Smart Residual Biomass Supply Chain: A Digital Tool to Boost Energy Potential Recovery and Mitigate Rural Fire Risk

Abstract

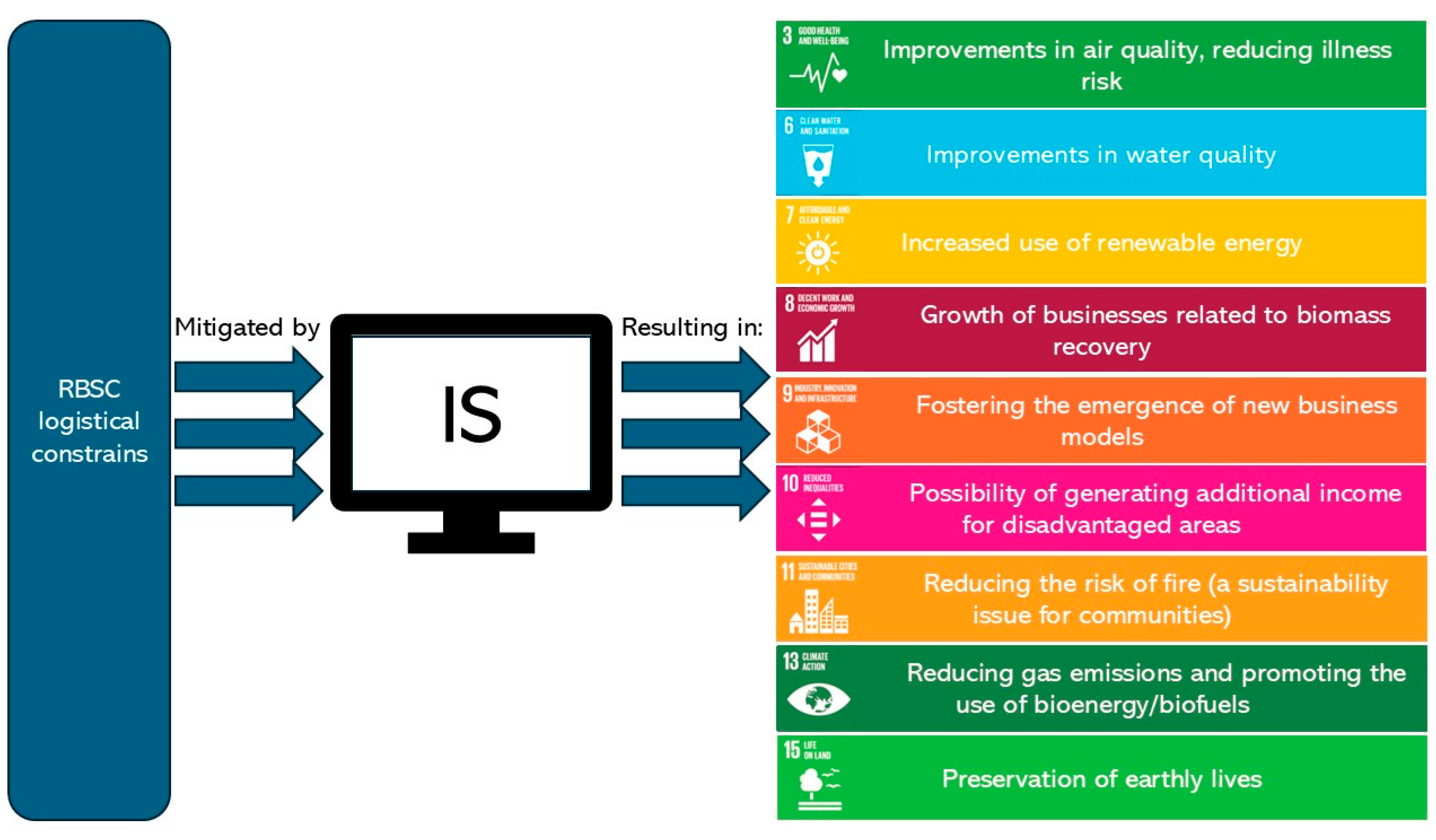

1. Introduction

2. Literature Review

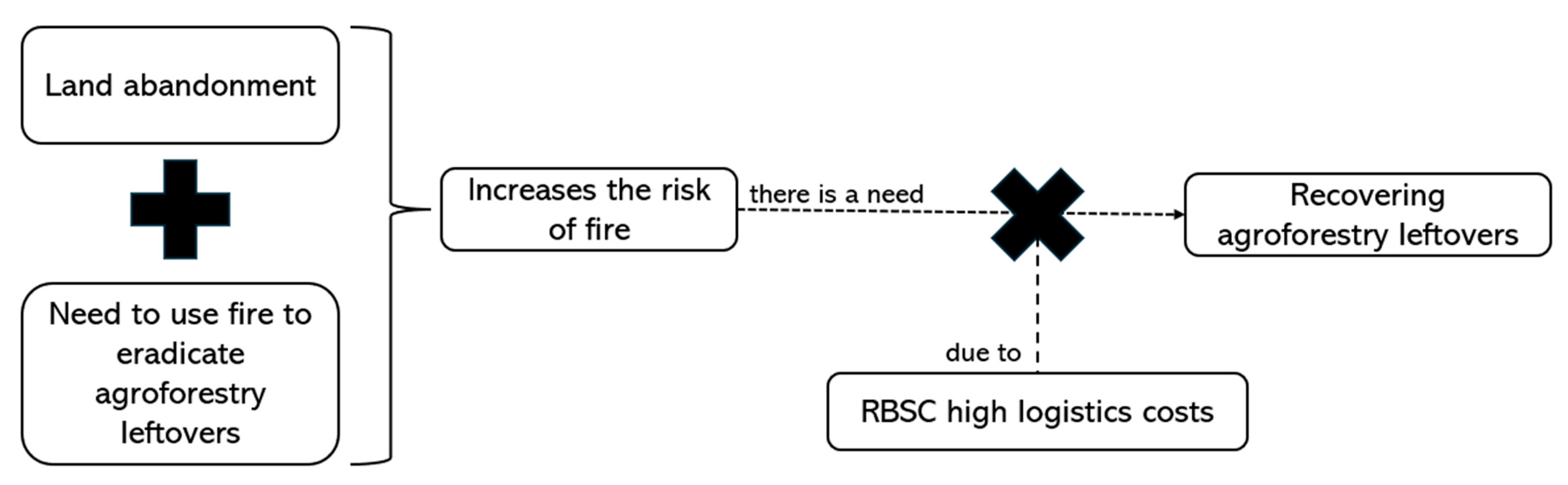

2.1. Mitigating Rural Fires Through Biomass Recovery—RBSC Challenges

2.2. Smartness Concept: Smart Supply Chain Management and Smart Cities

