Textile Materials Information for Digital Product Passport Implementation in the Textile and Clothing Ecosystem: A Review on the Role of Raw Fibers in a Substantial Transition

Abstract

1. Introduction

- New textile products must be conceived according to eco-design measures (i.e., fit for circularity, ensuring the uptake of secondary raw materials, boosting the market for sustainable and circular textiles, tackling the use of hazardous chemicals and materials, and facilitating access to reuse and repair by users);

- Provide incentives and support product-as-service models, circular materials, and production processes, and increase transparency through international cooperation;

- Achieve high levels of separate collection of textile waste;

- Increase the sorting, reuse, and recycling of textiles through innovation and encourage industrial applications and regulatory measures (e.g., extended producer responsibility).

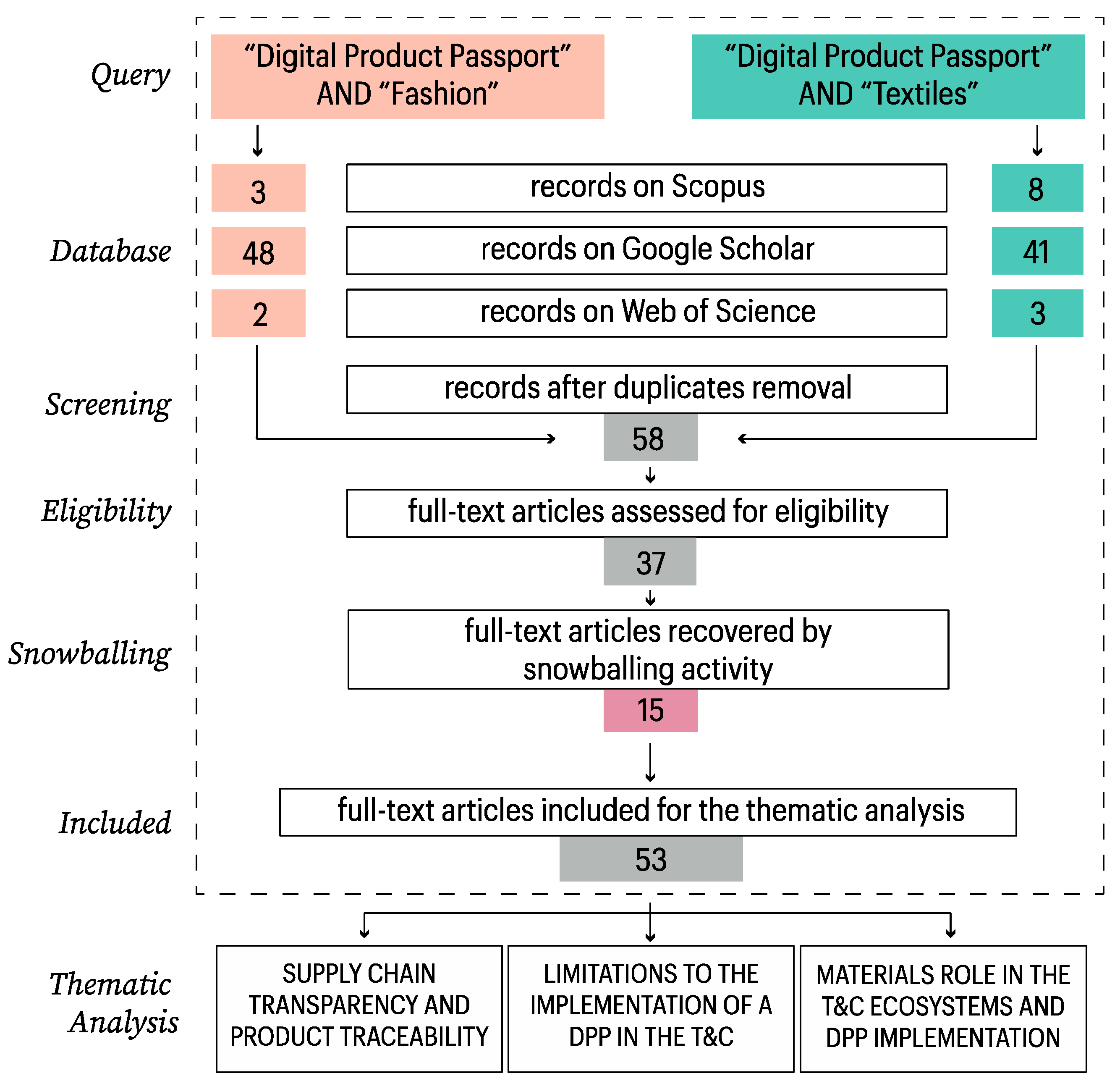

2. Methodology

- Exclusion of student thesis works.

- Exclusion of non-retrievable articles.

- Exclusion of papers describing case studies that are too narrow or have a different focus from the T&C ecosystem (e.g., articles focused solely on fashion trends).

- Exclusion of literature published before 2020 or published in non-institutional journals.

- Supply chain transparency and product traceability in the T&C sector;

- Limitations to the implementation of the DPP as a tool in the T&C sector;

- Materials’ role in the T&C ecosystem and the DPP implementation.

