Integrating Industry 4.0 and Sustainability Toward Attaining Smart Manufacturing Systems

Abstract

1. Introduction

- (1)

- What is the impact of Industry 4.0 technologies on the advancement of sustainability 4.0?

- (2)

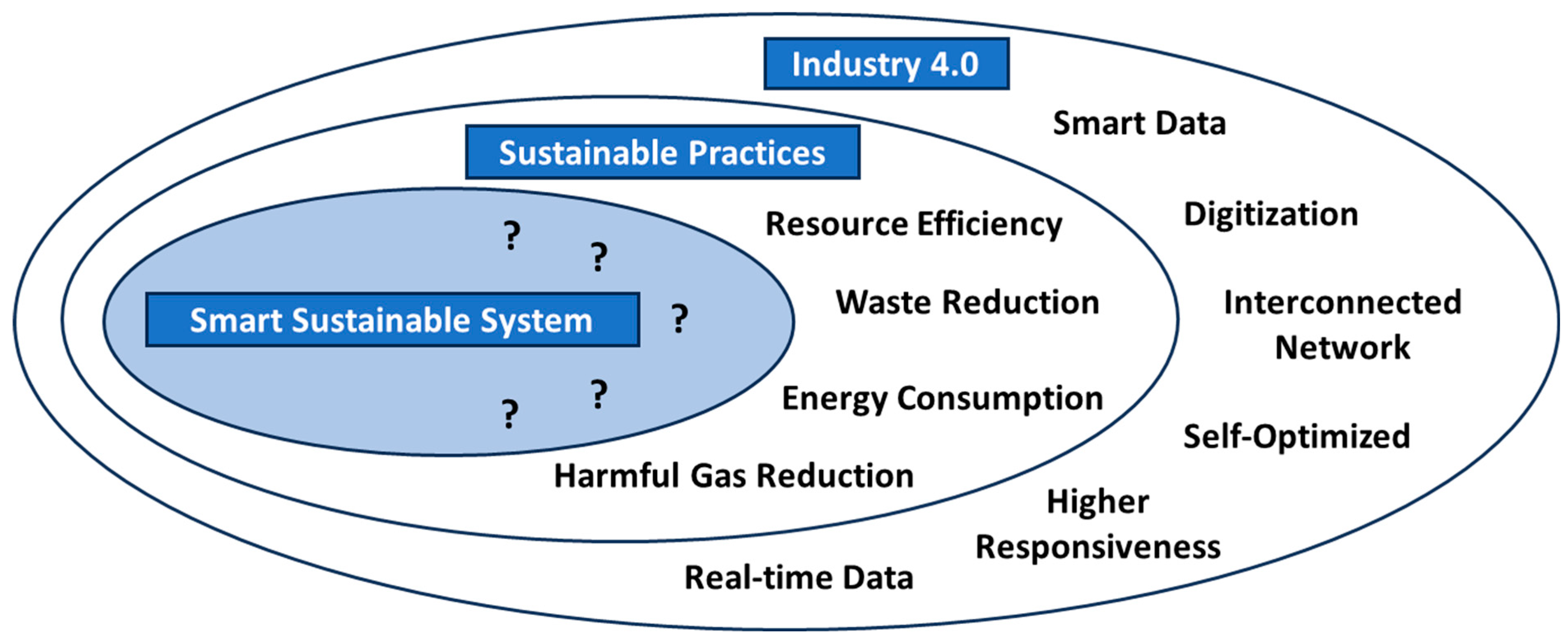

- How does the integration of smart technologies lead to the development of smart sustainable systems?

- (3)

- How can smart and sustainable practices contribute to economic sustainability 4.0, social sustainability 4.0, and environmental sustainability 4.0?

