1. Introduction

In the context of freight transport, the term “transportation components” refers to the set of customer needs that are satisfied through the application of satellite monitoring systems within the business processes of a transport company or logistics provider. The quality of transportation services is a critical attribute of transport systems, as it directly influences both customer satisfaction and overall industry performance. Previous research have shown that the concept of transportation service quality is highly complex and multidimensional. It encompasses a broad spectrum of indicators, such as reliability, speed, comfort and safety and relies on a combination of objective performance data and subjective customer assessments [

1]. However, existing methodologies often fail to fully capture this multidimensionality, especially when it comes to simultaneously considering technical, operational and customer-perceived quality factors.

Recent studies highlight the rapid expansion of multi-criteria decision-making (MCDM) methods across various industries, underlining their universality for complex decisions. For example, a review of machine selection problems in manufacturing and construction found a notable rise in MCDM-based decision support tools over 2017–2022, helping managers choose equipment by evaluating technical, economic and ergonomic criteria [

2]. Similarly, a comprehensive literature review of sustainable supplier selection for 2018–2022 confirmed that methods like TOPSIS, AHP, VIKOR and hybrid fuzzy models are now standard for simultaneously considering environmental, social and economic factors in supply chain decisions [

3]. These findings emphasize that multi-criteria frameworks have become key instruments for informed managerial decisions in logistics and production.

Recent work increasingly couples multi-criteria decision methods with the UN SDGs, with SDG 9 (industry, innovation and infrastructure) a central target [

4]. Valipour et al. (2020) embed SDG criteria in a material selection MCDM and show that SDG 9 dominates construction priorities [

5]. Brodny and Tutak (2023) combine CoCoSo, CODAS and entropy weighting to rank Polish regions on SDG 9 using 19 indicators [

6]. These studies indicate that aligning decision models with SDG targets links operational gains to resilient infrastructure and innovation [

4]. In logistics, a transport-service quality evaluation can thus serve both as a management instrument and as a contributor to SDG 9.

A systematic evaluation of transport service quality enables more efficient use of resources. Transport management systems with logistics monitoring reveal bottlenecks and cut delays, losses or damage [

7]. Route analytics and vehicle performance tracking optimize flows and schedules, lowering empty mileage, fuel use, maintenance costs and labor [

7]. These gains reduce operating expenditure and support corporate sustainability by curbing emissions and avoiding unnecessary trips, consistent with global environmental and energy efficiency goals [

8]. Thus, quality assessment serves not only as a technical control but as a managerial tool for achieving strategic and operational targets. Based on the analysis carried out within this study, the following requirements have been identified as the most important criteria that a transport monitoring system must satisfy from the perspective of transport stakeholders:

Monitoring the timeliness of cargo delivery to the customer or service requestor.

Planning and monitoring delivery route execution (plan vs. actual analysis).

Reducing costs associated with unproductive trips (deadhead miles) and excessive fuel consumption.

Enhancing cargo transport safety.

Enabling rapid response to abnormal or emergency situations.

In recent years, logistics service quality has been assessed not only by traditional performance metrics but within the triple bottom line, combining economic, environmental and social criteria. Accordingly, CO

2 emissions, energy efficiency, environmental impact and workplace safety are weighed alongside cost and delivery speed. Recent studies embed sustainability within MCDM models. For example, a 3PL evaluation fuses economic and environmental indicators into a single ranking [

9] and a multi-plane MCDM framework for freight routing that builds a five-level hierarchy of transport needs (geographical, economic, institutional, infrastructural, technological) and evaluates alternatives via a Petri net model [

10]. Such approaches let decision makers judge routes beyond cost and time to include environmental and policy constraints, aligning choices with sustainable logistics goals. However, most work remains conceptual and does not provide practical tools that integrate all three pillars simultaneously into transport quality assessments, leaving a clear gap for further development.

Another important direction for improving logistics service quality lies in enhancing energy efficiency and operational stability. In study [

11], the authors examined the use of both onboard and stationary energy storage systems to improve the energy efficiency and stability of urban electric transport networks. The analysis demonstrated significant reductions in peak loads, improved power supply stability and achieved overall energy savings through the introduction of energy storage technologies. The researchers emphasized the potential of these systems under real-world operational scenarios for urban public transport. However, their focus remained primarily on the technical and energy aspects, while the integral evaluation of passenger service quality and transport process efficiency was left largely unaddressed.

To assess transport service quality and monitor transportation efficiency comprehensively, a holistic approach is required—one that couples customer-oriented quality criteria with the economic benefits of satellite-based logistics monitoring. A recent study [

12] illustrates this logic by combining AHP with social cost–benefit analysis for urban freight initiatives: expert judgments rank city-logistics options (e.g., consolidation centers, alternative delivery modes) via multi-criteria scoring, after which the best candidates are appraised for financial and external costs. This dual scheme yields a decision basis that aligns strategic sustainability aims with demonstrated economic viability, offering managers and policymakers a practical framework for balanced planning.

Among the multi-criteria decision-making (MCDM) techniques widely used in the transport sector, the analytic hierarchy process (AHP) remains one of the most popular. Numerous researchers have applied AHP to rank alternatives and determine strategic priorities in transport system development. For instance, AHP has been utilized to assess the service quality of public transport networks, focusing on prioritizing comfort and accessibility criteria [

13]. The main advantage of AHP lies in its structured pairwise comparison methodology, which allows for expert judgment to be incorporated into the decision-making process for optimal logistics solutions. Nevertheless, traditional AHP does not adequately account for uncertainty and inconsistency in expert assessments, which limits its applicability when input data are imprecise or fuzzy.

Uncertainty and subjectivity in transport service quality have driven the growing use of fuzzy methods. Fuzzy TOPSIS, in particular, has been applied to public transport by mapping key dimensions (accessibility, safety, information) to fuzzy scores and ranking alternatives, effectively incorporating passenger perceptions into an integrated quality index [

14]. Yet these methods demand careful design of membership functions and rules and they seldom embed detailed economic performance metrics, leaving a gap between qualitative user judgments and quantitative operational efficiency.

A valuable contribution to the development of multi-criteria analysis methods was made in study [

15], where the authors proposed integrating failure mode, effects and criticality analysis (FMEA/FMECA) with MCDM techniques. The authors developed a hybrid methodology that uses risk identification to set priorities for corrective actions by applying AHP, TOPSIS and other decision-making tools. The approach was successfully validated in manufacturing environments, where it proved effective for enhancing the reliability of technical systems and minimizing operational risks. However, the methodology has only been tested under manufacturing conditions and has not yet been adapted to the specific requirements of transport and logistics systems, thereby presenting opportunities for further research aimed at applying this hybrid model for the assessment of transport service reliability and quality.