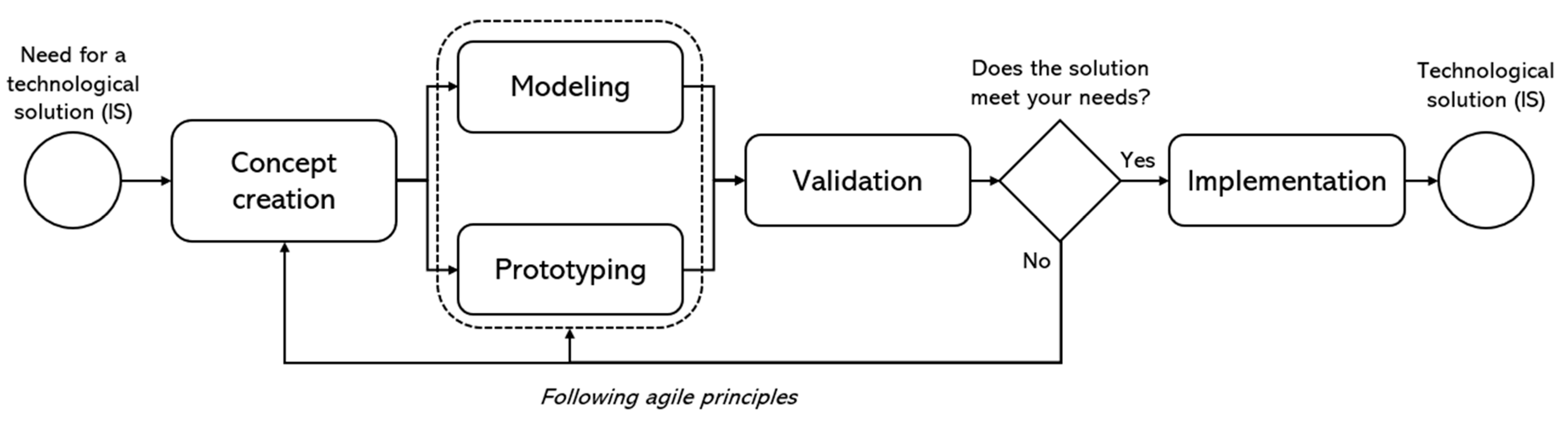

3. Materials and Methods

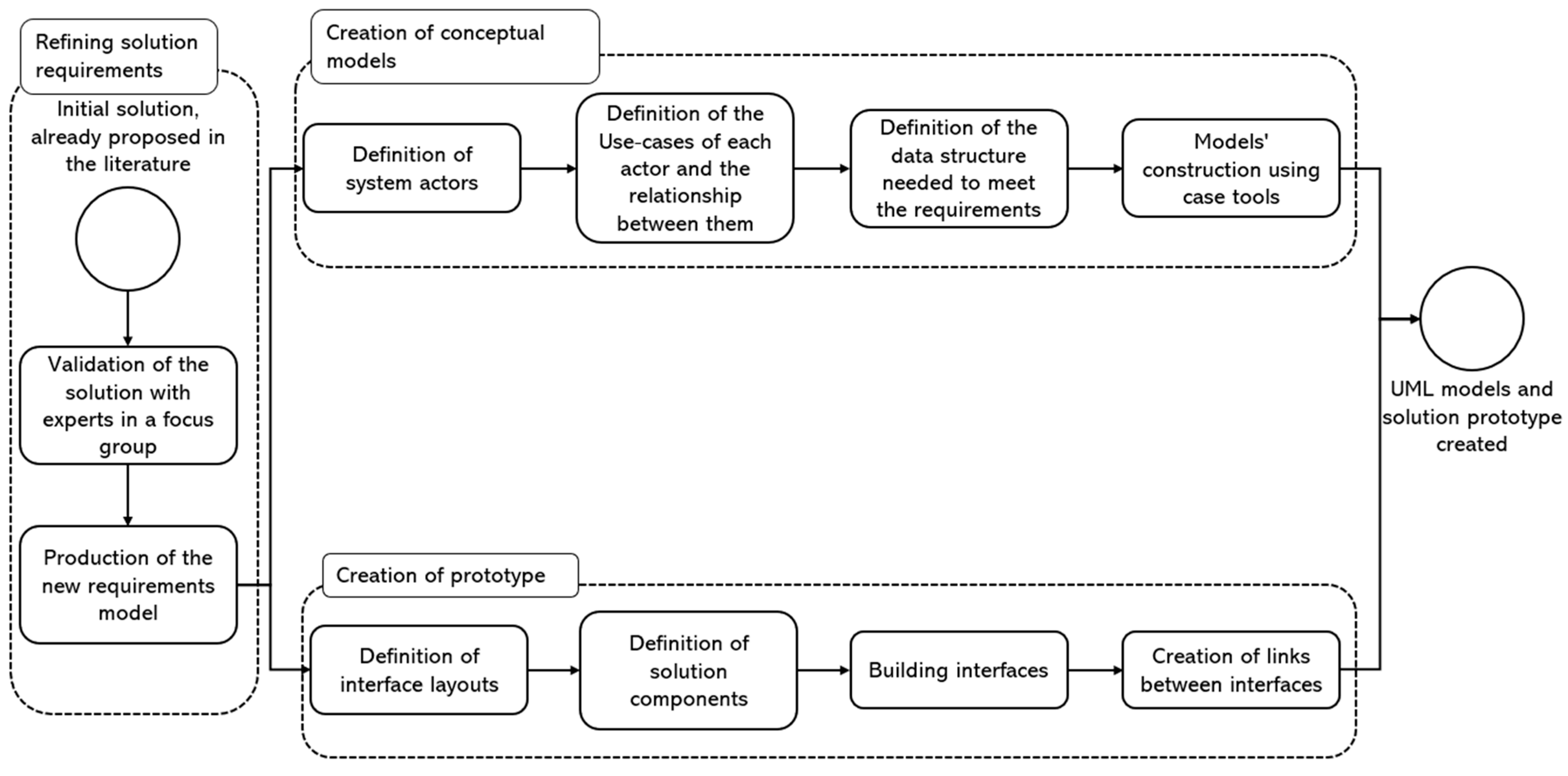

3.1. Refining Solution Requirements

- Which information model best meets the needs of the problem?

- Which system actors should be incorporated into the solution?

- What vicissitudes of the real context do practitioners face that are not reflected in the first version?

