A Critical Review on the Opportunities and Challenges of Offshore Carbon Capture, Utilization, and Storage

Abstract

1. Introduction

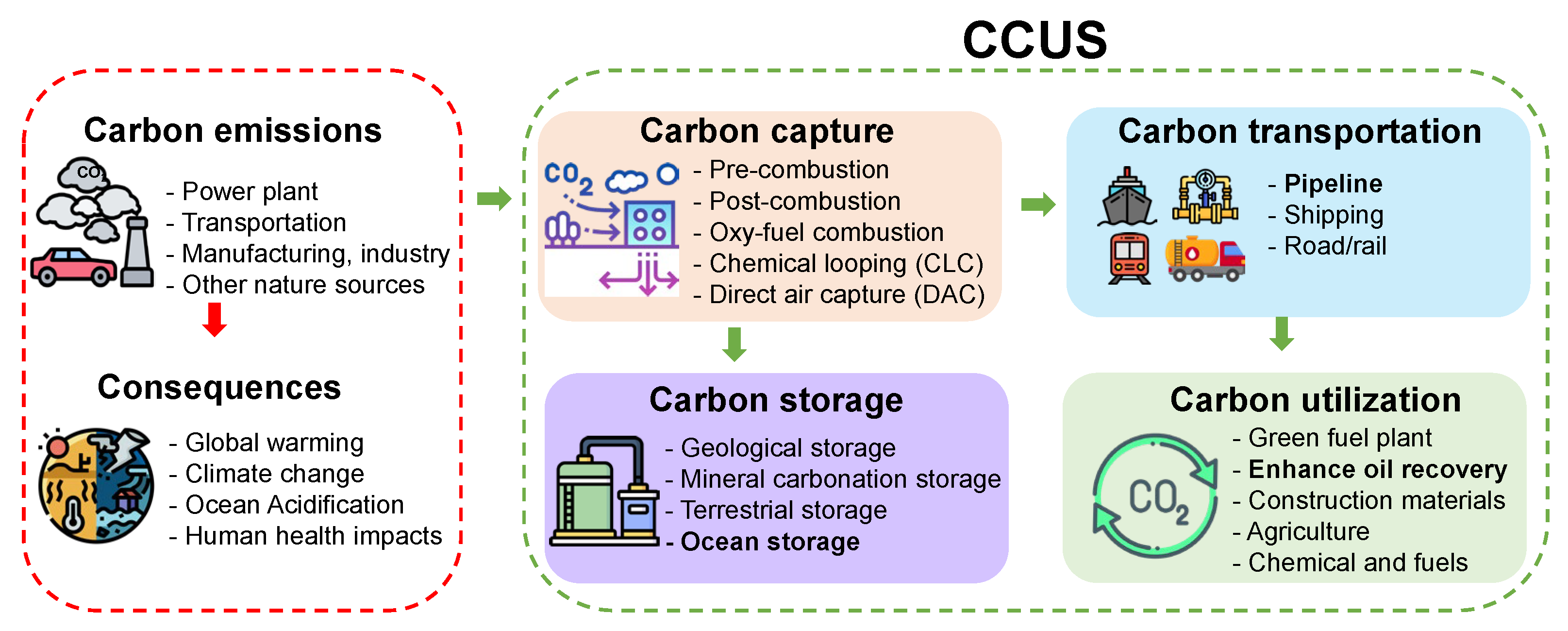

2. Principle of Carbon Life Cycle and CCUS

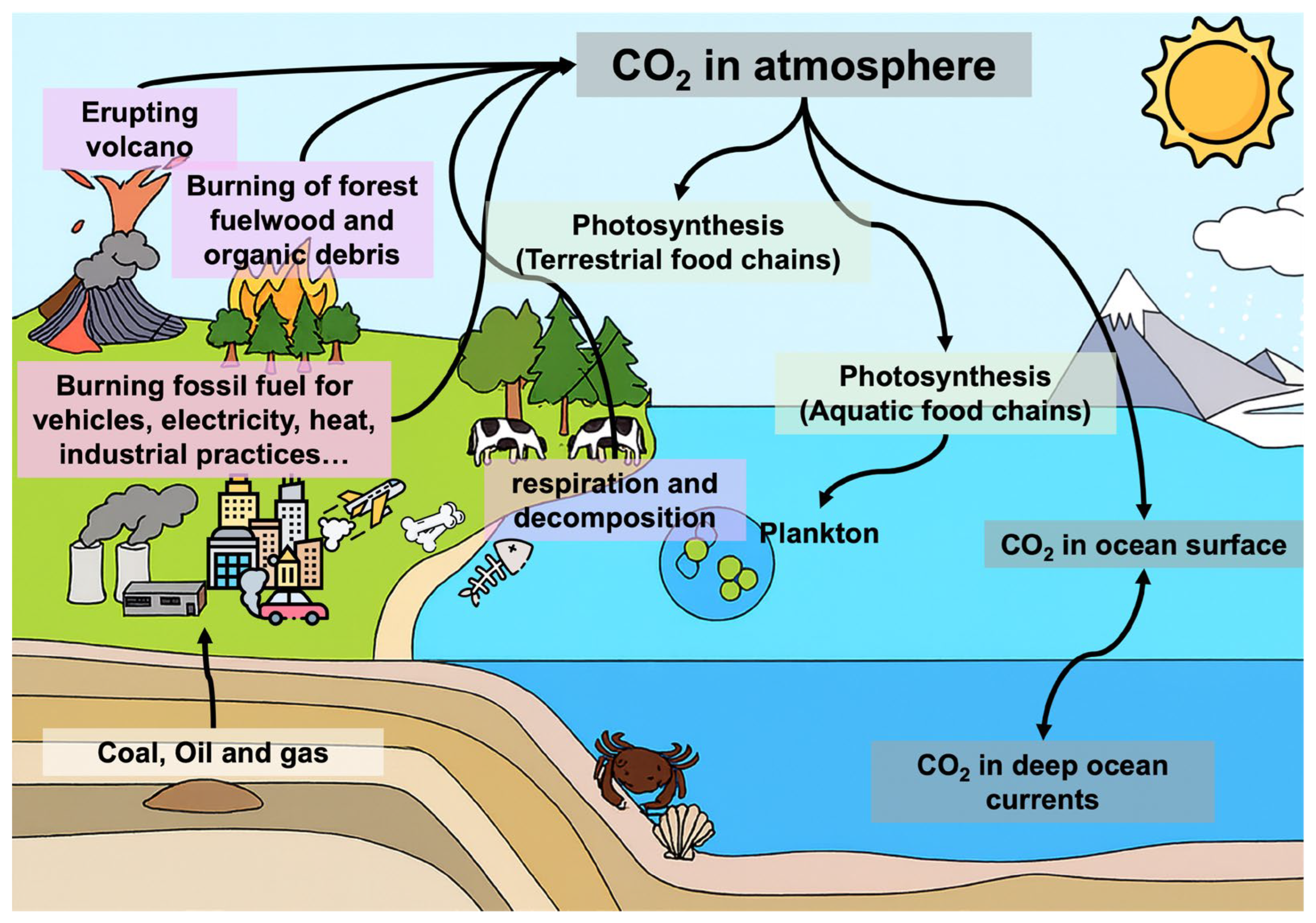

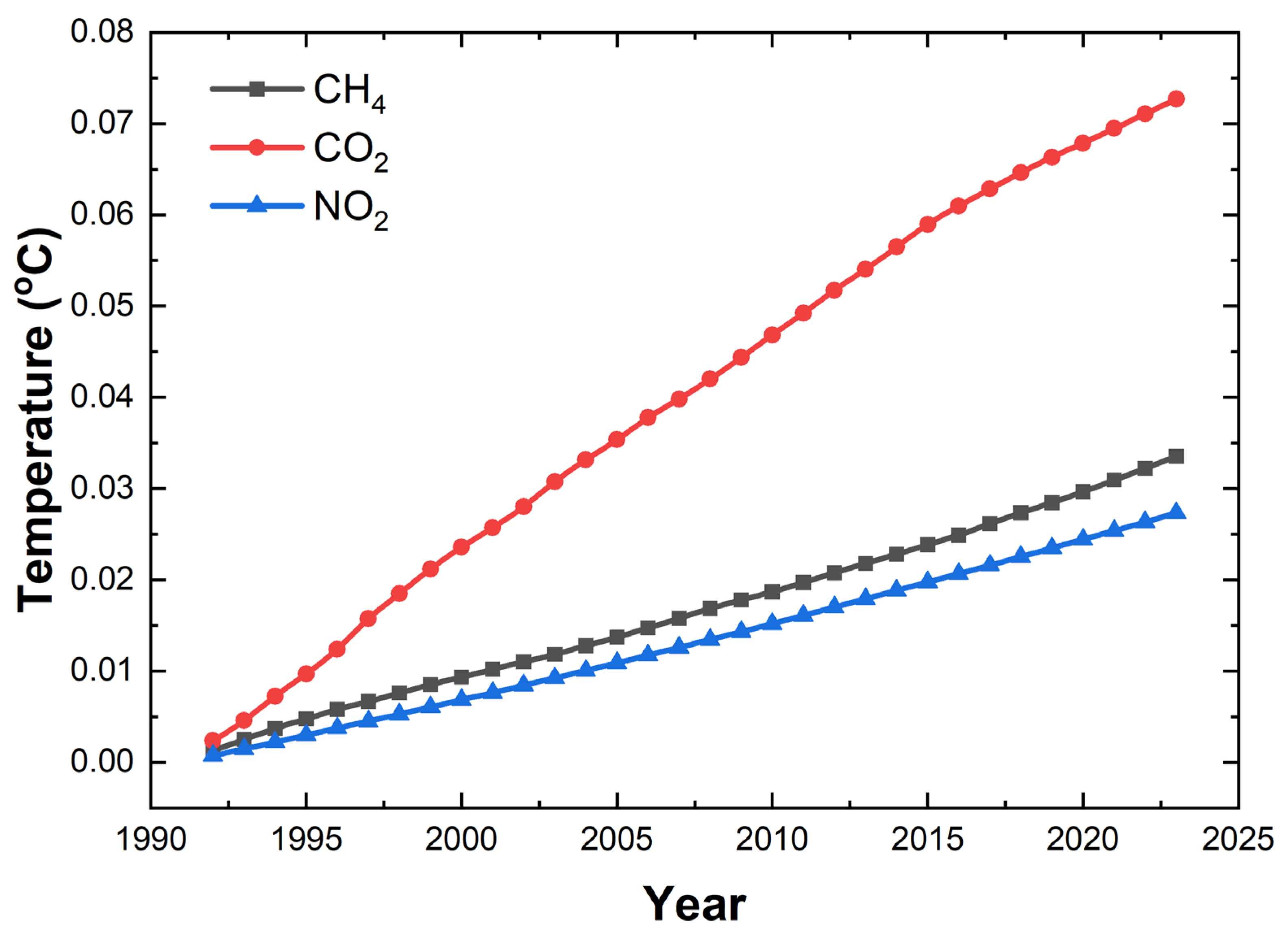

2.1. Life Cycle of Carbon

2.2. Overview and Role of CCUS in Net-Zero Pathways

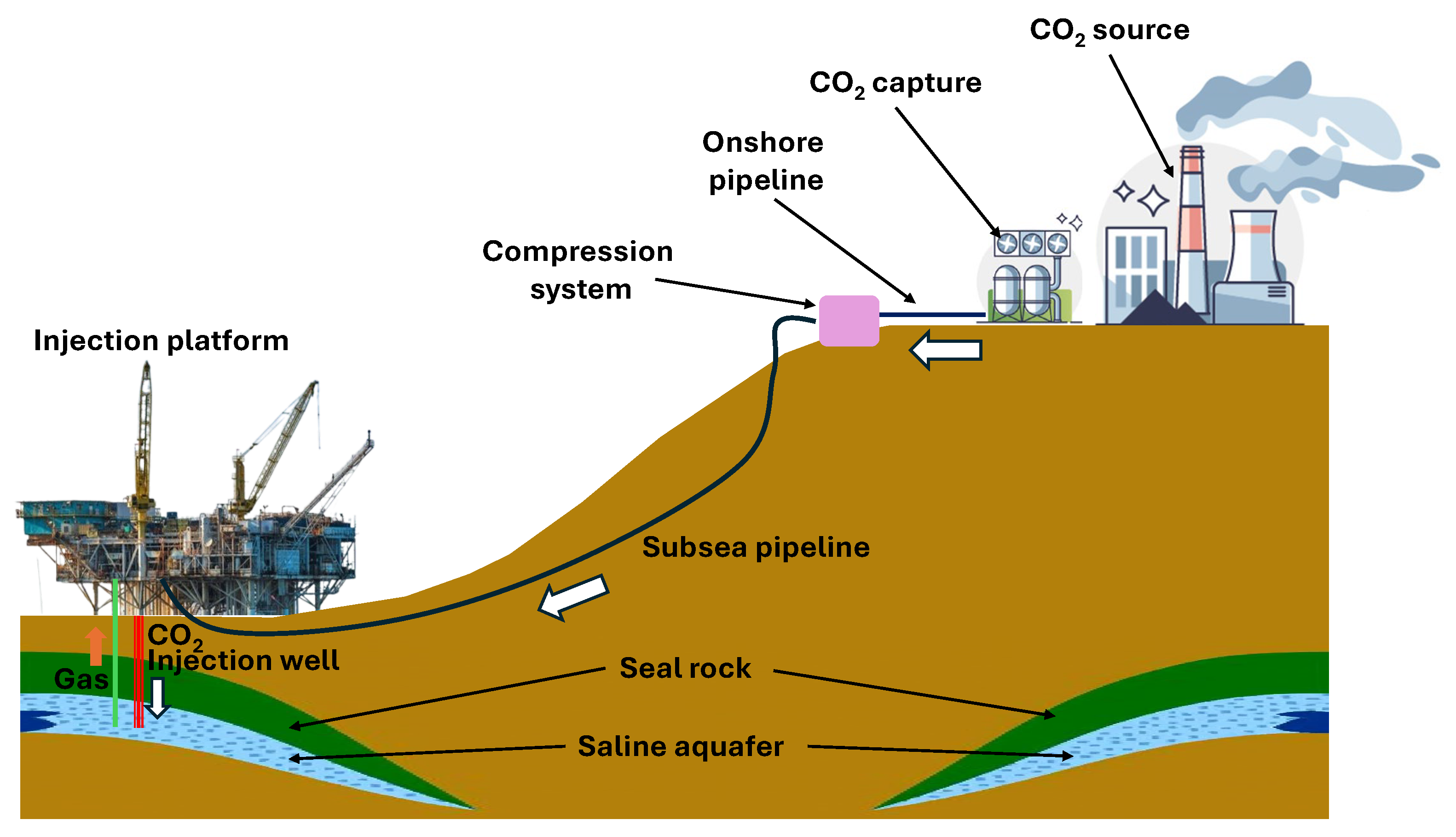

3. Technical Overview of Offshore CCUS

3.1. Carbon Capture Technologies

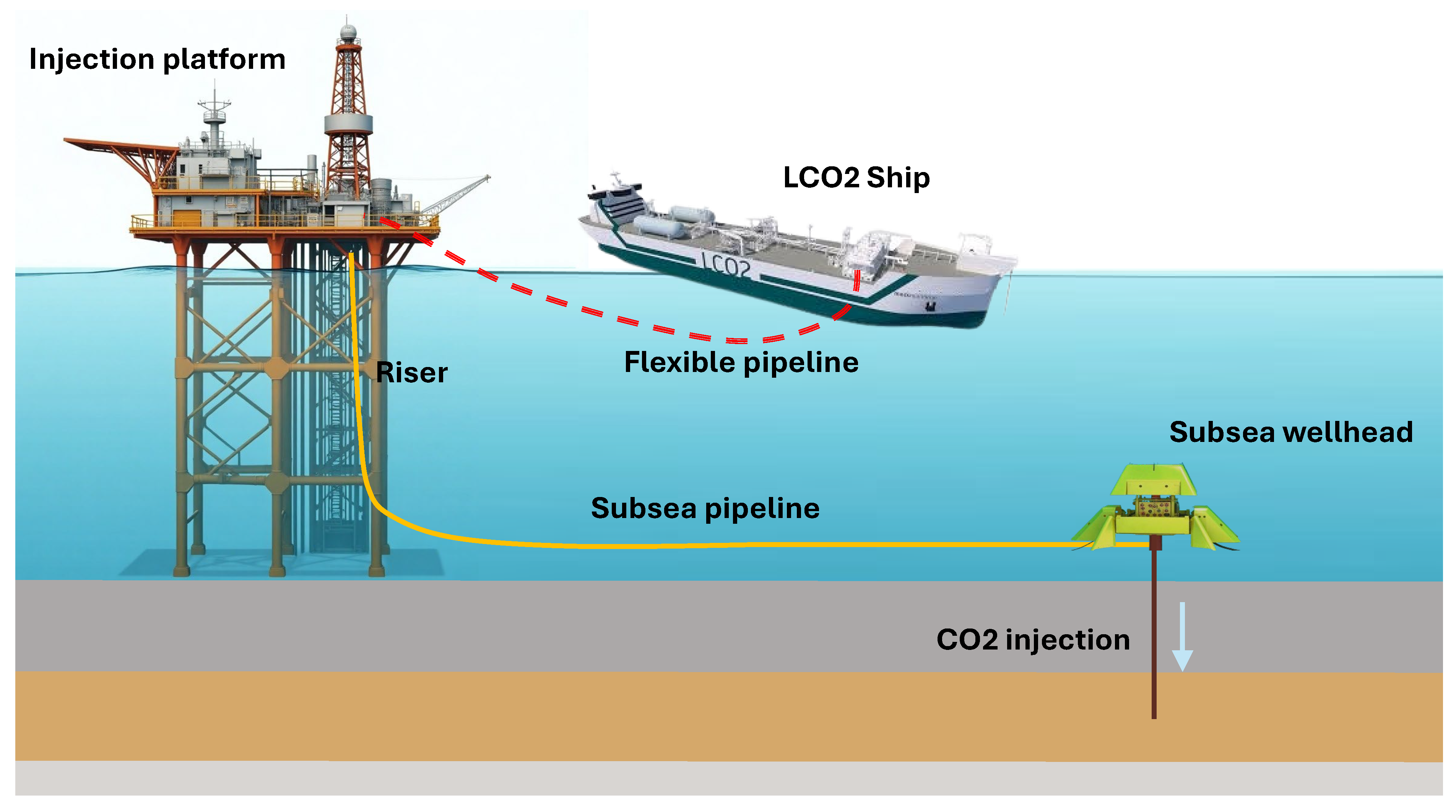

3.2. Carbon Transportation Technologies

3.3. Offshore Carbon Utilization Technologies

3.3.1. Enhanced Oil Recovery

| Technique | Application | Effectiveness | Limitations |

|---|---|---|---|

| Continuous CO2 Injection (Flooding) |

|

| |

| CO2 Huff ‘n’ Puff (Cyclic Injection) |

| ||

| Water Alternating Gas (WAG)/Water-Alternating CO2 (CO2 WAG) |

|

|

|

| Hybrid WAG (HWAG) |

|

| |

| Hybrid Thermal–NCG Process |

|

|

|

| CO2 Assisted Gravity Drainage (CO2-AGD) |

|

3.3.2. Geological Storage: Saline Aquifers, Depleted Reservoirs

3.4. Barriers and Challenges

4. Conclusions

- Cost reduction through modular capture units, shared infrastructure, and process integration with renewables.

- Improved transport and injection designs for phase stability and safety.

- Enhanced reservoir characterization and CO2 immigration, rock behavior, and numerical modeling for maximizing storage efficiency and monitoring gas leakage.

- Regulatory harmonization and financial mechanisms for de-risking investments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CAPEX | Capital Expenditure |

| CCS | Carbon Capture and Storage |

| CCUS | Carbon Capture, Utilization, and Storage |

| COP21 | Conference of the Parties |

| DAC | Direct Air Capture |

| EOR | Enhanced Oil Recovery |

| ESD | Emergency Shutdown |

| EU ETS | European Union Emissions Trading System |

| GHG | Greenhouse Gas |

| IGCC | Integrated Gasification Combined Cycle |

| IMO | International Maritime Organization |

| IPCC | Intergovernmental Panel on Climate Change |

| IRCC | Integrated Reforming Combined Cycle |

