Digital–Circular Synergies in Sustainable Supply Chain Management: An Integrative Framework for SME Performance Enhancement

Abstract

1. Introduction

Research Significance and Contribution

2. Literature Review

2.1. The Role of Digital Technologies and Industry 4.0

2.2. Circular Economy and Supply Chains

2.3. Policies, Metrics, and Performance

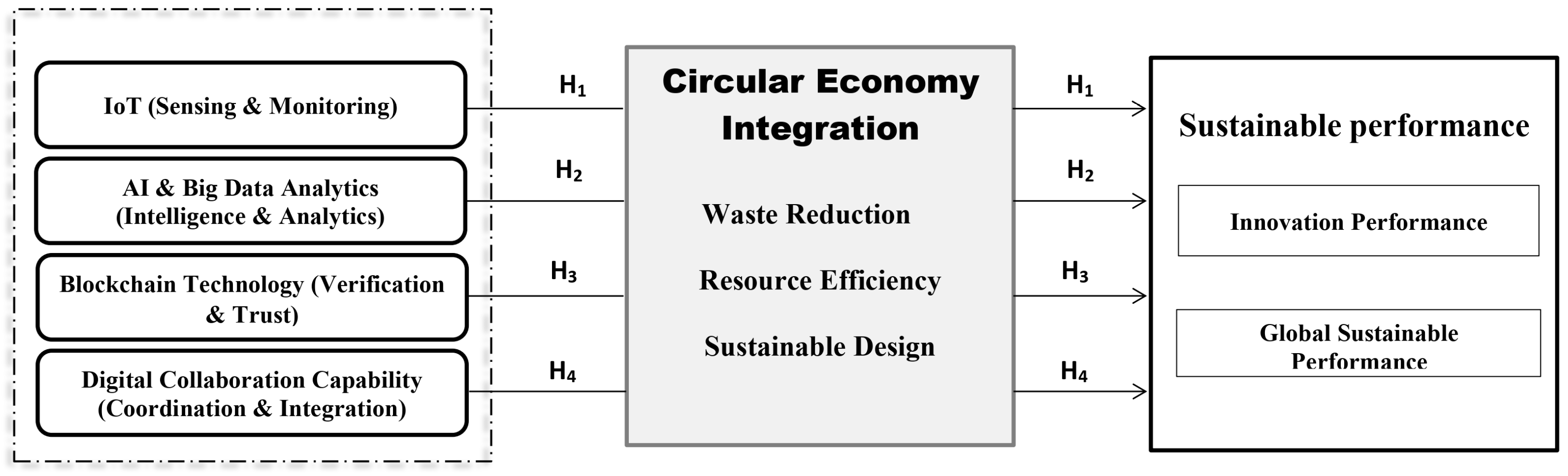

3. Conceptual Framework and Hypotheses

3.1. Internet of Things, CE Integration, and Performance

3.2. AI and Big Data Analytics, CE Integration, and Performance

3.3. Blockchain Technology, CE Integration, and Performance

3.4. Digital Collaboration Capability, CE Integration, and Performance

3.5. Synthesis of the Research Model

4. Research Design and Methods

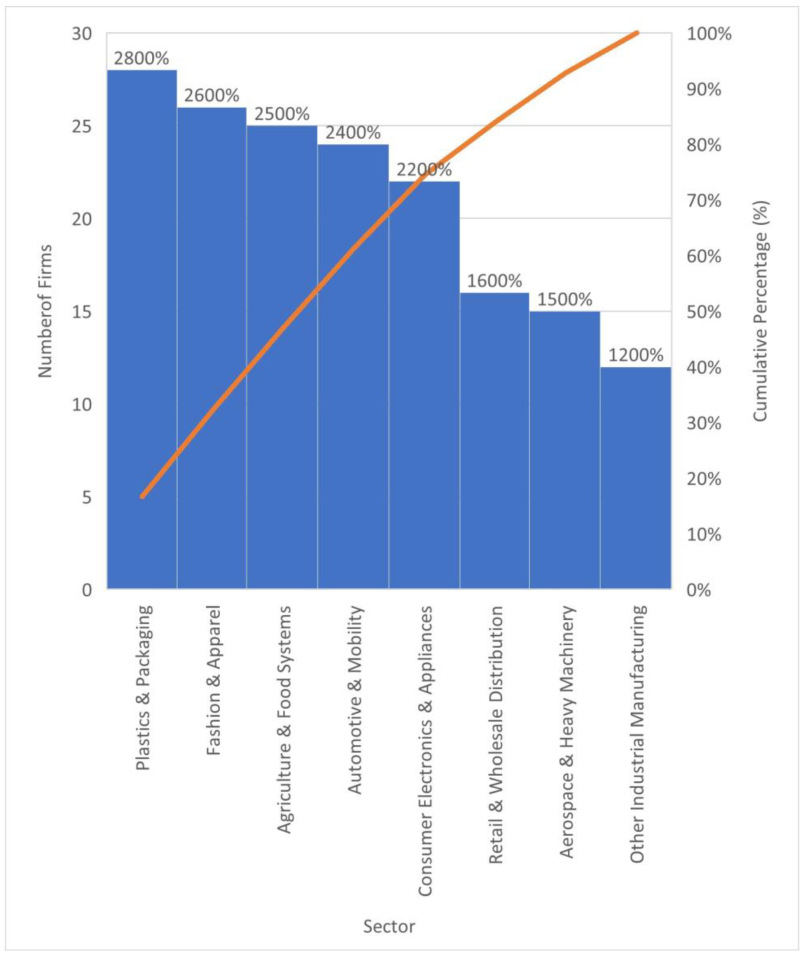

4.1. Respondent Characteristics

4.2. Sample Selection and Data Collection

Common Method Bias Assessment

4.3. Measurement of Variables

4.3.1. Independent Variables: Technological and Organizational Enablers

- IoT: IoT adoption was measured through items capturing the deployment of interconnected devices, sensors, and platforms enabling real-time data flows, process monitoring, and resource optimization. Prior research underscores IoT’s contribution to enhancing operational efficiency, promoting supply chain integration, and driving business model innovation, additionally highlighting persistent challenges concerning data privacy and security [39]. Effective adoption requires proactive change management, privacy impact assessments, and transparent communication strategies to ensure governance safeguards.

- AI & BDA: AI and BDA capabilities were measured using items capturing the firm’s ability to process large datasets, generate predictive insights, and implement AI-driven applications for strategic decision-making and innovation. These technologies support decision automation, enhance responsiveness, and improve organizational agility, with their effectiveness moderated by a data-driven culture and ethical oversight [40,41]. Human-centered governance frameworks are essential for mitigating risks such as algorithmic bias and data privacy concerns.

- Blockchain Technology: Blockchain was operationalized through items capturing its role in enhancing traceability, transparency, and data integrity across supply chains. Its decentralized architecture supports secure transactions, smart contracts, and trust-building mechanisms, improving sustainability and innovation performance [42]. Adoption is moderated by organizational readiness and regulatory environments, with challenges including regulatory uncertainty and technological immaturity.

- Digital Collaboration Capability: The construct was measured through items reflecting the firm’s capacity to leverage digital platforms to coordinate activities, share knowledge, and engage in joint innovation with supply chain partners. Digital collaboration enhances absorptive capacity, enabling firms to integrate external knowledge and co-develop solutions [43]. Governance requires hybrid mechanisms balancing centralized control and community-based trust to ensure equitable value distribution.

- Synthesis of Enablers: Each enabler contributes distinct mechanisms, IoT through real-time data, AI and BDA through predictive insights, Blockchain through trust and decentralization, and Digital Collaboration through absorptive integration. Their combined adoption drives holistic digital transformation, necessitating adaptive governance and cultural alignment to balance efficiency with ethical and regulatory considerations.

