1. Introduction

The construction industry remains one of the largest contributors to global environmental impacts. It is responsible for around 40% of global waste generation and 30% of raw materials consumption [

1]. In terms of emissions and energy use, the sector accounted for 21% of global greenhouse gas (GHG) emissions, 34% of total energy demand, and 37% energy and process-related CO2 emissions [

2]. These figures highlight the urgent need to adopt more sustainable and circular approaches in construction.

Mass Timber construction (MTC), which uses engineered wood products such as cross-laminated timber (CLT) and glue-laminated timber (GLT or glulam), is gaining increasing recognition as a sustainable alternative to conventional building materials [

3,

4,

5]. Although traditional wood construction has historically been limited by concerns over strength and fire resistance, mass timber (MT) products offer performance comparable to steel and concrete, while significantly reducing environmental impacts [

3,

4,

5,

6]. As a result, MT is attracting growing attention, with an increasing number of projects worldwide showcasing its potential [

7]. The MT industry is projected to grow at an annual rate of 15.5% in North America by 2032 [

8].

From an environmental perspective, wood is a renewable and sustainable resource that not only reduces emissions during production but also sequesters carbon throughout its life cycle [

3]. Previous life cycle assessment (LCA) studies have consistently shown that MT alternatives could achieve significantly lower carbon footprints compared to their concrete and steel counterparts. For example, Himes and Busby [

9] estimated that substituting conventional building materials such as reinforced concrete with MT can reduce greenhouse gas emissions by 69% during the construction phase, based on an analysis of 18 paired case studies spanning four continents. In addition, Kumar et al. [

10] found that MT alternatives in multistory residential buildings achieved reductions in global warming potential (GWP) of 81 to 94% relative to concrete buildings and 76 to 91% relative to steel buildings. In another study, Gu et al. [

11] quantified the carbon benefits of MT, including the avoided carbon emissions from replacing carbon-intensive materials such as steel and concrete, as well as the additional carbon stored in the timber products themselves. These benefits of MT can be substantial, with an estimated average of 0.38 tons of CO

2 per square meter of floor space.

In addition to reducing the carbon footprint, the adoption of MT also contributes to advancing the circular economy (CE) in the construction sector. CE emphasizes strategies such as waste reduction, reuse, and recycling to enhance resource efficiency, and ultimately fosters a paradigm shift away from the traditional linear economic model of “take-make-dispose” towards a regenerative and sustainable system [

12,

13]. MT aligns with CE principles in several ways [

6,

14,

15]. Its prefabrication and modular nature help reduce waste. With design for disassembly, adaptability, and durability, MT buildings can be taken apart, reconfigured, modified, or extended rather than simply demolished. In addition, MT components have the potential to serve as secondary materials, helping to divert waste from landfills and keep resources circulating within the built environment. A recent case study in Quebec [

15] demonstrated that a six-story MT building could substantially enhance circularity at the end of its life. Specifically, increasing material recycling and reuse by 20% each could significantly reduce global warming and resource-depletion impacts, and long-term strategies involving greater reuse and design-for-disassembly could further advance system circularity. Overall, adopting MT as a primary building material holds significant potential for contributing to a more sustainable and resilient built environment. Despite these advantages and promising developments, MT has not yet been widely adopted in the U.S., largely due to a perceived lack of awareness, knowledge, and uncertainty about associated risks among industry professionals and the public [

16,

17,

18,

19,

20]. Recent changes, such as the 2021 update to the International Building Code (IBC), which allows MT buildings up to 18 stories, are helping to build momentum [

21]. As familiarity with the material increases, MT is expected to play a larger role in sustainable construction.

While much of the existing research has centered on the environmental and structural benefits of MT, its social sustainability implications are underexplored. Specifically, occupational safety is an important aspect of social sustainability in the construction industry [

22,

23,

24]. Previous studies suggest that MT projects involve different construction methods and risks compared to traditional materials [

25], but little is known about how safety professionals perceive, experience, and manage these risks. Understanding these perspectives is critical, as they directly influence safety planning and on-site practices and can also guide decision-makers in evaluating whether MT offers “safer and healthier” alternatives from the standpoint of constructors.

Recent scholarly work further highlights the need to expand MT research beyond the environmental and structural domains. Kremer et al. [

6] conducted a 10-year systematic review mapping the evolution of MT research across design/engineering, codes and regulations, supply chains, and delivery models. They also recommended new design and construction practices to close the gap between research and industry adoption, highlighting the relevance of MT safety research. In parallel, project-level carbon accounting continues to clarify MT’s climate value. A recent case study by Chapagain and Crovella [

5] quantifies both embodied carbon and biogenic carbon storage, illustrating how structural system choices influence whole-building carbon. This environmental factor increasingly interacts with owner and regulator expectations regarding MT risk, performance, and, ultimately, jobsite practices. As the environmental and regulatory performance of MT becomes increasingly central to its acceptance, these developments highlight the importance of also addressing social sustainability factors such as occupational safety. Building on this need, this study aims to gather insights from construction safety professionals in the U.S. regarding their perceptions and experiences with MTC. In doing so, the study contributes to the body of knowledge by addressing occupational safety within the context of MT, a rapidly growing but underexplored research area. It also offers practical contributions by identifying safety risks associated with MT construction and highlighting best practices for enhancing safety on MT job sites. This information can be especially useful for owners, design teams, and contractors who are already working with MT or are considering entering the field.

2. Literature Review

2.1. MT Overview

MT refers to a class of engineered wood products designed for structural applications in building construction [

4,

6]. It can be classified into two main categories based on the bonding mechanism [

19]. Glued MT is manufactured by bonding smaller, dimensioned pieces of lumber with adhesives to form products such as CLT, GLT, and laminated veneer lumber (LVL). Non-glued MT refers to products constructed with mechanical fasteners such as dowels or nails, including dowel-laminated timber (DLT), nail-laminated timber (NLT), and cross nail-laminated timber (CNLT), and interlocking cross-laminated timber (ICLT). Each type has distinct advantages and limitations that make it suitable for different applications. For example, CLT offers high-dimensional stability, strength, and stiffness, making it well-suited for large floors, walls, and roof elements. However, its manufacturing costs are generally higher than those of mechanically fastened MT products such as NLT, as its production process requires dedicated manufacturing facilities and specialized equipment [

4]. Of the available options, CLT and GLT are the two common MT products [

26], and they have been applied in a broad spectrum of projects, including residential, commercial, institutional, and public buildings [

19].

CLT and other MT products were first developed in Europe during the 1990s [

27] and have gained traction since 2005 in Europe, the United States, and Australia, with manufacturing capacity expanding rapidly [

6]. This growth is primarily driven by increasing global concerns regarding sustainability and climate change due to the environmental impacts of conventional construction methods that rely on steel and concrete, as well as the rising worldwide demand for new housing and infrastructure [

19].

