Thermal Performance Analysis of Borehole Heat Exchangers Refilled with the Use of High-Permeable Backfills in Low-Permeable Rock Formations

Abstract

1. Introduction

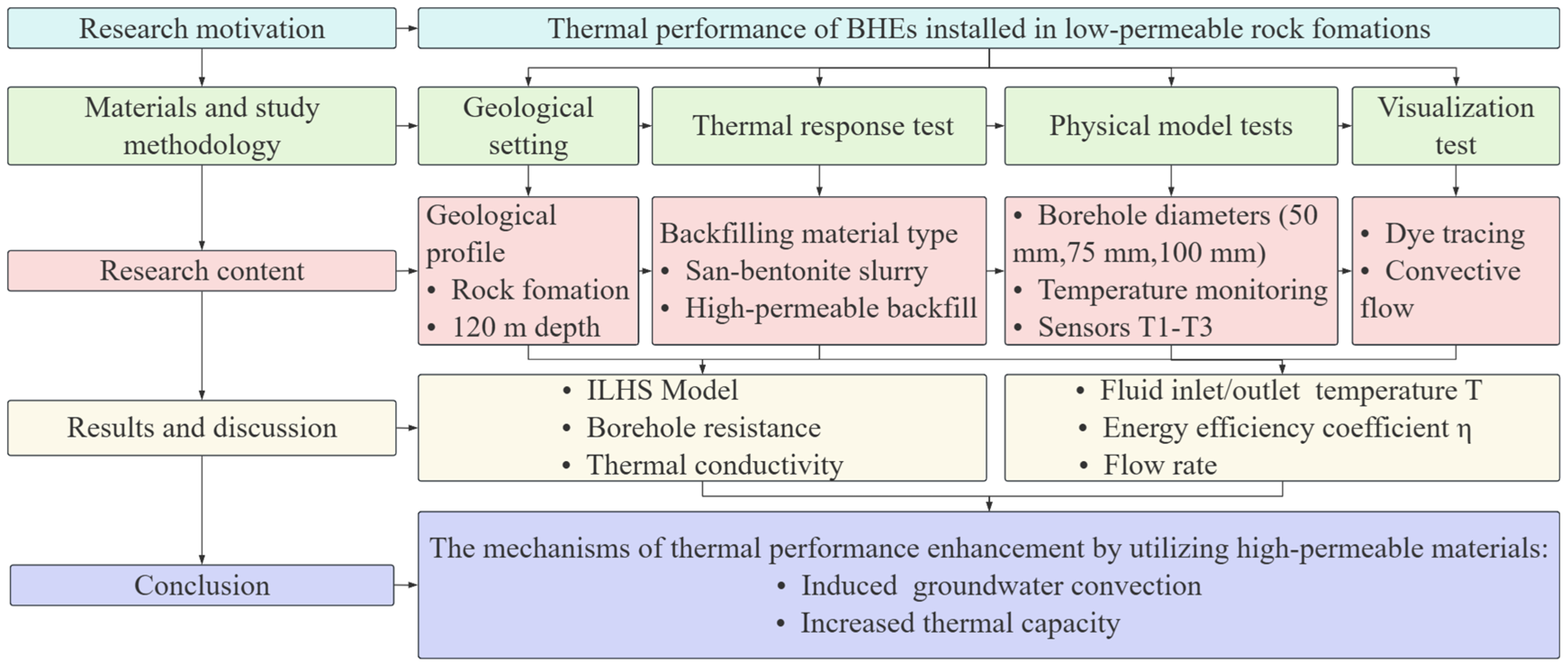

2. Materials and Study Methodology

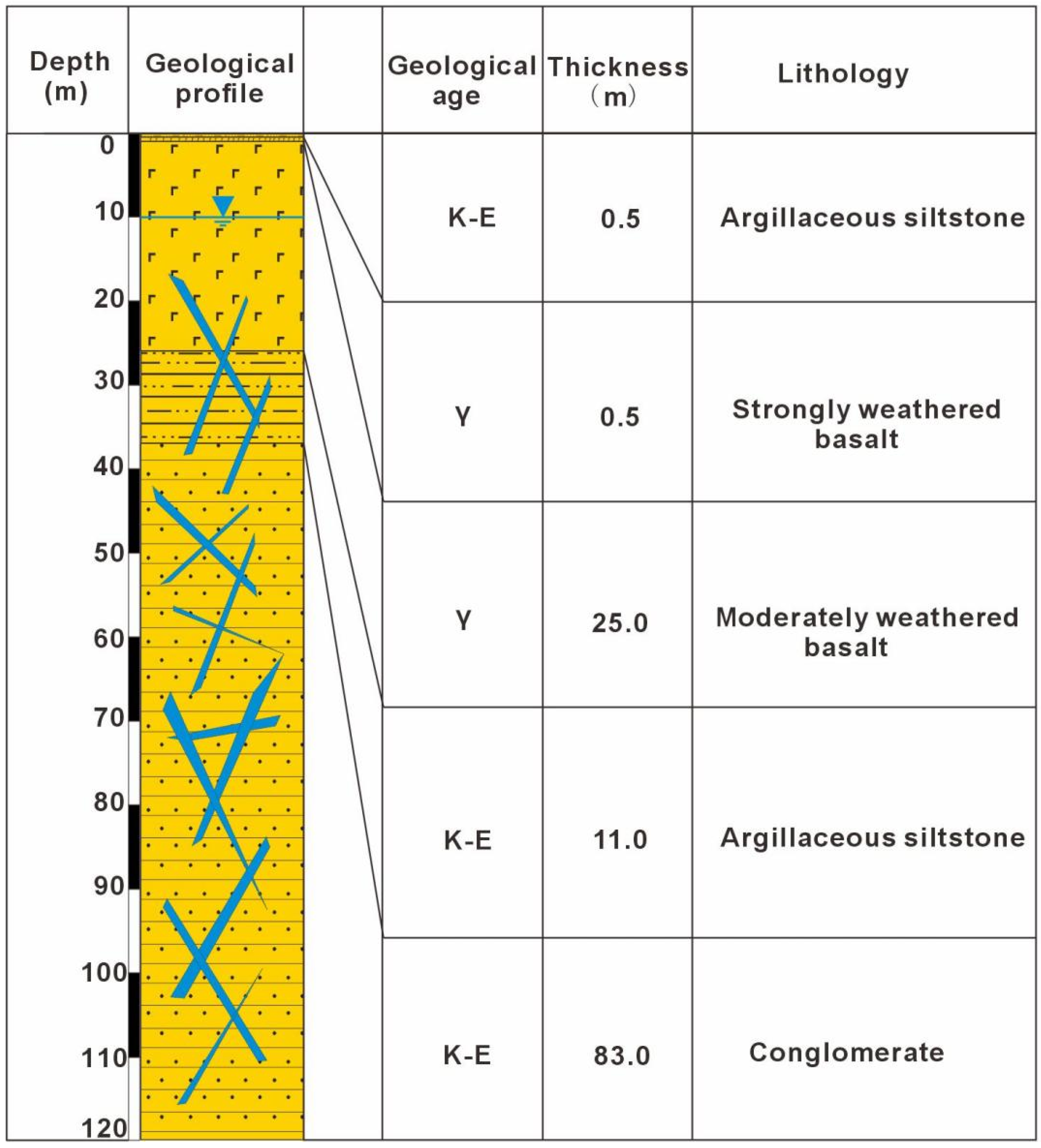

2.1. Geological Setting

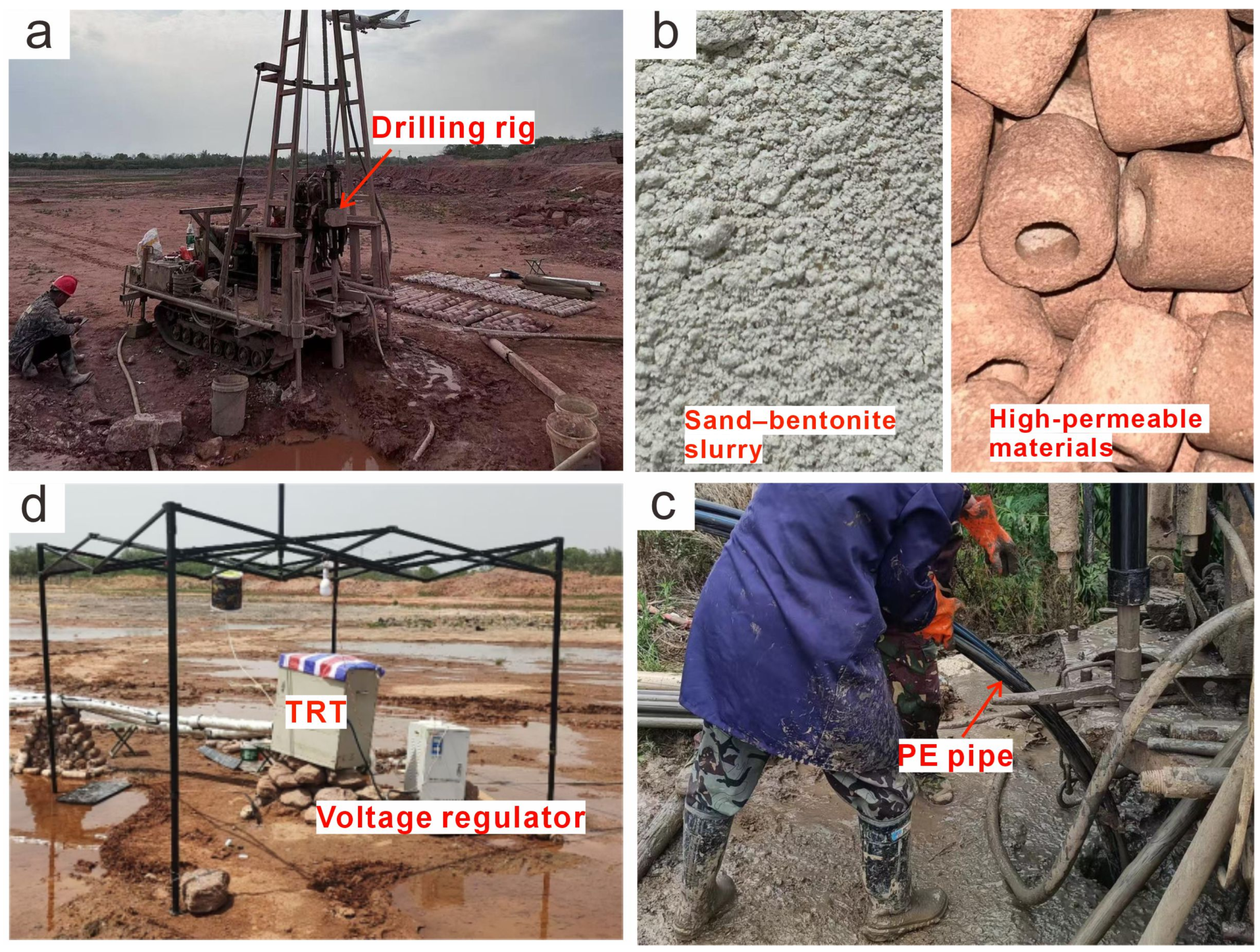

2.2. Field Thermal Response Test

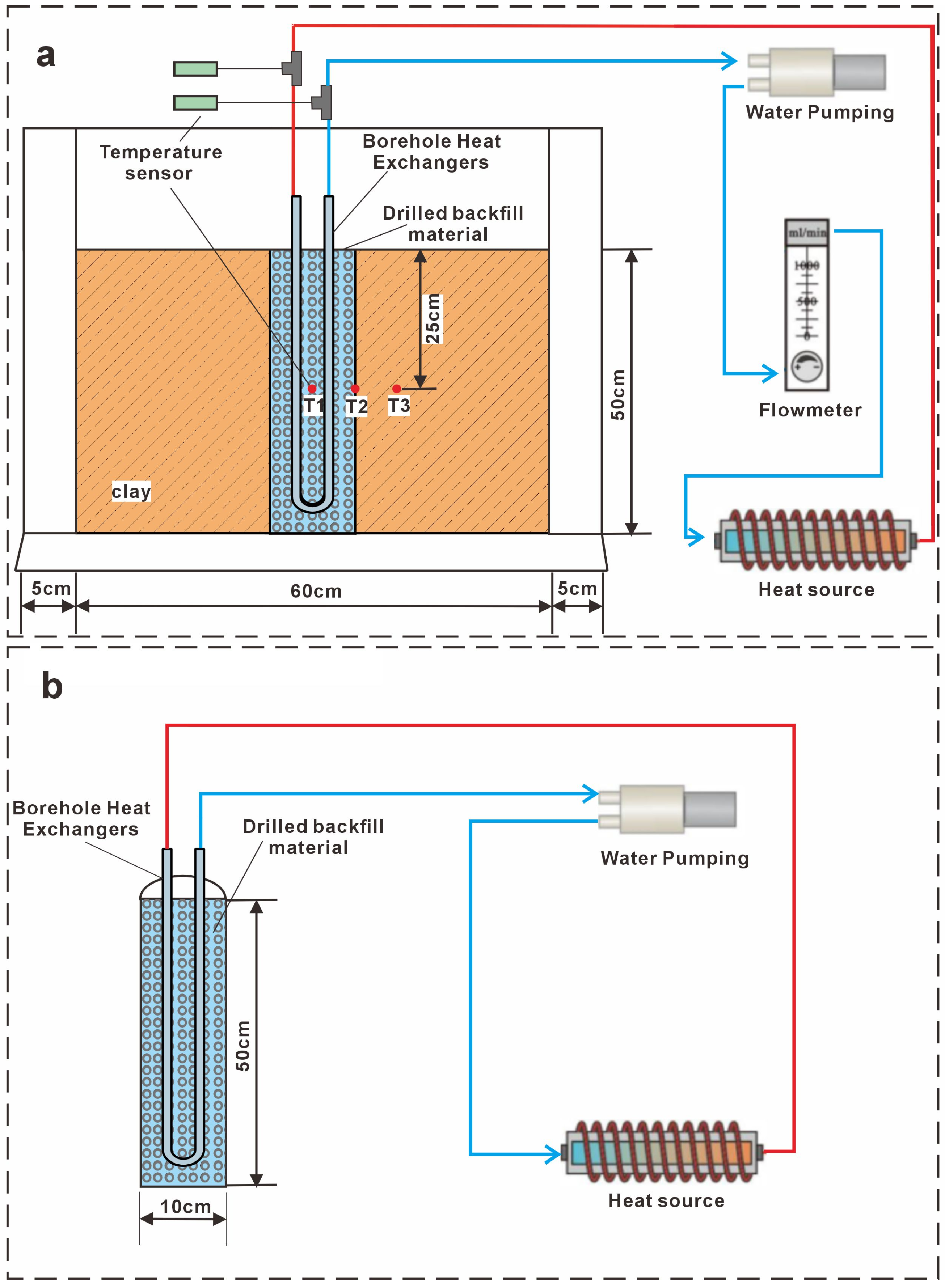

2.2.1. BHE Installation

2.2.2. Monitoring of the Temperature Response