4.3.2. Mediator Variable: Circular Economy Integration

4.3.3. Dependent Variable: Sustainable Performance

4.3.4. Control Variables

4.4. Analytical Methods

5. Results

- Establish a significant relationship between the independent variable(s) and the dependent variable. In the regression of the dependent variable on the independent variable , the coefficient must be statistically significant.

- Demonstrate a significant effect of the independent variable on the mediator . In the regression of on , the coefficient must be significant.

- Confirm a significant relationship between the mediator (M) and the dependent variable while controlling for . In the regression of Y on both M and , the coefficient for must remain significant.

- Verify mediation by assessing the change in the direct effect of on when is included. Full mediation is indicated if the coefficient () linking and becomes non-significant (i.e., ) when controlling for ; otherwise, the presence of a significant suggests partial mediation.

5.1. IoT Adoption and Sustainable Performance

5.2. AI and Big Data Analytics

5.3. Blockchain Technology

5.4. Digital Collaboration Capability

5.5. Model Fit and Control Variables

5.6. Sub-Dimensional Analysis

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| BDA | Big Data Analytics |

| CE | Circular Economy |

| EFA | Exploratory Factor Analysis |

| I4.0 | Industry 4.0 |

| IoT | Internet of Things |

| IT | Information Technology |

| KMO | Kaiser–Meyer–Olkin |

| LCA | Life Cycle Assessment |

| OECD | Organisation for Economic Co-operation and Development |

| OT | Operational Technology |

| PaaS | Product-as-a-Service |

| SDG | Sustainable Development Goals |

| SME | Small and Medium-sized Enterprises |

| SSCM | Sustainable Supply Chain Management |

| TBL | Triple Bottom Line |

| RBV | Resource-Based View |

Appendix A

| Construct | Measurement Items (5-Point Likert Scale) | Sources |

|---|---|---|

| IoT Adoption | 1. Our firm uses IoT devices and sensors to collect real-time data. 2. IoT improves monitoring and traceability of resources and operations. 3. IoT contributes to process optimization and energy efficiency. | [38,39,67] |

| AI & Big Data Analytics | 1. We use AI to analyze large and complex datasets. 2. Predictive analytics support strategic decision-making in our firm. 3. AI-enabled models are integrated into operational processes. | [40,41,68] |

| Blockchain Technology | 1. Our firm uses blockchain to improve transparency and traceability. 2. Blockchain adoption enhances the security of transactions and data. 3. Blockchain supports sustainable and ethical supply chain practices. | [42,69] |

| Digital Collaboration Capability | 1. We use digital platforms to enhance collaboration with supply chain partners. 2. Digital tools improve knowledge sharing and joint problem solving. 3. Our collaboration capability supports innovation and responsiveness. | [43,70,71,72] |

| Construct | Measurement Items (5-Point Likert Scale) | Sources |

|---|---|---|

| Circular Economy Integration | ||

| Dimension 1: Waste Reduction & Resource Recovery (CEWR) | 1. Our firm implements comprehensive recycling programs for production waste and end-of-life products. 2. We actively pursue reuse opportunities for materials and components across our operations. 3. Waste minimization is systematically integrated into our operational procedures. | [73] |