3. Results

- It is necessary to increase transparency in information disclosure to implement technologies such as the DPP and share information along textile supply chains.

- There are some important limitations to the introduction of DPP technologies that have been analyzed in the provided literature.

- The role of materials in T&C ecosystems and DPP implementation is crucial from the perspective of a sustainable transition; therefore, it has been analyzed as a topic to highlight minimum material-related information that should be considered in design and production.

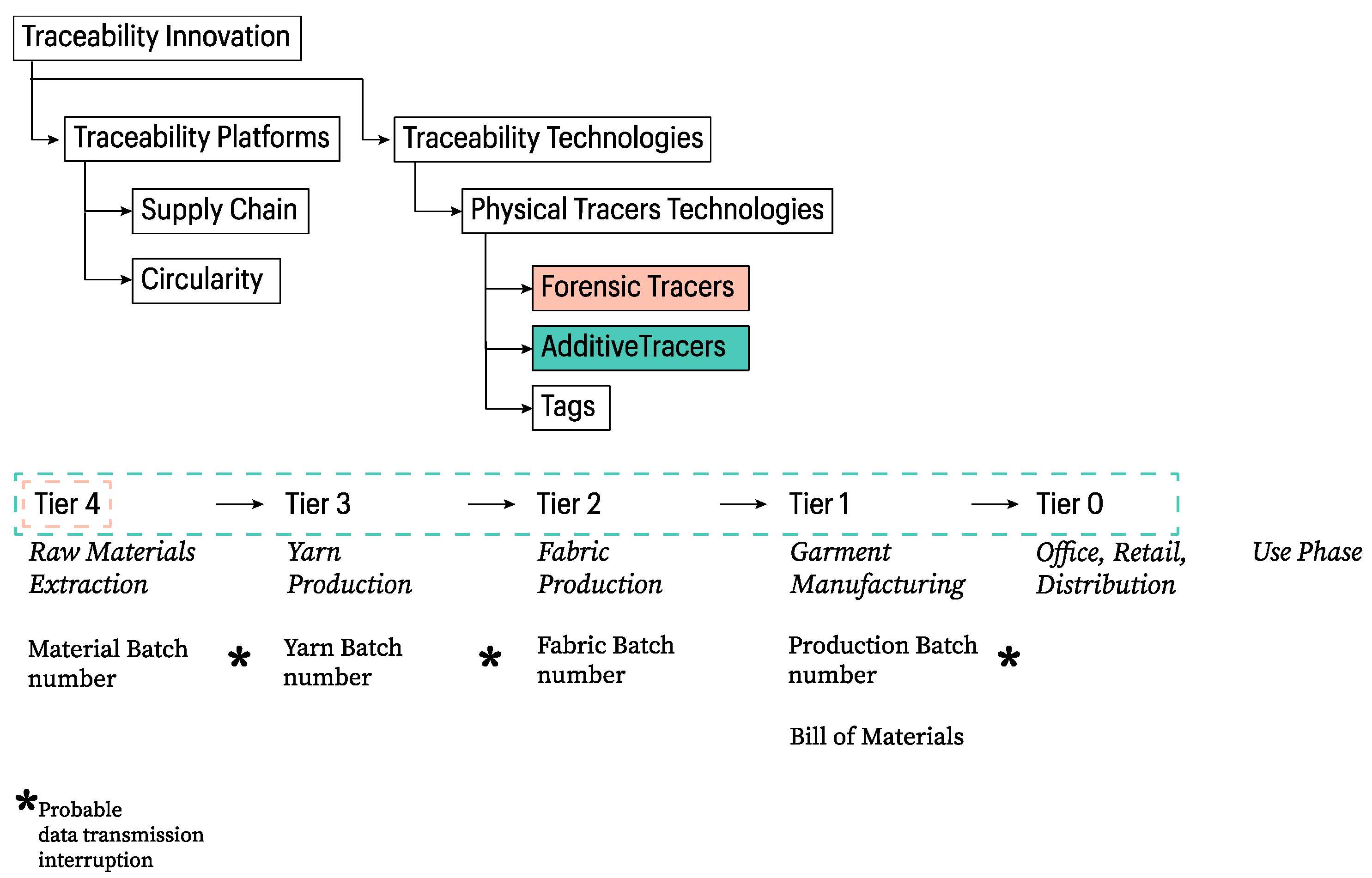

3.1. Supply Chain Transparency and Materials Traceability: The Challenge

3.2. Limitations to the Implementation of a DPP in the T&C

3.2.1. Lack of Standardization

3.2.2. Data Fragmentation and Privacy

3.2.3. Investments in Technology and Employees’ Education

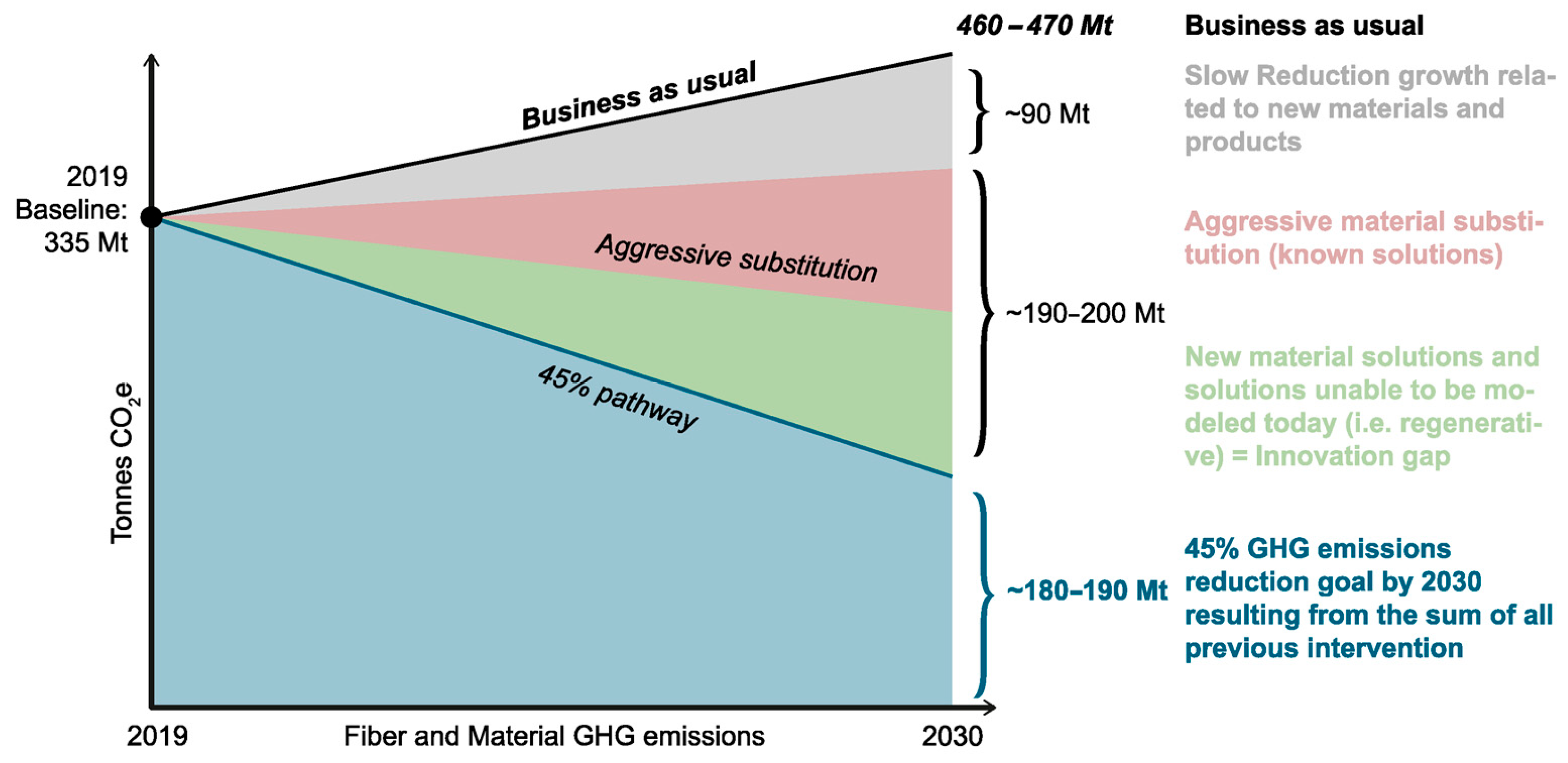

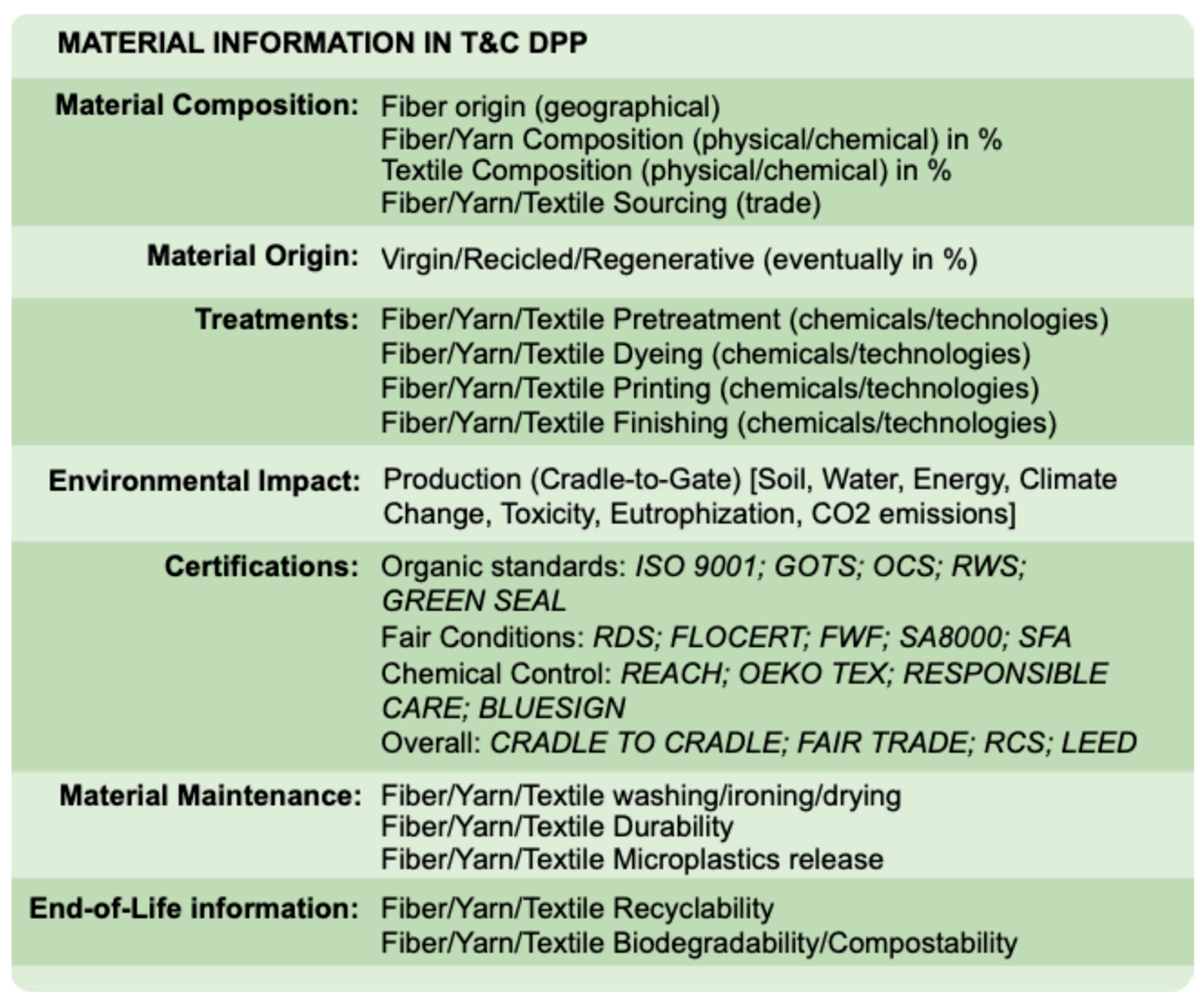

3.3. Materials Role in the T&C Ecosystems and DPP Implementation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. List of Titles Analyzed for the Literature Review

|

References

