Abstract

The olive flounder (Paralichthys olivaceus) is a significant aquaculture species in Korea, yet production has stagnated due to rising costs, environmental pressures, and shifting consumer preferences. Enhancing farm efficiency is critical not only for economic viability but also for environmental sustainability, as efficient production reduces resource waste, lowers feed inputs, and minimizes the carbon output of aquaculture operations. This study estimated the production function and efficiency of olive flounder farms in Korea using stochastic frontier analysis, drawing on survey data collected directly from producers. Results indicate that the Cobb–Douglas model is more suitable than the translog model for empirical analysis. The average farm efficiency was 0.38, with the lowest recorded efficiency at 0.13. Key determinants of production efficiency included fry quality, workforce size, and feed management. Regional differences were also observed in the technical inefficiency factor. By identifying inefficiencies and management gaps, this study highlights opportunities to enhance resource use efficiency, reduce environmental and economic waste, and promote more sustainable practices. The findings provide insights for policymakers and farm managers seeking to strengthen both the profitability and sustainability of the Korean olive flounder aquaculture industry.

1. Introduction

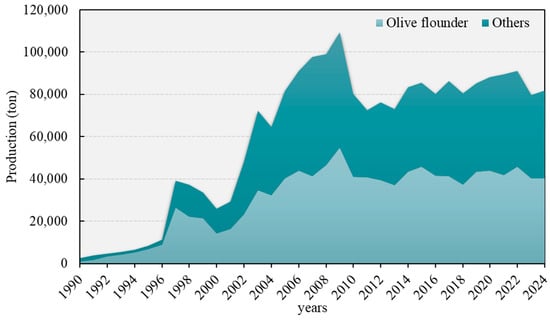

In the last twenty years, South Korea’s aquaculture industry has seen substantial growth, averaging an annual increase of 6.8%. Aquaculture production reached its apex in 2015, totaling 1,676,485 tons, thereby exceeding the output of marine fisheries, which was 1,658,976 tons. Following this rapid expansion phase, the industry has shown signs of stagnation and potential decline. The olive flounder (Paralichthys olivaceus) is a significant species in Korean aquaculture, accounting for approximately 50% of the nation’s farmed fish production. Olive flounder aquaculture industrialization commenced in the 1980s, propelled by the National Institute of Fisheries Science’s (NIFS) achievements in artificial seed production and the advancement of land-based aquaculture systems [1,2]. Advancements in olive flounder aquaculture technology have resulted in substantial production increases, reaching a peak of 54,674 tons in 2009 (Figure 1). Production has subsequently decreased, averaging around 41,484 tons from 2010 to 2024 [3].

Figure 1.

Aquaculture production of finfish in South Korea. Source: [3] Korean Statistical Information Service (2024).

The decline in olive flounder production is attributable to several factors, including elevated mortality rates due to bacterial diseases such as scuticociliatosis and emaciation disease, as well as environmental influences like increasing water temperatures and declining water quality linked to climate change [4,5]. Unstable farm gate prices have emerged as a significant issue for olive flounder farmers [6,7]. This instability is associated with declining domestic consumption attributed to the greater availability of imported farmed seafood, including salmon and amberjack, alongside a decline in exports to nations such as Japan. Decreasing productivity and profitability within olive flounder farming reveal considerable production inefficiencies. Key factors for improving the productivity of olive flounder aquaculture involve comparing the efficiency of various farms, assessing management practices, and pinpointing areas for enhancement. Productivity is a crucial element directly associated with profitability, while efficiency is closely related to both aspects [8,9,10,11]. Efficiency, defined as the ratio of output to input, is a critical metric for assessing a management entity’s productivity and profitability. Estimating efficiency offers essential insights for policymakers and farm managers to enhance productivity and management practices [10].

Efficiency estimation methods encompass stochastic frontier analysis (SFA) and data envelopment analysis (DEA) [12,13], which have found significant applications in aquaculture (Table A1 and Table A2). Data Envelopment Analysis (DEA), grounded in linear programming, establishes the production frontier using multiple input and output variables, facilitating comparisons with other assessment metrics. This functionality enables the analysis of relative efficiency without requiring a specific functional form assumption. The non-parametric, non-probabilistic nature of DEA complicates the identification of random error inherent in the efficiency score. Recent advancements addressed this issue by applying non-parametric methods for estimating confidence intervals for efficiency scores, including bootstrapping Data Envelopment Analysis (BDEA). Conversely, SFA evaluates efficiency by positing a production function and defining the distribution of technical inefficiency errors [14,15,16].

Despite the prominence of olive flounder in Korean aquaculture, no analysis of the efficiency of the associated farms has been conducted to date. The present study aims to estimate the production efficiency of olive flounder farms in South Korea’s Jeju and Wando regions and to explore methods for enhancing efficiency. Accordingly, the production efficiency of olive flounder aquafarms in Korea was estimated using Stochastic Frontier Analysis (SFA). The SFA model facilitated statistical inference by distinguishing between variation due to random error and due to inefficiency. In addition, a parametric estimation method grounded in probability distribution was employed to assess production efficiency statistically. Furthermore, one-on-one interviews were conducted with farmers to examine the overall production and cost status.

