1. Introduction

Denim, a durable and versatile fabric, has retained its relevance since the 17th century. Originally conceived as workwear, it has now become an icon of contemporary fashion [

1]. The growing demand for denim garments has intensified finishing processes, particularly washing, making it one of the most polluting stages in the textile value chain. It is estimated that producing a single pair of jeans may require up to 3781 litres of water, generate 33.4 kg of CO

2, and use approximately 12 m

2 of land [

2,

3].

The use of synthetic indigo, along with reactive dyes and dyeing auxiliaries, produces effluents loaded with toxic substances and microfibres that contaminate water bodies and soils [

4]. These practices, common in wet textile processing, exacerbate the environmental impact, with water consumption representing between 18% and 42% of the total used throughout the production chain [

5,

6]. Furthermore, prolonged exposure to harsh chemical agents poses significant risks to human health and biodiversity [

7,

8,

9].

In this context, sustainability emerges as a strategic axis for the denim industry and is directly linked to the Sustainable Development Goals (SDGs)particularly SDG 6 (Clean Water and Sanitation), SDG 9 (Industry, Innovation and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). The adoption of clean technologies in denim finishing processes has led to measurable improvements environmental performance response and a commitment to global targets for reducing water and carbon footprints, promoting the transition towards a circular economy, and mitigating the effects of climate change.

The circular economy refers to a production model aimed at minimizing waste and maximizing resource efficiency by extending product lifecycles through recycling, reuse, and sustainable design [

10]. Similarly, Life Cycle Assessment (LCA) is a standardized methodological framework (ISO 14040/14044) that quantifies the environmental impacts associated with a product or process throughout its entire lifecycle, from raw material extraction to disposal [

11].

Emerging technologies such as ozone washing, laser fading, enzymatic treatments, and wastewater reuse are positioned as alternatives with a lower ecological footprint [

8,

12,

13]. These innovations aim to significantly reduce the consumption of water, chemicals, and energy, as well as the generation of solid waste, aligning with the principles of circular economy. At the same time, the growing consumer interest in environmental impact has driven greater demand for sustainable denim garments, positioning sustainability as a key element in the transformation of denim finishing processes. As highlighted by Lou and Xu [

14], this trend reflects increased environmental awareness and represents a strategic opportunity for producers and retailers by aligning technological innovation with market expectations.

The effective implementation of sustainable treatments still faces significant challenges. Previous studies have highlighted the lack of comprehensive LCA, limitations in scalability and industrial replicability, and gaps in the measurement of economic and social indicators specific to the textile sector [

15,

16]. Although several reviews have addressed sustainability in textiles, these have typically focused on general processes or isolated technologies, without systematically integrating recent evidence related to denim. This research gap underscores the relevance of conducting an updated and comprehensive analysis that synthesizes the advances, barriers, and opportunities within the sector.

This systematic review addresses a significant research gap by integrating evidence on sustainable denim finishing technologies published between 2020 and 2024, a period of accelerated innovation toward carbon and water footprint reduction. Unlike earlier fragmented studies focused on single processes, this review consolidates findings across environmental, technological, and methodological dimensions.