| Dimension 2: Resource Efficiency & Optimization (CERE) | ||

| 4. Our firm continuously works to reduce material and energy inputs per unit of output. | ||

| 5. Resource efficiency improvement is a key performance indicator in our operations. | ||

| 6. We employ systematic approaches to optimize material utilization and reduce resource consumption. | ||

| Dimension 3: Sustainable Design (CESD) | ||

| 7. Environmental considerations are integrated into our product and process design decisions. | ||

| 8. We design products with end-of-life disassembly and material recovery in mind. | ||

| 9. Lifecycle thinking guides our innovation and development activities. | ||

| 10. Our supply chain partners are actively involved in collaborative circular economy initiatives. |

| Construct | Measurement Items (5-Point Likert Scale) | Sources |

|---|---|---|

| Sustainable Performance | 1. Our firm has improved operational efficiency through sustainability initiatives. 2. The environmental footprint has been reduced significantly. 3. Employee well-being and social responsibility have improved. 4. Circular and digital practices enhance our long-term competitiveness. | [74] |

References

- Luo, S.; Xiong, Z.; Liu, J. How does supply chain digitization affect green innovation? Evidence from a quasi-natural experiment in China. Energy Econ. 2024, 136, 107745. [Google Scholar] [CrossRef]

- Antoniou, S.; Fotiadis, T.; Chatzoglou, P.; Gasteratos, A. Digitalising the Supply Chain for Enhanced Efficiency and Customer Satisfaction. In Supply Chains; Kostavelis, I., Folinas, D., Aidonis, D., Achillas, C., Eds.; Springer: Cham, Switzerland, 2024; Volume 2111, pp. 321–334. [Google Scholar] [CrossRef]

- Issa, A.; Khadem, A.; Alzubi, A.; Berberoğlu, A. The Path from Green Innovation to Supply Chain Resilience: Do Structural and Dynamic Supply Chain Complexity Matter? Sustainability 2024, 16, 3762. [Google Scholar] [CrossRef]

- Radi, R.M.; Aydin, R.; Khan, S.A. The Impact of Digitalization on the Sustainability of the Supply Chain. In Proceedings of the 2024 IEEE International Conference on Technology Management, Operations and Decisions, ICTMOD 2024, Sharjah, United Arab Emirates, 4–6 November 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Wandhekar, S.; Bhatlawande, A.; Shinde, G.; Kshirsagar, R.B.; Agarkar, B.S.; Ghatge, P.U. Insights on Digitalizing the Supply Chain for Sustainable Organic Food Products. In Smart Innovation, Systems and Technologies; Ronzhin, A., Kostyaev, A., Bakach, M., Eds.; Springer Science and Business Media Deutschland GmbH: Cham, Switzerland, 2024; Volume 397, pp. 449–461. [Google Scholar] [CrossRef]

- Avinash, B.M.; Megha, B.; Potluri, R.M. Integration of Blockchain Technology and Explainable Artificial Intelligence in Supply Chains: Transforming Transparency and Efficiency. In Explainable AI and Blockchain for Secure and Agile Supply Chains: Enhancing Transparency, Traceability, and Accountability; CRC Press: Boca Raton, FL, USA, 2025; pp. 47–62. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Farfán Chilicaus, G.C.; Licapa-Redolfo, G.S.; Arbulú Ballesteros, M.A.; Corrales Otazú, C.D.; Apaza Miranda, S.J.; Flores Castillo, M.M.; Castro Ijiri, G.L.; Guzmán Valle, M.D.L.Á.; Arbulú Castillo, J.C. Digital Transformation and Sustainability in Post-Pandemic Supply Chains: A Global Bibliometric Analysis of Technological Evolution and Research Patterns (2020–2024). Sustainability 2025, 17, 3009. [Google Scholar] [CrossRef]

- Radavičiūtė, G.; Meidutė-Kavaliauskienė, I. Twin Transition in Supply Chains and Logistics: A Systematic Literature Review. In Lecture Notes in Intelligent Transportation and Infrastructure; Springer Nature: Cham, Switzerland, 2025; Volume Part F230, pp. 187–198. [Google Scholar] [CrossRef]

- Priyanshu, D.; Alabdulraheem, A.R.; Sadath, S.M.; Almuqbil, N. Optimizing AI-Driven Algorithms for Sustainable Supply Chains: Integrating IoT and Blockchain Technologies. In Proceedings of the 4th International Conference on Technological Advancements in Computational Sciences, ICTACS 2024; Chaudhary, N., Ed.; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024; pp. 570–574. [Google Scholar] [CrossRef]

- Hordieiev, M.; Nalyvaiko, N.; Parkhomenko-Kutsevil, O.; Molyboha, R.; Chabanov, A. The Metamorphosis of Global Trade Routes: Immediate Challenges and Advanced Logistics Techniques. Management 2025, 3, 257. [Google Scholar] [CrossRef]

- Petrillo, A.; Rehman, M.; De Felice, F. Optimizing coffee supply chain transparency and traceability through mobile application. Eur. J. Innov. Manag. 2025, 28, 267–300. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, X.; Xi, Y. Greening the chain: How digital transformation of supply chains drives corporate innovation in China’s A-share market. Int. Rev. Financ. Anal. 2025, 103, 104224. [Google Scholar] [CrossRef]