2. Literature Review

Aripin et al. [17] conducted a study using DEA to analyze production efficiency across different aquaculture systems. They found that cage aquaculture achieved a production efficiency of 0.92, while pond aquaculture reached 0.9. The results suggest that enhancing production capacity in complex aquaculture systems, as opposed to single systems, can improve productivity and economic efficiency. Iliyasu et al. [18] assessed the production efficiency of freshwater aquaculture systems through bootstrapping BDEA. Cage aquaculture demonstrated the highest efficiency at 0.80, while pen aquaculture exhibited the lowest efficiency at 0.63. In a different study, Long et al. [19] employed DEA, single bootstrapping DEA (SBDEA), and double bootstrapping DEA (DBDEA) to analyze the production efficiency of farms cultivating white-legged shrimp. The SBDEA method assesses efficiency using inputs and outputs, while DBDEA evaluates efficiency by incorporating additional information, including farm-specific and financial variables, alongside inputs and outputs. The authors [19] presented values of 0.77, 0.67, and 0.69 for DEA, SBDEA, and DBDEA, respectively. Aung et al. [20] analyzed the technical efficiency of small-scale fish farms employing DBDEA methodology. The authors observed that women’s participation in aquaculture correlated with enhanced technical efficiency, quantified at 0.44. This finding suggests that policy design and implementation should empower women to improve their technical efficiency. In addition, Mitra et al. [21] employed meta-frontier DEA to assess efficiency disparities by comparing the efficiency of pond aquaculture in regions with and without access to water. The findings indicated that areas with convenient access to water exhibited a higher production efficiency compared to those with restricted access (0.71), implying that distinct strategies are required to enhance efficiency.

Various studies also estimated the production efficiency of aquaculture using SFA. Awoyemi et al. [9] assessed the production efficiency of pond aquaculture, determining a specific average efficiency of 0.24. This finding suggests that enhancements can be achieved through increased stocking densities and expanded pond areas. Additionally, Chiang et al. [22] reported an average efficiency of 0.84 in milkfish aquaculture farms, identifying factors such as location, water type, operator education, and staffing levels as contributors to inefficiencies. In a separate study, Islam et al. [23] examined the production efficiency of cage aquaculture, finding an average efficiency of 0.37. The authors found that extended cultivation periods notably led to inefficiency. They recommended enhancing seed production technologies to mitigate this problem. Moreover, Long [24] employed SFA with double heteroskedasticity to examine technical inefficiency and production risk in white-legged shrimp aquaculture. The findings identified feed as a risk factor, while chemicals and pharmaceuticals were determined to be factors that reduce risk. The findings suggest that prioritizing technical training in chemical usage is crucial, as inadequate training can lead to misuse.

Mitra et al. [25] examined the influence of land ownership on productivity, efficiency, and profitability within the aquaculture sector. The study revealed that productivity and efficiency levels were greater in leased farms than in self-owned farms, whereas profitability was higher in self-owned farms than in leased ones. Moreover, the efficiency of self-owned farms diminished as farm size increased, while the efficiency of leased farms improved with larger sizes. The authors thus concluded that self-owned farms exhibit greater efficiency when they are smaller and managed by families. In a separate study, Khan et al. [26] evaluated the production efficiency of pond aquaculture, finding an average production efficiency of 0.92. Labor, feed, and capital investment enhanced production efficiency, underscoring the significance of high-quality feed production. Moreover, Singh et al. [10] evaluated the production efficiency of freshwater aquaculture, finding an average efficiency of 0.71 and highlighting seed quality as a key factor for enhancing efficiency. In addition, Thidza et al. [27] demonstrated that implementing new technologies and improving management practices in pond aquaculture could increase production efficiency by 71%. The authors indicated that such an increase necessitates enhancements in inputs, including feed, fingerlings, training, and accessibility.

These studies collectively indicate that the efficiency of aquaculture production is affected by various technical, managerial, and socio-economic factors. While DEA- and SFA-based approaches demonstrate differing efficiency levels in aquaculture systems, the results consistently emphasize the need to optimize resource utilization, enhance access to water and quality seed, implement advanced technologies, and reinforce management practices. Additionally, social factors, including gender participation, land ownership, and training, significantly influence efficiency outcomes. It is worth noting that prior research has inevitably identified capital, farm area, fingerlings, labor force size, feed quantity, feed cost, and chemicals as primary input variables in aquaculture production. Additionally, capital, fingerlings, feed quantity, and feed cost have played a key role in enhancing production efficiency [9,10,21,23,24].

Furthermore, smaller farm areas, fewer workers, and decreased chemical usage also lead to a substantial increase in production efficiency [10,24,27], with variables found to significantly influence outputs, thereby enhancing/diminishing production efficiency based on input utilization. On the other hand, prior research on the determinants of inefficiency indicated that factors such as manager age, education, experience, and income contribute to reduced inefficiency. Within this context, manager gender appears to be associated with increased inefficiency, with male managers seeming less inefficient than their female counterparts [10,28]. Thus, improving aquaculture efficiency necessitates a comprehensive approach that integrates technological innovation, input quality, and supportive institutional frameworks.

