Integrating Electromagnetic NDT and IoT for Enhanced Structural Health Monitoring of Corrosion in Reinforced Concrete as a Key to Sustainable Smart Cities

Abstract

1. Introduction

1.1. Motivation

1.2. Research Objectives and Novelty

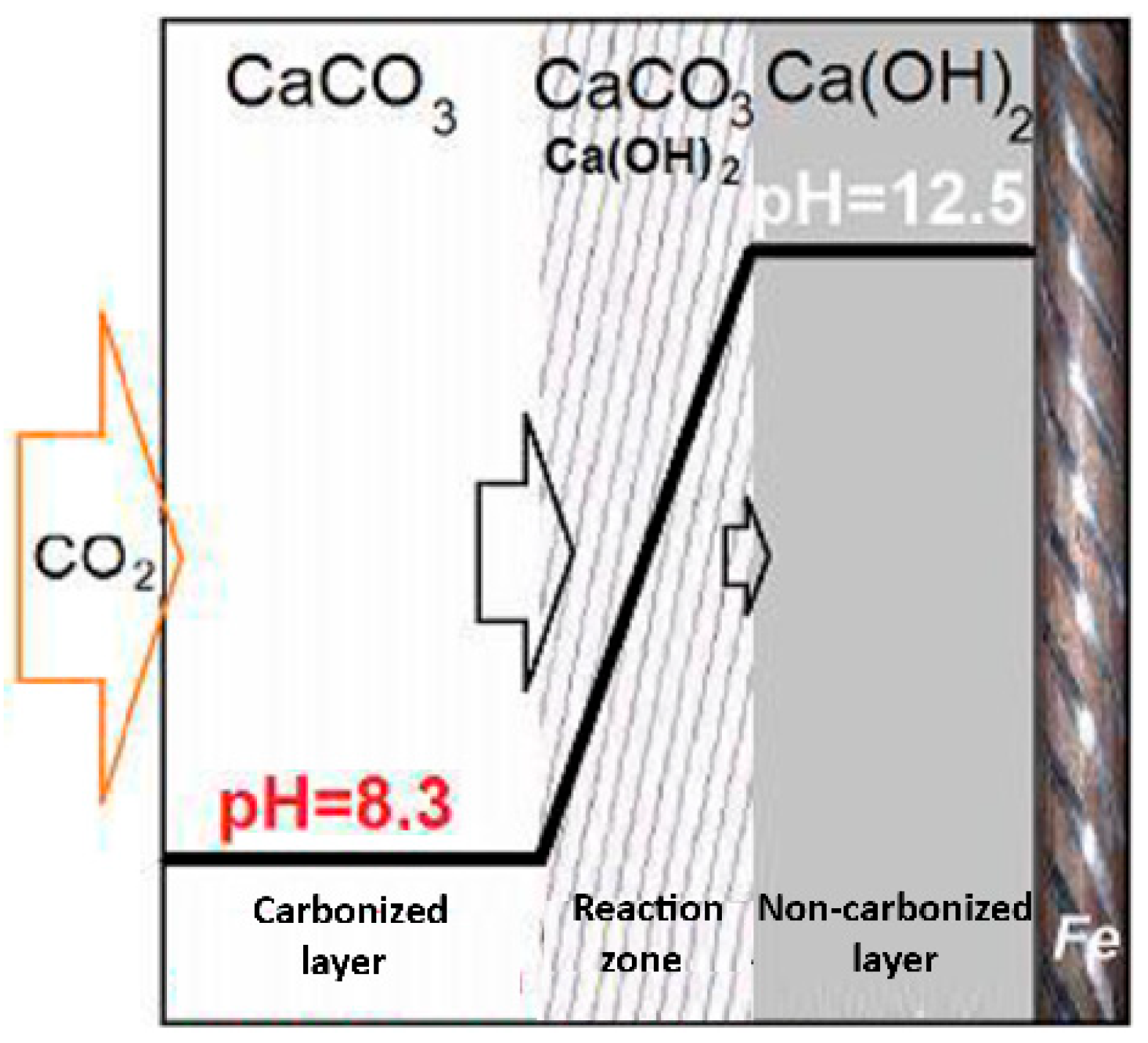

1.3. Process of Corrosion Degradation in Reinforced Concrete Structures

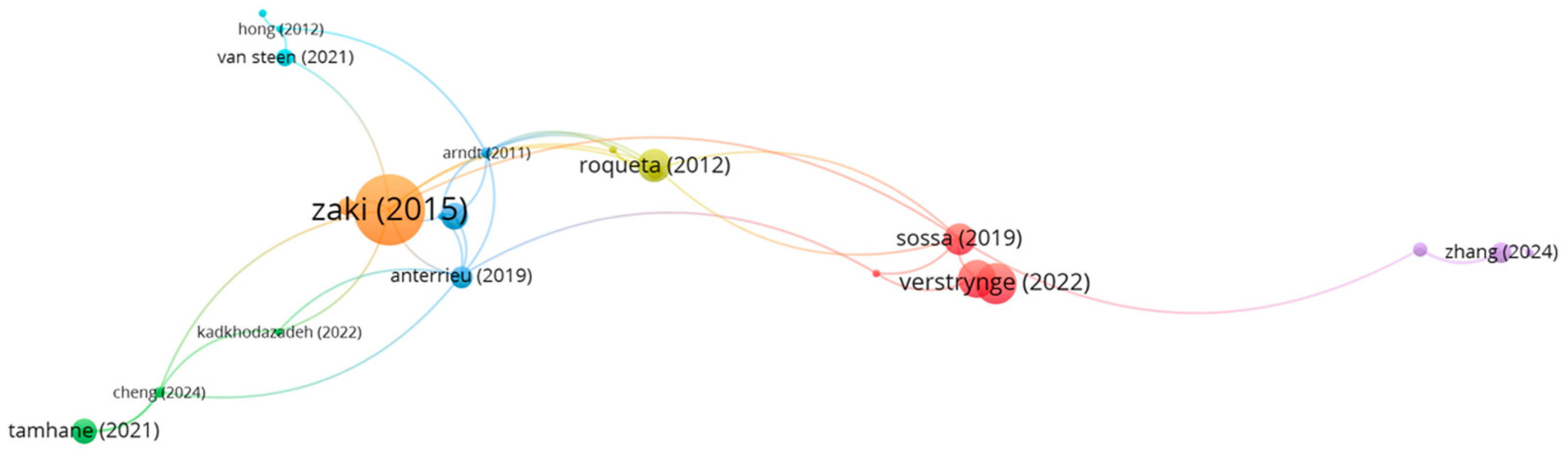

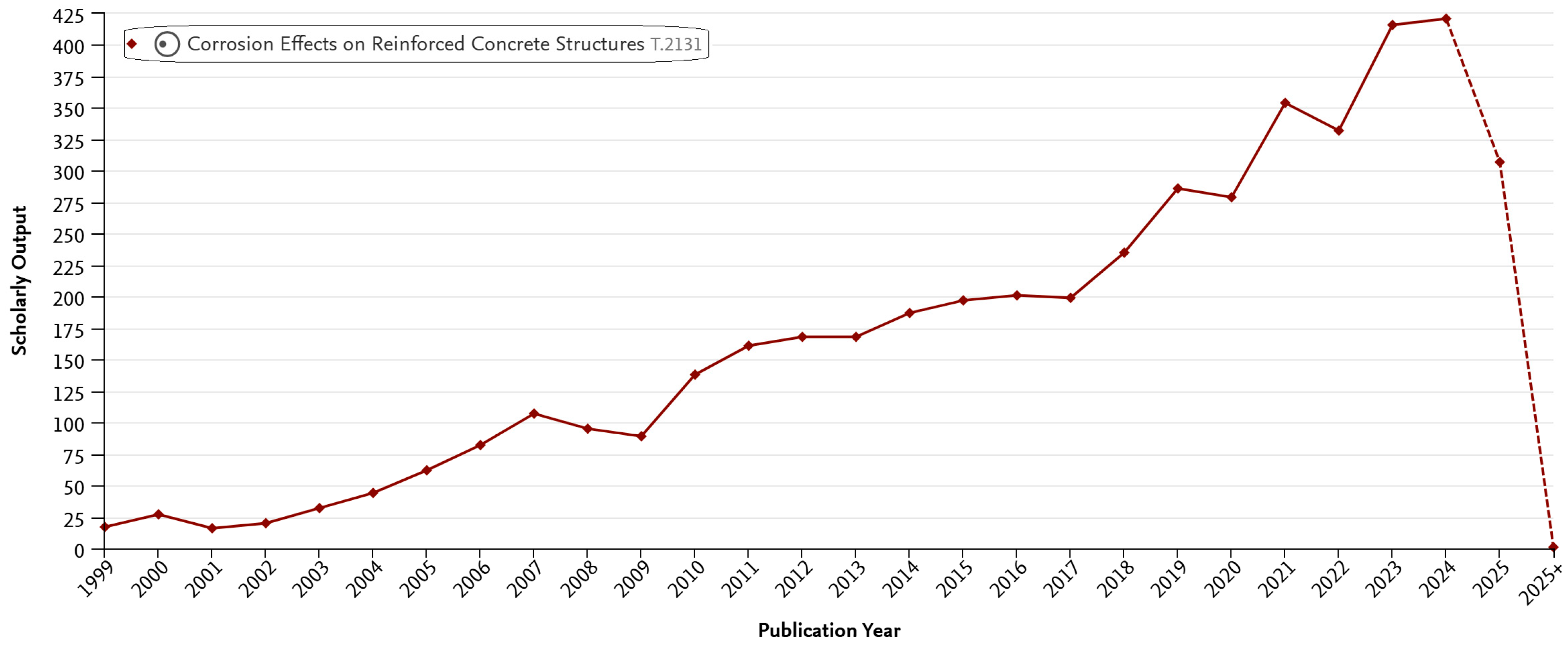

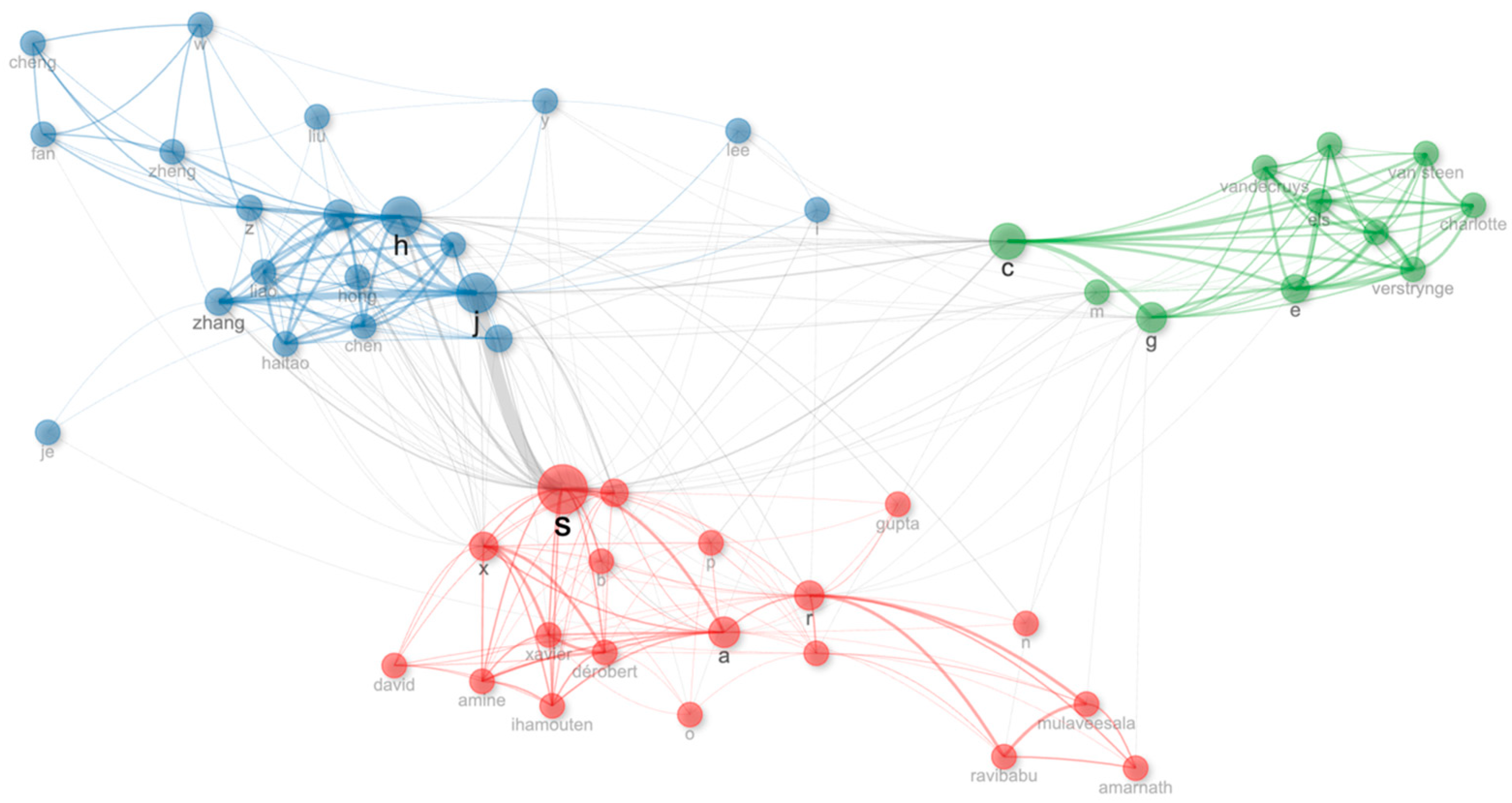

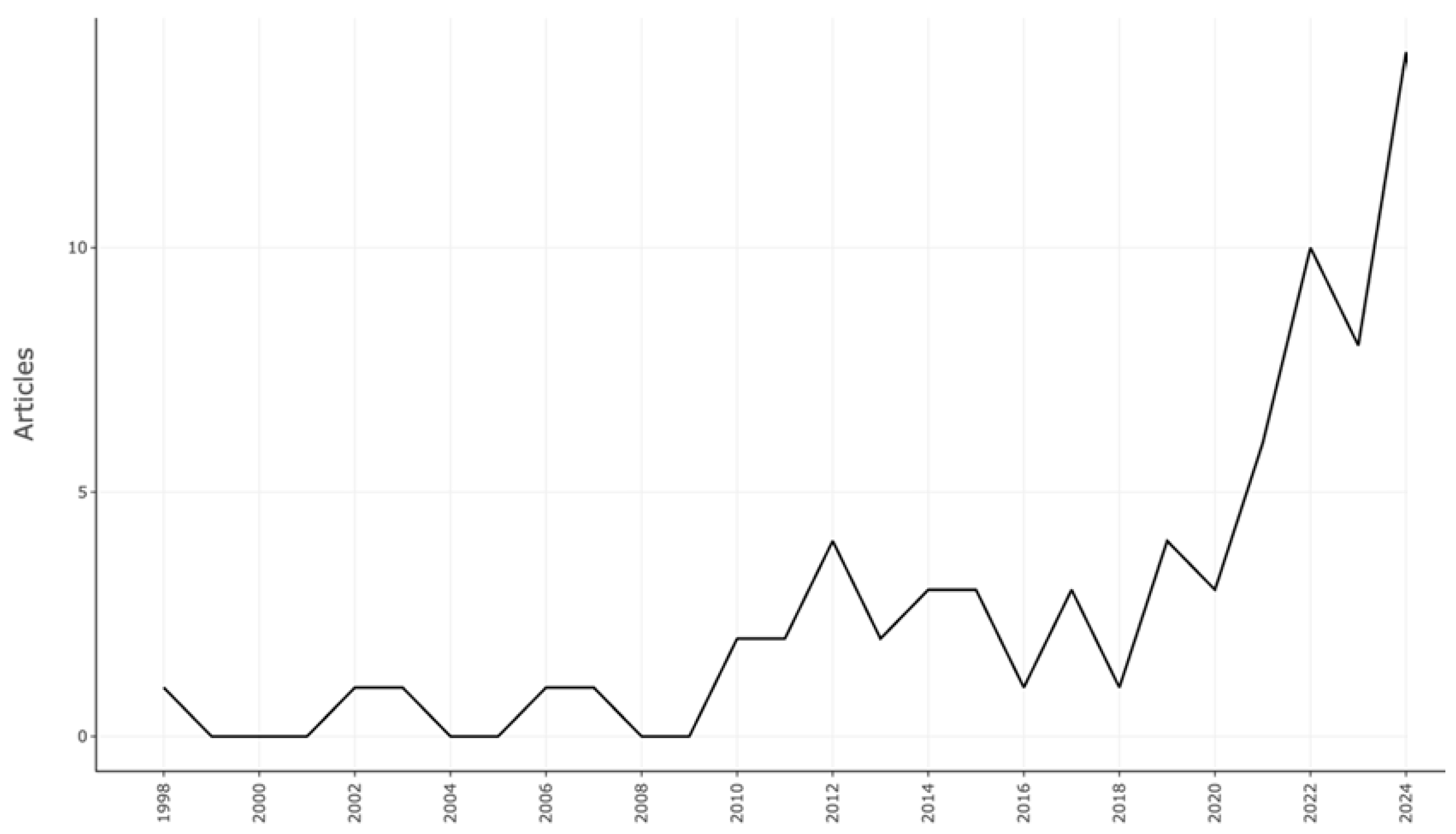

1.4. Systematic Literature Review of NDT Methods Used in Reinforced Concrete Structure Evaluation

- RQ1: What is the current state of knowledge on NDT techniques that provide direct sensitivity to early corrosion processes under typical concrete cover thickness?

- RQ2: To what extent can these methods be integrated with SHM/IoT solutions and ML processing?

- RQ3: How does the M5 method compare to other approaches in terms of early detection and implementation feasibility?

