Sustainable Performance and Interfacial Characteristics of Fully Recycled Concrete with Combined Recycled Concrete, Brick, and Ceramic Aggregates

Abstract

1. Introduction

2. Materials and Methods

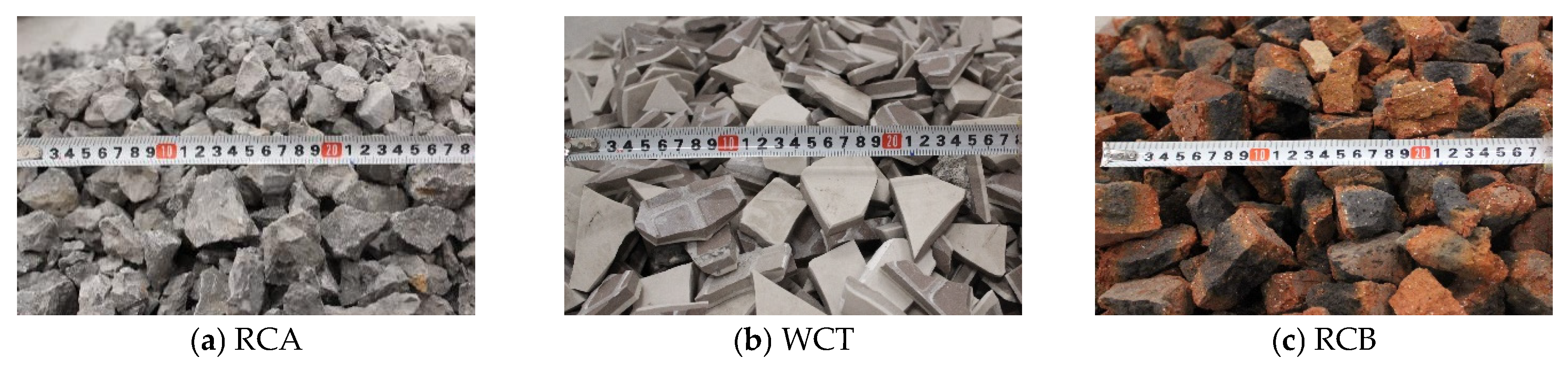

2.1. Materials

2.2. The Casting of Concrete Specimens and Mechanical Testing Methods

2.2.1. Concrete Mix Ratios and Samples

2.2.2. Mechanical Property Tests

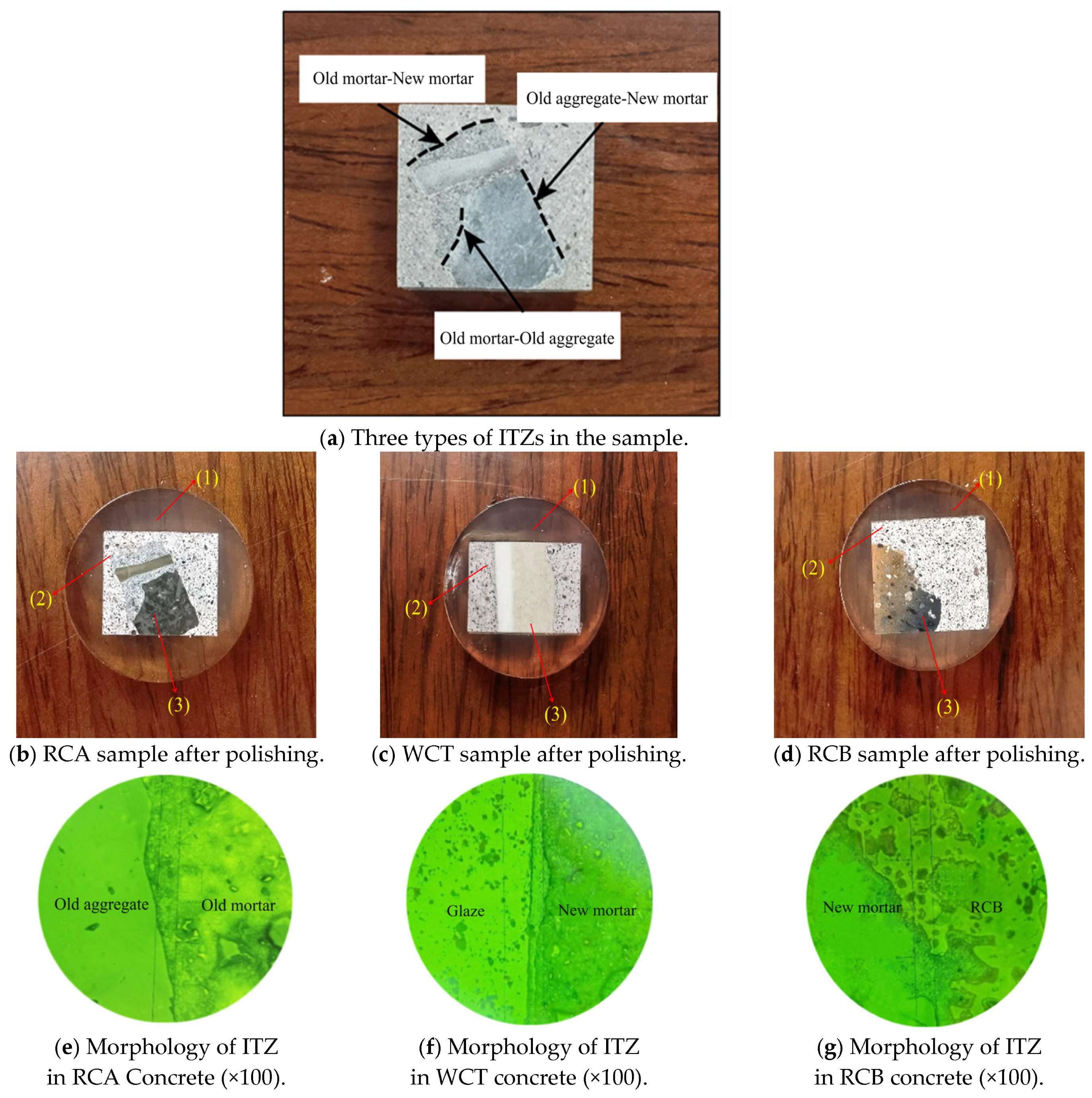

2.3. Test Method for Microhardness of the ITZ

2.3.1. Interface Transition Zone Sample Processing

- Concrete cubes (40 mm) cured for 28 days were sectioned into microhardness specimens measuring 15–30 mm. Each specimen was embedded in a 30 mm silicone mold using epoxy resin under vacuum conditions to ensure complete impregnation.

- After resin curing, surface preparation was carried out using a metallographic grinding machine. The specimens were sequentially ground with 800-grit (22.1 μm) and 1200-grit (14.5 μm) sandpapers, followed by polishing with oil-based diamond lapping films of 9 μm, 3 μm, and 1 μm particle sizes, and finally with a polishing cloth. The grinding and polishing durations were 5 min, 30 min, and 30 min, respectively. After each polishing step, ultrasonic cleaning in ethanol for 5 min was performed to remove residual abrasives. Throughout the process, a light load of 20 N, a rotation speed of 150 rpm, and a lubricant feed rate of 0.1 mL/s were maintained.

- Upon completion, the specimens underwent a final ultrasonic cleaning for 10 min to eliminate any remaining dust or diamond residue. The surface quality and smoothness were verified under a microscope, and the prepared samples were subsequently stored in airtight containers before microhardness testing.