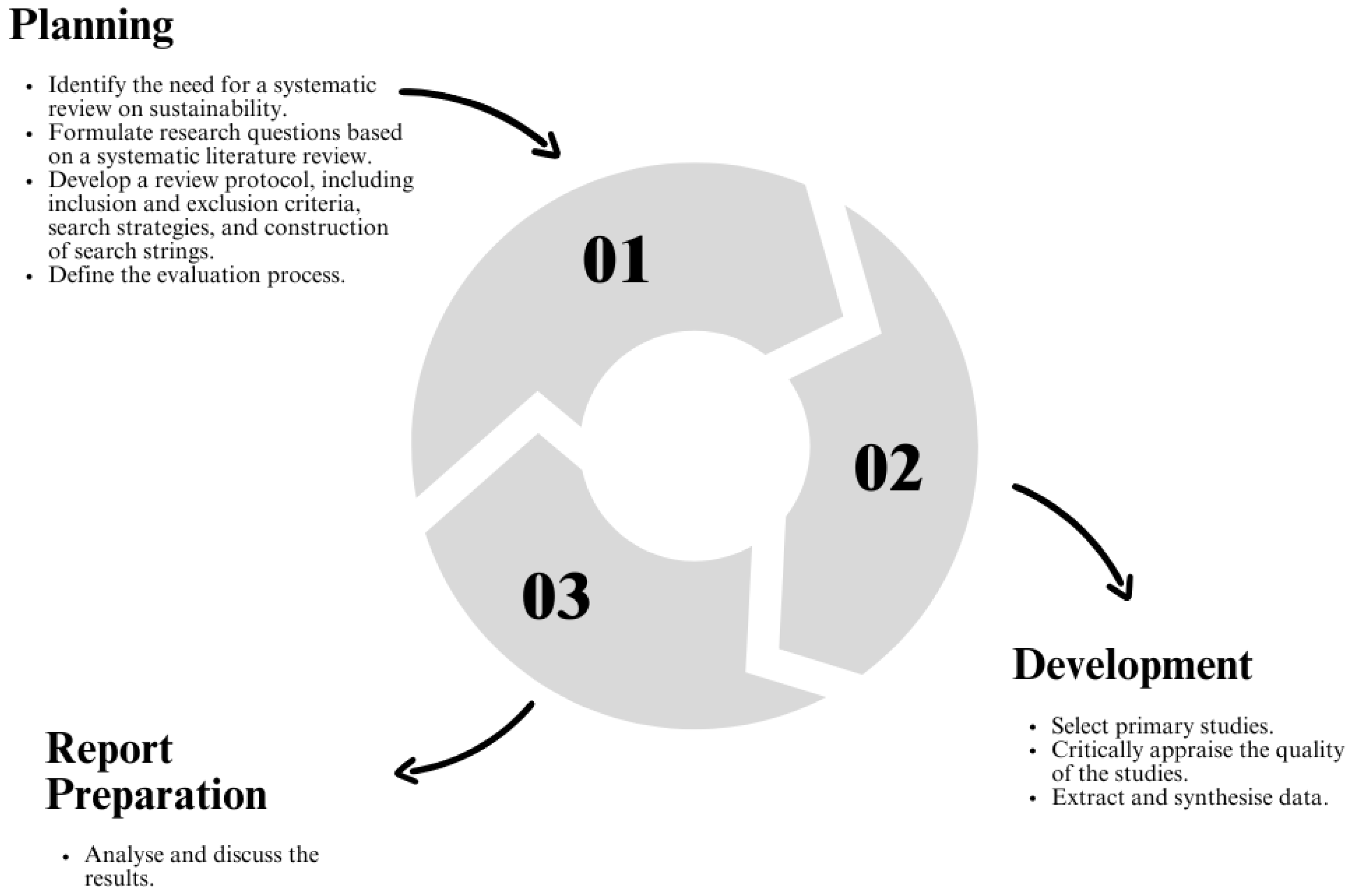

Given this scenario, the present Systematic Literature Review (SLR) aims to critically analyze sustainable treatments applied to denim, their environmental impacts, the methodologies used for their assessment, and the challenges and opportunities identified in the recent literature. To achieve this, studies published in the Scopus (Elsevier B.V., Amsterdam, Netherlands) and Web of Science Core Collection (Clarivate Analytics, Philadelphia, PA, USA) were compiled and examined, with the purpose of providing consolidated evidence that promotes the adoption of cleaner practices in the denim processing and contributes to mitigating its global environmental impact.

3. Results

This section provides the answers to the research questions formulated within the framework of the SLR, based on the analysis of data extracted from the selected studies.

Regarding the first research question (RQ1) What are the emerging sustainable treatments in the denim finishing processes and what evidence exists regarding their effectiveness in reducing specific environmental impacts (e.g., water consumption, carbon emissions, use of chemical products)? the results reveal a clear adoption of clean technologies by denim manufacturers and research institutions seeking to reduce water and chemical consumption

Of the 26 studies analyzed, 10 highlight the use of enzymes as the most frequently reported sustainable treatment, followed by 5 studies that describe the application of laser technology and ozone-based treatments, as well as others that mention alternatives such as pumice stone substitutes. These results are summarized in

Table 5.

It is important to note that the sum of the percentages presented in

Table 5 exceeds 100%. This occurs because a single study may report two or more sustainable treatments, either as complementary (inclusive) strategies or as comparative (exclusive) alternatives. Consequently, the percentages reflect the relative frequency of each treatment mentioned across the total number of articles analyzed, rather than the proportion of unique studies. This approach allows for a more accurate representation of the diversity of strategies documented in the literature.