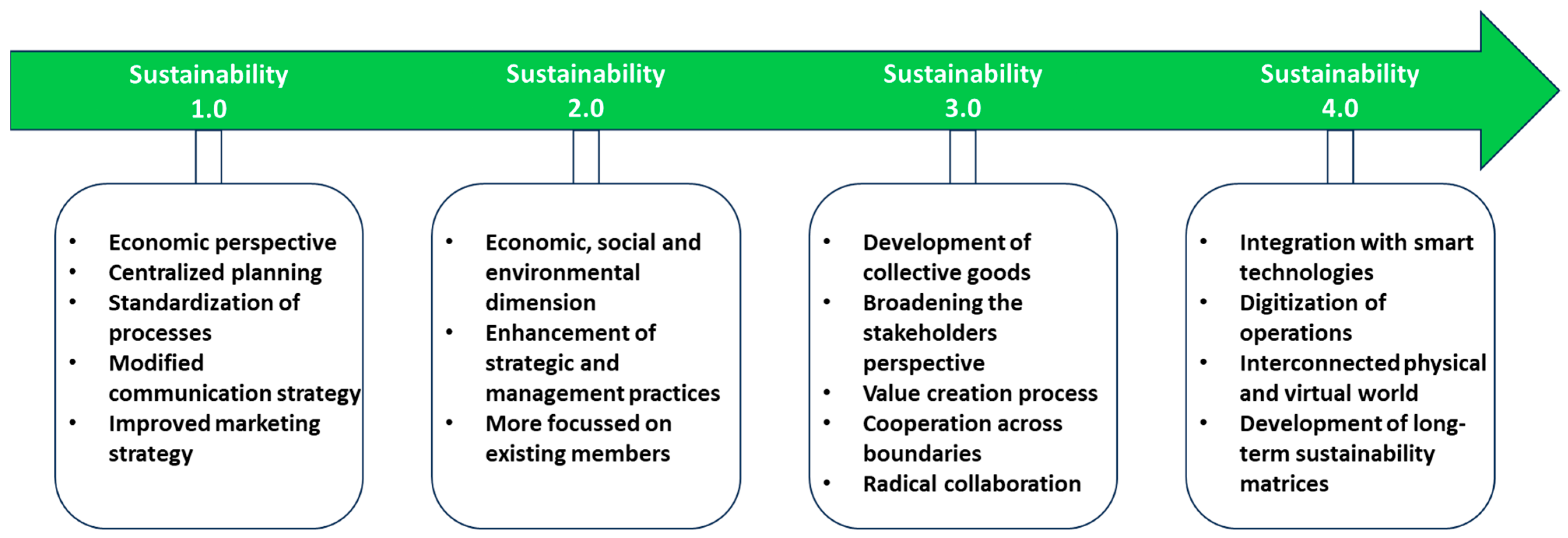

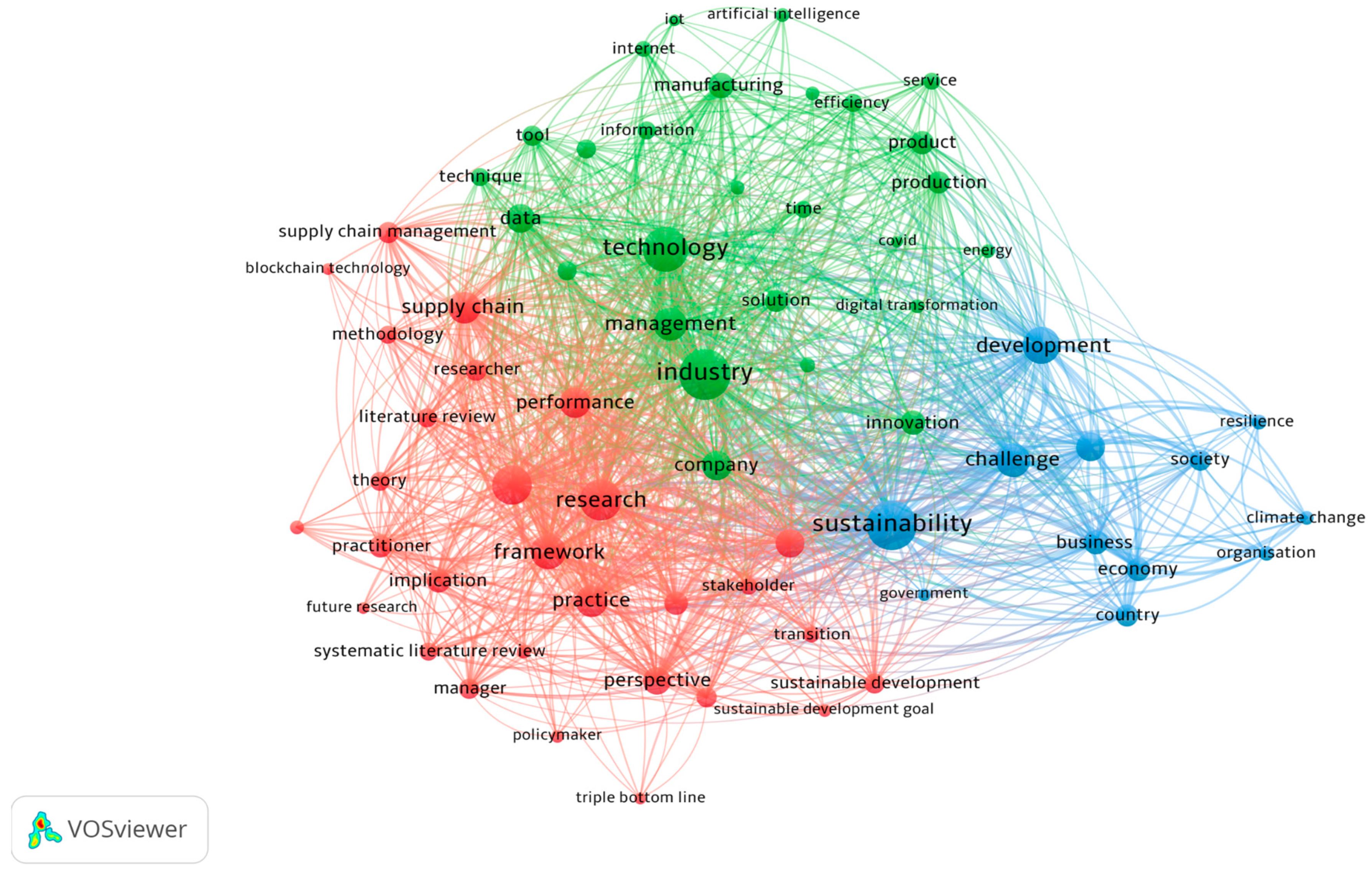

2. Literature Review

2.1. Industry 4.0 Advancements

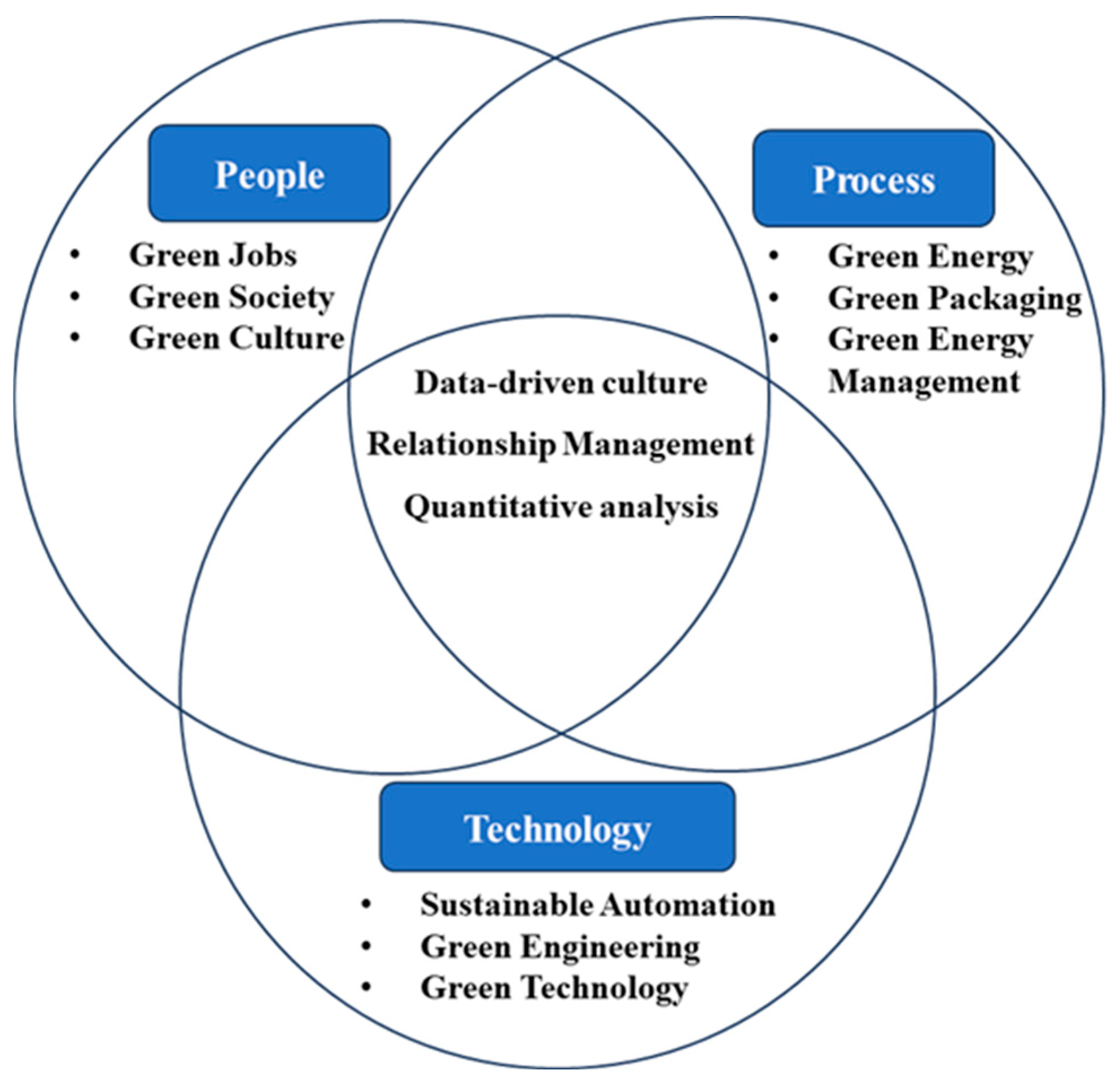

2.2. Correlation Between Smart Sustainability Practices and TBL Dimensions

2.3. The Changing Smart Manufacturing Paradigms

3. Multiple Case Study Analysis

- (1)

- All three cases are from the manufacturing industry.

- (2)

- They adopted Industry 4.0 technologies to enhance their business.

- (3)

- These cases are from the small and medium-sized enterprises category.