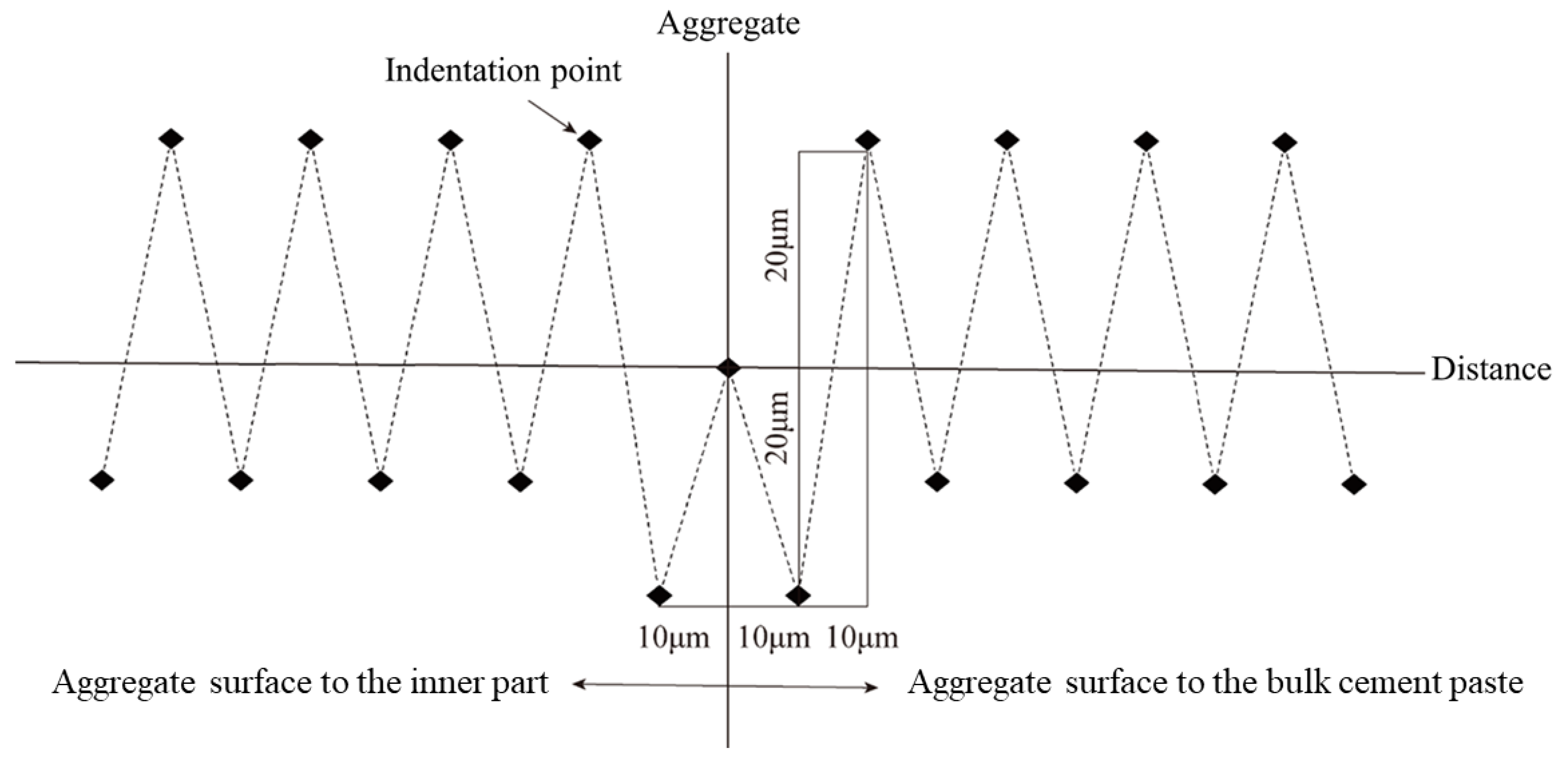

2.3.2. Vickers Hardness Test Dotting Method

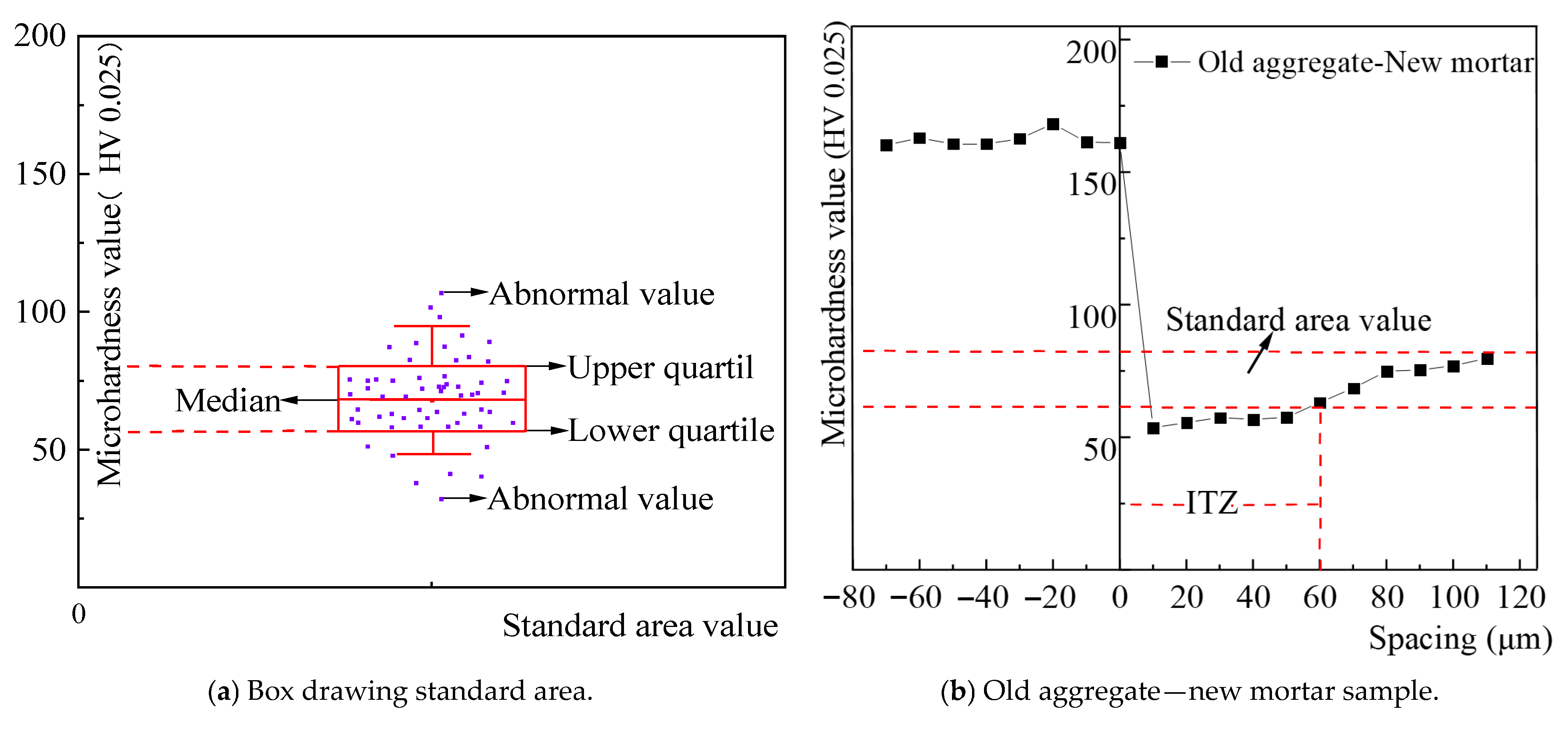

2.3.3. Test Principle and Data Processing

3. Results and Discussion

3.1. Density of Recycled Aggregate Concrete

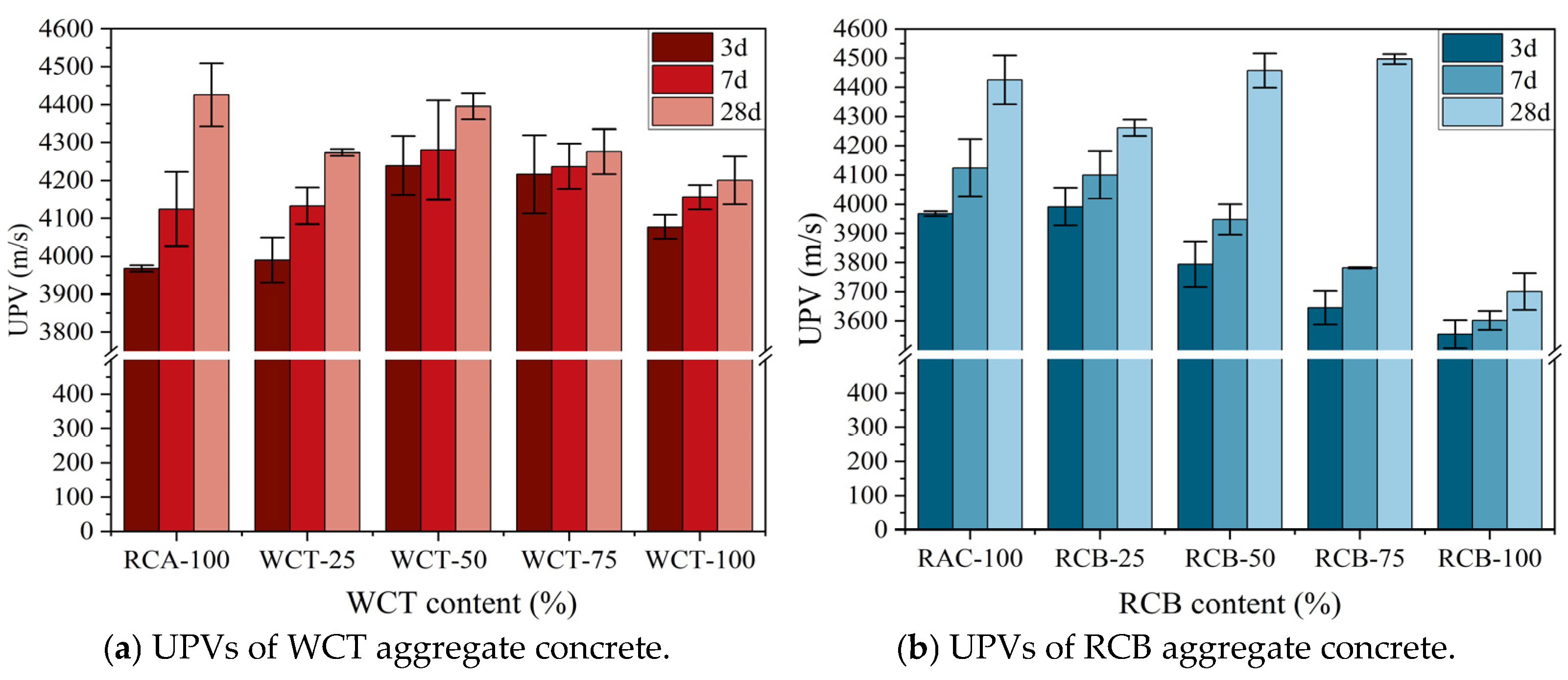

3.2. Ultrasonic Pulse Velocity Test

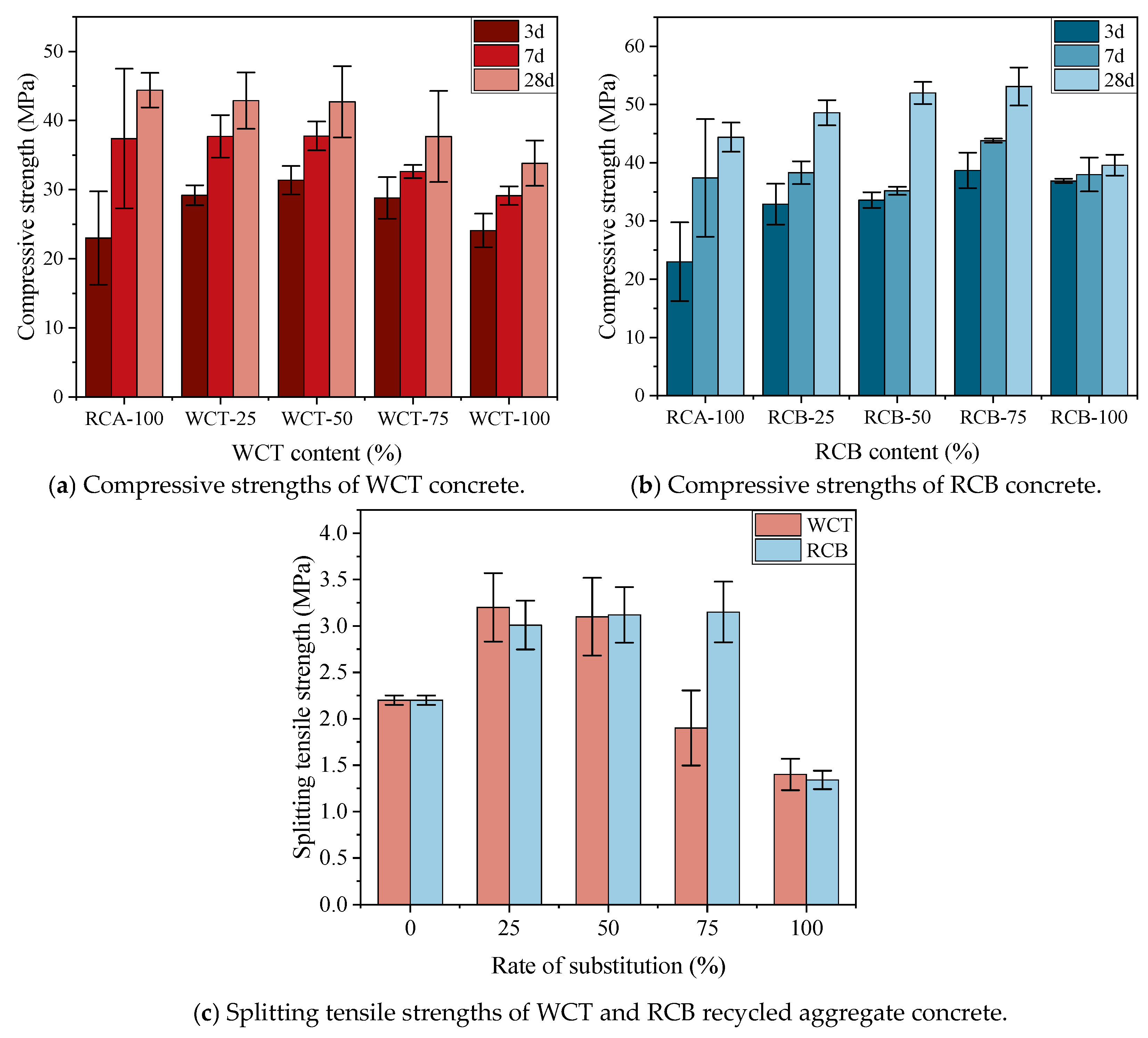

3.3. Mechanical Properties

3.3.1. Compressive Strength

3.3.2. Splitting Tensile Strength

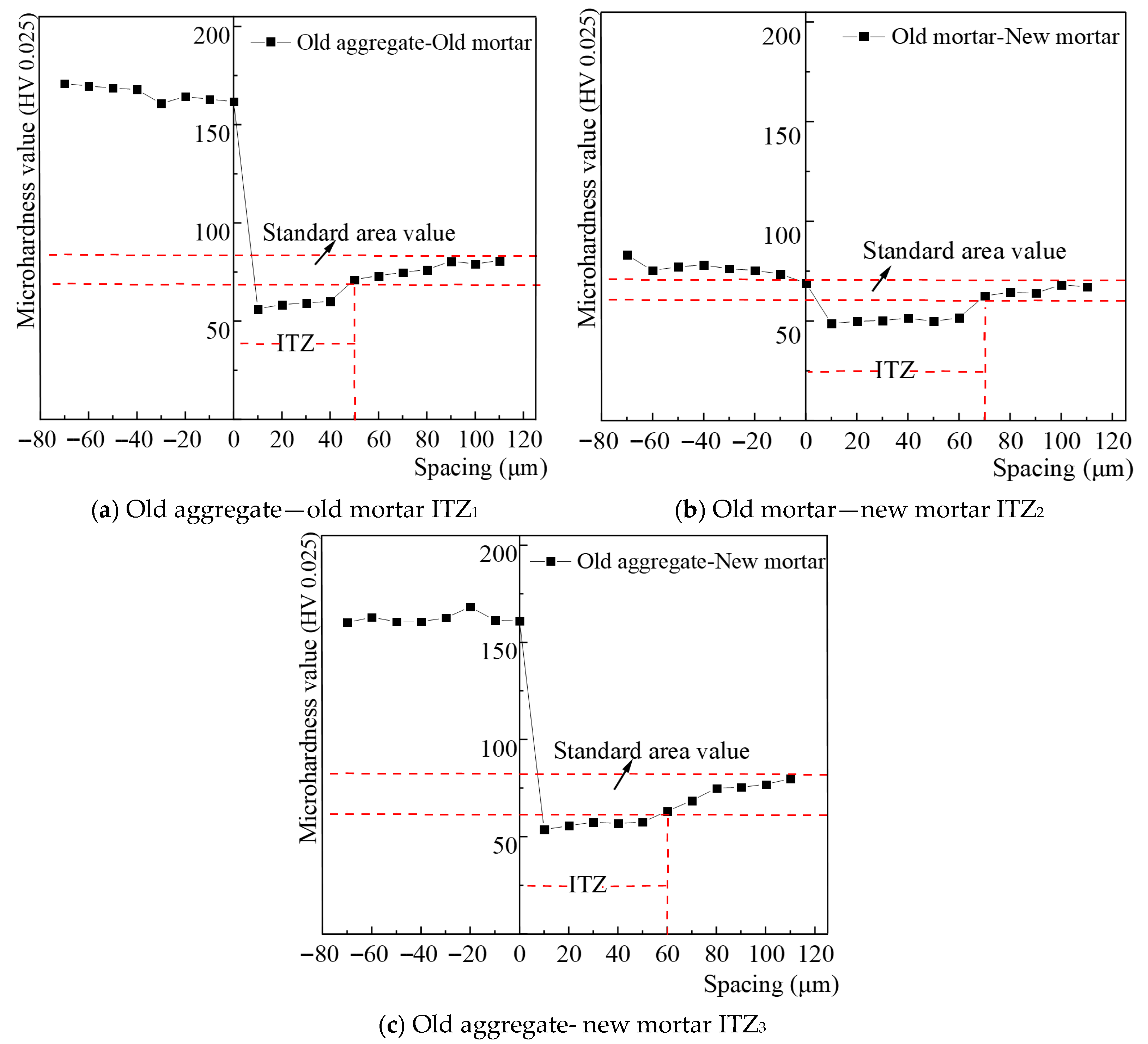

3.4. Microhardness Analysis of the ITZ

3.4.1. ITZ Microhardness in RCA Concrete

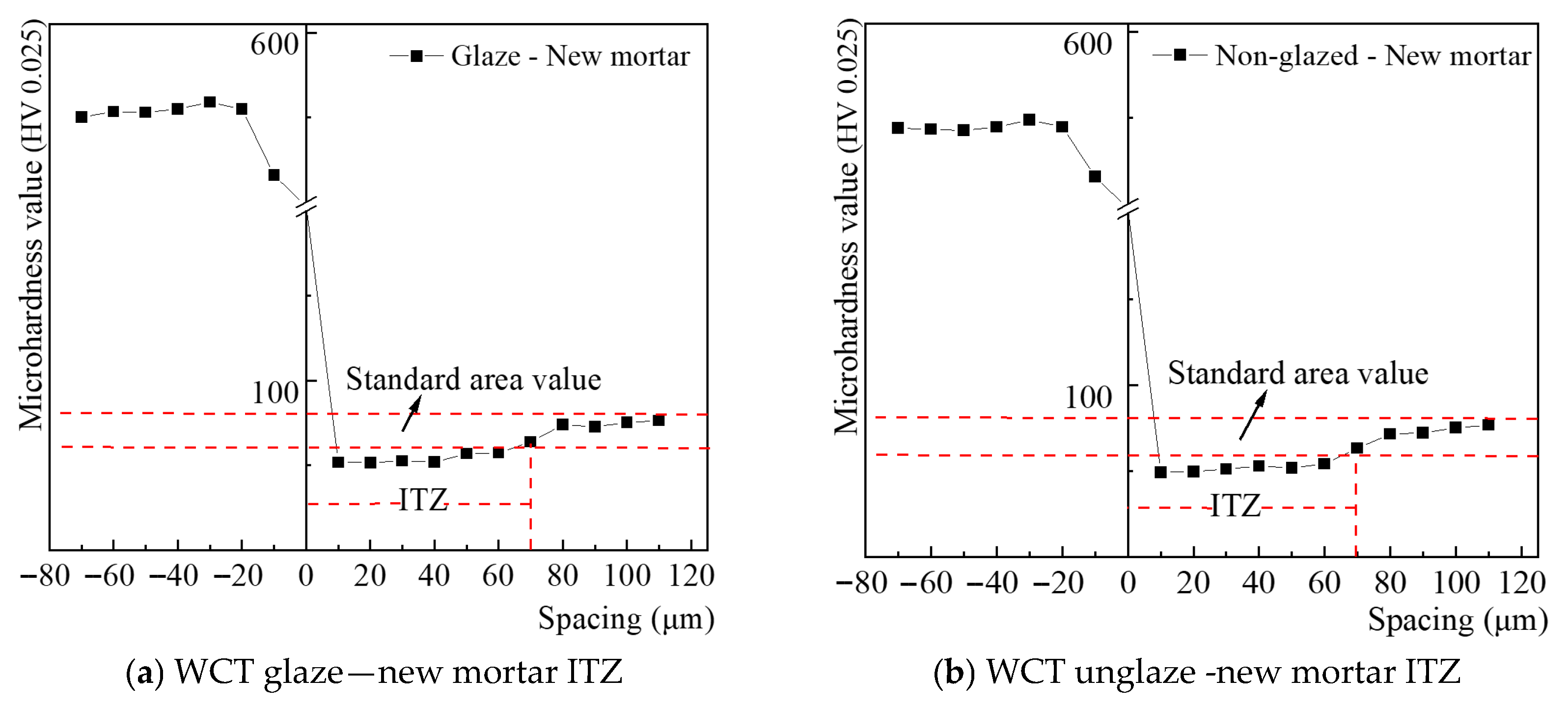

3.4.2. ITZ Microhardness in WCT Recycled Aggregate Concrete

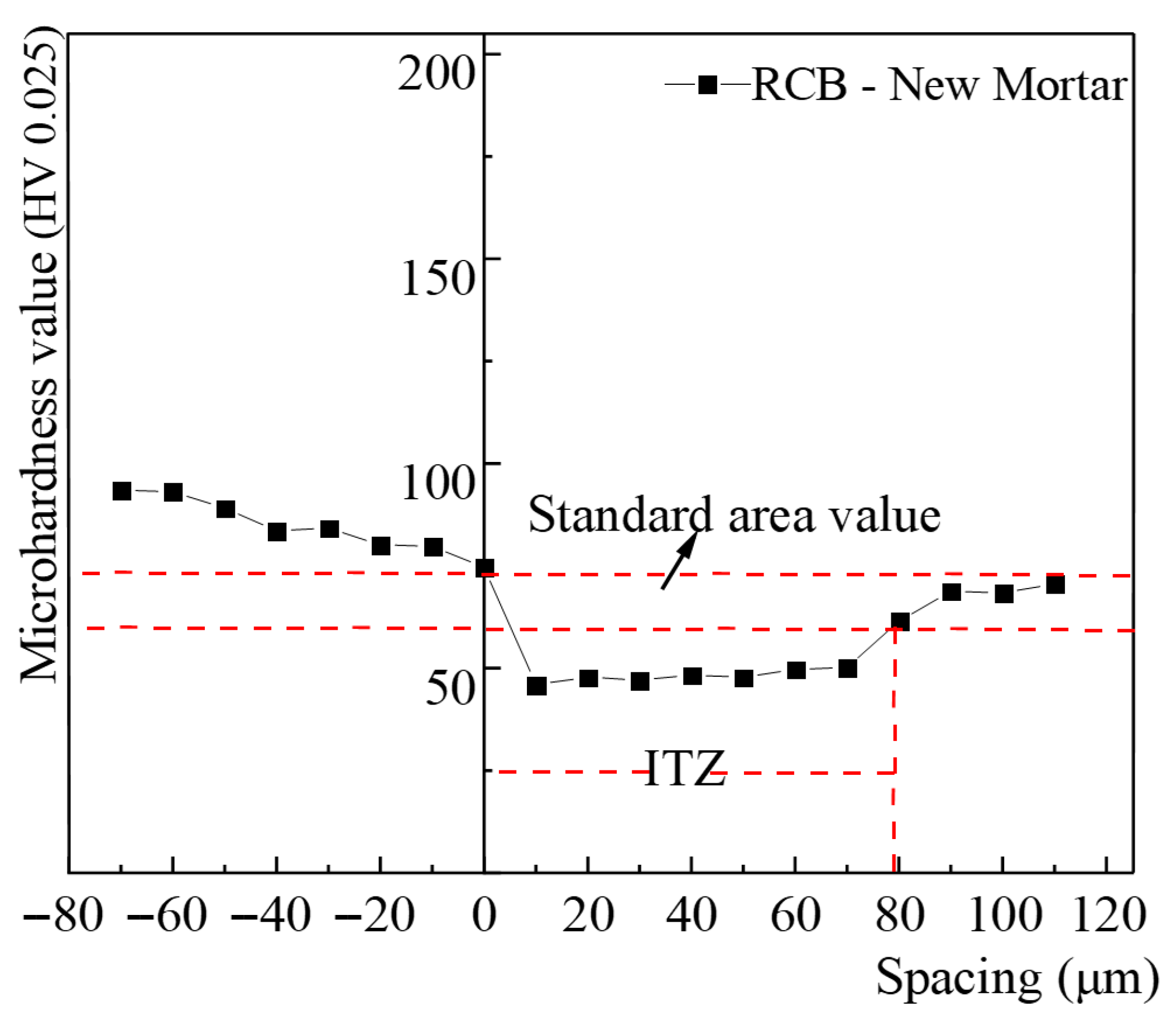

3.4.3. Microhardness of the ITZ of RCB Recycled Aggregate Concrete

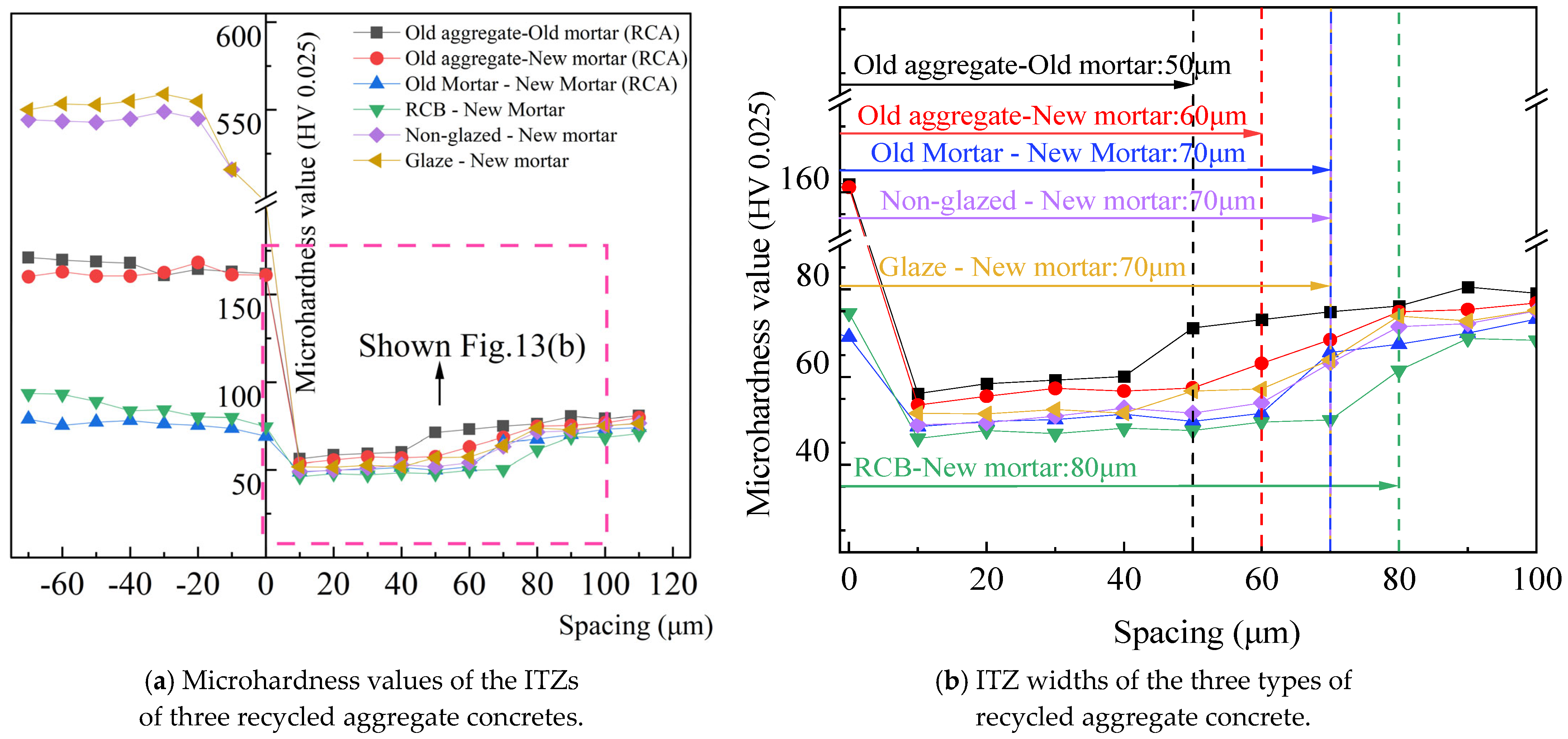

3.4.4. Microhardness of ITZs of Three Kinds of Recycled Aggregate Concrete