3. Materials and Methods

3.1. Materials

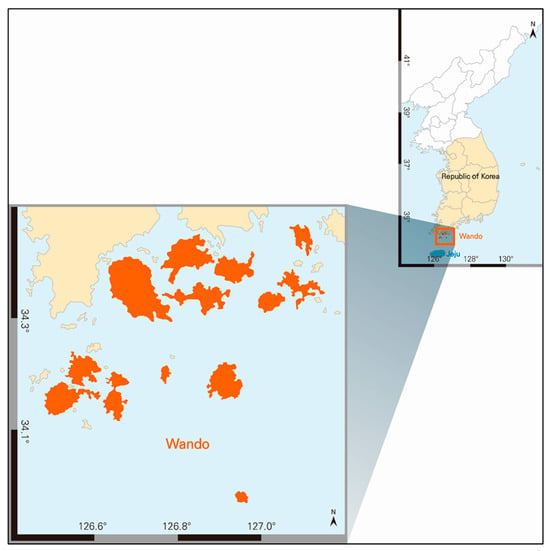

This study selected 90 olive flounder farms located in Jeju and Wando, recognized as the primary centers for olive flounder aquaculture production in Korea (Figure 2). About 53% of olive flounder in aquaculture is produced in Jeju, while 36% is produced in Wando [3]. In Korea, there are 476 olive flounder farms, comprising 235 in Jeju and 150 in Wando [3]. Due to the lack of official data regarding production and costs among aquaculture households in Korea, we used data obtained from one-on-one interviews conducted with 59 aquaculture households in Jeju and 31 in Wando in 2020. The households were sampled randomly, ensuring no bias. The questionnaire gathered data on the characteristics of each fish farmer, their production status, sale prices, and aquaculture production costs.

Figure 2.

Study areas in South Korea.

3.2. Description of Variables

Table 1 presents the output and input variables used in this study. The output variable analyzed was the annual production of olive flounder, quantified in kilograms. The input variables included only the number of workers, the total number of juvenile Paralichthys olivaceus stocked annually (fingerlings), and the amount of feed, to ensure comparability and robustness across all the farms assessed during the current study. The labor variable represented a farm’s full-time employees. The fingerlings represented the aggregate quantity of fish used for production. The feed variable represented the annual quantity of feed injected, quantified in kilograms.

Table 1.

Description of variables used in the stochastic frontier production function.

The present study used region and feed type as factors influencing inefficiency [3,10]. The region was categorized into Jeju and Wando, while the feed types were classified as raw fish-based moist pellets (MP), extruded pellets (EP), and mixed feed. The MP aquafeed mixture typically consists of powdered feed, additives, and young raw crushed fish with a moisture content of around 50–60%. The EP consists of dry aquafeed produced through extrusion, with a moisture content of less than 14%. While prior research concentrated on the factors contributing to inefficiency related to managerial information, the present study aims to assess inefficiency in the context of agricultural practices.

3.3. Data Analysis

Stochastic Frontier Analysis

The SFA model differentiates between a random error and a stochastic variable ( that represents inefficiency. The fundamental SFA model is represented by Equation (1) [29]. Taking the logarithm of both sides of this fundamental SFA model yields the function represented by Equation (2):

where, is the output of the production unit , is the production function comprising the input vector and the estimated coefficient vector ; is a stochastic error term assumed to follow a normal distribution with a mean of 0 and a variance , and assumed to be independent of ; represents the inefficiency level of aquaculture farm and is a stochastic variable within the range . In the equation, represents a reduction in productivity and is a positive value, and the negative sign indicates inefficiency.

The term can be expressed as in Equation (3) [30]. Here, is a variable that affects technical inefficiency and is determined by the sign of the estimated parameter δ and the significance of the coefficient. If the estimated coefficient is significantly negative (or positive), a significant negative (or positive) relationship exists between the variable and technical inefficiency; otherwise, no significant relationship exists between the two.

The technical efficiency of aquaculture farm is measured using Equation (4). This value ranges from 0 to 1, with values closer to 1 indicating more efficient production.

The SFA econometric model, which estimates the production frontier both stochastically and parametrically, requires specifying a specific production function. Commonly used production functions include the Cobb–Douglas and translog models, with statistical significance tests employed to evaluate the validity of these models. This study employed production functions and assessed model validity through the log-likelihood ratio (LR) test, as proposed by [30]. The Cobb–Douglas and translog models used in this study are represented by Equations (5) and (6), respectively.

The LR test statistic is calculated as , which follows a chi-square distribution. In this equation, represents the log-likelihood function value under the null hypothesis, and represents the log-likelihood function value under the alternative hypothesis. Herein, the null hypothesis was tested, asserting that the estimated regression coefficients for the second-order and interaction terms in the translog production function are zero. The model was estimated using Stata 18.0 statistical software (StataCorp LLC, College Station, TX, USA).