2. Materials and Methods

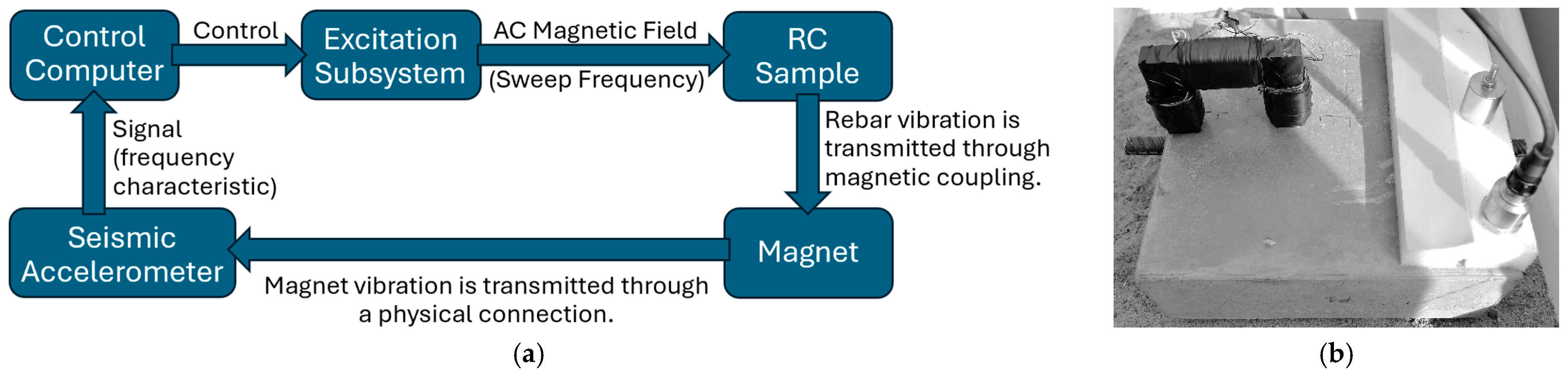

2.1. Magnetic Force-Induced Vibration Evaluation (M5) Measurement System

2.1.1. M5 System

2.1.2. Modal Analysis in the Evaluation of Reinforced Concrete Structures

2.1.3. Internet of Things as a Crucial Part of Structural Health Monitoring Systems

2.1.4. M5 Structural Health Monitoring

2.1.5. Comparison Between Structural Health Monitoring and Periodic Inspection Versions of the M5 System

2.2. Samples

2.3. Methodology

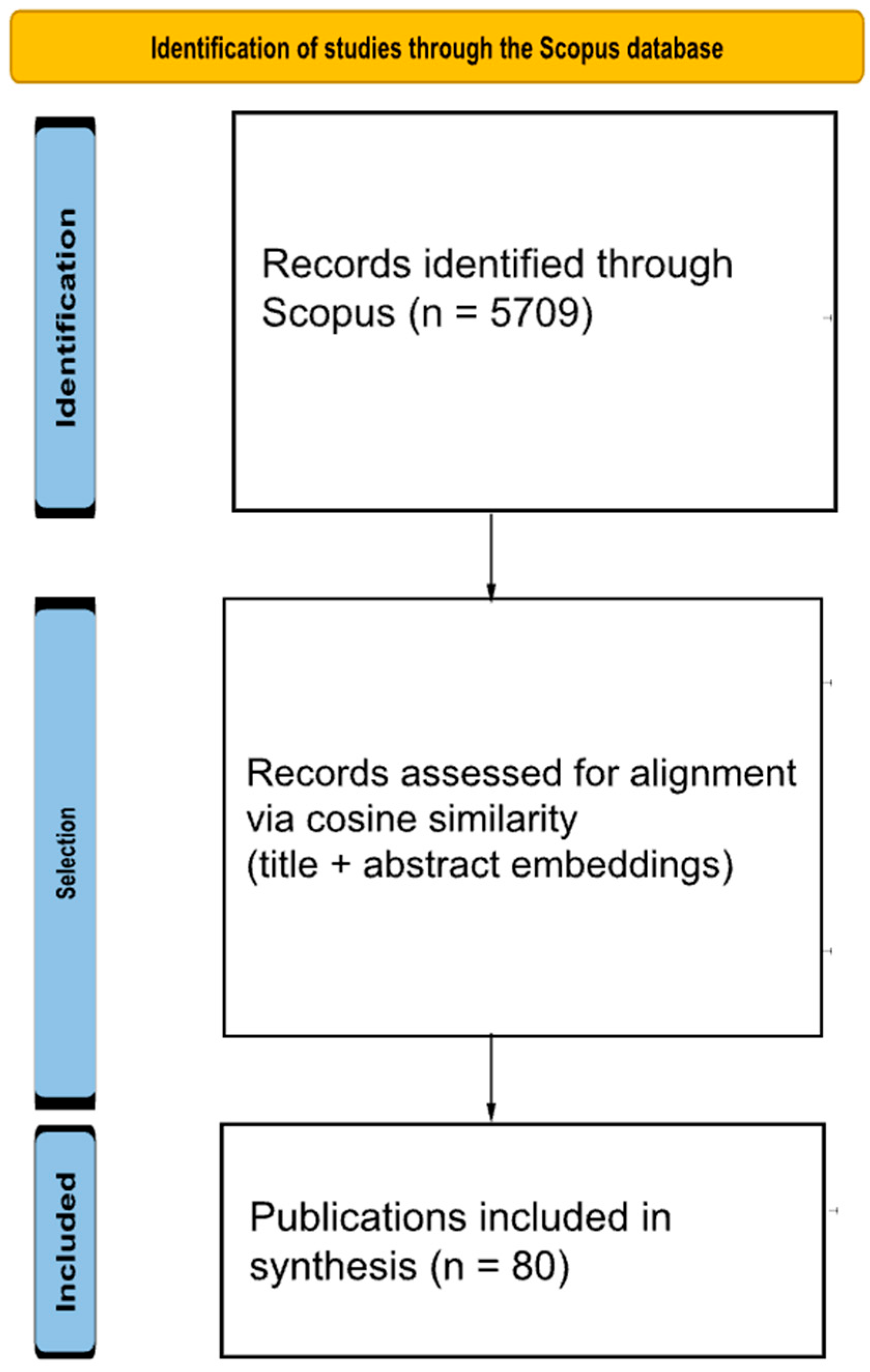

2.3.1. Methodology of Systematic Literature Review

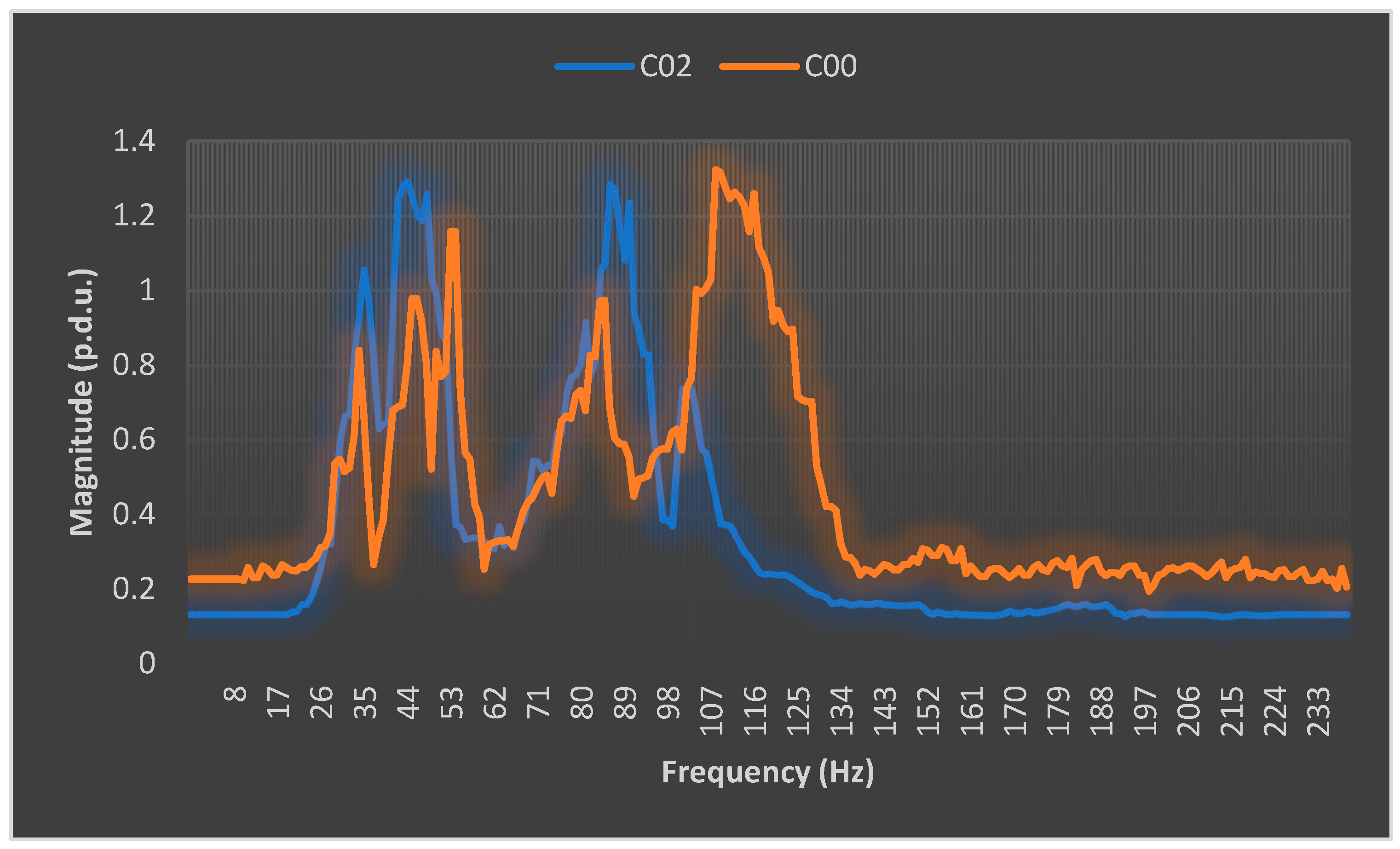

2.3.2. Feature Extraction from Frequency Characteristic

- Feature extraction through equal division in the domain of the independent variable.

- Feature extraction through equal division in the domain of the amplitude.

- Feature extraction through equal division with normalization.

- ACO decomposition.

2.3.3. Association Rules Analysis (ARA)

3. Results

[confidence = 100%, sensitivity = 10%]

4. Discussion

5. Conclusions

- Communication: Ensuring robust, low-latency communication for the M5’s sensor network is critical. The electromagnetic excitation and vibration data require reliable transmission, especially when deployed in complex urban environments with potential interference.

- Signal Damping: Variability in concrete cover thickness and material heterogeneity significantly affects signal quality and response, making accurate corrosion detection more challenging and necessitating careful sensor placement and calibration. The results obtained are promising, but further research is necessary.

- Implementation: M5 sensors should be placed close to rebars (within 5–10 mm) for sensitivity, but retrofitting existing structures can be costly and invasive. Deploying dense sensor networks across many smart city assets demands scalable, cost-effective solutions.

- Signal processing: Handling and analyzing high-frequency signal data from many sensors requires advanced feature extraction, noise reduction, and robust machine learning (ML) algorithms to identify corrosion progression stages accurately.

- Power Management: Long-term SHM requires sensors and communication nodes optimized for low power consumption or supported by energy harvesting to minimize maintenance needs.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koch, G.H.; Thompson, N.G.; Moghissi, O.; Payer, J.H.; Varney, J. IMPACT (International Measures of Prevention, Application and Economics of Corrosion Technology); Report No. OAPUS310GKOCH; NACE International: Houston, TX, USA, 2016. [Google Scholar]

- Koch, G.H.; Brongers, M.P.H.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Costs and Preventive Strategies in the United States; FHWA-RD-01-156; FHWA: McLean, VA, USA, 2002. Available online: https://rosap.ntl.bts.gov/view/dot/40697/dot_40697_DS1.pdf (accessed on 11 September 2025).

- Hernandez, J.D.C.; Valcarcel, J.M.L.; Kränkel, T.; Gehlen, C.; Keβler, S. Economic assessment of corrosion prevention measures in new structures. Ce/Papers 2023, 6, 1351–1356. [Google Scholar] [CrossRef]

- Frankowski, P.K.; Chady, T.; Zieliński, A. Magnetic force induced vibration evaluation (M5) method for frequency analysis of rebar-debonding in reinforced concrete. Measurement 2021, 182, 109655. [Google Scholar] [CrossRef]

- Crawford, R.H. Greenhouse gas emissions of global construction industries. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1218, 012047. [Google Scholar] [CrossRef]

- NACE. Corrosion Costs and Preventive Strategies in the United States. Available online: http://impact.nace.org/documents/ccsupp.pdf (accessed on 11 September 2025).

- Arndt, R.; Jalinoos, F. NDE for corrosion detection in reinforced concrete structures—A benchmark approach. In Proceedings of the NDTCE’09, Non-Destructive Testing in Civil Engineering, Nantes, France, 30 June–3 July 2009. [Google Scholar]

- Understanding and Monitoring Corrosion in Steel Reinforced Concrete. Available online: https://www.giatecscientific.com/education/understanding-concrete-corrosion/ (accessed on 11 September 2025).