2.2. MTC vs. Conventional Construction

Besides the long-term reduced environmental impact mentioned previously, existing studies have shown numerous advantages of MTC over traditional construction methods, such as using concrete and steel. One primary advantage of MT products lies in their prefabricated nature, which has been found to shorten construction time through off-site manufacturing and reduced on-site assembly requirements [

28]. As MT panels are fabricated in controlled factory settings, and sitework and foundations can be completed concurrently, the overall project timeline can be reduced [

25]. In contrast to traditional on-site construction, where site preparation, foundation work, and structural assembly are performed sequentially, the ability to execute these processes in parallel with MT construction helps mitigate the scheduling delays inherent in conventional methods [

25]. Existing studies consistently report schedule reductions associated with MTC, whether based on surveys capturing constructors’ perceptions [

18], case study analyses alone [

29], or mixed-method investigations involving interviews, surveys, and case studies with various stakeholders [

25].

Additionally, the use of MT materials only requires a small workforce for the installation and erection process [

18,

25]. For example, an eight-story MT apartment building in London was constructed with a team of four skilled workers and one supervisor, while a ten-story MT apartment building in Melbourne required only five workers and one supervisor during the construction phase [

4]. The small on-site crew required during construction contributes to lower labor costs in MTC. Furthermore, studies have also shown that timber buildings are lighter, resulting in reduced foundation requirements and consequently lower costs associated with earthworks and foundation construction [

25].

Despite these cost advantages, the overall cost benefits of MT projects remain inconclusive, with previous studies reporting mixed findings. For instance, when evaluating the cost performance of mid-rise MT buildings compared with concrete buildings in Australia, cost analyses have shown that MTC can achieve cost savings. These savings primarily result from reduced finish work and shorter construction durations [

30]. In contrast, a life-cycle cost analysis with a 60-year study period, which included operation and maintenance phases of a high-rise MT building in the Pacific Northwest region of the U.S., found that the MT option was 9.6% more expensive than an equivalent concrete building [

31]. This difference was mainly attributed to the higher upfront construction costs associated with MT materials. The authors of that study also noted that the use of CLT was in its early stages at the time and was considered a specialized product with higher costs. In addition, a study focused solely on the construction cost of an 18-story hybrid MT building in Canada found a 6.43% increase compared with the modeled cost of the same building constructed with concrete [

32].

Moreover, prefabrication also reduces reliance on heavy on-site machinery, which in turn decreases the generation of construction waste, noise, and dust [

3], supporting the environmental benefits of MTC. The lighter weight of timber compared to concrete and steel is likely to lessen the physical effort required from construction workers. In addition, studies have shown improved productivity and efficiency with MTC, particularly when prefabrication is integrated with digital coordination. For instance, Kasbar et al. [

33] assessed the construction productivity of an 18-story MT building in Canada and found significantly increased labor productivity, as well as a 50% reduction in on-site installation time for the MT structure and envelope system. These improvements were largely attributed to repetitive floor layouts and consistent connection details, which shortened installation times as crews became more familiar with the process.

2.3. Safety in MT Projects

Beyond its potential advantages in cost, schedule, and efficiency, MTC may also influence construction worker safety and health outcomes. A preliminary search was conducted from June to September 2025 to obtain a clearer understanding of the current state of safety research on MTC and to verify the novelty of the present study. The search was carried out in Web of Science using the Topic field (i.e., title, abstract, keywords) with the following query: “mass timber construction” OR “CLT construction” OR “Cross-laminated timber construction” OR “Glue-laminated timber construction” OR “GLT construction” OR “glulam construction” AND safety.

The preliminary search yielded 21 results. Most prior research studies examined safety in relation to fire (48%), moisture (29%), acoustics (10%), smoke (5%), structural vibrations (5%), and seismic performance (5%), with only one study addressing installer health in CLT connections [

34]. However, this study primarily focused on the development of a BIM and simulation-based tool to assess the potential risk of hand–arm vibration syndrome (HAVS) among installers, rather than addressing the broader scope of worker safety and health issues.

Beyond the studies identified in the preliminary search, a small number of prior MTC studies have also addressed worker safety, often only briefly, as their primary focus was on cost, schedule, sustainability, structural performance, or seismic behavior. For example, Smith et al. [

25] analyzed 18 case studies of MTC projects worldwide, gathering qualitative data for each case through literature sources and stakeholder questionnaires. The qualitative findings indicated that stakeholders generally viewed increased safety as one of the advantages of MTC. In one case, a nine-story structure, Forté, did not record a single first-aid incident during construction [

25]. This outcome was primarily attributed to the prefabricated nature of MTC. Panels were manufactured off-site, which significantly reduced the risk of on-site injuries. While these examples offer valuable insights into worker safety and health in MT projects, the topic remains underexplored and is rarely the central focus of previous research.

2.4. Point of Departure and Research Objectives

With the growing interest and adoption of MT in the U.S., driven by changes to the building codes, its environmental and economic sustainability benefits, and potential advantages in construction cost and schedule, construction workers are directly affected. Yet, to the best of the knowledge of the research team, no existing studies have systematically examined whether MTC provides safety benefits to construction workers during the construction phase compared to projects using conventional materials. In particular, no studies to date have specifically explored construction safety professionals’ understanding or perceptions specific to MT in the U.S. This gap in understanding presents a critical barrier to safe and efficient MT project adoption and implementation. As noted in previous studies, the lack of data on MTC performance has consistently hindered broader implementation [

25].

To address this gap, the present study investigates how construction safety professionals perceive occupational safety in MT projects. Specifically, this study seeks to answer the following research questions:

- RQ1.

What are the perceptions of occupational safety among construction safety professionals in MT projects?

- RQ2.

How do safety risks in MT construction compare to those in conventional materials such as concrete and steel?

- RQ3.

What safety hazards and challenges exist in MT projects?

3. Methodology

This study employed a cross-sectional, web-based survey to examine construction safety professionals’ perspectives on occupational safety in MT projects. The design enabled access to a geographically diverse population of practitioners actively engaged in safety oversight, supporting the goal of generating industry-relevant insights.

The survey included closed-ended items, which captured structured data on safety perceptions, hazards, and comparative judgments, along with open-ended questions that elicited narrative accounts of safety incidents and challenges. This integration enables both statistical analysis of trends and exploration of contextual details.

The web-based format maximized accessibility to a nationally dispersed sample, allowed rapid data collection, and used branching logic to tailor question paths by MT experience. This design addressed a key gap in the literature, while MT adoption in the U.S. has expanded due to its sustainability and structural benefits, little empirical evidence exists on safety professionals’ perceptions, comparisons with conventional materials, and related hazard exploration.

