Design Optimization and Field Validation of Industrial Fans with CFD for Cement Production: Performance, Energy Savings, and Environmental Benefits

Abstract

1. Introduction

2. Materials and Methods

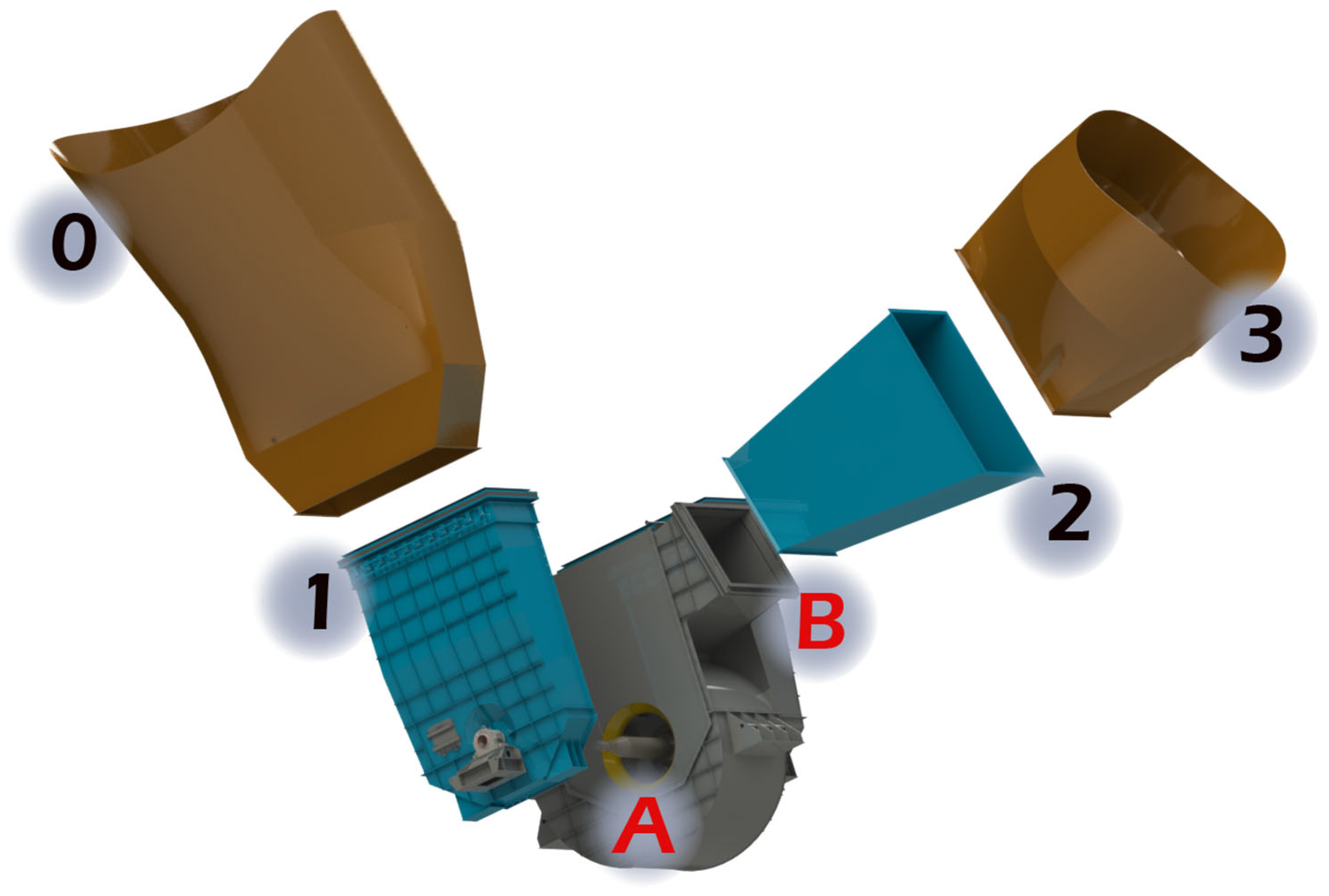

2.1. Fan Geometry and Design Criteria

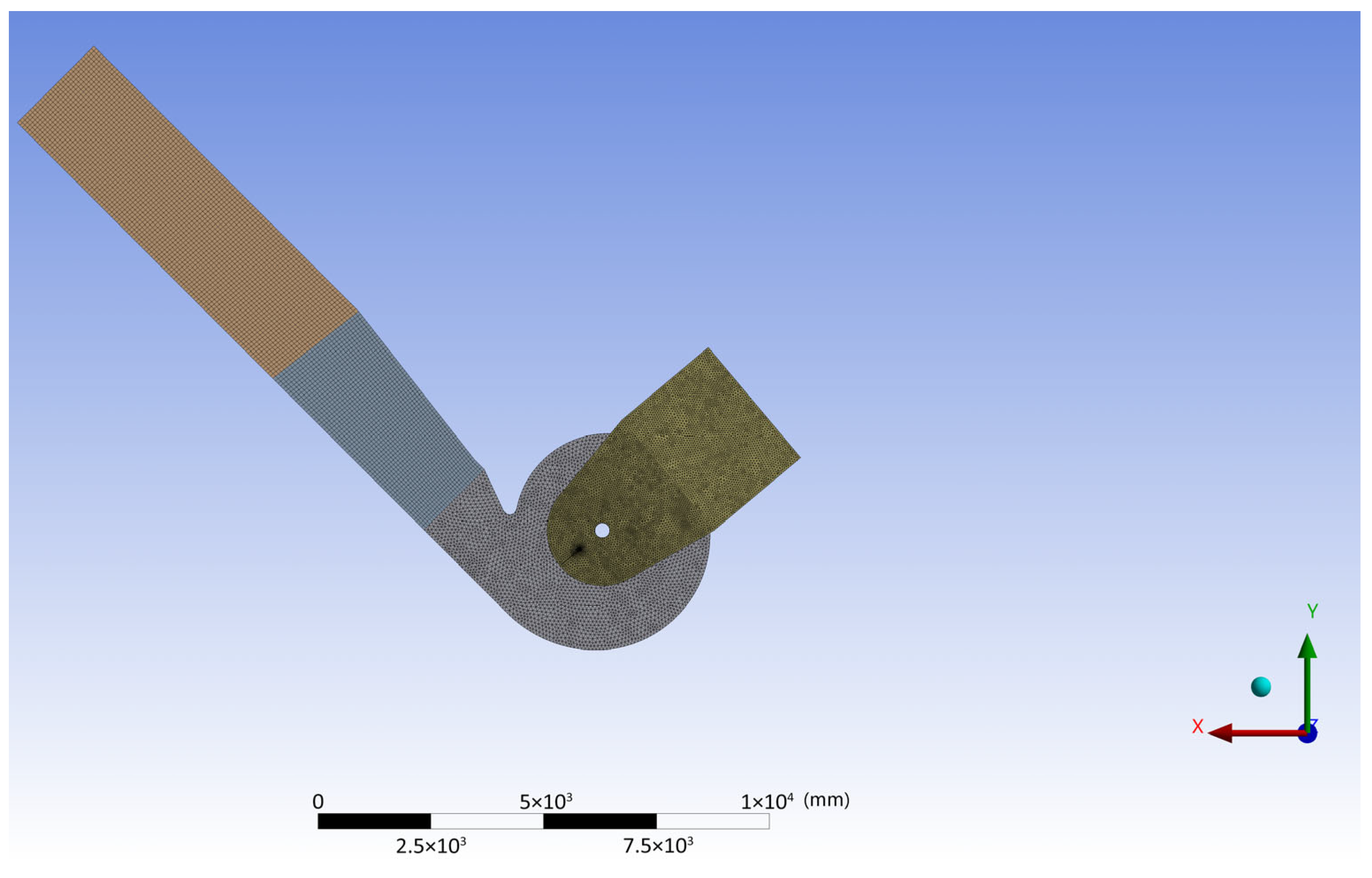

2.2. Numerical Modelling Approach

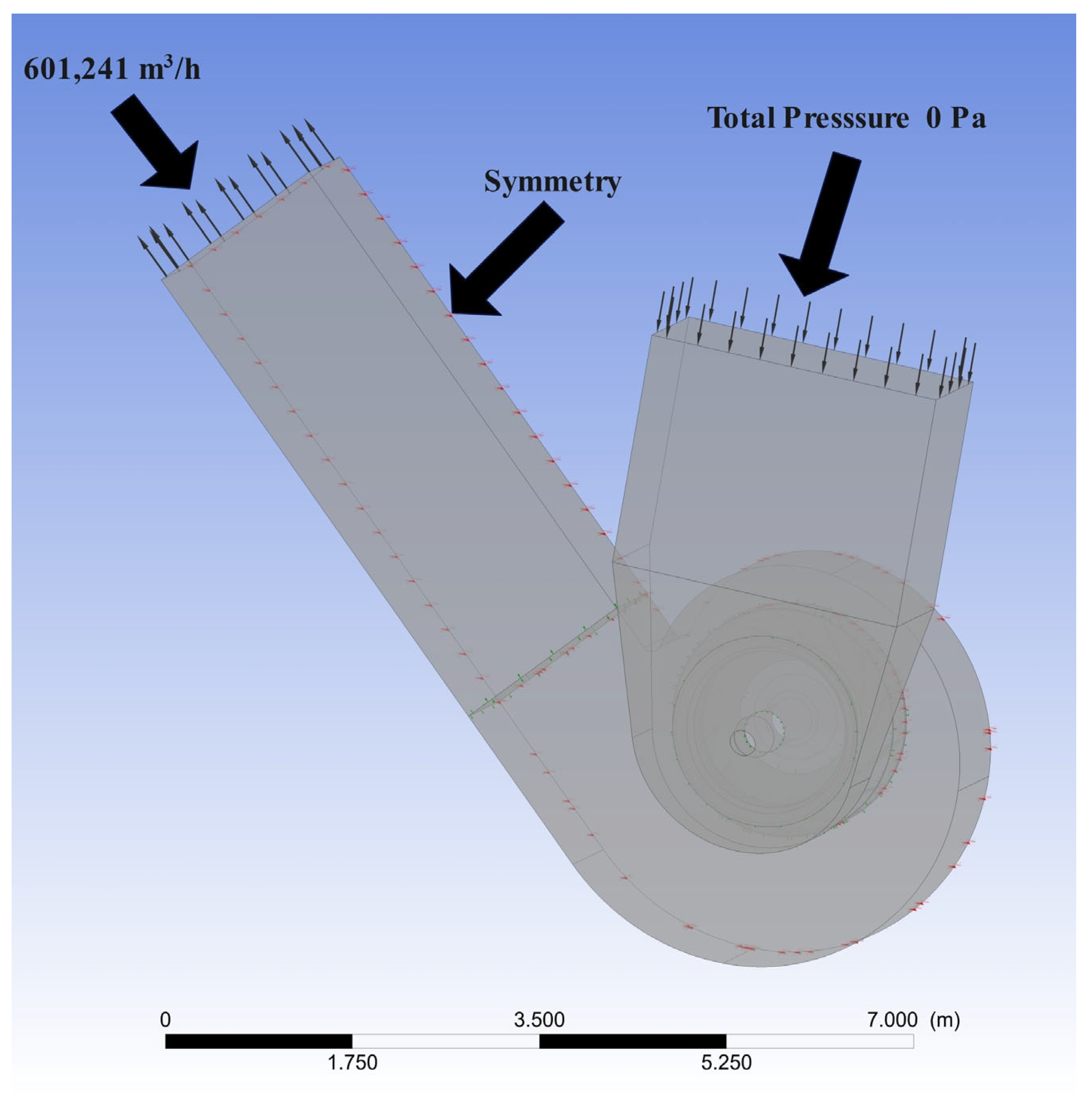

2.3. Boundary Conditions and Solution Parameters

2.4. Experimental Study

3. Results and Discussion

3.1. General Performance Comparison

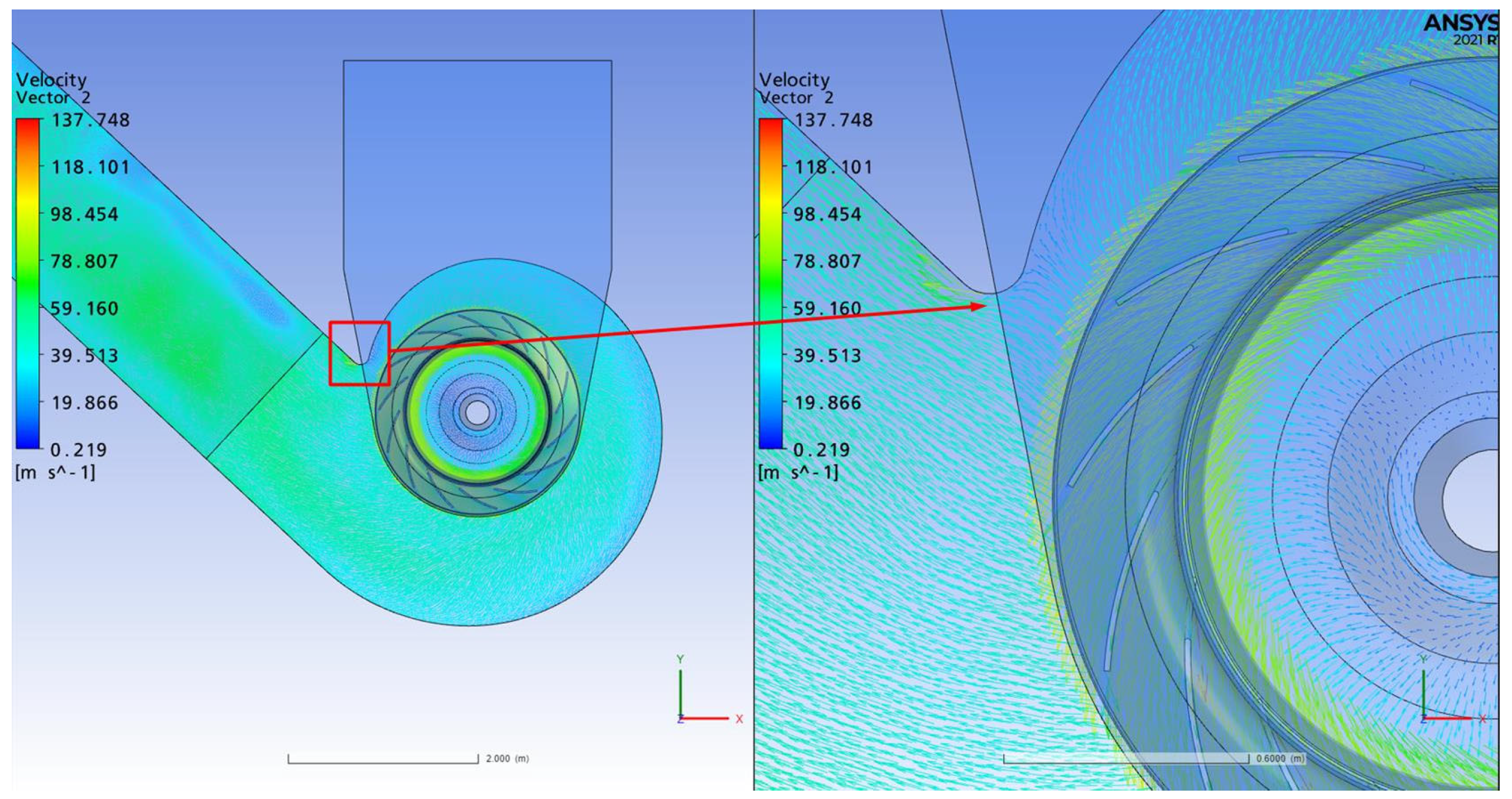

