1. Introduction

The acceleration of anthropogenic climate change [

1], primarily driven by carbon dioxide emissions from fossil fuel combustion [

2], poses a significant threat to global food systems [

3,

4]. Rising average temperatures, along with more frequent and intense heatwaves, are expected to substantially reduce crop yields in the coming decades [

5]. As global temperatures increase, so too does the necessity of climate-resilient agricultural strategies [

6]. Among the adaptive techniques being explored, passive shading of crops has emerged as a viable means to mitigate heat stress [

7]. These solutions, however, typically entail ongoing costs without providing any direct co-benefits that create additional value such as energy production. Agrivoltaics—the dual use of agricultural land for both crop production and solar energy generation—offers a compelling solution by integrating crop shading with the economic benefits of solar photovoltaic (PV) technologies [

8]. Farmers can either own and operate agrivoltaic systems to sell electricity to the grid or benefit from lease agreements with third-party solar developers. As a result, agrivoltaics represents a self-financing shading system that can improve crop performance [

9,

10,

11,

12] while diversifying farm income [

13]. Globally, agrivoltaic adoption is accelerating, with projects deployed across Europe [

14], Asia [

15,

16,

17], and North America [

18] in response to both land use efficiency and climate adaptation imperatives [

19,

20].

Concerns, however, have been raised about the long-term environmental risks of solar installations, particularly with regard to end-of-life decommissioning [

21,

22,

23]. Alberta, for instance, has experienced a proliferation of orphaned oil and gas wells, with the cost of remediation projected to exceed CAD

$100 billion [

24]. Such comparisons have prompted preemptive legislation targeting solar farms, raising questions about long-term land stewardship in the renewable energy sector and PV in particular [

25].

Given these concerns, it is essential to evaluate whether agrivoltaic systems—especially at the end of their electrical service life—continue to offer agronomic benefits that justify their physical presence on farmland. This study addresses this question by conducting a multi-phase investigation. First, the warranted and actual lifespans of key agrivoltaic system components, distinguishing between mechanical (e.g., racking, footings and PV modules) and electrical (e.g., PV modules energy generation and inverters) elements were evaluated. Second, the microclimate impacts of two agrivoltaic arrays: one fully powered with electricity extraction, and the other unpowered to simulate post-inverter-failure conditions are compared. Using in situ measurements of air and soil temperature as well as soil humidity, shading benefits in unpowered systems were assessed. Third, the yield gains associated with agrivoltaic shading based on crops previously shown to respond positively to such conditions were quantified in both agronomic and economic terms. Finally, how these benefits might change under projected future climate conditions, to assess whether unpowered agrivoltaics can be considered a semi-permanent climate adaptation strategy. Unpowered agrivoltaics are defined as PV arrays that are no longer connected to an inverter or a load (e.g., they are not producing electricity), but that continue to provide shading and microclimatic modifications through their physical structure on farmland. This scenario can occur after inverter failure, at the end of a project’s financial lifetime, or if arrays are intentionally repurposed for passive agricultural benefits.

2. Materials and Methods

2.1. Component Lifetimes

To assess the long-term value of agrivoltaic systems, published warranties and field data on the operational lifespans of key components was reviewed. Electrical components, particularly inverters, typically have the shortest expected lifespans [

26]. Photovoltaic modules, by contrast, can continue to function for longer—albeit with reduced output; for example, crystalline silicon modules typically exhibit a reduction in power output of approximately 0.5% per year [

27,

28,

29,

30]. Purely mechanical components, including racking systems and concrete or screw footings, generally have even longer operational lifespans [

31]. For instance, PV racking structures in long-standing installations in Europe remain operational after more than 35 years of field exposure, with refurbishments focused primarily on electrical components rather than structural systems [

32]. The implication is that the shading functionality of PV modules and their structural supports may outlast their ability to generate or deliver electricity, presenting an opportunity to evaluate their passive value to agriculture in an unpowered state.

2.2. Experimental Design

Two similar agrivoltaic arrays were installed on test plots, each comprising a series of fixed-tilt, bifacial crystalline silicon (c-Si) PV modules mounted on stilt-mounted racking [

33]. The treatments included modules with a nominal light transmittance of 8% [

34] and 44% [

35], manufactured by Brite Solar, Thessaloniki, Greece. The powered system was installed at a farm in Denfield, Ontario, Canada, while the unpowered system was deployed at the Western Innovation for Renewable Energy Deployment (WIRED) facility [

36], located at the Western University Field Station in Ilderton, Ontario, Canada, approximately 14 km from the Denfield site (

Figure 1). This design choice was necessitated by infrastructure availability and logistical constraints. As a result, background conditions such as soil type, drainage, and local microclimate may have differed between sites. While both sites are located in the same agro-climatic zone and subject to similar weather conditions, the possibility of confounding site effects should be considered when interpreting differences between powered and unpowered treatments. Vegetation differences, for example, grass vs. bare soil, may have influenced temperature dynamics. To ensure methodological rigor, each system was benchmarked against its respective control plot, enabling like-to-like comparisons. At the powered site (Denfield), the control plot consisted of bare-soil conditions, while at the unpowered site (Ilderton), the control consisted of open farmland under grass cover managed as pasture. These control plots enabled direct comparisons of shaded versus unshaded conditions at each location. Thus, the experiment comprised four treatment types in total: powered 44% c-Si array vs. grassed control (Denfield) and unpowered 8% and 44% c-Si arrays vs. bare-soil control (Ilderton).

In the first array (Denfield), electricity was extracted to a grid-tied system, maintaining the system in a powered state where the fraction of the energy converted to electricity striking the modules was removed from the local environment. In contrast, the second array (Ilderton) was configured to mimic an unpowered condition by disconnecting electrical outputs, simulating a post-inverter/PV module-failure scenario. In the unpowered array, absorbed solar energy is predominantly dissipated as heat due to carrier recombination, whereas in the powered array, a portion of this energy is exported as electricity. A complete surface-energy-balance analysis would be required to quantify these fluxes, which was beyond the scope of this study (for example, see Mattei et al. [

37] and Armstrong et al. [

38]). In both arrays, soil temperature measurements were collected at fixed intervals during peak summer conditions, with results compared to their respective unshaded control plots.

To capture additional microclimatic impacts of agrivoltaics, air temperature measurements were recorded for the 44% c-Si treatment and its control in the powered system, as this site aimed to evaluate potential thermal effects on crop canopies from active electricity generation. Conversely, soil humidity measurements were conducted at the unpowered site, where shading effects were expected to influence soil water retention more strongly in the absence of electrical operation. This complementary sensor deployment enabled site-specific insights into how powered and unpowered agrivoltaic systems differentially influence above- and below-ground microclimatic conditions.

Temperature and soil moisture were measured using Jericho TH-1 and Teros 10 by Meter Group, respectively. Each probe was installed at a depth of 7.6 cm (3 inches). For the probes, careful calibration was used to ensure accuracy. A three-point calibration was conducted in cold, warm, and hot water baths, yielding accuracies of ±0.5 °C for temperature, while the soil humidity sensor was factory calibrated at ±0.03 m3/m3 for volumetric water content. Logging was performed at 1 s intervals and down sampled to 5 min and 15 min for unpowered and powered arrays. Quality control included visual inspection of time series data, removal of spurious spikes, and consistency checks across diurnal cycles. Given the rigorous calibration and stable performance of the probes, single-sensor deployment was deemed sufficient for this pilot-scale study.

2.3. Statistical Analysis

Raw data were screened for quality assurance, and any incomplete or erroneous values (e.g., sensor dropouts, outliers) were excluded. The dataset was then compiled into treatment-wise time series for analysis. Daily averages were calculated for each treatment by generating pivot tables in a spreadsheet, grouping all sensor readings by date and treatment type.

For each variable (soil temperature, air temperature, and soil humidity), descriptive statistics were calculated, including mean, standard deviation (SD), standard error (SE), variance, skewness, and kurtosis. Treatment differences were assessed using one-way Analysis of Variance (ANOVA) (unpowered array: 8% c-Si, 44% c-Si, control; powered array: 44% c-Si vs. control). ANOVA outputs are reported with the F statistic, degrees of freedom, and associated p-values, alongside the critical F value for the given α = 0.05 significance threshold.

2.4. Yield-Responsive Crops

Data from published agrivoltaic studies identifying crops that exhibit increased yield or quality under partial shading conditions was compiled.

Table 1 reports the ranges of crop yield increase under agrivoltaic systems across various countries and crop types. Yield improvements are expressed in percentages for diverse crops, including cereals, vegetables, and herbs. The analysis is restricted to a fixed-tilt array with c-Si PV module technology. Reported transparencies are approximate, derived from module width and inter-row spacing, and thus, they provide non-uniform shading. It is important to note that in this study, the 8% and 44% transparent c-Si modules reflect manufacturer-reported optical transmittance values used in the experiment. These were agrivoltaic-specific bifacial modules, whereas the transparency values presented in

Table 1 for the literature synthesis represent effective shading fractions derived from conventional (fully opaque) modules, and the semi-transparency comes from module width and inter-row spacing, leaving unshaded gaps.

Table 2 outlines the crop type for each crop-country pairing, along with national and global production volumes (measured in million tonnes) and associated market prices. These data were compiled from various publicly accessible agricultural databases and commodity pricing sources.

Market-based examples of agrivoltaic systems further corroborate these findings. In France, the Sun’Agri pilot program reported grape yields 20–60% higher under dynamic PV shading compared to open-field controls [

76]. Similarly, agrivoltaic trials in Granges-sur-Lot demonstrated up to 50% higher eggplant harvests under modules than in unshaded plots [

77]. In addition, Ombrea’s asparagus demonstration site in Lot-et-Garonne revealed improved soil temperature regulation and crop resilience under PV cover [

78]. These market-linked case studies demonstrate that shading benefits are not only theoretical but have already translated into measurable agricultural and economic gains.

3. Results

3.1. Component Lifespan Summary

Figure 2 presents the range of lifetimes for key agrivoltaic system components. The inverter, as expected, demonstrates the shortest lifespan. PV modules and racking systems, however, remain structurally viable for shading even after their power-generating function diminishes or ceases. Based on this analysis, PV systems can continue to provide agronomic value in the form of passive shading for almost 100 years beyond inverter failure (

Table 3). While tempered glass used in PV modules possesses the intrinsic durability to last for centuries, actual operational lifespan is typically constrained by encapsulant degradation—particularly delamination and adhesive failure [

79,

80].