- Abdulkader, N.; Belgaroui, R. The Impact of the Follow-Up Process on Improving Training Outputs: A Case Study of the Education Department in Al Ahsa Region. Int. J. Financ. Adm. Econ. Sci. 2025, 4, 3. [Google Scholar] [CrossRef]

- Chrifi-Alaoui, C.; Bouhaddou, I.; Benabdellah, A.C.; Zekhnini, K. Industry 5.0 for Sustainable Supply Chains: A Fuzzy AHP Approach for Evaluating the adoption Barriers. In Procedia Computer Science; Solina, V., Longo, F., Romero, D., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2025; Volume 253, pp. 2645–2654. [Google Scholar] [CrossRef]

- Tarifa-Fernandez, J.; Aguilera, A.M.; Jiménez-Guerrero, J.F. Challenges of Digital Technologies in the Development of Supply Chains: A Guide for Their Selection. In Data Science and Analytics; Emerald Group Publishing Ltd.: Leeds, UK, 2020; pp. 151–166. [Google Scholar] [CrossRef]

- Naz, F.; Agrawal, R.; Kumar, A.; Gunasekaran, A.; Majumdar, A.; Luthra, S. Reviewing the applications of artificial intelligence in sustainable supply chains: Exploring research propositions for future directions. Bus. Strategy Environ. 2022, 31, 2400–2423. [Google Scholar] [CrossRef]

- Belgaroui, R.; Shili, A. Extending the Theory of Planned Behaviour to Understand Entrepreneurial Intention Among Female University Students in Saudi Arabia: The Role of Entrepreneurship Education. J. Posthumanism 2025, 5, 4226–4246. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Zhou, J.; Ren, J.; Toniolo, S. A Decision Support Framework for Safe and Sustainable By-Design Practices Promoting Circularity in Waste-to-Energy Supply Chains. Sustain. Prod. Consum. 2025, 54, 487–501. [Google Scholar] [CrossRef]

- Zhu, J.; Qin, Z.; Wang, X.; Wang, S. Does Supply Chain Digital Influence Green Innovation of Chinese Manufacturing Enterprises: A Quasi-Natural Experiment Based on Supply Chain Innovation and Application Policy Pilot. Pol. J. Environ. Stud. 2025, 34, 4955–4967. [Google Scholar] [CrossRef]

- Belgaroui, R.; Ben Hamad, S. The Good Practices of Academic Autonomy as Mechanism of Governance and Performance of Higher Education Institutions: Case of the University of Sfax. Int. J. Engl. Lit. Soc. Sci. 2021, 6, 177–184. [Google Scholar] [CrossRef]

- Mrad, M.; Frikha, M.A.; Boujelbene, Y. A Comprehensive Survey of Artificial Intelligence and Robotics for Reducing Carbon Emissions in Supply Chain Management. Logistics 2025, 9, 104. [Google Scholar] [CrossRef]

- Fan, W.; Wu, X.; He, Q. Digitalization drives green transformation of supply chains: A two-stage evolutionary game analysis. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Nethravathi, K.; Tiwari, A.; Uike, D.; Jaiswal, R.; Pant, K. Applications of Artificial Intelligence and Blockchain Technology in Improved Supply Chain Financial Risk Management. In Proceedings of the 5th International Conference on Contemporary Computing and Informatics, IC3I 2022, Uttar Pradesh, India, 14–16 December 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; pp. 242–246. [Google Scholar] [CrossRef]

- Mrad, M.; Boujelbene, Y. Demand Forecasting in the Tunisian Pharmaceutical Industry: A Comparative Study. Recent Pat. Biotechnol. 2025, 20, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Bhawna; Kang, P.S.; Sharma, S.K. Bridging the gap: A systematic analysis of circular economy, supply chain management, and digitization for sustainability and resilience. Oper. Manag. Res. 2024, 17, 1039–1057. [Google Scholar] [CrossRef]

- Shadkam, E.; Irannezhad, E. A comprehensive review of simulation optimization methods in agricultural supply chains and transition towards an agent-based intelligent digital framework for agriculture 4.0. Eng. Appl. Artif. Intell. 2025, 143, 109930. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Tatarczak, A. Mapping the landscape of artificial intelligence in supply chain management: A bibliometric analysis. Mod. Manag. Rev. 2024, 29, 43–57. [Google Scholar] [CrossRef]

- Ramadoss, T.S.; Alam, H.; Seeram, R. Artificial Intelligence and Internet of Things enabled Circular Economy. Int. J. Eng. Sci. 2018, 7, 55–63. [Google Scholar] [CrossRef]

- Morcillo-Bellido, J.; Isasi-Sanchez, L.; Garcia-Gutierrez, I.; Duran-Heras, A. Model based analysis of innovation in sustainable supply chains. Sustainability 2021, 13, 4868. [Google Scholar] [CrossRef]

- Iftikhar, A.; Ali, I.; Arslan, A.; Tarba, S. Digital Innovation, Data Analytics, and Supply Chain Resiliency: A Bibliometric-based Systematic Literature Review. Ann. Oper. Res. 2024, 333, 825–848. [Google Scholar] [CrossRef]

- Yan, M.-R.; Yan, H.; Chen, Y.-R.; Zhang, Y.; Yan, X.; Zhao, Y. Integrated green supply chain system development with digital transformation. Int. J. Logist. Res. Appl. 2025, 1–22. [Google Scholar] [CrossRef]

- Sharma, M.; Raut, R.D.; Sehrawat, R.; Ishizaka, A. Digitalisation of manufacturing operations: The influential role of organisational, social, environmental, and technological impediments. Expert Syst. Appl. 2023, 211, 118501. [Google Scholar] [CrossRef]