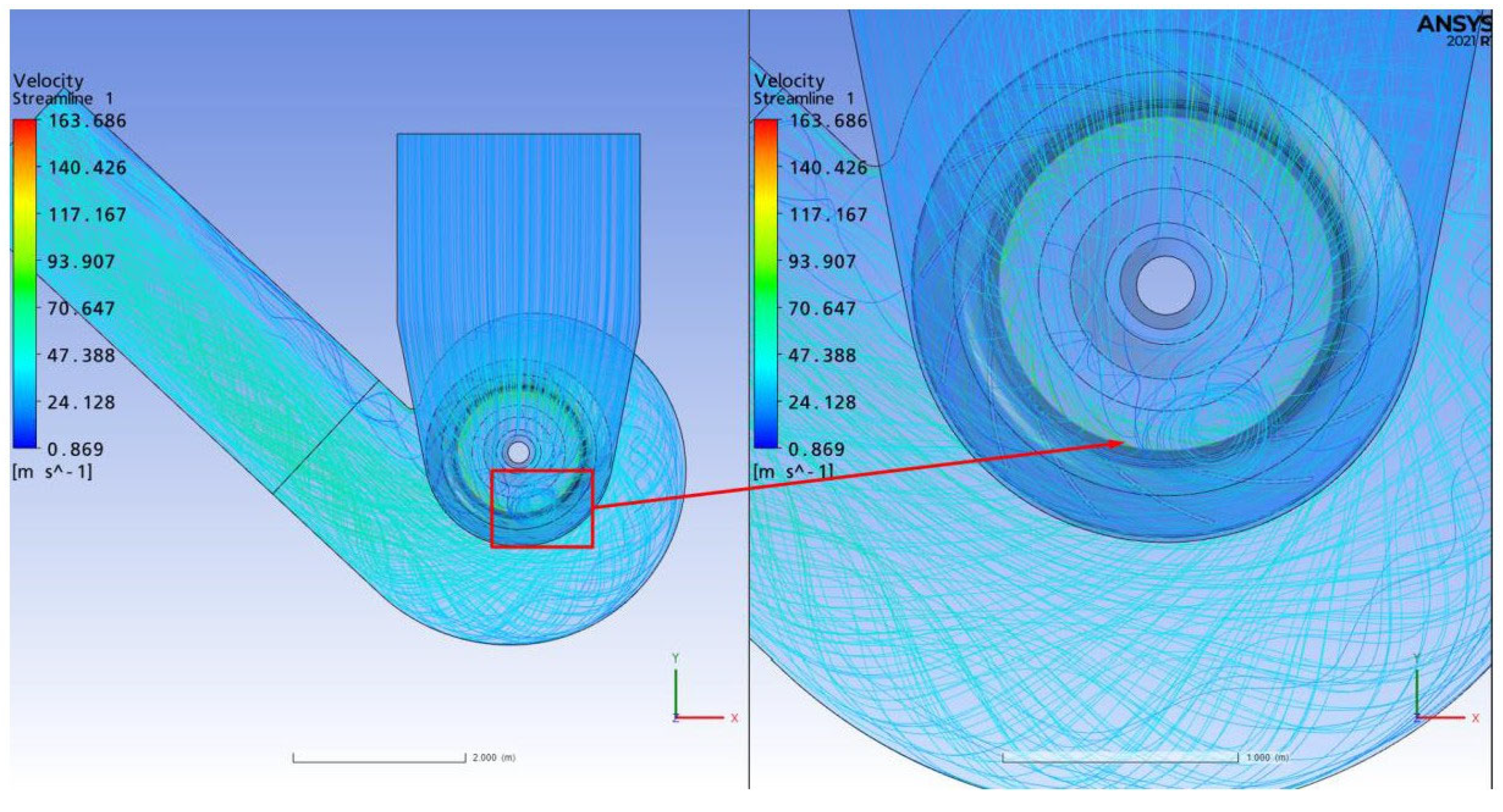

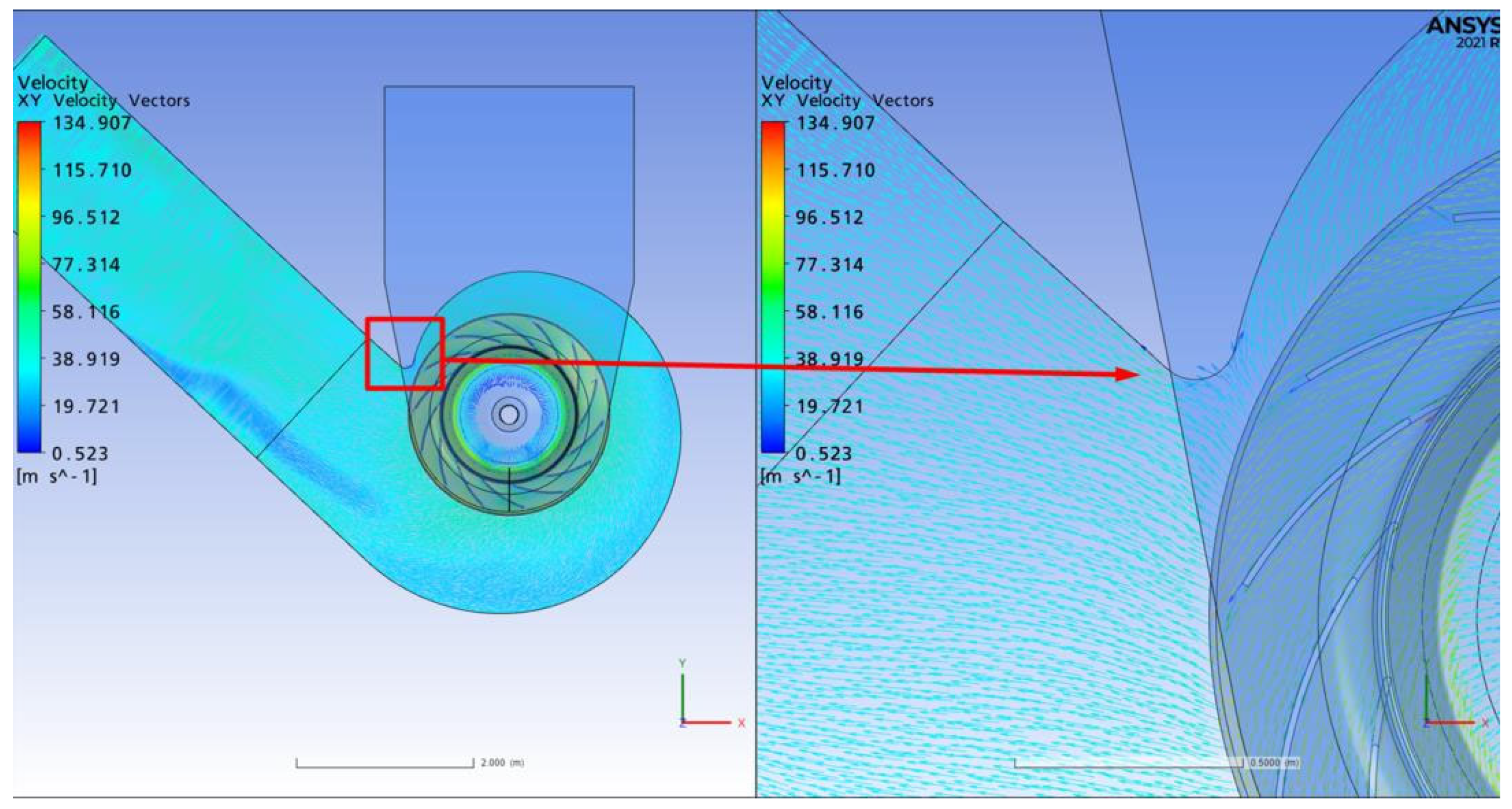

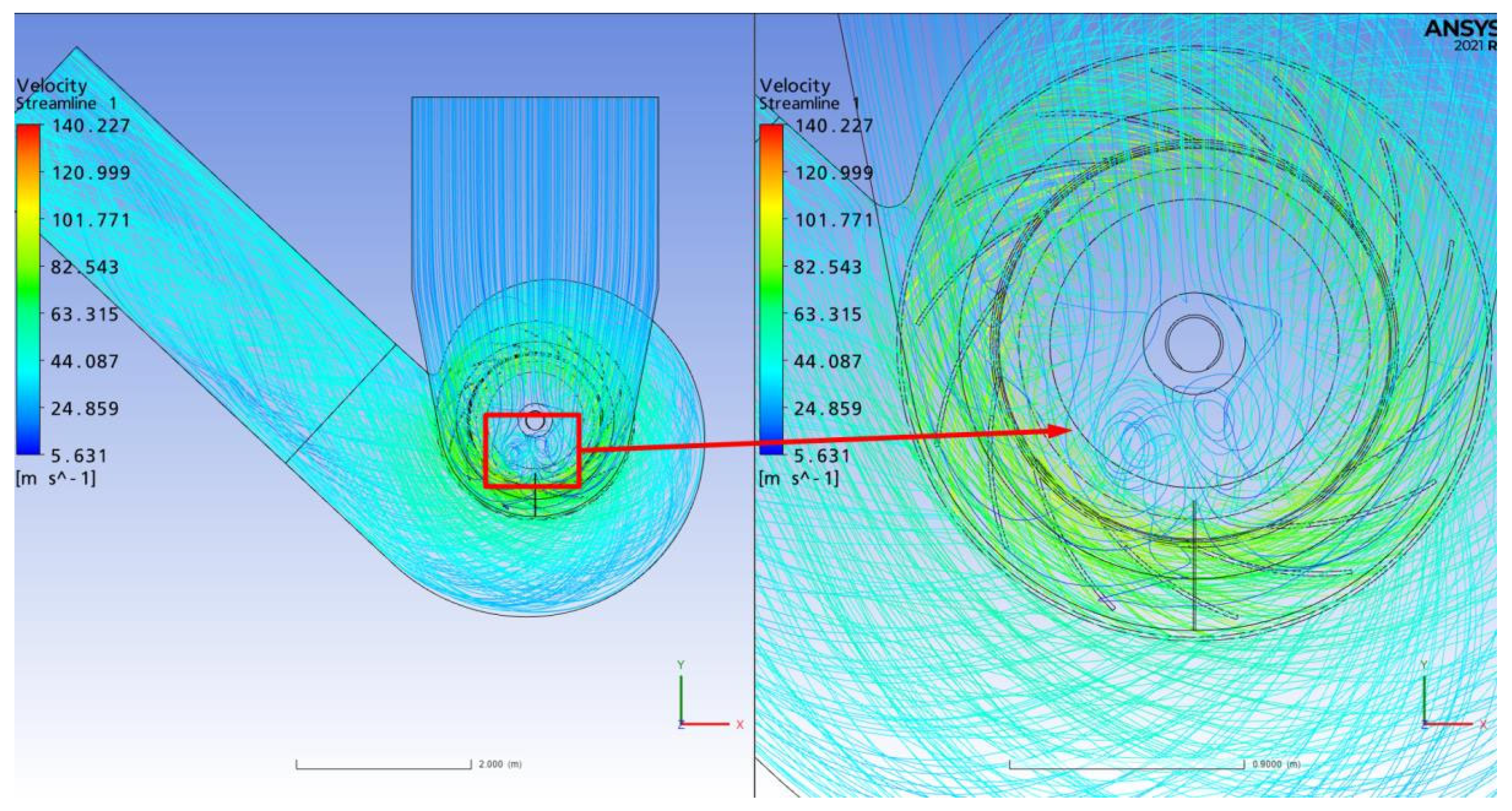

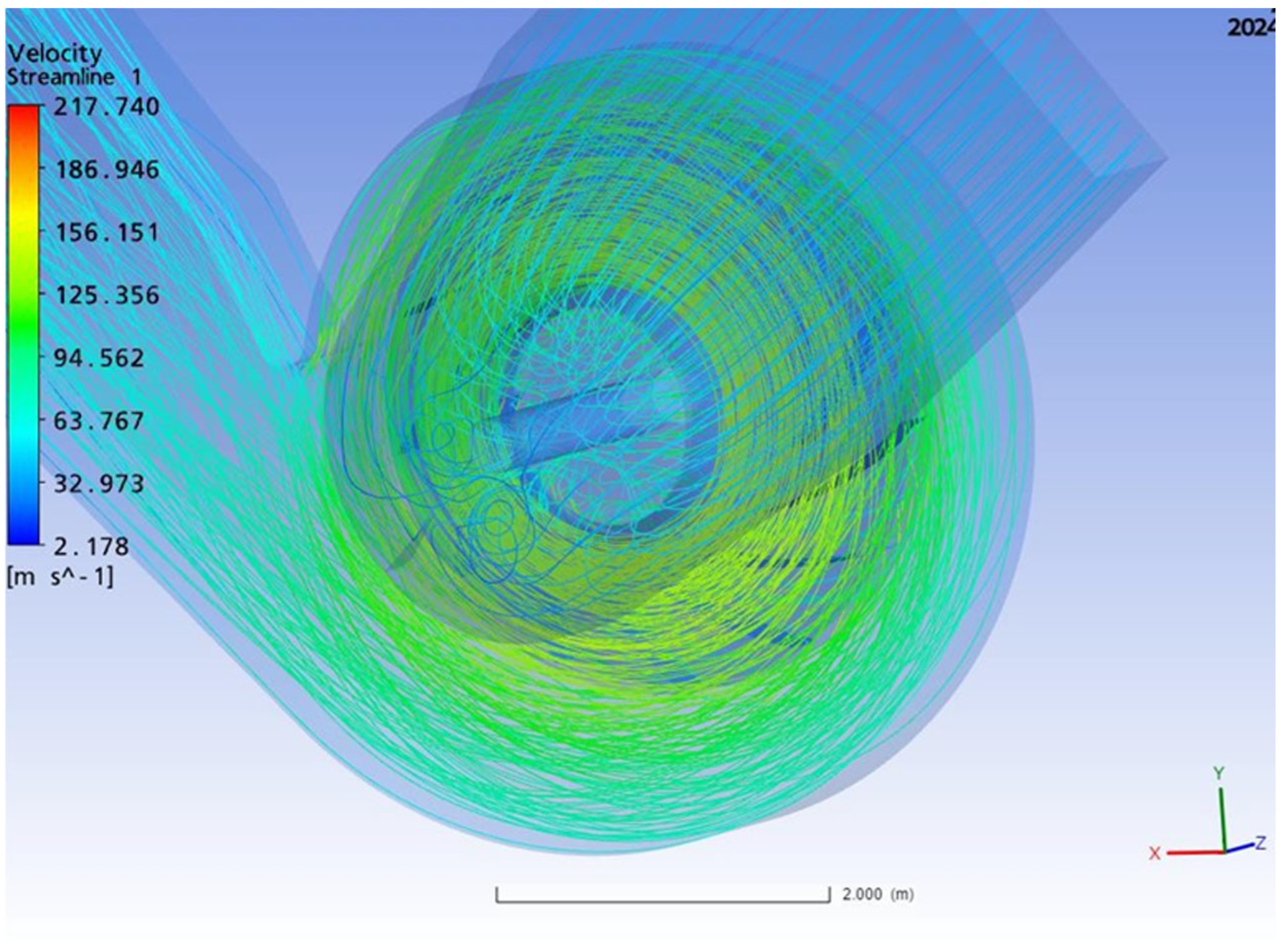

3.2. White Oven Fan Analysis Results

3.3. ID Fan Analysis Results

3.4. Field Tests and Comparative Performance Analysis

3.4.1. ID Fan Performance Comparison

3.4.2. White Oven Fan (19494) Performance Comparison

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lakshminarayana, B. Fluid Dynamics and Heat Transfer of Turbomachinery; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 1–809. [Google Scholar] [CrossRef]

