CFD-Based Evaluation of Waste Heat Recovery and Pressure Drop in Rotary Sinter Coolers Under Varying Bed Properties and Inlet Conditions

Abstract

1. Introduction

- Dual-outlet temperature analysis: For the first time, a detailed thermal assessment of two distinct air outlet zones ( and ) is conducted, highlighting their different heat transfer dynamics and implications for waste heat recovery efficiency.

- Rotary system evaluation: Unlike most studies focusing on vertical tanks or fixed-bed systems, this work presents an initial and comprehensive CFD-based evaluation of rotary sinter coolers, providing insights into their coupled thermal–fluid performance.

- Time-dependent pore/particle effects: The effects of varying porosity ratios and particle diameters are investigated in a time-varying manner, simultaneously considering their influence on both heat transfer and pressure drop—an approach rarely addressed in the existing literature.

2. Materials and Methods

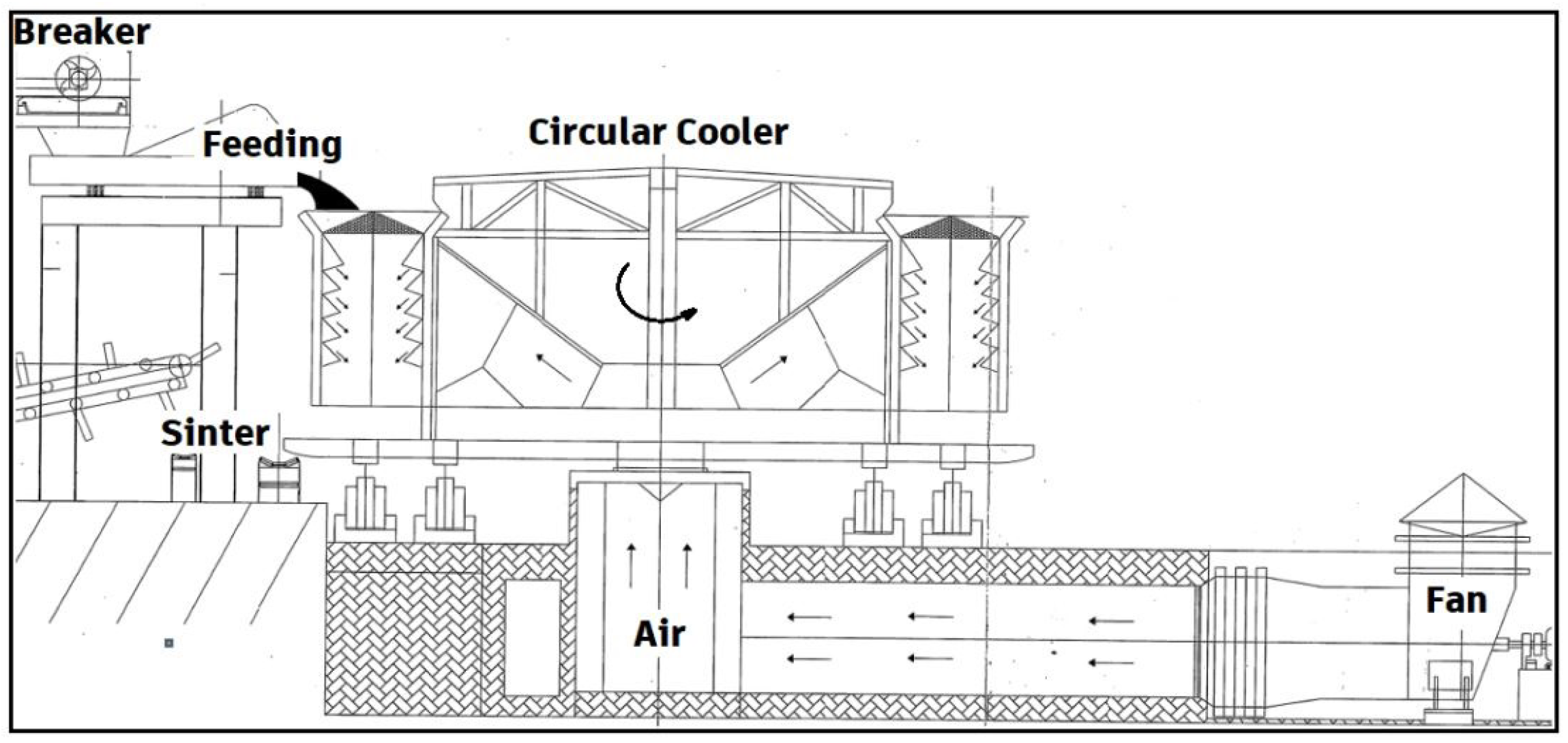

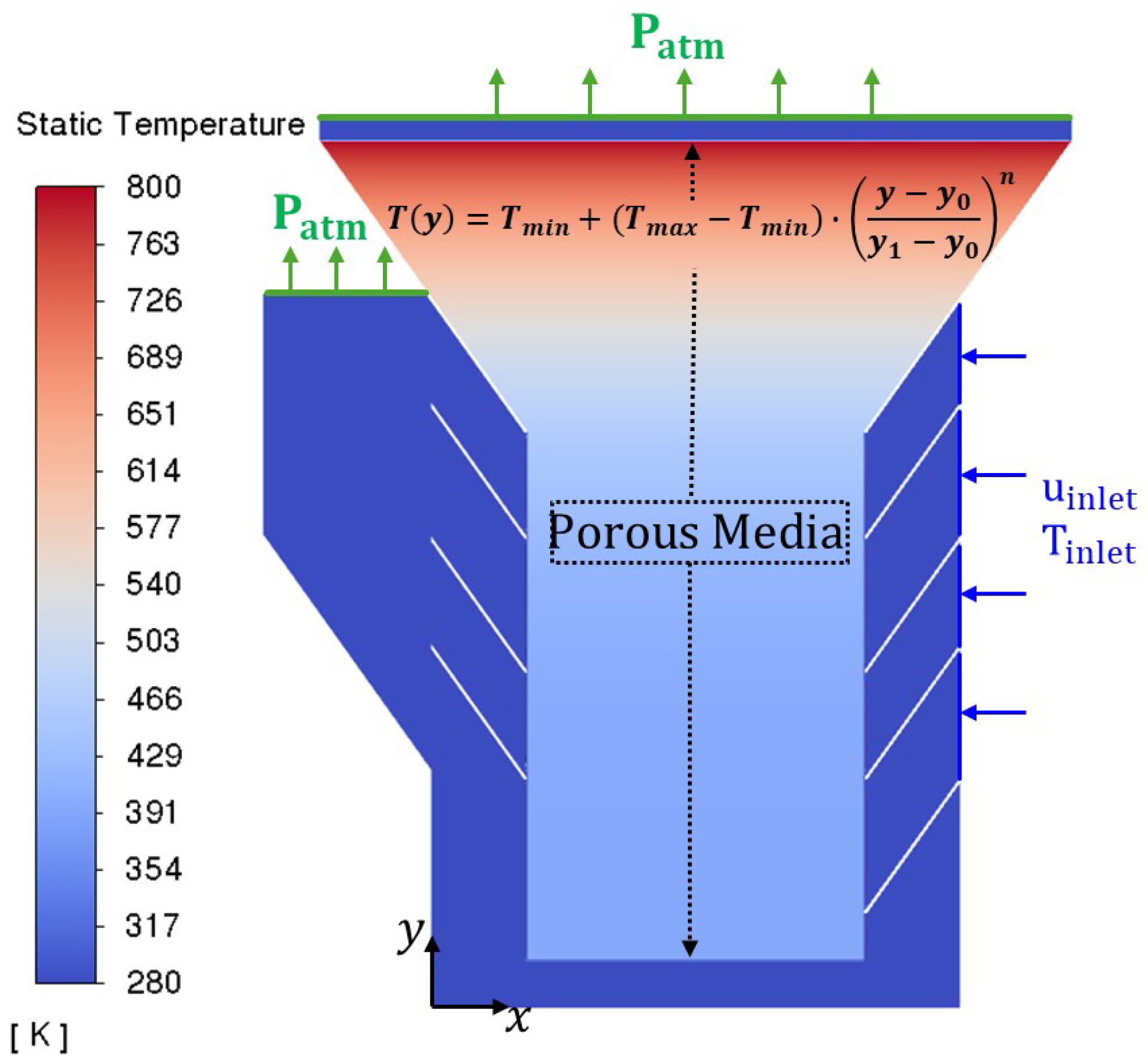

2.1. Problem Definition

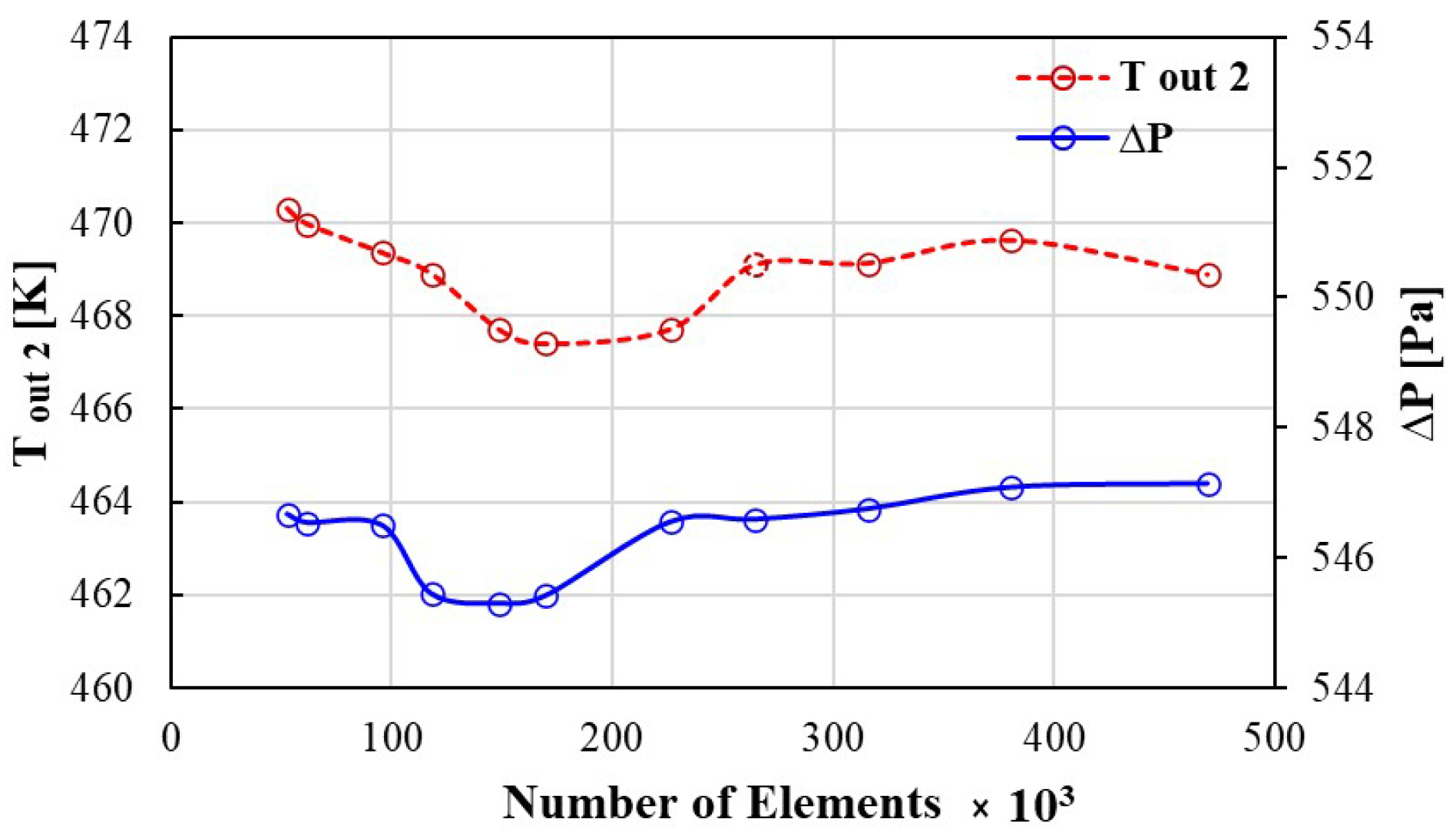

2.2. Numerical Modeling

3. Results and Discussion

3.1. Comparison of the Numerical Model with Experimental Observations

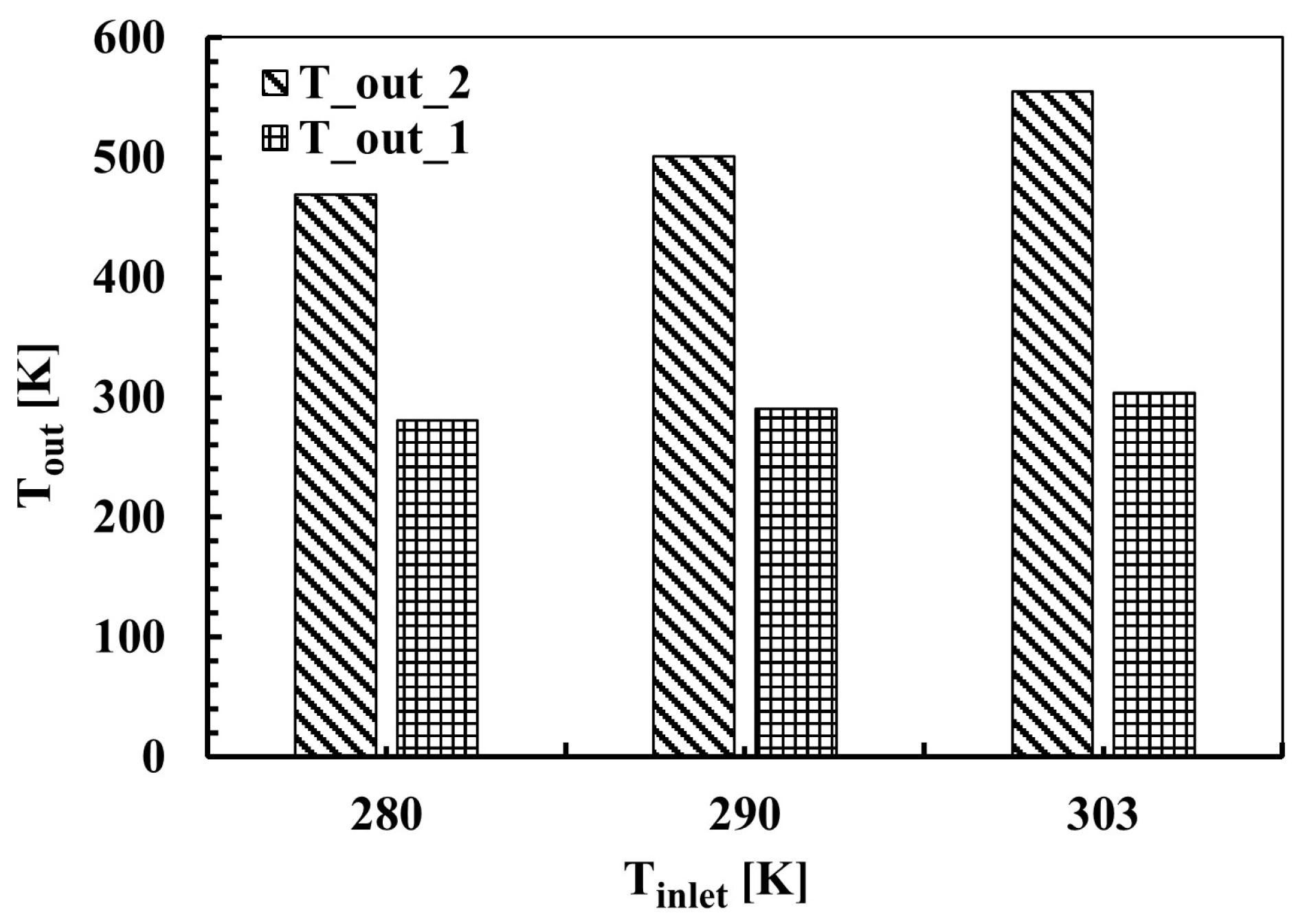

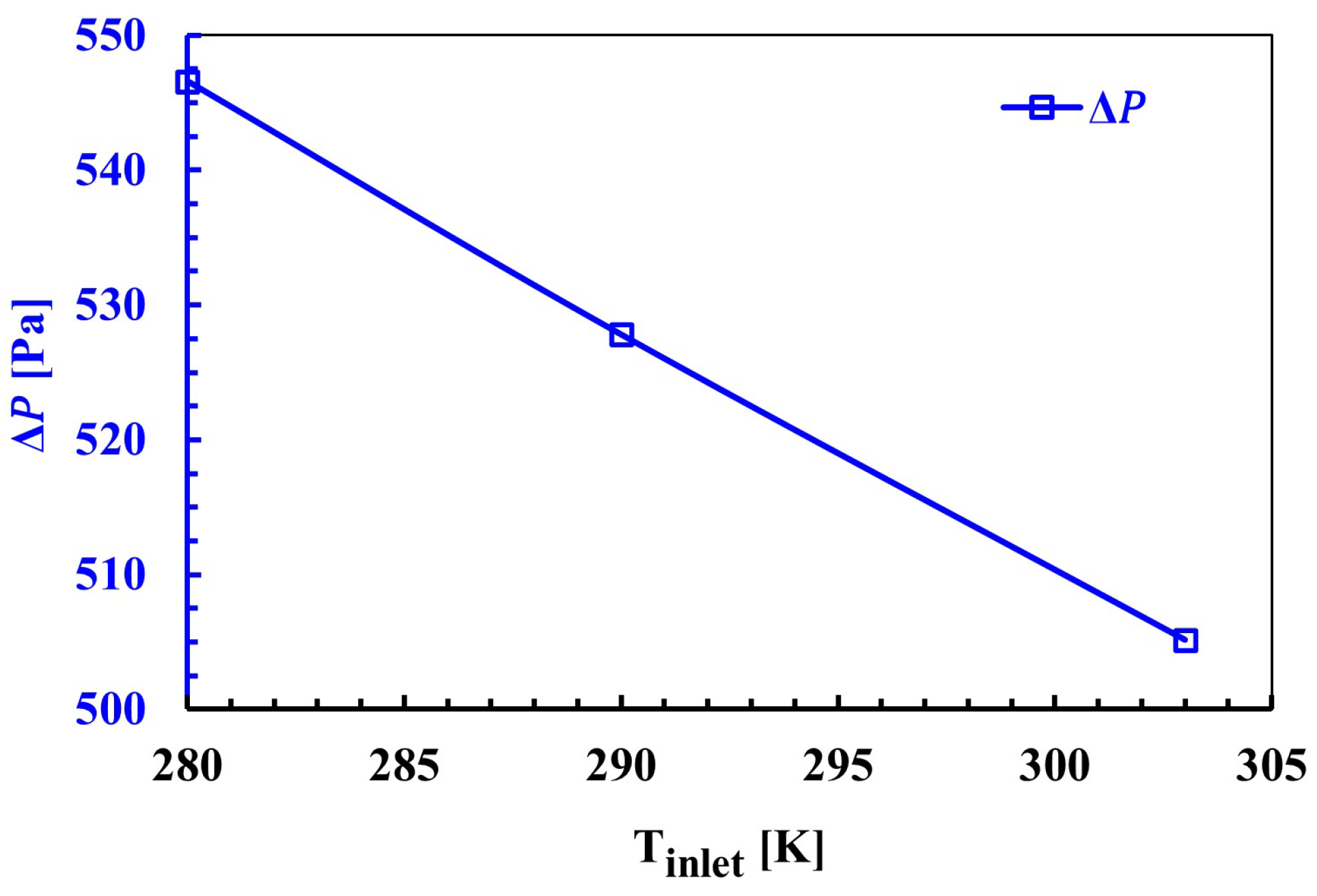

3.2. Effect of Inlet Temperature

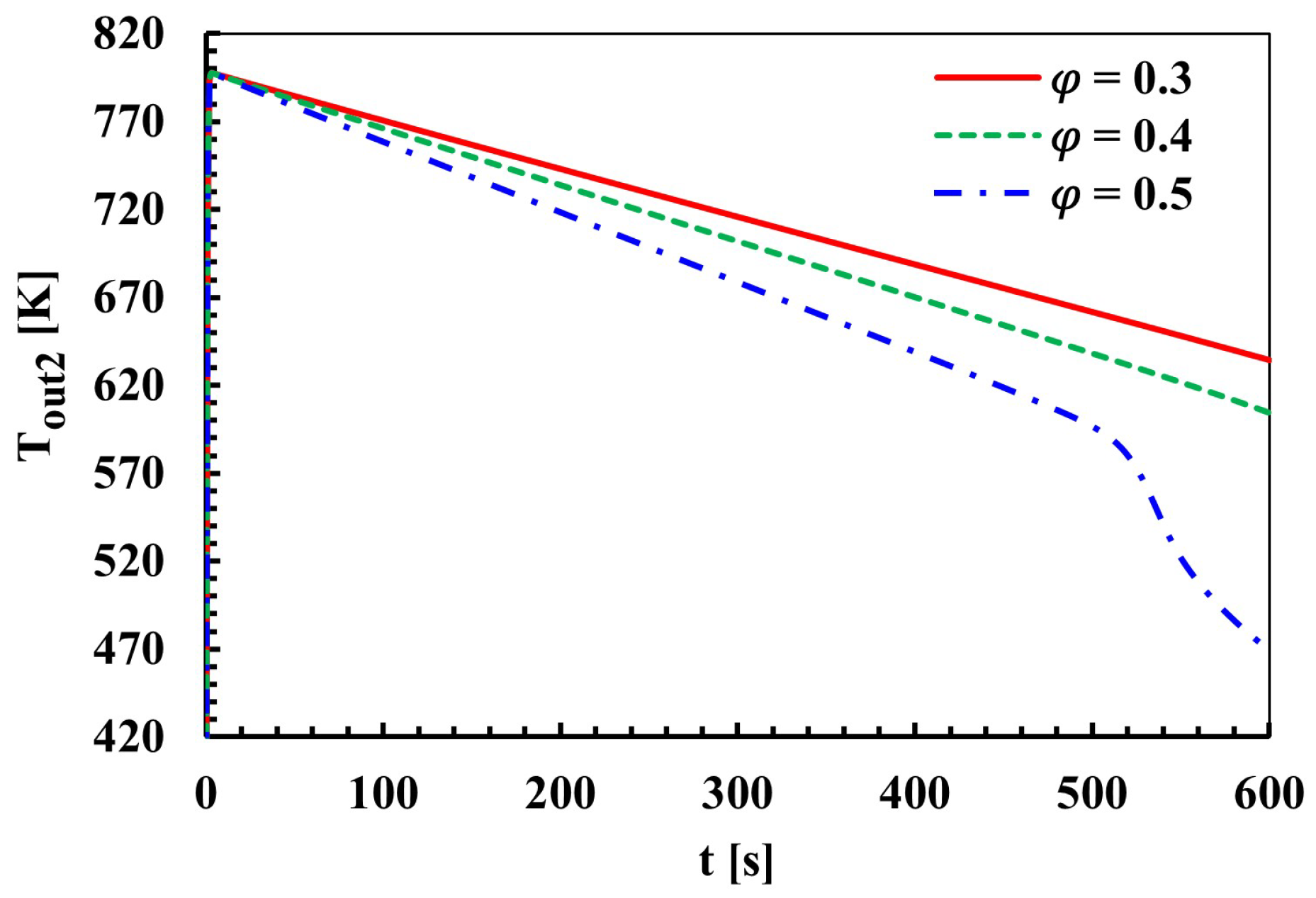

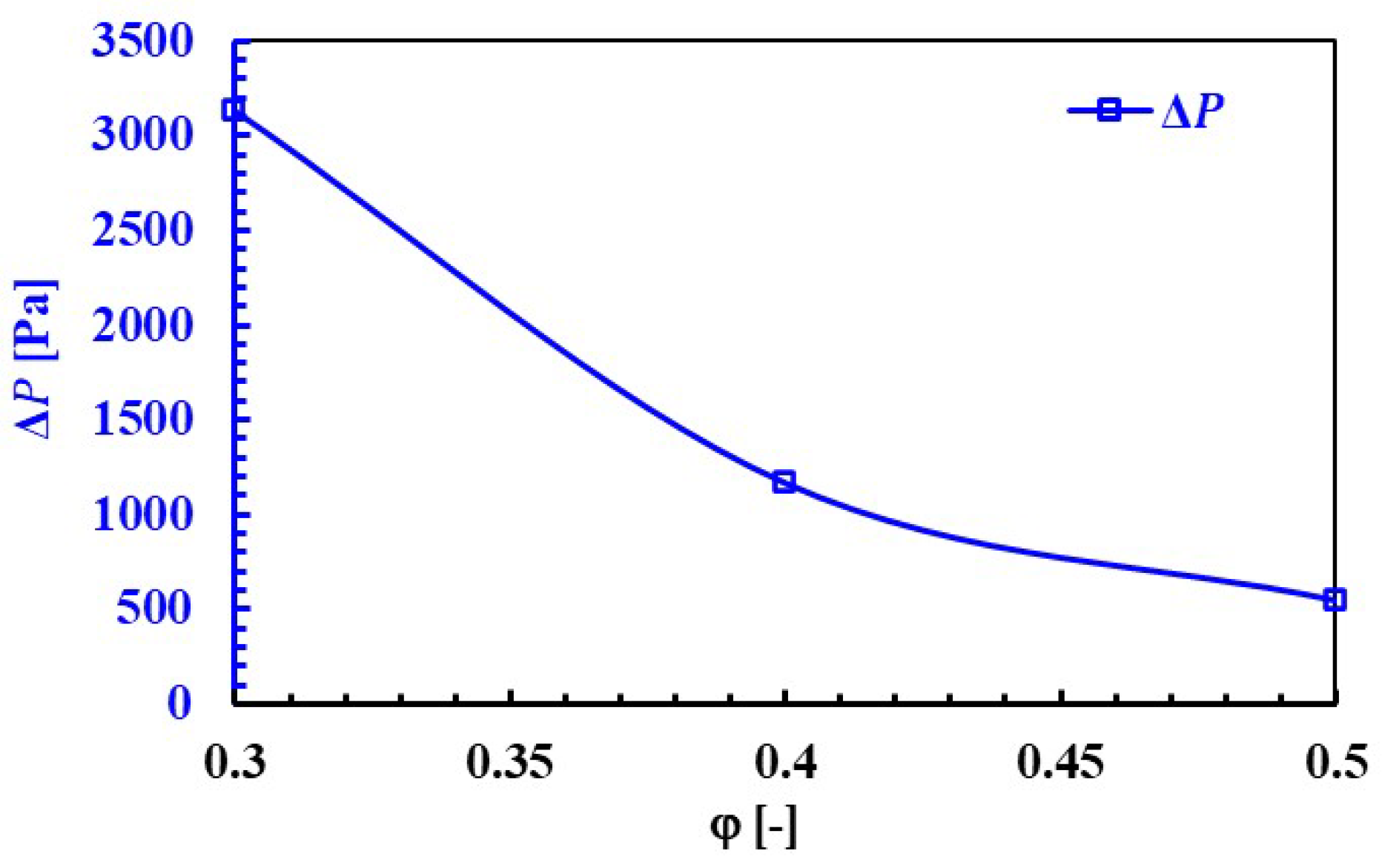

3.3. Effect of Porosity

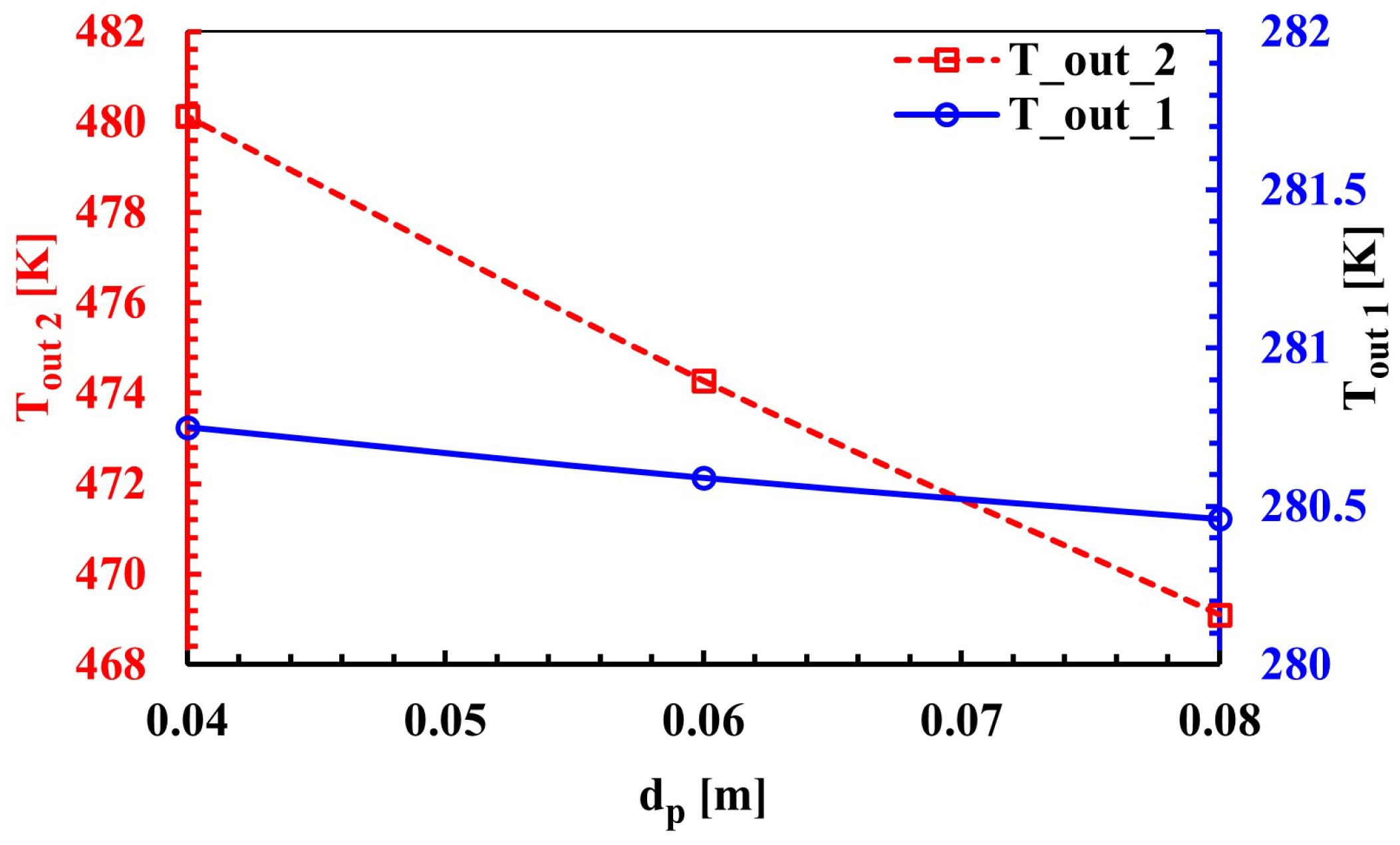

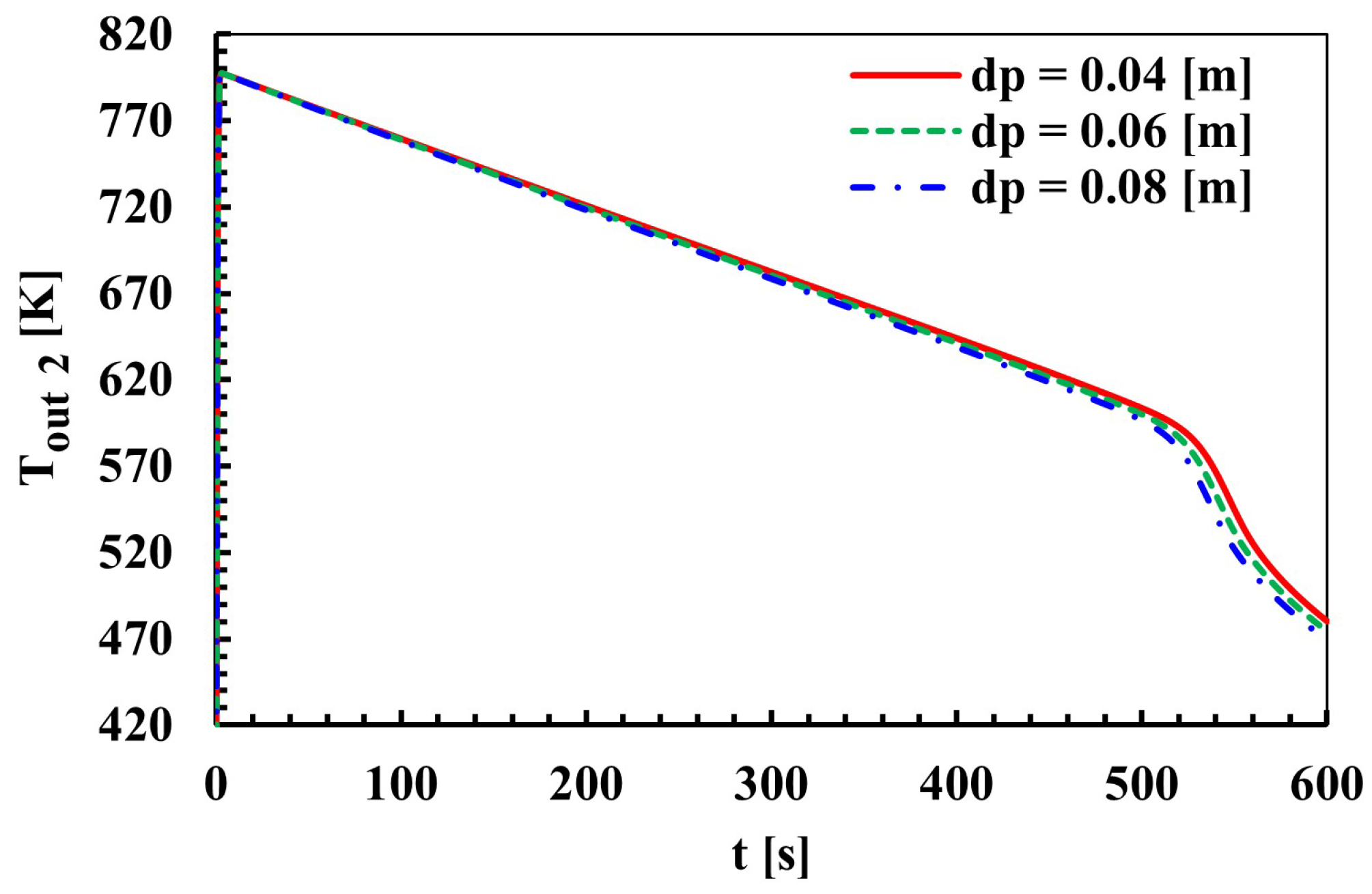

3.4. Effect of Particle Diameter