3.2. Creation of Technological Solution—Conceptual Models and Prototype

4. Results

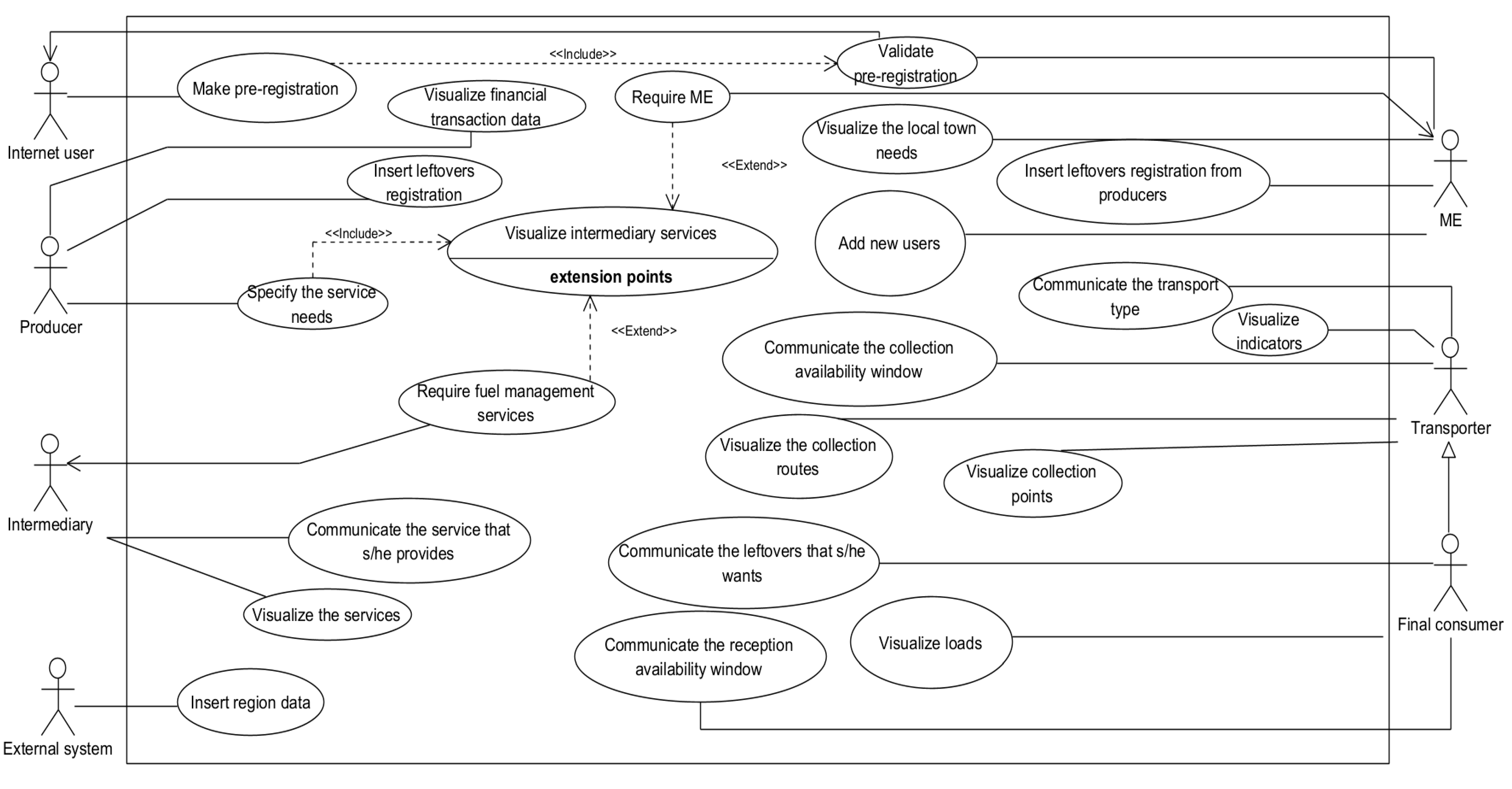

4.1. Concept: Actors and Main Requirements

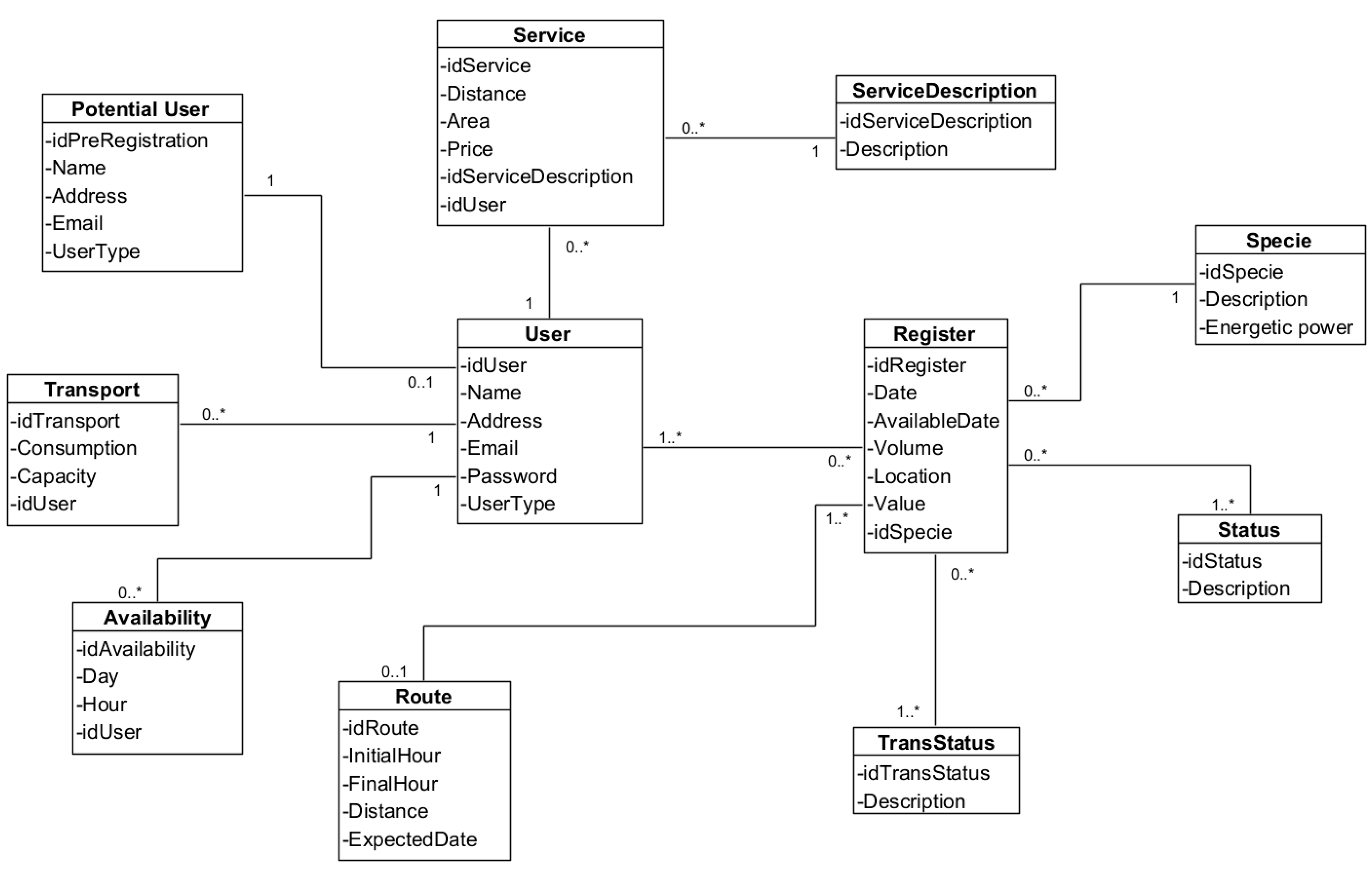

4.2. Data Model—Class Diagram

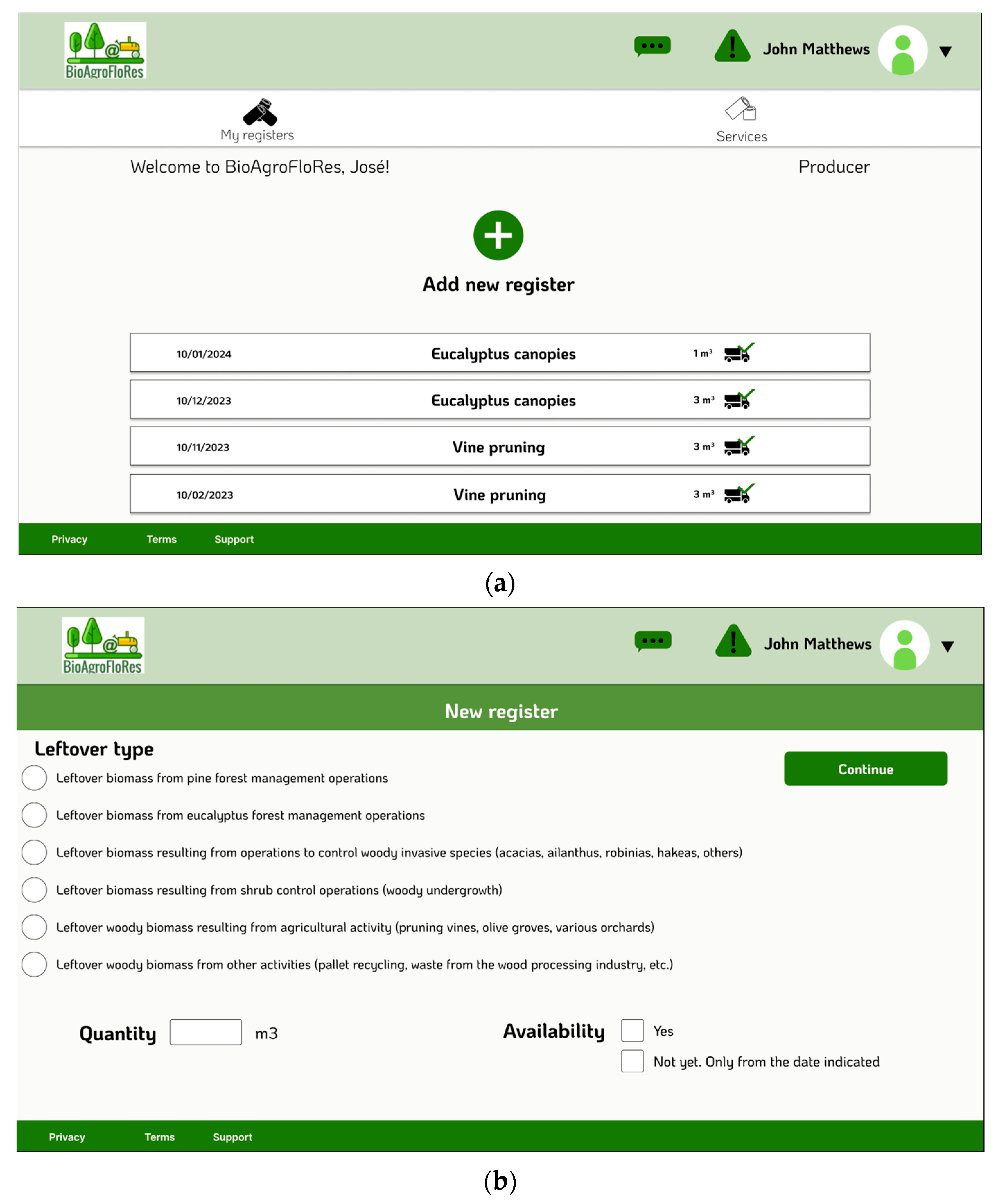

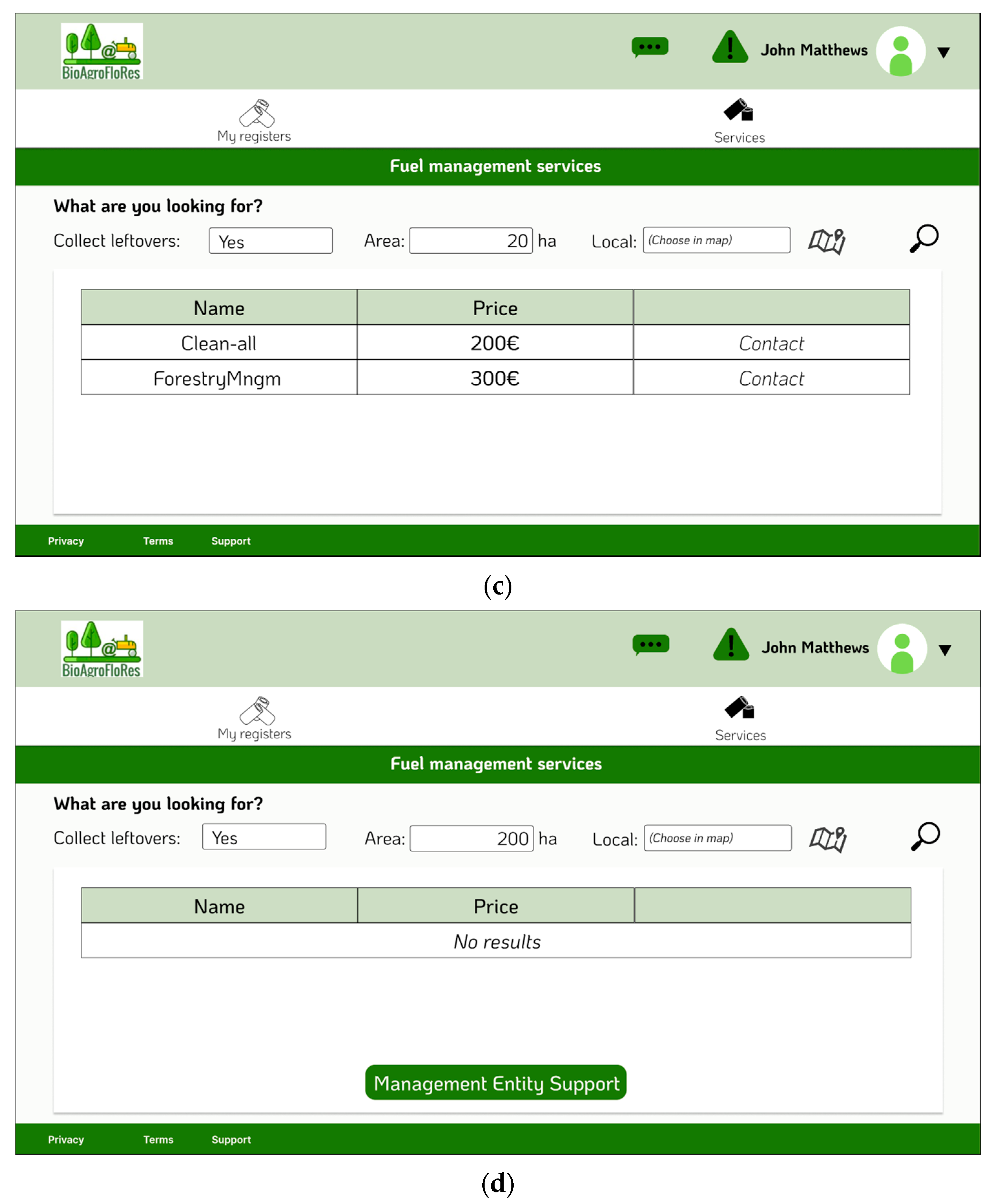

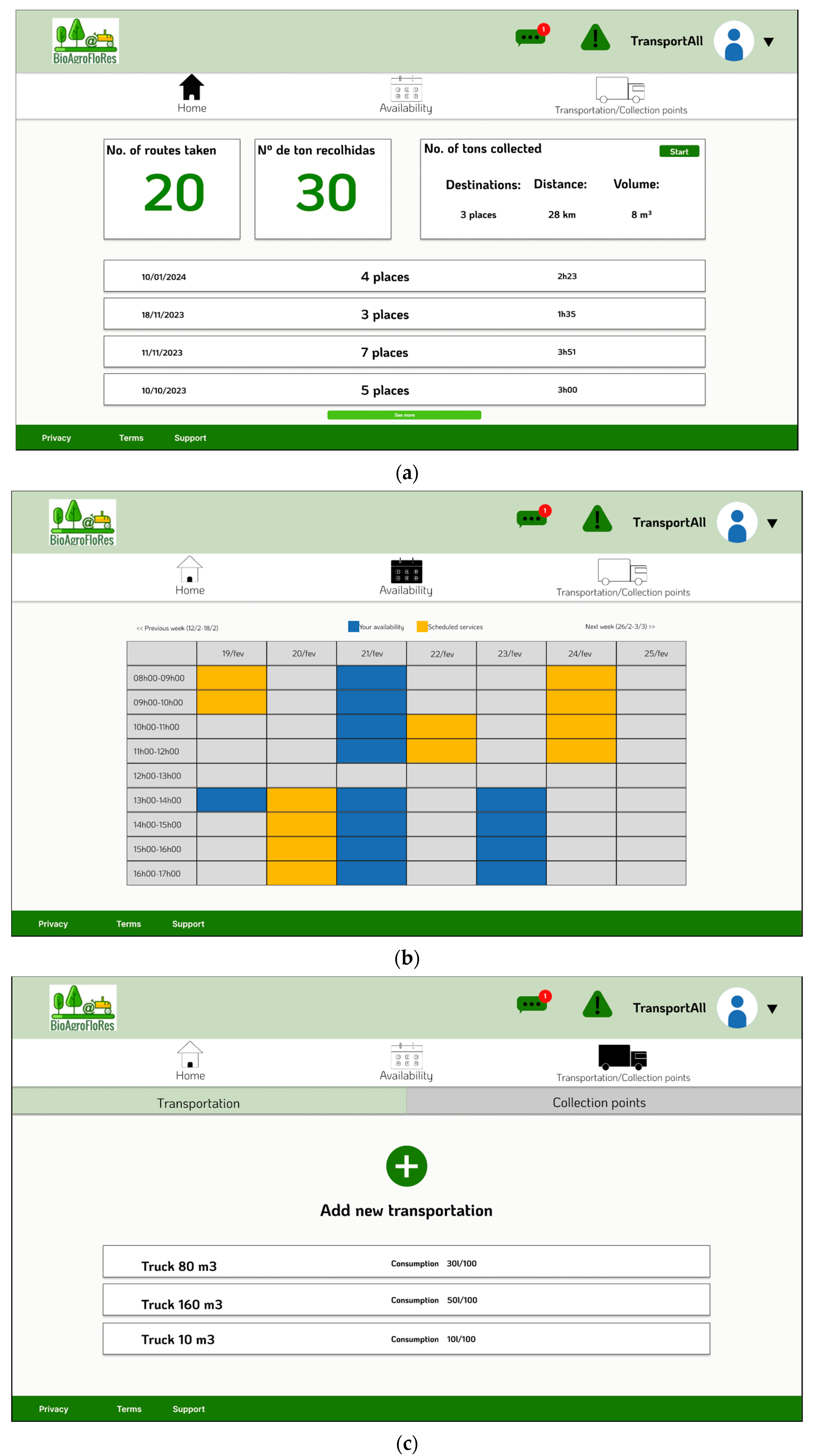

4.3. Technological Prototype

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SDG | Sustainable Development Goal |

| SC | Supply Chain |

| RBSC | Residual Biomass Supply Chain |

| I4.0 | Fourth Industrial Revolution or Industry 4.0 |

| RB | Residual Biomass |

| SSCM | Smart Supply Chain Management |

| IS | Information System |

| IoT | Internet of Things |

| AI | Artificial Intelligence |

| UML | Unified Modeling Language |

| CSS | Cascading Style Sheets |

| ME | Management Entity |

References

- Hong, A.Z.; Xiao, K. Digital economy structuring for sustainable development: The role of blockchain and artificial intelligence in improving supply chain and reducing negative environmental impacts. Sci. Rep. 2024, 14, 3912. [Google Scholar] [CrossRef]