- Moczko, P.; Odyjas, P.; Pietrusiak, D.; Więckowski, J.; Scholz, P.; Dix, M.; Osiecki, T.; Timmel, T.; Kroll, L. Enhancing efficiency of industrial centrifugal fans using blade adjustment mechanism. Energies 2022, 15, 893. [Google Scholar] [CrossRef]

- Ray, A.L.; Couse, D. Cement plant fan efficiency upgrades. IEEE Trans. Ind. Appl. 2017, 53, 1562–1568. [Google Scholar] [CrossRef]

- Fortini, A.; Suman, A.; Zanini, N. An experimental and numerical study of the solid particle erosion damage in an industrial cement large-sized fan. Eng. Fail. Anal. 2023, 146, 107058. [Google Scholar] [CrossRef]

- Choudhary, P.K.; Dubey, S.P. Energy efficient operation of induction motor drives: Economic and environmental analysis in cement manufacturing. Environ. Prog. Sustain. Energy 2019, 38, 672–679. [Google Scholar] [CrossRef]

- Cantini, A.; Leoni, L.; De Carlo, F.; Salvio, M.; Martini, C.; Martini, F. Technological energy efficiency improvements in cement industries. Sustainability 2021, 13, 3810. [Google Scholar] [CrossRef]

- Corsini, A.; Delibra, G.; Sheard, A.G. A critical review of computational methods and their application in industrial fan design. ISRN Mech. Eng. 2013, 2013, 625175. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Sahoo, N.; Kumar, A. Samsher Review on energy conservation and emission reduction approaches for cement industry. Environ. Dev. 2022, 44, 100767. [Google Scholar] [CrossRef]

- Catrini, P.; La Villetta, M.; Kumar, D.M.; Morale, M.; Piacentino, A. Analysis of the operation of air-cooled chillers with variable-speed fans for advanced energy-saving-oriented control strategies. Appl. Energy 2024, 367, 123393. [Google Scholar] [CrossRef]