In terms of environmental effectiveness, 14 studies provide evidence of a significant reduction in water and chemical consumption, directly contributing to the mitigation of the environmental impact associated with the denim finishing process:

Anam et al. [

25] report that ozone-based dyeing methods allow for a substantial reduction in the use of dyes and chemical auxiliaries, thereby contributing to cleaner and more sustainable processes.

Bidart et al. [

33] highlight the use of enzymes and biotechnology in indigo treatment as a more environmentally friendly alternative, reducing CO

2 emissions and minimizing worker exposure to hazardous substances.

Costa et al. [

34] demonstrate that the addition of montmorillonite in the biostoning process enabled the reuse of effluent across different stages, representing an effective strategy for reducing water consumption in the denim industry.

Hasan et al. [

28] base their study on the application of the nebulisation technique, which proved efficient in both energy and water consumption, while also generating less waste and pollution.

Madhu et al. [

35] investigated the application of immobilized cellulase enzymes for the biofinishing of denim fabrics, achieving efficient removal of surface impurities and enhanced colour fading performance. Their findings indicate that this enzymatic process allows denim garments to be reused for up to three finishing cycles while significantly reducing chemical consumption compared to conventional treatments. These results confirm that immobilized enzyme systems offer a practical and environmentally sustainable alternative for denim processing.

Shinde et al. [

44] analyze bleaching of denim fabrics using powder bleach, proposing an environmentally responsible alternative aligned with the concept of Zero Liquid Discharge (ZLD).

Unuofin [

36] explores the implementation of microbial technologies, applying bacterial strains Hb16c and Berl11b2 for the synthesis of fine biochemicals, thereby reducing waste and pollutants derived from bio-based processes.

Zhang et al. [

38] develop an optimized and controlled denim decolourisation process based on horseradish peroxidase with H

2O

2, achieving indigo degradation into low-molecular-weight compounds. The method reduces both chemical use and processing time, establishing itself as a sustainable alternative.

Ivedi and Cay [

45] demonstrate that the use of natural and synthetic materials under low liquor ratio conditions reduces chemical use, energy demand, and CO

2 emissions, highlighting peach kernel and synthetic stones as sustainable substitutes.

Nayak et al. [

27] emphasize the potential of waterless technologies such as laser and ozone treatments, noting that they can achieve up to a 97% reduction in water usage, while also minimizing chemical consumption and contributing to circular fashion.

Rathinamoorthy and Karthik [

43] analyze various stages of denim production, focusing on alternative wastewater treatment practices and demonstrating their effectiveness in reducing environmental pollution.

Samanta et al. [

29] conclude that water-free technologies, such as CO

2 laser fading, provide visual results comparable to conventional methods, while enabling more environmentally friendly production.

Unuofin [

39,

40] assessed the valorization of wheat bran through the production of a laccase enzyme (Jb1b) applied to denim dye decolourisation. Furthermore, effective bleaching using mandarin peel extract produced treated wastewater suitable for agricultural reuse, thereby closing a positive ecological cycle.

Regarding Research Question 2 (RQ2) How does the environmental performance of sustainable treatments compare with conventional denim finishing methods, and which studies have addressed this comparison using metrics such as LCA and carbon footprint? the results indicate that the vast majority of the studies included in the review explicitly address this issue. Of the 26 studies analyzed, 22 conducted a direct comparison between the environmental performance of sustainable and conventional treatments, confirming the growing of comparative environmental assessment in the textile finishing field.

The findings consistently demonstrate, based on comparative analyses, that sustainable treatments outperform conventional processes in key environmental indicators, including water, chemical, and energy use. In most cases, these technologies achieved reductions exceeding 50% in resource consumption and pollutant generation. Among the methods analyzed, enzymatic, ozone-based, and laser treatments were the most extensively validated alternatives, showing measurable improvements in water reuse, energy efficiency, and reduced effluent toxicity.

Table 6 summarizes these comparisons, organizing sustainable treatments according to their reference methods, evaluated metrics, and the implementation of analytical tools such as LCA and carbon footprint assessment. Although most studies evaluate specific parameters (e.g., water use, chemical load, CO

2 emissions), only a limited subset applies a complete life cycle perspective. This methodological gap underscores the need for greater standardization in sustainability assessments to enable comparability and scalability across studies.