2.2.3. Thermal Performance Analysis of BHE

2.3. Heat and Flow Transfer in Weakly Permeable Ground

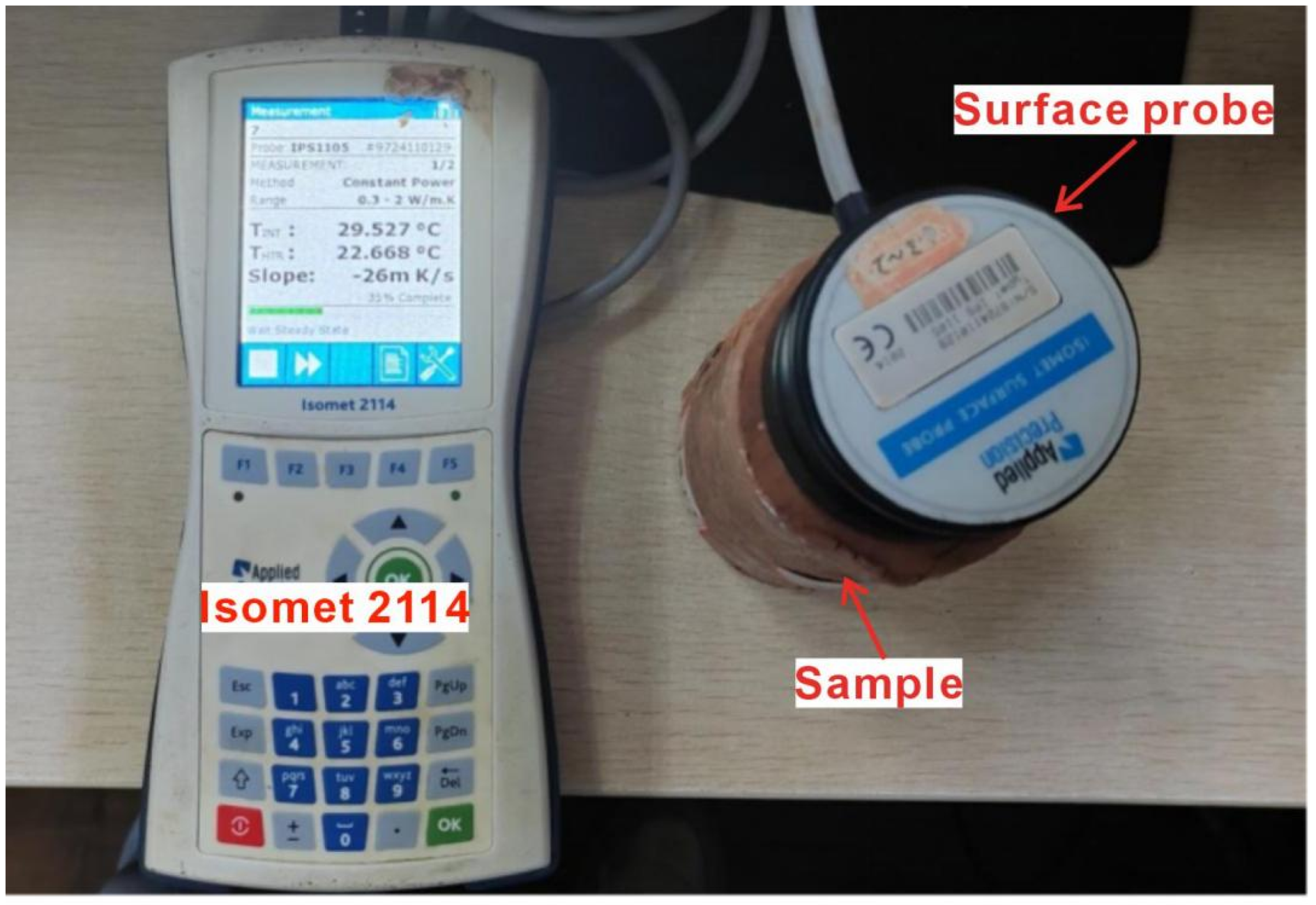

2.3.1. Heat Transfer of High-Permeable Materials

2.3.2. Heat and Flow Transfer of a BHE in a Borehole

3. Results and Discussion

3.1. Heat Transfer Performance

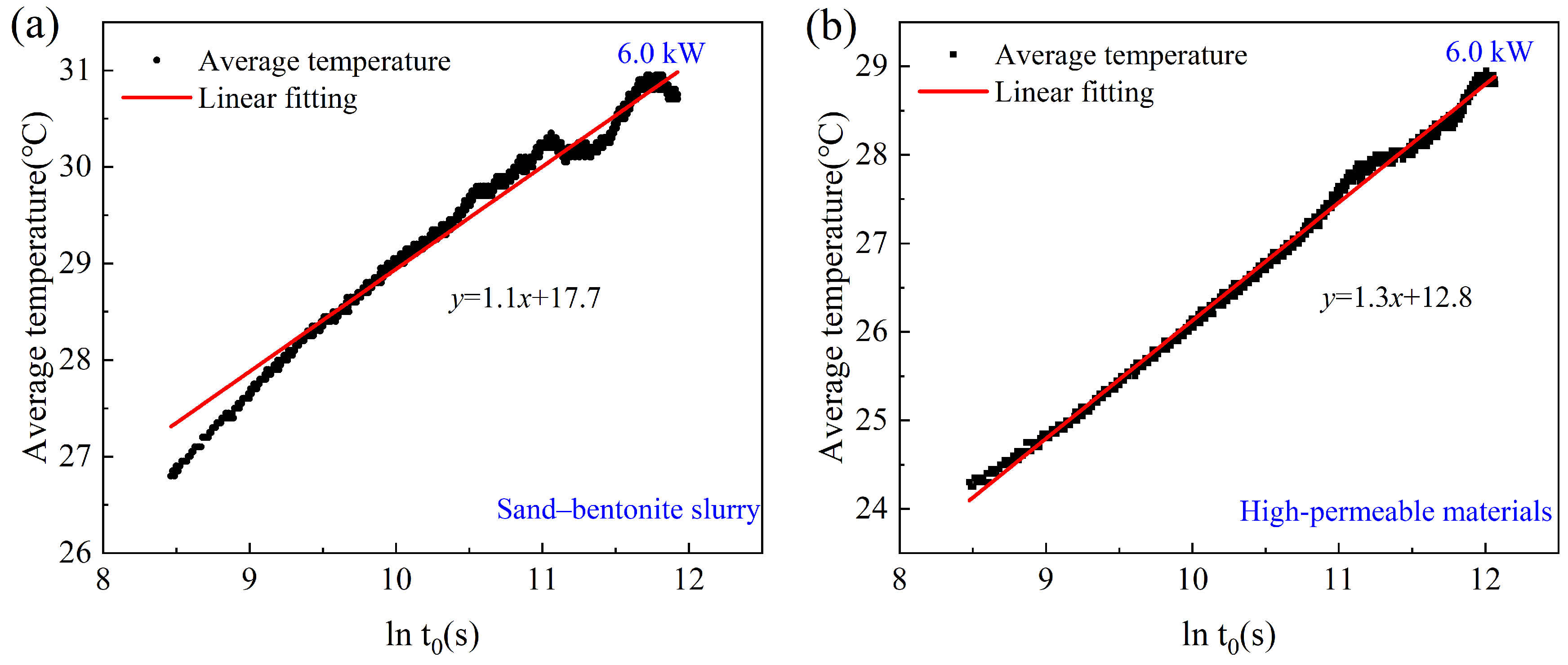

3.2. Borehole Thermal Parameters

3.3. Heat Transfer of BHE in Physical Model Test

3.3.1. Heat Transfer of BHE with Different Refilling Materials