3.1. Case A

3.2. Case B

3.3. Case C

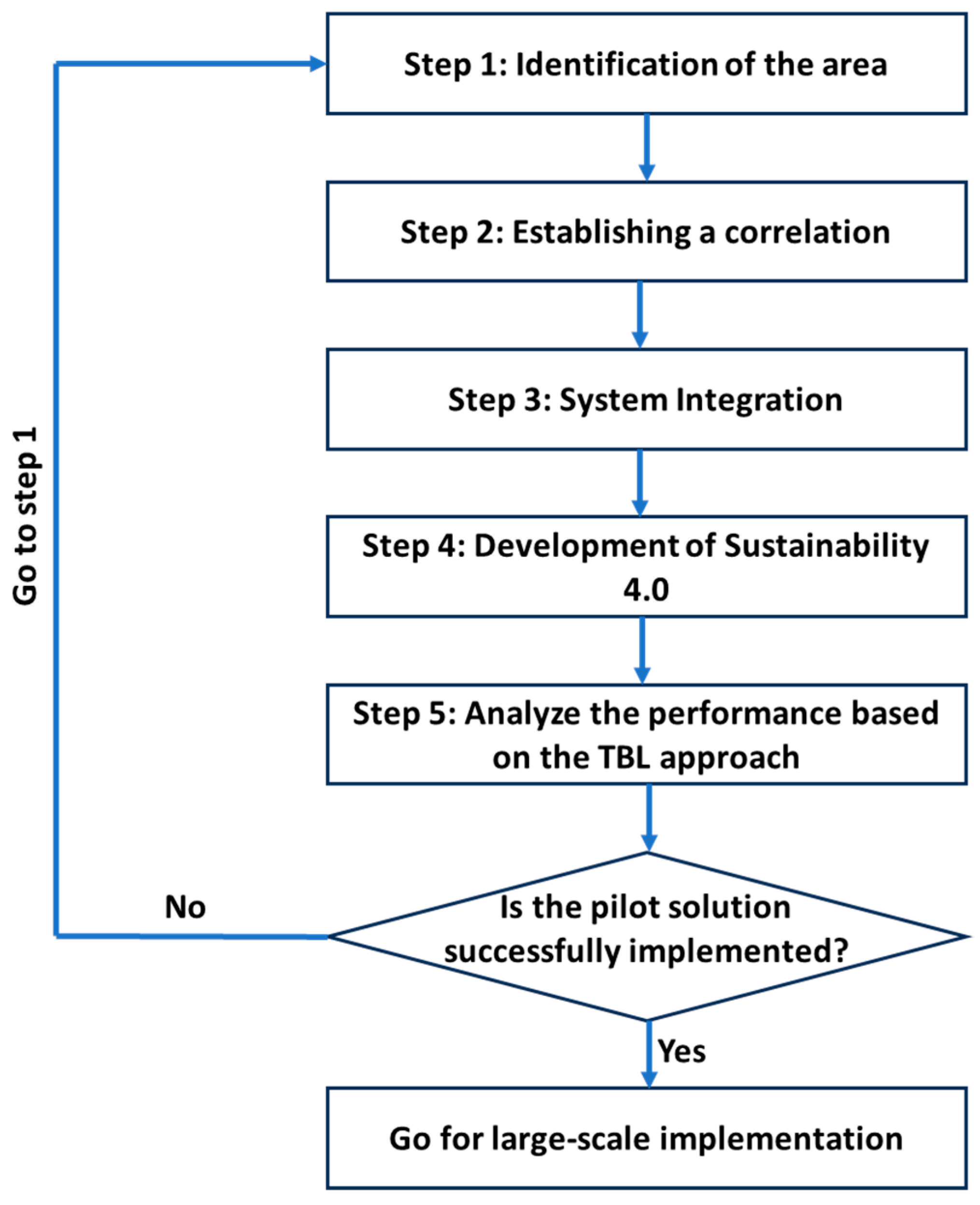

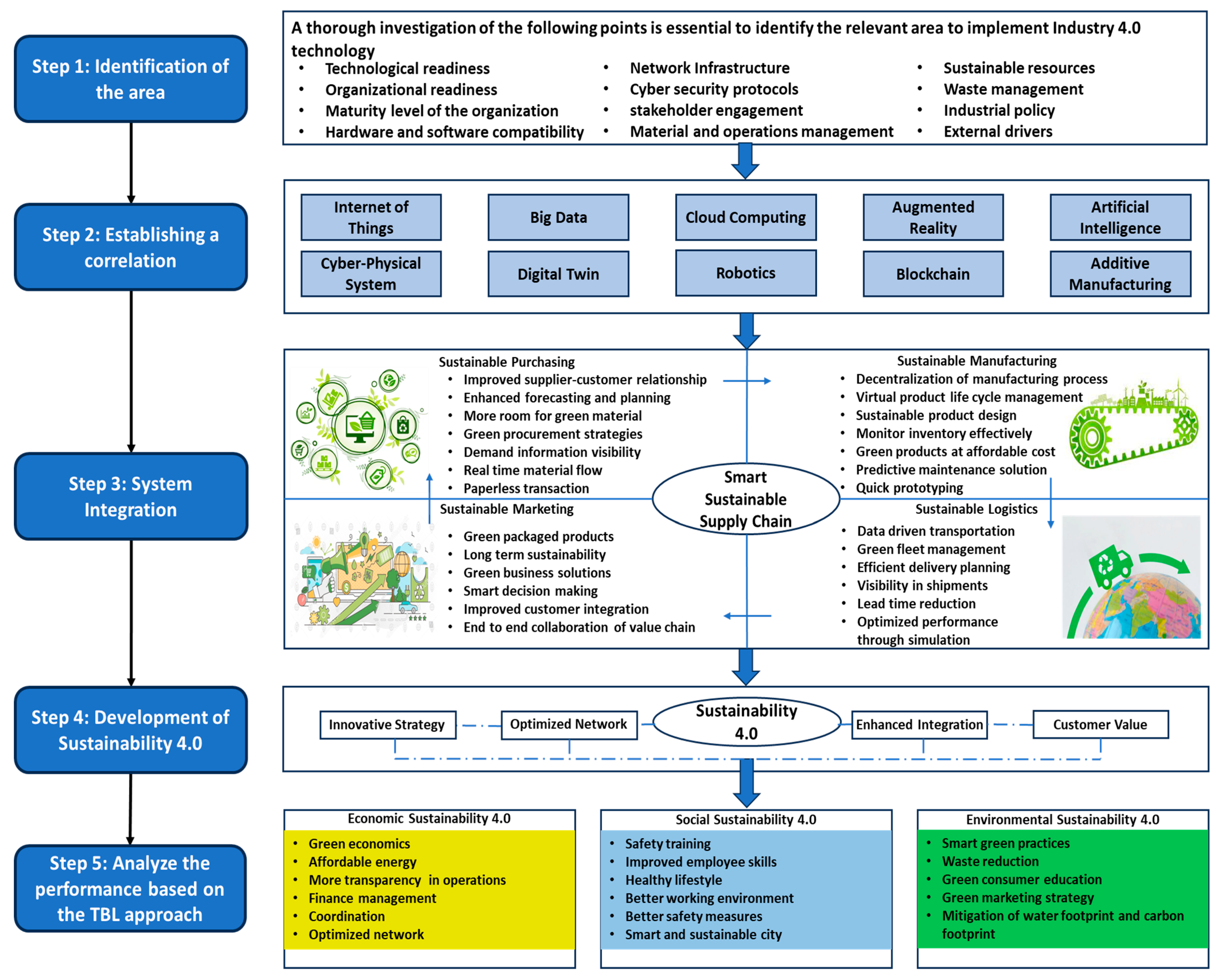

4. Discussion on the Implementation Framework of Smart Sustainable Systems

4.1. Step 1: Identification of the Area for Implementing Industry 4.0 Technologies

4.2. Step 2: Establishing a Correlation Between Industry 4.0 Technology and Organizational Practices

- Internet of Things: This technology will link virtual and physical objects to share and monitor data within the system [49]. It is used to make the system precise, responsive, and smooth in its communication flow.