- Yu, J.; Fu, W.; Wang, W.; Sun, P. Non-Axisymmetric Design and Flow Field Analysis of Boundary Layer Ingesting Fans. Aerosp. Sci. Technol. 2023, 140, 108429. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Astolfi, G. Advanced Process Control for Clinker Rotary Kiln and Grate Cooler. Sensors 2023, 23, 2805. [Google Scholar] [CrossRef]

- Amarasinghe, W.S.; Husum, I.; Tokheim, L.A. Waste Heat Availability in the Raw Meal Department of a Cement Plant. Case Stud. Therm. Eng. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Tang, G.; Liang, F.; Ma, Z.; Wang, Z.; Chen, J.; Zhu, Y.; Jin, M. Investigation of Cold Tube Structure on Flow Characteristics and Energy Separation in Vortex Tube Based on Numerical and Thermodynamic Analyses. Appl. Therm. Eng. 2024, 254, 123893. [Google Scholar] [CrossRef]

- Wang, J.; Kruyt, N.P. Design for High Efficiency of Low-Pressure Axial Fans with Small Hub-to-Tip Diameter Ratio by the Vortex Distribution Method. J. Fluids Eng. 2022, 144, 081201. [Google Scholar] [CrossRef]

- Maghsoudi, I.; Vaziry, M.A.; Mahmoodi, M. Experimental Investigation of Flow and Distortion Mitigation by Mechanical Vortex Generators in a Coupled Serpentine Inlet-Turbofan Engine System. Chin. J. Aeronaut. 2020, 33, 1375–1391. [Google Scholar] [CrossRef]

- Ryu, S.Y.; Cheong, C.; Kim, J.W.; Park, B.I. Analysis of Aerodynamic and Aeroacoustic Performances of Axial Flow Fans with Variable Winglet Curvature in Chordwise Direction. Results Eng. 2024, 21, 101857. [Google Scholar] [CrossRef]

- De Keulenaer, H. Energy Efficient Motor Driven Systems. Energy Environ. 2004, 15, 873–905. [Google Scholar] [CrossRef]

- Afkhami, B.; Akbarian, B.; Beheshti, A.N.; Kakaee, A.H.; Shabani, B. Energy Consumption Assessment in a Cement Production Plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

- Bae, Y.S.; Islam, M.D.; Choi, Y.D.; Kang, H.J.; Tae, S.J.; Kim, H.H. Back-Turn Approach for Optimal Operation of Booster Pump Systems. J. Appl. Fluid Mech. 2025, 18, 2202–2211. [Google Scholar] [CrossRef]

- Rakibuzzaman, M.; Kim, H.H.; Kim, K.W.; Suh, S.H.; Bae, Y.S. A Study on Booster Pump System with Flow Sensor for Individual Flow Control Method. J. Appl. Fluid Mech. 2022, 15, 889–900. [Google Scholar] [CrossRef]

- Van Rooij, M.; Medd, A. Reformulation of a Three-Dimensional Inverse Design Method for Application in a High-Fidelity CFD Environment. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; Volume 8, pp. 2395–2403. [Google Scholar] [CrossRef]

- Zhang, J.; Zangeneh, M. Multi-Point, Multi-Objective Optimisation of Centrifugal Fans by 3D Inverse Design Method. Int. J. Turbomach. Propuls. Power 2023, 8, 8. [Google Scholar] [CrossRef]

- Watanabe, H.; Zangeneh, M. Design of the Blade Geometry of Swept Transonic Fans by 3D Inverse Design. In Proceedings of the ASME Turbo Expo 2003, Collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 6A, pp. 603–612. [Google Scholar] [CrossRef]

- Namazizadeh, M.; Gevari, M.T.; Mojaddam, M.; Vajdi, M. Optimization of the Splitter Blade Configuration and Geometry of a Centrifugal Pump Impeller Using Design of Experiment. J. Appl. Fluid Mech. 2020, 13, 89–101. [Google Scholar] [CrossRef]

- Xie, X.; Li, Z.; Zhu, B.; Wang, H.; Zhang, W. Multi-Objective Optimization Design of a Centrifugal Impeller by Positioning Splitters Using GMDH, NSGA-III and Entropy Weight-TOPSIS. J. Mech. Sci. Technol. 2021, 35, 2021–2034. [Google Scholar] [CrossRef]

- Heo, M.W.; Kim, J.H.; Cha, K.H.; Kim, K.Y. Parametric Study on Aerodynamic Performance of a Centrifugal Fan with Additionally Installed Splitter Blades. In Proceedings of the ASME 2013 Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013; Volume 1B. [Google Scholar] [CrossRef]

- Rivera, E.D.J.; Besem-Cordova, F.; Bonaccorsi, J.C. Optimization of a High Pressure Industrial Fan. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, Virtual, Online, 7–11 June 2021; Volume 1. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Y.; Jin, L.; Chen, D. Performance and Flow Evolution of Windmilling Utilizing a Combination of Semi-Empirical Speed and CFD Models during Mode Transition of the Wide-Chord Fan. Aerosp. Sci. Technol. 2022, 123, 107468. [Google Scholar] [CrossRef]

- Zelenský, P.; Barták, M.; Zavrel, V.; Zmrhal, V.; Krupa, R. Numerical Analysis of Air Flow in a Modular Fan Unit Using CFD Simulation. E3S Web Conf. 2019, 111, 01008. [Google Scholar] [CrossRef]

- Darmanto, P.S.; Syahlan, A.; Wibowo, M.A. Redesign and Implementation of Big Fan Impellers for Enhancing Its Efficiency. Int. J. Fluid Mach. Syst. 2022, 15, 246–255. [Google Scholar] [CrossRef]

- McKervey, G.W.; Perry, B. Fan Applications in the Cement Industry. In Proceedings of the 35th IEEE Cement Industry Technical Conference, Toronto, ON, Canada, 23–27 May 1993; pp. 467–476. [Google Scholar] [CrossRef]

- Szpicer, A.; Bińkowska, W.; Stelmasiak, A.; Zalewska, M.; Wojtasik-Kalinowska, I.; Piwowarski, K.; Piepiórka-Stepuk, J.; Półtorak, A. Computational Fluid Dynamics Simulation of Thermal Processes in Food Technology and Their Applications in the Food Industry. Appl. Sci. 2025, 15, 424. [Google Scholar] [CrossRef]

- Oberkampf, W.L.; Trucano, T.G. Verification and Validation in Computational Fluid Dynamics. Prog. Aerosp. Sci. 2002, 38, 209–272. [Google Scholar] [CrossRef]

- Ahmad, R.; Kamaruddin, S. An Overview of Time-Based and Condition-Based Maintenance in Industrial Application. Comput. Ind. Eng. 2012, 63, 135–149. [Google Scholar] [CrossRef]

- da Silva, E.R.; Kyprianidis, K.G.; Camacho, R.G.R.; Säterskog, M.; Angulo, T.M.A. Preliminary Design, Optimization and CFD Analysis of an Organic Rankine Cycle Radial Turbine Rotor. Appl. Therm. Eng. 2021, 195, 117103. [Google Scholar] [CrossRef]