- European Commission. Textiles Industry Ecosystem Factsheet. Available online: https://single-market-economy.ec.europa.eu/sectors/textiles-ecosystem_en (accessed on 24 October 2024).

- Hörner Bussolo, G.; Bressanelli, G.; Visintin, F.; Saccani, N. Toward the European Union 2030 Strategy for Textiles: A Review. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Chemnitz, Germany, 8–12 September 2024; Springer Nature: Cham, Switzerland, 2024; pp. 382–397. [Google Scholar]

- McKinsey & Company, and Global Fashion Agenda. Fashion on Climate: How the Fashion Industry Can Urgently Act to Reduce Its Greenhouse Gas Emissions. 2020. Available online: https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/fashion%20on%20climate/fashion-on-climate-full-report.pdf (accessed on 24 October 2024).

- European Parliament. The Impact of Textile Production and Waste on the Environment (Infographics). Available online: https://www.europarl.europa.eu/topics/en/article/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographics (accessed on 18 October 2024).

- Global Fashion Agenda; Boston Consulting Group. Pulse of the Fashion Industry 2017. Available online: https://globalfashionagenda.org/resource/pulse-of-the-fashion-industry-2017/ (accessed on 24 October 2024).

- Global Fashion Agenda. Fashion CEO Agenda. Available online: https://globalfashionagenda.org/fashion-ceo-agenda/ (accessed on 24 October 2024).

- Adamkiewicz, J.; Kochańska, E.; Adamkiewicz, I.; Łukasik, R.M. Greenwashing and Sustainable Fashion Industry. Curr. Opin. Green Sustain. Chem. 2022, 38, 100710. [Google Scholar] [CrossRef]

- Global Fashion Agenda. The GFA Monitor. Available online: https://globalfashionagenda.org/the-gfa-monitor/ (accessed on 24 October 2024).

- Jæger, B.; Myrold, S. Textile Industry Circular Supply Chains and Digital Product Passports: Two Case Studies. In Proceedings of the IFIP WG 5.7 International Conference on Advances in Production Management Systems (APMS 2023), Trondheim, Norway, 17–21 September 2023; Springer: Cham, Switzerland, 2023; Volume 692, pp. 350–363. [Google Scholar] [CrossRef]

- Dzhengiz, T.; Haukkala, T.; Sahimaa, O. (Un)Sustainable Transitions towards Fast and Ultra-Fast Fashion. Fashion Text. 2023, 10, 19. [Google Scholar] [CrossRef]

- McKinsey & Company. The State of Fashion 2024 Report. Available online: https://www.mckinsey.com/industries/retail/our-insights/state-of-fashion (accessed on 24 October 2024).