4. Results

4.1. Descriptive Statistics and Cost Structure Analysis

Table 2 provides descriptive statistics for the variables used in the analysis. The average production, defined as the output variable (Y), was 124,682 kg. The mean number of workers per olive flounder farm, as an input variable, was five (range: 2–15). The annual average fry count was 184,083 fish, with a range of 37,500 to 700,000 fish. The annual average feed amounted to 493,393 kg, with a range of 1200 to 2,267,000 kg. Of the samples analyzed, 34% were from Wando and 66% from Jeju. Regarding feed type, 7% of the fish received EP exclusively, 62% were provided MP, and 31% were given a combination of EP and MP.

Table 2.

Summary statistics for the variables in this study.

Table 3 presents production costs and farmer revenues categorized by region. The average production in Wando was 108,065 kg, while in Jeju it was 133,413 kg. The cost per kilogram by region was USD 9.03 in Wando and USD 7.03 in Jeju, indicating that the cost in Wando was USD 2.00 higher. Wando exhibited a higher revenue per kilogram, at USD 11.92, compared to Jeju’s USD 10.10; however, Jeju reported a greater profit.

Table 3.

Production cost structure of olive flounder farms (90 farms).

4.2. Model Testing

An LR test was conducted to determine the most suitable functional form between the Cobb–Douglas and translog models. The calculated test statistic was 11.93, indicating a lack of statistical significance. The Cobb–Douglas production function was, therefore, adopted. We subsequently compared two prevalent assumptions: half-normal and truncated normal distributions. The selected Cobb–Douglas production function served as the base model for this comparison. The test result was significant at the 5% significance level, indicating an assumption of a truncated normal distribution (Table 4).

Table 4.

Result of the LR test for model specification.

4.3. Production Efficiency Analysis

The model test results indicate that the estimated coefficients of the Cobb–Douglas production function and the stochastic frontier production functions, assuming a truncated normal distribution, were significant at the 1% level for the input variables: number of workers, fry, and feed (Table 5). The estimated coefficients indicate the elasticity of production with respect to each input. The estimated coefficients for labor, fry, and feed inputs are 0.289, 0.485, and 0.214, respectively. This suggests that a 1% increase in each variable would result in increases of 0.289%, 0.485%, and 0.214% in olive flounder production, respectively.

Table 5.

Estimation of production function.

Technical inefficiency is quantified on a scale from 0 to 1, where 0 represents total efficiency and 1 denotes total inefficiency. The variance parameter for technical inefficiency, , was estimated as 0.999. The coefficient for region was significant at the 1% level, while the coefficient for feed type lacked statistical significance. The estimated coefficient for Wando was negative and statistically significant, suggesting that inefficiency levels in Wando were lower than those in Jeju. The coefficient for fish fed with MP was positive, while the coefficient for fish fed with mixed feed was negative. Nonetheless, the coefficients did not achieve statistical significance (Table 5).

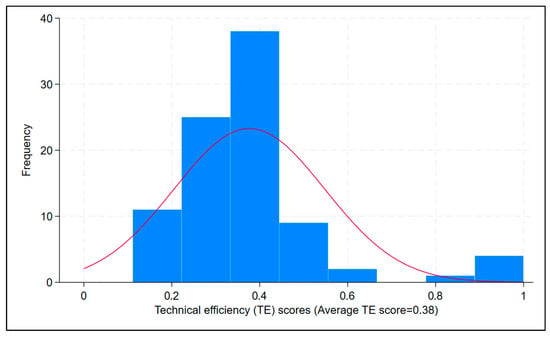

The Model SFA estimated an average production efficiency of 0.38 among the 90 olive flounder aquaculture farms surveyed (Table 6, Figure 3). Efficiency scores varied from 0.13, indicating the lowest efficiency, to 1.0, representing the highest efficiency. Table 6 indicates that the majority of farms (n = 55, 61%) attained efficiency scores ranging from 0.21 to 0.40. Twenty-one farms (23%) exhibited scores ranging from 0.41 to 0.60, while the remaining five farms (6%) scored between 0.81 and 1.00.

Table 6.

Frequency distribution of the efficiency index from SFA.

Figure 3.

Frequency distribution of technical efficiency score.

4.4. Input Use and Efficiency Levels

Table 7 presents the results of a comparative analysis of inputs based on production efficiency ranges. The results were derived based on the feed conversion ratio (total feed intake/net wet weight), and a negative correlation between the feed conversion ratio and the overall production efficiency was observed. Herein, the production efficiency was highest when the number of workers and feed input were at their lowest levels, specifically within the 0.81–1.00 range. Specifically, an annual feed input of 78,500 kg was attained in two of the five farms through the use of commercially formulated feed, which is lighter than raw fish-based moist pellets.

Table 7.

Use of different inputs based on the efficiency level.

The second-highest efficiency quartile, ranging from 0.41 to 0.60, exhibited the highest production levels alongside above-average inputs. Within the 0.21–0.40 range, production levels were below the overall average, while feed quantities were the highest across the entire range. The findings suggest that the fish were overfed relative to the feed quantity, necessitating an adjustment of input parameters. In the lowest efficiency range (0.0–0.20), the feed quantity was maximized, yet production levels were minimized, reflecting the least production efficiency. This finding indicates that enhancing productivity requires reducing, rather than increasing, inputs.