3.5. Assessment of Results with General Data Ranges

4. Conclusions

- The effect of sinter inlet air temperature on waste heat temperature was evaluated. When the inlet air temperature was increased from 280 K to 303 K, increased by about 19% from 470 K to 560 K. For the same temperature increase, the pressure loss in the system decreased by 7.7% from approximately 547 Pa to 505 Pa. In addition, the temperature distribution inside the sinter cooler was analyzed. Temperature distributions are important in determining the cooling time and temperature distribution of the sinter.

- When the porosity ratio was increased from 0.3 to 0.5, the temperature decreased by 26% from about 635 K to 470 K. The pressure loss decreased by 82.5% from 3150 Pa to 550 Pa. This shows that porosity both increases cooling efficiency and reduces energy loss.

- Particle diameter was analyzed and it was shown that larger particles provide lower pressure loss, but may limit heat transfer efficiency. The zone outlet temperature decreased from approximately 480.2 K to 469.0 K with an increase in particle diameter from 0.04 m to 0.08 m. The pressure loss decreased from 1000 Pa to 550 Pa with a 45% decrease.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Na, H.; Yuan, Y.; Sun, J.; Yang, Y.; Qiu, Z.; Che, Z.; Du, T. Integrated optimization for utilizing iron and steel industry’s waste heat with urban heating based on exergy analysis. Energy Convers. Manag. 2023, 295, 117593. [Google Scholar] [CrossRef]