- Nurhadiyanto, D.; Sianipar, S. The effect of anode-cathode distance and time in the nickel electroplating process on coating thickness and corrosion rate of AISI 1020 steel. AIP Conf. Proc. 2024, 3145, 020014. [Google Scholar] [CrossRef]

- Mitchell, D.; Marchand, J.; Croteau, P.; Cook, W.D. Concorde Overpass collapse: Structural aspects. J. Perform. Constr. Facil. 2011, 25, 545–553. [Google Scholar] [CrossRef]

- Rymsza, J. Causes of the Collapse of the Polcevera Viaduct in Genoa, Italy. Appl. Sci. 2021, 11, 8098. [Google Scholar] [CrossRef]

- Malerba, P.G. Bridge vulnerabilities and collapses: The Italian experience. Struct. Infrastruct. Eng. 2023, 20, 976–1001. [Google Scholar] [CrossRef]

- Almeida, H.F.; Higor, F.A.; Wilson, F. Responsabilidade civil e justiça ambiental no caso da contaminação química do Rio Tocantins após o colapso da ponte rodoviária. Humanidades Inovação 2024, 11, 65–75. [Google Scholar]

- Marx, S.; Scheerer, S.; Schacht, G.; Fiedler, M.; Ritter, R.; Clages, L.; Voigt, C.; Czeschka, D.; Ebell, G.; Marzahn, G. Einsturz der Carolabrücke in Dresden Teil 1: Vom ambitionierten Entwurf bis zum tragischen Teileinsturz. Beton-Und Stahlbetonbau 2025, 120, 526–536. [Google Scholar] [CrossRef]

- Granata, M.F. Seismic Retrofit of Concrete Buildings Damaged by Corrosion: A Case Study in Southern Italy. Buildings 2024, 14, 1064. [Google Scholar] [CrossRef]

- Broomfield, J.P. Corrosion of Steel in Concrete: Understanding, Investigation and Repair; E&FN Spon: London, UK, 2007; 277p. [Google Scholar]

- Wegen, G.; Polder, R.B.; Breugel, K. Guideline for service life design of structural concrete—A performance-based approach with regard to chloride induced corrosion. Heron 2012, 57, 153–168. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Pearson Education Limited: London, UK, 1995; ISBN 978-0-273-75580-7. [Google Scholar]

- Cappellesso, V.G.; dos Santos Petry, N.; Dal Molin, D.C.C.; Masuero, A.B. Use of crystalline waterproofing to reduce capillary porosity in concrete. J. Build. Pathol. Rehabil. 2016, 1, 9. [Google Scholar] [CrossRef]

- Scopus. Available online: https://www.scival.com/benchmarking/analyse (accessed on 11 September 2025).

- Rimshin, V.; Truntov, P. Determination of carbonation degree of existing reinforced concrete structures and their restoration. E3S Web Conf. 2019, 135, 03015. [Google Scholar] [CrossRef]

- Matysik, S.; Wiśniewska, J.; Frankowski, P.K. EmbedSLR: An Open-Source Python Framework for Efficient Embedding-Based Screening and Bibliometric Validation in Systematic Literature Review. SoftwareX 2025, 32, 102416. [Google Scholar] [CrossRef]

- PRISMA Statement. Available online: https://www.prisma-statement.org (accessed on 16 September 2025).

- Frankowski, P.K.; Wiśniewska, J.; Matysik, S. A Comparative Analysis of Embedding Models and Traditional Methods for Publication Selection in Systematic Literature Reviews—A Case Study in Gamification Marketing. In Proceedings of the 33rd International Conference on Information Systems Development (ISD 2025), Belgrade, Serbia, 3–5 September 2025. [Google Scholar]

- Matysik, S.; Wiśniewska, J.; Frankowski, P.K. Artificial Intelligence for Personalized Rankings of Articles—Novel Embedding Method Supporting Decision-Making in Systematic Literature Review. In Proceedings of the 28th European Conference on Artificial Intelligence, Bologna, Italy, 25–30 October 2025. [Google Scholar]

- Maierhofer, C.; Reinhardt, H.W.; Dobmann, G. Non Destructive Evaluation of Reinforced Concrete Structures: Non Destructive testing Methods; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar] [CrossRef]

- Fan, L.; Shi, X. Techniques of corrosion monitoring of steel reinforcement in concrete: A review. Struct. Health Monit. 2021, 21, 1879–1905. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, L.; Wen, S.; Huang, S. A Review on Concrete Structural Properties and Damage Evolution Monitoring Techniques. Sensors 2024, 24, 620. [Google Scholar] [CrossRef]

- Shevtsov, D.S.; Linh, C.N.; Nguyen, V.C.; Quang, N.; Le, H.; Nguyen, H. Progress in sensors for monitoring reinforcement corrosion in reinforced concrete structures—A review. Sensors 2022, 22, 3421. [Google Scholar] [CrossRef]

- Büyüköztürk, O. Imaging of concrete structures. NDT E Int. 1998, 31, 233–243. [Google Scholar] [CrossRef]

- Liu, L.; Zheng, D.; Zhou, J.; Yang, J.; Zhang, H. Parameters that influence corrosion detection in reinforced concrete based on eddy current thermography. Adv. Civ. Eng. 2020, 2020, 7962945. [Google Scholar] [CrossRef]

- Mukherjee, I.; Patil, J.; Banerjee, S.; Tallur, S.G. Phase-Sensitive Detection of Extent of Corrosion Using Anisotropic Magnetoresistive (AMR) Sensor in Steel Reinforcing Bars (Rebars). In Advances in Non-Destructive Evaluation; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Verstrynge, E.; van Steen, C.; Vandecruys, E.; Wevers, M.G. Steel corrosion damage monitoring in reinforced concrete structures with the acoustic emission technique: A review. Constr. Build. Mater. 2022, 349, 128732. [Google Scholar] [CrossRef]

- Arndt, R.W.; Cui, J.; Huston, D.R. Monitoring of Reinforced Concrete Corrosion and Deterioration by Periodic Multi-Sensor Non-Destructive Evaluation. AIP Conf. Proc. 2011, 1335, 1371–1378. [Google Scholar] [CrossRef]

- Vandecruys, E.; van Steen, C.; Martens, C.; Lombaert, G.; Verstrynge, E. Corrosion level prediction with acoustic emission signal classification: A data driven approach. In Smart & Sustainable Infrastructure: Building a Greener Tomorrow; RILEM Bookseries; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Cheng, W.; Sun, H.; Tan, K.H.; Fan, Z. Early detection of corrosion damage in reinforced concrete using GPR array imaging method. IEEE Trans. Instrum. Meas. 2024, 73, 6005009. [Google Scholar] [CrossRef]

- Cheng, W.; Yang, Z.; Fan, Z. Temperature insensitive corrosion monitoring in reinforced concrete structures using ground penetrating radar. IEEE Trans. Instrum. Meas. 2025, 74, 6509309. [Google Scholar] [CrossRef]

- Łaziński, P.; Jasiński, M.; Uściłowski, M.; Piotrowski, D.; Ortyl, Ł. GPR in damage identification of concrete elements—A case study of diagnostics in a prestressed bridge. Remote Sens. 2025, 17, 35. [Google Scholar] [CrossRef]

- Rathod, H.; Gupta, R. Sub surface simulated damage detection using non destructive testing techniques in reinforced concrete slabs. Constr. Build. Mater. 2019, 215, 754–764. [Google Scholar] [CrossRef]

- Tamhane, D.; Patil, J.; Banerjee, S.; Tallur, S.G. Feature Engineering of Time-Domain Signals Based on Principal Component Analysis for Rebar Corrosion Assessment Using Pulse Eddy Current. IEEE Sens. J. 2021, 21, 22086–22093. [Google Scholar] [CrossRef]

- Chen, H.; Liao, L.; Zhou, J.; Zhang, H.; Zhang, S.; Lan, T.; Zhang, Z.; Hu, C. Magnetic resonance eddy penetrating imaging for detecting reinforcement corrosion in concrete. Autom. Constr. 2024, 165, 105512. [Google Scholar] [CrossRef]

- Du Plooy, R.; Villain, G.G.; Palma Lopes, S.; Ihamouten, A.; Dérobert, X.; Thauvin, B. Electromagnetic non destructive evaluation techniques for water and chloride ingress into concrete: A comparative study. Mater. Struct. Mater. Constr. 2015, 48, 369–386. [Google Scholar] [CrossRef]

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-destructive evaluation for corrosion monitoring in concrete: A review and capability of acoustic emission technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Lai, W.W.L.; Helmerich, R.; Milmann, B. NDT-Based Monitoring of Accelerated Reinforcement Corrosion in Concrete. Constr. Build. Mater. 2012, 36, 253–260. [Google Scholar] [CrossRef]

- Van Steen, C.; Verstrynge, E.; Vandecruys, E.; Wevers, M.G.T. Degradation Monitoring in Reinforced Concrete with 3D Localization of Rebar Corrosion and Related Cracking. Appl. Sci. 2021, 11, 6772. [Google Scholar] [CrossRef]

- Roqueta, G.; Jofre-Roca, L.; Feng, M.Q. Analysis of the Electromagnetic Signature of Reinforced Concrete Structures for Nondestructive Evaluation of Corrosion Damage. IEEE Trans. Instrum. Meas. 2012, 61, 1090–1098. [Google Scholar] [CrossRef]