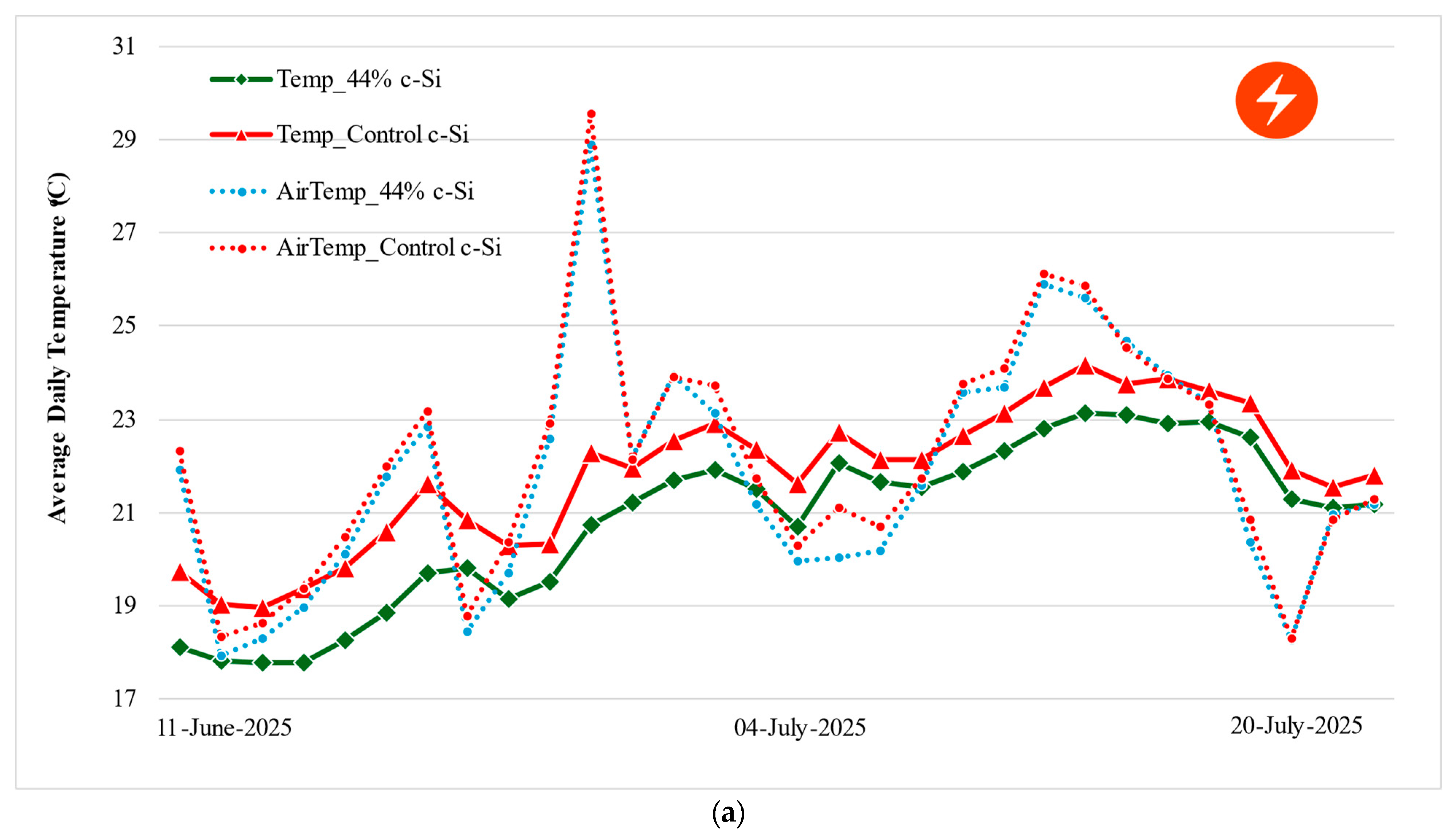

3.2. Microclimate Comparison: Powered vs. Unpowered

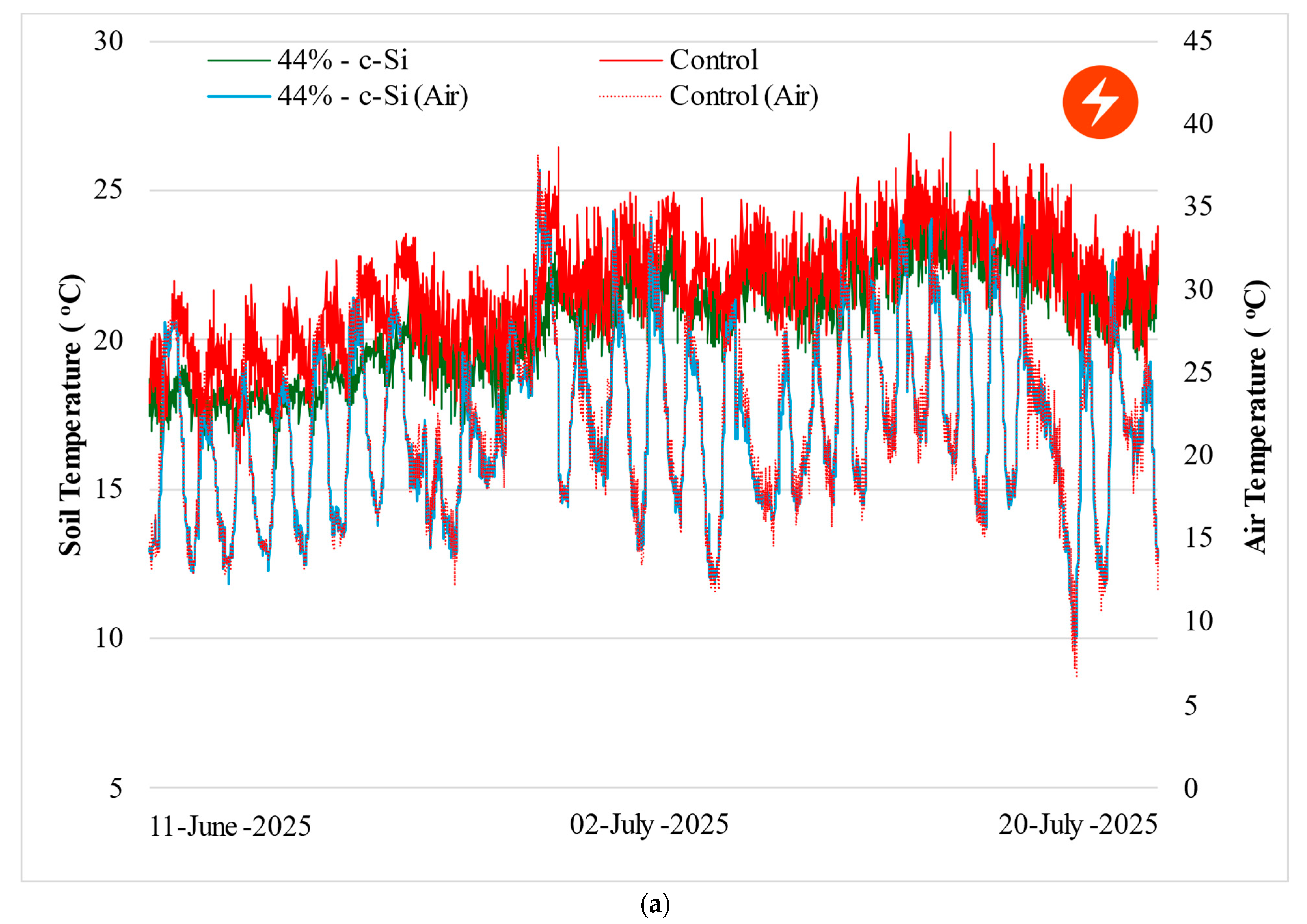

Significant soil temperature reductions were recorded beneath the 44% transparent PV modules in both powered and unpowered conditions (

Figure 3). For the powered array, the mean soil temperature under the 44%-transparency modules was 20.7 °C, compared to 21.7 °C in the unshaded control. This represents an average reduction of 1.0 °C over the two-month measurement period, with a maximum instantaneous reduction of 5.0 °C. In addition, air temperature measurements indicated a cooling effect under the 44%-transparent c-Si modules, with a mean temperature of 21.8 °C, approximately 0.3 °C lower than the control (22.1 °C), and a maximum reduction of 6.8 °C during peak daytime conditions.