- Cheng, Z.; Tan, Z.; Guo, Z.; Yang, J.; Wang, Q. Recent progress in sustainable and energy-efficient technologies for sinter production in the iron and steel industry. Renew. Sustain. Energy Rev. 2020, 131, 110034. [Google Scholar] [CrossRef]

- Feng, J.; Cheng, X.; Wang, H.; Zhao, L.; Wang, H.; Dong, H. Performance analysis and multi-objective optimization of organic Rankine cycle for low-grade sinter waste heat recovery. Case Stud. Therm. Eng. 2024, 53, 103915. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Wang, J.; Ding, X.; Cheng, Z.; Wang, Q. Prediction, parametric analysis and bi-objective optimization of waste heat utilization in sinter cooling bed using evolutionary algorithm. Energy 2015, 90, 24–35. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Cheng, Z.; Wang, J.; Wang, Q. Cost Benefits Analysis for Waste Heat Utilization in Sinter Cooling Bed. Chem. Eng. Trans. 2014, 39, 841–846. [Google Scholar] [CrossRef]

- Ja’fari, M.; Khan, M.I.; Al-Ghamdi, S.G.; Jaworski, A.J.; Asfand, F. Waste heat recovery in iron and steel industry using organic Rankine cycles. Chem. Eng. J. 2023, 477, 146925. [Google Scholar] [CrossRef]

- Zhang, S.; Wen, Z.; Liu, X.; Liu, X.; Wang, S.; Zhang, H. Experimental study on the permeability and resistance characteristics in the packed bed with the multi-size irregular particle applied in the sinter vertical waste heat recovery technology. Powder Technol. 2021, 384, 304–312. [Google Scholar] [CrossRef]

- Feng, J.; Dong, H.; Liu, J.; Liang, K.; Gao, J. Experimental study of gas flow characteristics in vertical tank for sinter waste heat recovery. Appl. Therm. Eng. 2015, 91, 73–79. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Zhang, J.; Ding, P.; Zhou, J. Simulation and optimization of waste heat recovery in sinter cooling process. Appl. Therm. Eng. 2013, 54, 7–15. [Google Scholar] [CrossRef]

- Tian, W.; Ni, B.; Jiang, C.; Wu, Z. Uncertainty analysis and optimization of sinter cooling process for waste heat recovery. Appl. Therm. Eng. 2019, 150, 111–120. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, L.; Feng, J.; Luo, X.; Dong, H. Thermal analysis of sinter vertical cooler based on waste heat recovery. Appl. Therm. Eng. 2019, 157, 113708. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Wang, J.; Cheng, Z.; Wang, Q. Energy and exergy analysis for waste heat cascade utilization in sinter cooling bed. Energy 2014, 67, 370–380. [Google Scholar] [CrossRef]