- Poland, E.J. Fashioning Compliance: The Fashion Charter for Climate Action and Strategies for Forming a More Effective Fashion Industry Agreement. Ga. J. Int. Comp. Law 2021, 49, 407–444. [Google Scholar]

- Siliņa, L.; Dāboliņa, I.; Lapkovska, E. Sustainable Textile Industry–Wishful Thinking or the New Norm: A Review. J. Eng. Fiber Fabr. 2024, 19, 15589250231220359. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. COM(2015)0614. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/?uri=CELEX%3A52015DC0614 (accessed on 24 October 2024).

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. COM(2020)0098. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2020%3A98%3AFIN (accessed on 24 October 2024).

- European Commission. EU Strategy for Sustainable and Circular Textiles. COM(2022)0141. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52022DC0141 (accessed on 24 October 2024).

- Publications Office of the European Union. Transition Pathway for the Textiles Ecosystem; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- European Parliament and the Council of the European Union. Directive 2008/98/EC on Waste and Repealing Certain Directives (Waste Framework Directive). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 24 October 2024).

- Nightingale, A. A Guide to Systematic Literature Reviews. Determ. Surg. Effic. 2009, 27, 381–384. [Google Scholar] [CrossRef]

- García-Peñalvo, F.J. Developing Robust State-of-the-Art Reports: Systematic Literature Reviews. Educ. Knowl. Soc. 2022, 23, e28600. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Estarli, M.; Barrera, E.S.A.; et al. Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA-P) 2015 Statement. Syst. Rev. 2015, 4, 148–160. [Google Scholar] [CrossRef]

- Wohlin, C. Guidelines for Snowballing in Systematic Literature Studies and a Replication in Software Engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering, London, UK, 13–14 May 2014; ACM International Conference Proceeding Series. Association for Computing Machinery: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Terry, G.; Hayfield, N.; Clarke, V.; Braun, V. The SAGE Handbook of Qualitative Research in Psychology; SAGE: London, UK, 2017. [Google Scholar] [CrossRef]

- Rukanova, B.D.; Ubacht, J.; Tan, Y.H. Border Crossing and Circular Economy Monitoring in a Global Context: Challenges and Opportunities. In Proceedings of the 25th Annual International Conference on Digital Government Research, Taipei, Taiwan, 11–14 June 2024; ACM International Conference Proceeding Series. Association for Computing Machinery: New York, NY, USA, 2024; pp. 331–340. [Google Scholar] [CrossRef]

- Stridsland, T.; Biørnstad, W.; Vigen, K.; Østergaard, K.L.; Sanderson, H. No-One Left Behind: An Open Access Approach to Estimating the Carbon Footprint of a Danish Clothing Company. J. Clean. Prod. 2023, 426, 139126. [Google Scholar] [CrossRef]

- Brun, A.; Karaosman, H.; Barresi, T. Supply Chain Collaboration for Transparency. Sustainability 2020, 12, 4429. [Google Scholar] [CrossRef]

- da Silva, S.B.G.; Barros, M.V.; Radicchi, J.Â.Z.; Puglieri, F.N.; Piekarski, C.M. Opportunities and Challenges to Increase Circularity in the Product’s Use Phase. Sustain. Futures 2024, 8, 100297. [Google Scholar] [CrossRef]

- Riemens, J.; Lemieux, A.-A.; Lassagne, M.; Lamouri, S. Apprehending Traceability Implementation in Support of Sustainable Value Chains: A Novel Analysis Framework for the Fashion Industry. J. Clean. Prod. 2023, 414, 137501. [Google Scholar] [CrossRef]

- Kumar, V.; Agrawal, T.K.; Wang, L.; Chen, Y. Contribution of Traceability towards Attaining Sustainability in the Textile Sector. Text. Cloth. Sustain. 2017, 3, 5. [Google Scholar] [CrossRef]

- Nosirova, C. Marketing and Production Activities of Textile Companies? Blockchain Technology Study. In Proceedings of the 6th International Conference on Future Networks & Distributed Systems, Tashkent, Uzbekistan, 15–16 December 2022; ACM: New York, NY, USA, 2022; pp. 152–158. [Google Scholar]

- Centobelli, P.; Abbate, S.; Nadeem, S.P.; Garza-Reyes, J.A. Slowing the Fast Fashion Industry: An All-Round Perspective. Curr. Opin. Green Sustain. Chem. 2022, 38, 100684. [Google Scholar] [CrossRef]

- Ospital, P.; Masson, D.H.; Beler, C.; Legardeur, J. Toward Total Traceability and Full Transparency Communication in Textile Industry Supply Chain. INCOSE Int. Symp. 2022, 32, 1–7. [Google Scholar] [CrossRef]

- Keeble, J. Young Consumers Hold the Key to Sustainable Brands. The Guardian, 18 April 2013. Available online: https://www.theguardian.com/sustainable-business/young-consumers-key-sustainable-brands (accessed on 24 October 2024).