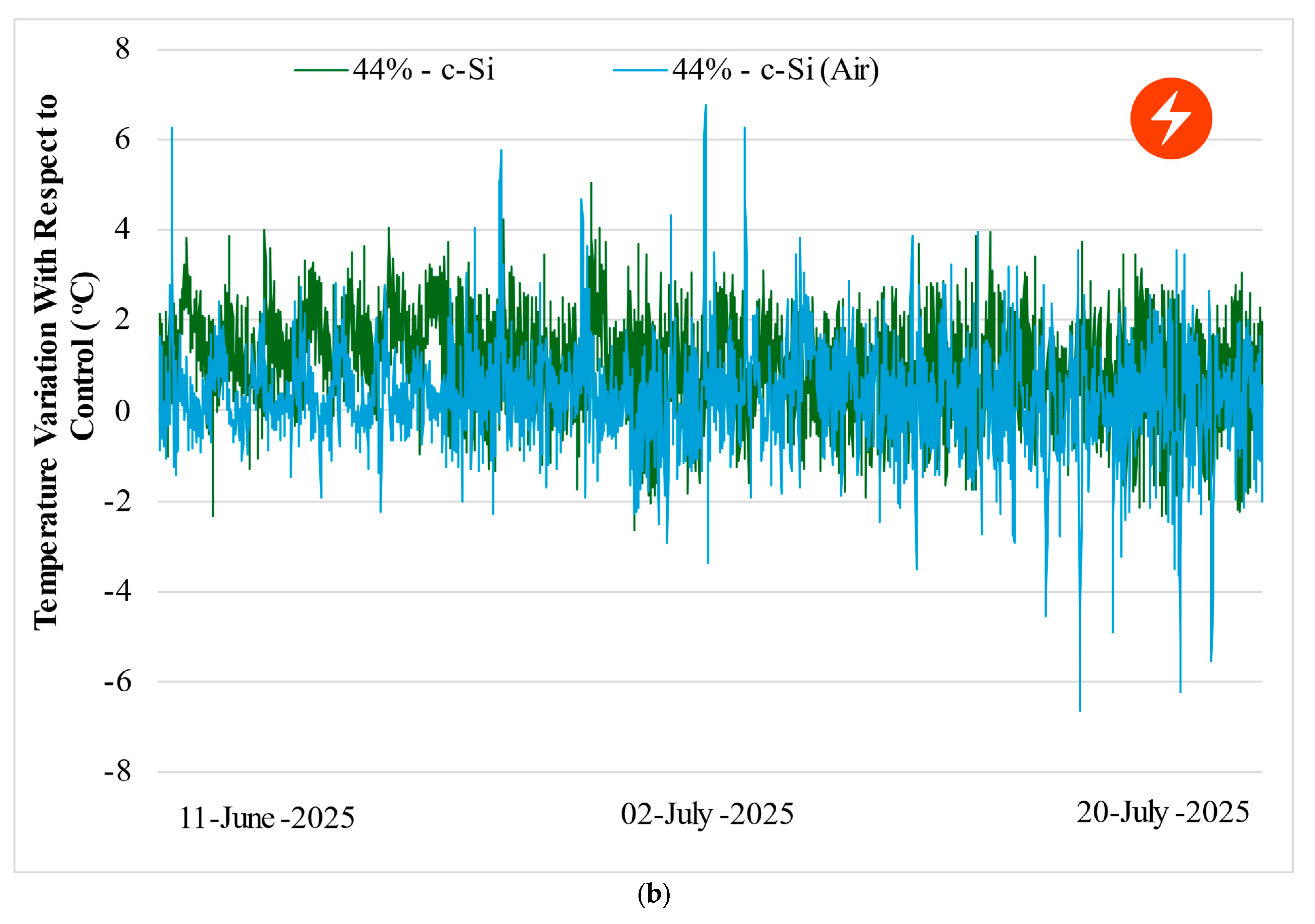

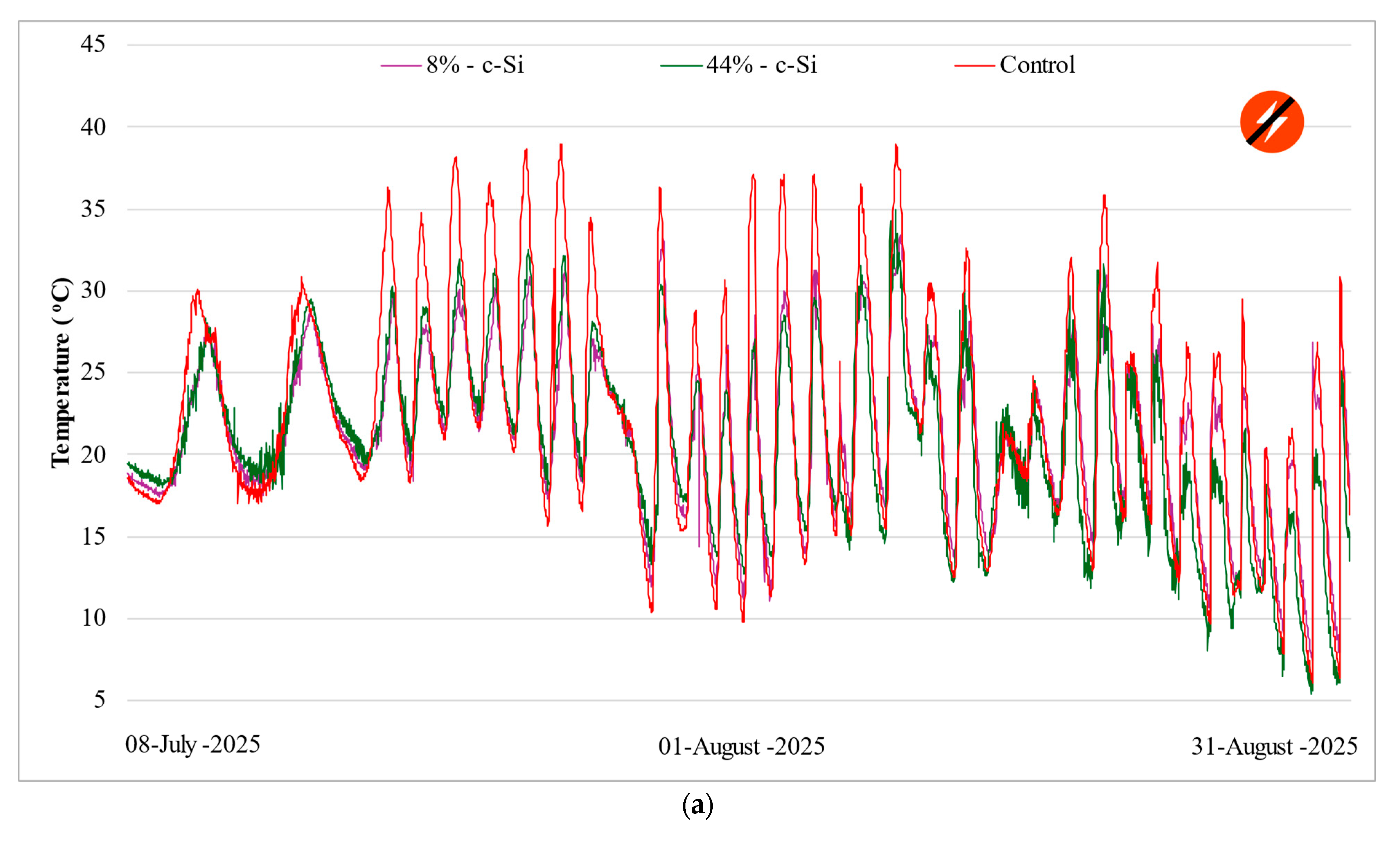

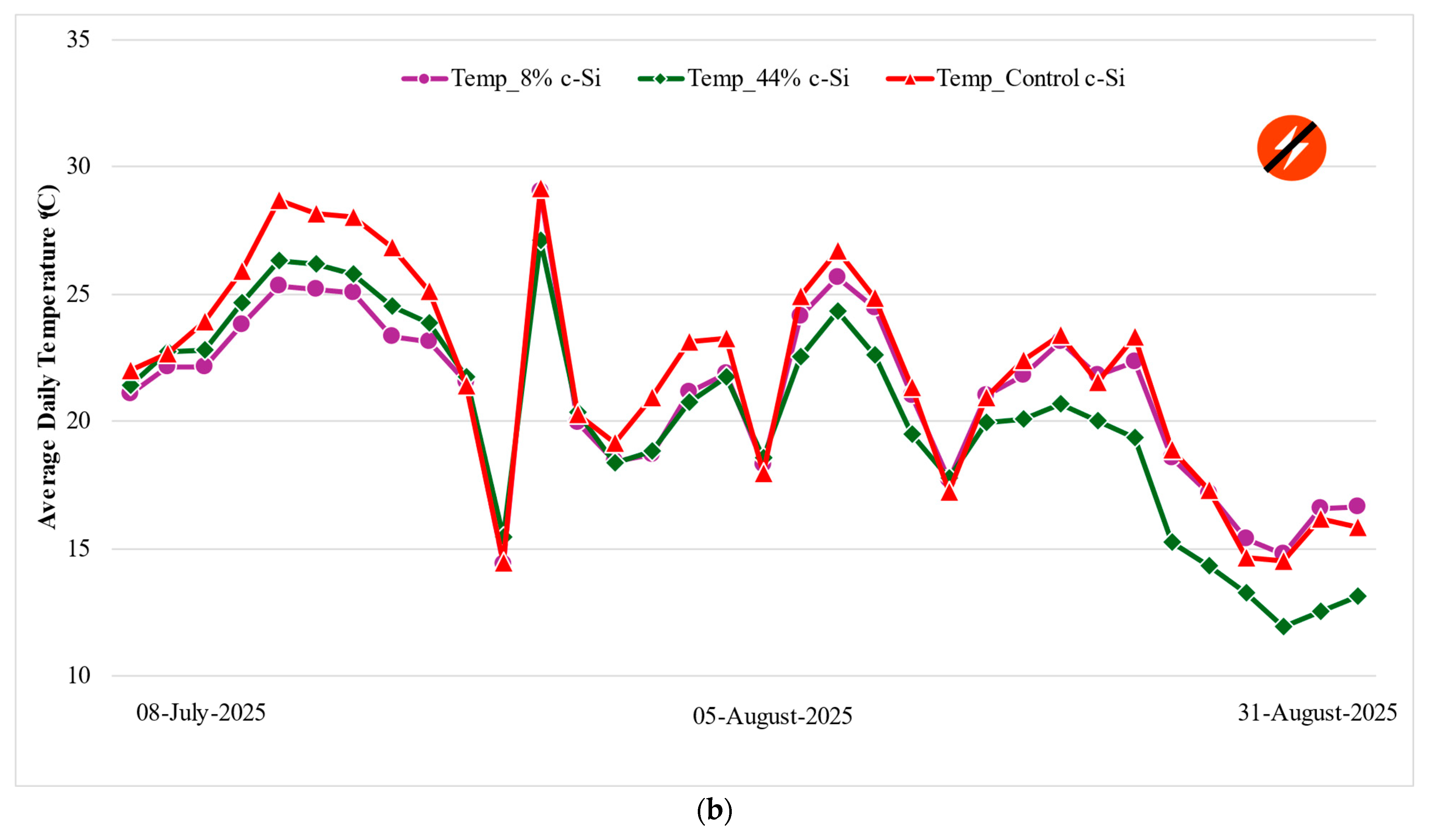

For the unpowered array, shading effects were more pronounced (

Figure 4). The mean soil temperature under the 8% transparent modules was 21.3 °C, and under the 44% transparent modules 20.7 °C, compared to 22.2 °C in the control. This equates to an average reduction of 0.9 °C beneath the 8% modules, with a maximum single-point reduction of 14.1 °C; and an average reduction of 1.6 °C beneath the 44% modules, with a maximum single-point reduction of 11.9 °C. Although the magnitude of reduction appeared stronger under the unpowered system, this may partly reflect differences in vegetation and substrate, which can influence soil albedo, evapotranspiration, and heat capacity. Nonetheless, in both systems, the agrivoltaic treatments consistently lowered soil temperatures compared to unshaded plots.

Complementary soil humidity measurements further supported these shading effects. The control plot consistently exhibited lower moisture retention (0.231 m

3/m

3) compared to the agrivoltaic treatments, which averaged 0.245 m

3/m

3 beneath the 8% modules, and 0.234 m

3/m

3 beneath the 44% modules.

These results indicate that unpowered PV shading not only moderates soil temperatures, but also enhances soil moisture conservation relative to unshaded conditions. These properties have already been shown to be beneficial for a wide range of crops (

Table 1) and are now confirmed for unpowered agrivoltaics.

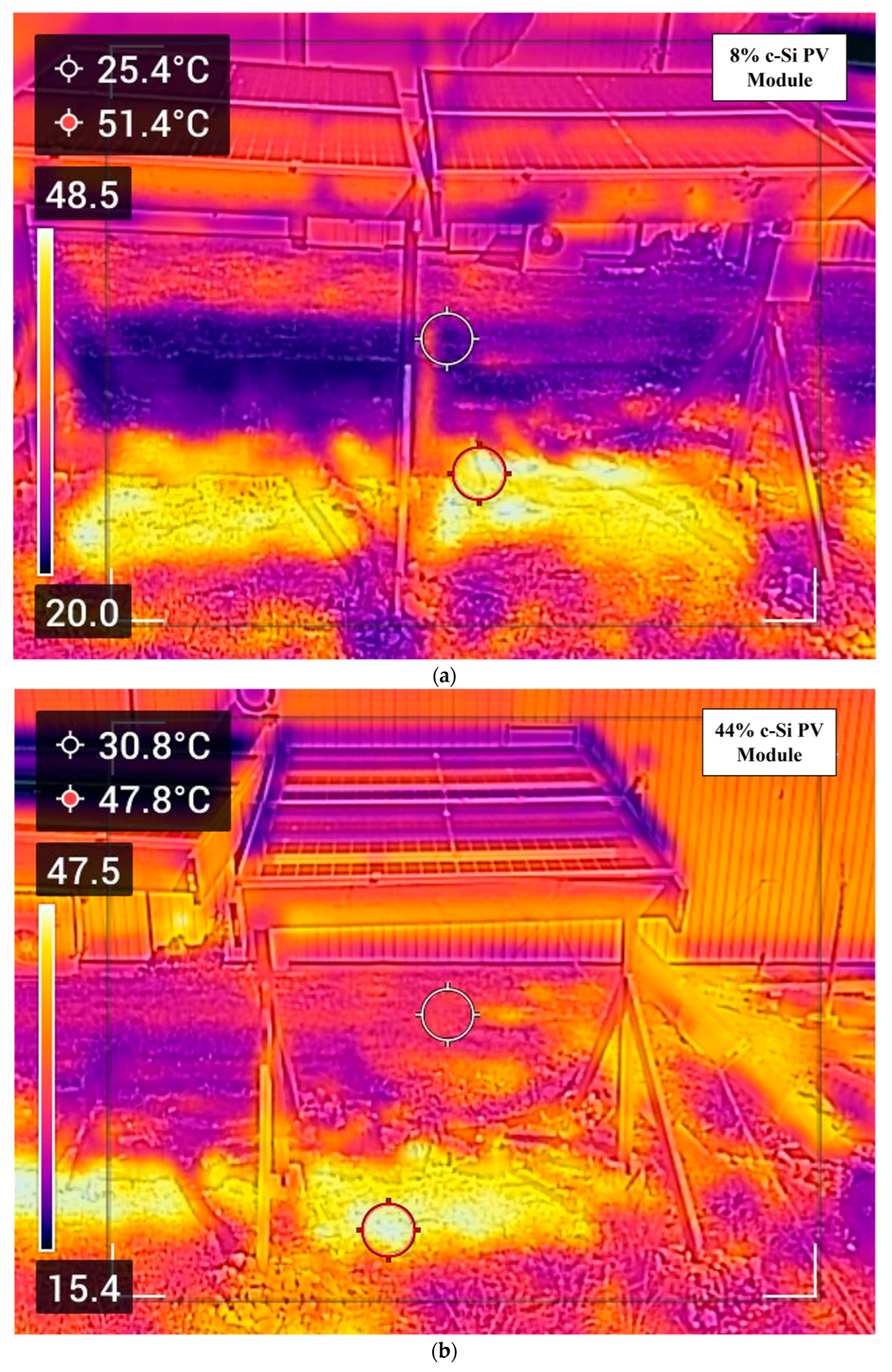

To further validate these findings, thermal imagery from the unpowered site is included (