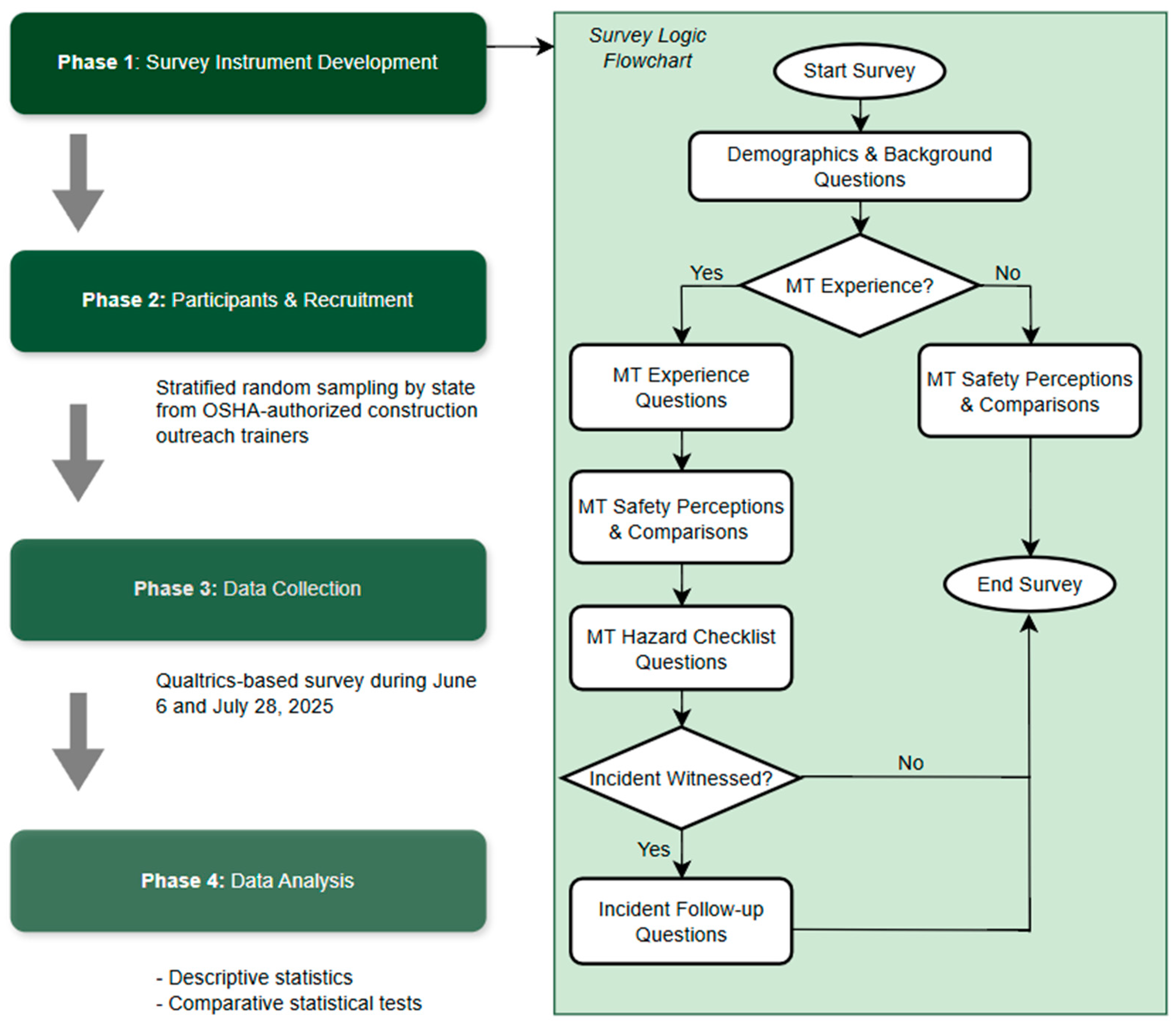

Figure 1 provides an overview of the four-phase research flowchart, including survey instrument development (with survey logic shown in the figure), participants and recruitment, data collection, and data analysis. The details of the four phases are presented below.

3.1. Phase 1: Survey Instrument Development

The survey instrument was developed to align directly with the study’s three research questions, ensuring that each item contributed to understanding occupational safety in MT projects. To address perceptions of MT occupational safety and compare these perceptions to those of conventional materials such as concrete and steel (RQ1 and RQ2), the survey included ordinal response items on the perceived safety of MT projects and two comparative items rating MT safety relative to concrete and steel. These measures were designed to capture both absolute and relative safety perceptions across respondents with varying levels of MT experience.

Additionally, to examine safety hazards and challenges in MTC (RQ3), the instrument included a hazard checklist covering relevant hazardous exposures. The hazard checklist was adapted from OSHA’s established hazard categories and prior literature on construction safety. It encompassed the leading causes of construction injuries (e.g., focus four hazards) along with additional hazards such as heat/cold stress, fire, and chemical exposure, etc., to ensure comprehensive coverage of both conventional and material-specific risks. This qualitative and descriptive approach is consistent with prior safety perception studies in construction [

35,

36]. Respondents with MT experience received follow-up questions on any incidents they had witnessed, including incident type, hazards involved, and a brief narrative description. Respondents who did not witness any incidents during their tenure were then presented with questions on their perceived understanding of the common hazards in MT projects.

The questionnaire also included items on respondents’ professional background and demographic characteristics (e.g., years of safety experience, roles, geographic region, etc.) to provide context for interpreting responses. No personally identifying information was collected within the survey, and confidentiality was maintained throughout the study.

The survey instrument underwent iterative review by the research team and senior safety practitioners to ensure clarity, relevance, and content validity. This refinement process ensured technical accuracy, practical accessibility, and a direct link between survey responses and the study’s research aims.

3.2. Phase 2: Participants and Recruitment

Participants were drawn exclusively from a national pool of approximately 11,800 OSHA-authorized outreach trainers. To ensure balanced representation across the United States, the research team applied a stratified random sampling strategy by state. Within each state, 50% of trainers were randomly selected and invited to participate. This approach safeguarded geographic coverage and reduced sampling bias, ensuring that responses reflected the perspectives of safety professionals from all regions rather than being concentrated in particular states.

Recruitment was conducted via professionally framed email invitations distributed under a Colorado State University-affiliated sender identity. The invitation described the study’s purpose, voluntary nature, and estimated completion time, and included a unique Qualtrics survey link. The message emphasized the importance of contributing to a better understanding of MT-specific safety challenges and training needs. To preserve confidentiality, no personally identifying information was collected in the survey itself, and those interested in a raffle incentive were directed to a separate, de-identified form.

This stratified sampling approach provided a highly relevant and geographically diverse respondent pool, combining domain expertise with national reach and confidentiality safeguards. It established a credible basis for gathering informed, experience-based responses to the study’s research questions.

3.3. Phase 3: Data Collection

Data were collected through the Qualtrics platform. In addition to the initial survey launch, two reminder invitations were distributed during this period. In line with the study’s inclusion criteria, all consenting respondents were initially retained. However, during data cleaning, responses with less than 50% completion were excluded from analysis. This threshold ensured that only participants who had engaged with a substantive portion of the survey were included, thereby improving data quality while still preserving a broad representation of professional perspectives within this specialized population.

The variables in the dataset were organized to reflect the three research questions, with related measures grouped into coherent analytical domains rather than treated as isolated items. Perceptions of MT safety and comparative safety relative to conventional materials were analyzed as ordered outcomes, preserving the inherent structure of the Likert scales. Hazard prevalence, hazard perception, and incident characteristics were modeled as binary or categorical indicators to facilitate frequency comparisons and pattern detection.