- Dragomir, V.D.; Dumitru, M. The State of the Research on Circular Economy in the European Union: A Bibliometric Review. Clean. Waste Syst. 2024, 7, 100127. [Google Scholar] [CrossRef]

- Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79. [Google Scholar] [CrossRef]

- Alves, D.I.; Barreiros, M.; Fangueiro, R.; Ferreira, D.P. Valorization of Textile Waste: Non-Woven Structures and Composites. Front. Environ. Sci. 2024, 12, 1365162. [Google Scholar] [CrossRef]

- Rosado da Cruz, A.; Silva, P.; Serra, S.; Rodrigues, R.; Pinto, P.; Cruz, E. Data Quality Assessment for the Textile and Clothing Value-Chain Digital Product Passport. In Proceedings of the 26th International Conference on Enterprise Information Systems, Angers, France, 28–30 April 2024; Scitepress: Setúbal, Portugal, 2024; pp. 288–295. [Google Scholar]

- Saccani, N.; Bressanelli, G.; Visintin, F. Circular Supply Chain Orchestration to Overcome Circular Economy Challenges: An Empirical Investigation in the Textile and Fashion Industries. Sustain. Prod. Consum. 2023, 35, 469–482. [Google Scholar] [CrossRef]

- Alcayaga, A.; Hansen, E.G. Smart Circular Economy as a Service Business Model: An Activity System Framework and Research Agenda. RD Manag. 2024, 55, 508–530. [Google Scholar] [CrossRef]

- Fashion Revolution. Fashion Transparency Index. Available online: https://www.fashionrevolution.org/fashion-transparency-index/ (accessed on 5 November 2024).

- Crowley, J.; Rademan, K.; Tan, E. The Textile Tracer Assessment. Fashion for Good Reports; Fashion for Good: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Fashion for Good. Fashion for Good Resource Library. Available online: https://reports.fashionforgood.com/report/textile-tracer/ (accessed on 5 November 2024).

- Bułkowska, K.; Zielińska, M.; Bułkowski, M. Implementation of Blockchain Technology in Waste Management. Energies 2023, 16, 7742. [Google Scholar] [CrossRef]

- Voulgaridis, K.; Lagkas, T.; Angelopoulos, C.M.; Boulogeorgos, A.A.A.; Argyriou, V.; Sarigiannidis, P. Digital Product Passports as Enablers of Digital Circular Economy: A Framework Based on Technological Perspective. Telecommun. Syst. 2024, 85, 699–715. [Google Scholar] [CrossRef]

- Hassan, R.; Acerbi, F.; Rosa, P.; Terzi, S. The Role of Digital Technologies in the Circular Transition of the Textile Sector. J. Text. Inst. 2024, 1–14. [Google Scholar] [CrossRef]

- Farmakis, T.; Koukopoulos, A.; Zois, G.; Mourtos, I.; Lounis, S.; Kalaboukas, K. Developing a Circular and Resilient Information System: A Design Science Approach. In Towards a Resilient and Circular Economy; Springer: Cham, Switzerland, 2024; pp. 64–79. [Google Scholar] [CrossRef]

- Zhang, A.; Seuring, S. Digital Product Passport for Sustainable and Circular Supply Chain Management: A Structured Review of Use Cases. Int. J. Logist. Res. Appl. 2024, 27, 2513–2540. [Google Scholar] [CrossRef]

- Berna-Martinez, J.V.; Macia-Perez, F. Overcoming Resistance to Change in Business Innovation Processes. Int. J. Eng. Technol. 2012, 4, 148. [Google Scholar]

- Hawkins, F. How Will Better Data (and Better Use of Data) Enable Us to Save the Planet? PLoS Biol. 2024, 22, e3002689. [Google Scholar] [CrossRef] [PubMed]

- Jansen, M.; Gerstenberger, B.; Bitter-Krahe, J.; Berg, H.; Sebestyén, J.; Schneider, J.; Jansen, M.; Berg, J. Current Approaches to the Digital Product Passport for a Circular Economy: An Overview of Projects and Initiatives; Wuppertal Institute: Wuppertal, Germany, 2024. [Google Scholar]

- Rukanova, B.; Lennartz, J.; Agahari, W.; Schmid, J.; Ubacht, J.; Tan, Y.H.; Rietveld, E.; Chirvasuta, T. What to Monitor? In Search for High-Level Concepts for Circular Economy and Sustainability Monitoring; Tilburg University, School of Economics and Management: Tilburg, The Netherlands, 2024. [Google Scholar]

- Alves, L.; Sá, M.; Cruz, E.F.; Alves, T.; Alves, M.; Oliveira, J.; Santos, M.; Rosado da Cruz, A.M. A Traceability Platform for Monitoring Environmental and Social Sustainability in the Textile and Clothing Value Chain: Towards a Digital Passport for Textiles and Clothing. Sustainability 2024, 16, 82. [Google Scholar] [CrossRef]

- Haupt, J.; Cerdas, F.; Herrmann, C. Derivation of Requirements for Life Cycle Assessment-Related Information to Be Integrated in Digital Battery Passports. Procedia CIRP 2024, 122, 300–305. [Google Scholar] [CrossRef]

- Massa, S.; Annosi, M.C.; Marchegiani, L.; Messeni Petruzzelli, A. Digital Technologies and Knowledge Processes: New Emerging Strategies in International Business. A Systematic Literature Review. J. Knowl. Manag. 2023, 27, 330–387. [Google Scholar] [CrossRef]