Hybrid decision frameworks are increasingly used to raise assessment accuracy across diverse criteria. Studies integrate fuzzy AHP with optimization or ranking, leveraging complementary strengths [

13]. A recent line of work proposes a magnitude-based fuzzy AHP for sustainable transport, combining expert pairwise judgments with fuzzy scores and deviation-sensitive weighting; the approach reports high accuracy and stable rankings for urban mobility scenarios [

10,

16]. Another study fuses fault tree analysis with interval-valued Pythagorean fuzzy AHP and fuzzy DEMATEL to support safety maintenance in public transit, isolating the failure modes and components with the greatest reliability impact and yielding prioritized actions for managers [

17]. While such hybrids improve robustness and decision relevance, they raise computational burden and data demands and remain scarce in day-to-day transport management, underscoring the need for simpler practice-ready adaptations.

Advances in IoT have greatly expanded logistics monitoring, with sensors and trackers streaming real-time data on cargo status, vehicle health and schedule adherence [

18]. Yet, using these data for comprehensive quality assessment remains difficult, as legacy models are static while logistics data are continuous and time-varying. Recent work proposes dynamic schemes that update a transport quality index in real time from sensor inputs [

19]. One study integrates MCDM decision support into an intelligent IT stack for multimodal freight, enabling online evaluation of intermodal corridors between Eastern and Western Europe on efficiency and sustainability using live context data [

20]. These approaches couple AI and machine learning with multi-criteria logic to adapt weights as operating conditions change, giving dispatchers actionable guidance such as automatic re-routing. However, no universal methodology has yet been established to integrate real-time logistics monitoring data with multi-criteria decision-making frameworks for operational decision support. This lack of integration represents a critical gap in both scientific research and practical applications.

The literature analysis confirms the existence of a wide variety of methods and approaches for evaluating transport and logistics service quality, ranging from classic customer satisfaction surveys to complex hybrid algorithms [

21]. Each method contributes to the understanding of specific aspects of quality or efficiency; some focus on technical parameters [

22], others emphasize customer perceptions, while yet others incorporate sustainability dimensions or leverage real-time data. Nevertheless, there remains an urgent need for an integrated methodology capable of consolidating these disparate dimensions into a unified quality assessment framework. In particular, the development of an assessment model that simultaneously addresses heterogeneous criteria (technical, economic, social), uncertainty and subjectivity of expert evaluations and dynamic monitoring data remains unresolved. Consequently, there is a clearly identified gap in the current body of research: the absence of a holistic approach combining multi-criteria decision analysis, fuzzy logic and digital real-time monitoring for the comprehensive evaluation of transport service quality. The present study aims to address this gap.

One of the promising approaches for developing an integrated transport quality indicator is the use of Harrington’s desirability function, which allows for the quantitative evaluation of customer satisfaction across various aspects of the transport process by incorporating both subjective customer requirements and objective operational indicators [

23]. The method transforms individual quality attributes—such as timeliness, cost-efficiency, safety and others—into a single dimensionless metric that reflects the overall desirability of the outcome from the customer’s perspective. This provides a flexible framework for assessing the quality of transport processes, enabling the assignment of weights to individual indicators according to their relative importance to the customer.

The primary objective of this study is to perform a comprehensive evaluation of the transport service quality provided by transportation companies, firms and logistics providers through the use of logistics monitoring systems and the application of Harrington’s desirability function. It allows to apply the desirability function methodology to the evaluation of transport service quality with an emphasis on strategic planning and sustainable development.

To accomplish this objective, the following tasks were set:

- –

To define the system of quality indicators for transport services under logistics monitoring conditions;

- –

To establish the relationship between the partial desirability functions and the controllable quality parameters of transport service provision by companies and providers;

- –

To conduct a customer survey using logistics monitoring data of freight transport services;

- –

To provide an integrated assessment of transport service quality based on logistics monitoring and the Harrington desirability function;

- –

To develop an algorithm for automating the evaluation process of transport service quality.

In order to clarify the focus of this work, the key research questions were formulated. These research questions guided this work’s methodology and analyses, ensuring a focused investigation into developing an integrated sustainability-oriented transport service quality evaluation tool. The questions are as follows:

- –

Which core quality indicators of transport service can be effectively monitored and quantified using a logistics tracking system to reflect both customer satisfaction and operational efficiency?

- –

How can Harrington’s desirability function be applied to integrate these multiple indicators into a single comprehensive service quality index at the enterprise level?

- –

To what extent can the proposed desirability-based index inform managerial decisions and align transport service improvements with sustainable development objectives?

2. Materials and Methods

In current freight transportation practices, the service provision process can be logically divided into six key stages.

At the first stage, the core set of service provision indicators is formulated by experts from relevant professional fields, based on research into baseline customer needs and accumulated experience in positioning logistics monitoring systems [

24]. Typically, in the context of transport service provision, this set consists of five key indicators or criteria. A smaller number would not fully capture the customer requirements addressed by the process, while a larger number would lead to excessive complexity and dilution of indicator relevance.

