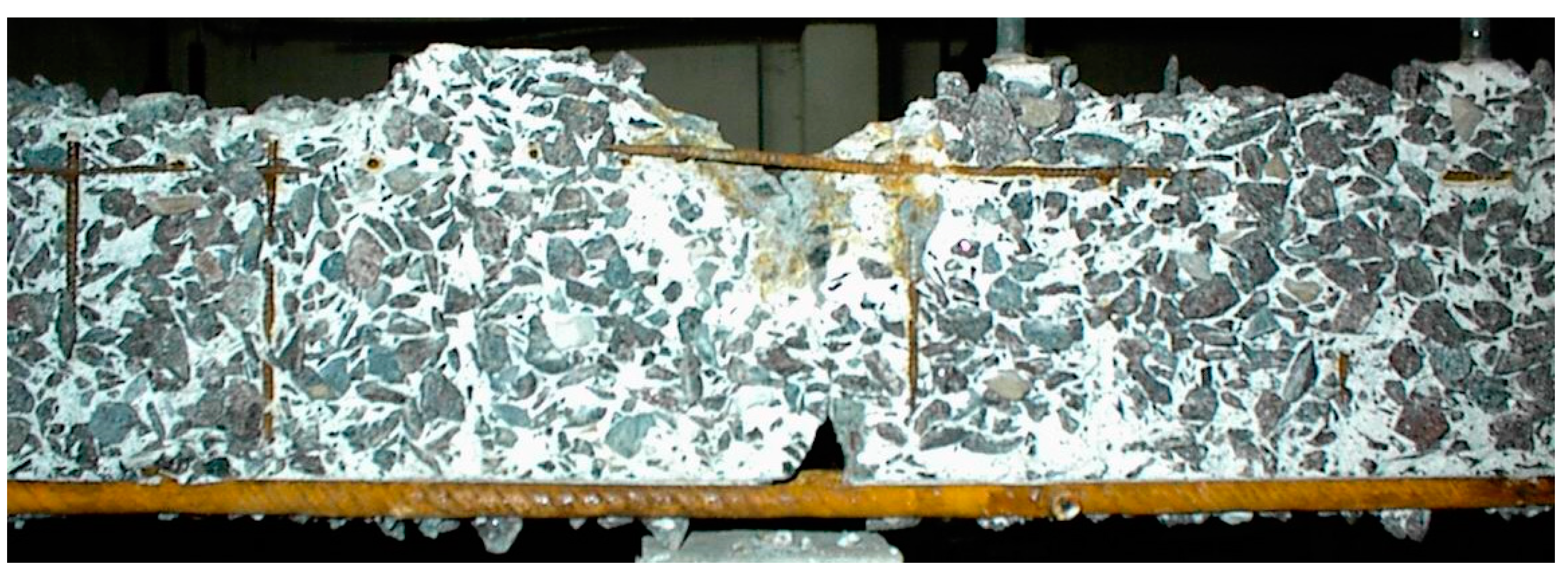

- Lobodanov, M.; Vegera, P.; Khmil, R.; Blikharskyy, Z. Influence of Damages in the Compressed Zone on Bearing Capacity of Reinforced Concrete Beams. In EcoComfort 2020; Lecture Notes in Civil Engineering; Blikharskyy, Z., Ed.; Springer: Cham, Switzerland, 2021; Volume 100. [Google Scholar] [CrossRef]

- Borysiuk, O.; Ziatiuk, Y. Experimental Research Results of the Bearing Capacity of the Reinforced Concrete Beams Strengthened in the Compressed and Tensile Zones. In EcoComfort 2020; Lecture Notes in Civil Engineering, Blikharskyy, Z., Eds.; Springer: Cham, Switzerland, 2021; Volume 100. [Google Scholar] [CrossRef]

- Li, Y.; Li, X. Repair methods for cracks in reinforced concrete structures: A review. Constr. Build. Mater. 2023, 309, 126798. [Google Scholar] [CrossRef]

- Panasyuk, V.V.; Marukha, V.I.; Sylovanyuk, V.P. Efficient injection materials and the technologies of restoration of the serviceability of damaged building structures intended for long-term operation. Mater. Sci. 2018, 54, 154–162. [Google Scholar] [CrossRef]

- Kim, J.-W.; Lee, J.-H.; Lee, S.-H.; Kim, M.-H.; Kim, K.-S. Influence of injection pressure on the effectiveness of epoxy resin injection repair of concrete beams with cracks. J. Struct. Eng. 2022, 148, 04022088. [Google Scholar]

- Issa, C.A.; Debs, P. Experimental study of epoxy repairing of cracks in concrete. Constr. Build. Mater. 2007, 21, 157–163. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y. A new repair method for cracks in reinforced concrete structures. J. Constr. Eng. Manag. 2023, 149, 04023028. [Google Scholar]

- Al-Sulaimani, A.A.A.; Al-Sulaimani, H.E.; Al-Sulaimani, A.H. Repair of reinforced concrete beams with injecting nanocomposites. J. Build. Eng. 2022, 38, 103560. [Google Scholar]

- Ma, M.L.; Wu, A.C.; Chen, J.C.; Chen, C.Y.; Wang, A.J. Repair of shear cracks in reinforced concrete beams using a novel fiber-reinforced polymer injection system. Constr. Build. Mater. 2019, 218, 1165–1174. [Google Scholar]

- Saliah, S.N.M.; Nor, N.M.; Abd Rahman, N.; Abdullah, S.; Tahir, M.S. Evaluation of severely damaged reinforced concrete beam repaired with epoxy injection using acoustic emission technique. Theor. Appl. Fract. Mech. 2021, 112, 102890. [Google Scholar] [CrossRef]

- Balogun, T.B.; Tomor, A.; Lamond, J.; Gouda, H.; Booth, C.A. Life-cycle assessment environmental sustainability in bridge design and maintenance. Proc. Inst. Civ. Eng. Eng. Sustain. 2020, 173, 365–375. [Google Scholar] [CrossRef]

- Du, G. Life Cycle Assessment of Bridges, Model Development and Case Studies. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2015. Available online: https://www.diva-portal.org/smash/get/diva2:793949/FULLTEXT03.pdf (accessed on 9 March 2025).