Figure 5), which visually illustrates the cooler soil surface temperatures beneath agrivoltaic modules compared to adjacent unshaded areas. For example, under the 8% c-Si PV modules, the temperature under the shade is approximately 20 °C as compared to around 40 °C on the outside.

Single-day soil temperature profiles were examined for both the powered and unpowered systems to provide finer resolution of diurnal dynamics (

Figure 6). In both the powered and the unpowered system, soil temperatures remained consistently lower beneath the 44%c-Si modules compared to the control.

3.3. Statistical Analysis

For the powered array, soil temperature under the 44% c-Si treatment averaged 20.71 °C, compared to 21.73 °C in the unshaded control. Variability was relatively low across treatments (SD ≈ 1.9 °C for 44% and 1.8 °C for the control). ANOVA indicated a highly significant treatment effect (F(1, 4882) = 359.19, p < 0.001), confirming that the 44% c-Si treatment significantly reduced soil temperatures relative to the control.

Air temperature followed a similar but weaker pattern, averaging 21.81 °C under the 44% c-Si array compared to 22.11 °C in the control (SD ≈ 5.07 °C vs. 5.20 °C, respectively). ANOVA results showed a small but statistically significant difference (F(1, 4882) = 4.22, p = 0.04). This suggests that the shading effect of the 44% c-Si array moderated air temperature compared to the unshaded condition.

For the unpowered array, descriptive statistics indicated that mean soil temperature varied across treatments, with values of 21.31 °C under the 8% c-Si array, 20.68 °C under the 44% c-Si array, and 22.25 °C in the control. Variability was lowest in the 8% treatment (variance = 23.97) and highest in the control (variance = 46.84). The one-way ANOVA showed significant differences in mean temperature among treatments (F = 63.56, df = 2.10218, p < 0.001). Comparisons suggest that both shaded treatments reduced temperature compared to the control, with the 44% array having the greatest cooling effect.

Mean soil humidity was 0.245 m3/m3 under the 8% c-Si array, 0.234 m3/m3 under the 44% c-Si array, and 0.231 m3/m3 in the control. Variability was lowest in the control (variance = 0.00065) and highest in the 44% treatment (variance = 0.00267). ANOVA results indicated significant differences among treatments (F = 95.06, df = 2.10218, p < 0.001). Soil humidity was consistently higher under both shaded treatments compared to the control, with the 8% array producing the greatest increase.

Figure 7 presents the daily temperature patterns for the powered and unpowered arrays, illustrating consistently lower temperatures beneath the modules compared to the respective controls.

3.4. Quantified Yield Gains and Economic Impacts

Yield enhancements were converted into estimated additional farm income by applying current market prices for each crop. As summarized in

Table 4, the results illustrate the potential economic co-benefits of passive shading provided by unpowered agrivoltaic systems. These income calculations are presented as illustrative estimates based on extrapolations from reported crop yield responses under agrivoltaic systems. Given that the underlying studies span diverse contexts, crop management practices, and market conditions, these figures should not be interpreted as precise forecasts, but rather as indicative of the potential economic scale, subject to practical constraints on land use, adoption, and system design.

4. Discussion

4.1. Agronomic Value of Powered Versus Unpowered Agrivoltaics

The experimental results demonstrate that both powered and unpowered agrivoltaic systems can significantly reduce soil temperature relative to unshaded controls. For example, beneath 44% transparent modules, the unpowered system lowered average soil temperature by 1.6 °C compared to the control, with single-point reductions as high as 11.9 °C. In contrast, the powered system produced a smaller average reduction of 1.0 °C and a maximum of 6.8 °C. Although the unpowered site showed more pronounced reductions, the local vegetation and ground cover differences may have amplified this effect. Even accounting for such site-specific variation, the persistence of cooling in both systems supports the broader conclusion that agrivoltaic structures offer enduring microclimate benefits even after electrical generation ceases. Previous studies have shown similar soil temperature reduction characteristics ranging from 1 °C [

8] to 5 °C [

92].

These findings align with controlled experimental observations that show shaded ground under PV modules can be 3–4 °C cooler, due to reduced solar radiation and increased evapotranspiration effects [

93]. Similar results have been reported in agrivoltaic contexts where shading produced soil temperature drops of 0.5–2.3 °C compared to full-sun controls [

94]. Cover crops and vegetative covers have been shown to reduce spring time soil temperatures—by intercepting solar radiation and increasing latent heat flux—compared to bare soil, with reductions ranging up to several degrees Celsius; additionally, vegetative covers modify soil thermal properties such as heat capacity and moisture retention, further influencing temperature dynamics [

95].

The subsequent implications of reduced soil temperatures are very significant. Studies show that soils with increased temperatures increase the decomposition of soil organic matter [

96,

97,

98,

99,

100], thus exacerbating soil carbon dioxide efflux and subsequently, contributing to global warming [

95]. This is complemented by the fact that previous study on agrivoltaic systems in warmer climates have shown enhanced soil moisture, organic carbon, nitrogen–phosphorus–potassium nutrients, microbial biomass, and urease activity [

101].

4.2. Policy Implications

Current policy debates around solar PV decommissioning should be reframed to account for the enduring utility of agrivoltaic structures. While electrical components such as inverters and modules may degrade in electrical performance over time, the mechanical infrastructure retains its function as an agronomic asset through partial shading. The systems can provide shade that can reduce heat stress on crops [

102,

103], leading to improved growth and yield (

Table 1). The shading provided by agrivoltaic systems have also shown to be beneficial for pollination services [

42]. In addition, agrivoltaic grazing systems allow for sustainable livestock grazing beneath solar panels by providing cover for animals [

104]. Policymakers should consider alternative frameworks for post-electrical-use agrivoltaics—such as permitting reduced regulatory obligations if systems continue to deliver farm productivity benefits. Thus agrivoltaics can be viewed as analogous to shelterbelt programs which serve as effective tools for soil conservation, reducing wind and water erosion, improving soil fertility, and enhancing biodiversity [

105]. Similarly agrivoltaics can be treated as shade net installations which also ameliorate solar radiation, temperatures, and relative humidity, leading to improved soil conditions and enhanced vegetable performance [

106,

107]. Thus, unpowered agrivoltaics represent a passive climate adaptation tool worthy of long-term consideration. Future work is necessary to determine if policies should be adapted to encourage repowering such agronomic assets.

4.3. Study Limitations

While this study provides preliminary evidence that unpowered agrivoltaic systems can continue to deliver valuable agronomic benefits, several limitations should be acknowledged.

4.3.1. Temporal Scope

The duration of the experimental observation—limited to peak summer conditions in one year—may not capture the full variability of plant and soil responses across an entire growing season or multiple climatic conditions. Microclimate effects, particularly those related to soil temperature and humidity, can vary with precipitation patterns [

108,

109] and local weather fluctuations [

110]. As such, short-term measurements may not fully represent long-term shading benefits, particularly in light of the impact of future climate change [

111].

4.3.2. Crop Diversity

The study relies on a limited number of crop types and shading configurations. While crops such as lettuce [

9,

12], strawberries [

10,

11], and amaranth [

19] are well-documented beneficiaries of partial agrivoltaic shading in Canada, the generalizability of results to other crops—particularly grains and root vegetables—remains uncertain. Moreover, the experimental arrays used fixed-tilt stilt mounted [

33], bifacial modules [

35,

112], which may not replicate the shading dynamics of more diverse or advanced agrivoltaic configurations (e.g., tracking systems, or dynamic shading systems).

4.3.3. Structural Integrity

This study assumes that PV modules and racking systems will remain structurally intact and safe after inverter failure. In reality, degradation [

113,

114,

115], wind damage [

116], corrosion [

117], or vandalism may compromise the physical integrity of modules or mounting systems over time, especially without ongoing maintenance [

118]. This raises questions about liability, safety, and the potential for diminishing shading benefits in the absence of electrical function and should be addressed in future work.

4.3.4. Economic Assumptions

The economic valuation of increased crop yields is based on current market prices and yield responses from literature. These values are highly context-dependent and may not reflect the profitability of unpowered agrivoltaics under fluctuating commodity prices [

119] or evolving farm input costs [

120]. Moreover, the yield-based income values reported are illustrative in nature. They reflect broad extrapolations from diverse agrivoltaic studies and economic assumptions and therefore should not be interpreted as predictive forecasts for specific regions or crops. Instead, these figures serve to demonstrate the potential magnitude of co-benefits, while acknowledging that actual outcomes will depend on adoption ceilings, logistical feasibility, and economic considerations.

4.3.5. Social and Regulatory Factors

The acceptance of leaving unpowered PV arrays on agricultural land as permanent infrastructure may vary depending on local policy frameworks, community attitudes, and perceptions about land stewardship. Although, studies in Canada [

121] and the U.S. [

122] have shown increased support from agrivoltaics, resistance from regulators or neighbors may limit the practical implementation of the study’s findings, even if agronomic benefits are demonstrable.

4.3.6. Experimental Conditions—Measurement Context

In the unpowered system, temperature was measured in pots surrounded by grass, whereas the powered system measurements were taken with bare soil directly underneath modules. Variations in ground cover and substrate (grass versus soil) are known to significantly impact soil temperature through changes in ground albedo, evapotranspiration, and heat capacity [

95]. Research has shown that vegetated surfaces under PV modules can reduce surface temperatures through evapotranspiration compared to bare ground [

123]. Therefore, differences in measurement context likely contributed to the observed temperature differentials between powered and unpowered arrays.