- Anterrieu, O.; Giroux, B.G.; Gloaguen, E.G.; Carde, C. Non-Destructive Evaluation Using a Functional Magnetic Material Sensor for Corrosion Monitoring in Concrete. J. Build. Eng. 2019, 22, 193–206. [Google Scholar] [CrossRef]

- Souriou, D.; Kadkhodazadeh, S.; Dérobert, X.; Guilbert, D.; Ihamouten, A. Experimental Parametric Study of a Functional-Magnetic Material Sensor for Corrosion Monitoring in Reinforced Concrete Structures. Remote Sens. 2022, 14, 3623. [Google Scholar] [CrossRef]

- Sossa, V.A.; Perez-Gracia, V.; Gonzalez-Drigo, R.; Rasol, M. Lab Non-Destructive Test to Analyze the Effect of Corrosion on Ground Penetrating Radar Scans. Remote Sens. 2019, 11, 2814. [Google Scholar] [CrossRef]

- van de Velde, M.; Vandecruys, E.; Verstrynge, E.; Reynders, E.P.B.; Lombaert, G. Vibration monitoring and acoustic emission sensing during progressive load tests of corroded reinforced concrete beams. Eng. Struct. 2024, 306, 117851. [Google Scholar] [CrossRef]

- Majhi, S.; Asilo, L.K.; Mukherjee, A.; George, N.V.; Uy, B. Multimodal monitoring of corrosion in reinforced concrete for effective lifecycle management of built facilities. Sustainability 2022, 14, 9696. [Google Scholar] [CrossRef]

- Oh, R.O.; Kim, H.; Choo, Y.; Park, S.; Rodrigazo, S.A.; Yeon, J.; Park, C. Evaluation of delaminations and defects in concrete deck using non destructive multi physical scanning technology. Sustainability 2024, 16, 9225. [Google Scholar] [CrossRef]

- Frankowski, P.K.; Majzner, P.; Mąka, M.; Chady, T. Enhancing the Identification of Corrosion in Reinforced Concrete Structures Using Association Rules Analysis and the Non-Destructive M5 Method. In Proceedings of the 33rd International Conference on Information Systems Development (ISD 2025), Belgrade, Serbia, 3–5 September 2025. [Google Scholar]

- Chady, T.; Frankowski, P.; Waszczuk, P.; Zieliński, A. Evaluation of reinforced concrete structures using the electromagnetic method. AIP Conf. Proc. 2018, 1949, 040004. [Google Scholar] [CrossRef]

- Kam, T.Y.; Lee, T.Y. Detection of cracks in structures using modal test data. Eng. Fract. Mech. 1992, 42, 381–387. [Google Scholar] [CrossRef]

- Krishnan, S.S.R.; Karuppan, M.K.N.; Khadidos, A.O.; Khadidos, A.O.; Selvarajan, S.; Tandon, S.; Balusamy, B. Comparative analysis of deep learning models for crack detection in buildings. Sci. Rep. 2025, 15, 2125. [Google Scholar] [CrossRef] [PubMed]

- Cosoli, G.; Martarelli, M.; Mobili, A.; Tittarelli, F.; Revel, G.M. Identification of damages in a concrete beam: A modal analysis based method. J. Phys. Conf. Ser. 2024, 2698, 012014. [Google Scholar] [CrossRef]

- Surianinov, M.H.; Murashko, O.V.; Korneychuk, T.S. Modal Analysis of Reinforced Concrete and Fiber Reinforced Concrete Hollow Core Floor Slabs. Lond. J. Eng. Res. 2021, 21, 5–12. [Google Scholar]

- Lund, M.S.M.; Hansen, K.K.; Brincker, R.; Jensen, A.H.; Amador, S.D.R. Evaluation of freeze-thaw durability of pervious concrete by use of operational modal analysis. Cem. Concr. Res. 2018, 106, 57–64. [Google Scholar] [CrossRef]

- Whelan, M.J.; Gangone, M.V.; Janoyan, K.D.; Hoult, N.A.; Middleton, C.R.; Soga, K. Wireless operational modal analysis of a multi-span prestressed concrete bridge for structural identification. Smart Struct. Syst. 2010, 6, 579–593. [Google Scholar] [CrossRef]

- Scuro, C.; Sciammarella, P.F.; Lamonaca, F.; Olivito, R.S.; Carni, D.L. IoT for structural health monitoring. IEEE Instrum. Meas. Mag. 2018, 21, 4–14. [Google Scholar] [CrossRef]

- Moyo, E.H.; Pisa, N. Short Food Supply Chain Status and Pathway in Africa: A Systematic Literature Review. Sustainability 2025, 17, 8047. [Google Scholar] [CrossRef]

- Biancifiori, S.; Torabi Moghadam, S.; Lombardi, P. Participatory Digital Solutions for Nature-Based Solution Urban Projects: A Systematic PRISMA Literature Review. Sustainability 2025, 17, 7945. [Google Scholar] [CrossRef]

- Rosário, A.T.; Dias, J.C. The Role of Digital Marketing in Shaping Sustainable Consumption: Insights from a Systematic Literature Review. Sustainability 2025, 17, 7784. [Google Scholar] [CrossRef]

- Linnenluecke, M.K.; Marrone, M.; Singh, A.K. Conducting systematic literature reviews and bibliometric analyses. Aust. J. Manag. 2020, 45, 175–194. [Google Scholar] [CrossRef]

- Simsek, Z.; Fox, B.C.; Heavey, C. Systematicity in organizational research literature reviews: A framework and assessment. Organ. Res. Methods 2023, 26, 292–321. [Google Scholar] [CrossRef]

- Chigbu, U.E.; Atiku, S.O.; Du Plessis, C.C. The science of literature reviews: Searching, identifying, selecting, and synthesising. Publications 2023, 11, 2. [Google Scholar] [CrossRef]

- Ferreira, J.J.M.; Fernandes, C.I.; Ratten, V. A co citation bibliometric analysis of strategic management research. Scientometrics 2016, 109, 1–32. [Google Scholar] [CrossRef]

- Frankowski, P.K.; Mąka, M.; Ziętek, R.D.; Jankowski, S.; Stawicki, T.; Matysik, S. Feature Extraction Methods in Signal Processing—A Review and New Selection Algorithm. In Proceedings of the 28th European Conference on Artificial Intelligence, Bologna, Italy, 25–30 October 2025. [Google Scholar]

- Frankowski, P.K.; Chady, T. Evaluation of Reinforced Concrete Structures with Magnetic Method and ACO (Amplitude-Correlation-Offset) Decomposition. Materials 2023, 16, 5589. [Google Scholar] [CrossRef]

- Tirumalasetty, S.; Aruna, A.; Padmini, A.; Sagaru, D.V.; Tejeswini, A. An Enhanced Apriori with Interestingness of Patterns using cSupport and rSupport. Int. J. Comput. Sci. Mob. Comput. 2021, 10, 20–27. [Google Scholar] [CrossRef]

- Frankowski, P.K.; Alforque, M.J.; Chady, T. AI Identification of Key Frequency Response Patterns for Nondestructive Corrosion Assessment in Reinforced Concrete Structures Using Electromagnetic Methods. In Proceedings of the 2025 International Conference on Power, Energy and Innovations (ICPEI 2025), Pataya City, Thailand, 15–17 October 2025. [Google Scholar]

- Frankowski, P.K.; Majzner, P.; Mąka, M.; Stawicki, T. Non-Destructive Evaluation of Reinforced Concrete Structures with Magnetic Flux Leakage and Eddy Current Methods—Comparative Analysis. Appl. Sci. 2024, 14, 11965. [Google Scholar] [CrossRef]

- Frankowski, P.K.; Majzner, P.; Mąka, M.; Stawicki, T.; Chady, T. Magnetic Non-Destructive Evaluation of Reinforced Concrete Structures—Methodology, System, and Identification Results. Appl. Sci. 2024, 14, 11695. [Google Scholar] [CrossRef]