- Bastos, T.; Teixeira, L. Digital Transition and Sustainable Development Goals: A Theoretical Reflection on the Impact of I4.0 Technologies. In Proceedings of the International Conference on Flexible Automation and Intelligent Manufacturing, Taichung, Taiwan, 23–26 June 2024; Springer: Berlin/Heidelberg, Germany, 2024; pp. 713–720. [Google Scholar] [CrossRef]

- Aravindaraj, K.; Chinna, P.R. A systematic literature review of integration of industry 4.0 and warehouse management to achieve Sustainable Development Goals (SDGs). Clean. Logist. Supply Chain. 2022, 5, 100072. [Google Scholar] [CrossRef]

- Silva, D.; Ferreira, T.M.; Rodrigues, H. Assessing the Accuracy of the Wildland–Urban Interface Index in Portuguese Rural Villages’ Context: A Case Study of the 2017 Pedrógão Grande Wildfire. Fire 2024, 7, 90. [Google Scholar] [CrossRef]

- Wibbenmeyer, M.; Sloggy, M.R.; Sánchez, J.J. Economic Analysis of Wildfire Impacts to Water Quality: A Review. J. For. 2023, 121, 374–382. [Google Scholar] [CrossRef]

- Oliveira, M.; Delerue-Matos, C.; Pereira, M.C.; Morais, S. Environmental particulate matter levels during 2017 large forest fires and megafires in the center region of Portugal: A public health concern? Int. J. Environ. Res. Public Health 2020, 17, 1032. [Google Scholar] [CrossRef]

- Kalogiannidis, S.; Chatzitheodoridis, F.; Kalfas, D.; Patitsa, C.; Papagrigoriou, A. Socio-Psychological, Economic and Environmental Effects of Forest Fires. Fire 2023, 6, 280. [Google Scholar] [CrossRef]

- Pierobon, F.; Sifford, C.; Velappan, H.; Ganguly, I. Air quality impact of slash pile burns: Simulated geo-spatial impact assessment for Washington State. Sci. Total Environ. 2022, 818, 151699. [Google Scholar] [CrossRef] [PubMed]

- Nunes, L.J.R.; Raposo, M.A.M.; Gomes, C.J.P. A historical perspective of landscape and human population dynamics in Guimarães (Northern Portugal): Possible implications of rural fire risk in a changing environment. Fire 2021, 4, 49. [Google Scholar] [CrossRef]

- de Oliveira, E.; Lobo-do-Vale, R.; Colaço, M.C. Incident analysis of traditional burns in Portugal. Int. J. Disaster Risk Reduct. 2023, 95, 103852. [Google Scholar] [CrossRef]

- Rijal, P.; Carvalho, H.; Matias, J.; Garrido, S.; Pimentel, C. Towards a Conceptual Framework for Agroforestry Residual Biomass Sustainable Business Models. In International Conference on Quality Innovation and Sustainability; Springer International Publishing: Cham, Switzerland, 2023; pp. 211–221. [Google Scholar] [CrossRef]

- Rijal, P.; Carvalho, H.; Matias, J.; Garrido, S.; Pimentel, C. Drivers and Barriers of Residual Agroforestry Biomass Valorization: A Bibliometric Analysis. In International Conference on Flexible Automation and Intelligent Manufacturing; Springer International Publishing: Cham, Switzerland, 2024; pp. 887–895. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Casau, M.; Dias, M.F.; Matias, J.C.O.; Teixeira, L.C. Agroforest woody residual biomass-to-energy supply chain analysis: Feasible and sustainable renewable resource exploitation for an alternative to fossil fuels. Results Eng. 2023, 17, 101010. [Google Scholar] [CrossRef]

- Chidozie, B.C.; Ramos, A.L.; Ferreira, J.V.; Ferreira, L.P. Residual Agroforestry Biomass Supply Chain Simulation Insights and Directions: A Systematic Literature Review. Sustainability 2023, 15, 9992. [Google Scholar] [CrossRef]

- Chidozie, B.; Ramos, A.; Vasconcelos, J.; Ferreira, L.P.; Gomes, R. Highlighting Sustainability Criteria in Residual Biomass Supply Chains: A Dynamic Simulation Approach. Sustainability 2024, 16, 9709. [Google Scholar] [CrossRef]

- Fernandez-Lacruz, R.; Eriksson, A.; Bergström, D. Simulation-based cost analysis of industrial supply of chips from logging residues and small-diameter trees. Forests 2020, 11, 1. [Google Scholar] [CrossRef]

- Paulson, J.; Kizha, A.; Han, H.-S. Integrating Biomass Conversion Technologies with Recovery Operations In-Woods: Modeling Supply Chain. Logistics 2019, 3, 16. [Google Scholar] [CrossRef]

- Casau, M.; Dias, M.F.; Teixeira, L.; Matias, J.C.O.; Nunes, L.J.R. Reducing Rural Fire Risk through the Development of a Sustainable Supply Chain Model for Residual Agroforestry Biomass Supported in a Web Platform: A Case Study in Portugal Central Region with the Project BioAgroFloRes. Fire 2022, 5, 61. [Google Scholar] [CrossRef]

- Rijal, P.; Carvalho, H.; Matias, J.; Garrido, S.; Pimentel, C. Drivers and barriers of residual agroforestry biomass valorization: A systematic literature review. Agrofor. Syst. 2025, 99, 81. [Google Scholar] [CrossRef]

- Demir, S.; Gunduz, M.A.; Kayikci, Y.; Paksoy, T. Readiness and Maturity of Smart and Sustainable Supply Chains: A Model Proposal. EMJ—Eng. Manag. J. 2023, 35, 181–206. [Google Scholar] [CrossRef]

- Moretti, L.; Milani, M.; Lozza, G.G.; Manzolini, G. A detailed MILP formulation for the optimal design of advanced biofuel supply chains. Renew. Energy 2021, 171, 159–175. [Google Scholar] [CrossRef]

- Piedra-Jimenez, F.; Torres, A.I.; Rodriguez, M.A. A robust disjunctive formulation for the redesign of forest biomass-based fuels supply chain under multiple factors of uncertainty. Comput. Chem. Eng. 2024, 181, 108540. [Google Scholar] [CrossRef]

- Basile, F.; Pilotti, L.; Ugolini, M.; Lozza, G.; Manzolini, G. Supply chain optimization and GHG emissions in biofuel production from forestry residues in Sweden. Renew. Energy 2022, 196, 405–421. [Google Scholar] [CrossRef]

- Bastos, T.; Teixeira, L.C.; Nunes, L.J.R. Forest 4.0: Technologies and digitalization to create the residual biomass supply chain of the future. J. Clean. Prod. 2024, 467, 143041. [Google Scholar] [CrossRef]

- Rijal, P.; Bras, P.; Garido, S.; Matias, J.; Pimentel, C.; Carvalho, H. Residual Forestry Biomass Supply Chain: A Mapping Approach. Int. J. Ind. Eng. Manag. 2023, 14, 244–256. [Google Scholar] [CrossRef]

- Bastos, T.; Teixeira, L.C.; Matias, J.C.O.; Nunes, L.J.R. Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform. Logistics 2023, 7, 56. [Google Scholar] [CrossRef]