4.3.7. Experimental Conditions—Location Context

A key limitation of this study is that powered and unpowered arrays were installed at different sites (Denfield Vs. Ilderton). Although both are within the same regional climate zone, site-level differences in soil composition, moisture retention, and surrounding vegetation may have contributed to microclimate variation. Therefore, the results should not be interpreted as a direct head-to-head comparison, but rather as an indicative demonstration of how powered and unpowered agrivoltaic shading can influence soil temperature and moisture. Future research should aim to evaluate powered and unpowered configurations at the same site under otherwise identical conditions to isolate treatment effects more rigorously.

4.4. Directions of Future Research

Future research should expand on both the temporal and spatial scope of this study to improve the robustness and policy relevance of the findings.

4.4.1. Multi-Season Field Trials

Multi-season and multi-year field trials should be conducted to observe the agronomic effects of unpowered agrivoltaics across entire crop cycles. These studies should include a broader diversity of crops, soil types, and climate zones to enhance generalizability. Crop responses should be measured not only in terms of yield, but also quality, pest and disease incidence, nutrient benefits, and water use efficiency.

4.4.2. Powered Versus Unpowered Comparison

Comparative studies between powered and unpowered systems under identical environmental and agronomic conditions should be extended to quantify the precise biophysical differences—if any—that occur when electrical generation ceases. This includes evaluating potential changes in module surface temperature, longwave radiation absorption by crops, and convective air flows, which may influence plant growth under different energy states of the array.

4.4.3. Mechanical Degradation

Mechanical degradation over time should be studied more rigorously. This includes assessing corrosion of racking systems, structural integrity under snow and wind loads, and the risk of glass delamination or module breakage after electrical failure. Such work would clarify the realistic lifespan of shading functionality, inform maintenance requirements, and help define standards for long-term structural safety in unpowered agrivoltaic systems.

4.4.4. Economic Modeling

Economic models should be developed that incorporate full life-cycle costs and benefits of agrivoltaic installations under various ownership, maintenance, and energy generation scenarios. Sensitivity analyses can help evaluate the robustness of economic outcomes under different assumptions about inverter replacement, land value, crop prices, and climate change impacts. Moreover, open-source, low-cost racking designs [

124,

125], mounting mechanisms [

126], as well as measurement instruments [

127] could help immensely in improving the economic viability of agrivoltaic systems.

4.4.5. Legal and Regulatory Frameworks

Legal, regulatory, and governance frameworks surrounding agrivoltaic decommissioning and residual land use should be critically examined. Researchers should engage with policymakers to explore whether current solar end of life regulations adequately account for the dual-use value of agrivoltaics, and to propose updated permitting or tax schemes that support passive climate adaptation infrastructure.

4.4.6. Climate Change Scenarios

Lastly, as climate change advances, predictive models that integrate agronomic and energy outcomes under future temperature, precipitation, and solar radiation regimes should be developed. These models would allow researchers and decision-makers to evaluate the potential adaptive value of unpowered agrivoltaics under mid- and high-emission climate scenarios for 2050 and 2100.

5. Conclusions

This study demonstrates that agrivoltaic systems, even after the cessation of power generation, can continue to deliver meaningful agronomic and economic value through passive shading. At the system level, lifespan analysis revealed that while inverters typically fail within 5–20 years, PV modules remain electrically viable for at least 25–35 years and mechanically viable for up to ~1000 years, and racking and foundations can endure for 40 to more than 100 years depending on material design. This finding underscores the long-term shading potential of existing infrastructure, suggesting that decommissioned or unpowered arrays should not be dismissed as obsolete but rather reconsidered as durable agronomic assets. Analogous to shelterbelts or shade nets, these systems can continue to support soil conservation, reduce crop heat stress, and sustain livestock grazing even beyond their energy-producing lifespans.

Experimental findings showed that unpowered arrays provided stronger soil cooling effects than powered ones, with reductions of up to 11.9 °C beneath 44% transparent modules compared to unshaded controls. Soil moisture retention also improved, with volumetric water content increasing from 0.231 m3/m3 in control plots to as high as 0.245 m3/m3 under 8% modules. Air temperature reductions of up to 6.8 °C further demonstrate the potential of these systems to mitigate microclimate extremes. Such cooling effects have important implications for soil health, nutrient cycling, and crop productivity, reinforcing the role of unpowered agrivoltaics as a passive climate adaptation tool.

Yield modeling further indicated that these microclimate benefits can translate into substantial economic gains, with positive implications for farm resilience under increasingly volatile climate and market conditions. For example, unpowered agrivoltaic shading was associated with additional farm income of USD $3.9 billion for potatoes in Germany, and USD $32 billion for tomatoes in the U.S., with global potential exceeding USD $580 billion annually across major crops. These results illustrate the significant economic co-benefits of retaining PV infrastructure as a form of passive agricultural shading.

Policy frameworks must adapt to this dual-use reality. Current solar decommissioning regulations, which focus narrowly on electrical end-of-life management, overlook the enduring utility of PV infrastructure in agriculture. Integrating agronomic co-benefits into decommissioning policy could help reduce regulatory and economic barriers, while supporting long-term farm productivity, biodiversity, and climate resilience.

Nevertheless, future research should therefore expand multi-season trials, rigorously compare powered versus unpowered configurations under identical conditions, evaluate mechanical integrity over decades, and integrate life-cycle economics with climate adaptation modeling. In sum, the evidence presented here highlights the need to rethink agrivoltaics not solely as an energy technology but as a multi-functional agricultural infrastructure. By recognizing the post-electricity utility of these systems, policymakers, farmers, and researchers can unlock new pathways for sustainable land use, resilient food systems, and climate adaptation.

Author Contributions

Conceptualization, J.M.P.; methodology, U.J. and J.M.P.; validation, U.J. and J.M.P.; formal analysis, U.J. and J.M.P.; investigation, U.J.; resources, J.M.P.; data curation, U.J.; writing—original draft preparation, U.J. and J.M.P.; writing—review and editing, U.J. and J.M.P.; visualization, U.J.; supervision, J.M.P.; project administration, J.M.P.; funding acquisition, J.M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Canada Foundation for Innovation, the Ontario Research Fund, the Natural Sciences and Engineering Research Council of Canada and the Thompson Endowment.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to thank Martin De Groot for his support and helpful technical discussions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Callaghan, T.V.; Bergholm, F.; Christensen, T.R.; Jonasson, C.; Kokfelt, U.; Johansson, M. A New Climate Era in the Sub-Arctic: Accelerating Climate Changes and Multiple Impacts. Geophys. Res. Lett. 2010, 37, L14705. [Google Scholar] [CrossRef]

- Wuebbles, D.J.; Jain, A.K. Concerns about Climate Change and the Role of Fossil Fuel Use. Fuel Process. Technol. 2001, 71, 99–119. [Google Scholar] [CrossRef]

- Lobell, D.B.; Burke, M.B.; Tebaldi, C.; Mastrandrea, M.D.; Falcon, W.P.; Naylor, R.L. Prioritizing Climate Change Adaptation Needs for Food Security in 2030. Science 2008, 319, 607–610. [Google Scholar] [CrossRef]

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate Change and Food Systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef]

- Hultgren, A.; Carleton, T.; Delgado, M.; Gergel, D.R.; Greenstone, M.; Houser, T.; Hsiang, S.; Jina, A.; Kopp, R.E.; Malevich, S.B.; et al. Impacts of Climate Change on Global Agriculture Accounting for Adaptation. Nature 2025, 642, 644–652. [Google Scholar] [CrossRef]

- Keesstra, S.; Veraart, J.; Verhagen, J.; Visser, S.; Kragt, M.; Linderhof, V.; Appelman, W.; van den Berg, J.; Deolu-Ajayi, A.; Groot, A. Nature-Based Solutions as Building Blocks for the Transition towards Sustainable Climate-Resilient Food Systems. Sustainability 2023, 15, 4475. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading Greenhouses to Improve the Microclimate, Energy and Water Saving in Hot Regions: A Review. Sci. Hortic. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic Systems to Optimise Land Use for Electric Energy Production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Jamil, U.; Rahman, M.M.; Pearce, J.M. Photosynthetically Active Radiation Complexities in Agrivoltaic Policy Mandates: Insights from Controlled Environment Yields under Semitransparent Photovoltaics. J. Clean. Prod. 2025, 523, 146392. [Google Scholar] [CrossRef]

- Jamil, U.; Givans, J.; Pearce, J.M. Impacts of Type of Partial Transparency on Strawberry Agrivoltaics: Uniform Illumination Thin Film Cadmium-Telluride and Non-Uniform Crystalline Silicon Solar Photovoltaic Modules. Renew. Energy 2025, 247, 122913. [Google Scholar] [CrossRef]

- Jamil, U.; Pearce, J.M. Experimental Impacts of Transparency on Strawberry Agrivoltaics Using Thin Film Photovoltaic Modules under Low Light Conditions. Sol. Energy 2025, 290, 113375. [Google Scholar] [CrossRef]

- Jamil, U.; Rahman, M.M.; Hayibo, K.S.; Alrayes, L.; Fordjour, E.; Thomas, R.; Pearce, J.M. Transparency Effects in Agrivoltaics Lettuce Cultivation Using Uniform/Non-Uniform Semitransparent Photovoltaic Modules in Controlled Environments. Sol. Energy 2025, 302, 114006. [Google Scholar] [CrossRef]

- Giri, N.C.; Mohanty, R.C. Agrivoltaic System: Experimental Analysis for Enhancing Land Productivity and Revenue of Farmers. Energy Sustain. Dev. 2022, 70, 54–61. [Google Scholar] [CrossRef]

- Rösch, C.; Fakharizadehshirazi, E. The Spatial Socio-Technical Potential of Agrivoltaics in Germany. Renew. Sustain. Energy Rev. 2024, 202, 114706. [Google Scholar] [CrossRef]

- U.S. Department of Energy DOE. Market Research Study Agrivoltaics; U.S. Department of Energy DOE: Washington, DC, USA, 2022.

- Shulman Advisory. Overview of the Agrivoltaic Industry in Japan. Shulman Advisory, 20 September 2023. Available online: https://shulman-advisory.com/overview-of-the-agrivoltaic-industry-in-japan/ (accessed on 6 October 2025).

- Tajima, M.; Iida, T. Evolution of Agrivoltaic Farms in Japan. AIP Conf. Proc. 2021, 2361, 030002. [Google Scholar] [CrossRef]

- InSPIRE InSPIRE/Agrivoltaics Map. Available online: https://openei.org/wiki/InSPIRE/Agrivoltaics_Map (accessed on 1 June 2025).

- Jamil, U.; Alrayes, L.; Pearce, J.M.; Thomas, R. Optimizing Agrivoltaic Shading for Climate-Resilient Crop Production: Amaranth Performance Under Current and Future Climatic Scenarios. 2025. Available online: https://ssrn.com/abstract=5355177 (accessed on 16 August 2025).

- Jamil, U.; Alrayes, L.; Fordjour, E.; Thomas, R.; Pearce, J.M. Toward Climate-Adapted Food Systems: Mitigating Climate Change Impacts on Lettuce Production Through Agrivoltaic Systems 2025. Available online: https://ssrn.com/abstract=5413119 (accessed on 16 August 2025).