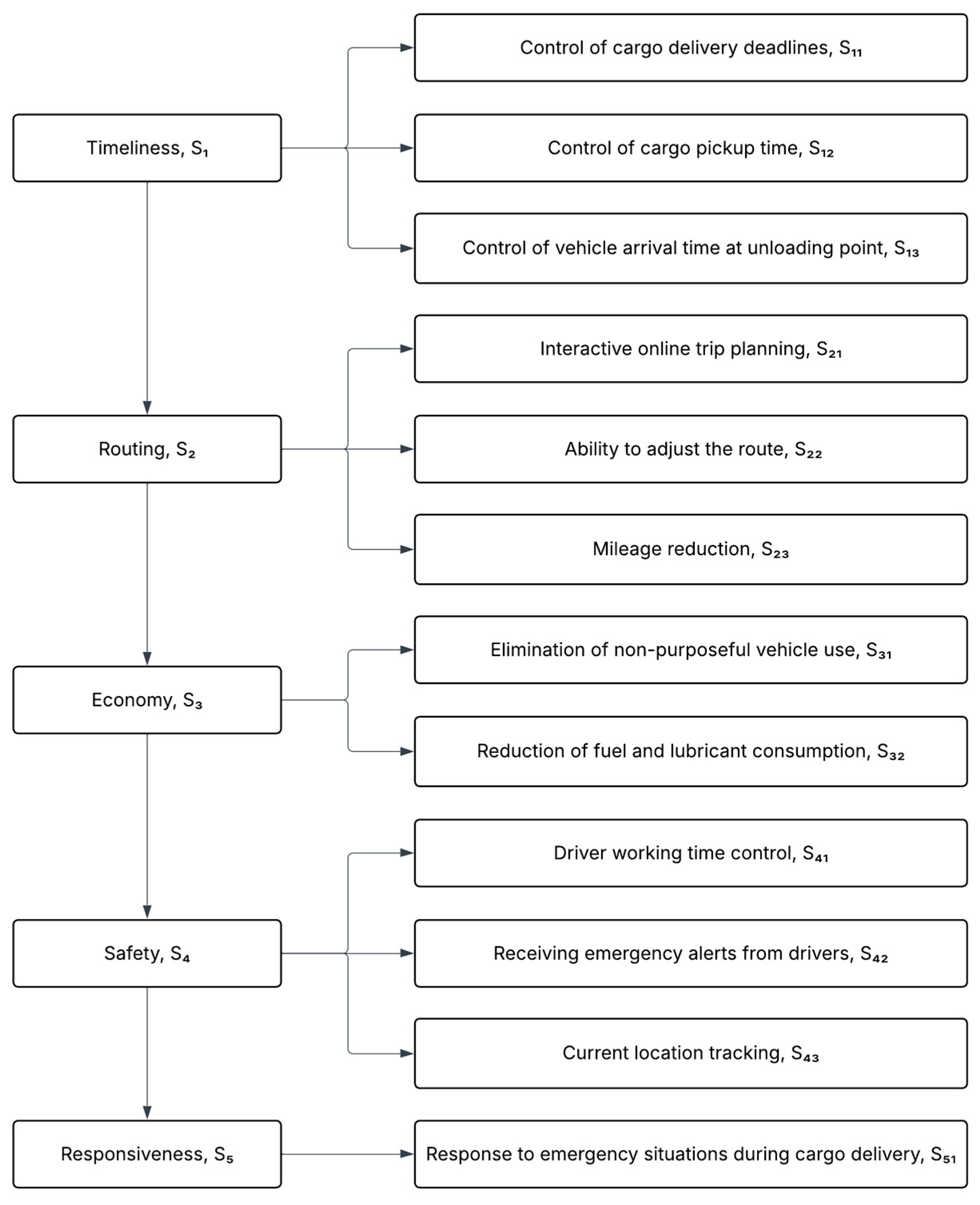

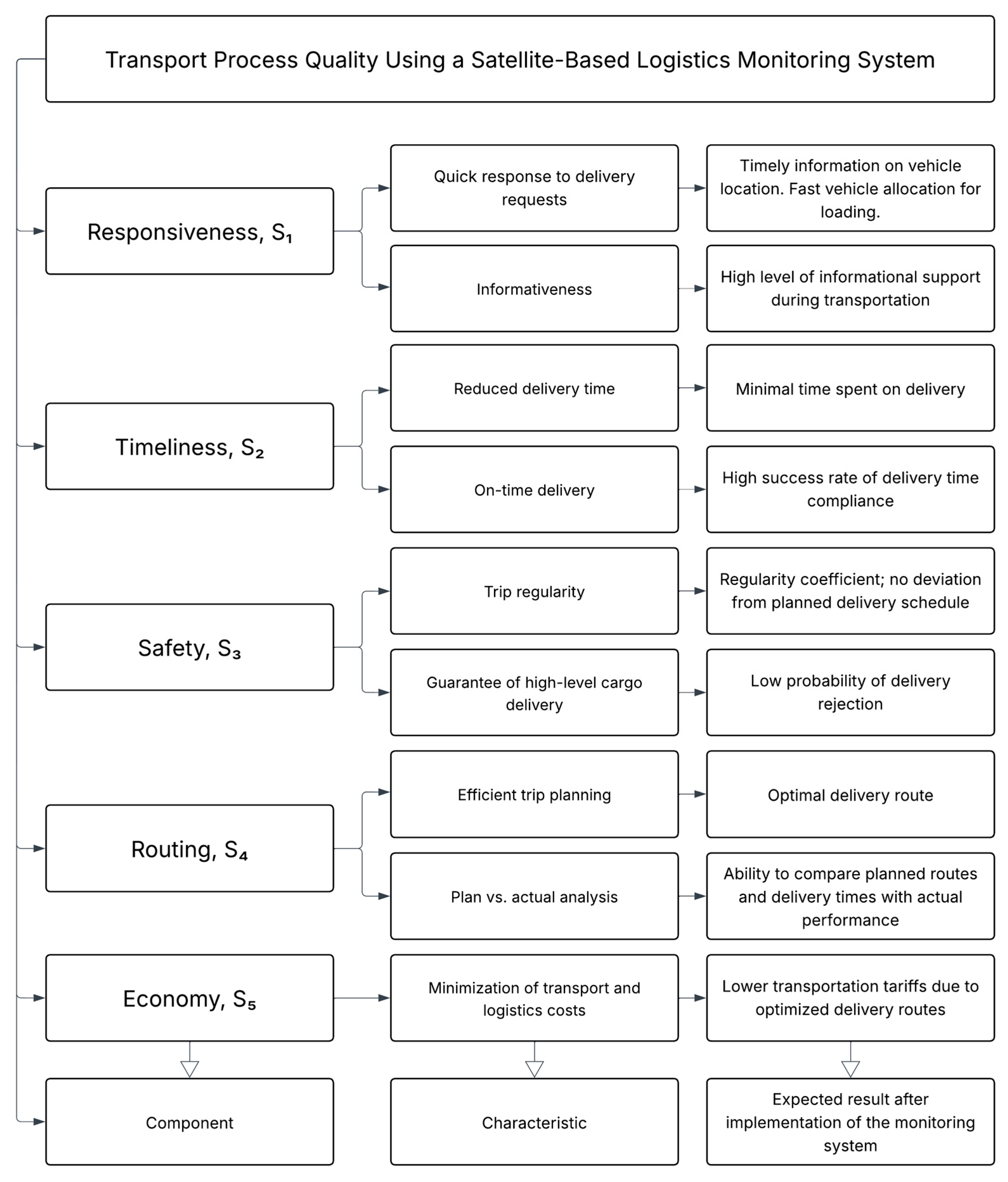

For simplicity and brevity, the quality indicators for the transport process are symbolically designated as follows:

S1—timeliness;

S2—routing;

S3—cost efficiency;

S4—safety;

S5—responsiveness (

Table 1).