| LCA | Life Cycle of Carbon |

| LPG | Liquefied Petroleum Gas |

| LNG | Liquefied Natural Gas |

| MEA | Monoethanolamine |

| NCG | Non-Condensable Gas |

| OFC | Oxyfuel Combustion |

| OPEX | Operating Expenditure |

| ppm | Parts per Million |

| WAG | Water Alternating Gas |

References

- Agyekum, E.B.; Khan, T.; Tahir, M.; Sultan, S.M.; Mbasso, W.F.; Rashid, F.L.; Togun, H. Evolution, trends, and future research directions of carbon capture, utilization and storage—A comprehensive bibliometric and systematic review. Energy Rep. 2025, 13, 5357–5374. [Google Scholar] [CrossRef]

- Hanson, E.; Nwakile, C.; Hammed, V.O. Carbon capture, utilization, and storage (CCUS) technologies: Evaluating the effectiveness of advanced CCUS solutions for reducing CO2 emissions. Results Surf. Interfaces 2025, 18, 100381. [Google Scholar] [CrossRef]

- Kim, M.; Kim, K.; Kim, T.-h.; Kim, J. Economic and environmental benefit analysis of a renewable energy supply system integrated with carbon capture and utilization framework. Chem. Eng. Res. Des. 2019, 147, 200–213. [Google Scholar] [CrossRef]

- Mondal, M.K.; Balsora, H.K.; Varshney, P. Progress and trends in CO2 capture/separation technologies: A review. Energy 2012, 46, 431–441. [Google Scholar] [CrossRef]

- Nath, F.; Mahmood, M.N.; Yousuf, N. Recent advances in CCUS: A critical review on technologies, regulatory aspects and economics. Geoenergy Sci. Eng. 2024, 238, 212726. [Google Scholar] [CrossRef]

- Odunlami, O.A.; Vershima, D.A.; Oladimeji, T.E.; Nkongho, S.; Ogunlade, S.K.; Fakinle, B.S. Advanced techniques for the capturing and separation of CO2—A review. Results Eng. 2022, 15, 100512. [Google Scholar] [CrossRef]

- Shyam, A.; Ahmed, K.R.A.; Kumar, J.P.N.; Iniyan, S.; Goic, R. Path of carbon dioxide capture technologies: An overview. Next Sustain. 2025, 6, 100118. [Google Scholar] [CrossRef]

- El-Kady, A.H.; Amin, M.T.; Khan, F.; El-Halwagi, M.M. Analysis of CO2 pipeline regulations from a safety perspective for offshore carbon capture, utilization, and storage (CCUS). J. Clean. Prod. 2024, 439, 140734. [Google Scholar] [CrossRef]