- Liu, X.; Dang, Q.; Xi, G. Performance Improvement of Centrifugal Fan by Using CFD. Eng. Appl. Comput. Fluid Mech. 2008, 2, 130–140. [Google Scholar] [CrossRef]

- Martin, V.; Falk, M. Optimizing the Performance and Reliability of Process Fans: Achieve Success and Avoid Problems by Implementing the Right Strategy. In Proceedings of the IEEE Cement Industry Technical Conference, Phoenix, AZ, USA, 9–14 April 2006; Volume 2006, pp. 345–358. [Google Scholar] [CrossRef]

- Zhou, S.; Luo, Y.; Mao, Z.; Lu, L.; Feng, W. Machine-Learning and CFD Based Optimization and Comprehensive Experimental Study on Diagonal Flow Fan for Energy Conservation and Efficiency Enhancement. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2310608. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Q.; Zhang, Y.; Jia, X. Numerical Simulation and Experiment Research on Aerodynamic Characteristics of a Multi-Blade Centrifugal Fan. Adv. Mater. Res. 2011, 317–319, 2157–2161. [Google Scholar] [CrossRef]

- Venter, A.J.; Owen, M.T.F.; Muiyser, J. Benchmarking the Performance of the Actuator-Disk Method for Low-Pressure Axial Flow Fan Simulation. J. Fluids Eng. 2025, 147, 011001. [Google Scholar] [CrossRef]

- Cai, J.C.; Zhang, J.Q.; Yang, C. Numerical Study of the Unsteady Flow Inside a Centrifugal Fan and Its Downstream Pipe Using Detached Eddy Simulation. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Virtual, Online, 16–19 November 2020; Volume 10. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Nisa, E.C.; Kuan, Y.-D.; Luo, W.-J.; Feng, C.-C. Combining Deep Neural Network with Genetic Algorithm for Axial Flow Fan Design and Development. Processes 2023, 11, 122. [Google Scholar] [CrossRef]

- Zoka, H.M.; Tabor, G.; Moxey, D.; Page, M.; Stokes, M. Multi-Point Aerodynamic Optimization of a Backward-Curved Impeller Fan. In Proceedings of the ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition, London, UK, 24–28 June 2024; Volume 6. [Google Scholar] [CrossRef]

- Demkowicz, L. A Note on Symmetry Boundary Conditions in Finite Element Methods. Appl. Math. Lett. 1991, 4, 27–30. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, Z.; Sun, Y.; Zhang, K.; Xi, G. Symmetric Boundary Condition for the MPS Method with Surface Tension Model. Comput. Fluids 2022, 235, 105283. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, J.; Li, B.; Xia, C.; Zhang, Y. Noise Reduction and Aerodynamic Performance Improvement of a Multi-Blade Centrifugal Fan. Phys. Fluids 2024, 36, 125168. [Google Scholar] [CrossRef]

- Le Floch, A.; Weiss, J.; Mohammed-Taifour, A.; Dufresne, L. Measurements of Pressure and Velocity Fluctuations in a Family of Turbulent Separation Bubbles. J. Fluid Mech. 2020, 902, A13. [Google Scholar] [CrossRef]

- Mollicone, J.P.; Battista, F.; Gualtieri, P.; Casciola, C.M. Effect of Geometry and Reynolds Number on the Turbulent Separated Flow behind a Bulge in a Channel. J. Fluid Mech. 2017, 823, 100–133. [Google Scholar] [CrossRef]

- Chen, Z.; He, H.; Yang, H.; Wei, Y.; Zhang, W. Asymmetric Flow in a Double-Suction Centrifugal Fan Induced by an Inclined Impeller. Phys. Fluids 2024, 36, 017113. [Google Scholar] [CrossRef]

- Bian, T.; Shen, X.; Feng, J. Numerical Study of the Influence of Splitter Geometry on Secondary Flow Control. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 235, 643–650. [Google Scholar] [CrossRef]

- Liśkiewicz, G.; Kabalyk, K.; Jaeschke, A.; Grapow, F.; Kulak, M.; Stajuda, M.; Kryłłowicz, W. Unstable Flow Structures Present at Different Rotational Velocities of the Centrifugal Compressor. Energies 2020, 13, 4146. [Google Scholar] [CrossRef]

- Pretorius, J.P.; Erasmus, J.A. Effect of Tip Vortex Reduction on Air-Cooled Condenser Axial Flow Fan Performance: An Experimental Investigation. J. Turbomach. 2022, 144, 031001. [Google Scholar] [CrossRef]

- Liu, Z.; Huang, G.; Chen, J.; Yu, Z. Coupling Effect between Inlet Distortion Vortex and Fan. J. Therm. Sci. 2023, 32, 1089–1104. [Google Scholar] [CrossRef]

- Ottersten, M.; Yao, H.D.; Davidson, L. Inlet Gap Effect on Aerodynamics and Tonal Noise Generation of a Voluteless Centrifugal Fan. J. Sound Vib. 2022, 540, 117304. [Google Scholar] [CrossRef]

- Chelabi, M.A.; Hamidou, M.K.; Hamel, M. Effects of Cone Angle and Inlet Blade Angle on Mixed Inflow Turbine Performances. Period. Polytech. Mech. Eng. 2017, 61, 225–233. [Google Scholar] [CrossRef]

- Leonard, T.; Spence, S.; Starke, A.; Filsinger, D. Numerical and Experimental Investigation of the Impact of Mixed Flow Turbine Inlet Cone Angle and Inlet Blade Angle. J. Turbomach. 2019, 141, 081001. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, T.; Mao, Z.; Lu, L. Analysis and Optimization Design of Internal Flow Evolution of Large Centrifugal Fans Under Inlet Distortion Effects. Appl. Sci. 2025, 15, 3521. [Google Scholar] [CrossRef]

- Ottersten, M.; Yao, H.D.; Davidson, L. Inlet Gap Influence on Low-Frequency Flow Unsteadiness in a Centrifugal Fan. Aerospace 2022, 9, 846. [Google Scholar] [CrossRef]

- Avşar, G.; Ezertaş, A.A.; Perçin, Ö.B. Aerodynamic Design and Performance Optimization of a Centrifugal Fan Impeller. In Proceedings of the ASME Turbo Expo 2023: Turbomachinery Technical Conference and Exposition, Boston, MA, USA, 26–30 June 2023; Volume 13D. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, P.; Li, J. Multi-Objective Multi-Variable Large-Size Fan Aerodynamic Optimization by Using Multi-Model Ensemble Optimization Algorithm. J. Therm. Sci. 2024, 33, 914–930. [Google Scholar] [CrossRef]