- Aman, M.M.; Solangi, K.H.; Hossain, M.S.; Badarudin, A.; Jasmon, G.B.; Mokhlis, H.; Bakar, A.H.A.; Kazi, S.N. A Review of Safety, Health and Environmental (SHE) Issues of Solar Energy System. Renew. Sustain. Energy Rev. 2015, 41, 1190–1204. [Google Scholar] [CrossRef]

- Ndzibah, E.; Andrea Pinilla-De La Cruz, G.; Shamsuzzoha, A. End of Life Analysis of Solar Photovoltaic Panel: Roadmap for Developing Economies. Int. J. Energy Sect. Manag. 2021, 16, 112–128. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global Status of Recycling Waste Solar Panels: A Review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Corkal, V. Who Will Pay for Alberta’s Orphan Wells? | International Institute for Sustainable Development. Available online: https://www.iisd.org/articles/insight/who-will-pay-albertas-orphan-wells (accessed on 12 July 2025).

- Government of Alberta Reclamation Security for Solar and Wind Renewable Energy Operations: Fact Sheet for Landowners—Open Government. Available online: https://open.alberta.ca/publications/reclamation-security-for-solar-and-wind-renewable-energy-operations-fact-sheet-for-landowners (accessed on 12 July 2025).

- NenPower. How Long Is the Life of Solar Materials? NenPower. 2024. Available online: https://nenpower.com/blog/how-long-is-the-life-of-solar-materials/ (accessed on 1 September 2025).

- Brice Solar How Many Years Does Solar Power Last? How Long Is the Lifespan of Photovoltaic Modules? Available online: https://bricesolar.com/blog/how-many-years-does-solar-power-last--how-long-is-the-lifespan-of-photovoltaic-modules-? (accessed on 1 September 2025).

- Jordan, D.; Kurtz, S. Overview of Field Experience-Degradation Rates & Lifetimes; National Renewable Energy Laboratory: Golden, CO, USA, 2015. [Google Scholar]

- National Renewable Energy Laboratory. Lifetime of PV Panels. 2023. Available online: https://www.nrel.gov/pv/lifetime? (accessed on 2 September 2025).

- Pascual, J.; Martinez-Moreno, F.; García, M.; Marcos, J.; Marroyo, L.; Lorenzo, E. Long-Term Degradation Rate of Crystalline Silicon PV Modules at Commercial PV Plants: An 82-MWp Assessment over 10 Years. Prog. Photovolt. Res. Appl. 2021, 29, 1294–1302. [Google Scholar] [CrossRef]

- Haina Solar How Long Is the Service Life of Photovoltaic Mounting Systems?—Haina Solar. Available online: https://www.hainasolar.com/How-Long-Is-The-Service-Life-of-Photovoltaic-Mounting-Systems-id45646846.html? (accessed on 1 September 2025).

- Bellini, E. Exploring the Depths of Europe’s Oldest Grid-Connected PV System. Pv Magazine International, 2 July 2021. Available online: https://www.pv-magazine.com/2021/07/02/exploring-the-depths-of-europes-oldest-grid-connected-pv-system/ (accessed on 2 October 2025).

- Jamil, U.; Vandewetering, N.; Pearce, J.M. Solar Photovoltaic Wood Racking Mechanical Design for Trellis-Based Agrivoltaics. PLoS ONE 2023, 18, e0294682. [Google Scholar] [CrossRef]

- Brite. Solar Greenhouse Solar Glass (BSG-450/8-F); Brite: Thessaloniki, Greece, 2024. [Google Scholar]

- Brite. Solar Greenhouse Solar Glass (BSG-275/44-F); Brite: Thessaloniki, Greece, 2024. [Google Scholar]

- Appropedia Western Innovation for Renewable Energy Deployment (WIRED). Available online: https://www.appropedia.org/Western_Innovation_for_Renewable_Energy_Deployment_(WIRED) (accessed on 22 August 2025).

- Mattei, M.; Notton, G.; Cristofari, C.; Muselli, M.; Poggi, P. Calculation of the Polycrystalline PV Module Temperature Using a Simple Method of Energy Balance. Renew. Energy 2006, 31, 553–567. [Google Scholar] [CrossRef]

- Armstrong, A.; Ostle, N.J.; Whitaker, J. Solar Park Microclimate and Vegetation Management Effects on Grassland Carbon Cycling. Environ. Res. Lett. 2016, 11, 074016. [Google Scholar] [CrossRef]

- Weselek, A.; Bauerle, A.; Hartung, J.; Zikeli, S.; Lewandowski, I.; Högy, P. Agrivoltaic System Impacts on Microclimate and Yield of Different Crops within an Organic Crop Rotation in a Temperate Climate. Agron. Sustain. Dev. 2021, 41, 59. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Weselek, A.; Högy, P.; Obergfell, T. Combining Food and Energy Production: Design of an Agrivoltaic System Applied in Arable and Vegetable Farming in Germany. Renew. Sustain. Energy Rev. 2021, 140, 110694. [Google Scholar] [CrossRef]

- Weselek, A.; Bauerle, A.; Zikeli, S.; Lewandowski, I.; Högy, P. Effects on Crop Development, Yields and Chemical Composition of Celeriac (Apium Graveolens L. Var. Rapaceum) Cultivated Underneath an Agrivoltaic System. Agronomy 2021, 11, 733. [Google Scholar] [CrossRef]

- Semeraro, T.; Scarano, A.; Curci, L.M.; Leggieri, A.; Lenucci, M.; Basset, A.; Santino, A.; Piro, G.; De Caroli, M. Shading Effects in Agrivoltaic Systems Can Make the Difference in Boosting Food Security in Climate Change. Appl. Energy 2024, 358, 122565. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics Provide Mutual Benefits across the Food–Energy–Water Nexus in Drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Adeh, E.H.; Selker, J.S.; Higgins, C.W. Remarkable Agrivoltaic Influence on Soil Moisture, Micrometeorology and Water-Use Efficiency. PLoS ONE 2018, 13, e0203256. [Google Scholar] [CrossRef]

- Zheng, J.; Meng, S.; Zhang, X.; Zhao, H.; Ning, X.; Chen, F.; Omer, A.A.A.; Ingenhoff, J.; Liu, W. Increasing the Comprehensive Economic Benefits of Farmland with Even-Lighting Agrivoltaic Systems. PLoS ONE 2021, 16, e0254482. [Google Scholar] [CrossRef]

- Sekiyama, T.; Nagashima, A. Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic Systems for Corn, A Typical Shade-Intolerant Crop. Environments 2019, 6, 65. [Google Scholar] [CrossRef]

- Abidin, M.A.Z.; Mahyuddin, M.N.; Zainuri, M.A.A.M. Optimal Efficient Energy Production by PV Module Tilt-Orientation Prediction Without Compromising Crop-Light Demands in Agrivoltaic Systems. IEEE Access 2023, 11, 71557–71572. [Google Scholar] [CrossRef]

- Reeza, A.A.; Noor, N.F.M.; Ahmed, O.H.; Masuri, M.A. Shading Effect of Photovoltaic Panels on Growth of Selected Tropical Vegetable Crops. Sci. Hortic. 2024, 324, 112574. [Google Scholar] [CrossRef]

- World-grain Focus on Germany. Available online: https://www.world-grain.com/articles/17639-focus-on-germany (accessed on 4 June 2025).

- Federal Reserve Bank of St. Louis Global Price of Wheat. Available online: https://fred.stlouisfed.org/series/PWHEAMTUSDM (accessed on 4 June 2025).

- U.S. Department of Agriculture Wheat Explorer. Available online: https://web.archive.org/web/20250731083240/https://ipad.fas.usda.gov/cropexplorer/cropview/commodityView.aspx?cropid=0410000 (accessed on 4 June 2025).

- European Union. The EU Potato Sector-Statistics on Production, Prices and Trade. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=The_EU_potato_sector_-_statistics_on_production,_prices_and_trade (accessed on 4 June 2025).

- Statista Potatoes: Prices Worldwide by Country 2023. Available online: https://www.statista.com/statistics/1099814/global-potato-market-price/ (accessed on 4 June 2025).

- Potato News Today. Global Potato Production: Insights from the FAO’s Latest Data. Potato News Today, 6 January 2024. [Google Scholar]

- ReportLinker Forecast: Celeriac Harvested Production in Germany 2023–2027. Available online: https://www.reportlinker.com/dataset/3c511df9f9e9a87f371b1790c6ed87d49bd06d82 (accessed on 4 June 2025).

- Tridge. Fresh Celeriac Price in United States. Available online: https://dir.tridge.com/prices/fresh-celeriac/US (accessed on 4 June 2025).

- Tridge. Trends of Chicory Production in Italy. Available online: https://www.tridge.com/intelligences/chicory-leaf/IT/production (accessed on 4 June 2025).

- Tridge. Fresh Chicory Price in United States. Available online: https://dir.tridge.com/prices/fresh-chicory/US (accessed on 4 June 2025).

- HelgiLibrary Which Country Produces the Most Chicory Roots? Available online: https://www.helgilibrary.com/charts/which-country-produces-the-most-chicory-roots (accessed on 4 June 2025).

- Guan, Z.; Biswas, T.; Wu, F. FE1027/FE1027: The US Tomato Industry: An Overview of Production and Trade. Available online: https://edis.ifas.ufl.edu/publication/FE1027 (accessed on 4 June 2025).

- Selina Wamucii US Tomatoes Prices. Selina Wamucii. 2025. Available online: https://www.selinawamucii.com/insights/prices/united-states-of-america/tomatoes/ (accessed on 1 October 2025).

- Tridge. China Jerusalem Artichoke Market Overview. 2024. Available online: https://www.tridge.com/intelligences/jerusalem-artichoke/CN (accessed on 4 June 2025).

- Tridge. Fresh Jerusalem Artichoke Price in United States. Available online: https://dir.tridge.com/prices/fresh-jerusalem-artichoke/US (accessed on 4 June 2025).

- Manokhina, A.A.; Dorokhov, A.S.; Kobozeva, T.P.; Fomina, T.N.; Starovoitov, V.I. Jerusalem Artichoke as a Strategic Crop for Solving Food Problems. Agronomy 2022, 12, 465. [Google Scholar] [CrossRef]

- Indexmundi. Japan Corn Production by Year (1000 MT). Available online: https://www.indexmundi.com/agriculture/?country=jp&commodity=corn&graph=production (accessed on 4 June 2025).

- Tridge. Global Maize Price. Available online: https://dir.tridge.com/prices/maize (accessed on 4 June 2025).

- U.S. Department of Agriculture Corn. USDA Foreign Agricultural Service. Available online: https://web.archive.org/web/20250821215413/https://www.fas.usda.gov/data/production/commodity/0440000 (accessed on 4 June 2025).

- Government of Canada, S.C. Strawberry Fields Forever? Available online: https://www.statcan.gc.ca/o1/en/plus/1300-strawberry-fields-forever (accessed on 25 July 2024).

- Producepay Strawberry Analysis 2021—Production, Prices & Covid Impact 2021. Available online: https://unindexed-files.s3.us-west-2.amazonaws.com/whitepaper-strawberry.pdf (accessed on 1 August 2024).

- HelgiLibrary. Okra Production in Malaysia. Available online: https://www.helgilibrary.com/indicators/okra-production/malaysia (accessed on 4 June 2025).

- Tridge. Global Fresh Okra Price. Available online: https://dir.tridge.com/prices/fresh-okra (accessed on 4 June 2025).

- HelgiLibrary. Which Country Produces the Most Okra? Available online: https://www.helgilibrary.com/charts/which-country-produces-the-most-okra (accessed on 4 June 2025).