- Memon, S.U.R.; Manzoor, R.; Fatima, A.; Javed, F.; Zainab, A.; Ali, L.; Ullah, U.; Saleem, A.; Ullah, Q. A comprehensive review of Carbon Capture, Utilization, and Storage (CCUS): Technological advances, environmental impact, and economic feasibility. Sch. Acad. J. Biosci. 2024, 7, 184–204. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Z.; Kato, T.; Shi, C.; Xu, T.; Gao, W. Decoding the mechanisms influencing public acceptance of carbon dioxide capture and storage technology in China. Energy 2024, 313, 133888. [Google Scholar] [CrossRef]

- Kumar, S.; Jufar, S.R.; Kumar, S.; Foroozesh, J.; Kumari, S.; Bera, A. Underground hydrogen storage and its roadmap and feasibility in India toward Net-Zero target for global decarbonization. Fuel 2023, 350, 128849. [Google Scholar] [CrossRef]

- Rui, Z.; Zeng, L.; Dindoruk, B. Challenges in the large-scale deployment of CCUS. Engineering 2025, 44, 17–20. [Google Scholar] [CrossRef]

- Tardin-Coelho, R.; Bharadwaj, B.; Ashworth, P. Carbon capture utilisation and storage (CCUS) and public perceptions: A systematic literature review. Int. J. Greenh. Gas Control 2025, 145, 104393. [Google Scholar] [CrossRef]

- Shukla, P.R.; Skea, J.; Slade, R.; Al Khourdajie, A.; van Diemen, R.; McCollum, D.; Pathak, M.; Some, S.; Vyas, P.; Fradera, R. Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; The Intergovernmental Panel on Climate Change: Edinburgh, UK, 2022. [Google Scholar]

- Cuéllar-Franca, R.M.; Azapagic, A. Carbon capture, storage and utilisation technologies: A critical analysis and comparison of their life cycle environmental impacts. J. CO2 Util. 2015, 9, 82–102. [Google Scholar] [CrossRef]

- Liu, Z.-x.; Gao, M.; Zhang, X.-m.; Liang, Y.; Guo, Y.-j.; Liu, W.-l.; Bao, J.-w. CCUS and CO2 injection field application in abroad and China: Status and progress. Geoenergy Sci. Eng. 2023, 229, 212011. [Google Scholar] [CrossRef]

- Volaity, S.S.; Aylas-Paredes, B.K.; Han, T.; Huang, J.; Sridhar, S.; Sant, G.; Kumar, A.; Neithalath, N. Towards decarbonization of cement industry: A critical review of electrification technologies for sustainable cement production. Npj Mater. Sustain. 2025, 3, 23. [Google Scholar] [CrossRef]