While the results suggest that excessive input use, particularly feed, was associated with lower efficiency, it would be misleading to conclude that input reduction alone is sufficient to enhance productivity. In the high-efficiency group, better performance was not only related to lower feed quantities but also to the use of commercially formulated feed, which differs significantly from moist pellets in quality and digestibility. Thus, efficiency gains should be understood as a combined outcome of optimized input levels and improved input quality.

5. Discussion

The present study estimates olive flounder aquaculture production efficiency in Korea using SFA. Cross-sectional data from 2019 were used, with annual production serving as the output variable. The input variables included the number of workers, fry, and feed. The factors influencing technical inefficiency were assessed by using production region and feed type as variables. The Cobb–Douglas production function and the truncated normal distribution model were deemed suitable for this analysis, as determined by likelihood ratio tests employed to identify the appropriate functional form and the distribution of the error term. Additionally, the adoption of such Cobb–Douglas functional form was found to be consistent with prior aquaculture efficiency studies conducted by Chiang et al. [22], Bukenya et al. [11], Islam et al., 2016 [23], and Mitra et al. [25], which highlighted its parsimony, interpretability, and suitability for estimating input elasticities. Estimation of the stochastic frontier production function indicated that the number of workers, fry, and feeding rate have statistically significant effects on production efficiency. This finding aligns with the results of [9,23,24,25], which identified these three inputs as crucial for enhancing production efficiency. Mussa et al. [28] and Zuzeni Thidza et al. [27] reported negative coefficients for the labor input variable, suggesting that labor inputs were overused. In a production risk analysis of aquaculture, Long [24] demonstrated that excessive feed usage depleted oxygen and elevated ammonia levels. Consequently, these factors diminished production efficiency due to elevated energy consumption associated with enhanced water recirculation.

The study region significantly influenced technical inefficiency in production, with Wando exhibiting lower levels of inefficiency compared to Jeju. The two regions exhibit distinct aquaculture methods and breeding conditions, particularly in terms of water temperature. There are differences in the breeding period and shipping size. Aquaculture farms in Jeju use underground seawater, maintaining a consistent temperature of 15–18 °C throughout the year. This temperature is typically higher than that of natural seawater, which averages 12–13 °C, especially in winter. Consequently, olive flounders in Jeju have faster growth rates compared to those in Wando [2]. Aquaculture farms in Wando use heat pumps or medium-grown fish as stock to maintain optimal water temperature, thereby addressing this impediment [7]. A business survey indicated that operating costs in Wando exceeded those in Jeju, while sales figures were greater in Wando. Moreover, Wando farms reportedly adopt stricter biosecurity protocols and maintain longer grow-out periods, allowing fish to be harvested at larger market-preferred sizes, further enhancing profitability. In contrast, Jeju farms, which rely heavily on underground seawater systems as outlined above, often emphasize faster turnover but incur higher energy costs for water recirculation and disease management. These operational contrasts provide context for the higher efficiency observed in Wando, despite higher production costs. Correspondingly, Wando’s fish are priced higher than Jeju’s due to their larger size at the time of shipping following stocking. Mussa et al. [3] conducted a study indicating that the production region influences inefficiency, noting that Zomba has a longstanding history of aquaculture, while Dowa primarily provides fry to aquaculture farmers. Zomba was consequently more efficient. While feed type was not identified as a determinant of inefficiency in this study, Zuzeni Thidza et al. [27] indicated that the utilization of commercial feeds correlated with increased production efficiency, highlighting the significance of market access for the broader adoption of commercial feeds.

Results indicate that fry quality, feeding practices, and workforce size are the main factors influencing efficiency. The average efficiency level across farms was 0.38, with some farms achieving only 0.13, indicating substantial room for improvement. Feed was particularly critical, as excessive use not only increased costs but also created environmental stress by depleting oxygen and elevating ammonia levels, which in turn required greater energy for water recirculation. Labor input was, in some cases, overutilized, suggesting that workforce productivity could be improved without reducing output. Fry quality also emerged as a determinant of performance, underscoring the importance of investing in healthy, genetically improved seed.

Regional comparisons revealed that farms in Wando were generally more efficient than those in Jeju, reflecting differences in local conditions and production practices. This suggests that location-specific strategies are needed to improve both farm performance and resilience against climate and environmental variability.

The findings highlight important sustainability implications. Improving feed efficiency reduces nutrient waste and energy demand, directly lowering the environmental footprint of aquaculture. Optimizing labor and resource use enhances economic viability, while high-quality fry reduce mortality and waste, supporting both ecological and financial resilience. Together, these efficiency gains align with broader goals of sustainable aquaculture by promoting resource conservation, profitability, and climate adaptation.

In conclusion, enhancing productive efficiency is not only an economic imperative but also a pathway to environmental sustainability in Korean olive flounder aquaculture. By targeting feed management, fry quality, and labor use, farms and policymakers can reduce waste, strengthen resilience, and advance the transition toward a more sustainable aquaculture sector.