The five indicators reflect widely accepted dimensions of transport service quality and logistics performance. Timeliness and routing capture reliability and process efficiency that directly shape customer satisfaction and resource use [

1]. Cost efficiency reflects economic viability at the firm level and is standard in logistics KPI frameworks. Safety is a non-substitutable quality dimension with demonstrable managerial relevance in freight operations. Responsiveness measures the system’s ability to detect and resolve disruptions, a capability repeatedly emphasized in MCDM-based logistics assessments as a determinant of competitiveness [

7]. Together these indicators balance customer-perceived and operational criteria while keeping the model tractable for managerial use.

Each quality indicator of the road transport process consists of sub-components that characterize its essence at a more detailed level. Based on the structure of these indicators, they can be represented as a hierarchical tree structure (

Figure 1).

In the second stage, the focus is on determining consumer perceptions of the core quality indicators related to the provision of transport services using satellite-based logistics remote monitoring of road vehicles.

To assess the constituent components of the transportation process through online vehicle tracking, survey data from potential customers are used [

25]. Based on the previously defined transport service quality indicators—namely timeliness, routing, cost efficiency, safety and responsiveness—a structured customer survey is designed. The survey serves the following two main purposes:

To determine the weight (importance) of each transport service quality indicator (freight transportation) when provided under logistics monitoring conditions from the perspective of the potential customer;

To capture the customer’s assessment of each quality indicator of the monitored process using a four-point differential scale.

The survey process begins by asking respondents to evaluate the relative importance of the parameters of the freight transport process, as well as the degree of performance of these quality indicators when using a logistics monitoring system [

26]. The survey is conducted following the completion of the customer’s cargo transport operation performed by road transport under logistics monitoring.

Once preliminary data sorting has been conducted according to identified customer segments, the datasets are then processed and analyzed. The overall database is divided into separate arrays corresponding to the number of customer segments j. Each of these data arrays, which represent distinct market segments, is then processed individually. Data accumulation and analysis are carried out based on a predefined computational framework.

The third stage involves the assignment of relative weights to the constituent elements of the transport process monitored by the logistics system [

27]. This is accomplished by converting the raw database values into normalized weights for each quality indicator. The process typically involves summing values across defined fields, followed by data normalization for each customer segment. This procedure allows for the determination of the relative importance (weight) of individual transport process components as perceived by consumers. The resulting distribution of weights provides valuable insights for management decision making regarding the potential need to strengthen specific quality components in subsequent freight transport orders involving GPS tracking systems [

28]. Thus, the third stage facilitates the systematization and analysis of customer feedback data to enable more efficient implementation and continuous improvement of transport processes through the use of monitoring technologies.

In the fourth stage, customer satisfaction levels regarding the quality indicators of the transportation process and the overall performance of road freight delivery using a logistics monitoring system are assessed.

At this point, it is important to highlight the specific challenges associated with evaluating the quality of transportation processes when monitoring technologies are applied. These challenges are as follows:

The transportation process does not represent a tangible industrial product, which makes its quality difficult to assess directly;

The quality-defining attributes must be relevant and meaningful, primarily from the perspective of the customer who uses transport monitoring as part of a transport company’s business processes;

Quality is not an absolute parameter and therefore must be interpreted relative to individual customer requirements and expectations. As a result, the assessment of transport quality through satellite monitoring effectively becomes a comparison between customer expectations and actual service performance;

The concept of transport service quality inherently involves meeting customer requirements and expectations at the time-of-service provision.

To facilitate a comprehensive assessment of the transport process when using vehicle monitoring technologies, a composite transport quality indicator is proposed. This integrated metric serves as a tool for monitoring the performance and quality of the transportation process (Equation (1)).

where

Si are the transport process quality indicators (responsiveness, timeliness, safety, cost efficiency and routing);

ki are the weight coefficients corresponding to the quality indicators.

Customer satisfaction with the individual components of transportation, monitored using an online vehicle tracking system, is calculated based on an existing dataset. The calculation process mirrors the weight assignment approach: data are grouped into corresponding columns (to distinguish core components such as safety, cost efficiency, timeliness, responsiveness and routing, denoted as m1, m2, …, m5). The recalculated values are then expressed using a visual comparison scale ranging from 0 to 5 points.

The constituent elements of the transportation process under logistics monitoring (designated as Cij) can be systematically analyzed to assess which components have been successfully implemented during the design and operation of the transport service.

The fourth stage thus enables a comprehensive analysis of customer satisfaction with the individual components of the transportation process under logistics monitoring. It includes the assessment of each component’s contribution to the overall delivery system performance. The results of this analysis provide valuable insights into how each quality indicator impacts customer satisfaction and help identify opportunities to improve the transport process in order to ensure the optimal quality of transport services.

The concept of customer satisfaction with transport services under a logistics monitoring system is expressed by a composite parameter referred to as the consumer satisfaction criterion. It is calculated using the following weighted summation Equation (2):

where

C is the consumer satisfaction criterion (CSC);

is the weight of the

ij-th transport service quality indicator under the logistics monitoring system;

Cij is the satisfaction rating for the

ij-th indicator of the monitored transportation process.

In the analysis of the consumer satisfaction criterion (CSC), it is logical to compare its value with the performance of competing firms or to track its changes over time. The CSC itself is a relative benchmarking indicator and does not carry standalone meaning. Instead, it provides a basis for ranking the transportation process efficiency of different companies and logistics providers using satellite monitoring systems within the competitive landscape. Furthermore, it offers a means to assess how effectively management has influenced process outcomes through the system of transport service quality indicators proposed in this study.

The comparison of CSC values within the framework of additional benefits delivered to clients through satellite-monitored transport services is performed by establishing ranking positions. This ranking allows for the identification of the most advantageous market segments for promoting freight transport services incorporating satellite-based logistics monitoring systems.

Accordingly, the primary criterion for such a market positioning is the level of customer satisfaction achieved within a given segment of the transport process under satellite monitoring conditions. Identifying the segment that maximizes customer satisfaction (denoted as CSCmax) enables companies to optimize their service offerings and improve competitiveness within the marketplace.

During the fifth stage, the transport process components that require improvement or redesign are identified based on the developed comprehensive transport process evaluation methodology. If the calculated CSC value for a company is lower than the CSC value of a competing firm (CSC < CSCk), it indicates the need for adjustments or enhancements to improve customer-perceived service attributes within the monitored transportation process.