- Ammar, S.B.; Mosbahi, H.; Aissaoui, T. Smart Supply Chain: A Lever for Strategic Excellence. In Proceedings of the 2024 International Conference on Control, Automation and Diagnosis, ICCAD 2024, Paris, France, 15–17 May 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Schilling, L.; Seuring, S. Linking the digital and sustainable transformation with supply chain practices. Int. J. Prod. Res. 2024, 62, 949–973. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Podsakoff, N.P. Sources of method bias in social science research and recommendations on how to control it. Annu. Rev. Psychol. 2012, 63, 539–569. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organizational research: Problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Pavlou, P.; Liang, H.; Xue, Y. Understanding and mitigating uncertainty in online exchange relationships: A principal-agent perspective. MIS Q. 2007, 31, 105–136. [Google Scholar] [CrossRef]

- Lopes, A.J.; Marquez, I.R.; Rahman, M.F.; Tseng, T.-L.B.; Luna, S. Smart Manufacturing for Underserved Workforce Development. In Proceedings of the ASEE Annual Conference and Exposition, Minneapolis, MN, USA, 26–29 June 2022; American Society for Engineering Education: Washington, DC, USA, 2022. [Google Scholar]

- Irfan, M.; Verma, J.; Parameswaran, S.; Sheikh, I.A. Integrating Emerging Technologies: Enhancing Supply Chain Optimization Through AI, IoT, and Blockchain. In Enhancing Social Sustainability in Manufacturing Supply Chains; IGI Global: Hershey, PA, USA, 2025; pp. 199–220. [Google Scholar] [CrossRef]

- Bo, Y. Research on the application and innovation mode of Internet of Things technology in enterprise digital supply chain. In Proceedings of the SPIE—The International Society for Optical Engineering; Buja, G., Lu, H.-H., Eds.; SPIE: Bellingham, WA, USA, 2025; Volume 13684, p. 1368406. [Google Scholar] [CrossRef]

- Lai, K.-H.; Feng, Y.; Zhu, Q. Digital transformation for green supply chain innovation in manufacturing operations. Transp. Res. Part E Logist. Transp. Rev. 2023, 175, 103145. [Google Scholar] [CrossRef]

- Mance, D.; Vilke, S.; Debelić, B. Information and Communication Technology, and Supply Chains as Economic Drivers in the European Union. Logistics 2025, 9, 49. [Google Scholar] [CrossRef]

- Safa, M.; Green, K.W.; Zelbst, P.J.; Sower, V.E. Enhancing Supply Chain through Implementation of Key IIoT Technologies. J. Comput. Inf. Syst. 2023, 63, 410–420. [Google Scholar] [CrossRef]

- van der Heijden, A.; Cramer, J.M. Change agents and sustainable supply chain collaboration: A longitudinal study in the Dutch pig farming sector from a sensemaking perspective. J. Clean. Prod. 2017, 166, 967–987. [Google Scholar] [CrossRef]

- Frikha, M.A.; Mrad, M. AI-Enabled Demand Forecasting, Technological Capability, and Supply Chain Performance: Empirical Evidence from the Global Logistics Sector. Int. J. Adv. Comput. Sci. Appl. 2025, 16. [Google Scholar] [CrossRef]

- Garg, A.; Vemaraju, S. Artificial Intelligence Applications in Predictive Maintenance for Sustainable Logistics. In Proceedings of the 2024 IEEE 4th International Conference on ICT in Business Industry and Government, ICTBIG 2024, Indore, India, 13–14 December 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Abilakimova, A.; Bauters, M. Understanding twin transition dynamics in the Estonian metal manufacturing industry. Proc. Est. Acad. Sci. 2025, 74, 98–102. [Google Scholar] [CrossRef]

- Tiwari, S.; Sharma, P.; Jha, A.K. Digitalization & COVID-19: An institutional-contingency theoretic analysis of supply chain digitalization. Int. J. Prod. Econ. 2024, 267, 109063. [Google Scholar] [CrossRef]

- Bian, Z.; Luo, M. Digital transformation’s impact on upstream green technology innovation: A supply chain perspective. Appl. Econ. 2025, 1–18. [Google Scholar] [CrossRef]

- Stroumpoulis, A.; Kopanaki, E.; Chountalas, P.T. Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis. Sustainability 2024, 16, 6778. [Google Scholar] [CrossRef]

- Shete, P.C.; Ansari, Z.N.; Kant, R. A Pythagorean fuzzy AHP approach and its application to evaluate the enablers of sustainable supply chain innovation. Sustain. Prod. Consum. 2020, 23, 77–93. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Castaño-Moraga, C.A. Industry 4.0 and supply chain. A Systematic Science Mapping analysis. Technol. Forecast. Soc. Change 2022, 181, 121788. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, Y. The effects of supply chain collaboration on green innovation performance: An interpretive structural modeling analysis. Sustain. Prod. Consum. 2020, 23, 1–10. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef]

- Feng, D.; Wang, H.; Zhao, L. Digital Technologies for Sustainable Supply Chain Performance: Source-Push and Value Chain-Pull Mechanisms. Sustainability 2025, 17, 5524. [Google Scholar] [CrossRef]

- Wamba, S.F.; Gunasekaran, A.; Akter, S.; Ren, S.J.F.; Dubey, R.; Childe, S.J. Big data analytics and firm performance: Effects of dynamic capabilities. J. Bus. Res. 2017, 70, 356–365. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Sustainable supply chains with blockchain, IoT and RFID: A simulation on order management. Sustainability 2021, 13, 6372. [Google Scholar] [CrossRef]