6. Study Limitations

The current study has several limitations. First, the efficiency analysis, using Stochastic Frontier Analysis (SFA), is highly sensitive to the choice of input variables. This study utilized fundamental inputs for aquaculture, including labor, fry, and feed, primarily to ensure comparability and robustness across the assessed farms. However, production efficiency in aquaculture is influenced by several factors, including the environment, methods employed, and seed quality and health. Thus, future research may be improved by integrating a wider array of input variables to accurately identify inefficiencies.

Second, the limited sample size and reliance on a single-year cross-sectional dataset limited our ability to account for temporal shocks such as climate variability or episodic disease outbreaks, thus hindering the generalizability of our findings. In this context, future research employing panel data across multiple years and investigating production efficiency in various regions engaged in olive flounder aquaculture to analyze regional disparities would provide stronger control for such fluctuations and enhance the robustness of efficiency estimates. Furthermore, acquiring multi-year data that capture variations in productivity due to technological advancements or feed development would enable comprehensive long-term analyses of production efficiency. Further research addressing these limitations can enhance the reliability of production efficiency analysis. This would also facilitate the formulation of policy measures designed to enhance productivity and management for aquaculture farmers.

Author Contributions

N.-L.K.: Conceptualization, formal analysis, and writing–original draft. D.-H.K.: Supervision and writing–review and editing. K.-W.K.: Data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant from the National Institute of Fisheries Science (R2025045). The funding agency had no role in relation to the study design; collection, analysis, and interpretation of the data; writing of the report; and the decision to submit the article for publication.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available upon request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Abbreviations

The following abbreviations are used in this manuscript:

| MP | Moist pellets |

| EP | Extruded pellets |

| LR | Log-likelihood ratio |

| TE | Technical efficiency |

| SFA | Stochastic frontier approach |

| DEA | Data envelopment analysis |

| NIFS | National Institute of Fisheries Science |

| BDEA | Bootstrapping DEA |

| SBDEA | Single bootstrapping DEA |

| DBDEA | Double BDEA |

Appendix A

Table A1.

DEA applications in aquaculture.

Table A1.

DEA applications in aquaculture.

| Authors | Country | Production Technology | Method | First Stage | Second Stage | ||

|---|---|---|---|---|---|---|---|

| Sample Size | TE | Regression Analysis | Factors Affecting TE | ||||

| Aripin et al. (2020) [17] | Malaysia | Cage | DEA | 70 | 0.92 | Tobit model | Age (−), Experience (+), Education (+), Generation (−), Polyculture (+), Kelantan (+), Penang (−) *, Terengganu (−) ***, Year (+) |

| Malaysia | Pond | DEA | 33 | 0.95 | Tobit model | Experience (+) *, Education (+), Generation (−) **, Polyculture (+) **, Penang (−), Terengganu (−), Year (+) | |

| Aung et al. (2021) [20] | Myanmar | Small-scale aquaculture | DBDEA | 423 | 0.44 | Double bootstrap truncated model | Age (+), Age squared (−), Experience (+), Extension services (−), Education level (−), Household expenditure per year (−), Gender (−) **, Women’s participation in decision-making index (−) **, Integrated fish farming (−), Polyculture (−) **, Pond size (−) ***, Household adopted mitigation strategies against climatic shocks (−) **, Climatic shocks that affected fish farming in the previous production cycle (+) |

| Iliyasu et al. (2016) [18] | Malaysia | Freshwater aquaculture | SBDEA | 212 | 0.80 | OLS model | Experience (+) *, Age (−) *, Extension visit (+) ***, Education (+), Family number (+) *, Farm status (+) |

| Malaysia | Pond | SBDEA | 66 | 0.77 | - | - | |

| Malaysia | Cage | SBDEA | 69 | 0.80 | - | - | |

| Malaysia | Tank | SBDEA | 57 | 0.77 | - | - | |

| Malaysia | Pen culture | SBDEA | 20 | 0.63 | - | - | |

| Long et al. (2020) [19] | Vietnam | White-leg shrimp | DBDEA | 318 | 0.69 | Tobit model | Education (−), Experience (−), Training (+), Occupation status (+), Farm size (−) ***, Culture length (+) ***, Access to formal credit (−), Phu Yen (−), Khanh Hoa (−), Ninh Thuan (+) |

| Vietnam | White-leg shrimp | DEA | 318 | 0.77 | - | - | |

| Vietnam | White-leg shrimp | SBDEA | 318 | 0.67 | - | - | |

| Mitra et al. (2022a) [21] | Bangladesh | Pond aquaculture (water available) | Meta-frontier DEA | 77 | 0.71 | Tobit model | Farm area (−) *, Feed conversion ratio (−) ***, Access to open water (+) ***, Male (−) **, Education (−), Experience (−), Training (+) **, Land tenure (−) ***, Financial inclusion (+) *** |

| Bangladesh | Pond aquaculture (water deficit) | Meta-frontier DEA | 234 | 0.60 | - | - | |

SBDEA: Single bootstrap DEA; DBDEA: Double bootstrap DEA; ***, **, * Significant at 1, 5, and 10% levels, respectively.