- WCT concrete exhibited the highest aggregate hardness (≈ 550 kgf/mm2) and the narrowest ITZ (~70 μm), due to its sintered ceramic structure and low crushing index. The glazed surface formed a continuous barrier with uniform hardness, while the unglazed surface enhanced local bonding through rough interlock.

- RCA concrete showed moderate microhardness and a multi-layered ITZ structure, reflecting the coexistence of old and new cementitious phases. The relatively denser ITZ3 explains the superior compressive performance of RCA concrete.

- RCB concrete had the lowest microhardness and widest ITZ (~80 μm), attributed to the high porosity and water-retentive nature of brick aggregates, which weakened interfacial compactness.

4. Conclusions

- At the macroscopic level, both apparent density and ultrasonic pulse velocity (UPV) decreased with increasing replacement rates of WCT or RCB, reflecting the influence of aggregate porosity and stiffness on the overall packing density and internal homogeneity of concrete. While the overall trend showed a decrease in density and UPV with increasing replacement, the RCB concrete exhibited a local maximum UPV at 75% replacement, indicating a non-linear relationship between replacement ratio and compactness. WCT concrete exhibited the lowest density reduction (≈5.6% at 100% substitution), while RCB concrete showed the largest (≈7%), owing to its higher water absorption and microstructural heterogeneity. These trends indicate that the internal continuity and compactness of the composite skeleton are governed not only by the intrinsic aggregate density but also by the degree of hydration achieved at the interfacial zones.