To identify those elements of transport quality within the satellite monitoring system that require the greatest focus for improvement, it is necessary to isolate those attributes associated with the minimum CSC values (Cij, where C1 = min) and the maximum assigned weight . This combination indicates that process components with the lowest satisfaction scores and high importance weights demand the most urgent refinement.

To calculate the adjustment or modernization coefficient for consumer service attributes, an equation that incorporates both of these variables can be applied. Specifically, the higher the importance weight of a component , the lower the tolerance for underperformance. Similarly, the higher the corresponding CSC score Cij, the lower the need for adjustment. This principle reflects the notion that transport service quality indicators that already meet high customer satisfaction thresholds require minimal intervention or redesign.

Thus, at the fifth stage, it is essential to regularly assess and analyze individual components of the transport service quality framework in order to determine which attributes of the transportation process require modification. This ensures that the quality of customer service under logistics monitoring conditions is continually enhanced to meet evolving customer expectations.

The necessity for the adjustment of transport service quality indicators is determined using the following Equation (3):

where

NCCij is the priority (or necessity) coefficient for adjusting the

ij-th component of the transportation process under satellite monitoring conditions;

C is the overall consumer satisfaction criterion;

Cij is the consumer satisfaction score for the individual component.

In the sixth stage, the effectiveness of the adjustment measures for transport process components is evaluated using the logistics monitoring system. Following the implementation of modifications to individual components of the transport process, a repeated analysis is conducted to assess the quality indicators and determine the effectiveness of the corrective actions for further refinements. The effectiveness coefficient is defined as follows (Equation (4)):

where

Ec is the effectiveness of the correction measures;

C is the initial value of the consumer satisfaction criterion before correction;

C′ is the alue of the consumer satisfaction criterion after the correction has been applied.

The next logical step in improving the methodology for evaluating transport service quality is the application of the Harrington desirability function scale. This approach converts quantitative or qualitative indicator values into a single unified metric that reflects the level of desirability or user satisfaction with the transport service outcome from the customer’s point of view [

29]. The Harrington desirability function has two principal types of dependencies, depending on whether the criterion is considered a “larger is better” or “target is best” type. The desirability function with a one-sided limit applies in cases where desirability sharply increases after surpassing a defined threshold. The constraint system for this function type is expressed as follows (Equation (5)):

The equation for the partial desirability function with a one-sided limit can also take the form of an exponential relationship that allows smooth transition between minimum and maximum desirability values (Equation (6)):

where

is the partial desirability function indicating the acceptance or desirability level of criterion value

y;

y’ is the caled value of the criterion calculated as follows (Equation (7)):

where

b0 and

b1 are linear function coefficients determined to ensure proper scaling and transformation of the criterion value y into the corresponding desirability level.

The desirability function with two-sided limits applies when a criterion is optimal within a specific range and gradually decreases outside of this range. This relationship is expressed as follows (Equation (8)):

The equation for the desirability function with two-sided limits is expressed as follows (Equation (9)):

To calculate the scaled parameter

y′ the following Equation (10) is used:

The indicator

n, denoting the degree of desirability, can be calculated by setting a given value of y and obtaining the corresponding desirability level from the “good” or “very good” range of the desirability scale (Equation (11)):

The generalized desirability function

D is used to evaluate the overall quality of a process or object involving multiple criteria, each of which is assessed using partial desirability functions. It combines individual desirability measures (partial functions) for separate criteria into a single metric, providing a comprehensive assessment of the process. The equation for calculating the generalized desirability function is (Equation (12)):

where

n is the number of criteria;

dn is the partial desirability functions for individual criteria;

are the weighting coefficients reflecting the relative importance of individual criteria.

The proposed methodology is designed not only for theoretical research but also as a practical tool to support decision making for freight transportation companies. Using a logistics monitoring system and multi-criteria transport quality evaluation model, managers can obtain real-time service quality assessments, identify problem areas and take timely corrective actions [

30]. This approach integrates business intelligence tools, which are widely used in modern transportation and logistics systems [

31]. Logistics monitoring systems, as applied in this research, structure the data flow according to key criteria such as timeliness, route optimization, trip cost efficiency, transport safety and operational responsiveness. The collected data are transformed into partial desirability functions, which allows the creation of an integrated transport quality index, serving as a universal metric for management decision making.

In designing this evaluation framework, we also note its alignment with SDG 9 (industry, innovation and infrastructure). The systematic improvement of transport service quality via logistics monitoring and multi-criteria analysis exemplifies how innovative management practices can enhance infrastructure reliability and efficiency in freight transport. By converting raw performance data into actionable insights, the method provides a data-driven approach for strengthening operational infrastructure, directly supporting SDG 9’s aims of promoting sustainable industrialization and fostering innovation in logistics.