- Yin, H.; Zhao, H.; Li, Y.; Zhao, J.; Zhang, K. Airfoil Design and Flow Analysis of a Multi-Blade Centrifugal Fan: An Experimental and Simulation Study. Appl. Sci. 2024, 14, 11229. [Google Scholar] [CrossRef]

- Zhang, W.; Vahdati, M. A Parametric Study of the Effects of Inlet Distortion on Fan Aerodynamic Stability. J. Turbomach. 2019, 141, 011011. [Google Scholar] [CrossRef]

- Ren, F.; Rabault, J.; Tang, H. Applying Deep Reinforcement Learning to Active Flow Control in Weakly Turbulent Conditions. Phys. Fluids 2021, 33, 037121. [Google Scholar] [CrossRef]

- Zhang, X.; Ju, Y.; Li, Z.; Liu, F.; Zhang, C. Optimization of Three-Dimensional Blade and Variable Stators for Efficiency and Stability Enhancement of Multistage Axial Flow Compressor at Variable Speeds. J. Turbomach. 2024, 146, 041004. [Google Scholar] [CrossRef]

- Zhou, S.; Zhou, H.; Yang, K.; Dong, H.; Gao, Z. Research on Blade Design Method of Multi-Blade Centrifugal Fan for Building Efficient Ventilation Based on Hicks-Henne Function. Sustain. Energy Technol. Assess. 2021, 43, 100971. [Google Scholar] [CrossRef]

- Bamberger, K.; Carolus, T.; Belz, J.; Nelles, O. Development, Validation, and Application of an Optimization Scheme for Impellers of Centrifugal Fans Using Computational Fluid Dynamics-Trained Metamodels. J. Turbomach. 2020, 142, 111005. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, W.; Yang, H.; Wei, Y. Optimization Design and Experiment of a Double-Suction Centrifugal Fan with Flow Physics Analysis. Phys. Fluids 2025, 37, 027183. [Google Scholar] [CrossRef]

- Danieli, P.; Masi, M.; Delibra, G.; Corsini, A.; Lazzaretto, A. Assessment of MULTALL as Computational Fluid Dynamics Code for the Analysis of Tube-Axial Fans. J. Turbomach. 2021, 143, 071005. [Google Scholar] [CrossRef]

- Ma, T.; Lu, H.; Li, Q. Optimization Design Method Based on Parameter Reduction and Active Subspaces: Redistribution of Chordwise Loading at Blade Tips in a Transonic Axial-Flow Fan. Phys. Fluids 2024, 36, 095103. [Google Scholar] [CrossRef]

- ISO 5802; Industrial Fans—Performance Testing Using Standardized Airways. International Organization for Standardization: Geneva, Switzerland, 2001.

- DIN 24166; Industrial Fans—Technical Specifications. Deutsches Institut für Normung (DIN): Berlin, Germany, 1987.

| Fan Type | Flow Rate (m3/h) | Static Pressure (Pa) | Total Pressure (Pa) | Shaft Power (kW) | Efficiency (%) |

|---|---|---|---|---|---|

| Flour Kiln Fan | 601,241 | 2156 | 2447 | 490.1 | 83 |

| ID Fan | 441,643 | 8744 | 8544 | 1217 | 83 |

| Design Parameter | Narrow-Body Fan | Wide-Body Fan |

|---|---|---|

| Total Casing Width | 1982 mm | 2520 mm |

| Outlet Width | 1808 mm | 1858 mm |

| Vortex Breaker | Not present | Included |

| Shaft Cone Geometry | Unoptimized | Optimized |

| Separation Observed | Yes (in tongue) | Minimized |

| Expected Flow Uniformity | Low | High |

| Parameters | Design Value | CFD Analyses Results |

|---|---|---|

| Flow rate (m3/h) | 601,241 | 601,241 |

| Static Pressure (Pa) | 2156 | 2200 |

| Total Pressure (Pa) | 2447 | 2580 |

| Shaft Power (kW) | 490.1 | 520 |

| Efficiency (%) | 83 | 83 |

| Parameters | Design Value | CFD Analyses Results |

|---|---|---|

| Flow rate (m3/h) | 441,643 | 441,643 |

| Static Pressure (Pa) | 8744 | 8653 |

| Total Pressure (Pa) | 8544 | 9203 |

| Shaft Power (kW) | 1217 | 1356 |

| Efficiency (%) | 83 | 83.24 |

| Parameter | Old Fan (15 November 2023) | New Fan (8 May 2025, Corrected) | Difference (New-Old) | % Change |

|---|---|---|---|---|

| Volumetric Flow Rate (m3/h) | 401,494 | 401,494 | 0 | 0.0 |

| Total Pressure (mmSS) | 742.7 | 656.0 | −86.7 | −11.7 |

| Shaft Power (kW) | 1204.9 | 889.0 | −315.9 | −26.2 |

| Total Efficiency (%) | 67.4 | 80.6 | +13.2 pp | +19.6 |

| Parameter | Old Fan (15 November 2023) | New Fan (8 May 2025) | Difference (New-Old) | % Rate of Change |

|---|---|---|---|---|

| Flow Rate (m3/h) | 388,681 | 331,880 | −56,801 | −14.6 |

| Total Pressure (mmSS) | 102.4 | 102.4 | 0.0 | 0.0 |

| Shaft Power (with kiln) (kW) | 162.9 | 106.8 | −56.1 | −34.4 |

| Total Efficiency (%) | 66.5 | 86.7 | +20.2 | +30.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demir, F.; Özer, S.; Demir, U.; Körükçü, K.; Oduncu, H.; Ekin, M.Ş. Design Optimization and Field Validation of Industrial Fans with CFD for Cement Production: Performance, Energy Savings, and Environmental Benefits. Sustainability 2025, 17, 10279. https://doi.org/10.3390/su172210279

Demir F, Özer S, Demir U, Körükçü K, Oduncu H, Ekin MŞ. Design Optimization and Field Validation of Industrial Fans with CFD for Cement Production: Performance, Energy Savings, and Environmental Benefits. Sustainability. 2025; 17(22):10279. https://doi.org/10.3390/su172210279

Chicago/Turabian StyleDemir, Fatma, Salih Özer, Usame Demir, Kadir Körükçü, Hamza Oduncu, and Mehmet Şirin Ekin. 2025. "Design Optimization and Field Validation of Industrial Fans with CFD for Cement Production: Performance, Energy Savings, and Environmental Benefits" Sustainability 17, no. 22: 10279. https://doi.org/10.3390/su172210279

APA StyleDemir, F., Özer, S., Demir, U., Körükçü, K., Oduncu, H., & Ekin, M. Ş. (2025). Design Optimization and Field Validation of Industrial Fans with CFD for Cement Production: Performance, Energy Savings, and Environmental Benefits. Sustainability, 17(22), 10279. https://doi.org/10.3390/su172210279