- Cyber–Physical System: This technology interacts with people via human–machine Interfaces (HMI). It improves various areas of business, including quality control, logistics management, and engineering practices [10].

- Big Data: This technology is useful in various areas of supply chain management, like inventory management, warehouse management, logistics, manufacturing, and customer relationship management. It facilitates informed decision-making by timely acquisition and analysis of data [50].

- Cloud Computing: This technology is usually used for storing and distributing data as per the requirements. It operates on various algorithms, including cognitive agents and swarm intelligence, to effectively integrate and evaluate data [51].

- Artificial Intelligence: This technology reduces the need for a human operator at the workplace by conducting data analysis autonomously. It monitors extensive data in production and manufacturing operations, offering an improved solution for a complex problem [52].

- Digital Twin: It is a virtual presentation of a physical model to perform its operations virtually. A new model is created virtually and tested for different working conditions. Results obtained from experiments are used to examine the performance of the product [53].

- Additive Manufacturing: It is referred to as 3D Printing or Rapid Prototyping. A three-dimensional object is created by layer-by-layer deposition of material, which can be in either liquid or particle form. The final product is achieved by applying a thin coating of raw material [54].

- Robotics: Robots are built using various electronic devices and software. They can handle multiple operations simultaneously [55]. The advantages of using robots at the industry level are employee cost-cutting, quality enhancement, and operational time reduction.

- Blockchain: This technology enables the establishment of a secure and collaborative platform that supports the seamless data exchange among stakeholders [49]. It allows for transparent communication and sharing of information gathered from suppliers, manufacturers, retailers, and customers.

4.3. Step 3: System Integration

4.3.1. Sustainable Purchasing

4.3.2. Sustainable Manufacturing

4.3.3. Sustainable Logistics

4.3.4. Sustainable Marketing

4.4. Step 4: Development of Sustainability 4.0

4.5. Step 5: Analyze the Performance Based on the TBL Approach

4.5.1. Economic Sustainability 4.0

4.5.2. Social Sustainability 4.0

4.5.3. Environmental Sustainability 4.0

5. Challenges to Smart Sustainable Systems

- Security Issues: To share information over the Internet, all data must be secure and encrypted from end to end. Therefore, every part of the network should be secure from external attacks and unauthorized data usage [70].

- Incompatibility of devices: The second challenge in establishing a smart sustainable system is combining new technologies with existing equipment. Certain communication methods for controlling older machines may be outdated, and newer devices may use a different protocol. The incompatibility between old and new devices makes it difficult to use smart technologies [71].

- Interoperability: It refers to different systems’ capacity to comprehend and utilize each other’s functionalities independently. Differences in communication bandwidth, operational frequency, communication mode, hardware capabilities, etc., limit the system’s ability to work with other systems [72].

- Limited resources: One problem with switching to smart sustainable systems is insufficient resources. Specifically, it is related to economic limitations, as currently available solutions require high investments and long amortization periods [73].

- Return on Investment: A meticulous analysis of financial implications and return on investment is essential when transitioning from an existing manufacturing system to a more advanced technology. The time it takes to get a return on the investment with the current system would be compared to the amount of money that should be spent to get newer technology [73].

- Diverse requirements: It can be difficult for some businesses to identify the needs of all market participants, including clients, partners, and suppliers. Since every company is trying its best to fulfill customers’ demands, many products in the market provide the same service. The lifecycle of a product is getting shorter. Customer requirements are changing day by day. However, a company must quickly adopt and recognize the requirements to remain competitive in business today [74].

- Cultural restraints: Supervisory-level staff are unwilling to adopt the changes in the smart factory over the traditional ones. In small and medium-sized industries, employees are reluctant to actively participate in acquiring new skills and underestimate the potential benefits of digitization [75].

6. Conclusions

6.1. Academic Implications

6.2. Managerial Implications

6.3. Future Research Areas in the Field of Sustainability 4.0

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Mayer, C.H.; Oosthuizen, R.M. Sustainability in Industry 4.0 Business Practice: Insights from a Multinational Technology Company. Front. Sustain. 2022, 3, 886986. [Google Scholar] [CrossRef]

- Panigrahi, S.S.; Bahinipati, B.; Jain, V. Sustainable supply chain management: A review of literature and implications for future research. Manag. Environ. Qual. Int. J. 2018, 30, 1001–1049. [Google Scholar] [CrossRef]

- Almashhadani, M.; Almashhadani, H.A. The Impact of Sustainability Reports to Enhance Company Performance and its Sustainability. Int. J. Sci. Manag. Res. 2023, 6, 149–163. [Google Scholar] [CrossRef]

- Siekmann, F.; Schlör, H.; Venghaus, S. Linking sustainability and the Fourth Industrial Revolution: A monitoring framework accounting for technological development. Energy Sustain. Soc. 2023, 13, 26. [Google Scholar] [CrossRef]

- Da-Rocha, A.B.T.; de Oliveira, K.B.; Espuny, M.; da Motta Reis, J.S.; Oliveira, O.J. Business transformation through sustainability based on Industry 4.0. Heliyon 2022, 8, 10015. [Google Scholar] [CrossRef]

- Keller, A. Sustainability 3.0 in Libraries: A Challenge for Management. Publications 2023, 11, 6. [Google Scholar] [CrossRef]

- Henao-Hernández, I.; Solano-Charris, E.L.; Muñoz-Villamizar, A.; Santos, J.; Henríquez-Machado, R. Control and monitoring for sustainable manufacturing in the Industry 4.0: A literature review. IFAC-PapersOnLine 2019, 52, 195–200. [Google Scholar] [CrossRef]