- Bastos, T.; Teixeira, L.C.; Matias, J.C.O.; Nunes, L.J.R. Optimizing the agroforestry residual biomass supply chain: A disruptive tool for mitigating logistic costs and enhancing forest management. Results Eng. 2023, 20, 101500. [Google Scholar] [CrossRef]

- González-Pelayo, O.; Prats, S.; Amd, V.; Dcs, V.; Maia, P.; Keizer, J. Impacts of barley (Hordeum vulgare L.) straw mulch on post-fire soil erosion and ground vegetation recovery in a strawberry tree (Arbutus unedo L.) stand. Ecol. Eng. 2023, 195, 107074. [Google Scholar] [CrossRef]

- Scarpa, C.; Bacciu, V.; Ascoli, D.; Costa-Saura, J.M.; Salis, M.; Sirca, C.; Marchetti, M.; Spano, D. Estimating annual GHG and particulate matter emissions from rural and forest fires based on an integrated modelling approach. Sci. Total Environ. 2024, 907, 167960. [Google Scholar] [CrossRef] [PubMed]

- Tedim, F.; Samora-Arvela, A.; Coimbra, C.; Aranha, J.; Correia, F.; Pinto, D.M.; Figueiras, C.; Magalhães, C. Limitations and Opportunities of Spatial Planning to Enhance Wildfire Risk Reduction: Evidences from Portugal. Forests 2023, 14, 303. [Google Scholar] [CrossRef]

- Iglesias-Merchan, C.; López-Santiago, J.; Silván-Rico, R.; Millán-Castillo, R.S.; Gómez-Villarino, M.T. Impact of Depopulation on Forest Fires in Spain: Primary School Distribution as a Potential Socioeconomic Indicator. Forests 2024, 15, 1938. [Google Scholar] [CrossRef]

- Rodrigues, A.; Santiago, A.; Laím, L.; Viegas, D.X.; Zêzere, J.L. Rural Fires—Causes of Human Losses in the 2017 Fires in Portugal. Appl. Sci. 2022, 12, 12561. [Google Scholar] [CrossRef]

- Pippal, P.S.; Kumar, R.; Singh, A.; Singh, S.; Kumar, P.; Shrestha, S. Forest fire consequences under the influence of changing climate: A systematic review with bibliometric analysis in the context of sustainable development goals. Discov. Sustain. 2025, 6, 541. [Google Scholar] [CrossRef]

- Quishpe-Vásquez, C.; Oliva, P.; López-Barrera, E.A.; Casallas, A. Wildfires impact on PM2.5 concentration in galicia Spain. J. Environ. Manag. 2024, 367, 122093. [Google Scholar] [CrossRef] [PubMed]

- Habib, M.S.; Hwang, S.-J. Developing sustainable, resilient, and responsive biofuel production and distribution management system: A neutrosophic fuzzy optimization approach based on artificial intelligence and geographic information systems. Appl. Energy 2024, 372, 123683. [Google Scholar] [CrossRef]

- Alcocer-Garcia, H.; Segovia-Hernandez, J.G.; Sanchez-Ramirez, E.; Tominac, P.; Zavala, V.M. Coordinated markets for furfural and levulinic acid from residual biomass: A case study in Guanajuato, Mexico. Comput. Chem. Eng. 2022, 156, 107568. [Google Scholar] [CrossRef]

- Chidozie, B.; Ramos, A.; Vasconcelos, J.; Ferreira, L.P. Development of a Residual Biomass Supply Chain Simulation Model Using AnyLogistix: A Methodical Approach. Logistics 2024, 8, 107. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Silva, S. Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis. Logistics 2023, 7, 48. [Google Scholar] [CrossRef]

- Sperandio, G.; Acampora, A.; Civitarese, V.; Bajocco, S.; Bascietto, M. Transport cost estimation model of the agroforestry biomass in a small-scale energy chain. Forests 2021, 12, 158. [Google Scholar] [CrossRef]

- Vittoria, B.; Simona, D.F.; Laura, V. Sustainable Energy Paths: Harnessing Residual Biomass Potential in Southern Italy. Int. J. Des. Nat. Ecodynamics 2024, 19, 1657–1663. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Nogueira, J.; Rodrigues, J.B.; Azevedo, J.C.; Oliveira, E.; de Figueiredo, T.; Picos, J. Modern Animal Traction to Enhance the Supply Chain of Residual Biomass. Agriengineering 2023, 5, 1039–1050. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Yang, G. Smart supply chain management in Industry 4.0: The review, research agenda and strategies in North America. Ann. Oper. Res. 2023, 322, 1075–1117. [Google Scholar] [CrossRef] [PubMed]

- Shi, T.; Lee, S.J.; Li, Q. Smart supply chain management in business education: Reflection on the pandemics. Decis. Sci. J. Innov. Educ. 2024, 22, 19–32. [Google Scholar] [CrossRef]

- Liu, Z.; Sampaio, P.; Pishchulov, G.; Mehandjiev, N.; Cisneros-Cabrera, S.; Schirrmann, A.; Jiru, F.; Bnouhanna, N. The architectural design and implementation of a digital platform for Industry 4.0 SME collaboration. Comput. Ind. 2022, 138, 103623. [Google Scholar] [CrossRef]

- Nayernia, H.; Bahemia, H.; Papagiannidis, S. A systematic review of the implementation of industry 4.0 from the organisational perspective. Int. J. Prod. Res. 2022, 60, 4365–4396. [Google Scholar] [CrossRef]

- Qian, X.; Chen, M.; Zhao, F.; Ling, H. An assessment framework of global smart cities for sustainable development in a post-pandemic era. Cities 2024, 150, 104990. [Google Scholar] [CrossRef]

- Wu, P.; Zhang, Z.; Peng, X.; Wang, R. Deep learning solutions for smart city challenges in urban development. Sci. Rep. 2024, 14, 5176. [Google Scholar] [CrossRef]

- Dixit, A.; Shaw, R. Smart Cities in Nepal: The concept, evolution and emerging patterns. Urban. Gov. 2023, 3, 211–218. [Google Scholar] [CrossRef]

- Reddy, P.D.K.; Margala, M.; Shankar, S.S.; Chakrabarti, P. Early fire danger monitoring system in smart cities using optimization-based deep learning techniques with artificial intelligence. J. Reliab. Intell. Environ. 2024, 10, 197–210. [Google Scholar] [CrossRef]

- Kaur, P.; Kaur, K.; Singh, K.; Kim, S.K. Early Forest Fire Detection Using a Protocol for Energy-Efficient Clustering with Weighted-Based Optimization in Wireless Sensor Networks. Appl. Sci. 2023, 13, 3048. [Google Scholar] [CrossRef]

- Maraveas, C.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G. Applications of artificial intelligence in fire safety of agricultural structures. Appl. Sci. 2021, 11, 7716. [Google Scholar] [CrossRef]

- Vatan, E.; Ardali, G.A.R.; Shahin, A. Selecting information systems development models based on organizational culture: An integrated approach of DEMATEL and ANP. VINE J. Inf. Knowl. Manag. Syst. 2022, 54, 531–560. [Google Scholar] [CrossRef]

- Almeida, F.; Simões, J.; Lopes, S. Exploring the Benefits of Combining DevOps and Agile. Future Internet 2022, 14, 63. [Google Scholar] [CrossRef]

- Teixeira, L.; Xambre, A.R.; Figueiredo, J.; Alvelos, H. Analysis and Design of a Project Management Information System: Practical Case in a Consulting Company. Procedia Comput. Sci. 2016, 100, 171–178. [Google Scholar] [CrossRef]

- Martikainen, S.; Kaipio, J.; Lääveri, T. End-user participation in health information systems (HIS) development: Physicians’ and nurses’ experiences. Int. J. Med. Inf. 2020, 137, 104117. [Google Scholar] [CrossRef]

- Zaki, T.; Islam, M.N.; Zaki, T. Neurological and physiological measures to evaluate the usability and user-experience (UX) of information systems: A systematic literature review. Comput. Sci. Rev. 2021, 40, 100375. [Google Scholar] [CrossRef]