3.4. Phase 4: Data Analysis

Analytical methods were chosen to directly address the study’s aims. Descriptive statistics were used to characterize the sample and provide an initial overview of safety perceptions and hazard selections. In addition, differences between MT-experienced and non-experienced respondents were tested for categorical variables and ordinal variables. Key ordinal outcomes, e.g., overall MT safety perception and comparative safety ratings versus concrete and steel, were tested. To address RQ1 (“What are the perceptions of occupational safety among construction safety professionals in MT projects?”) and RQ2 (“How do safety risks in MT construction compare to those in conventional materials such as concrete and steel?”), the survey included questions on the following:

Overall perception of MT projects in relation to occupational safety (5-point Likert scale: Very Safe to Very Unsafe);

Overall perception of non-MT (concrete and steel) projects in relation to occupational safety (5-point Likert scale);

Comparison of worker safety in MT projects versus traditional concrete projects (6-point scale: Significantly Safer to I Don’t Know);

Comparison of worker safety in MT projects versus traditional steel projects (6-point scale).

Chi-square tests of independence were conducted for each survey question to assess whether perceptions differed between respondents with and without MT experience. The null hypothesis is that prior MT experience is not associated with safety perceptions, whereas the alternative hypothesis indicates an association. Expected counts were calculated for each cell, and standardized residuals were examined to identify patterns of association.

Because chi-square tests assess only the presence of associations but not differences in the distribution of ordinal safety ratings across groups, Mann–Whitney U tests were subsequently performed [

37]. These tests evaluated whether the distributions of perceived safety ratings differed between participants with and without experience in MT. For the Mann–Whitney U tests, one-sided tests were purposefully conducted based on the directional assumption that individuals with prior MTC experience would perceive higher levels of safety. Accordingly, the null hypothesis for these tests is that the distributions of safety ratings are the same for both groups, while the alternative hypothesis (one-sided) specifies that participants with prior MT experience reported significantly higher median safety ratings than those without experience. For both sets of tests, statistical significance was assessed at α = 0.05, and

p-values smaller than 0.05 were interpreted as evidence against the null hypothesis.

Finally, hazard checklists and qualitative data from narrative responses addressing RQ3 (“What safety hazards and challenges exist in MT projects?”) were reviewed and interpreted to gain contextual understanding and to capture hazard mechanisms and contributing factors. This integration of quantitative and qualitative evidence allowed the study to move beyond identifying patterns to explain them, producing findings that are both statistically robust and grounded in the lived experiences of safety professionals.

4. Results

A total of 312 responses were received following the sampling and recruitment strategy described earlier. Some initial email invitations were returned as undeliverable, and certain individuals appeared in the OSHA-authorized outreach trainer database under multiple email addresses, potentially resulting in duplicate contacts. Additionally, recipients may have forwarded the survey link to colleagues or other interested safety professionals, thereby expanding participation beyond the original mailing list. For these reasons, the exact number of individuals reached cannot be confirmed. Using the initial distribution list as a baseline and adjusting for undelivered messages, the estimated response rate is 6%. The relatively low response rate was expected, given that MT is still an emerging construction material with limited awareness and hesitancy toward adoption in the industry [

38].

Of the 312 recorded responses, 303 included confirmed consent to participate. Some participants did not progress far enough in the survey to provide information relevant to the research questions, as they completed only the demographic section. These cases were excluded from the final analysis. A total of 262 responses were included in the final analysis.

4.1. Survey Sample Overview

Among the 262 responses, participants reflected varied levels of experience in their safety roles within the construction industry, with more than 30% having over 25 years of experience, followed by 20.2% with 6 to 10 years of experience, and 17.2% with 16 to 20 years of experience. Only 6.1% reported having 1 to 5 years of experience. In terms of job titles, participants represented a wide range of roles, including safety managers, directors, and consultants, as well as owners or presidents of safety consulting and training businesses, professors, and vocational instructors. Overall, the participants’ substantial experience and diverse professional backgrounds demonstrate their strong credentials and suitability for contributing to the present survey study on safety perceptions and understanding.

When asked whether they had been involved in MT projects, 61 participants responded yes (23.3%). With about one-quarter of the participants reporting direct experience, their involvement offers valuable insights into the perceptions, challenges, risks, and safety considerations associated with MT projects.

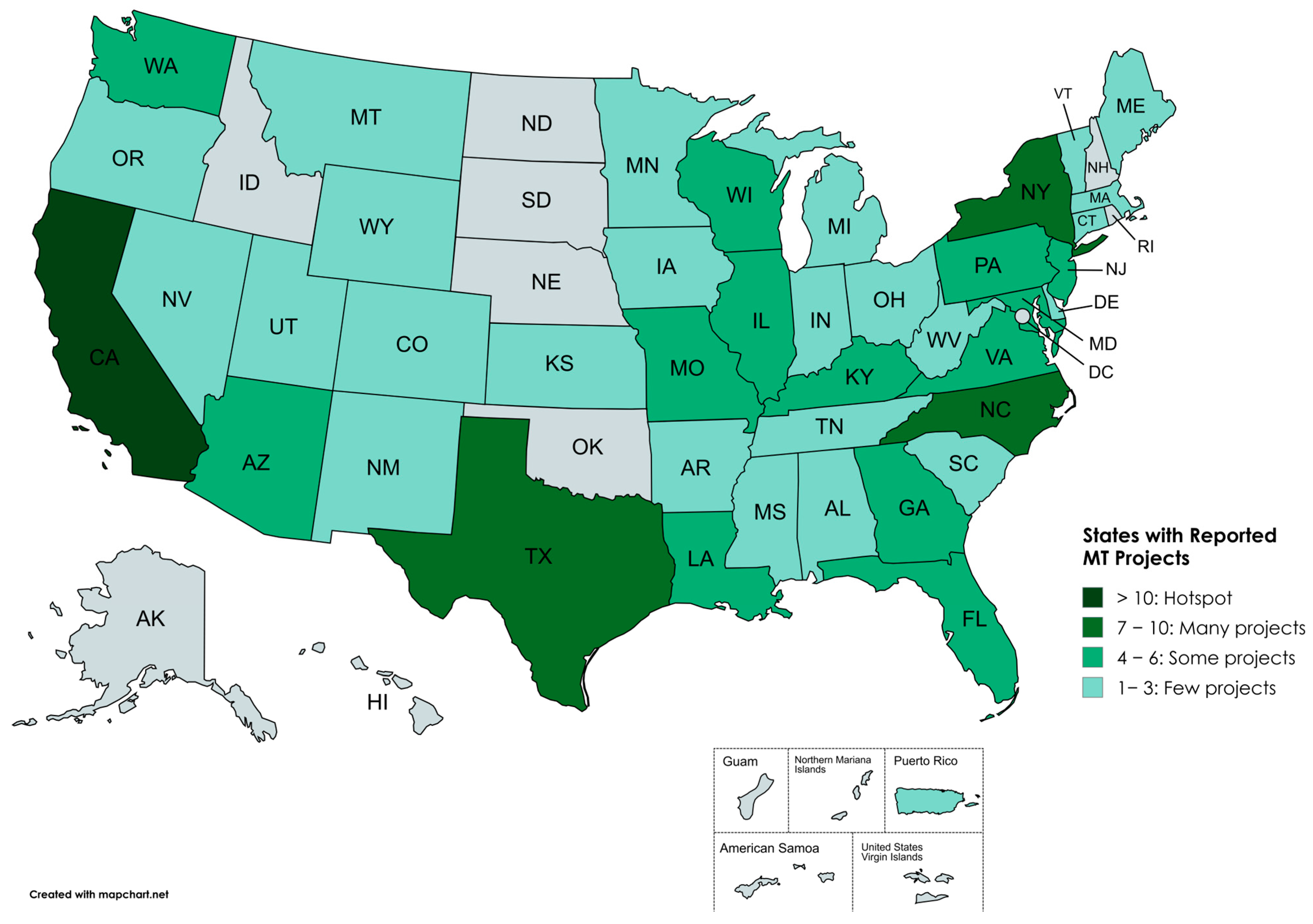

Figure 2 presents a map of the U.S. that shows the states where participants reported MT project involvement. The darkest shaded state, California, represents a hotspot with 11 projects. States such as New York, North Carolina, and Texas reported 7 to 8 projects, while others, including Arizona, Illinois, Pennsylvania, and Florida, reported 4 to 6 projects. Survey participants reported involvement in only 1 to 3 projects across a larger number of states, including Alabama, Colorado, and Michigan, among others. Conversely, participants did not report involvement in MT projects in several states, including Idaho, North Dakota, South Dakota, and Rhode Island.