- Feng, J.; Zhao, L.; Zhang, S.; Dong, H. Exergy analysis and parameter optimization of sinter cooling process in vertical moving bed for waste heat recovery. Appl. Therm. Eng. 2020, 175, 115370. [Google Scholar] [CrossRef]

- Feng, J.; Dong, H.; Gao, J.; Liu, J.; Liang, K. Experimental study of gas-solid overall heat transfer coefficient in vertical tank for sinter waste heat recovery. Appl. Therm. Eng. 2016, 95, 136–142. [Google Scholar] [CrossRef]

- Feng, J.; Dong, H.; Gao, J.; Li, H.; Liu, J. Numerical investigation of gas-solid heat transfer process in vertical tank for sinter waste heat recovery. Appl. Therm. Eng. 2016, 107, 135–143. [Google Scholar] [CrossRef]

- Salmon, F.; Ghadim, H.B.; Godin, A.; Haillot, D.; Veillere, A.; Lacanette, D.; Duquesne, M. Optimizing performance for cooling electronic components using innovative heterogeneous materials. Appl. Energy 2024, 362, 122983. [Google Scholar] [CrossRef]

- Zheng, Y.; Cai, J.; Dong, H.; Feng, J.; Liu, J. Experimental investigation of volumetric exergy transfer coefficient in vertical moving bed for sinter waste heat recovery. Energy 2019, 167, 428–439. [Google Scholar] [CrossRef]

- Erdoğan, B.; Topal, H.İ.; Aydın, N.Ö.; Bayramoğlu, K.; Zengin, İ.; Ulukaya, Ş. Integrated thermal and techno-economic analysis of waste heat recovery from sinter cooling in the iron-steel industry utilizing real data. Therm. Sci. Eng. Prog. 2025, 65, 103923. [Google Scholar] [CrossRef]

- Wang, W.; Li, S.; Zhen, J.; Guo, J.; Xu, W. Numerical study and orthogonal analysis of optimal performance parameters for vertical cooling of sintered ore. Sci. Rep. 2024, 14, 4904. [Google Scholar] [CrossRef]

- Feng, J.; Yan, Y.; Zhao, L.; Dong, H. Numerical study of gas–solid counterflow heat transfer in sinter vertical cooling furnace based on energy and exergy analysis. Appl. Therm. Eng. 2024, 244, 122773. [Google Scholar] [CrossRef]

- Ergun, S. Fluid Flow through Packed Columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Cheng, Z.; Wang, H.; Feng, J.; Xia, Y.; Dong, H. Energy and Exergy Efficiency Analysis of Fluid Flow and Heat Transfer in Sinter Vertical Cooler. Energies 2021, 14, 4522. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, L.; Feng, J.; Luo, X.; Dong, H. Parameter optimization of gas–solid heat transfer process in sinter packed bed based on further exergy analysis. Chem. Eng. Res. Des. 2019, 146, 499–508. [Google Scholar] [CrossRef]

| Operating Parameters | Symbol | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| Particle size [m] | 0.04 | 0.06 | 0.08 * | |

| Porosity [-] | 0.3 | 0.4 | 0.5 * | |

| Inlet air temperature [K] | 280 * | 290 | 303 |

| Sinter Inlet | Air Flow | Air Inlet | Sinter Bed | Bed Inner | Air Outlet | |

|---|---|---|---|---|---|---|

| Temperature [K] | Rate [kg/s] | Temperature [K] | Height [m] | Diameter [m] | Temperature [K] | |

| Present study | 800 | 130 | 280–303 | 3.6 | 10 | 469–634 |

| 2020_Feng [13] | 973 | 160–190 | 293 | 7 | 9 | 750–800 |

| 2021_Cheng [22] | 993–1146 | 190 | 293 | 7 & 9 | 9 | 727–867 |

| 2019_Zhang [23] | 1023 | – | 380–425 | 1.4 | 36.6 | 678–637 |

| 2013_Zhang [9] | 1023 | – | 404–434 | 1.4–1.8 | – | 525–760 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zengin, İ.; Bayramoğlu, K.; Aydın, N.Ö.; Topal, H.İ.; Erdoğan, B.; Ulukaya, Ş. CFD-Based Evaluation of Waste Heat Recovery and Pressure Drop in Rotary Sinter Coolers Under Varying Bed Properties and Inlet Conditions. Sustainability 2025, 17, 8066. https://doi.org/10.3390/su17178066

Zengin İ, Bayramoğlu K, Aydın NÖ, Topal Hİ, Erdoğan B, Ulukaya Ş. CFD-Based Evaluation of Waste Heat Recovery and Pressure Drop in Rotary Sinter Coolers Under Varying Bed Properties and Inlet Conditions. Sustainability. 2025; 17(17):8066. https://doi.org/10.3390/su17178066

Chicago/Turabian StyleZengin, İbrahim, Kubilay Bayramoğlu, Nuri Özgür Aydın, Halil İbrahim Topal, Beytullah Erdoğan, and Şeyma Ulukaya. 2025. "CFD-Based Evaluation of Waste Heat Recovery and Pressure Drop in Rotary Sinter Coolers Under Varying Bed Properties and Inlet Conditions" Sustainability 17, no. 17: 8066. https://doi.org/10.3390/su17178066

APA StyleZengin, İ., Bayramoğlu, K., Aydın, N. Ö., Topal, H. İ., Erdoğan, B., & Ulukaya, Ş. (2025). CFD-Based Evaluation of Waste Heat Recovery and Pressure Drop in Rotary Sinter Coolers Under Varying Bed Properties and Inlet Conditions. Sustainability, 17(17), 8066. https://doi.org/10.3390/su17178066