Enzymatic treatments exhibit superior performance in reducing chemical oxygen demand (COD) and CO

2 emissions compared to traditional bleaching, primarily due to their lower energy requirements and biodegradability of enzymatic catalysts. Likewise, ozone-based processes achieve notable reductions in water and chemical consumption, up to 60% according to Atav et al. [

50], while maintaining the colour quality of denim fabrics. Laser fading, meanwhile, stands out for its capacity to minimize wastewater discharge and chemical use, making it one of the most promising alternatives for large-scale adoption.

Despite these advances, the limited implementation of full LCA or carbon footprint evaluations suggests that the environmental benefits of these innovations may still be underreported. Comprehensive studies integrating multiple impact categories (e.g., eutrophication, toxicity, and energy footprint) are required to validate these improvements under real industrial conditions. Furthermore, the results highlight that sustainability gains are not only dependent on technological innovation but also on process integration, operator training, and the use of renewable energy sources within production systems.

The sustainable denim finishing technologies consistently demonstrate superior environmental performance relative to conventional treatments. However, the absence of unified methodological frameworks and the predominance of laboratory-scale analyses highlight the need for broader, multi-impact evaluations that can substantiate their long-term environmental benefits and industrial feasibility.

Findings related to research question 3 (RQ3): What are the challenges and limitations reported in the implementation and adoption of sustainable treatments in the denim industry, and how have these been addressed in the scientific literature? (See

Figure 3).

Among the studies analyzed, economic limitations were identified as the main barrier to the adoption of sustainable treatments in the denim industry, representing 22% of all mentions [

25,

26,

28,

29,

31,

32,

33,

34,

37,

38,

39,

41,

43,

44,

45,

46,

47,

48,

51]. This difficulty, referring to the economic barriers hindering the adoption of sustainable technologies, is linked to high investment costs in technology and infrastructure, as well as the limited availability of long-term financing, particularly affecting small- and medium-sized enterprises (SMEs).

Scalability ranked second (21%) [

25,

26,

28,

29,

31,

32,

33,

34,

37,

38,

39,

41,

43,

44,

45,

46,

47,

48,

51], since many sustainable treatments demonstrate positive results at the pilot stage but face significant obstacles when transferred to real industrial environments. These difficulties arise mainly from increased operational costs and the lack of large-scale technical validation.

Other, less frequent barriers with an incidence between 3% and 5% include technological challenges, cultural resistance to innovation, and the absence of clear regulatory frameworks supporting sustainable implementation [

25,

28,

32,

34,

40,

41,

43,

49,

51].

In parallel, the reviewed literature proposes several strategies to overcome these limitations. Among them, technological improvements driven by leading companies stand out (14%) [

25,

26,

28,

29,

31,

32,

33,

34,

37,

38,

41,

44,

47,

48,

49,

51,

52], along with public–private collaboration, process optimization, and the implementation of training programmes (8%) [

25,

26,

29,

35,

43,

45,

48,

51], which strengthen knowledge transfer to the industrial sector. Additionally, 3% of the studies [

23,

33,

41] highlight the importance of clear regulatory policies and government incentives, which are regarded as key instruments to facilitate the transition towards a more sustainable and efficient production model in the denim sector.

With regard to Research Question 4 (RQ4) What methodologies are used to evaluate the environmental impacts of sustainable treatments in denim, and to what extent are these methodologies adequate and consistent for comparison across studies? a notable methodological diversity was observed among the 26 articles analyzed.

Approximately 11.53% of the studies, including those by Bidart et al. [

33], Nergis [

51], and Rathinamoorthy & Karthik [

43], applied LCA as an evaluation tool. However, the remaining 88.45% presented partial or qualitative assessments, and in many cases, the functional unit used was not specified, which limits the comparability of results across studies.

In relation to the adequacy of the methodologies applied to sustainable treatments, it was identified that 16 studies directly implemented specific techniques. Two investigations analyzed ozone-based technologies [

25,

26], while Nayak et al. [

27], Nergis [

51], and Samanta et al. [

29] focused on the application of laser technology. Enzymatic treatments constitute the most widely represented category, with significant contributions found in the works of Atav et al. [

31], Ben Fraj & Jaouachi [

32], Bidart et al. 33], Costa et al. [

34], Madhu [

35], as well as in several studies by Unuofin [

36,

39,

40], Ivedi and Cay [

45], Shinde et al. [

44], and Zhang et al. [

38]. In addition, practices aimed at water recycling were also documented, demonstrating thematic consistency with the sustainability principles that guide these innovations.