- Vreja, L.O.; BĂLAN, S. The fourth industrial revolution and Sustainability. In Proceedings of the International Management Conference 2020, Bucharest, Romania, 5–6 November 2020; Volume 14, pp. 1103–1113. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and smart manufacturing: An integrated approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D. Metaverse supply chain and operations management. Int. J. Prod. Res. 2023, 61, 8179–8191. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart manufacturing: Characteristics, technologies and enabling factors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 1342–1361. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.C.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2021, 28, 1410–1450. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Tran, N.H.; Park, H.S.; Nguyen, Q.V.; Hoang, T.D. Development of a smart cyber-physical manufacturing system in the industry 4.0 context. Appl. Sci. 2019, 9, 3325. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lim, M.K.; Wu, K.J. Improving the benefits and costs on sustainable supply chain finance under uncertainty. Int. J. Prod. Econ. 2019, 218, 308–321. [Google Scholar] [CrossRef]

- Schroeder, A.; Ziaee Bigdeli, A.; Galera Zarco, C.; Baines, T. Capturing the benefits of industry 4.0: A business network perspective. Prod. Plan. Control. 2019, 30, 1305–1321. [Google Scholar] [CrossRef]

- Telukdarie, A.; Buhulaiga, E.; Bag, S.; Gupta, S.; Luo, Z. Industry 4.0 implementation for multinationals. Process Saf. Environ. Prot. 2018, 118, 316–329. [Google Scholar] [CrossRef]

- Raji, I.O.; Shevtshenko, E.; Rossi, T.; Strozzi, F. Modelling the relationship of digital technologies with lean and agile strategies. Supply Chain. Forum Int. J. 2021, 22, 323–346. [Google Scholar] [CrossRef]

- Valilai, O.F.; Sodachi, M. Inspiration of Industry 4.0 to enable a proactive sustainability assessment model through the supply chain. Procedia Manuf. 2020, 52, 356–362. [Google Scholar] [CrossRef]

- Popolo, V.; Vespoli, S.; Gallo, M.; Grassi, A. A systemic analysis of the impacts of Product 4.0 on the triple bottom-line of Sustainability. IFAC-PapersOnLine 2022, 55, 1110–1115. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Mohamed, M. Challenges and benefits of industry 4.0: An overview. Int. J. Supply Oper. Manag. 2018, 5, 256–265. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.I. Development of a risk framework for Industry 4.0 in the context of sustainability for established manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Margherita, E.G.; Braccini, A.M. Organizational impacts on sustainability of industry 4.0: A systematic literature review from empirical case studies. In Digital Business Transformation Organizing, Managing and Controlling in the Information Age; Springer: Cham, Switzerland, 2020; pp. 173–186. [Google Scholar] [CrossRef]

- Sanchez, M.; Exposito, E.; Aguilar, J. Industry 4.0: Survey from a system integration perspective. Int. J. Comput. Integr. Manuf. 2020, 33, 1017–1041. [Google Scholar] [CrossRef]

- Yang, H.; Kumara, S.; Bukkapatnam, S.T.; Tsung, F. The Internet of Things for Smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Singh, M.; Goyat, R.; Panwar, R. Fundamental pillars for industry 4.0 development: Implementation framework and challenges in manufacturing environment. TQM J. 2024, 36, 288–309. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Rahman, T.; Rahman, M.H.; Ali, S.M.; Paul, S.K. Drivers to sustainable manufacturing practices and circular economy: A perspective of leather industries in Bangladesh. J. Clean. Prod. 2018, 174, 1366–1380. [Google Scholar] [CrossRef]

- Liu, B.; Giovanni, P. Green process innovation through Industry 4.0 technologies and supply chain coordination. Ann. Oper. Res. 2019, 349, 767–802. [Google Scholar] [CrossRef]

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Jayashree, S.; Hassan Reza, M.N.; Malarvizhi, C.A.N.; Maheswari, H.; Hosseini, Z.; Kasim, A. The impact of technological innovation on industry 4.0 implementation and sustainability: An empirical study on Malaysian small and medium sized enterprises. Sustainability 2021, 13, 10115. [Google Scholar] [CrossRef]

- ElMaraghy, H.; ElMaraghy, W. Adaptive cognitive manufacturing system (ACMS)—A new paradigm. Int. J. Prod. Res. 2022, 60, 7436–7449. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Kusiak, A. Predictive models in digital manufacturing: Research, applications, and future outlook. Int. J. Prod. Res. 2023, 61, 6052–6062. [Google Scholar] [CrossRef]

- Ricci, R.; Battaglia, D.; Neirotti, P. External knowledge search, opportunity recognition and industry 4.0 adoption in SMEs. Int. J. Prod. Econ. 2021, 240, 108234. [Google Scholar] [CrossRef]

- Aichouni, A.B.E.; Silva, C.; Ferreira, L.M.D. A systematic literature review of the integration of total quality management and industry 4.0: Enhancing sustainability performance through dynamic capabilities. Sustainability 2024, 16, 9108. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.K.; Yeh, R.H.; Chen, Y.P. Lean manufacturing in industry 4.0: A smart and sustainable manufacturing system. Machines 2023, 11, 72. [Google Scholar] [CrossRef]

- Filgueiras, I.F.L.V.; Melo, F.J.C.D. Sustainability 4.0 in services: A systematic review of the literature. Benchmarking Int. J. 2024, 31, 1771–1796. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring organizational sustainability of industry 4.0 under the triple bottom line: The case of a manufacturing company. Sustainability 2018, 11, 36. [Google Scholar] [CrossRef]