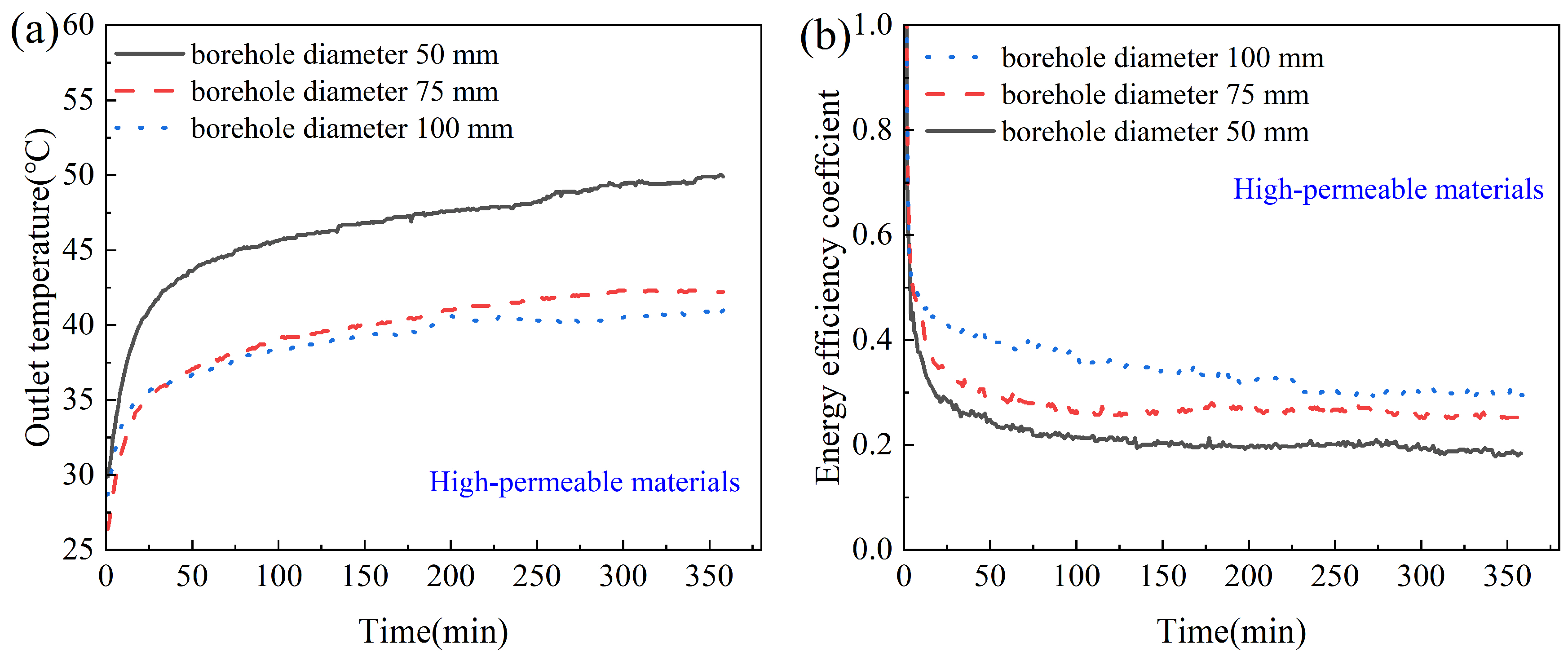

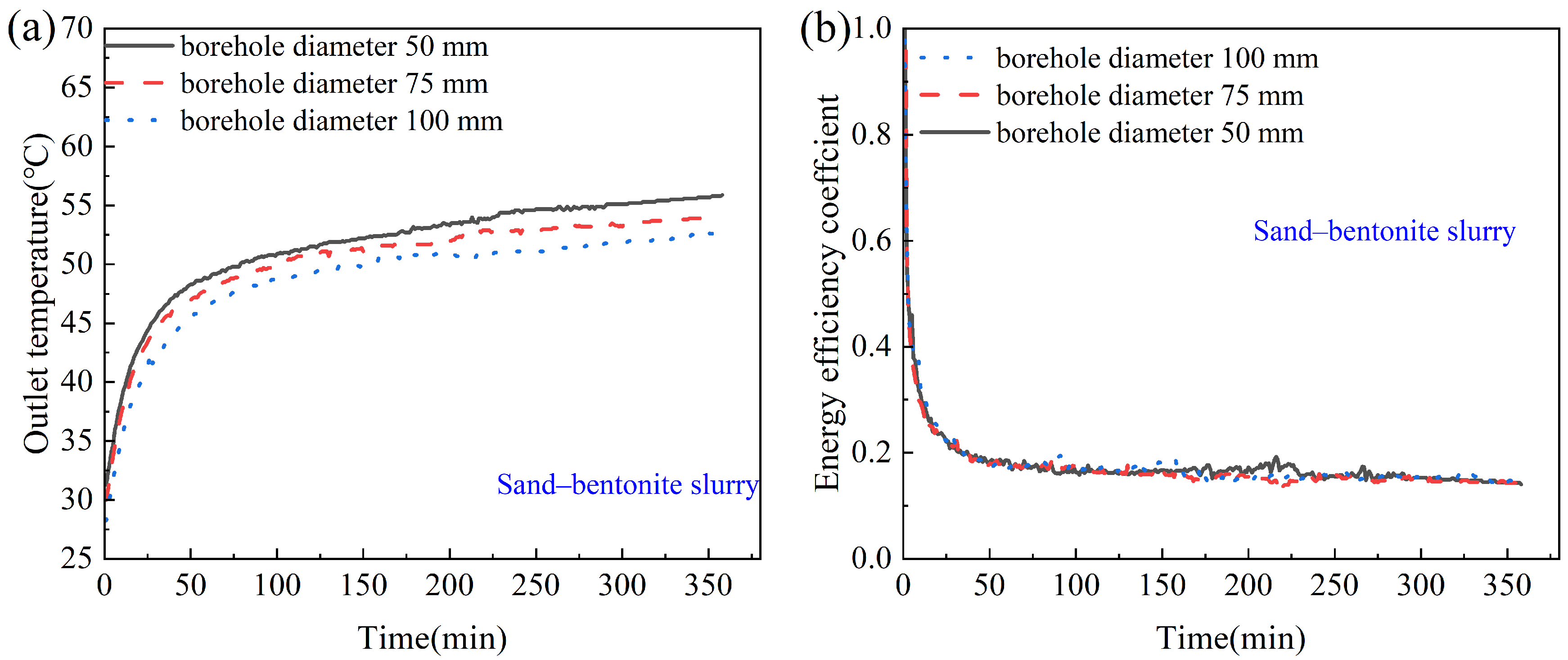

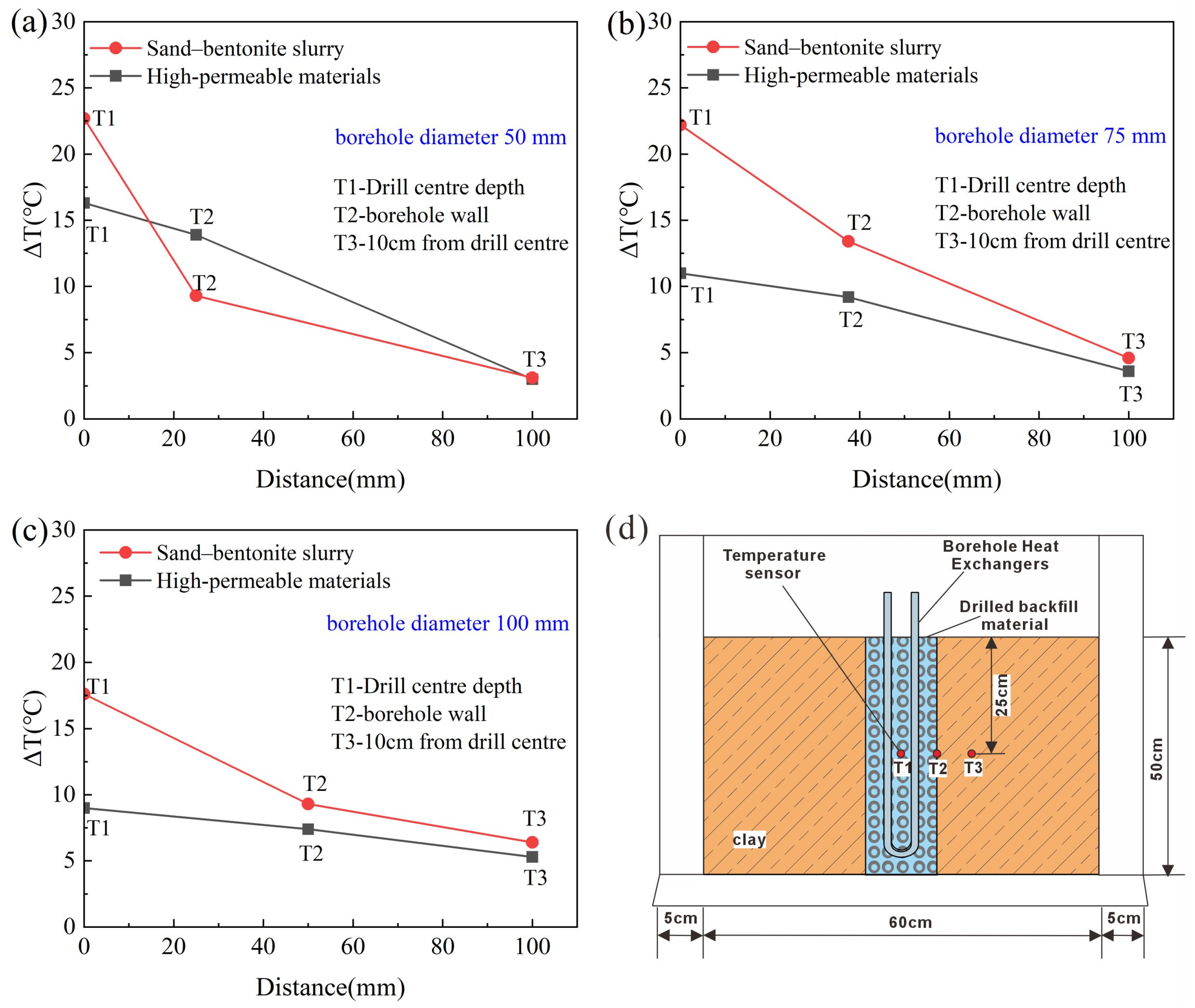

3.3.2. Heat Transfer Performance of BHE with Different Borehole Diameters

3.3.3. Temperature Response of BHE in Constant Heat Power

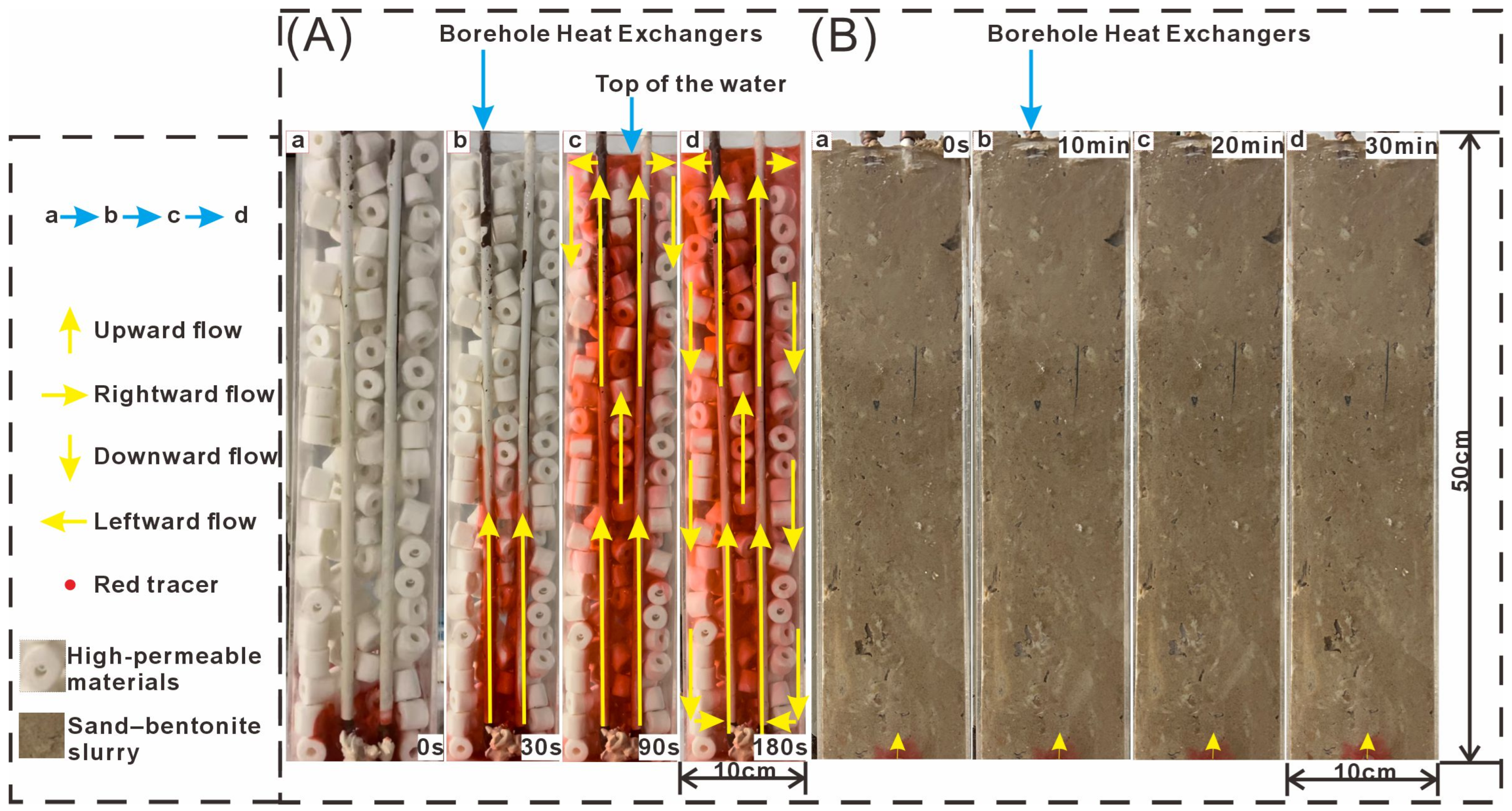

3.4. Heat Transfer Process of BHE Inside a Borehole

4. Conclusions

- The comparison of TRT results between BHEs backfilled with sand–bentonite slurry and those with high-permeability materials demonstrated that the latter had a 2.5 °C lower fluid outlet temperature. It indicates that thermal performance enhancement of BHE can be achieved by deploying high-permeable materials in low-permeable rock formations. Additionally, the energy efficiency coefficient increased by 18.5% relative to the sand–bentonite system, confirming the superior heat performance of the BHE with the use of high-permeable backfills.

- Physical model tests showed that increased borehole diameter effectively reduced fluid outlet temperature using high-permeability materials. In a 100 mm diameter borehole, the fluid outlet temperature with high-permeable material backfill reached up to 49.9 °C. Compared with a 50 mm diameter borehole, the fluid outlet temperature was 8.9 °C lower, leading to an improved energy efficiency coefficient of 62.5%. Increasing the groundwater volume in a borehole will enhance thermal performance. The tracing of thermally induced groundwater flow by the operation of BHE showed that the fluid flowed upward along the pipe once it occurred. Later, it moved horizontally once it reached the water surface. It then descended along the borehole wall, eventually returning to the pipe surface, forming a continuous circuit. This process carried the heat generated at the pipe surface away, maintaining the temperature difference between the heat-carrier fluid and the borehole, thereby alleviating the thermal accumulation around the pipe, enhancing the heat performance.