However, several limitations were identified in the literature. Among them, the most notable are the scarcity of direct comparisons between sustainable and conventional processes, and the lack of specific primary data related to the denim washing process. The most frequently used indicators include water and energy consumption, effluent pollutant load, and CO2 emissions, which were already addressed in the results of the first research question (RQ1).

Table 7 responds to Research Question 5 (RQ5) What are the main recommendations and priority areas for future research on sustainable denim treatments, based on the trends and gaps identified in the current literature?

From the analysis of the reviewed studies, five key areas were identified that require priority attention in future research. These recommendations emerge from the conceptual, methodological, and applied gaps detected in the literature and aim to guide the development of more effective, scalable, and environmentally sustainable solutions in denim treatment.

4. Discussion

The objective of this SLR was to identify and critically analyze the main sustainable technologies applied to denim finishing, their environmental impacts, implementation barriers, and the gaps in scientific literature. The findings provide a comprehensive overview of the recent advances and the persistent challenges within the sector.

Firstly, it was observed that enzymes constitute the most frequently reported sustainable treatment in the literature, followed by laser- and ozone-based technologies. This trend aligns with the findings of Periyasamy et al. [

53], who highlight biological and oxidative methods as the most promising innovations for sustainable denim finishing. Similarly, Hasan et al. [

28] report that ozone and laser technologies, applied individually or in complementary stages, significantly reduce water and chemical consumption while improving the aesthetic quality of denim fabrics compared with conventional washing methods.

However, some discrepancies were also identified. While most studies emphasize the efficacy of enzymatic treatments, research by Khan and Mondal [

54] warns that inadequate application may negatively affect the mechanical strength of garments. Likewise, although laser technology is considered one of the cleanest and most scalable solutions, some studies report undesirable thermal effects when high power levels are applied [

55]. These results suggest that, although the effectiveness of emerging technologies is evident, further optimization processes are still required to ensure consistent and reproducible large-scale results.

Enzymatic treatments demonstrate notable operational and environmental advantages, particularly in the desizing and decolourisation stages of denim processing [

53,

56,

57]. Beyond their effectiveness, their low energy demand reinforces their viability as an eco-friendly alternative to conventional methods. Similarly, ozone technology has been shown to reduce chemical use and effluent pollutant load by up to 60%, consistent with the findings of Atav et al. [

50] and Powar et al. [

58]. These benefits are further enhanced by shorter processing times and lower water consumption.

In turn, laser fading stands out as one of the cleanest and most scalable technologies, as it maintains the aesthetic and quality characteristics of the final product while significantly reducing CO

2 emissions [

27,

29], findings consistent with those reported by Hung et al. [

59].

Although technological innovations in denim finishing have yielded measurable environmental improvements, several studies continue to report the use of potentially hazardous substances such as potassium permanganate (KMnO

4) [

13,

28]. These compounds, despite being integral to certain bleaching or fading processes, pose ongoing ecological and occupational health risks, reinforcing the need for continued substitution with safer alternatives.

Emerging innovations have also been reported, such as the use of recycled materials (e.g., peach kernel and plastic bottle caps) as sustainable substitutes for pumice stones, thereby promoting the valorization of agro-industrial waste [

30,

45]. Overall, the reviewed studies show reductions exceeding 50% in water and chemical consumption, as well as lower sludge generation, toxic waste, and pollutant emissions, consistent with the findings of Rahaman et al. [

60].

While the use of recycled materials such as plastic bottle caps offers waste-reduction benefits, it may paradoxically contribute to microplastic release during mechanical abrasion. Moreover, the continued reliance on synthetic dyes and high-impact auxiliaries poses challenges to achieving full process circularity, underscoring the need for stricter chemical management and substitution with bio-based alternatives.

Regarding evaluation methodologies, the results indicate that only a minority of studies apply comprehensive approaches such as LCA, while most are limited to isolated parameters such as water use, chemical consumption, or CO2 emissions. Although a considerable number of studies include direct comparisons between sustainable and conventional treatments, most of these analyses are limited to isolated parameters rather than comprehensive evaluations. The scarcity lies not in the quantity of comparative research, but in the methodological depth and consistency across studies, as few employ full life cycle approaches or integrate multiple environmental indicators.