- Compressive and splitting tensile strengths followed trends consistent with the UPV results, underscoring the dominant role of the ITZ in load transfer efficiency. For WCT concrete, strength initially increased at a 25% substitution level due to the filler and nucleation effects of fine ceramic particles, which promoted ITZ densification. However, excessive WCT incorporation (≥75%) led to interfacial debonding and brittleness, attributed to the smooth, impermeable surface of the ceramic aggregates that hindered hydration product anchoring. Conversely, RCB replacement improved strength up to 75%, benefiting from its rough, porous surface, which enhanced mechanical interlocking and localized hydration. Beyond this threshold, the low intrinsic strength and weak structure of brick aggregates caused a decline in compressive and tensile strength. These competing effects suggest that mechanical behavior in recycled concretes is controlled more by ITZ microstructure evolution than by the inherent strength of aggregates themselves.

- Vickers microhardness profiling provided direct microstructural evidence for these macroscopic trends. The ITZ between old aggregate and new mortar in RCA concrete exhibited a hardness of 53–57 kgf/mm2 and a width of approximately 60 µm, whereas the ITZs in WCT and RCB concretes showed wider and softer interfacial zones—around 70 µm and 80 µm, respectively. The glazed surface of WCT displayed a dense, high-hardness shell (~550 kgf/mm2) yet formed a weak mechanical bond with the surrounding matrix, while the rough RCB surface promoted more extensive C–S–H formation but increased the ITZ porosity through water release during curing. A strong inverse relationship was established between ITZ width and microhardness, confirming that narrower and denser interfacial zones correspond to superior mechanical properties and higher overall concrete compactness.