- Yang, H.Y.; Cheng, S.L.; Li, X.F.; Yan, Q.; Wang, B.; Xin, Y.J.; Sun, Y.T.; Ding, Q.; Yan, H.; Zhao, Q.X. Propagation mechanism of low-frequency elastic waves and vibrations in a new tetragonal hybrid metamaterial. Int. J. Solids Struct. 2023, 285, 112536. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kamchoom, V.; Ebid, A.M.; Hanandeh, S.; Polo, S.M.Z.; Silva, V.F.N.; Murillo, R.O.S.; Vizuete, R.F.Z.; Awoyera, P.; Avudaiappan, S. Evaluating the strength of industrial wastesbased concrete reinforced with steel fiber using advanced machine learning. Sci. Rep. 2025, 15, 8082. [Google Scholar] [CrossRef]

| SHM Version | Periodic Inspection Version | |

|---|---|---|

| Purpose | Continuous and automated monitoring of structural health + facilitating periodic inspections | Scheduled, periodic inspections of reinforced concrete |

| Implementation | Embedded sensor network near rebars (5–10 mm) | Sensors or devices used temporarily during inspection |

| Data Collection | Real-time, continuous acquisition | Intermittent data collection during inspection visits |

| Sensitivity | High sensitivity due to close placement and monitoring | Effective but limited by inspection frequency and coverage |

| Cost and Installation | Higher upfront cost and complexity, planned installation | Lower immediate cost, but repeated regularly over time |

| Data Analysis | Advanced data integration—usually carried out locally on microcontrollers, in the cloud, or at dedicated processing centers | Semi-automated data analysis after data collection |

| Detection Capability | Early detection of corrosion and structural changes | Detect corrosion or damage present at inspection times |

| Integration | IoT-enabled, with remote data transmission and edge processing | Standalone system requiring manual data handling |

| Maintenance | Enables predictive, condition-based maintenance | Supports preventive maintenance triggered by inspections |

| Operational Impact | Minimal disruption; sensors continuously deployed | Temporary disruption during inspection activities |