- Strandhagen, J.W.; Buer, S.V.; Semini, M.; Alfnes, E.; Strandhagen, J.O. Sustainability challenges and how Industry 4.0 technologies can address them: A case study of a shipbuilding supply chain. Prod. Plan. Control. 2022, 33, 995–1010. [Google Scholar] [CrossRef]

- Jena, M.C.; Mishra, S.K.; Moharana, H.S. Application of Industry 4.0 to enhance sustainable manufacturing. Environ. Prog. Sustain. Energy 2020, 39, 13360. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M. Deep learning for manufacturing sustainability: Models, applications in Industry 4.0 and implications. Int. J. Inf. Manag. Data Insights 2022, 2, 100107. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Bista, R. Challenges, opportunities and future directions of smart manufacturing: A state of art review. Sustain. Futures 2020, 2, 100023. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Akarte, M. Smart manufacturing: A framework for managing performance. Int. J. Comput. Integr. Manuf. 2021, 34, 227–256. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M.; Guthrie, C.; Braganza, A. Industry experiences of artificial intelligence (AI): Benefits and challenges in operations and supply chain management. Prod. Plan. Control. 2022, 33, 1493–1497. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Jaspert, D.; Ebel, M.; Eckhardt, A.; Poeppelbuss, J. Smart retrofitting in manufacturing: A systematic review. J. Clean. Prod. 2021, 312, 127555. [Google Scholar] [CrossRef]

- Ferreira, J.J.; Lopes, J.M.; Gomes, S.; Rammal, H.G. Industry 4.0 implementation: Environmental and social sustainability in manufacturing multinational enterprises. J. Clean. Prod. 2023, 404, 136841. [Google Scholar] [CrossRef]

- Hamza, A.J.; Esteves, L.S.; Cvitanović, M.; Kairo, J.G. Sustainable natural resource management must recognise community diversity. Int. J. Sustain. Dev. World Ecol. 2023, 30, 727–744. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Gunasekaran, A.; Sethuraman, K. Reflecting on an empirical study of the digitalization initiatives for sustainability on logistics: The concept of Sustainable Logistics 4.0. Clean. Logist. Supply Chain. 2022, 4, 100058. [Google Scholar] [CrossRef]

- Jamkhaneh, H.B.; Shahin, R.; Tortorella, G.L. Analysis of Logistics 4.0 service quality and its sustainability enabler scenarios in emerging economy. Clean. Logist. Supply Chain. 2022, 4, 100053. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Beltrami, M.; Orze, G.; Sarkis, J.; Sartor, M. Industry 4.0 and sustainability: Towards conceptualization and theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- Rauch, E.; Brown, C.A. Teaching axiomatic design for a long-term sustainable introduction of industry 4.0 in SMEs. Procedia CIRP 2021, 91, 69–174. [Google Scholar] [CrossRef]

- Yeshey, R.J.; Ford, R.M.; Nitschke, C.R. Sustainable development implications of human wildlife conflict: An analysis of subsistence farmers in Bhutan. Int. J. Sustain. Dev. World Ecol. 2023, 30, 548–563. [Google Scholar] [CrossRef]

- Celik, A.; Usman, O.; Alola, A.A. Material productivity and material intensity as drivers of environmental sustainability in G-7 economies. Int. J. Sustain. Dev. World Ecol. 2024, 31, 43–56. [Google Scholar] [CrossRef]

- Ocelík, V.; Kolk, A.; Ciulli, F. Multinational enterprises, industry 4.0 and sustainability: A multidisciplinary review and research agenda. J. Clean. Prod. 2023, 413, 137434. [Google Scholar] [CrossRef]

- Serrano-Ruiz, J.C.; Mula, J.; Poler, R. Development of a multidimensional conceptual model for job shop smart manufacturing scheduling from the Industry 4.0 perspective. J. Manuf. Syst. 2022, 63, 185–202. [Google Scholar] [CrossRef]

- Maggi, F.; Balduzzi, M.; Vosseler, R.; Rösler, M.; Quadrini, W.; Tavola, G.; Pogliani, M.; Quarta, D.; Zanero, S. Smart factory security: A case study on a modular smart manufacturing system. Procedia Comput. Sci. 2021, 180, 666–675. [Google Scholar] [CrossRef]

- Makris, D.; Hansen, Z.N.L.; Khan, O. Adapting to supply chain 4.0: An explorative study of multinational companies. Supply Chain. Forum Int. J. 2019, 20, 116–131. [Google Scholar] [CrossRef]

- Asif, M. Are QM models aligned with Industry 4.0? A perspective on current practices. J. Clean. Prod. 2020, 258, 120820. [Google Scholar] [CrossRef]

- Valero, M.R.; Newman, S.T.; Nassehi, A. Link4Smart: A new framework for smart manufacturing linking Industry 4.0 relevant technologies. Procedia CIRP 2022, 107, 1594–1599. [Google Scholar] [CrossRef]

- Sharma, R.; Villányi, B. Evaluation of corporate requirements for smart manufacturing systems using predictive analytics. Internet Things 2022, 19, 100554. [Google Scholar] [CrossRef]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J.G. Industry 4.0 smart reconfigurable manufacturing machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- Satyro, W.C.; De Almeida, C.M.V.B.; Pinto Jr, M.J.A.; Contador, J.C.; Giannetti, B.F.; de Lima, A.F.; Fragomeni, M.A. Industry 4.0 implementation: The relevance of sustainability and the potential social impact in a developing country. J. Clean. Prod. 2022, 337, 130456. [Google Scholar] [CrossRef]

- Alkhodair, M.; Alkhudhayr, H. Harnessing industry 4.0 for SMEs: Advancing smart manufacturing and logistics for sustainable supply chains. Sustainability 2025, 17, 13. [Google Scholar] [CrossRef]