4.2. Perceptions of Occupational Safety in MT Projects (RQ1)

For the question “what is your overall perception of MT projects in relation to occupational safety?”, the chi-square test revealed a statistically significant association between MT experience and safety perceptions, χ2(4, N = 258) = 11.78, p = 0.019. This indicates that perceptions of MT safety differed depending on whether respondents had prior experience with MT.

Table 1 shows the standardized residuals, suggesting that respondents with experience were more likely than expected to perceive MT projects as Somewhat safe (residual = 1.65) and Very safe (residual = 1.50), and less likely than expected to perceive them as Neither safe nor unsafe (residual = −1.77). Participants without experience, on the other hand, tended to be more neutral (neither safe nor unsafe) compared to expectations. This pattern suggests that experience with MT is associated with a more favorable perception of occupational safety. In contrast, those without direct experience are more uncertain or cautious in their assessments.

Regarding the question “What is your overall perception of Non-MT (e.g., concrete and steel structure) projects in relation to occupational safety?”, the chi-square test of independence revealed no significant association between MT experience and perceptions of occupational safety on non-MT projects, χ

2(4, N = 260) = 3.01,

p = 0.56. Respondents with and without MT experience expressed similar distributions of safety perceptions. As shown in

Table 2, standardized residuals indicated no response category deviated substantially from expected values, confirming the lack of substantial group differences.

4.3. Comparison of Safety Risks in MT and Conventional Construction (RQ2)

The chi-square analysis revealed a statistically significant association between MT experience and perceptions of relative safety, χ

2(5, N = 262) = 18.22,

p = 0.003. As shown in

Table 3, the analysis of standardized residuals for the comparison between MT vs. concrete projects revealed clear perceptual differences associated with experience level. OSHA trainers with prior MT experience were substantially more likely to describe MT projects as significantly safer than concrete projects (standardized residual = +2.15) and markedly less likely to select “I don’t know” (–2.30). Conversely, respondents without MT experience displayed greater uncertainty (i.e., “I don’t know”) and modestly higher frequencies in the significantly less safe category. These residual patterns suggest that direct exposure to MT projects enhances confidence in their safety practices, while unfamiliarity fosters indeterminate or cautious views.

Similarly, when comparing perceptions of MT vs. steel projects, the chi-square test indicated a statistically significant association between experience with MT and perception of worker safety, χ

2(5, N = 261) = 11.89,

p = 0.036. As shown in

Table 4, the analysis of standardized residuals for the comparison between MT and steel projects showed that experience with MT modestly influences perceptions of safety. Safety professionals with MT experience were more likely to describe MT projects as somewhat safer (standardized residual = +1.81) and less likely to respond with “I don’t know” (–1.97), suggesting greater confidence and familiarity with MT safety practices. Those without MT experience exhibited slightly more uncertainty and were marginally more likely to consider MT projects less safe. However, both groups most frequently selected about the same, indicating a general perception of comparable safety between MT and steel construction. Overall, these results suggest that direct experience fosters greater assurance in MT safety performance but does not entirely shift the broader perception that MT and steel projects share similar safety profiles.

Table 5 provides a summary of the chi-square analysis, revealing that perceptions of MT worker safety were significantly associated with experience with MT. For the overall perception of MT projects, χ

2(4, N = 261) = 11.81,

p = 0.019, indicating that respondents with MT experience were more likely to rate MT projects as Very Safe or Somewhat Safe, while those without experience were more uncertain or neutral. In contrast, perceptions of Non-MT projects did not differ significantly between groups, χ

2(4, N = 261) = 4.17,

p = 0.38.

When comparing MT projects to traditional concrete projects (χ2(5, N = 261) = 13.91, p = 0.016) and MT projects to traditional steel projects (χ2(5, N = 261) = 11.89, p = 0.036), both analyses showed a significant association between MT experience and perception of worker safety. Respondents with MT experience tended to perceive MT projects as safer than traditional concrete or steel projects, whereas those without experience expressed more uncertainty or rated MT projects as less safe. These results suggest that direct experience with MT influences confidence in occupational safety assessments, highlighting the importance of training and exposure in shaping perceptions.

To further examine differences in safety perceptions between respondents with and without MT experience, a series of Mann–Whitney U tests was conducted. These non-parametric tests were chosen to compare distributions of ordinal survey responses across the two groups, providing a complementary analysis to the chi-square tests. Results are summarized in

Table 6, with one-sided

p-values reported to reflect the directional expectation that respondents with MT experience would rate MT projects as safer.

The Mann–Whitney U tests confirm the patterns observed in the chi-square analyses. Respondents with MT experience rated MT projects as significantly safer than their non-experienced counterparts for both the overall MT occupational safety question (W = 7383.5, p = 0.002) and in comparisons with concrete (W = 7773.5, p < 0.001) and steel (W = 7794, p < 0.001). Removing the “I don’t know” category slightly reduced the strength of these associations, but they remained statistically significant (p = 0.032 for MT vs. Concrete; p = 0.011 for MT vs. Steel). In contrast, perceptions of non-MT projects did not differ significantly between groups (p = 0.056).

Taken together, these results provide convergent evidence that direct experience with MT is consistently associated with higher perceived safety, especially when comparing MT to traditional concrete and steel construction, and that uncertainty among non-experienced respondents partly drives the observed differences.

4.4. Safety Hazards and Challenges in MT Projects (RQ3)

To address RQ3, i.e., what safety hazards and challenges exist in MT projects?, the research team first extracted the respondents who answered ‘Yes’ to the question of whether they were ever involved in an MT project. 61 respondents indicated that they have been involved in MT projects. Further analyses were conducted on responses from these participants, including both quantitative and qualitative data.

Among the 61 respondents, 38 reported having witnessed at least one safety incident or near-miss on a mass timber project, while 23 indicated that they had not. This finding underscores a high baseline exposure to safety-related events among professionals involved in mass timber construction. All subsequent analyses of incident types, hazard types, and incident descriptions were conducted using only the subset of (n = 38) respondents who answered “Yes” to having witnessed an incident.

Table 7 below shows the number of respondents who had witnessed incidents, reported a range of incident types, including near misses, non-fatal recordable injuries, and non-fatal non-recordable injuries.