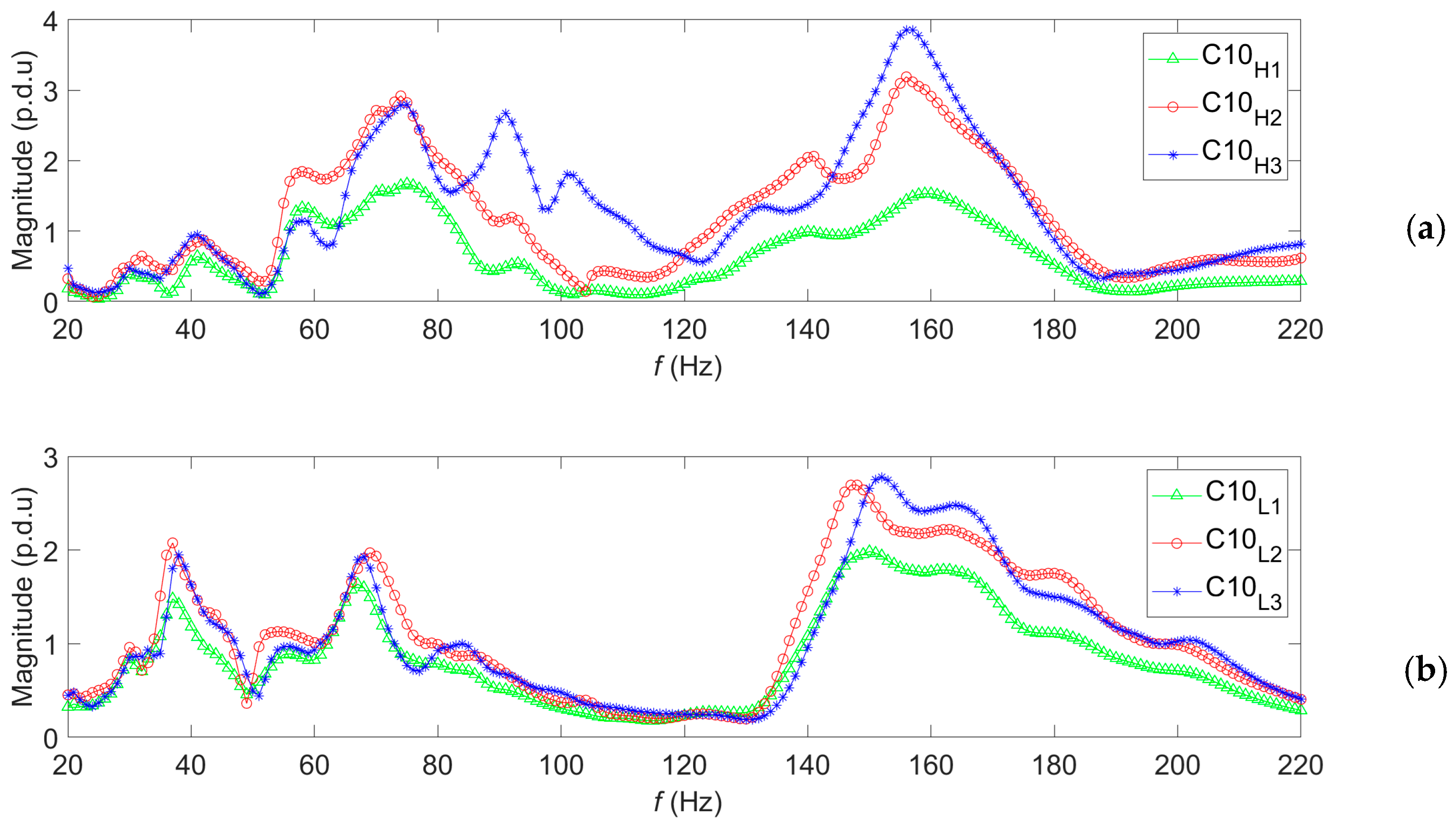

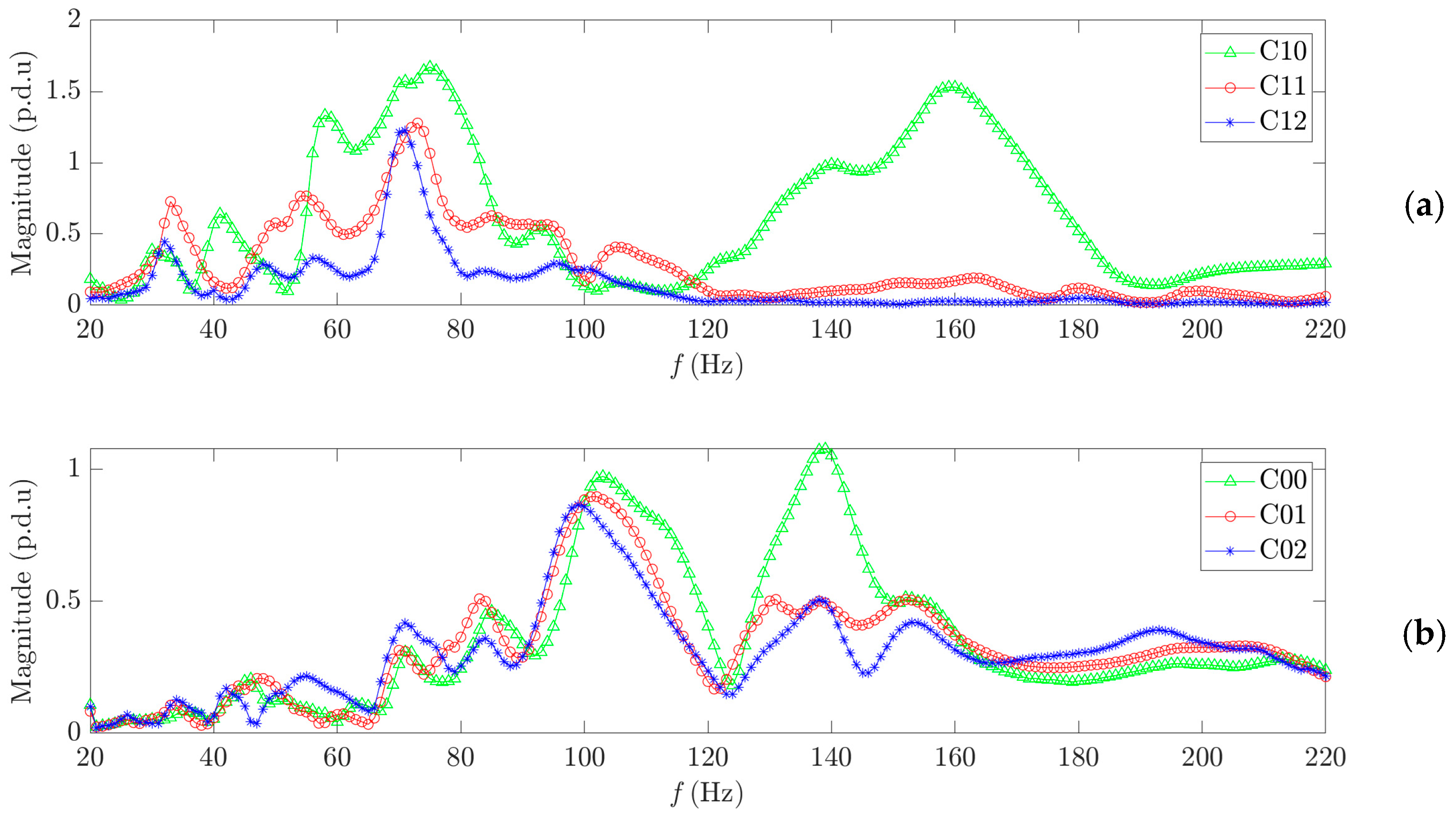

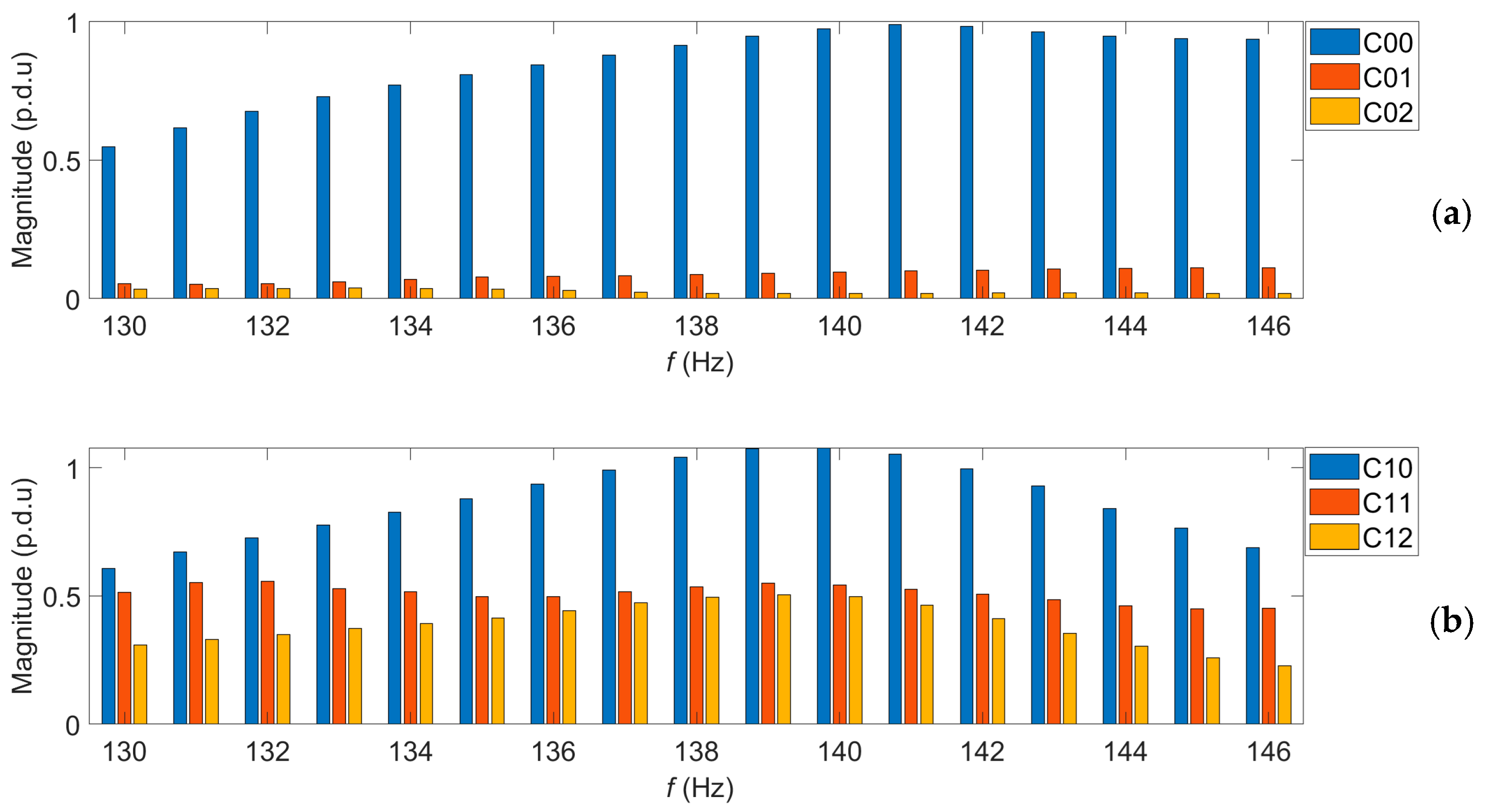

| Laboratory Sample | Field Sample | |

|---|---|---|

| No corrosion | C00 | C10 |

| Partially corroded | C01 | C11 |

| Fully corroded | C02 | C12 |

| Rebar diameter | Large (D = 20 mm) | Small (D = 10 mm) |

| Steel yield strength | Very high (class A-III) | Very low (class A-I) |

| C00 | C01 | C02 | C10L | C10H | C11 | C12 | |

|---|---|---|---|---|---|---|---|

| C00 | 100 | 85 | 74 | 69 | 21 | 19 | 16 |

| C01 | 85 | 100 | 92 | 22 | 16 | 11 | 7 |

| C02 | 74 | 92 | 100 | 28 | 13 | 1 | 6 |

| C10L | 69 | 22 | 28 | 100 | 60 | 39 | 38 |

| C10H | 21 | 16 | 13 | 60 | 100 | 5 | 5 |

| C11 | 19 | 11 | 1 | 39 | 5 | 100 | 89 |

| C12 | 16 | 7 | 6 | 38 | 5 | 89 | 100 |

| C10H1 | C10H2 | C10H3 | C10H4 | C10H5 | C10H6 | |

|---|---|---|---|---|---|---|

| C10H1 | 100 | 67 | 65 | 42 | 44 | 46 |

| C10H2 | 67 | 100 | 97 | 78 | 68 | 63 |

| C10H3 | 65 | 97 | 100 | 85 | 75 | 65 |

| C10H4 | 42 | 78 | 85 | 100 | 74 | 55 |

| C10H5 | 44 | 68 | 75 | 74 | 100 | 68 |