This trend aligns with Watson and Wiedemann [

61], who point out that the textile industry faces methodological constraints in its environmental assessments, as many LCAs omit key impact categories such as eutrophication, acidification, or toxicity due to data inventory gaps and the limited coverage of existing methods. The lack of standardization in system boundaries (cradle-to-gate vs. cradle-to-grave), functional units, and indicators employed hinders comparability between studies, confirming the observations of Sari et al. [

62]. Although the carbon footprint has become a useful comparative indicator, particularly for clean technologies such as laser finishing [

63], there remains a methodological inconsistency that limits the generalization of results.

In terms of implementation challenges, the main barriers identified were economic (22%) and technological scalability (21%). These limitations are consistent with those reported by Periyasamy and Periyasami [

53] and Catarino et al. [

64], who acknowledge that high investment costs, lack of incentives, and difficulties in transferring pilot results to industrial contexts constitute significant obstacles. Cultural and organizational barriers were also detected, including resistance to change and poorly integrated supply chains within the denim finishing sector [

27,

32,

40,

43,

51], as well as fragmented regulations that restrict international investment and process comparability [

25,

41,

45,

49]. These findings are in line with Thatta and Polisetty [

65], who identify persistent structural challenges even within established sustainability frameworks.

To address these limitations, the literature proposes a range of strategies, including the improvement of production processes, the development of technical capacities, and multisectoral collaboration among academia, industry, and government bodies [

25,

29,

35,

43,

45,

48,

51]. Fiscal and regulatory policies aimed at promoting textile circularity are also recommended [

66]. Convergently, recent studies [

46,

67] emphasize the need to close technological and methodological gaps, prioritizing the development of innovations that integrate sustainability from their design phase, such as optimized enzymes, biosurfactants, waterless processes, and digitalisation tools.

Furthermore, the improvement of LCA implementation is highlighted as a critical step, particularly through the use of real data on energy consumption, emissions, and textile-specific inputs, alongside the creation of standardized databases that enable rigorous cross-study comparisons. In line with Ermini et al. [

68], ecodesign, effluent recycling, and waste valorisation emerge as key pathways for achieving a structural transformation of the textile production model.

The findings expand existing literature by providing a consolidated framework that compares the environmental efficiency of sustainable denim treatments and identifies methodological trends in the application of LCA in textile finishing studies.

Finally, from a socio-economic perspective, there remains a strong need to evaluate the economic feasibility of these technologies across different production scales, encompassing both large industries and small and medium-sized enterprises (SMEs) [

69,

70,

71]. Similarly, consumer acceptance remains a largely unexplored area, despite its direct influence on the adoption of sustainable innovations.

5. Conclusions

This SLR provides a critical and up-to-date synthesis of sustainable treatments applied to denim finishing, highlighting both technical advances and persistent limitations in the recent scientific literature.

First, technologies such as enzymes (laccases and celluloses), ozone, laser, nebulization, and the use of recycled materials demonstrate superior environmental performance compared with conventional methods. These innovations achieve reductions of up to 60% in water and chemical consumption, along with significant decreases in CO2 emissions and solid waste generation, positioning themselves as viable alternatives for cleaner production.

Nevertheless, relevant methodological limitations were identified: only 11.53% of the studies employed comprehensive LCA approaches, and the lack of standardization in system boundaries, functional units, and indicators limits comparability among studies. This methodological heterogeneity underscores the urgency of adopting internationally standardized protocols (ISO 14040/14044) and strengthening sector-specific databases with representative primary data.

In terms of industrial implementation, the main barriers identified are economic and technological—notably, high initial investment costs, scalability challenges, and the absence of consistent regulatory frameworks. Added to these are organizational and cultural resistances that slow down large-scale adoption. Overcoming these obstacles requires combined strategies, including regulatory incentives, technical training programmers, multisectoral collaboration, and the development of emerging technologies designed under sustainability principles.

Finally, the findings reveal that the transition towards sustainable denim demands the integration of not only the environmental dimension, but also the economic and social ones. In this regard, future research should focus on assessing the economic feasibility of these technologies at different production scales, as well as analyzing industrial and consumer acceptance dimensions that remain underexplored yet are crucial for the adoption of sustainable innovations.

The structural transformation of the denim finishing sector will depend on the convergence of technological innovation, methodological standardization, and coherent regulatory frameworks, in synergy with active collaboration between academia, industry, and government. Only through this integrated approach will it be possible to consolidate a sustainable, resilient, and SDG-aligned textile production model.