Near-miss incidents alone are reported by approximately 68% of those with incident experience. Subsequently, both non-fatal recordable and non-recordable injuries were reported by approximately 55% of respondents. The results revealed that only one respondent had witnessed a fatal incident at MT projects. This high prevalence of near-misses suggests that workers are frequently exposed to unsafe conditions or breakdowns in controls, but that these exposures have not always resulted in injury. Such patterns often indicate latent system weaknesses (e.g., inadequate pre-task planning, unclear exclusion zones, or rushed sequencing) that could lead to serious incidents if uncorrected. This aligns with previous research, which shows that near-miss rates are a leading indicator of systemic safety performance failure on complex construction projects [

39]. In the context of MT, the data suggest that hazard controls are not consistently keeping pace with the novel workflows introduced by MTC methods.

The qualitative descriptions of these incidents provide additional context. Many respondents described incidents associated with the lifting and rigging of large, prefabricated elements (e.g., CLT or glulam panels), often involving loss of control, swinging loads, or workers entering restricted areas. Others recounted falls or near falls from temporary edges or openings created during assembly, as well as slips on wet or sawdust-covered surfaces following rainfall or water intrusion. Several narratives noted poor planning of lift sequencing and limited use of temporary bracing, suggesting that inadequate pre-task planning and coordination contributed to the incidents.

Following up, the next set of questions was designed to compare real, experienced hazards with the hazards that practitioners perceive. To do that, we split the sample by experience of incidents. The observed profile in

Table 8 reflects only respondents (

n = 38) who had actually witnessed an incident on a mass timber project, while the perceived profile reflects only respondents who had mass timber experience but had not witnessed any incident (

n = 23).

As shown in

Table 8, struck-by hazards were the most frequently reported hazard, affecting approximately 71% of participants. Falls from height were also highly prevalent, reported by approximately 55% participants, followed by caught-in/between exposures (~39%), same-level slips, trips, and falls (~34%), and heat or cold stress (~32%). Overexertion and repetitive motion injuries were noted by nearly a third of witnesses (~29%), while fire hazards, noise, and electrocution were less frequent, and confined space or chemical exposures were not reported at all. These figures align with the physical characteristics of mass timber erection, where large, prefabricated elements are moved and aligned at height using cranes, producing dynamic loads, swing paths, and pinch points that are difficult to control manually.

When we turn to the perceptions of respondents who had experience with mass timber but had not personally witnessed an incident, a different emphasis emerges. Among this group, the most perceived hazards were falls from height (~65%) and struck-by incidents (~48%). Fire hazards (~35%) and exposure to harmful chemicals (~17%) were also perceived as elevated, even though they were much less prevalent or entirely absent from the list of observed hazards. Safety hazards, such as slips and trips, noise, and confined space exposures, appeared in their perceptions at levels modestly above those reported by witnesses, reflecting general site awareness.

Comparing the two profiles highlights the perception gap. Hazards most central to actual incidents, such as struck-by, caught-in/between, and heat or cold stress, are consistently under-recognized by non-witnesses. Struck-by alone shows a gap of more than 23%, while heat or cold stress and caught-in/between are underestimated by 14% and 9%, respectively. By contrast, hazards such as fire, chemical exposure, and falls from height are systematically over-emphasized in perception relative to their observed prevalence. This suggests that without first-hand incident experience, practitioners rely on familiar safety risk categories rather than those most distinctive to MT erection.

5. Discussion

Our study reveals that the sampled safety professionals generally held positive attitudes and perceptions toward occupational safety in MT projects. The findings also indicate that the lived construction experience has a strong influence on perceptions of MT safety. Respondents with direct exposure to MT projects generally rated them as safer. In contrast, those without such experience were more neutral or uncertain. This finding suggests that firsthand engagement with MT workflows reduces ambiguity and fosters a more confident assessment of safety risks. A similar pattern emerged in comparisons with conventional materials (concrete and steel). Safety professionals familiar with MTC tended to view it as safer than concrete or steel, whereas those without MT experience were more undecided. It should be noted that the findings from the statistical analyses using chi-square tests indicate statistical associations rather than causal relationships. Meanwhile, the Mann–Whitney U test results indicate differences in perceived safety ratings between experienced and non-experienced MT groups.

These results indicate that familiarity and understanding play a critical role in shaping safety perceptions. However, previous studies have demonstrated that confidence rooted in experience often drifts into complacency and risk-taking behavior [

40,

41,

42]. To ensure that perceptions remain grounded in evidence, organizations should pair experiential learning with measurable leading indicators, such as near-miss density and exclusion-zone breaches, and review these metrics with rigorous scrutiny. This integrated approach fosters a culture where rising confidence reflects verifiable control and disciplined safety management, rather than relying solely on routine comfort or familiarity.

Subsequently, from the analysis of RQ3, our study also demonstrates a high rate of near misses coupled with recurring non-fatal injuries in the MT projects. In the context of MTC projects, where crews perform multiple lifts daily, manage shifting exclusion zones, and work in weather-exposed environments, such conditions create frequent opportunities for errors to accumulate. Construction safety management must go beyond compliance to embed resilience, reinforcing pre-task planning, requiring point-of-work verification before each task, and institutionalizing near-miss reporting and rapid feedback loops [

43]. By treating near misses as leading indicators and acting on them promptly, organizations can systematically enhance temporary works, sequencing practices, and crew role clarity, ultimately reducing the likelihood that minor deviations will escalate into serious incidents.

Additionally, this study highlights a difference between observed and perceived hazards in MT projects. This difference between hazards experienced by witnesses and hazards perceived by non-witnesses signals a substantive gap in understanding that can elevate risk on mass timber projects. When the workforce underestimates the hazards most frequently implicated in incidents, they are less likely to anticipate, plan for, and control those exposures in real time [

44,

45]. On the other hand, over-attributing distinctiveness to hazards that are less prominent in the incident record can divert attention and training time away from the tasks where hazards originate.

This misalignment becomes even more important when considered alongside our other findings. From RQ1 and RQ2, we found that respondents with MT experience generally viewed MT projects as safer than traditional concrete or steel construction. However, RQ3 revealed that even among those with MT experience, there is still a noticeable gap between the hazards they have actually encountered on-site (e.g., struck-by events, caught-in/between incidents, and heat or cold stress) and the hazards they perceive to be most significant (e.g., fire, chemical exposure, and falls). This combination of findings highlights the need for targeted occupational safety training that can support both groups. Those without MT experience, who need opportunities to build an accurate understanding of MT hazards before working on these projects, and those with experience, who may benefit from recalibrating their perceptions to focus on the hazards most often responsible for real incidents. By addressing both ends of this spectrum, training programs can help ensure that all workers, regardless of their prior experience, develop a realistic and evidence-based understanding of MT safety risks and how to manage them effectively.