- Jaskó, S.; Ruppert, T. The Future of Manufacturing and Industry 4.0. Appl. Sci. 2025, 15, 4655. [Google Scholar] [CrossRef]

- Bermeo-Ayerbe, M.A.; Ocampo-Martínez, C.; Diaz-Rozo, J. Adaptive predictive control for peripheral equipment management to enhance energy efficiency in smart manufacturing systems. J. Clean. Prod. 2021, 291, 125556. [Google Scholar] [CrossRef]

| Country of Origin | Strategy Name | Originating Year | Aim | Focus Areas | References |

|---|---|---|---|---|---|

| Germany | German sustainable development | 2002 | To build a sustainable society by aligning national policy with the UN’s sustainable goals. | Human well-being and social justice, climate action, energy transition, circular economy, sustainable agriculture, and pollutant-free environment. | [10,12,13] |

| India | Sustainable India 2047 | 2003 | To promote sustainable living and responsible use of natural resources throughout all socio-economic sectors to increase the nation’s production. | Renewable energy, net zero emission, clean fuel, green and cleaner processes, sustainable agriculture, and technology. | [12,13,14] |

| Austria | OSTRAT | 2010 | To attain sustainable improvement in all areas of society. | Climate change, resource management, social welfare, sustainable economic growth, knowledge and innovation, and international cooperation. | [4,7,15] |

| UK | A Green Future | 2013 | To build a sustainable industrial ecosystem in the UK. | Waste management, water conservation, leadership in low-carbon technology, and energy regulation. | [2,3,5] |

| Japan | Super Smart Society | 2016 | To deal with social problems by using digital technology. | Healthcare, transportation, infrastructure, and Industry 4.0 technology. | [3,12,16] |

| Switzerland | Sustainable Development Strategy 2030 | 2016 | To establish a sustainable world in alignment with nature, fostering peace, prosperity, and collaboration. | Sustainable consumption and production, climate change, biodiversity, equal opportunities, and social cohesion. | [10,12] |

| Finland | Society’s commitment to sustainable development | 2016 | To achieve a prosperous, socially equitable, and environmentally conscious society by 2050. | Skillful society, social equality, sustainable economy, carbon neutrality, renewable energy, and biodiversity. | [10,11,14] |

| Sweden | Produktion 2030 | 2017 | To achieve long-term sustainability in an industrial environment. | Sustainable production and delivery, flexible, integrated, and human-centered production development. | [2,10,14] |

| European Union | Factories of the Future | 2018 | To enable a more sustainable and competitive European industry. | Remanufacturing Systems, manufacturer-centric circular economy, zero defect manufacturing, and human-centric solutions. | [2,13,15] |

| Denmark | A changing world: Partnerships in development | 2025 | To tackle sustainability issues through the enhancement of global partnerships. | Clean energy, environmental cooperation, poverty reduction, renewable energy, and water management. | [14,15,17] |

| Index | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|---|---|

| EBITDA | €8,035,000 | €7,500,000 | €6,100,000 | €8,150,000 | €11,300,000 | €15,000,000 | €13,000,000 |

| Sales | €36,860,000 | €35,495,000 | €36,335,000 | €39,293,00 | €43,280,000 | €48,585,000 | €47,480,000 |

| Net Profit | €2,330,000 | €2,032,000 | €1,248,000 | €1,590,000 | €4,115,000 | €6,293,000 | €5,376,000 |

| Workers | 284 | 284 | 267 | 237 | 237 | 224 | 233 |

| Cases | Sustainability Dimensions | Outcomes of Industry 4.0 Technologies |

|---|---|---|

| A | Economic | EBITDA index enhanced by 30% |

| A | Economic | Increment in sales and net profit |

| A | Economic | No change in employee population |

| A | Economic | Production output enhanced by 30% |

| A | Economic | Defect rate reduction from 30% to 9% |

| B | Social | Efficient information sharing |

| B | Social | Better coordination among various departments |

| B | Social | Close collaboration with suppliers |

| B | Social | Better working environment for employees |

| B | Social | Reduction in hazardous activities |

| C | Environmental | 12.79% reduction in process waste |

| C | Environmental | 9.33% decrease in energy consumption |

| C | Environmental | 9.33% reduction in carbon footprint |

| C | Environmental | 3.12% decrease in water consumption |

| All | Social | minimal human participation |

| All | Economic | More efficient production process |

| All | Environmental | Reduction in energy consumption |

| All | Social | More work autonomy for workers |

| All | Social | Safe working environment |

| All | Economic, Social, Environmental | Better coordination among supply chain partners |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kandarkar, P.C.; V, R.; Subramoniam, S.; D, B. Integrating Industry 4.0 and Sustainability Toward Attaining Smart Manufacturing Systems. Sustainability 2025, 17, 10674. https://doi.org/10.3390/su172310674

Kandarkar PC, V R, Subramoniam S, D B. Integrating Industry 4.0 and Sustainability Toward Attaining Smart Manufacturing Systems. Sustainability. 2025; 17(23):10674. https://doi.org/10.3390/su172310674

Chicago/Turabian StyleKandarkar, Prajakta Chandrakant, Ravi V, Suresh Subramoniam, and Bijulal D. 2025. "Integrating Industry 4.0 and Sustainability Toward Attaining Smart Manufacturing Systems" Sustainability 17, no. 23: 10674. https://doi.org/10.3390/su172310674

APA StyleKandarkar, P. C., V, R., Subramoniam, S., & D, B. (2025). Integrating Industry 4.0 and Sustainability Toward Attaining Smart Manufacturing Systems. Sustainability, 17(23), 10674. https://doi.org/10.3390/su172310674