Appendix B

Table A2.

SFA applications in aquaculture.

Table A2.

SFA applications in aquaculture.

| Authors | Country | Production Technology | Method | Sample Size | Functional Form | TE | Factors Affecting TE |

|---|---|---|---|---|---|---|---|

| Awoyemi et al. (2003) [9] | Nigeria | Pond aquaculture | SFA | 46 | Cobb–Douglas | 0.24 | Capital (+) **, Pond size (+) **, Fingerlings (+) **, Chemicals (+) *, Labor (+) ** |

| Chiang et al. (2004) [22] | Taiwan | Milkfish | SFA | 433 | Translog | 0.84 | Acreage (+) ***, Fry cost (+) ***, Feed cost (+) ***, Water and electricity (+) ***, Other costs (+) *** |

| Islam et al. (2016) [23] | Malaysia | Cage aquaculture | SFA | 78 | Cobb–Douglas | 0.37 | Fry (+) ***, Feed (+) *, Labor (+) ***, Operational cost (−), Energy (+), Other input (−) |

| Khan et al. (2020) [26] | Bangladesh | Pond aquaculture | SFA | 225 | Translog | 0.92 | Labor (+) ***, Feed (+) ***, Capital (+) *** |

| Long (2024) [24] | Vietnam | White-leg shrimp | SFA | 102 | Cobb–Douglas | 0.88 | Seed (+) ***, Labor (+) ***, Feed (+) ***, Chemicals (−) ***, Electricity (+), Farm size (+) *** |

| Mitra et al. (2022b) [25] | Bangladesh | Fish aquaculture | SFA | 517 | Cobb–Douglas | 0.74 | Labor (+) ***, Feed (+) ***, Fingerlings (+) ***, Salt (+), Lime (−) **, Potassium permanganate (+), Water exchange frequency (+) ** |

| Singh et al. (2009) [10] | India | Freshwater aquaculture | SFA | 101 | Cobb–Douglas | 0.71 | Pond area (+) ***, Lime (+) *, Chemical fertilizers (−), Rice bran (−), Oil cake (−), Fish health care (+), Fingerlings stocked (+) ***, Labor (+) ** |

| Zuzeni Thidza et al. (2024) [27] | Malawi | Pond aquaculture | SFA | 96 | Cobb–Douglas | 0.29 | Fingerlings (+) **, Feed (+), Labor (−), Manure (+), Pond size (−) *, Type of feed (+) ***, Pond area (+) |

***, **, and * significant at the 1, 5, and 10% levels, respectively.

References

- National Institute of Fisheries Science (NIFS). Standard Manual of Olive Flounder Culture; NIFS: Busan, Republic of Korea, 2006; pp. 1–2. [Google Scholar]

- National Institute of Fisheries Science (NIFS). The History of Korean Aquaculture; NIFS: Busan, Republic of Korea, 2016; pp. 178–182. [Google Scholar]

- Korean Statistical Information Service (KOSIS). Statistic Database for Aquaculture Production; KOSIS: Daejeon, Republic of Korea, 2024; Available online: https://kostat.go.kr/portal/korea/index (accessed on 9 April 2024).

- Jee, B.Y.; Shin, K.W.; Lee, D.W.; Kim, Y.J.; Lee, M.K. Monitoring of the mortalities and medications in the inland farms of olive flounder, Paralichthys Olivaceus, in South Korea. J. Fish Pathol. 2014, 27, 77–83. [Google Scholar] [CrossRef]

- Kim, S.M.; Jun, L.J.; Park, M.A.; Jung, S.H.; Jeong, H.D.; Jeong, J.B. Monitoring of emaciation disease in cultured olive flounder Paralichthys Olivaceus in Jeju (2010–2013), Korea. Korean J. Parasitol. 2019, 32, 29–35. [Google Scholar] [CrossRef][Green Version]

- Jwa, M.S.; Park, K.I.; Kim, D.H. The current status and an economic analysis of Jeju olive flounder aquaculture. J. Korean Soc. Fish. Mar. Educ. 2020, 32, 1612–1622. [Google Scholar] [CrossRef]

- Kim, N.L.; Park, K.I.; Lee, B.J.; Kim, D.H. An economic analysis of olive flounder (Paralichthys olivaceus) aquaculture in Wando Region. J. Korean Soc. Fish. Mar. Educ. 2021, 33, 734–743. [Google Scholar] [CrossRef]

- Bravo-Ureta, B.E.; Pinheiro, A.E. Technical, economic, and allocative efficiency in peasant farming: Evidence from the Dominican Republic. J. Dev. Econ. 1997, 35, 4–67. [Google Scholar] [CrossRef]

- Awoyemi, T.T.; Amao, J.O.; Ehirim, N.C. Technical efficiency in aquaculture in Oyo State, Nigeria. Indian J. Agric. Sci. 2003, 58, 812–819. [Google Scholar] [CrossRef]