- Chiaroni, D.; Chiesa, V.; Frattini, F. The Open Innovation Journey: How firms dynamically implement the emerging paradigm. Technovation 2011, 31, 34–43. [Google Scholar] [CrossRef]

- Kim, H.; Park, Y. The effects of open innovation activity on performance of SMEs: The case of Korea. Int. J. Technol. Manag. 2010, 52, 236–256. [Google Scholar] [CrossRef]

- van de Vrande, V.; de Jong, J.P.J.; Vanhaverbeke, W.; de Rochemont, M. Open innovation in SMEs: Trends, motives and management challenges. Technovation 2009, 29, 423–437. [Google Scholar] [CrossRef]

- Jusoh, A.; Mahmood, R.; Ahmad, Z.; Zahari, A.S.M.; Ibrahim, N.B. The impact of digital supply chain on business performance: A comparative analysis of gas processing and oil refinery departments. In Global Partnerships and Governance of Supply Chain Systems; IGI Global: Hershey, PA, USA, 2025; pp. 287–312. [Google Scholar] [CrossRef]

- Benatiya Andaloussi, M. A Bibliometric Literature Review of Digital Supply Chain: Trends, Insights, and Future Directions. SAGE Open 2024, 14, 21582440241240340. [Google Scholar] [CrossRef]

- Andrea Thomas, P.; Natal, M.S.; Sreethi Rebeka, R.; Josephine, J.; Singha, S.; Singha, R.; Jose, J. Innovative paths to energy efficiency and CO2 reduction in supply chains. In Multi-Stakeholder Collaboration for Sustainable Supply Chain; IGI Global: Hershey, PA, USA, 2025; pp. 335–358. [Google Scholar] [CrossRef]

- Ansari, M.F.; Kant, R. Exploring the impact of supply chain practices on supply chain performance: An empirical study from Indian manufacturing industry. Int. J. Product. Perform. Manag. 2017, 66, 868–898. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Luthra, S.; Ishizaka, A. Mapping the trends of sustainable supply chain management research: A bibliometric analysis of peer-reviewed articles. Front. Sustain. 2023, 4, 1129046. [Google Scholar] [CrossRef]

- Sánchez-Flores, R.B.; Cruz-Sotelo, S.E.; Ojeda-Benítez, S.; Ramírez-Barreto, M.E. Sustainable supply chain management—A literature review on emerging economies. Sustainability 2020, 12, 6972. [Google Scholar] [CrossRef]

- Rebs, T.; Brandenburg, M.; Seuring, S. System dynamics modeling for sustainable supply chain management: A literature review and systems thinking approach. J. Clean. Prod. 2019, 208, 1265–1280. [Google Scholar] [CrossRef]

- Romagnoli, S.; Tarabu’, C.; Vishkaei, B.M.; De Giovanni, P. The impact of digital technologies and sustainable practices on circular supply chain management. Logistics 2023, 7, 1. [Google Scholar] [CrossRef]

- OECD. Digital Transformation in the Age of AI; OECD Publishing: Paris, France, 2023; Available online: https://www.oecd.org/en/topics/digital-transformation.html (accessed on 9 November 2025).

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Leonardi, P.M. COVID 19 and the New Technologies of Organizing: Digital Exhaust, Digital Footprints, and Artificial Intelligence in the Wake of Remote Work. J. Manag. Stud. 2021, 58, 249–253. [Google Scholar] [CrossRef]

- Bai, C.; Quayson, M.; Sarkis, J. COVID-19 pandemic digitization lessons for sustainable development of smart and resilient supply chains. Resour. Conserv. Recycl. 2021, 173, 105688. [Google Scholar] [CrossRef]

- Cenamor, J.; Parida, V.; Wincent, J. How entrepreneurial SMEs compete through digital platforms: The roles of digital platform capability, network capability and ambidexterity. J. Bus. Res. 2019, 100, 196–206. [Google Scholar] [CrossRef]

- Schaltegger, S.; Wagner, M. Integrative management of sustainability performance, measurement and reporting. Int. J. Account. Audit. Perform. Eval. 2006, 3, 1–19. [Google Scholar] [CrossRef]

| Respondent Role | Number | Percentage (%) |

|---|---|---|

| CEO/President | 64 | 38.1 |

| General Manager | 46 | 27.4 |

| Operations Director | 31 | 18.5 |

| Sustainability/Supply Chain Manager | 27 | 16.0 |

| Total | 168 | 100.0 |

| Sector | Number of Firms | Percentage | Cumulative Percentage |

|---|---|---|---|

| Automotive & Mobility | 24 | 14.3% | 14.3% |

| Plastics & Packaging | 28 | 16.7% | 31.0% |

| Consumer Electronics & Appliances | 22 | 13.1% | 44.1% |

| Agriculture & Food Systems | 25 | 14.9% | 59.0% |

| Aerospace & Heavy Machinery | 15 | 8.9% | 67.9% |

| Fashion & Apparel | 26 | 15.5% | 83.4% |

| Retail & Wholesale Distribution | 16 | 9.5% | 92.9% |

| Other Industrial Manufacturing | 12 | 7.1% | 100.0% |

| Total | 168 | 100.0% |

| Constructs | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. IoT Adoption | 1.000 | |||||||||