- Kose, B.O. Business process management approach for improving agile software process and agile maturity. J. Softw. Evol. Process 2021, 33, e2331. [Google Scholar] [CrossRef]

- Guzmán-Bello, H.; López-Díaz, I.; Aybar-Mejía, M.; de Frias, J.A. A Review of Trends in the Energy Use of Biomass: The Case of the Dominican Republic. Sustainability 2022, 14, 3868. [Google Scholar] [CrossRef]

- Girona-García, A.; Cretella, C.; Fernández, C.; Robichaud, P.R.; Vieira, D.C.S.; Keizer, J.J. How much does it cost to mitigate soil erosion after wildfires? J. Environ. Manag. 2023, 334, 117478. [Google Scholar] [CrossRef]

- Karnik, N.; Bora, U.; Bhadri, K.; Kadambi, P.; Dhatrak, P. A comprehensive study on current and future trends towards the characteristics and enablers of industry 4.0. J. Ind. Inf. Integr. 2022, 27, 100294. [Google Scholar] [CrossRef]

- Leviäkangas, P.; Sønvisen, S.; Casado-Mansilla, D.; Mikalsen, M.; Cimmino, A.; Drosou, A.; Hussain, S. Towards smart, digitalised rural regions and communities—Policies, best practices and case studies. Technol. Soc. 2025, 81, 102824. [Google Scholar] [CrossRef]

- Alabdali, S.A.; Pileggi, S.F.; Cetindamar, D. Influential Factors, Enablers, and Barriers to Adopting Smart Technology in Rural Regions: A Literature Review. Sustainability 2023, 15, 7908. [Google Scholar] [CrossRef]

- Fernández, C.G.; Peek, D. Connecting the Smart Village: A Switch towards Smart and Sustainable Rural-Urban Linkages in Spain. Land 2023, 12, 822. [Google Scholar] [CrossRef]

| Actor | Description | Specific Requirements |

|---|---|---|

| Producer | The owner of the biomass, whether it is land in need of fuel management activities or biomass that has already been cut. | - Insert leftovers registration; - Visualize financial transaction data; - Visualize the intermediary services; - Require fuel management services, specifying the service needs (cutting operations and/or leftovers collection); - Require management entity (ME) help when no intermediaries. |

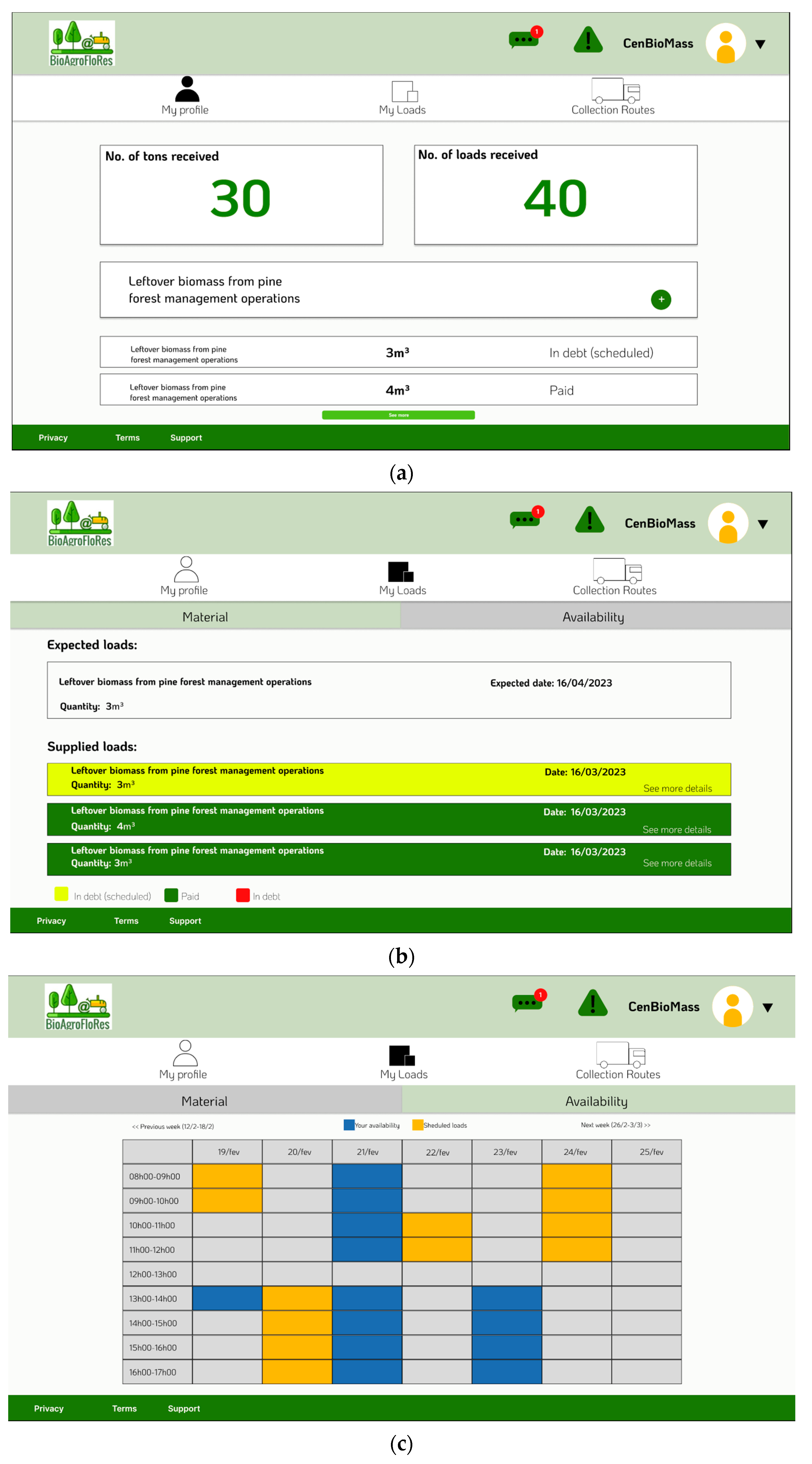

| Intermediary | Responsible for agricultural and fuel management activities. Can also carry out pre-treatment or transportation activities. | - Communicate the service that they provide (vegetation cutting, leftovers collection, land conditions to carry out operations); - Visualize services (future and history). |