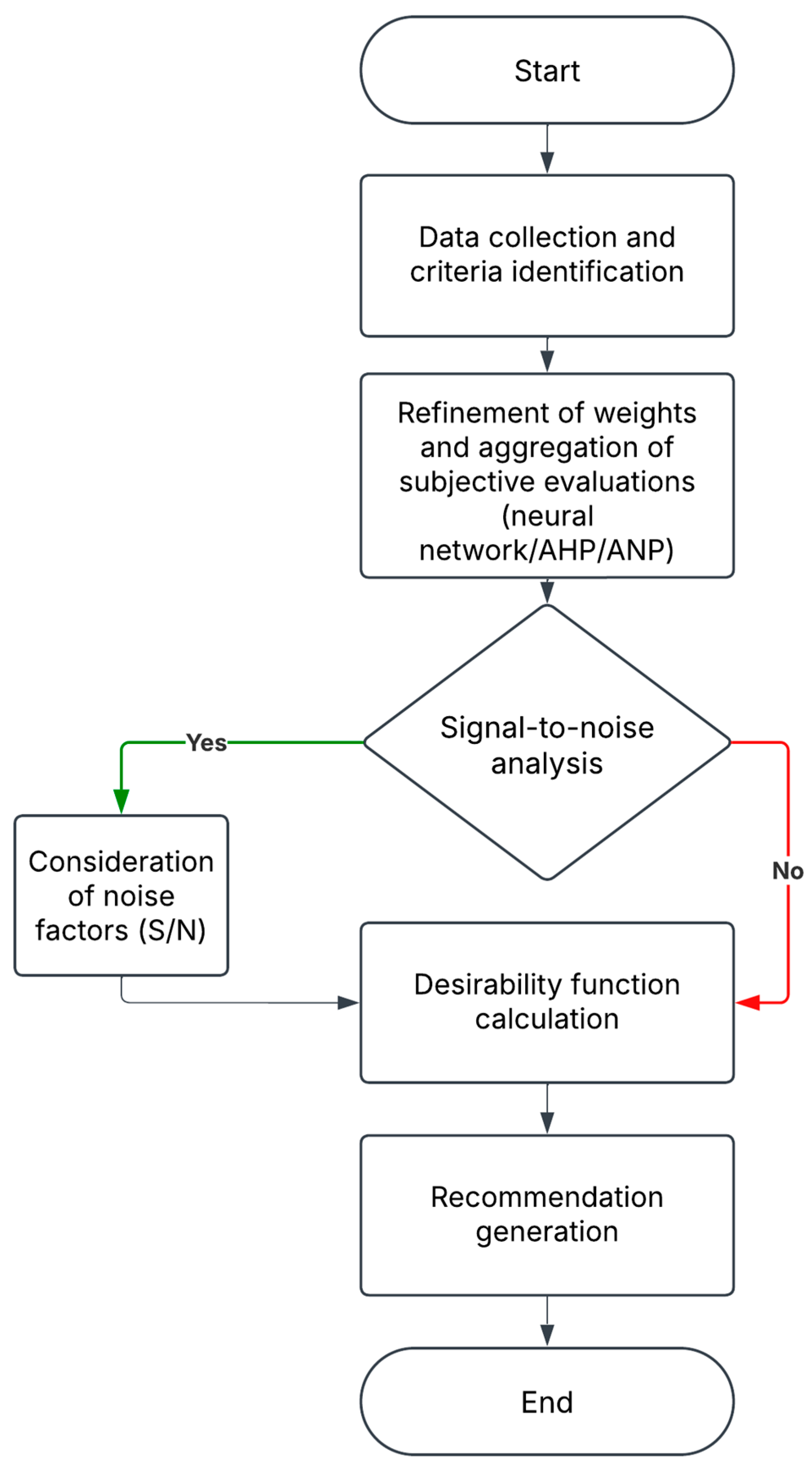

An important direction for expanding the proposed approach is the integration of Harrington’s desirability function with other multi-criteria decision-making (MCDM) tools, which enables greater flexibility in transport quality evaluations [

32]. One of the most effective approaches for refining priority weights of indicators is the analytic hierarchy process (AHP) or its network-based extension, the analytic network process (ANP), which allows evaluation of decision criteria interdependencies. The foundation of these methods is based on the concept of pairwise comparisons of evaluation indicators, which facilitates the determination of weighting coefficients, particularly when the measured criteria are of different types or belong to various levels of a hierarchical structure. Once the weights have been established in this way, the calculated coefficients can be directly incorporated into the generalized desirability function, thereby extending its applicability to more complex evaluation systems.

When it comes to improving the robustness of a process, an optimal approach involves the combination of signal-to-noise (S/N) ratios with the Harrington desirability function [

33]. Initially, S/N analysis is used to identify the optimal levels of controllable factors or to determine the degree of influence of noise factors on the final outcome. Subsequently, an overall integrated desirability value for the full set of process parameters is computed to assess how closely the system approaches an ideal state.

The general sequence of actions for integrating various multi-criteria evaluation tools with the desirability function can be illustrated by a block diagram (

Figure 2). In this scheme, the process begins with data collection and initial pre-processing, followed by the refinement of weights or resolution of uncertainty (using AHP/ANP or fuzzy logic techniques). Only after these steps is the generalized desirability function calculated, based on the resulting coefficients and adjusted indicator values. This integrated approach provides a comprehensive assessment of transport service quality by combining both quantitative and qualitative aspects while also considering process dynamics and the variability of transport conditions.

In practical applications, the proposed methodology can be implemented as a software module integrated into the information system of a transport company or within a vehicle fleet management system. It provides automated data collection, real-time data processing and the generation of comprehensive evaluations of transport service quality, enabling management to rapidly identify deficiencies and apply corrective measures [

7]. In addition, the application of this methodology allows for the creation of baseline productivity levels, which facilitates the introduction of benchmarking systems across company divisions and enables continuous monitoring of transport quality indicators over time [

7].

3. Results and Discussion

To validate the proposed methodology for evaluating transport service quality, the first stage involved assessing the quality of freight transportation services by road using a logistics monitoring system. Selected results of the customer survey, which involved potential clients of road freight transportation services, are presented as a data array in

Table 2.

The customer survey was administered by a private freight operator in Kropyvnytskyi (Ukraine) as part of a quality improvement initiative. Respondents were recent users of road freight services who evaluated the five criteria (timeliness, routing, cost efficiency, safety, responsiveness) on a five-point differential scale. The survey was anonymous and non-personalized. Participants were informed that responses would be used in aggregate for research and managerial quality monitoring and only those providing verbal consent proceeded. Records were grouped by customer segment before analysis; weights and partial satisfactions were then computed per segment and normalized for comparability across the sample.

In the next step, the weights

for each transport service quality criterion under logistics monitoring were obtained from client’s judgments informed by received services. The results are presented in

Table 3.

Next, an assessment of customer satisfaction with the transport process quality indicators under the logistics vehicle monitoring system, as well as the overall delivery quality, was performed. For each segment

the satisfaction score

for criterion

was computed as the arithmetic mean of respondents ratings (after linear rescaling to a common 0–5 scale where needed), and the segment-level composite

was obtained as the weighted sum

. The results of this assessment are presented in

Table 4.

The evaluation of transport process quality under logistics monitoring was conducted by calculating the quality indicator scores, the customer satisfaction criterion and the adjustment necessity coefficient according to Equations (2) and (3). These results are summarized in

Table 5. Higher coefficient values indicate areas requiring more attention.

Based on the results of the first stage of the freight transport quality assessment methodology using a logistics monitoring system, the second stage involved the calculation of the generalized transport quality indicator using Harrington’s generalized desirability function. For this purpose, the individual quality components of the transport process (

Table 1) were converted into partial desirability functions d, and the overall integrated quality indicator D for the transport process was calculated. The calculation was based on the assumption of a linear relationship between the transport process quality indicator and its corresponding partial desirability function. Specifically, the minimum acceptable value of the quality indicator corresponded to the lowest desirability level, while the optimal value of the quality indicator corresponded to the maximum desirability value d. The types of quality indicators and their allowable value ranges were determined in accordance with

Table 2 and are presented in

Table 6.