- Montag, L. Roadmap to a Circular Economy by 2030: A Comparative Review of Circular Business Model Visions in Germany and Japan. Sustainability 2023, 15, 5374. [Google Scholar] [CrossRef]

- Apel, C.; Kümmerer, K.; Sudheshwar, A.; Nowack, B.; Som, C.; Colin, C.; Walter, L.; Breukelaar, J.; Meeus, M.; Ildefonso, B.; et al. Safe-and-Sustainable-by-Design: State of the Art Approaches and Lessons Learned from Value Chain Perspectives. Curr. Opin. Green Sustain. Chem. 2024, 45, 100876. [Google Scholar] [CrossRef]

- European Commission: Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs. Transition Pathway for the Textiles Ecosystem; Publications Office of the European Union: Alicante, Spain, 2023; Available online: https://data.europa.eu/doi/10.2873/86186 (accessed on 24 October 2024).

- Mügge, J.; Seegrün, A.; Hoyer, T.K.; Riedelsheimer, T.; Lindow, K. Digital Twins within the Circular Economy: Literature Review and Concept Presentation. Sustainability 2024, 16, 2748. [Google Scholar] [CrossRef]

- Lanz, I.E.; Laborda, E.; Chaine, C.; Blecua, M. A Mapping of Textile Waste Recycling Technologies in Europe and Spain. Textiles 2024, 4, 359–390. [Google Scholar] [CrossRef]

- Medina, C.; Samarina, T.; Tervonen, A.; Laatikainen, O. Post-Consumer Textile Recycling: Challenges and Opportunities, Northern Periphery and Arctic Communities’ Perspective. In Proceedings of the World Congress on New Technologies, Barcelona, Spain, 25–27 August 2024. [Google Scholar] [CrossRef]

- Charter, M.; Sanchez-Moreno, L. Global Policy Covering Sustainability in Fashion and Clothing: A Review and Implications. In Accelerating Sustainability in Fashion, Clothing and Textiles; Routledge: Abingdon, UK, 2023; pp. 55–76. [Google Scholar]

- Pavko Čuden, A. Knitting towards Sustainability, Circular Economy and Industry 4.0. Appl. Res. 2023, 2, e202200087. [Google Scholar] [CrossRef]

- Ospital, P.; Masson, D.; Beler, C.; Legardeur, J. Toward Product Transparency: Communicating Traceability Information to Consumers. Int. J. Fash. Des. Technol. Educ. 2023, 16, 186–197. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Periyasami, S. Rise of Digital Fashion and Metaverse: Influence on Sustainability. Digit. Econ. Sustain. Dev. 2023, 1, 16. [Google Scholar] [CrossRef]

- Apel, C.; Sudheshwar, A.; Kümmerer, K.; Nowack, B.; Midander, K.; Strömberg, E.; Soeteman-Hernández, L.G. Safe-and-Sustainable-by-Design Roadmap: Identifying Research, Competencies, and Knowledge Sharing Needs. RSC Sustain. 2024, 2, 2833–2838. [Google Scholar] [CrossRef]

- Azam, F.; Ahmad, F.; Ahmad, S.; Haji, A.d. Sustainable Raw Materials; Springer Nature: Cham, Switzerland, 2023; pp. 59–128. [Google Scholar]

- Islam, S. Sustainable Raw Materials. In Sustainable Technologies for Fashion and Textiles; Elsevier: Amsterdam, The Netherlands, 2020; pp. 343–357. [Google Scholar]

- Fermeglia, M. Recent Developments in EU Environmental Policy and Legislation. J. Eur. Environ. Plan. Law 2023, 20, 373–381. [Google Scholar] [CrossRef]

- Mazzitelli, M.; Papile, F.; Del Curto, B. Materials Selection and Fashion Design: Strengthening Reflections on Fibre’s Nature in Fibres and Textiles Selection. Discov. Sustain. 2024, 5, 1–17. [Google Scholar] [CrossRef]

- Sandvik, I.M.; Stubbs, W. Circular Fashion Supply Chain through Textile-to-Textile Recycling. J. Fash. Mark. Manag. Int. J. 2019, 23, 366–381. [Google Scholar] [CrossRef]

- Sá, M.; Guise, C.; Costa, F.; Rodrigues, P.; Oliveira, J.; Barros, A.; Silva, R.; Alves, T.; Santos, M.; da Cruz, A.M.R.; et al. STVgoDigital: A Digital Product Passport Solution. In Communications in Computer and Information Science; Springer: Cham, Switzerland, 2024; Volume 1937, pp. 368–376. [Google Scholar] [CrossRef]

- Licence to Greenwash: How Certification Schemes and Voluntary Initiatives Are Fuelling Fossil Fashion-Changing Markets. Available online: https://changingmarkets.org/report/licence-to-greenwash-how-certification-schemes-and-voluntary-initiatives-are-fuelling-fossil-fashion/ (accessed on 12 November 2024).