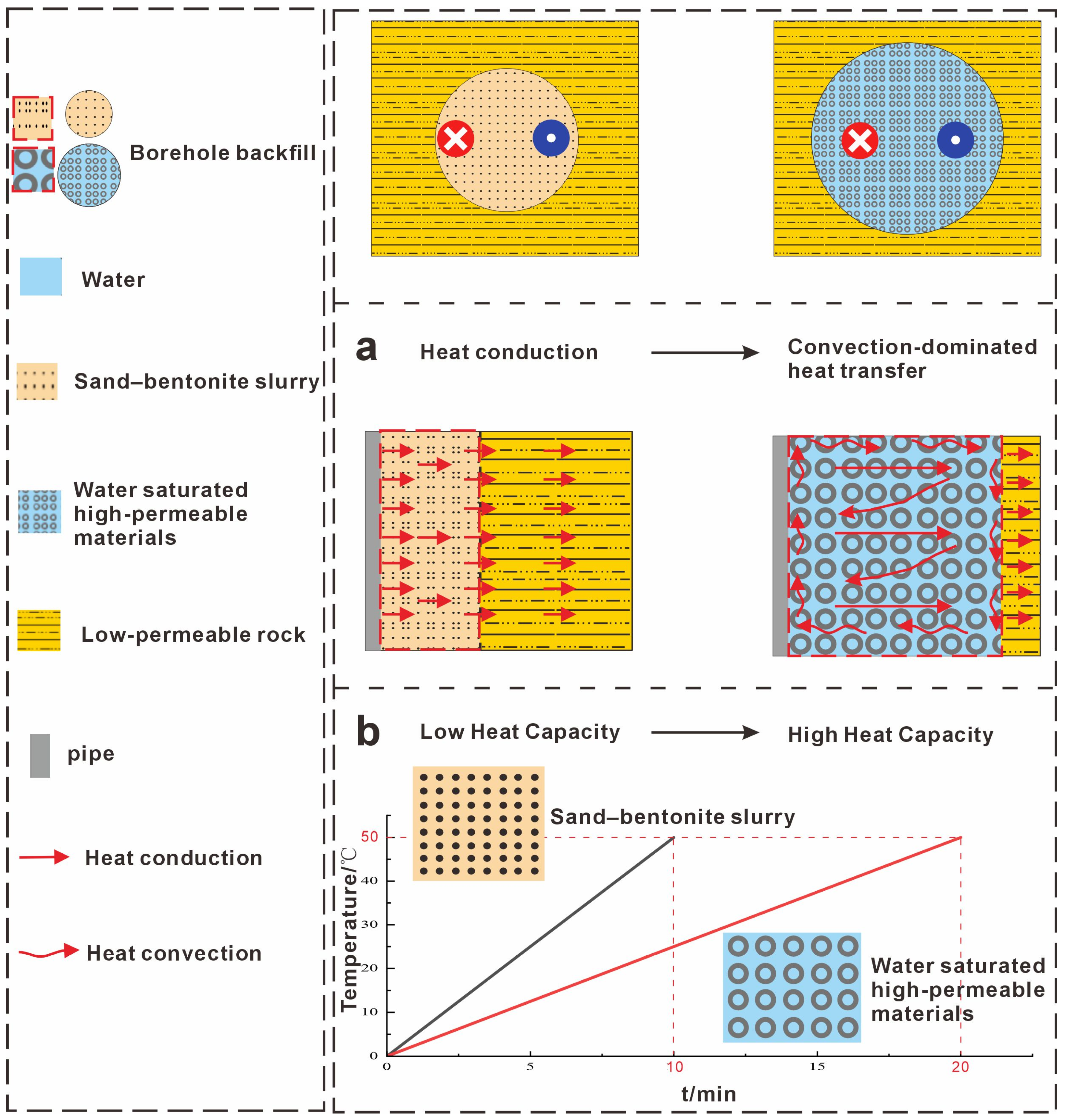

- The enhancement of the thermal performance of the BHE backfilled using high-permeable material is primarily attributed to two aspects: first, the conduction-dominated heat transfer of low-permeable-material-grouted BHE was transited to convection-dominated heat transfer when high-permeable materials were deployed due to the induced groundwater flow. The Nusselt number for the high-permeability material backfill was measured at 61.57, meaning the heat transfer on the pipe surface can be much faster than pure water heat conduction. On the other hand, the increment in volume of groundwater inside a borehole also acts as a temperature stabilizer due to the high specific heat capacity. The higher the volume of the groundwater inside a borehole, the more stable the borehole temperature can be achieved, resulting in a sustainable and high heat-transfer performance. Thus, these dual effects collectively enhance the overall system’s thermal performance as it is observed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| BHE | Borehole Heat Exchanger |

| BHEs | Borehole Heat Exchangers |

| TRT | Thermal Response Test |

| GSHP | Ground source heat pump |

| PE | Polythene |

| λ | Thermal conductivity (W/(m·K)) |

| cρ | Volume heat capacity (MJ/m3·K) |

| α | Thermal diffusivity (m2/s) |

| Tin | Fluid Inlet temperature (°C) |

| Fluid outlet temperature (°C) | |

| m | Mass flow rate of water (kg/s) |

| h | Convective heat transfer coefficient(W/(m2·K)) |

| A | Heat transfer area of the outer wall of the pipe(m2) |

| Twall | Borehole wall temperature (°C) |

| T | Initial temperature (°C) |

| t | Time (s) |

| Rb | Borehole thermal resistance (m·K/W) |

| η | Energy efficiency coefficient of a BHE (-) |

| Qa | Actual heat exchanged in subsurface (kW) |

| ρ | Density water (kg/m3) |

| Cp | Specific heat capacity of water (J/(kg·K)) |

| Lc | characteristic length (m) |

References

- Shu, B.; Bao, Y.; Markides, C.N.; Besagni, G.; Moore, J. Overview and outlook of thermal processes in geothermal energy extraction. Appl. Therm. Eng. 2025, 272, 126329. [Google Scholar] [CrossRef]

- Tang, F.; Nowamooz, H. Factors influencing the performance of shallow Borehole Heat Exchanger. Energy Convers. Manag. 2019, 181, 571–583. [Google Scholar] [CrossRef]

- Sanner, B.; Reuss, M.; Mands, E.; Müller, J. Thermal response test-experiences in Germany. Proc. Terrastock 2000, 1, 177–182. [Google Scholar]

- Kerme, E.D.; Fung, A.S. Heat transfer simulation, analysis and performance study of single U-tube borehole heat exchanger. Renew. Energy 2020, 145, 1430–1448. [Google Scholar] [CrossRef]

- Dai, L.H.; Shang, Y.; Li, X.L.; Li, S.F. Analysis on the transient heat transfer process inside and outside the borehole for a vertical U-tube ground heat exchanger under short-term heat storage. Renew. Energy 2016, 87, 1121–1129. [Google Scholar] [CrossRef]

- Gustafsson, A.M.; Gehlin, S. Thermal response test: Power injection dependence. In Proceedings of the International Conference on Thermal Energy Storage, Galloway, NJ, USA, 31 May–2 June 2006. [Google Scholar]

- Delaleux, F.; Py, X.; Olives, R.; Dominguez, A. Enhancement of geothermal borehole heat exchangers performances by improvement of bentonite grouts conductivity. Appl. Therm. Eng. 2012, 33, 92–99. [Google Scholar] [CrossRef]

- Lee, C.; Lee, K.; Choi, H.; Choi, H.P. Characteristics of thermally-enhanced bentonite grouts for geothermal heat exchanger in South Korea. Sci. China Ser. E Technol. Sci. 2010, 53, 123–128. [Google Scholar] [CrossRef]

- Javadi, H.; Urchueguía, J.F.; Badenes, B.; Mateo, M.Á.; Ghafar, A.N.; Chaudhari, O.A.; Zirgulis, G.; Lemus, L.G. Laboratory and numerical study on innovative grouting materials applicable to borehole heat exchangers (BHE) and borehole thermal energy storage (BTES) systems. Renew. Energy 2022, 194, 788–804. [Google Scholar] [CrossRef]