| C10H6 | 46 | 63 | 65 | 55 | 68 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frankowski, P.K.; Matysik, S. Integrating Electromagnetic NDT and IoT for Enhanced Structural Health Monitoring of Corrosion in Reinforced Concrete as a Key to Sustainable Smart Cities. Sustainability 2025, 17, 10307. https://doi.org/10.3390/su172210307

Frankowski PK, Matysik S. Integrating Electromagnetic NDT and IoT for Enhanced Structural Health Monitoring of Corrosion in Reinforced Concrete as a Key to Sustainable Smart Cities. Sustainability. 2025; 17(22):10307. https://doi.org/10.3390/su172210307

Chicago/Turabian StyleFrankowski, Paweł Karol, and Sebastian Matysik. 2025. "Integrating Electromagnetic NDT and IoT for Enhanced Structural Health Monitoring of Corrosion in Reinforced Concrete as a Key to Sustainable Smart Cities" Sustainability 17, no. 22: 10307. https://doi.org/10.3390/su172210307

APA StyleFrankowski, P. K., & Matysik, S. (2025). Integrating Electromagnetic NDT and IoT for Enhanced Structural Health Monitoring of Corrosion in Reinforced Concrete as a Key to Sustainable Smart Cities. Sustainability, 17(22), 10307. https://doi.org/10.3390/su172210307