The quality components defined in

Table 7 represent one-sided constraints based on expert or customer assessment on a 1–5 scale, where 1 indicates the lowest transport service quality and 5 indicates the highest.

The dataset of transport process quality indicators (as the aggregated results of customer interviews under logistics monitoring conditions) was formed according to the system of quality criteria and is shown in

Table 8.

In

Table 8, each row corresponds to a specific observation period (survey instance) and shows the aggregated values of the five transport service quality indicators for that period. In total, eight such instances were recorded (two per week over a four-week span, labeled as rows 1–8). Thus, each numbered row in

Table 8 captures one distinct profile of transport service performance across the five criteria for a given time period or customer segment in this study.

For single-sided constraints on the controlled parameters

, the conversion of controlled parameter values into partial desirability function values

d was performed according to Equation (6). To determine the coefficients

b0 and

b1 used in Equation (7), a linear relationship between

y and

d was assumed, whereby the lowest permissible quality indicator value corresponded to a desirability level of 0.37 (“poor”) and the highest permissible value corresponded to a desirability level of 0.8 (“very good”) for the same quality component (

Table 8). According to the Equation (6) the following results were obtained:

d = 0.8,

y’ = 1.5;

d = 0.37 and

y’ = 0.0058.

As an example, the unknown coefficients

b0 and

b1 for the timeliness indicator were calculated as follows using linear Equation (7):

b0 = 1.5 and

b1 = 0.0058. As a result of solving this system, the final values of the coefficients were

b0 = −0.368 and

b1 = 0.0374. Since all five of the presented transport process quality indicators (from

Table 8) shared the same measurement scale and boundary values, these calculated coefficients

b0 and

b1 were used uniformly for all indicators.

Thus, the relationship between the partial desirability function and the corresponding quality indicator of the transport process component was described by the following Equation (13):

According to Equation (6), the quality indicator values of the transport process were recalculated into partial desirability functions and the overall desirability function value was determined using Equation (12). The results are presented in

Table 9.

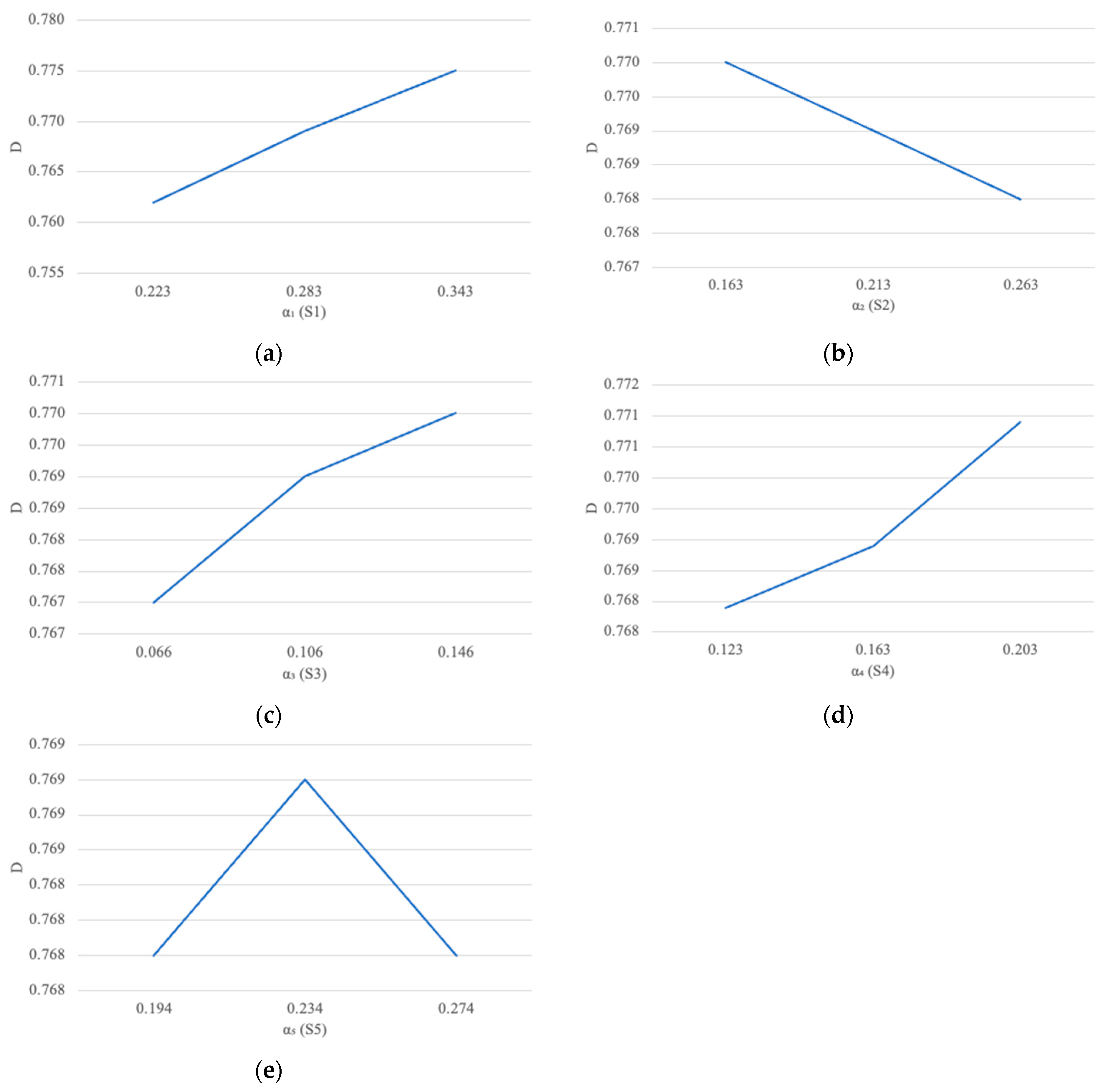

To evaluate the impact of weighting coefficient variation on the generalized desirability function, a sensitivity analysis of the weight coefficients was conducted. This analysis helps to determine how significantly the overall desirability index D fluctuates when the priority of individual criteria is varied while keeping the importance of the remaining criteria constant. Such a procedure allows for the assessment of whether the evaluation system is excessively “sensitive” to subjective factors or expert judgments and it also identifies which specific criteria exert the greatest influence on the overall result and therefore require special attention during real-world transport planning.

The graphical results of the sensitivity analysis are presented in

Figure 3. In each case, only the weight of a single criterion was varied, while the weights of the remaining criteria were proportionally redistributed to maintain the original relative balance.