- Papile, F.; Del Curto, B. Material Selection to Reinforce Circular Economy Trajectories in Industrial Companies: The O.S.M.O.S.I.S. Methodology. In For Nature/with Nature: New Sustainable Design Scenarios; Springer: Cham, Switzerland, 2024; pp. 335–355. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

| Objectives [The Strategy aims to create a greener, more competitive sector that is more resistant to global shocks.] | Actions [The Strategy lays out a forward-looking set of actions.] | Implementation |

|---|---|---|

| All textile products placed on the EU market are durable, repairable and recyclable, to a great extent made of recycled fibres, free of hazardous substances, produced in respect of social rights and the environment | Set design requirements for textiles to make them last longer, easier to repair and recycle, as well as requirements on minimum recycled content | The Ecodesign for Sustainable Products Regulation, proposed in 2022, creates a framework to set ecodesign requirements for products, including textiles. |

| ”fast fashion is out of fashion” and consumers benefit longer from high quality affordable textiles | Introduce clearer information and a Digital Product Passport | The Empowering Consumers in the Green Transition Directive and Green Claims Directive, proposed in 2022 and 2023, aim to tackle greenwashing. |

| profitable re-use and repair services are widely available | Reverse overproduction and overconsumption, and discourage the destruction of unsold or returned textiles | The “Reset the Trend” campaign (#ReFashionNow) was launched in 2023 to raise awareness about sustainable fashion. |

| the textiles sector is competitive, resilient and innovative with producers taking responsibility for their products along the value chain with sufficient capacities for recycling and minimal incineration and landfilling | Address the unintentional release of microplastics from synthetic textiles | The Waste Shipment Regulation, proposed in 2021, will help restrict the export of textile waste. |

| Tackle greenwashing to empower consumers and raise awareness about sustainable fashion | Transition Pathway for the Textiles Ecosystem, published in 2023,and the European Circular Economy Stakeholder Platform (since 2018) promote and foster cooperation between industry, public authorities, social partners and other stakeholders. | |

| Introduce mandatory and harmonised Extender Producer Responsibility rules for textiles in all Member States and incentivise producers to design products that are more sustainable | Calls have been launched under Horizon Europe to further develop technologies and processes increasing the circularity and sustainability of the textiles sector. | |

| Restrict the export of textile waste and promote sustainable textiles globally | In 2023 the Commission proposed a revision to the Waste Framework Directive to introduce mandatory and harmonised Extended Producer Responsibility (EPR) schemes for textiles in all EU Member States. | |

| Incentivise circular business models, including reuse and repair sectors | In 2023 the Commission launched a plan to update and revise the Textile Labelling Regulation. | |

| Encourage companies and Member States to support the objectives of the Strategy |

| Company/ Entity | Type of DPP | Key Features |

|---|---|---|

| Nobody’s Child | QR code pilot via Fabacus | Fiber-to-finish traceability; Tier 5 (raw material) transparency; ~110 data points per product; boosts consumer trust and supports circular fashion. |

| Tammam | Blockchain-based DPP (ESA collection) | Fiber-to-finish tracking; blockchain ensures data security and sustainability claims. |

| Bon+Berg | Public blockchain DPP (Polygon) via PicoNext | Immutable environmental data; long-term traceability even if brand ownership changes. |

| The Morphbag | Cloud-based QR DPP (future migration to blockchain declared) | Tracks vegan certifications, audits, and social impact (tree planting, charitable donations). |

| PANGAIA | ReWear Digital ID with QR (via EON) | Full lifecycle visibility; resale support; optimized for longevity and reuse. |

| LVMH | DPP via Aura Blockchain Consortium | Tracks authenticity, material origin, and full product history (used by Louis Vuitton, Bulgari, etc.). |

| Circular.fashion | Plug-and-play DPP tools | Helps fashion brands integrate circular design principles and create interoperable DPPs. |

| Kappahl & Marimekko | QR-based DPP pilot via Trace4Value | Over 3000 garments equipped with QR codes; supports interoperability, value chain visibility, and EU compliance. |

| Certilogo (partner brands) | Interactive DPP platform for luxury brands | Enhances consumer interaction; supports authentication, anti-counterfeiting, and resale (used by Giorgio Armani, Diesel, etc.). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papile, F.; Del Curto, B. Textile Materials Information for Digital Product Passport Implementation in the Textile and Clothing Ecosystem: A Review on the Role of Raw Fibers in a Substantial Transition. Sustainability 2025, 17, 8804. https://doi.org/10.3390/su17198804

Papile F, Del Curto B. Textile Materials Information for Digital Product Passport Implementation in the Textile and Clothing Ecosystem: A Review on the Role of Raw Fibers in a Substantial Transition. Sustainability. 2025; 17(19):8804. https://doi.org/10.3390/su17198804

Chicago/Turabian StylePapile, Flavia, and Barbara Del Curto. 2025. "Textile Materials Information for Digital Product Passport Implementation in the Textile and Clothing Ecosystem: A Review on the Role of Raw Fibers in a Substantial Transition" Sustainability 17, no. 19: 8804. https://doi.org/10.3390/su17198804

APA StylePapile, F., & Del Curto, B. (2025). Textile Materials Information for Digital Product Passport Implementation in the Textile and Clothing Ecosystem: A Review on the Role of Raw Fibers in a Substantial Transition. Sustainability, 17(19), 8804. https://doi.org/10.3390/su17198804