- van Ruijven, B.J.; van Vuuren, D.P.; Boskaljon, W.; Neelis, M.L.; Saygin, D.; Patel, M.K. Long-term model-based projections of energy use and CO2 emissions from the global steel and cement industries. Resour. Conserv. Recycl. 2016, 112, 15–36. [Google Scholar] [CrossRef]

- Urban, F.; Nurdiawati, A.; Harahap, F.; Morozovska, K. Decarbonizing maritime shipping and aviation: Disruption, regime resistance and breaking through carbon lock-in and path dependency in hard-to-abate transport sectors. Environ. Innov. Soc. Transit. 2024, 52, 100854. [Google Scholar] [CrossRef]

- Acampora, L.; Grilletta, S.; Costa, G. The Integration of Carbon Capture, Utilization, and Storage (CCUS) in Waste-to-Energy Plants: A Review. Energies 2025, 18, 1883. [Google Scholar] [CrossRef]

- Itul, A.; Diaz, R.A.; Eulaerts, O.D.; Georgakaki, A.; Grabowska, M.; Kapetaki, Z.; Ince, E.; Letout, S.; Kuokkanen, A.; Mountraki, A. Clean Energy Technology Observatory: Carbon Capture Storage and Utilisation in the European Union-2023 Status Report on Technology Development, Trends, Value Chains and Markets; Publications Office of the European Union: Luxembourg, 2023.

- Oladipo, O.T. Carbon Capture, Utilization, and Storage (CCUS) in Offshore and Onshore Oil Platforms. Int. J. Res. Innov. Soc. Sci. 2025, 9, 1642–1653. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, T.; Blunt, M.J.; Anthony, E.J.; Park, A.-H.A.; Hughes, R.W.; Webley, P.A.; Yan, J. Advances in carbon capture, utilization and storage. Appl. Energy 2020, 278, 115627. [Google Scholar] [CrossRef]

- Fan, J.-L.; Shen, S.; Xu, M.; Yang, Y.; Yang, L.; Zhang, X. Cost-benefit comparison of carbon capture, utilization, and storage retrofitted to different thermal power plants in China based on real options approach. Adv. Clim. Change Res. 2020, 11, 415–428. [Google Scholar] [CrossRef]

- Jiang, K.; Ashworth, P. The development of Carbon Capture Utilization and Storage (CCUS) research in China: A bibliometric perspective. Renew. Sustain. Energy Rev. 2021, 138, 110521. [Google Scholar] [CrossRef]

- Cao, C.; Zhu, H.; Hou, Z. Advances in Carbon Capture, Utilization and Storage (CCUS). Energies 2024, 17, 4784. [Google Scholar] [CrossRef]

- Mon, M.T.; Tansuchat, R.; Yamaka, W. CCUS Technology and Carbon Emissions: Evidence from the United States. Energies 2024, 17, 1748. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, S.; Li, H.; Li, P.; Zhong, X.; Chen, C.; Tu, G.; Liu, X.; Xu, Z. Current Status and Reflections on Ocean CO2 Sequestration: A Review. Energies 2025, 18, 942. [Google Scholar] [CrossRef]

- Holloway, S. Underground sequestration of carbon dioxide—A viable greenhouse gas mitigation option. Energy 2005, 30, 2318–2333. [Google Scholar] [CrossRef]

- Nooraiepour, M.; Gladysz, P.; Melaaen, E. Norwegian–Polish carbon capture and storage network: Bilateral collaboration for European climate action. Energy Res. Soc. Sci. 2025, 126, 104106. [Google Scholar] [CrossRef]

- Chadwick, R.A. 10—Offshore CO2 storage: Sleipner natural gas field beneath the North Sea. In Geological Storage of Carbon Dioxide (CO2); Gluyas, J., Mathias, S., Eds.; Woodhead Publishing: Delhi, India, 2013; pp. 227–250, 251e–253e. [Google Scholar] [CrossRef]

- Furre, A.-K.; Eiken, O.; Alnes, H.; Vevatne, J.N.; Kiær, A.F. 20 Years of Monitoring CO2-injection at Sleipner. Energy Procedia 2017, 114, 3916–3926. [Google Scholar] [CrossRef]

- Furre, A.-K.; Meneguolo, R.; Ringrose, P.; Kassold, S. Building confidence in CCS: From Sleipner to the Northern Lights Project. First Break 2019, 37, 81–87. [Google Scholar] [CrossRef]

- Trupp, M.; Frontczak, J.; Torkington, J. The Gorgon CO2 Injection Project—2012 Update. Energy Procedia 2013, 37, 6237–6247. [Google Scholar] [CrossRef]

- Song, X.; Du, S.; Deng, C.; Shen, P.; Xie, M.; Zhao, C.; Chen, C.; Liu, X. Carbon emissions in China’s steel industry from a life cycle perspective: Carbon footprint insights. J. Environ. Sci. 2025, 148, 650–664. [Google Scholar] [CrossRef]

- Saravia de los Reyes, R.; Fernández-Sánchez, G.; Esteban, M.D.; Rodríguez, R.R. Carbon footprint of a port infrastructure from a life cycle approach. Int. J. Environ. Res. Public Health 2020, 17, 7414. [Google Scholar] [CrossRef]

- Real, S.; Sousa, V.; Meireles, I.; Bogas, J.A.; Carriço, A. Life cycle assessment of thermoactivated recycled cement production. Materials 2022, 15, 6766. [Google Scholar] [CrossRef]

- Huang, Z.; Zhou, H.; Miao, Z.; Tang, H.; Lin, B.; Zhuang, W. Life-cycle carbon emissions (LCCE) of buildings: Implications, calculations, and reductions. Engineering 2024, 35, 115–139. [Google Scholar] [CrossRef]

- Duan, Z. Impact of climate change on the life cycle greenhouse gas emissions of cross-laminated timber and reinforced concrete buildings in China. J. Clean. Prod. 2023, 395, 136446. [Google Scholar] [CrossRef]

- Deng, Z.; Zhu, B.; Davis, S.J.; Ciais, P.; Guan, D.; Gong, P.; Liu, Z. Global carbon emissions and decarbonization in 2024. Nat. Rev. Earth Environ. 2025, 6, 231–233. [Google Scholar] [CrossRef]

- Kabir, M.; Habiba, U.E.; Khan, W.; Shah, A.; Rahim, S.; Rios-Escalante, P.R.D.l.; Farooqi, Z.-U.-R.; Ali, L.; Shafiq, M. Climate change due to increasing concentration of carbon dioxide and its impacts on environment in 21st century; a mini review. J. King Saud Univ. Sci. 2023, 35, 102693. [Google Scholar] [CrossRef]

- Möller, T.; Högner, A.E.; Schleussner, C.-F.; Bien, S.; Kitzmann, N.H.; Lamboll, R.D.; Rogelj, J.; Donges, J.F.; Rockström, J.; Wunderling, N. Achieving net zero greenhouse gas emissions critical to limit climate tipping risks. Nat. Commun. 2024, 15, 6192. [Google Scholar] [CrossRef]

- Houghton, R.A. Historic Changes in Terrestrial Carbon Storage. In Recarbonization of the Biosphere: Ecosystems and the Global Carbon Cycle; Lal, R., Lorenz, K., Hüttl, R.F., Schneider, B.U., von Braun, J., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 59–82. [Google Scholar] [CrossRef]

- Curran, J.C.; Curran, S.A. Natural sequestration of carbon dioxide is in decline: Climate change will accelerate. Weather 2025, 80, 85–87. [Google Scholar] [CrossRef]

- Venkata Mohan, S.; Modestra, J.A.; Amulya, K.; Butti, S.K.; Velvizhi, G. A Circular Bioeconomy with Biobased Products from CO2 Sequestration. Trends Biotechnol. 2016, 34, 506–519. [Google Scholar] [CrossRef]

- Jones, M.W.; Peters, G.P.; Gasser, T.; Andrew, R.M.; Schwingshackl, C.; Gütschow, J.; Houghton, R.A.; Friedlingstein, P.; Pongratz, J.; Le Quéré, C. National contributions to climate change due to historical emissions of carbon dioxide, methane, and nitrous oxide since 1850. Sci. Data 2023, 10, 155. [Google Scholar] [CrossRef]

- Wang, P.; Shi, B.; Li, N.; Kang, R.; Li, Y.; Wang, G.; Yang, L. CCUS development in China and forecast its contribution to emission reduction. Sci. Rep. 2023, 13, 17811. [Google Scholar] [CrossRef] [PubMed]

- Sherif, Z.; Sarfraz, S.; Jolly, M.; Salonitis, K. A Critical Review of the Decarbonisation Potential in the UK Cement Industry. Materials 2025, 18, 292. [Google Scholar] [CrossRef]