- Gustafsson, A.M.; Westerlund, L. Heat extraction thermal response test in groundwater-filled borehole heat exchanger–Investigation of the borehole thermal resistance. Renew. Energy 2011, 36, 2388–2394. [Google Scholar] [CrossRef]

- Gustafsson, A.M.; Westerlund, L. Multi-injection rate thermal response test in groundwater filled borehole heat exchanger. Renew. Energy 2010, 35, 1061–1070. [Google Scholar] [CrossRef]

- Gustafsson, A.M.; Westerlund, L.; Hellström, G. CFD-modelling of natural convection in a groundwater-filled borehole heat exchanger. Appl. Therm. Eng. 2010, 30, 683–691. [Google Scholar] [CrossRef]

- Johnsson, J.; Adl-Zarrabi, B. Modelling and evaluation of groundwater filled boreholes subjected to natural convection. Appl. Energy 2019, 253, 113555. [Google Scholar] [CrossRef]

- Chiasson, A.D.; Rees, S.J.; Spitler, J.D. A Preliminary Assessment of the Effects of Groundwater Flow on Closed-Loop Ground Source Heat Pump Systems; Oklahoma State University: Stillwater, OK, USA, 2000. [Google Scholar]

- Spitler, J.D.; Javed, S.; Ramstad, R.K. Natural convection in groundwater-filled boreholes used as ground heat exchangers. Appl. Energy 2016, 164, 352–365. [Google Scholar] [CrossRef]

- Wang, H.; Qi, C.; Du, H.; Gu, J. Thermal performance of borehole heat exchanger under groundwater flow: A case study from Baoding. Energy Build. 2009, 41, 1368–1373. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Zhang, Y.P.; Zhan, G.H.; Yu, Y.N. Study on heat transfer model of underground heat exchangers with groundwater advection. J. Zhejiang Univ. (Eng. Sci.) 2012, 46, 1450–1456. [Google Scholar]

- Luo, J.; Rohn, J.; Bayer, M.; Priess, A.; Xiang, W. Analysis on performance of borehole heat exchanger in a layered subsurface. Appl. Energy 2014, 123, 55–65. [Google Scholar] [CrossRef]

- Luo, J.; Yang, B.; Hu, X.; Pei, K.; Shao, Y. Thermal performance enhancement of borehole heat exchanger by thermally induced groundwater convection in fractured rock. Appl. Therm. Eng. 2024, 252, 123741. [Google Scholar] [CrossRef]

- Luo, J.; Shao, Y.; Yan, Z.; Han, X.; Guo, Q. Thermal performance enhancement of borehole heat exchangers by thermally induced groundwater convection in aquifers. Renew. Energy 2025, 243, 122539. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Hu, P.F.; Hu, L.; Plateau, X.D. Experimental Study on Heat Transfer Characteristics of Vertical U-tube Ground Heat Exchanger. Gas Heat 2008, 28, A04–A07. (In Chinese) [Google Scholar]

- Javed, S.; Spitler, J.D. Calculation of borehole thermal resistance. In Advances in Ground-Source Heat Pump Systems; Elsevier: Amsterdam, The Netherlands, 2016; pp. 63–95. [Google Scholar]

- Sohn, B.-H. Evaluation of ground effective thermal conductivity and borehole effective thermal resistance from simple line-source model. Korean J. Air-Cond. Refrig. Eng. 2007, 19, 512–520. [Google Scholar]

- Holmberg, H.; Acuña, J.; Næss, E.; Sønju, O.K. Numerical model for non-grouted borehole heat exchangers, Part 2—Evaluation. Geothermics 2016, 59, 134–144. [Google Scholar] [CrossRef][Green Version]

| Lithology | λ (W/(m·K)) | cρ (MJ/m3·K) | α (10−6 m2/s) |

|---|---|---|---|

| Argillaceous siltstone | 1.50 | 1.52 | 0.98 |

| Strongly weathered basalt | 1.15 | 1.71 | 0.67 |

| Moderately weathered basalt | 1.55 | 1.94 | 0.80 |

| Argillaceous siltstone | 3.30 | 1.85 | 1.78 |

| Conglomerate | 2.81 | 1.98 | 1.55 |

| Test # | Materials Type | Drilled Hole Size | Power Input | Testing Duration (h) |

|---|---|---|---|---|

| 1 | High-permeable materials | 50 mm | 100 W | 6 |

| 2 | Sand–bentonite slurry | 50 mm | 100 W | 6 |

| 3 | High-permeable materials | 75 mm | 100 W | 6 |

| 4 | Sand–bentonite slurry | 75 mm | 100 W | 6 |

| 5 | High-permeable materials | 100 mm | 100 W | 6 |

| 6 | Sand–bentonite slurry | 100 mm | 100 W | 6 |

| Hole Diameter | Distance to Heater (mm) | Temperature Sensors |

|---|---|---|

| 50 mm | 0, 25, 100 | T1, T2, T3 |

| 75 mm | 0, 37.5, 100 | T1, T2, T3 |

| 100 mm | 0, 50, 100 | T1, T2, T3 |

| Backfills (Heating Power) | Initial Ground Temperature (°C) | Effective Thermal Conductivity (W/(m·K)) | Borehole Thermal Resistance ((m·K)/W) |

|---|---|---|---|

| High-permeable materials (6.0 kW) | 20.0 ± 0.2 | 3.06 (±5%) | 0.06 (±5%) |

| Sand–bentonite slurry (6.0 kW) | 20.0 ± 0.2 | 3.62 (±5%) | 0.11 (±5%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Cao, B.; Xiong, Y.; Luo, J. Thermal Performance Analysis of Borehole Heat Exchangers Refilled with the Use of High-Permeable Backfills in Low-Permeable Rock Formations. Sustainability 2025, 17, 8851. https://doi.org/10.3390/su17198851

Liu Y, Cao B, Xiong Y, Luo J. Thermal Performance Analysis of Borehole Heat Exchangers Refilled with the Use of High-Permeable Backfills in Low-Permeable Rock Formations. Sustainability. 2025; 17(19):8851. https://doi.org/10.3390/su17198851

Chicago/Turabian StyleLiu, Yuxin, Bing Cao, Yuchen Xiong, and Jin Luo. 2025. "Thermal Performance Analysis of Borehole Heat Exchangers Refilled with the Use of High-Permeable Backfills in Low-Permeable Rock Formations" Sustainability 17, no. 19: 8851. https://doi.org/10.3390/su17198851

APA StyleLiu, Y., Cao, B., Xiong, Y., & Luo, J. (2025). Thermal Performance Analysis of Borehole Heat Exchangers Refilled with the Use of High-Permeable Backfills in Low-Permeable Rock Formations. Sustainability, 17(19), 8851. https://doi.org/10.3390/su17198851