- Du, G.; Karoumi, R. Life cycle assessment framework for railway bridges: Literature survey and critical issues. Struct. Infrastruct. Eng. 2014, 10, 277–294. [Google Scholar] [CrossRef]

- Bouhaya, L.; Le Roy, R.; Feraille-Fresnet, A. Simplified environmental study on innovative bridge structure. Environ. Sci. Technol. 2009, 43, 2066–2071. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V. Multiobjective optimization of post-tensioned concrete box-girder road bridges considering cost, CO2 emissions, and safety. Eng. Struct. 2016, 125, 325–336. [Google Scholar] [CrossRef]

- Coelho, A.; de Brito, J. Environmental analysis of a construction and demolition waste recycling plant in Portugal–Part I: Energy consumption and CO2 emissions. Waste Manag. 2013, 33, 1258–1267. [Google Scholar] [CrossRef]

- Chong, W.K.; Hermreck, C. Understanding transportation energy and technical metabolism of construction waste recycling. Resour. Conserv. Recycl. 2010, 54, 579–590. [Google Scholar] [CrossRef]

- Klym, A.; Blikharskyy, Y.; Panchenko, O.; Sobko, Y. The Analysis of the Influence of Damaged Concrete Compression Zone on the RC Beam Using FEM. In International Conference Current Issues of Civil and Environmental Engineering Lviv-Košice–Rzeszów; Springer Nature: Cham, Switzerland, 2023; pp. 164–177. [Google Scholar] [CrossRef]

- Klym, A.; Blikharskyy, Y.; Panchenko, O.; Sobko, Y.; Blikharskyy, Z. Load-Bearing Capacity of the Repaired RC Beam Using Sika MonoTop 4012. In International Scientific Conference EcoComfort and Current Issues of Civil Engineering; Springer Nature: Cham, Switzerland, 2024; pp. 212–224. [Google Scholar] [CrossRef]

- Pang, B.; Yang, P.; Wang, Y.; Kendall, A.; Xie, H.; Zhang, Y. Life cycle environmental impact assessment of a bridge with different strengthening schemes. Int. J. Life Cycle Assess. 2015, 20, 1300–1311. [Google Scholar] [CrossRef]

- Klym, Y.; Blikharskyy, I. Injection of cracks in a RC beam with epoxy resin using the gravity flow method. J. Tech. Univ. Lviv Polytech. Build. Archit. 2023, 52, 23–34. [Google Scholar] [CrossRef]

- Hiete, M.; Stengel, J.; Ludwig, J.; Schultmann, F. Matching construction and demolition waste supply to recycling demand: A regional management chain model. Build. Res. Inf. 2011, 39, 333–351. [Google Scholar] [CrossRef]

- Martin, A.J. Concrete bridges in sustainable development. Proc. Inst. Civ. Eng.-Eng. Sustain. 2004, 157, 219–230. [Google Scholar] [CrossRef]

- Khouri Chalouhi, E.; Zelmanovitz Ciulla, G.; García-Brioles Bueno, J.; Pacoste, C.; Karoumi, R. Environmental and economical optimization of reinforced concrete overhang bridge slabs. Struct. Multidiscip. Optim. 2023, 66, 66. [Google Scholar] [CrossRef]

- Kopiika, N.; Klym, A.; Blikharskyy, Y.; Katunský, D.; Popovych, V.; Blikharskyy, Z. Evaluation of the stress-strain state of the RC beam with the use of DIC. Prod. Eng. Arch. 2024, 30, 463–476. [Google Scholar] [CrossRef]

- Blikharskyy, Y.; Kopiika, N.; Khmil, R.; Selejdak, J.; Blikharskyy, Z. Review of Development and Application of Digital Image Correlation Method for Study of Stress–Strain State of RC Structures. Appl. Sci. 2022, 12, 10157. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klym, A.; Blikharskyy, Y.; Gunka, V.; Poliak, O.; Selejdak, J.; Blikharskyy, Z. An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges. Sustainability 2025, 17, 2506. https://doi.org/10.3390/su17062506

Klym A, Blikharskyy Y, Gunka V, Poliak O, Selejdak J, Blikharskyy Z. An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges. Sustainability. 2025; 17(6):2506. https://doi.org/10.3390/su17062506

Chicago/Turabian StyleKlym, Andrii, Yaroslav Blikharskyy, Volodymyr Gunka, Olha Poliak, Jacek Selejdak, and Zinoviy Blikharskyy. 2025. "An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges" Sustainability 17, no. 6: 2506. https://doi.org/10.3390/su17062506

APA StyleKlym, A., Blikharskyy, Y., Gunka, V., Poliak, O., Selejdak, J., & Blikharskyy, Z. (2025). An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges. Sustainability, 17(6), 2506. https://doi.org/10.3390/su17062506