- Ostovari, H.; Müller, L.; Skocek, J.; Bardow, A. From unavoidable CO2 source to CO2 sink? A cement industry based on CO2 mineralization. Environ. Sci. Technol. 2021, 55, 5212–5223. [Google Scholar] [CrossRef]

- Greig, C.; Uden, S.; Vosshage, O. Defining the Value of Carbon Capture, Utilisation and Storage for a Low-Carbon Future; IEAGHG: Cheltenham, UK, 2022. [Google Scholar]

- Quarton, C.J.; Samsatli, S. The value of hydrogen and carbon capture, storage and utilisation in decarbonising energy: Insights from integrated value chain optimisation. Appl. Energy 2020, 257, 113936. [Google Scholar] [CrossRef]

- Zhao, K.; Jia, C.; Li, Z.; Du, X.; Wang, Y.; Li, J.; Yao, Z.; Yao, J. Recent Advances and Future Perspectives in Carbon Capture, Transportation, Utilization, and Storage (CCTUS) Technologies: A Comprehensive Review. Fuel 2023, 351, 128913. [Google Scholar] [CrossRef]

- Dubey, A.; Arora, A. Advancements in carbon capture technologies: A review. J. Clean. Prod. 2022, 373, 133932. [Google Scholar] [CrossRef]

- Hong, W.Y. A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future. Carbon Capture Sci. Technol. 2022, 3, 100044. [Google Scholar] [CrossRef]

- Marques, L.; Monteiro, M.; Cenci, C.; Mateus, M.; Condeço, J. Review of Post-Combustion Carbon Capture in Europe: Current Technologies and Future Strategies for Largest CO2-Emitting Industries. Energies 2025, 18, 3539. [Google Scholar]

- Di Lorenzo, G.; Barbera, P.; Ruggieri, G.; Witton, J.; Pilidis, P.; Probert, D. Pre-combustion carbon-capture technologies for power generation: An engineering-economic assessment. Int. J. Energy Res. 2013, 37, 389–402. [Google Scholar] [CrossRef]

- Stanger, R.; Wall, T.; Spörl, R.; Paneru, M.; Grathwohl, S.; Weidmann, M.; Scheffknecht, G.; McDonald, D.; Myöhänen, K.; Ritvanen, J.; et al. Oxyfuel combustion for CO2 capture in power plants. Int. J. Greenh. Gas Control 2015, 40, 55–125. [Google Scholar] [CrossRef]

- Wall, T.; Liu, Y.; Spero, C.; Elliott, L.; Khare, S.; Rathnam, R.; Zeenathal, F.; Moghtaderi, B.; Buhre, B.; Sheng, C.; et al. An overview on oxyfuel coal combustion—State of the art research and technology development. Chem. Eng. Res. Des. 2009, 87, 1003–1016. [Google Scholar] [CrossRef]

- Nemitallah, M.A.; Habib, M.A.; Badr, H.M.; Said, S.A.; Jamal, A.; Ben-Mansour, R.; Mokheimer, E.M.; Mezghani, K. Oxy-fuel combustion technology: Current status, applications, and trends. Int. J. Energy Res. 2017, 41, 1670–1708. [Google Scholar] [CrossRef]

- Talei, S.; Fozer, D.; Varbanov, P.S.; Szanyi, A.; Mizsey, P. Oxyfuel Combustion Makes Carbon Capture More Efficient. ACS Omega 2024, 9, 3250–3261. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Ditaranto, M.; Willson, D.; Yan, J. Optimization of Cryogenic CO2 Purification for Oxy-coal Combustion. Energy Procedia 2013, 37, 1341–1347. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, L.; Zhuang, Y.; Wu, Y.; Bi, X. Energy and Economic Assessment of Oxy-Fuel Combustion CO2 Capture in Coal-Fired Power Plants. Energies 2024, 17, 4626. [Google Scholar] [CrossRef]

- García-Luna, S.; Ortiz, C.; Carro, A.; Chacartegui, R.; Pérez-Maqueda, L.A. Oxygen production routes assessment for oxy-fuel combustion. Energy 2022, 254, 124303. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Y.; Xiang, X.; Xie, X. A review of offshore carbon dioxide geological storage from a source-sink perspective. Renew. Sustain. Energy Rev. 2025, 222, 115989. [Google Scholar] [CrossRef]

- Noothout, P.; Wiersma, F.; Hurtado, O.; Macdonald, D.; Kemper, J.; van Alphen, K. CO2 Pipeline Infrastructure—Lessons Learnt. Energy Procedia 2014, 63, 2481–2492. [Google Scholar] [CrossRef]

- Holm, S.E.; Winther, M.S.; Straus, J.; Roussanaly, S. How to best transport CO2 to offshore storages? Carbon Capture Sci. Technol. 2025, 15, 100416. [Google Scholar] [CrossRef]

- Turrell, W.R.; Berx, B.; Bresnan, E.; León, P.; Rouse, S.; Webster, L.; Walsham, P.; Wilson, J.; Wright, P. A Review of National Monitoring Requirements to Support Offshore Carbon Capture and Storage. Front. Mar. Sci. 2022, 9, 838309. [Google Scholar] [CrossRef]

- Simonsen, K.R.; Hansen, D.S.; Pedersen, S. Challenges in CO2 transportation: Trends and perspectives. Renew. Sustain. Energy Rev. 2024, 191, 114149. [Google Scholar] [CrossRef]

- Dugstad, A.; Halseid, M.; Morland, B. Experimental techniques used for corrosion testing in dense phase CO2 with flue gas impurities. In Proceedings of the CORROSION 2014, San Antonio, TX, USA, 9–13 March 2014; pp. 1–11. [Google Scholar]

- Quynh Hoa, L.; Baessler, R.; Bettge, D. On the corrosion mechanism of CO2 transport pipeline steel caused by condensate: Synergistic effects of NO2 and SO2. Materials 2019, 12, 364. [Google Scholar] [CrossRef]

- Dugstad, A.; Halseid, M.; Morland, B. Testing of CO2 specifications with respect to corrosion and bulk phase reactions. Energy Procedia 2014, 63, 2547–2556. [Google Scholar] [CrossRef]

- De Visser, E.; Hendriks, C.; Barrio, M.; Mølnvik, M.J.; de Koeijer, G.; Liljemark, S.; Le Gallo, Y. Dynamis CO2 quality recommendations. Int. J. Greenh. Gas Control 2008, 2, 478–484. [Google Scholar] [CrossRef]

- ISO/TR 27921:2020; Carbon Dioxide Capture, Transportation, and Geological Storage-Cross Cutting Issues-CO2 Stream Composition. ISO: Geneva, Switzerland, 2020.

- Haugan, P.M.; Drange, H. Effects of CO2 on the ocean environment. Energy Convers. Manag. 1996, 37, 1019–1022. [Google Scholar] [CrossRef]

- Cao, L.; Caldeira, K.; Jain, A.K. Effects of carbon dioxide and climate change on ocean acidification and carbonate mineral saturation. Geophys. Res. Lett. 2007, 34, L05607. [Google Scholar] [CrossRef]

- Bielka, P.; Kuczyński, S.; Włodek, T.; Nagy, S. Risks and Safety of CO2 Pipeline Transport: A Case Study of the Analysis and Modeling of the Risk of Accidental Release of CO2 into the Atmosphere. Energies 2024, 17, 3943. [Google Scholar] [CrossRef]

- Karo, N.; Itov, G.; Mayraz, O.; Vogt, C. Carbon dioxide sequestration through mineralization from seawater: The interplay of alkalinity, pH, and dissolved inorganic carbon. Chem. Eng. J. 2024, 500, 156380. [Google Scholar] [CrossRef]

- Dai, T.; Yang, S.; Xing, Y.; Ma, Y. Dynamic design and analysis of subsea CO2 discharging flowline for cargo submarines used for CCS in low-carbon and renewable energy value chains. Front. Mar. Sci. 2022, 9, 1016062. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Al-Ammari, W.A.; Vesely, L.; Kapat, J.S. Carbon Dioxide Transport Pipeline Systems: Overview of Technical Characteristics, Safety, Integrity and Cost, and Potential Application of Digital Twin. J. Energy Resour. Technol. 2022, 144, 092106. [Google Scholar] [CrossRef]

- Mohitpour, M.; Seevam, P.; Botros, K.K.; Rothwell, B.; Ennis, C.; Mohitpour, M.; Seevam, P.; Botros, K.K.; Rothwell, B.; Ennis, C. CO2 Pipeline System Development and Design. In Pipeline Transportation of Carbon Dioxide Containing Impurities; ASME Press: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Serpa, J.; Morbee, J.; Tzimas, E. Technical and Economic Characteristics of a CO2 Transmission Pipeline Infrastructure; JRC: Petten, The Netherlands, 2011; pp. 1–43. [CrossRef]