| 2. AI & Big Data Analytics | 0.476 | 1.000 | ||||||||

| 3. Blockchain Technology | 0.542 | 0.421 | 1.000 | |||||||

| 4. Digital Collaboration | 0.298 | 0.507 | 0.639 | 1.000 | ||||||

| 5. CE Integration | 0.419 | 0.463 | 0.552 | 0.694 | 1.000 | |||||

| 6. Innovation Performance | 0.411 | 0.612 | 0.721 | 0.842 | 0.822 | 1.000 | ||||

| 7. Overall Sustainable Performance | 0.573 | 0.524 | 0.765 | 0.729 | 0.589 | 0.827 | 1.000 | |||

| 8. Firm Size | 0.261 | 0.398 | 0.581 | 0.691 | 0.728 | 0.796 | 0.634 | 1.000 | ||

| 9. Firm Age | −0.068 | 0.057 | 0.044 | 0.061 | −0.014 | −0.007 | −0.004 | −0.011 | 1.000 | |

| 10. Technological Innovation Systems | 0.179 | 0.409 | 0.534 | 0.653 | 0.711 | 0.782 | 0.692 | 0.693 | 0.051 | 1.000 |

| Constructs Analyzed | Retained Factors | KMO Measure of Sampling Adequacy | Cumulative Variance Explained (%) | Cronbach’s α |

|---|---|---|---|---|

| IoT Adoption | [IOT] | 0.811 (0.000) * | 82.145 | 0.921 |

| AI & Big Data Analytics | [AIBA] | 0.891 (0.000) * | 80.334 | 0.872 |

| Blockchain Technology | [BCT] | 0.866 (0.000) * | 85.612 | 0.914 |

| CE Integration (Global) | [CEINT] | 0.720 (0.000) * | 78.903 | 0.811 |

| CE—Waste Reduction | [CEWR] | 0.702 (0.000) * | 82.445 | 0.853 |

| CE—Resource Efficiency | [CERE] | 0.745 (0.000) * | 84.129 | 0.787 |

| CE—Sustainable Design | [CESD] | 0.786 (0.000) * | 87.332 | 0.942 |

| Innovation Performance | [INP] | 0.871 (0.000) * | 72.032 | 0.874 |

| Overall Sustainable Performance | [OSP] | 0.892 (0.000) * | 79.614 | 0.923 |

| First Step: (IoT → PER) | Second Step: (IoT → CEINT) | Third and Fourth Steps: (IoT → CEINT → PER) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| INP (M1) | OSP (M2) | CEINT (M3) | OSP (M4) | |||||||||

| β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | |

| Constant | −0.875 *** | −3.981 | 0.000 | −0.591 *** | −2.715 | 0.006 | −1.146 *** | −5.295 | 0.000 | −0.511 *** | −3.014 | 0.002 |

| IoT | 0.118 NS | 1.482 | 0.130 | 0.602 *** | 8.924 | 0.000 | 0.382 *** | 5.672 | 0.000 | 0.242 *** | 3.598 | 0.000 |

| SIZE | 0.279 *** | 4.739 | 0.000 | 0.243 *** | 4.514 | 0.000 | 0.098 ** | 2.013 | 0.046 | 0.091 ** | 2.095 | 0.038 |

| AGE | 0.007 NS | 0.082 | 0.933 | 0.041 NS | 0.761 | 0.447 | −0.023 NS | −0.475 | 0.647 | 0.042 NS | 0.992 | 0.321 |

| TIS | 0.511 *** | 6.855 | 0.000 | 0.035 NS | 0.558 | 0.577 | 0.465 *** | 7.066 | 0.000 | 0.121 ** | 2.371 | 0.018 |

| CEINT | - | - | - | - | - | - | - | - | - | 0.557 *** | 9.498 | 0.000 |

| Adjusted R2 | 0.558 | 0.612 | 0.621 | 0.763 | ||||||||

| F | 45.311 *** | 55.982 *** | 59.241 | 92.170 | ||||||||

| Variation Adjusted R2 | 0.151 | |||||||||||

| First Step: (AIBA → PER) | Second Step: (AIBA → CEINT) | Third and Fourth Steps: (AIBA → CEINT → PER) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| INP (M5) | OSP (M6) | CEINT (M7) | INP (M8) | OSP (M9) | |||||||||||

| β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | |

| Constant | −0.812 *** | −4.076 | 0.000 | −0.743 *** | −4.209 | 0.000 | 0.933 *** | −6.163 | 0.000 | −0.488 *** | −2.720 | 0.007 | −0.461 *** | −2.894 | 0.004 |

| AIBA | 0.563 *** | 8.640 | 0.000 | 0.684 *** | 12.042 | 0.000 | 0.587 *** | 12.008 | 0.000 | 0.359 *** | 5.571 | 0.000 | 0.518 *** | 9.030 | 0.000 |

| SIZE | 0.211 *** | 3.831 | 0.000 | 0.225 *** | 4.606 | 0.000 | 0.048 NS | 1.151 | 0.251 | 0.071 NS | 1.386 | 0.167 | 0.103 ** | 2.272 | 0.024 |

| AGE | −0.033 NS | −0.614 | 0.541 | 0.105 ** | 2.066 | 0.042 | 0.009 NS | 0.175 | 0.863 | −0.029 NS | −0.643 | 0.528 | 0.007 NS | 0.175 | 0.863 |

| TIS | 0.171 ** | 2.603 | 0.010 | 0.014 NS | 0.186 | 0.852 | 0.361 *** | 7.249 | 0.000 | 0.169 *** | 2.961 | 0.005 | 0.101 ** | 2.428 | 0.018 |