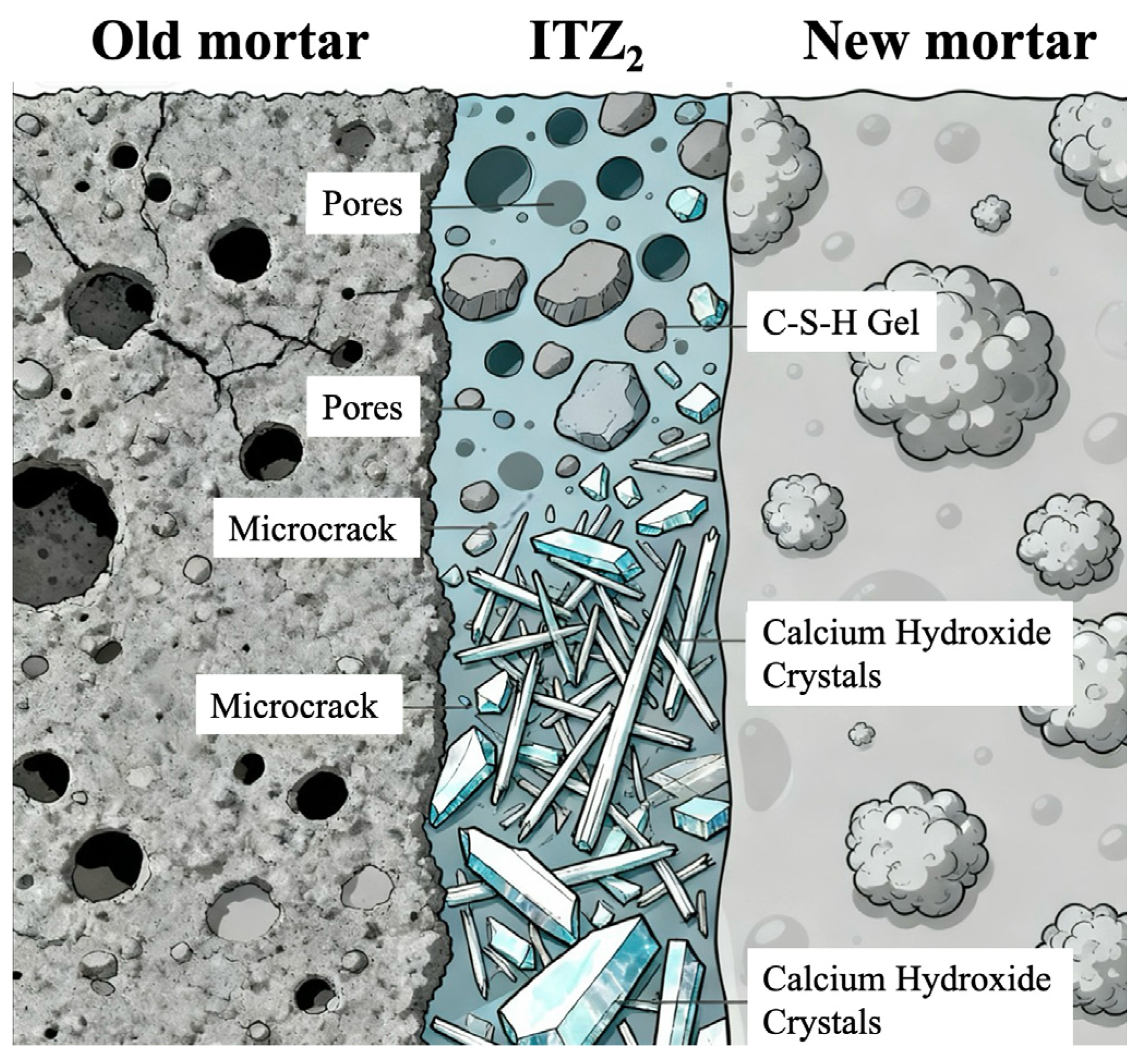

- Comparative analysis of the three ITZ types—old aggregate–old mortar, old mortar–new mortar, and old aggregate–new mortar—further revealed that the weakest bonding occurred at the old–new mortar interface (ITZ2), primarily due to incomplete hydration and water redistribution during mixing. The old aggregate–new mortar interface (ITZ3) benefited from a wall effect that promoted localized precipitation of calcium hydroxide and ettringite, leading to slightly higher hardness and improved bonding. These observations indicate that optimizing interfacial compatibility between recycled and new phases is critical for enhancing mechanical stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yi, Y.; Liu, J.; Cristina Lavagnolo, M.; Manzardo, A. Evaluating the Carbon Emission Reduction in Construction and Demolition Waste Management in China. Energy Build. 2024, 324, 114932. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Wang, J.; Hu, X.; Ran, B.; Wu, T.; Zhou, X.; Xiong, Y. Physical Performance, Durability, and Carbon Emissions of Recycled Cement Concrete and Fully Recycled Concrete. Constr. Build. Mater. 2024, 447, 138128. [Google Scholar] [CrossRef]

- Luo, J.; Huang, R.; Wang, J.; Zhang, Y. Carbon Sequestration by Preparing Recycled Cement, Recycled Aggregates, and Recycled Concrete from Construction and Demolition (C&D) Wastes. Materials 2024, 17, 5020. [Google Scholar] [CrossRef] [PubMed]

- Bao, J.; Li, S.; Zhang, P.; Ding, X.; Xue, S.; Cui, Y.; Zhao, T. Influence of the Incorporation of Recycled Coarse Aggregate on Water Absorption and Chloride Penetration into Concrete. Constr. Build. Mater. 2020, 239, 117845. [Google Scholar] [CrossRef]

- Liu, X.; Wu, J.; Zhao, X.; Yan, P.; Ji, W. Effect of Brick Waste Content on Mechanical Properties of Mixed Recycled Concrete. Constr. Build. Mater. 2021, 292, 123320. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, X.; Liu, H.; Wang, Z.; Chen, C.; Li, H. Recycling of Waste Recycled Aggregate Concrete in Freeze-Thaw Environment and Energy Analysis of Concrete Recycling System. J. Build. Eng. 2024, 96, 110377. [Google Scholar] [CrossRef]

- Danish, P.; Ganesh, S.; Mahajan, A.; Sharma, S. Recycle and Reuse: Demolished Concrete Coarse Aggregate as Partial Replacement in the Conventional Concrete. In Innovative Technologies for Smart and Sustainable Infrastructure; Springer Nature: Cham, Switzerland, 2025; pp. 175–186. ISBN 978-3-031-92800-0. [Google Scholar]

- Sivakumar, A.; Srividhya, S.; Sathiyamoorthy, V.; Seenivasan, M.; Subbarayan, M.R. Impact of Waste Ceramic Tiles as Partial Replacement of Fine and Coarse Aggregate in Concrete. Mater. Today Proc. 2022, 61, 224–231. [Google Scholar] [CrossRef]

- Anderson, D.J.; Smith, S.T.; Au, F.T. Francis Mechanical Properties of Concrete Utilising Waste Ceramic as Coarse Aggregate. Constr. Build. Mater. 2016, 117, 20–28. [Google Scholar] [CrossRef]

- Keshavarz, Z.; Mostofinejad, D. Porcelain and Red Ceramic Wastes Used as Replacements for Coarse Aggregate in Concrete. Constr. Build. Mater. 2019, 195, 218–230. [Google Scholar] [CrossRef]

- Narasimhulu, E.; Munichandu, M.; Keerthi, L.; Lalusab, K.; Reddy, K.P.K.; Pradeep, G.S.; Meghana, N. Enhancing Mechanical Properties of M30 Grade Concrete through Ceramic Waste as Coarse Aggregate Replacement. Appl. Mech. Mater. 2024, 923, 103–107. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with Recycled Concrete Aggregate and Crushed Clay Bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Jie, C.; Yue, G.; Yuyin, W.; Wenjing, S. Basic Mechanical Properties and Stress-Strain Relationship for Recycled Concrete Including Crushed Clay Bricks. J. Build. Struct. 2020, 41, 184–192. [Google Scholar] [CrossRef]

- Chao, Z.; Wentao, Z.; Weihang, Y.; Chao, L. Basic Mechanical Properties and Constitutive Model of Recycled Brick-Concrete Aggregate. Fuhe Cailiao Xuebao 2024, 01, 898. [Google Scholar] [CrossRef]

- Bommisetty, J.; Keertan, T.S.; Ravitheja, A.; Mahendra, K. Effect of Waste Ceramic Tiles as a Part-ial Replacement of Aggregates in Concrete. Mater. Today Proc. 2019, 19, 875–877. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Akinmusuru, J.O.; Dawson, A.R.; Ndambuki, J.M.; Thom, N.H. Microstructural Characteristics, Porosity and Strength Development in Ceramic-Laterized Concrete. Cem. Concr. Compos. 2018, 86, 224–237. [Google Scholar] [CrossRef]

- Yue, G.; Ma, Z.; Liu, M.; Liang, C.; Ba, G. Damage Behavior of the Multiple ITZs in Recycled Aggregate Concrete Subjected to Aggressive Ion Environment. Constr. Build. Mater. 2020, 245, 118419. [Google Scholar] [CrossRef]

- Olofinnade, O.; Ogara, J. Workability, Strength, and Microstructure of High Strength Sustainable Concrete Incorporating Recycled Clay Brick Aggregate and Calcined Clay. Clean. Eng. Technol. 2021, 3, 100123. [Google Scholar] [CrossRef]

- Liu, J.; Ma, K.; Shen, J.; Zhu, J.; Long, G.; Xie, Y.; Liu, B. Influence of Recycled Concrete Aggregate Enhancement Methods on the Change of Microstructure of ITZs in Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 371, 130772. [Google Scholar] [CrossRef]

- GB 175-2020; Sand for Construction. Standards Press of China: Beijing, China, 2020.

- ASTM C150/C150M-20; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2020.

- Yu, Y.; Jayathilakage, R.; Liu, Y.; Hajimohammadi, A. Intelligent compressive strength prediction of sustainable rubberised concrete using an optimised interpretable deep CNN-LSTM model with attention mechanism. Appl. Soft Comput. 2025, 185, 113993. [Google Scholar] [CrossRef]

- ASTM C597-16; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Architecture & Building Press: Beijing, China, 2019.