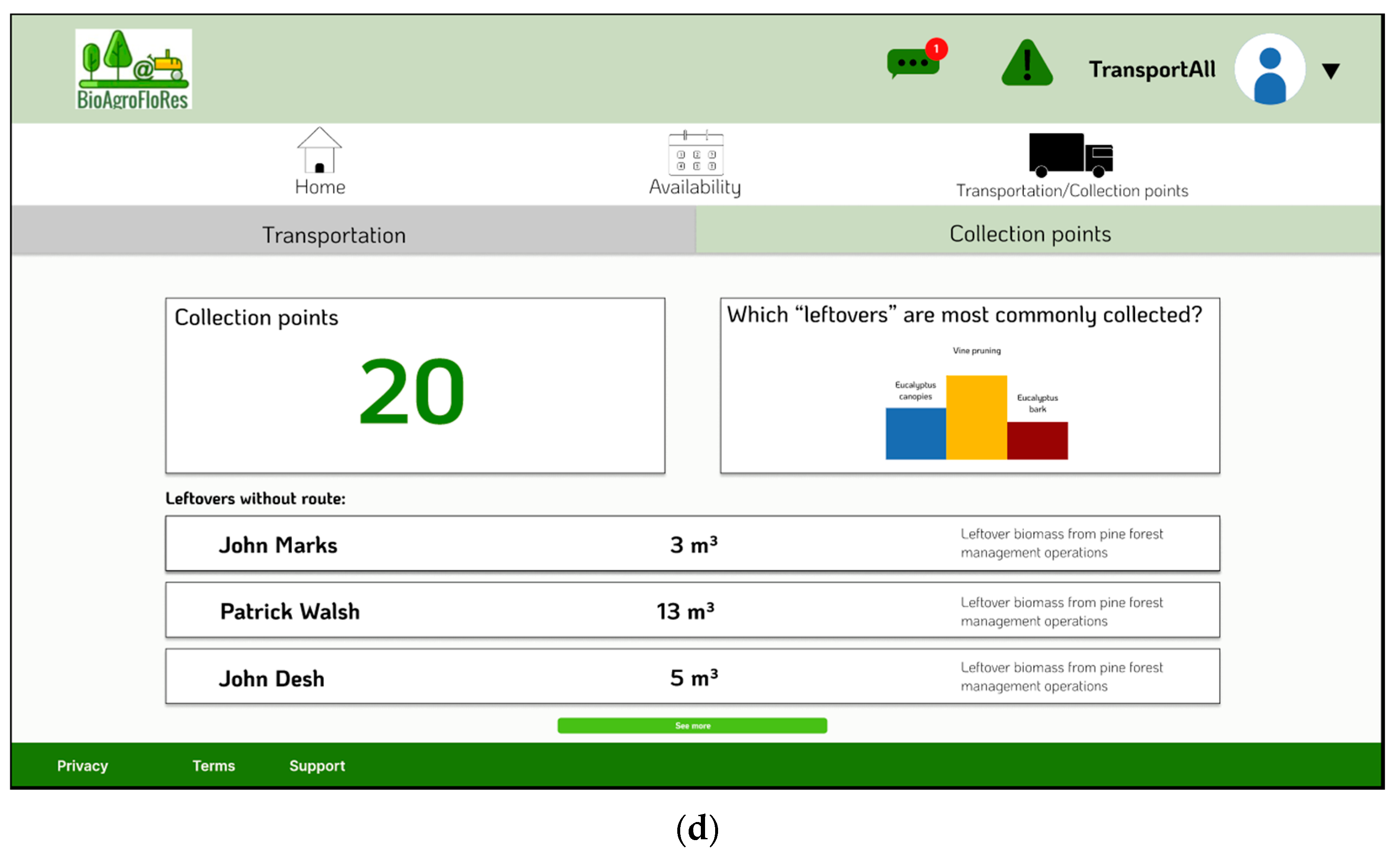

| Transporter | It ensures the transportation of leftovers from the place of harvest to the place of destination and can incorporate just one or several producers. | - Visualize indicators; - Visualize the collection routes (future and already executed); - Communicate the collection availability window; - Communicate the transport type (capacity, fuel usage…); - Visualize collection points. |

| End Consumer | Final actor in the chain, they receive the biomass. This can be of various natures, from biomass plants to pellet industries. | - Communicate the leftovers that they want; - Visualize loads (future and history); - Communicate the reception availability window; - Visualize the collection routes (future and already executed); - Communicate the collection availability window; - Communicate the transport type (capacity, fuel usage…); - Visualize collection points. |

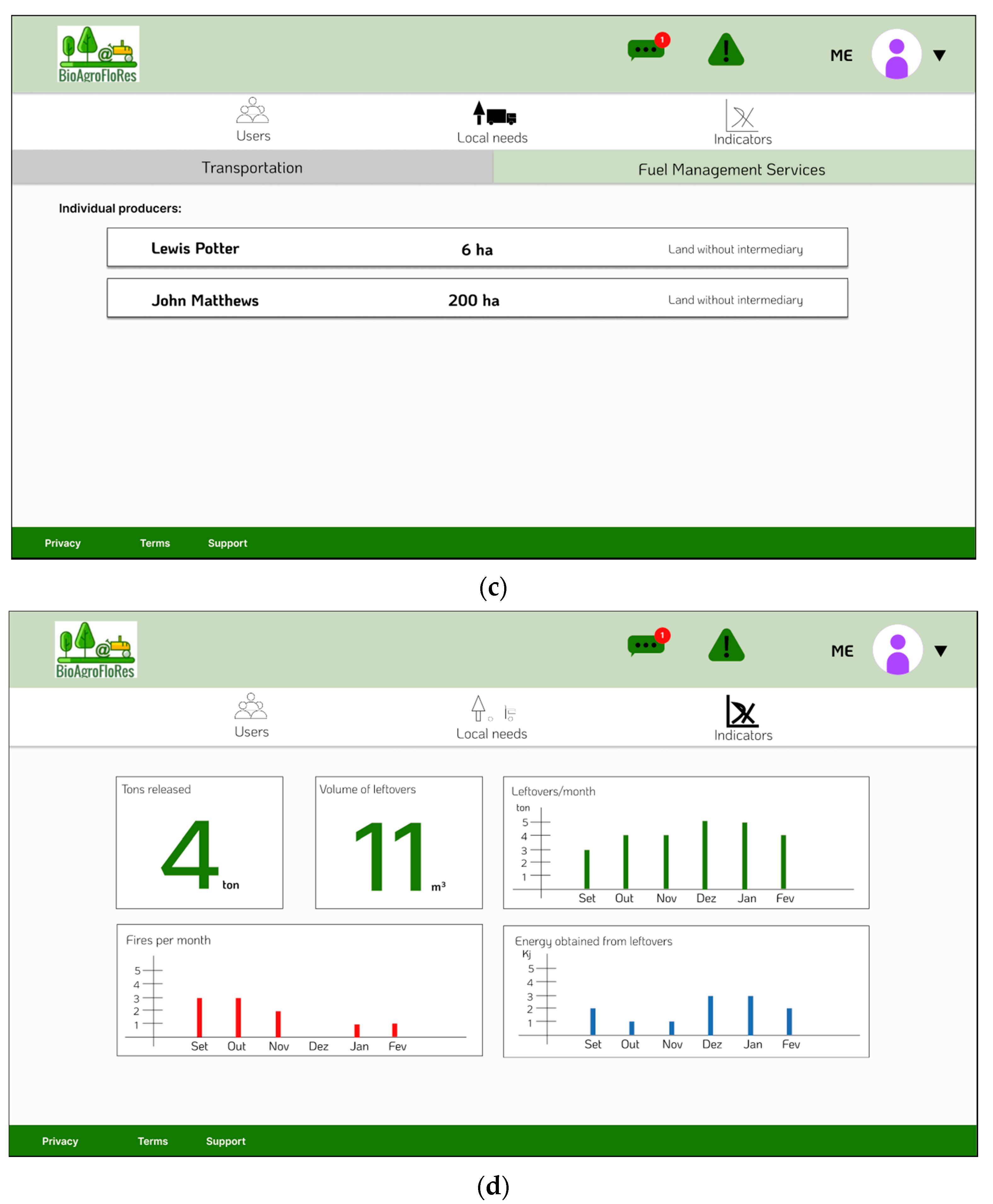

| Management Entity | Entity that manages the entire model (platform and leftovers recovery model), it also functions as a reactive entity, responsible for acting in the absence of actors, ensuring fuel management or transportation activities. It should be noted that this actor is reactive and should not create any kind of unfair competition with other actors. | - Visualize the local town needs (transportation and fuel management operations); - Add/validate new users; - Insert leftovers registration from producers that have no access. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastos, T.; Nunes, L.J.R.; Teixeira, L. Smart Residual Biomass Supply Chain: A Digital Tool to Boost Energy Potential Recovery and Mitigate Rural Fire Risk. Sustainability 2025, 17, 7863. https://doi.org/10.3390/su17177863

Bastos T, Nunes LJR, Teixeira L. Smart Residual Biomass Supply Chain: A Digital Tool to Boost Energy Potential Recovery and Mitigate Rural Fire Risk. Sustainability. 2025; 17(17):7863. https://doi.org/10.3390/su17177863

Chicago/Turabian StyleBastos, Tiago, Leonel J. R. Nunes, and Leonor Teixeira. 2025. "Smart Residual Biomass Supply Chain: A Digital Tool to Boost Energy Potential Recovery and Mitigate Rural Fire Risk" Sustainability 17, no. 17: 7863. https://doi.org/10.3390/su17177863

APA StyleBastos, T., Nunes, L. J. R., & Teixeira, L. (2025). Smart Residual Biomass Supply Chain: A Digital Tool to Boost Energy Potential Recovery and Mitigate Rural Fire Risk. Sustainability, 17(17), 7863. https://doi.org/10.3390/su17177863