| CEINT | - | - | - | - | - | - | - | - | - | 0.419 *** | 6.755 | 0.000 | 0.356 *** | 6.463 | 0.000 |

| Adjusted R2 | 0.601 | 0.692 | 0.771 | 0.698 | 0.762 | ||||||||||

| F-statistic | 54.221 *** | 81.040 *** | 121.300 *** | 66.811 *** | 92.743 *** | ||||||||||

| Variation Adjusted R2 | 0.097 | 0.070 | |||||||||||||

| First Step: (BCT → PER) | Second Step: (BCT → CEINT) | Third and Fourth Steps: (BCT → CEINT → PER) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| INP (M10) | OSP (M11) | CEINT (M12) | INP (M13) | |||||||||

| β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | |

| Constant | −2.155 *** | −13.671 | 0.000 | −2.610 *** | −10.574 | 0.000 | −1.864 *** | −9.366 | 0.000 | −1.381 *** | −8.522 | 0.000 |

| BCT | 0.612 *** | 9.763 | 0.000 | 0.078 NS | 1.622 | 0.107 | 0.628 *** | 8.215 | 0.000 | 0.402 *** | 7.281 | 0.000 |

| SIZE | 0.253 *** | 4.946 | 0.000 | 0.211 *** | 4.002 | 0.000 | 0.265 *** | 4.154 | 0.000 | 0.095 ** | 2.134 | 0.035 |

| AGE | 0.061 NS | 0.980 | 0.329 | −0.024 NS | −0.272 | 0.786 | −0.161 ** | −2.075 | 0.040 | 0.062 NS | 1.235 | 0.219 |

| TIS | 0.192 ** | 2.624 | 0.040 | 0.711 *** | 9.211 | 0.000 | 0.129 ** | 2.070 | 0.040 | 0.171 ** | 2.329 | 0.031 |

| CEINT | - | - | - | - | - | - | - | - | - | 0.467 *** | 8.945 | 0.000 |

| Adjusted R2 | 0.649 | 0.658 | 0.487 | 0.779 | ||||||||

| F-statistic | 66.521 *** | 69.110 *** | 33.918 *** | 100.214 *** | ||||||||

| Variation Adjusted R2 | 0.130 | |||||||||||

| First Step: (DCC → PER) | Second Step: (DCC → CEINT) | Third and Fourth Steps: (DCC → CEINT → PER) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| INP (M14) | OSP (M15) | CEINT (M16) | INP (M17) | INP (M18) | |||||||||||

| β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | β | Student’s t | Sig | |

| Constant | −0.471 *** | −3.088 | 0.002 | −0.552 *** | −2.998 | 0.003 | −1.153 *** | −5.770 | 0.000 | −0.419 *** | −2.843 | 0.005 | −0.445 ** | −2.480 | 0.014 |

| DCC | 0.762 *** | 15.375 | 0.000 | 0.703 *** | 11.595 | 0.000 | 0.406 *** | 6.417 | 0.000 | 0.034 NS | 0.841 | 0.402 | 0.453 *** | 6.289 | 0.000 |

| SIZE | 0.131 *** | 2.902 | 0.005 | 0.171 *** | 3.292 | 0.001 | 0.003 NS | 0.017 | 0.987 | 0.578 *** | 8.916 | 0.000 | 0.095 * | 1.938 | 0.056 |

| AGE | 0.075 NS | 1.554 | 0.123 | 0.055 NS | 1.156 | 0.253 | 0.004 NS | 0.043 | 0.974 | 0.018 NS | 0.435 | 0.664 | 0.048 NS | 1.128 | 0.262 |

| TIS | 0.012 NS | 0.231 | 0.819 | 0.024 NS | 0.357 | 0.731 | 0.517 *** | 8.683 | 0.000 | 0.134 *** | 3.115 | 0.003 | 0.045 NS | 0.863 | 0.391 |

| OPEN | - | - | - | - | - | - | - | - | - | 0.259 *** | 4.168 | 0.000 | 0.382 *** | 5.683 | 0.000 |

| Adjusted R2 | 0.781 | 0.682 | 0.641 | 0.804 | 0.739 | ||||||||||

| F-statistic | 128.330 *** | 76.921 *** | 64.281 *** | 11.100 *** | 81.953 *** | ||||||||||

| Variation Adjusted R2 | 0.023 | 0.057 | |||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mrad, M.; Belgaroui, R. Digital–Circular Synergies in Sustainable Supply Chain Management: An Integrative Framework for SME Performance Enhancement. Sustainability 2025, 17, 10616. https://doi.org/10.3390/su172310616

Mrad M, Belgaroui R. Digital–Circular Synergies in Sustainable Supply Chain Management: An Integrative Framework for SME Performance Enhancement. Sustainability. 2025; 17(23):10616. https://doi.org/10.3390/su172310616

Chicago/Turabian StyleMrad, Mariem, and Rym Belgaroui. 2025. "Digital–Circular Synergies in Sustainable Supply Chain Management: An Integrative Framework for SME Performance Enhancement" Sustainability 17, no. 23: 10616. https://doi.org/10.3390/su172310616

APA StyleMrad, M., & Belgaroui, R. (2025). Digital–Circular Synergies in Sustainable Supply Chain Management: An Integrative Framework for SME Performance Enhancement. Sustainability, 17(23), 10616. https://doi.org/10.3390/su172310616