- Singh, K.; Dey, M.M.; Rabbani, A.G.; Sudhakaran, P.O.; Thapa, G. Technical efficiency of freshwater aquaculture and its determinants in Tripura, India. Agric. Econ. Res. Rev. 2009, 22, 185–195. [Google Scholar] [CrossRef]

- Bukenya, J.O.; Hyuha, T.S.; Molnar, J.; Twinamasiko, J. Efficiency of resource use among pond fish farmers in Central Uganda: A stochastic frontier production function approach. Aquac. Econ. Manag. 2013, 17, 148–170. [Google Scholar] [CrossRef]

- Theodoridis, A.M.; Anwar, M.M. A comparison of DEA and SFA methods: A case study of farm households in Bangladesh. J. Dev. Areas 2011, 45, 95–110. [Google Scholar] [CrossRef]

- Suarez-Fernandez, S.; Quiroga-Garcia, R.; Manzano-Perez, I. A Comparison of DEA and SFA approaches: Application to the US non-life insurance market. Appl. Econ. 2020, 28, 107–127. [Google Scholar]

- Odeck, J.; Bråthen, S. A Meta-analysis of DEA and SFA studies of the technical efficiency of seaports: A comparison of fixed and random-effects regression models. Transp. Res. A Policy Pract. 2012, 46, 1574–1585. [Google Scholar] [CrossRef]

- Malik, M.; Efendi, S.; Zarlis, M. Data envelopment analysis (DEA) model in operation management. IOP Conf. Ser. Mater. Sci. Eng. 2018, 300, 012008. [Google Scholar] [CrossRef]

- Vu, L.T.; Nguyen, N.T.; Dinh, L.H. Measuring banking efficiency in Vietnam: Parametric and non-parametric methods. Banks Bank. Syst. 2019, 14, 55–66. [Google Scholar]

- Aripin, A.; Coglan, L.; Pascoe, S.; Hoang, V.-N. Productive efficiency and capacity utilization of sea bass grow-out culture in peninsular Malaysia. Aquac. Econ. Manag. 2019, 24, 102–121. [Google Scholar] [CrossRef]

- Iliyasu, A.; Mohamed, Z.A.; Terano, R. Comparative analysis of technical efficiency for different production culture systems and species of freshwater aquaculture in Peninsular Malaysia. Aquac. Rep. 2016, 3, 51–57. [Google Scholar] [CrossRef]

- Long, L.K.; Van Thap, L.; Hoai, N.T.; Pham, T.T.T. Data envelopment analysis for analyzing technical efficiency in aquaculture: The bootstrap methods. Aquac. Econ. Manag. 2020, 24, 422–446. [Google Scholar] [CrossRef]

- Aung, Y.M.; Khor, L.Y.; Tran, N.; Shikuku, K.M.; Zeller, M. Technical efficiency of small-scale aquaculture in Myanmar: Does women’s participation in decision-making matter? Aquac. Rep. 2021, 21, 100841. [Google Scholar] [CrossRef]

- Mitra, S.; Khan, M.A.; Nielsen, R.; Rahman, M.T. Improving aquaculture productivity, efficiency and profitability in Bangladesh: Does land ownership matter? Aquac. Econ. Manag. 2022, 26, 215–231. [Google Scholar] [CrossRef]

- Chiang, F.-S.; Sun, C.-H.; Yu, J.-M. Technical efficiency analysis of milkfish (Chanos Chanos) production in Taiwan—An application of the stochastic frontier production function. Aquaculture 2004, 230, 99–116. [Google Scholar] [CrossRef]

- Islam, G.M.N.; Tai, S.Y.; Kusairi, M.N. A stochastic frontier analysis of technical efficiency of fish cage culture in Peninsular Malaysia. SpringerPlus 2016, 5, 1127. [Google Scholar] [CrossRef]

- Long, L.K. Analyzing technical inefficiency and production risk in aquaculture—The stochastic frontier production function with double heteroskedasticity. Aquac. Econ. Manag. 2024, 28, 681–703. [Google Scholar] [CrossRef]

- Mitra, S.; Khan, M.A.; Rahman, M.T.; Nielsen, R. Effects of open water availability on productivity and efficiency of tilapia fish farming. Aquac. Econ. Manag. 2022, 27, 315–334. [Google Scholar] [CrossRef]

- Khan, M.A.; Begum, R.; Nielsen, R.; Hoff, A. Production risk, technical efficiency, and input use nexus: Lessons from Bangladesh aquaculture. J. World. Aquac. Soc. 2020, 52, 57–72. [Google Scholar] [CrossRef]

- Zuzeni Thidza, I.; Viet Nguyen, T.; Már Kristófersson, D. Analysis of pond aquaculture in the northern Malawi: Application of stochastic frontier analysis. Aquac Econ Manag. 2024, 29, 113–130. [Google Scholar] [CrossRef]

- Mussa, H.; Kaunda, E.; Jere, W.W.L.; Ng’ong’ola, D.H. Resource use efficiency in tilapia production in central and southern Malawi. Aquac Econ Manag. 2019, 24, 213–231. [Google Scholar] [CrossRef]

- Kumbhakar, S.C.; Lovell, C.A. Stochastic Frontier Analysis; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).