- Igarashi, S.; Bentur, A.; Mindess, S. Microhardness Testing of Cementitious Materials. Adv. Cem. Based Mater. 1996, 4, 48–57. [Google Scholar] [CrossRef]

- Zhang, Y. Microhardness Evolution Characteristics of the Interface Transition Zone of Coral Aggregate Seawater Concrete under High Temperature. J. Build. Eng. 2024, 98, 111348. [Google Scholar] [CrossRef]

- Yang, Y.; Xiao, Y.; Zhou, W.; Jiskani, I.M.; Luan, B. Strength Analysis of Geopolymer-Rock Interface: Mohr-Coulomb Shear and Interface Tr-ansition Zone (ITZ) Nanoindentation Testing. Constr. Build. Mater. 2025, 458, 139544. [Google Scholar] [CrossRef]

- Tang, Q.; Guo, H.; Zheng, H.; Hou, D.; Wang, M.; Zhang, Y.; Du, Z.; Wang, P. Molecular Insights into Enhancing Bonding and Erosion Resistance in Recycled Aggregate Concrete ITZ through Carbonation. J. Build. Eng. 2025, 110, 113125. [Google Scholar] [CrossRef]

- Wang, L.; Yi, S.; Yu, Y.; Gao, C.; Samali, B. Automated ultrasonic-based diagnosis of concrete compressive damage amidst temperature variations utilizing deep learning. Mech. Syst. Signal Process. 2024, 221, 111719. [Google Scholar] [CrossRef]

- Chen, R.; Mo, K.H.; Ling, T.-C. Offsetting strength loss in concrete via ITZ enhancement: From the perspective of utilizing new alternative aggregate. Cem. Concr. Compos. 2022, 127, 104385. [Google Scholar] [CrossRef]

- GongBing, Y. Study on the Recycled Concrete Multi-Interface Structure and the Damage Mechanism of Performance; Qingdao University of Technology: QingDao, China, 2018. [Google Scholar]

- Yu, Y.; Rashidi, M.; Dorafshan, S.; Samali, B.; Farsangi, E.N.; Yi, S.; Ding, Z. Ground penetrating radar-based automated defect identification of bridge decks: A hybrid approach. J. Civ. Struct. Health Monit. 2025, 15, 521–543. [Google Scholar] [CrossRef]

- Momotaz, H.; Rahman, M.M.; Karim, M.R.; Zhuge, Y.; Ma, X.; Levett, P. Properties of the Interfacial Transition Zone in Rubberised Concrete—An Investigation Using Nano-Indentation and EDS Analysis. J. Build. Eng. 2023, 77, 107405. [Google Scholar] [CrossRef]

- Sang-Yeop, C.; Ji-Su, K. Investigation of Gradient Properties for Cement Mortar Interfacial Transition Zones and Their Effects on Mechanical Characteristics Using Micro-CT. Dev. Built Environ. 2024, 18, 100390. [Google Scholar] [CrossRef]

- Huang, Q.; Qian, Z.; Hu, J.; Zheng, D.; Chen, L.; Zhang, M.; Yu, J. Investigation on the Properties of Aggregate-Mastic Interfacial Transition Zones (ITZs) in Asphalt Mixture Containing Recycled Concrete Aggregate. Constr. Build. Mater. 2021, 269, 121257. [Google Scholar] [CrossRef]

- JiaHua, W. Research on Preparation and Performance of Waste Ceramic Tile Recycled Aggregate Concrete. Master’s Thesis, Hunan University of Science and Technology, Xiangtan, China, 2015. [Google Scholar]

- Li, Y.; Zhang, H.; Liu, G.; Hu, D.; Ma, X. Multi-Scale Study on Mechanical Property and Strength Prediction of Aeolian Sand Concrete. Constr. Build. Mater. 2020, 247, 118538. [Google Scholar] [CrossRef]

- Yu, Y.; Al-Damad, I.M.A.; Foster, S.; Nezhad, A.A.; Hajimohammadi, A. Compressive strength prediction of fly ash/slag-based geopolymer concrete using EBA-optimised chemistry-informed interpretable deep learning model. Dev. Built Environ. 2025, 23, 100736. [Google Scholar] [CrossRef]

| SO3 | MgO | Cl- | Slag | Gypsum | Ignition Loss | Specific Surface Area | Density |

|---|---|---|---|---|---|---|---|

| 2.85% | 2.52% | 0.04% | 12% | 6% | 3.06% | 369 m2/kg | 3.17 g/m3 |

| RCA/WCT/RCB | 4.75 mm | 10 mm | 16 mm | 20 mm |

|---|---|---|---|---|

| Cumulative passing percentage (%) | 100% | 75% | —— | 5% |

| Fractional passing residue (%) | 25% | 70% | —— | 5% |

| Type of Coarse Aggregates | Needle Flake Particle Content Ratio(%) | Ruggedness Coefficient(%) | Crushing Indicator (%) | Apparent Density (kg/m3) | Packing Density (kg/m3) | Water Absorption (%) |

|---|---|---|---|---|---|---|

| RCA | 3 | 7.9 | 16 | 2650 | 1276 | 5.7 |

| WCT | 10 | 5.2 | 7 | 2407 | 1267 | 1.2 |

| RCB | 7 | 10.1 | 29 | 2431 | 980 | 17 |

| Mix ID | RCA | RCB | Cement | Water | RCA | MA | NRS |

|---|---|---|---|---|---|---|---|

| RCA-100 | 100 | 0 | 690 | 345 | 1115.6 | 0 | 628 |

| RCB-25 | 75 | 25 | 690 | 345 | 836.7 | 253.3 | 628 |

| RCB-50 | 50 | 50 | 690 | 345 | 557.9 | 506.7 | 628 |

| RCB-75 | 25 | 75 | 690 | 345 | 278.8 | 760.0 | 628 |

| RCB-100 | 0 | 100 | 690 | 345 | 0 | 1013.3 | 628 |

| WCT-25 | 75 | 25 | 690 | 345 | 836.7 | 253.3 | 628 |

| WCT-50 | 50 | 50 | 690 | 345 | 557.9 | 506.7 | 628 |

| WCT-75 | 25 | 75 | 690 | 345 | 278.8 | 760.0 | 628 |

| WCT-100 | 0 | 100 | 690 | 345 | 0 | 1013.3 | 628 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhang, X.; Cao, X.; Yu, Y. Sustainable Performance and Interfacial Characteristics of Fully Recycled Concrete with Combined Recycled Concrete, Brick, and Ceramic Aggregates. Sustainability 2025, 17, 10503. https://doi.org/10.3390/su172310503

Li C, Zhang X, Cao X, Yu Y. Sustainable Performance and Interfacial Characteristics of Fully Recycled Concrete with Combined Recycled Concrete, Brick, and Ceramic Aggregates. Sustainability. 2025; 17(23):10503. https://doi.org/10.3390/su172310503

Chicago/Turabian StyleLi, Chenxi, Xuetao Zhang, Xuemei Cao, and Yang Yu. 2025. "Sustainable Performance and Interfacial Characteristics of Fully Recycled Concrete with Combined Recycled Concrete, Brick, and Ceramic Aggregates" Sustainability 17, no. 23: 10503. https://doi.org/10.3390/su172310503

APA StyleLi, C., Zhang, X., Cao, X., & Yu, Y. (2025). Sustainable Performance and Interfacial Characteristics of Fully Recycled Concrete with Combined Recycled Concrete, Brick, and Ceramic Aggregates. Sustainability, 17(23), 10503. https://doi.org/10.3390/su172310503