- Bielka, P.; Kuczyński, S.; Nagy, S. CO2 compression and dehydration for transport and geological storage. Energies 2023, 16, 1804. [Google Scholar] [CrossRef]

- Peletiri, S.P.; Rahmanian, N.; Mujtaba, I.M. Effects of impurities on CO2 pipeline performance. Chem. Eng. Trans. 2017, 57, 355–360. [Google Scholar]

- Onuoha, M.D.U.; Duan, M.; Wang, Y. Dynamic response and stress impact analysis of production riser under severe slug flow. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Rhodes, Greece, 16–21 June 2024; p. ISOPE-I-16-520. [Google Scholar]

- Domene, G.A.; Crawford, C. Internal flow effect of a flexible riser system for a floating offshore wind turbine with on-board carbon dioxide capture. Ocean Eng. 2025, 316, 119821. [Google Scholar] [CrossRef]

- Smith, R. Bending Stiffeners for Extreme and Fatigue Loading of Unbonded Flexible Risers. In Proceedings of the ASME 2008 27th International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; pp. 405–413. [Google Scholar]

- Zheng, W.; Mahgerefteh, H.; Martynov, S.; Brown, S. Modeling of CO2 Decompression across the Triple Point. Ind. Eng. Chem. Res. 2017, 56, 10491–10499. [Google Scholar] [CrossRef]

- Tang, C.; Chen, B.; Qi, W.; Zhao, Q.; Wang, X. Prediction of Hydrate Formation in Long-Distance Transportation Pipeline for Supercritical-Dense Phase CO2 Containing Impurities. ACS Omega 2024, 9, 49728–49738. [Google Scholar] [CrossRef]

- Vree, B.; Ahmad, M.; Buit, L.; Florisson, O. Rapid depressurization of a CO2 pipeline—An experimental study. Int. J. Greenh. Gas Control 2015, 41, 41–49. [Google Scholar] [CrossRef]

- Al Baroudi, H.; Awoyomi, A.; Patchigolla, K.; Jonnalagadda, K.; Anthony, E.J. A review of large-scale CO2 shipping and marine emissions management for carbon capture, utilisation and storage. Appl. Energy 2021, 287, 116510. [Google Scholar] [CrossRef]

- Element Energy; Engineering Brevik; SINTEF; Polarkonsult. Shipping CO2 UK Cost Estimation Study; Element Energy Limited: Cambridge, UK, 2018. [Google Scholar]

- Gassnova, G. Feasibility Study for Full-Scale CCS in Norway; Ministry of Petroleum and Energy: Oslo, Norway, 2016; pp. 1–62.

- Ozaki, M.; Ohsumi, T.; Kajiyama, R. Ship-based Offshore CCS Featuring CO2 Shuttle Ships Equipped with Injection Facilities. Energy Procedia 2013, 37, 3184–3190. [Google Scholar] [CrossRef]

- Costa, A.; Dubois, L.; Thomas, D.; De Weireld, G. Optimization of liquefaction cycles applied to CO2 coming from onshore pipeline to offshore ship transportation. Carbon Capture Sci. Technol. 2024, 13, 100280. [Google Scholar] [CrossRef]

- Seo, Y.; Huh, C.; Lee, S.; Chang, D. Comparison of CO2 liquefaction pressures for ship-based carbon capture and storage (CCS) chain. Int. J. Greenh. Gas Control 2016, 52, 1–12. [Google Scholar] [CrossRef]

- Vermeulen, T. CO2 Liquid Logistics Shipping Concept (LLSC) Overall Supply Chain Optimization; Global CCS Institute: Canberra, Australia, 2011. [Google Scholar]

- Cooperation, A.-P.E. Building Capacity for CO2 Capture and Storage in the APEC Region; Asia-Pacific Economic Cooperation: Singapore, 2019. [Google Scholar]

- Argüello, G.; Bokareva, O. Transboundary transportation of CO2 streams by ships: Regulatory barriers for scaling up carbon capture and sub-seabed storage. Front. Mar. Sci. 2024, 11, 1423962. [Google Scholar] [CrossRef]

- Oeuvray, P.; Burger, J.; Roussanaly, S.; Mazzotti, M.; Becattini, V. Multi-criteria assessment of inland and offshore carbon dioxide transport options. J. Clean. Prod. 2024, 443, 140781. [Google Scholar] [CrossRef]

- Ku, H.; Miao, Y.; Wang, Y.; Chen, X.; Zhu, X.; Lu, H.; Li, J.; Yu, L. Frontier science and challenges on offshore carbon storage. Front. Environ. Sci. Eng. 2023, 17, 80. [Google Scholar] [CrossRef]

- Alcalde, J.; Heinemann, N.; Mabon, L.; Worden, R.H.; de Coninck, H.; Robertson, H.; Maver, M.; Ghanbari, S.; Swennenhuis, F.; Mann, I.; et al. Acorn: Developing full-chain industrial carbon capture and storage in a resource- and infrastructure-rich hydrocarbon province. J. Clean. Prod. 2019, 233, 963–971. [Google Scholar] [CrossRef]

- Yuksel, O.; Goksu, B. Effects of transportation of electric vehicles by a RoPax ship on carbon intensity and energy efficiency. Sustain. Energy Technol. Assess. 2025, 75, 104238. [Google Scholar] [CrossRef]

- Huang, J.; Duan, X. A comprehensive review of emission reduction technologies for marine transportation. J. Renew. Sustain. Energy 2023, 15, 032702. [Google Scholar] [CrossRef]

- Ning, Y.; Wang, L.; Yu, X.; Li, J. Recent development in the decarbonization of marine and offshore engineering systems. Ocean Eng. 2023, 280, 114883. [Google Scholar] [CrossRef]

- Ma, Y.; Xing, Y.; Ong, M.C.; Hemmingsen, T.H. Baseline design of a subsea shuttle tanker system for liquid carbon dioxide transportation. Ocean Eng. 2021, 240, 109891. [Google Scholar] [CrossRef]

- Irani, M.; Telkov, V. Research and Simulation Study of Different Technological Processes of Miscible CO2 Water Alternating Gas Injection. SOCAR Proc. 2023, 1–5. [Google Scholar] [CrossRef]

- Satter, A.; Iqbal, G.M. 17—Enhanced oil recovery processes: Thermal, chemical, and miscible floods. In Reservoir Engineering; Satter, A., Iqbal, G.M., Eds.; Gulf Professional Publishing: Boston, MA, USA, 2016; pp. 313–337. [Google Scholar] [CrossRef]

- Junior, A.N.; Queiroz, G.N.; Godoy, M.G.; de Silva Cardoso, V.; Cedrola, S.M.L.; Mansoldo, F.R.P.; Firpo, R.M.; Gomes Paiva, L.M.; Sohrabi, M.; Vermelho, A.B. Assessing EOR strategies for application in Brazilian pre-salt reservoirs. Geoenergy Sci. Eng. 2023, 223, 211508. [Google Scholar] [CrossRef]

- Xia, W.; Li, Q.; Shi, Q.; Xu, R.; Wu, J.; Deng, S. Enhanced Oil Production Forecasting in CCUS-EOR Systems via KAN-LSTM Neural Network. Energies 2025, 18, 2795. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Sambo, C.; Liu, N.; Shaibu, R.; Ahmed, A.A.; Hashish, R.G. A Technical Review of CO2 for Enhanced Oil Recovery in Unconventional Oil Reservoirs. Geoenergy Sci. Eng. 2023, 221, 111185. [Google Scholar] [CrossRef]

- Iglauer, S.; Pentland, C.H.; Busch, A. CO2 wettability of seal and reservoir rocks and the implications for carbon geo-sequestration. Water Resour. Res. 2015, 51, 729–774. [Google Scholar] [CrossRef]

- Koyanbayev, M.; Hazlett, R.D.; Wang, L.; Hashmet, M.R. An Experimental Investigation of Surfactant-Stabilized CO2 Foam Flooding in Carbonate Cores in Reservoir Conditions. Energies 2024, 17, 3353. [Google Scholar] [CrossRef]

- Bello, A.; Dorhjie, D.B.; Ivanova, A.; Cheremisin, A. A numerical feasibility study of CO2 foam for carbon utilization and storage in a depleted, high salinity, carbonate oil reservoir. Sci. Rep. 2024, 14, 20585. [Google Scholar] [CrossRef] [PubMed]