While these findings provide valuable insights into safety perceptions and understanding of MTC, their generalizability may be limited by the sampling frame and sample size. The intended target population comprised U.S. construction safety professionals involved in managing or overseeing workplace safety. To reach this population, the study drew participants from a pool of OSHA-authorized outreach trainers. This group represents an experienced and professionally engaged subset of the safety community within the U.S. construction industry. However, because OSHA-authorized trainers constitute only a portion of the broader safety professional population, the sample may not fully capture the diversity of perspectives present across the industry, particularly among those with direct experience in MTC. In addition, the study findings primarily reflect the views of the safety professionals who voluntarily chose to participate in the online survey. Participants may have been more interested in or experienced MTC compared to non-participants, which could affect the representativeness of the findings. This self-selection may have introduced bias and further limited the generalizability of the results to the broader construction safety community.

Furthermore, the geographic distribution of survey participants in relation to their MT project involvement (

Figure 2) suggests that the study findings may not fully represent the range of occupational safety perceptions associated with MTC across the U.S. Some states, such as Idaho, North Dakota, and Rhode Island, had no participants who reported MT project involvement. However, data from WoodWorks [

7] indicate that MT projects have been designed and constructed in those states. Similarly, while states such as Oregon have a high number of MT projects, relatively few survey participants reported involvement in them.

6. Conclusions

This study provides one of the first practitioner-centered investigations of occupational safety in MTC, offering empirical evidence from a national sample of construction safety professionals. Findings reveal that perceptions of MT safety are largely influenced by direct experience. Respondents with prior MT exposure viewed MT projects as safer compared to traditional concrete or steel, whereas those without experience were more neutral. However, even among experienced professionals, the nature of observed hazards differed from the hazards most often perceived as distinctive. This difference points to a gap between experience and perception that may obscure where the safety risks actually occur. Addressing this gap will require safety programs that build both accurate perceptions and technical competence, ensuring that confidence in MT’s safety is grounded in data and control, not familiarity alone.

From a practical standpoint, the results demonstrate the need for safety training and planning frameworks specifically tailored to MT’s unique construction processes. Such programs should emphasize issues such as rigging and lifting protocols, temporary stability, exclusion zones, environmental risk management, etc., while leveraging near-miss learning systems to continuously strengthen hazard detection, risk awareness, and operational discipline.

Future research is recommended to include a broader range of construction safety professionals, particularly those with direct, hands-on experience in MTC. In addition, incorporating frontline workers who directly engage with MTC activities would provide valuable insights into on-site safety risks and hazards. The present study relied on self-reported perceptions from safety professionals, which are inherently subjective and may be influenced by individual experience and judgment. Future studies could consider employing additional research methods beyond surveys, such as interviews, field observations, case studies, the analysis of empirical safety data, or longitudinal and comparative research, as well as incorporating risk assessment and statistical modeling techniques, to validate and expand upon the findings of this study. Furthermore, future research should build on these findings through multi-stakeholder, cross-national studies that integrate quantitative and qualitative approaches. Longitudinal and experimental designs could evaluate how training interventions, exposure to the MTC workplace, and evolving regulations influence both perception and performance over time. As MT continues to expand globally, understanding how experience, design practices, and organizational culture interact to shape safety outcomes will be vital for ensuring that sustainability advances are matched by equivalent progress in worker protection.

Author Contributions

Conceptualization, Z.J., S.M.J.U. and R.V.-V.; methodology, Z.J., S.M.J.U. and R.V.-V.; software, Z.J., and R.V.-V.; validation, Z.J., S.M.J.U. and R.V.-V.; formal analysis, Z.J., S.M.J.U. and R.V.-V.; investigation, Z.J., S.M.J.U. and R.V.-V.; data curation, Z.J., S.M.J.U. and R.V.-V.; writing—original draft preparation, Z.J., S.M.J.U. and R.V.-V.; writing—review and editing, Z.J., S.M.J.U. and R.V.-V.; visualization, Z.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Review Board of Colorado State University (IRB#6887; approved on 29 May 2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are available upon request.

Acknowledgments

We gratefully acknowledge the contributions of all OSHA authorized trainer participants who generously shared their time and insights for this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| MT | Mass Timber |

| MTC | Mass Timber Construction |

| OSHA | Occupational Safety and Health Administration |

| U.S. | United States |

References

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The Circular Economy in the Construction and Demolition Waste Sector—A Review and an Integrative Model Approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- United Nations Global Status Report for Buildings and Construction|UNEP-UN Environment Programme. Available online: https://www.unep.org/resources/report/global-status-report-buildings-and-construction (accessed on 1 October 2025).

- Harte, A.M. Mass Timber—The Emergence of a Modern Construction Material. J. Struct. Integr. Maint. 2017, 2, 121–132. [Google Scholar] [CrossRef]

- Abed, J.; Rayburg, S.; Rodwell, J.; Neave, M. A Review of the Performance and Benefits of Mass Timber as an Alternative to Concrete and Steel for Improving the Sustainability of Structures. Sustainability 2022, 14, 5570. [Google Scholar] [CrossRef]

- Chapagain, A.; Crovella, P. Building Sustainable Futures: Evaluating Embodied Carbon Emissions and Biogenic Carbon Storage in a Cross-Laminated Timber Wall and Floor (Honeycomb) Mass Timber Building. Sustainability 2025, 17, 5602. [Google Scholar] [CrossRef]

- Kremer, P.D.; Abbasnejad, B.; Ahankoob, A.; Wakefield, R. Advancing Global Mass Timber Construction—A Decade of Progress, Challenges, and Future Directions: A Systematic Literature Review. Build. Environ. 2025, 284, 113458. [Google Scholar] [CrossRef]

- WoodWorks Mass Timber Projects in Design & Constructed-WoodWorks. Available online: https://www.woodworks.org/resources/mapping-mass-timber/ (accessed on 6 October 2025).

- Woodworking Network 2025 Predictions for Mass Timber. Available online: https://www.woodworkingnetwork.com/news/woodworking-industry-news/2025-predictions-mass-timber (accessed on 24 July 2025).

- Himes, A.; Busby, G. Wood Buildings as a Climate Solution. Dev. Built Environ. 2020, 4, 100030. [Google Scholar] [CrossRef]

- Kumar, V.; Lo Ricco, M.; Bergman, R.D.; Nepal, P.; Poudyal, N.C. Environmental Impact Assessment of Mass Timber, Structural Steel, and Reinforced Concrete Buildings Based on the 2021 International Building Code Provisions. Build. Environ. 2024, 251, 111195. [Google Scholar] [CrossRef]

- Gu, H.; Nepal, P.; Bergman, R. Carbon Credits for Mass Timber Construction. Bioprod. Bus. 2023, 8, 1–12. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Sariatli, F. Linear Economy versus Circular Economy: A Comparative and Analyzer Study for Optimization of Economy for Sustainability. Visegrad J. Bioecon. Sustain. Dev. 2017, 6, 31–34. [Google Scholar] [CrossRef]

- Abad, F.; Rameezdeen, R.; Chileshe, N. Circular Economy Design Strategies in Mass Timber Construction: A Systematic Literature Review. Smart Sustain. Built Environ. 2024. [Google Scholar] [CrossRef]

- Hosseini, Z.; Blanchet, P.; Laratte, B.; Cogulet, A. Evaluating Circular Economy Strategies at the End-of-Life Stage of a Mass Timber Building: Pathways for Sustainable Construction. Archit. Eng. Des. Manag. 2025, 1–21. [Google Scholar] [CrossRef]