- Phooi, C.L.; Azman, E.A.; Ismail, R. Enzymatic Activities of Bok Choy (Brassica rapa subsp. Chinensis) Grown Soil with the Amendment of Sandwich Compost. Int. J. Agron. 2022, 2022, 7311957. [Google Scholar] [CrossRef]

- Tridge. Fresh Bok Choy Price in United States. Available online: https://dir.tridge.com/prices/fresh-bok-choy/US (accessed on 4 June 2025).

- Fruta-Hortalizas. Chinese Cabbage—Origin and Production. Available online: https://www.frutas-hortalizas.com/Vegetables/Origin-production-Chinese-cabbage.html (accessed on 4 June 2025).

- Deboutte, G. Agrivoltaics Can Increase Grape Yield by up to 60%. Pv Magazine International, 29 November 2024. [Google Scholar]

- Badra, M. Farm Achieves 50% Gain in Eggplant Harvest with Agrivoltaic System. Canal Solar, 8 February 2023. [Google Scholar]

- Ombrea. Ombrea Inaugurates an Agrivoltaic Market-Gardening Site in the South-West of France. Ombrea, 20 September 2023. [Google Scholar]

- Meena, R.; Pareek, A.; Gupta, R. A Comprehensive Review on Interfacial Delamination in Photovoltaic Modules. Renew. Sustain. Energy Rev. 2024, 189, 113944. [Google Scholar] [CrossRef]

- NREL. Photovoltaic Failure Fact Sheets 2025; IEA PVPS: Paris, France, 2025.

- Huawei Solar Panel Longevity: The Real Lifespan of PV Systems | HUAWEI Smart PV Global. Available online: https://solar.huawei.com/en/blog/2024/lifespan-of-solar-panels (accessed on 12 July 2025).

- Tongwei What Is the Lifespan of Solar PV—BLOG—Tongwei Co., Ltd. Available online: https://en.tongwei.cn/blog/147.html (accessed on 12 July 2025).

- Enders, K. What Is the Lifespan of a Solar Panel System? Advanced Energy Systems. 2024. Available online: https://aesrenew.com/knowledge-base/what-is-the-lifespan-of-a-solar-panel-system/ (accessed on 12 July 2025).

- Jantzen, C.M. Prediction of Glass Durability as a Function of Environmental Conditions. MRS Online Proc. Libr. 1988, 125, 143–159. [Google Scholar] [CrossRef]

- Oreski, G.; Omazic, A.; Eder, G.C.; Voronko, Y.; Neumaier, L.; Mühleisen, W.; Hirschl, C.; Ujvari, G.; Ebner, R.; Edler, M. Properties and Degradation Behaviour of Polyolefin Encapsulants for Photovoltaic Modules. Prog. Photovolt. Res. Appl. 2020, 28, 1277–1288. [Google Scholar] [CrossRef]

- Kennedy, R. How Long Do Residential Solar Inverters Last? Pv Magazine USA, 6 August 2025. Available online: https://pv-magazine-usa.com/2021/09/15/how-long-do-residential-solar-inverters-last/ (accessed on 12 July 2025).

- Arifin, M.D.; Dariansyah, M.R. Lifespan Estimation of Galvanized Steel and Stainless Steel Pipe. Int. J. Mar. Eng. Innov. Res. 2023, 8, 468–476. [Google Scholar] [CrossRef]

- Metal Pro Buildings. Steel Building Lifespan: How Long Do They Really Last? Metal Pro Buildings: Ontario, Canada, 2025. [Google Scholar]

- Rossi, B. Discussion on the Use of Stainless Steel in Constructions in View of Sustainability. Thin-Walled Struct. 2014, 83, 182–189. [Google Scholar] [CrossRef]

- Bushong, S. White Paper: Foundation Selection for Ground Mounted PV Solar Systems. Solar Power World, 18 July 2014. [Google Scholar]

- Perma Pier Foundation Repair. How Long Does a Concrete Foundation Last [Timeline]. Available online: https://permapier.com/blog/how-long-does-concrete-foundation-last/ (accessed on 4 September 2025).

- Chae, S.-H.; Kim, H.J.; Moon, H.-W.; Kim, Y.H.; Ku, K.-M. Agrivoltaic Systems Enhance Farmers’ Profits through Broccoli Visual Quality and Electricity Production without Dramatic Changes in Yield, Antioxidant Capacity, and Glucosinolates. Agronomy 2022, 12, 1415. [Google Scholar] [CrossRef]

- Yue, S.; Wu, W.; Zhou, X.; Ren, L.; Wang, J. The Influence of Photovoltaic Panels on Soil Temperature in the Gonghe Desert Area. Environ. Eng. Sci. 2021, 38, 910–920. [Google Scholar] [CrossRef]

- Hickey, T.; Uchanski, M.; Bousselot, J. Vegetable Crop Growth under Photovoltaic (PV) Modules of Varying Transparencies. Heliyon 2024, 10, e36058. [Google Scholar] [CrossRef]

- Yang, X.M.; Reynolds, W.D.; Drury, C.F.; Reeb, M.D. Cover Crop Effects on Soil Temperature in a Clay Loam Soil in Southwestern Ontario. Can. J. Soil. Sci. 2021, 101, 761–770. [Google Scholar] [CrossRef]

- Dalias, P.; Anderson, J.M.; Bottner, P.; Coûteaux, M.-M. Long-Term Effects of Temperature on Carbon Mineralisation Processes. Soil Biol. Biochem. 2001, 33, 1049–1057. [Google Scholar] [CrossRef]

- Davidson, E.A.; Janssens, I.A. Temperature Sensitivity of Soil Carbon Decomposition and Feedbacks to Climate Change. Nature 2006, 440, 165–173. [Google Scholar] [CrossRef] [PubMed]

- Jenkinson, D.S.; Ayanaba, A. Decomposition of Carbon-14 Labeled Plant Material Under Tropical Conditions. Soil Sci. Soc. Am. J. 1977, 41, 912–915. [Google Scholar] [CrossRef]

- Lloyd, J.; Taylor, J.A. On the Temperature Dependence of Soil Respiration. Funct. Ecol. 1994, 8, 315–323. [Google Scholar] [CrossRef]

- Webb, E.E.; Schuur, E.A.G.; Natali, S.M.; Oken, K.L.; Bracho, R.; Krapek, J.P.; Risk, D.; Nickerson, N.R. Increased Wintertime CO2 Loss as a Result of Sustained Tundra Warming. J. Geophys. Res. Biogeosciences 2016, 121, 249–265. [Google Scholar] [CrossRef]

- Luo, J.; Luo, Z.; Li, W.; Shi, W.; Sui, X. The Early Effects of an Agrivoltaic System within a Different Crop Cultivation on Soil Quality in Dry–Hot Valley Eco-Fragile Areas. Agronomy 2024, 14, 584. [Google Scholar] [CrossRef]

- Ali Abaker Omer, A.; Li, M.; Zhang, F.; Hassaan, M.M.E.; El Kolaly, W.; Zhang, X.; Lan, H.; Liu, J.; Liu, W. Impacts of Agrivoltaic Systems on Microclimate, Water Use Efficiency, and Crop Yield: A Systematic Review. Renew. Sustain. Energy Rev. 2025, 221, 115930. [Google Scholar] [CrossRef]

- Gentes, Z. Solar Panels Cast Shade on Agriculture in a Good Way—Ecological Society of America; Ecological Society of America: Washington, DC, USA, 2019. [Google Scholar]

- Bacon, T.; Monlezun, A.C.; Hong, M.; Macknick, J.; de Vries, N.; Edwards-Callaway, L.; Paustian, K. Agrivoltaic Grazing Systems for a Sustainable Future: A Multi-Disciplinary Review & Gap Analysis. Earth’s Future 2025, 13, e2024EF005429. [Google Scholar] [CrossRef]

- Enescu, C.M.; Mihalache, M.; Ilie, L.; Dinca, L.; Constandache, C.; Murariu, G. Agricultural Benefits of Shelterbelts and Windbreaks: A Bibliometric Analysis. Agriculture 2025, 15, 1204. [Google Scholar] [CrossRef]

- Kabir, Y.M.; Nambeesan, S.U.; Díaz-Pérez, J.C. Shade Nets Improve Vegetable Performance. Sci. Hortic. 2024, 334, 113326. [Google Scholar] [CrossRef]

- Pallotti, L.; Silvestroni, O.; Dottori, E.; Lattanzi, T.; Lanari, V. Effects of Shading Nets as a Form of Adaptation to Climate Change on Grapes Production: A Review. OENO One 2023, 57, 467–476. [Google Scholar] [CrossRef]

- Gebremedhin, M.; Brown, J.; Ries, I. Soil Management and Microclimate Effects on Ecosystem Evapotranspiration of Winter Wheat–Soybean Cropping in Northern Alabama. Atmosphere 2022, 13, 1653. [Google Scholar] [CrossRef]

- Yu, P.; Ganjurjav, H.; Wan, Z.; Hu, G.; Gu, R.; Gao, Q. Changes in Soil Respiration after Eight Years of Warming and Increased Precipitation in a Semiarid Temperate Steppe. Agric. Ecosyst. Environ. 2024, 373, 109110. [Google Scholar] [CrossRef]

- Jafarian, N.; Mirzaei, J.; Omidipour, R.; Kooch, Y. Effects of Micro-Climatic Conditions on Soil Properties along a Climate Gradient in Oak Forests, West of Iran: Emphasizing Phosphatase and Urease Enzyme Activity. CATENA 2023, 224, 106960. [Google Scholar] [CrossRef]

- Williams, R.A.; Lizzadro-McPherson, D.J.; Pearce, J.M. The Impact of Snow Losses on Solar Photovoltaic Systems in North America in the Future. Energy Adv. 2023, 2, 1634–1649. [Google Scholar] [CrossRef]

- Brite. Solar Greenhouse Solar Glass (BSG-150/69-F); Brite: Thessaloniki, Greece, 2024. [Google Scholar]

- Aghaei, M.; Fairbrother, A.; Gok, A.; Ahmad, S.; Kazim, S.; Lobato, K.; Oreski, G.; Reinders, A.; Schmitz, J.; Theelen, M.; et al. Review of Degradation and Failure Phenomena in Photovoltaic Modules. Renew. Sustain. Energy Rev. 2022, 159, 112160. [Google Scholar] [CrossRef]

- Kwasinski, A.; Andrade, F.; Castro-Sitiriche, M.J.; O’Neill-Carrillo, E. Hurricane Maria Effects on Puerto Rico Electric Power Infrastructure. IEEE Power Energy Technol. Syst. J. 2019, 6, 85–94. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Nwokolo, S.C.; Udo, S.O.; Obiwulu, A.U.; Onnoghen, U.N.; Alarifi, S.S.; Eldosouky, A.M.; Ekwok, S.E.; Andráš, P.; Akpan, A.E. Solar PV Systems under Weather Extremes: Case Studies, Classification, Vulnerability Assessment, and Adaptation Pathways. Energy Rep. 2025, 13, 929–959. [Google Scholar] [CrossRef]

- Kwasinski, A. Effects of Hurricane Maria on Renewable Energy Systems in Puerto Rico. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; pp. 383–390. [Google Scholar]

- Rana, Z.; Zamora, P.P.; Soliz, A.; Soler, D.; Reyes Cruz, V.E.; Cobos-Murcia, J.A.; Galleguillos Madrid, F.M. Solar Panel Corrosion: A Review. Int. J. Mol. Sci. 2025, 26, 5960. [Google Scholar] [CrossRef]

- Al Mahdi, H.; Leahy, P.G.; Alghoul, M.; Morrison, A.P. A Review of Photovoltaic Module Failure and Degradation Mechanisms: Causes and Detection Techniques. Solar 2024, 4, 43–82. [Google Scholar] [CrossRef]

- Alam, H.; Alam, M.A.; Butt, N.Z. Techno Economic Modeling for Agrivoltaics: Can Agrivoltaics Be More Profitable than Ground Mounted PV? IEEE J. Photovolt. 2022, 13, 174–186. [Google Scholar] [CrossRef]

- Di Francia, G.; Cupo, P. A Cost–Benefit Analysis for Utility-Scale Agrivoltaic Implementation in Italy. Energies 2023, 16, 2991. [Google Scholar] [CrossRef]

- Jamil, U.; Pearce, J.M. Shining Light on Agrivoltaics: Public Opinion on Agrivoltaic Applications and Topologies Across Canada. 2025. Available online: https://ssrn.com/abstract=5248372 (accessed on 6 October 2025).