- Jian, G.; Fernandez, C.A.; Puerto, M.; Sarathi, R.; Bonneville, A.; Biswal, S.L. Advances and challenges in CO2 foam technologies for enhanced oil recovery in carbonate reservoirs. J. Pet. Sci. Eng. 2021, 202, 108447. [Google Scholar] [CrossRef]

- Xian, B.; Hao, H.; Deng, S.; Sun, T.; Wu, H.; Cheng, L.; Tang, Z.; Gao, X.; Wang, Y.; Cai, S. Laboratory experiments of hydrocarbon gas flooding and its influencing factors on oil recovery in a low permeability reservoir with medium viscous oil. ACS Omega 2024, 9, 8381–8396. [Google Scholar] [CrossRef]

- Wu, R.; Wei, B.; Li, S.; Zhang, Y.; Luo, Q. Enhanced oil recovery in complex reservoirs: Challenges and methods. Adv. Geo-Energy Res. 2023, 10, 208–212. [Google Scholar] [CrossRef]

- Bera, A.; Satapathy, S.; Daneti, J. Perspectives of CO2 injection strategies for enhanced oil recovery and storage in Indian oilfields. Energy Fuels 2024, 38, 10613–10633. [Google Scholar] [CrossRef]

- Li, X.; Peng, B.; Liu, Q.; Liu, J.; Shang, L. Micro and nanobubbles technologies as a new horizon for CO2-EOR and CO2 geological storage techniques: A review. Fuel 2023, 341, 127661. [Google Scholar] [CrossRef]

- Kumar, N.; Sampaio, M.A.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental aspects, mechanisms and emerging possibilities of CO2 miscible flooding in enhanced oil recovery: A review. Fuel 2022, 330, 125633. [Google Scholar] [CrossRef]

- Ji, Z.; Zhao, J.; Chen, X.; Gao, Y.; Xu, L.; He, C.; Ma, Y.; Yao, C. Three-dimensional physical simulation of horizontal well pumping production and water injection disturbance assisted CO2 huff and puff in shale oil reservoir. Energies 2022, 15, 7220. [Google Scholar] [CrossRef]

- Zheng, W.; Li, Z.; Huang, H.; Cao, X.; Wu, G.; Wang, J.; Kang, H. Evaluation and improvement of CO2 assisted gravity drainage for enhanced oil production in China. Energy Rep. 2023, 10, 4465–4473. [Google Scholar] [CrossRef]

- Dang, C.; Nghiem, L.; Nguyen, N.; Chen, Z.; Nguyen, Q. Evaluation of CO2 low salinity water-alternating-gas for enhanced oil recovery. J. Nat. Gas Sci. Eng. 2016, 35, 237–258. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, Q.; Chen, L.; Guo, L.; Miao, Y.; Wang, Y.; Jin, H. Experimental investigation of enhanced oil recovery and in-situ upgrading of heavy oil via CO2-and N2-assisted supercritical water flooding. Chem. Eng. Sci. 2023, 268, 118378. [Google Scholar] [CrossRef]

- Al-Obaidi, D.A.; Al-Mudhafar, W.J.; Al-Jawad, M.S. Experimental evaluation of Carbon Dioxide-Assisted Gravity Drainage process (CO2-AGD) to improve oil recovery in reservoirs with strong water drive. Fuel 2022, 324, 124409. [Google Scholar] [CrossRef]

- Li, C.; Tien, N.-C.; Zhang, K.; Jen, C.-P.; Hsieh, P.-S.; Huang, S.-Y.; Maggi, F. Assessment of large-scale offshore CO2 geological storage in Western Taiwan Basin. Int. J. Greenh. Gas Control 2013, 19, 281–298. [Google Scholar] [CrossRef]

- Tan, Q.; Peng, H.; Tian, J.; Cao, Z. A review on mechanisms of CO2-fluid-rock interaction during CO2 injection into carbonate reservoirs. Geoenergy Sci. Eng. 2025, 249, 213773. [Google Scholar] [CrossRef]

- Bachu, S.; Adams, J.J. Sequestration of CO2 in geological media in response to climate change: Capacity of deep saline aquifers to sequester CO2 in solution. Energy Convers. Manag. 2003, 44, 3151–3175. [Google Scholar] [CrossRef]

- Wang, L.; Cai, S.; Chen, W.; Lei, G. Integrated Study on Carbon Dioxide Geological Sequestration and Gas Injection Huff-n-Puff to Enhance Shale Oil Recovery. Energies 2024, 17, 1957. [Google Scholar] [CrossRef]

- Heidarabad, R.G.; Shin, K. Carbon Capture and Storage in Depleted Oil and Gas Reservoirs: The Viewpoint of Wellbore Injectivity. Energies 2024, 17, 1201. [Google Scholar] [CrossRef]

- Birkholzer, J.T.; Zhou, Q.; Tsang, C.-F. Large-scale impact of CO2 storage in deep saline aquifers: A sensitivity study on pressure response in stratified systems. Int. J. Greenh. Gas Control 2009, 3, 181–194. [Google Scholar] [CrossRef]

- Nicot, J.-P. Evaluation of large-scale CO2 storage on fresh-water sections of aquifers: An example from the Texas Gulf Coast Basin. Int. J. Greenh. Gas Control 2008, 2, 582–593. [Google Scholar] [CrossRef]

- Alafnan, S. Utilization of depleted heavy oil reservoirs for carbon dioxide storage and sequestration: A molecular level assessment. Int. J. Greenh. Gas Control 2022, 119, 103741. [Google Scholar] [CrossRef]

- Hughes, D.S. Carbon storage in depleted gas fields: Key challenges. Energy Procedia 2009, 1, 3007–3014. [Google Scholar] [CrossRef]

- Zoback, M.; Smit, D. Meeting the challenges of large-scale carbon storage and hydrogen production. Proc. Natl. Acad. Sci. USA 2023, 120, e2202397120. [Google Scholar] [CrossRef]

- Callas, C.; Saltzer, S.D.; Steve Davis, J.; Hashemi, S.S.; Kovscek, A.R.; Okoroafor, E.R.; Wen, G.; Zoback, M.D.; Benson, S.M. Criteria and workflow for selecting depleted hydrocarbon reservoirs for carbon storage. Appl. Energy 2022, 324, 119668. [Google Scholar] [CrossRef]

- Tang, W.; Li, W.; Lin, Z.; Zhu, J.; Zhou, S.; Kuang, Y.; Zheng, Y. Geophysical monitoring technology and simulation in CO2 geological storage: A comprehensive review. Gas Sci. Eng. 2025, 143, 205725. [Google Scholar] [CrossRef]

- Meng, L.; Zheng, J.; Yang, R.; Peng, S.; Sun, Y.; Xie, J.; Li, D. Microseismic Monitoring Technology Developments and Prospects in CCUS Injection Engineering. Energies 2023, 16, 3101. [Google Scholar] [CrossRef]

- Hema, G.; Maurya, S.P.; Kant, R.; Singh, A.P.; Verma, N.; Singh, R.; Singh, K.H. Enhancement of CO2 monitoring in the sleipner field (north sea) using seismic inversion based on simulated annealing of time-lapse seismic data. Mar. Pet. Geol. 2024, 167, 106962. [Google Scholar] [CrossRef]

- Alnes, H.; Eiken, O.; Nooner, S.; Sasagawa, G.; Stenvold, T.; Zumberge, M. Results from Sleipner gravity monitoring: Updated density and temperature distribution of the CO2 plume. Energy Procedia 2011, 4, 5504–5511. [Google Scholar] [CrossRef]

- Weijermars, R. Concurrent challenges in practical operations and modeling of geological carbon-dioxide sequestration: Review of the Gorgon project and FluidFlower benchmark study. Energy Strategy Rev. 2024, 56, 101586. [Google Scholar] [CrossRef]

- Jackson, W.A.; Hampson, G.J.; Jacquemyn, C.; Jackson, M.D.; Petrovskyy, D.; Geiger, S.; Machado Silva, J.D.; Judice, S.; Rahman, F.; Costa Sousa, M. A screening assessment of the impact of sedimentological heterogeneity on CO2 migration and stratigraphic-baffling potential: Johansen and Cook formations, Northern Lights project, offshore Norway. Int. J. Greenh. Gas Control 2022, 120, 103762. [Google Scholar] [CrossRef]

- Gentile, V.; Cauchois, G.; Ålund, I.; Renzi, N. Carbon Footprint of the Northern Lights JV CO2 Transport and Storage Value Chain; North Lights: Stavanger, Norway, 2023; Available online: https://norlights.com/reports-2/ (accessed on 13 December 2024).