- Mallo, M.F.L.; Espinoza, O. Awareness, Perceptions and Willingness to Adopt Cross-Laminated Timber by the Architecture Community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- Larasatie, P.; Guerrero, J.E.; Conroy, K.; Hall, T.E.; Hansen, E.; Needham, M.D. What Does the Public Believe about Tall Wood Buildings? An Exploratory Study in the US Pacific Northwest. J. For. 2018, 116, 429–436. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Feasibility Assessment of Mass Timber as a Mainstream Building Material in the US Construction Industry: Level of Involvement, Existing Challenges, and Recommendations. Pract. Period. Struct. Des. Constr. 2021, 26, 04021008. [Google Scholar] [CrossRef]

- Zaman, A.; Chan, Y.-Q.; Jonescu, E.; Stewart, I. Critical Challenges and Potential for Widespread Adoption of Mass Timber Construction in Australia—An Analysis of Industry Perceptions. Buildings 2022, 12, 1405. [Google Scholar] [CrossRef]

- Giorgio, B.; Barlet, A.; Blanchet, P.; Cabral, M.R.; Perez, C.; Gaudelas, A. Using Mass Timber in Multi-Storey and Non-Residential Construction Projects: Motivations and Barriers for Professionals in Quebec. BioResources 2025, 20, 1931–1970. [Google Scholar] [CrossRef]

- International Code Council 2021 Mass Timber Buildings and the IBC®. Available online: https://codes.iccsafe.org/content/MTBIBC2021P2 (accessed on 19 October 2024).

- Ahmad, T.; Thaheem, M.J. Developing a Residential Building-Related Social Sustainability Assessment Framework and Its Implications for BIM. Sustain. Cities Soc. 2017, 28, 1–15. [Google Scholar] [CrossRef]

- Passos Neto, G.d.M.; Alencar, L.H.; Valdes-Vasquez, R. Multiple-Criteria Methods for Assessing Social Sustainability in the Built Environment: A Systematic Review. Sustainability 2023, 15, 16231. [Google Scholar] [CrossRef]

- Giorgio, B.; Blanchet, P.; Barlet, A. Social Representations of Mass Timber and Prefabricated Light-Frame Wood Construction for Multi-Story Housing: The Vision of Users in Quebec. Buildings 2022, 12, 2073. [Google Scholar] [CrossRef]

- Smith, R.E.; Griffin, G.; Rice, T.; Hagehofer-Daniell, B. Mass Timber: Evaluating Construction Performance. Archit. Eng. Des. Manag. 2018, 14, 127–138. [Google Scholar] [CrossRef]

- Evison, D.C.; Kremer, P.D.; Guiver, J. Mass Timber Construction in Australia and New Zealand—Status, and Economic and Environmental Influences on Adoption. Wood Fiber Sci. 2018, 50, 128–138. [Google Scholar] [CrossRef]

- Svatoš-Ražnjević, H.; Orozco, L.; Menges, A. Advanced Timber Construction Industry: A Review of 350 Multi-Storey Timber Projects from 2000–2021. Buildings 2022, 12, 404. [Google Scholar] [CrossRef]

- Kremer, P.D.; Symmons, M.A. Mass Timber Construction as an Alternative to Concrete and Steel in the Australia Building Industry: A PESTEL Evaluation of the Potential. Int. Wood Prod. J. 2015, 6, 138–147. [Google Scholar] [CrossRef]

- Jacobs, A.; Timmers, M.; Sundnes, J.; Baker, A. Mass Timber High-Rise Design, Cost and Schedule Research: Competitive Advantages of Wood over Concrete. In Structures and Architecture; CRC Press: Boca Raton, FL, USA, 2016; pp. 1481–1489. [Google Scholar]

- Jolly, R.; Fairweather, H.; Rayburg, S.; Rodwell, J. Life Cycle Assessment and Cost Analysis of Mid-Rise Mass Timber vs. Concrete Buildings in Australia. Sustainability 2024, 16, 6465. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R. Environmental Life-Cycle Assessment and Life-Cycle Cost Analysis of a High-Rise Mass Timber Building: A Case Study in Pacific Northwestern United States. Sustainability 2021, 13, 7831. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Analysis of Cost Comparison and Effects of Change Orders during Construction: Study of a Mass Timber and a Concrete Building Project. J. Build. Eng. 2021, 33, 101856. [Google Scholar] [CrossRef]

- Kasbar, M.; Staub-French, S.; Pilon, A.; Poirier, E.; Teshnizi, Z.; Froese, T. Construction Productivity Assessment on Brock Commons Tallwood House. Constr. Innov. 2021, 21, 951–968. [Google Scholar] [CrossRef]

- BuHamdan, S.; Duncheva, T.; Alwisy, A. Developing a BIM and Simulation-Based Hazard Assessment and Visualization Framework for CLT Construction Design. J. Constr. Eng. Manag. 2021, 147, 04021003. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D. Why Operatives Engage in Unsafe Work Behavior: Investigating Factors on Construction Sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Hinze, J.; Thurman, S.; Wehle, A. Leading Indicators of Construction Safety Performance. Saf. Sci. 2013, 51, 23–28. [Google Scholar] [CrossRef]

- Ramsey, F.; Schafer, D. The Statistical Sleuth: A Course in Methods of Data Analysis; Cengage Learning: Southbank, Australia; Boston, MA, USA, 2013; ISBN 978-1-133-49067-8. [Google Scholar]

- Ahmed, S.; Dharmapalan, V.; Jin, Z. A Subject Review on the Use of Mass Timber in the US Construction Industry. In Proceedings of the Construction Research Congress 2024, Des Moines, IA, USA, 20–23 March 2024; pp. 287–295. [Google Scholar] [CrossRef]

- Woźniak, Z.; Hoła, B. Analysing Near-Miss Incidents in Construction: A Systematic Literature Review. Appl. Sci. 2024, 14, 7260. [Google Scholar] [CrossRef]

- Törner, M.; Pousette, A. Safety in Construction—A Comprehensive Description of the Characteristics of High Safety Standards in Construction Work, from the Combined Perspective of Supervisors and Experienced Workers. J. Safety Res. 2009, 40, 399–409. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, P. Risk Compensation Behaviours in Construction Workers’ Activities. Int. J. Inj. Contr. Saf. Promot. 2015, 22, 40–47. [Google Scholar] [CrossRef]

- Lee, B.; Kim, H. Measuring Effects of Safety-Reminding Interventions against Risk Habituation. Saf. Sci. 2022, 154, 105857. [Google Scholar] [CrossRef]

- Memarian, B.; Brooks, S.B.; Le, J.C. Pre-task Planning for Construction Worker Safety and Health: Implementation and Assessment. Am. J. Ind. Med. 2025, 68, S88–S97. [Google Scholar] [CrossRef]

- Jeelani, I.; Albert, A.; Gambatese, J.A. Why Do Construction Hazards Remain Unrecognized at the Work Interface? J. Constr. Eng. Manag. 2017, 143, 04016128. [Google Scholar] [CrossRef]

- Liu, D.; Ham, Y. Multistage Cognitive Dynamics for Team-Based Teleoperation in Challenging Environments. Autom. Constr. 2025, 180, 106537. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).