- Pascaris, A.S.; Schelly, C.; Rouleau, M.; Pearce, J.M. Do Agrivoltaics Improve Public Support for Solar? A Survey on Perceptions, Preferences, and Priorities. Green Technol. Resil. Sustain. 2022, 2, 8. [Google Scholar] [CrossRef]

- Williams, H.J.; Hashad, K.; Wang, H.; Max Zhang, K. The Potential for Agrivoltaics to Enhance Solar Farm Cooling. Appl. Energy 2023, 332, 120478. [Google Scholar] [CrossRef]

- Jamil, U.; Vandewetering, N.; Sadat, S.A.; Pearce, J.M. Wood- and Cable-Based Variable Tilt Stilt-Mounted Solar Photovoltaic Racking System. Designs 2024, 8, 6. [Google Scholar] [CrossRef]

- Vandewetering, N.; Jamil, U.; Pearce, J.M. Ballast-Supported Foundation Designs for Low-Cost Open-Source Solar Photovoltaic Racking. Designs 2024, 8, 17. [Google Scholar] [CrossRef]

- Jamil, U.; Sadat, S.A.; Pearce, J.M. Distributed Manufacturing for Distributed Generation: 3-D Printed Solar Photovoltaic Module Mounting Mechanisms for Wood Racking. Renew. Energy 2024, 228, 120651. [Google Scholar] [CrossRef]

- Rahman, M.M.; Jamil, U.; Pearce, J.M. Open-Source Photosynthetically Active Radiation Sensor for Enhanced Agricultural and Agrivoltaics Monitoring. Electronics 2025, 14, 2225. [Google Scholar] [CrossRef]

Figure 1.

(a) Powered 44% transparent c-Si PV modules and powered 8% transparent c-Si PV modules; (b) Unpowered 8% transparent c-Si PV modules; (c) Unpowered 44% transparent c-Si PV module; (d) Control plot at the powered site; (e) Control plot at the unpowered site; (f) Map of Ontario showing the proximity of the two experimental sites; and (g) Close-up view highlighting the specific locations.

Figure 1.

(a) Powered 44% transparent c-Si PV modules and powered 8% transparent c-Si PV modules; (b) Unpowered 8% transparent c-Si PV modules; (c) Unpowered 44% transparent c-Si PV module; (d) Control plot at the powered site; (e) Control plot at the unpowered site; (f) Map of Ontario showing the proximity of the two experimental sites; and (g) Close-up view highlighting the specific locations.

Figure 2.

Estimated operational lifespan of agrivoltaic system components.

Figure 2.

Estimated operational lifespan of agrivoltaic system components.

Figure 3.

(a) Soil temperature variation beneath powered PV modules at 44% c-Si c-Si coverage, compared with control (unshaded) soil, including corresponding air temperature measurements; (b) Temperature differences relative to the control, where negative values indicate higher temperatures under PV modules and positive values indicate lower temperatures under PV modules.

Figure 3.

(a) Soil temperature variation beneath powered PV modules at 44% c-Si c-Si coverage, compared with control (unshaded) soil, including corresponding air temperature measurements; (b) Temperature differences relative to the control, where negative values indicate higher temperatures under PV modules and positive values indicate lower temperatures under PV modules.

Figure 4.

(a) Soil temperature dynamics beneath unpowered PV modules at 8%, and 44% c-Si coverage, alongside control (unshaded) soils; (b) Temperature differences relative to the control, where negative values indicate higher temperatures under PV modules and positive values indicate lower temperatures under PV modules; and (c) Soil humidity variations beneath unpowered PV modules at 8%, and 44% c-Si coverage, alongside control (unshaded) soils.

Figure 4.

(a) Soil temperature dynamics beneath unpowered PV modules at 8%, and 44% c-Si coverage, alongside control (unshaded) soils; (b) Temperature differences relative to the control, where negative values indicate higher temperatures under PV modules and positive values indicate lower temperatures under PV modules; and (c) Soil humidity variations beneath unpowered PV modules at 8%, and 44% c-Si coverage, alongside control (unshaded) soils.

Figure 5.

Thermal images of the unpowered agrivoltaic array showing (a) 8% c-Si, (b) 44% c-Si, and (c) 69% c-Si PV module configurations.

Figure 5.

Thermal images of the unpowered agrivoltaic array showing (a) 8% c-Si, (b) 44% c-Si, and (c) 69% c-Si PV module configurations.

Figure 6.

Soil temperature variation over a single day under 44% c-Si PV modules and control (unshaded) conditions for both powered and unpowered systems. The legend indicates powered system measurements with “(P)”; shading effects are more pronounced in the unpowered system.

Figure 6.

Soil temperature variation over a single day under 44% c-Si PV modules and control (unshaded) conditions for both powered and unpowered systems. The legend indicates powered system measurements with “(P)”; shading effects are more pronounced in the unpowered system.

Figure 7.

Average daily air and soil temperatures observed in (a) the powered agrivoltaic array and (b) the unpowered agrivoltaic array.

Figure 7.

Average daily air and soil temperatures observed in (a) the powered agrivoltaic array and (b) the unpowered agrivoltaic array.

Table 1.

Increased crop yields under agrivoltaics from past literature *.

Table 1.

Increased crop yields under agrivoltaics from past literature *.

| Country | Low | High | Transparency (%) | Sources |

|---|

| Germany | 2.7% (winter wheat) | 11% (potatoes) | 64.9% | [39] |

| 3% (winter wheat) | 12% (celeriac) | 70.0% | [40] |

| 31.9% (Celeriac) | 48% (Celeriac) | 70.0% | [41] |

| Italy | - | 69% (chicory) | 100.0% (Plants under the shadows of modules) | [42] |

| U.S. | 200% (tomatoes) | 300% (chiltepin pepper) | 38.4% | [43] |

| - | 90% (pasture) | 50.0% | [44] |

| China | - | 23% (Jerusalem artichoke) | 33.3% | [45] |

| Japan | - | 5.5% (corn) | 55.3% | [46] |

| Canada | 4% (strawberries) | 18% (strawberries) | 44–69% | [10] |

| Malysia | - | 159% (Andrographis paniculata) | 59.08% | [47] |

| - | 2.9% (okra) | 38.5% | [48] |

| - | 2% (Chinese cabbage) | | [48] |

| - | 37.5% (pennywort) | | [48] |

Table 2.

Crop types, national and global production volumes (in million tonnes), and market prices for selected crop-country combinations *.

Table 2.

Crop types, national and global production volumes (in million tonnes), and market prices for selected crop-country combinations *.

| Country | Crop | Country Production (Million Tonnes) | Price

(Per tonne) | World Production

(Million Tonnes) |

|---|

| Germany | Winter wheat | 21.8 [49] | 179.6 [50] | 808.521 [51] |

| Potatoes | 11.6 [52] | 3080 [53] | 375 [54] |

| Celeriac | 0.0845 [55] | 1540 [56] | - |

| Italy | Chicory | 0.0006382 [57] | 2630 [58] | 0.032662 [59] |

| U.S. | Tomatoes | 16 [60] | 2000 [61] | 170 [60] |

| China | Jerusalem artichoke | 0.0007436 [62] | 5400 [63] | 75 [64] |

| Japan | Corn | 0.016 [65] | 240 [66] | 1220 [67] |

| Canada | Strawberries | 0.02349 [68] | 6510 [10] | 8.885028 [69] |

| Malaysia | Okra | 0.063074 [70] | 320 [71] | 11.232656 [72] |

| Chinese cabbage | 0.15 [73] | 1470 [74] | 0.048241 [75] |

Table 3.

Operational lifespan of agrivoltaic system components.

Table 3.

Operational lifespan of agrivoltaic system components.

| Component | Expected Functional Lifespan Range | Key Notes and Sources |

|---|

| PV module (electrical) | 25–35 years for electrical operation | - Monocrystalline Si: 25–30 year typical [81], up to 35 yr [82]

- Polycrystalline Si: 20–25 yr [82]

- Thin-film: 15–20 yr [82]

- Warranties guarantee ≥ 80% of rated power at year 25 [83]. |

| PV module (mechanical/glass) | 35–1000 years | - Simulated medieval glasses showed durability around 103 years (approximately one millennium), while highly stable glass types may last up to 106 years [84]

- Advanced encapsulants (e.g., POE, silicone-based) have demonstrated projected service lifetimes of >35 years [85] |

| Inverter | 5–20 years | - 5–10 yr, extendable to 20 yr [86] |

| Racking structure (stainless teel) | 40–100 years | Stainless-steel systems routinely last the life of the PV array [87,88,89] |

| Foundations and footings | 40–200 years | - Hot dip galvanized steel piles can last up to 40 yr [90]

- Concrete foundations can last up to 200 years [91] |

Table 4.

Indicative estimated additional farm income per year resulting from yield increases under unpowered agrivoltaic shading. Income calculations are based on documented yield improvements and current market prices for each crop *.

Table 4.

Indicative estimated additional farm income per year resulting from yield increases under unpowered agrivoltaic shading. Income calculations are based on documented yield improvements and current market prices for each crop *.

| Country | Crop | Additional Yield—Country (Million Tonnes) | Additional Income (Million USD) | Additional Yield—World (Million Tonnes) | Additional Income (Million USD) |

|---|

| Germany | Winter Wheat | 0.654 | 117.5 | 24.3 | 4356 |

| Potatoes | 1.276 | 3930.1 | 41.3 | 127,050 |

| Italy | Chicory | 0.000440344 | 1.2 | 0.02 | 59 |

| U.S. | Tomatoes | 16 | 32,000.0 | 170.0 | 340,000 |

| China | Jer. artichoke | 0.000171035 | 0.9 | 17.3 | 93,150 |

| Japan | Corn | 0.00088 | 0.2 | 67.1 | 16,104 |

| Malaysia | Okra | 0.001829146 | 0.6 | 0.3 | 104 |

| Chinese cabbage | 0.003 | 4.4 | 0.001 | 1.4 |

| Canada | Strawberries | 0.004228 | 19.8 | 1.60 | 7496 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).