- Nagabhushan, D.; Russell, R.H.; Waltzer, K.; Thompson, J.; Beck, L.; Jaruzel, M. Carbon capture: Prospects and policy agenda for CO2-neutral power generation. Electr. J. 2021, 34, 106997. [Google Scholar] [CrossRef]

- Belhadj, M. Northern Lights: Innovating for the Future of Carbon Transport and Storage. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu, Dhabi, 4–7 November 2025; p. D021S050R005. [Google Scholar]

- Yusmananto, S.; Fahmi, B.; Ferreira, I.; Ibrhim, S.; Koeshidayatullah, A. CO2 storage and utilization potential in the Middle East: Lessons learned from the Cretaceous carbonate reservoirs. In Proceedings of the 84th EAGE Annual Conference & Exhibition, Vienna, Austria, 5–8 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Li, J. Accelerating the offshore CCUS to carbon-neutral China. Fundam. Res. 2025, 5, 715–726. [Google Scholar] [CrossRef]

- Schrag, D.P. Storage of Carbon Dioxide in Offshore Sediments. Science 2009, 325, 1658–1659. [Google Scholar] [CrossRef]

- Eide, L.I.; Batum, M.; Dixon, T.; Elamin, Z.; Graue, A.; Hagen, S.; Hovorka, S.; Nazarian, B.; Nøkleby, P.H.; Olsen, G.I. Enabling large-scale carbon capture, utilisation, and storage (CCUS) using offshore carbon dioxide (CO2) infrastructure developments—A review. Energies 2019, 12, 1945. [Google Scholar] [CrossRef]

- Mortezaei, K.; Amirlatifi, A.; Ghazanfari, E.; Vahedifard, F. Potential CO2 leakage from geological storage sites: Advances and challenges. Environ. Geotech. 2019, 8, 3–27. [Google Scholar] [CrossRef]

- Ng, C.Y.; Ong, M.C.; Chiu, G.L.F. Economic feasibility of offshore carbon capture and utilization systems in Southeast Asia. Innov. Energy 2025, 2, 100100. [Google Scholar] [CrossRef]

- Makuch, Z.; Georgieva, S.; Oraee-Mirzamani, B. Innovative Regulatory and Financial Parameters for Advancing Carbon Capture and Storage Technologies. Fordham Environ. Law Rev. 2020, 32, 1–45. [Google Scholar]

- Reyes-Lúa, A.; Jordal, K. Industrial CO2 capture projects: Lessons learned and needs for progressing towards full-scale implementation. Changes 2020, 1, 10. [Google Scholar]

- Gola, S.; Noussia, K. From CO2 sources to sinks: Regulatory challenges for trans-boundary trade, shipment and storage. Resour. Conserv. Recycl. 2022, 179, 106039. [Google Scholar] [CrossRef]

- Teece, D. Fundamental Issues in Strategy: Time to Reassess? 2019. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5053779 (accessed on 13 December 2024).

- Zhang, H. Regulations for carbon capture, utilization and storage: Comparative analysis of development in Europe, China and the Middle East. Resour. Conserv. Recycl. 2021, 173, 105722. [Google Scholar] [CrossRef]

| Categories | Technical Specifications and Literature-Based Insights |

|---|---|

| Risk of leaks | In regional offshore CCS systems (~20 Mtpa), the most frequent events are CO2 pipeline leaks, expected every ~2–10 years across the industry; rarer but higher-impact “total failures” are estimated at ~1–10 years [67]. These frequencies underpin monitoring design and emergency planning. The consequence of a CO2 leak in the marine environment depends on pipeline pressure and release rate. CO2 leaks may lead to ocean acidification and a potential asphyxiation hazard in the marine environment. In addition, the addition of CO2 in seawater results in a pH decrease and detrimental effects on ocean life [74,75,76,77]. |

| Design and validation | Offshore CO2 flowlines/risers are validated for pressure containment, collapse, local/global buckling, and fatigue following submarine pipeline practice with corrosion allowance and impurity-dependent material selection [78]. Offshore codes and standards are used for CO2 subsurface sequestration [79]. |

| Operating conditions (phase and pressure–temperature window) | Dense-phase operation is preferred to avoid two-phase transients. Typical design/operation windows reported in the literature are ≥80 bar at ~20 °C (minimum operating pressure) and often 100–150 bar for trunk lines; internal temperatures are commonly in the range of 4 °C to 44 °C, or specifically 15 °C to 30 °C [68,80,81,82,83]. Impurities tend to raise the critical pressure, narrowing the single-phase envelope; this must be reflected in compression/dehydration and set points. |

| Dynamic response (hydro-environmental and flow-induced) | Dynamic analyses address current/wave/vessel-motion loading and flow-induced effects (slugging, Vortex-Induced Vibrations), tracking effective tension, bending moments, von Mises stress, and local buckling [78,84,85]. Recent subsea CO2 flowline studies demonstrate the need for coupled hydrodynamic–structural modeling to keep stress ranges within fatigue design curves [78]. |

| Ancillary components (interfaces and fatigue control) | Bend stiffeners at hang-offs/I-tubes limit curvature to above the riser’s minimum bending radius and reduce cyclic strain accumulation; proper sizing materially improves the fatigue life of flexible/dynamic risers [85,86]. |

| Phase stability and transient safety (blowdown/depressurization) | Rapid depressurization can cross the triple point (≈5.2 bar, −56.6 °C), forming dry ice and hydrates, sharply cooling the fluid and pipe wall; staged/blended blowdown strategies are therefore required [87]. Experiments and models show large temperature drops and potential solid CO2 mass fractions during decompression, reinforcing the need for Emergency Shutdown set points that maintain a margin with respect to the triple point and hydrate lines [64,88,89]. |

| No | Project | Depth | Advantages | Challenges |

|---|---|---|---|---|

| 1 | Location: Sleipner field, Norway Start date: 1996 Capacity: 0.9 Mt/yr CO2 Source: Sleipner field [31] | 800–1000 m below the sea | This is the 1st offshore CCS in the world. CO2 was injected into the saline, highly porous Utsira Fm through an injection well in the Sleipner field [31]. There is no evidence for CO2 migration [31]. | Injectivity due to sand influx. Lack of geophysical and environmental monitoring [140]. High uncertainties regarding the reservoir’s temperature and seismic characteristics [141]. |

| 2 | Location: Gorgon field, Australia Start date: 2019 Capacity: 3.3–4 Mt/yr CO2 source: LNG plant [34] | 2000 m beneath Barrow Island | Gorgon is the world’s largest CCS project [34]. Highly reliable 3-D seismic profile [142]. | Temperature and pressure variations [34]. High concentration of solids in produced formation water [142]. |

| 3 | Location: Northern Lights, Norway Start date: 2024 Capacity: 0.4 t/year CO2 source: cement factory [143] | 2600 m below the sea | Deep geological formation [144]. The bridged CCS funding gap [30]. | It is a greenfield project, with inadequate subsurface data [145]. Long distance of CO2 transport by vessel and pipeline [144,146]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bui, T.V.; Dao, H.H.; Nguyen, H.T.; Ta, Q.D.; Le, H.N.N.; Kieu, P.; Mai, C.L.; Tran, T.D.; Nguyen, H.S.; Nguyen, H.D.; et al. A Critical Review on the Opportunities and Challenges of Offshore Carbon Capture, Utilization, and Storage. Sustainability 2025, 17, 9250. https://doi.org/10.3390/su17209250

Bui TV, Dao HH, Nguyen HT, Ta QD, Le HNN, Kieu P, Mai CL, Tran TD, Nguyen HS, Nguyen HD, et al. A Critical Review on the Opportunities and Challenges of Offshore Carbon Capture, Utilization, and Storage. Sustainability. 2025; 17(20):9250. https://doi.org/10.3390/su17209250

Chicago/Turabian StyleBui, Trong Vinh, Hong Hai Dao, Huynh Thong Nguyen, Quoc Dung Ta, Hai Nam Nguyen Le, Phuc Kieu, Cao Lan Mai, Trung Dung Tran, Huu Son Nguyen, Hoang Dung Nguyen, and et al. 2025. "A Critical Review on the Opportunities and Challenges of Offshore Carbon Capture, Utilization, and Storage" Sustainability 17, no. 20: 9250. https://doi.org/10.3390/su17209250

APA StyleBui, T. V., Dao, H. H., Nguyen, H. T., Ta, Q. D., Le, H. N. N., Kieu, P., Mai, C. L., Tran, T. D., Nguyen, H. S., Nguyen, H. D., & Huynh, T. T. (2025). A Critical Review on the Opportunities and Challenges of Offshore Carbon Capture, Utilization, and Storage. Sustainability, 17(20), 9250. https://doi.org/10.3390/su17209250