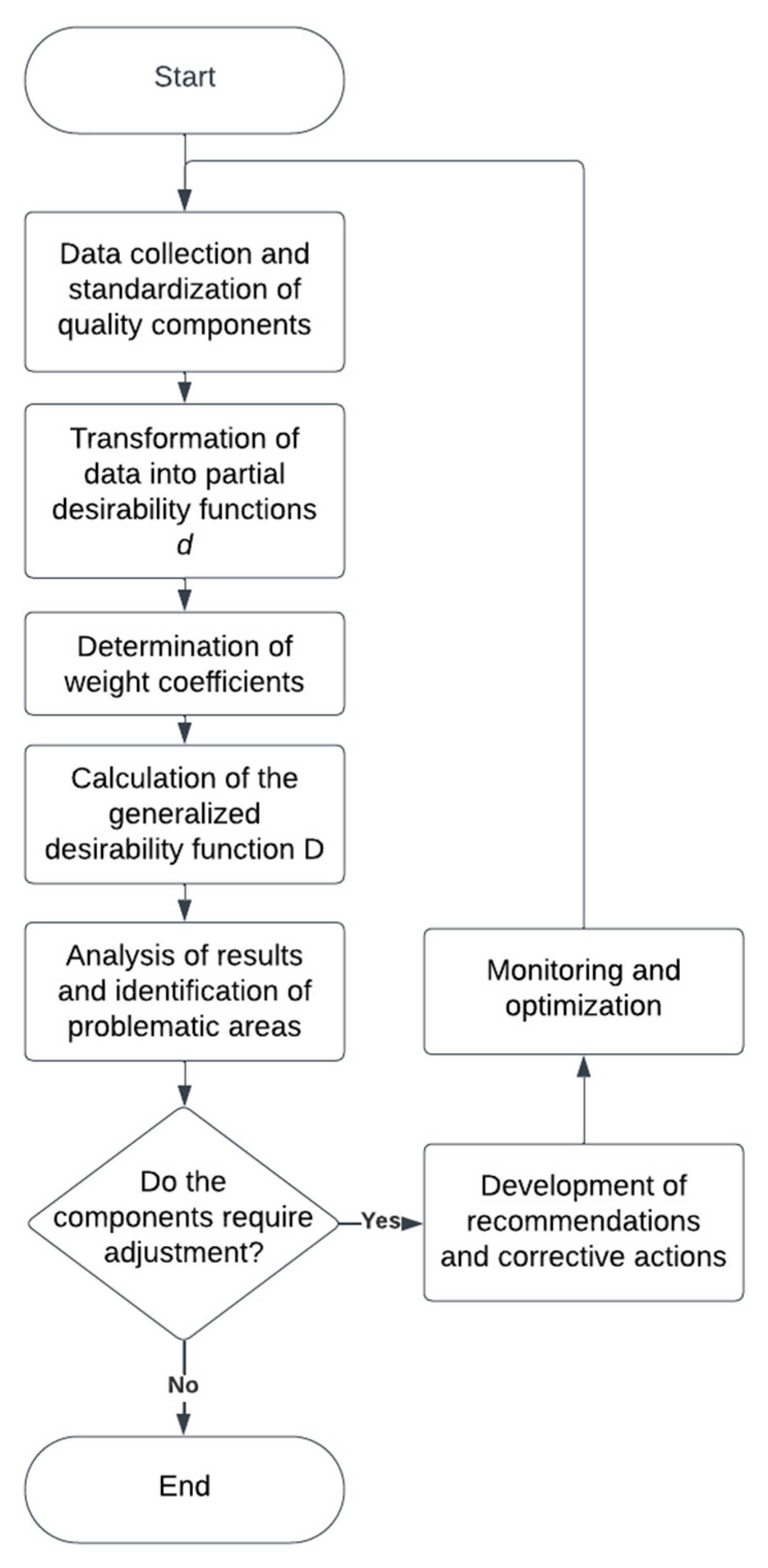

According to the proposed methodology for evaluating transport service quality, the next step involved the development of an algorithm for automating the assessment process of transport process quality (

Figure 4).

The developed algorithm (

Figure 4) enables not only the determination of the overall level of customer satisfaction but also the clear identification of critical aspects requiring corrective action. It supports more accurate and effective decision making for transport service improvement by integrating Big Data technologies, which allow for the processing of large volumes of heterogeneous information from logistics monitoring systems and external sources (e.g., traffic data, weather conditions, fuel prices). In practical applications, the Big Data architecture combines servers, cloud storage and distributed computing resources, enabling the algorithm from

Figure 4 to be scaled for the simultaneous analysis of real-time data streams. The ability to process large flows of information makes it possible to continuously update service quality indicators, detect deviations from optimal routes or transit times and promptly respond to technical or logistical problems.

Data from various segments of the logistics chain are automatically transferred to the Big Data repository. The subsequent analysis of this data is carried out considering weight coefficients, reliability indicators and various target metrics defined within the developed methodology for evaluating transport service quality. The results of this multifactor analysis can be used to improve predictive modeling and develop new optimization approaches, as the system gains self-learning capabilities based on large historical datasets. In this configuration, the algorithm evolves into a comprehensive software solution that provides not only static assessment but also dynamic monitoring of the entire transportation process.

Considering the enhanced functionality enabled by Big Data analysis, the next step was the development of a Python-based (version 3) software tool capable of fully implementing the described algorithm and data processing methods. An example of Python code that applies the proposed methodology for transport process quality evaluation using Harrington’s desirability function, weight coefficients and the ability to integrate with Big Data environments is presented in

Figure 5. The code is designed to handle large datasets from various logistics monitoring sources (specialized systems, sensors, GPS trackers, etc.). The presented code fragment includes data import, normalization of indicators, calculation of partial and overall desirability functions and the generation of generalized conclusions about transport process effectiveness. It also supports data import from CSV files, as well as from PySpark or other distributed platforms for Big Data environments.

At the end of the script execution, a table is generated that provides a fast and intuitive assessment of the desirability level (i.e., quality level) for each record within large transport datasets. An example of the output table structure is shown in

Figure 6.

The structure of transport process quality indicators under the logistics vehicle monitoring system is presented in

Figure 7. Each of these indicators has a significant influence on the overall transportation process.

These quality indicators allow transport organizations, enterprises, firms and companies to assess the significance of specific aspects of the transport process and to forecast the expected outcomes from introducing satellite monitoring systems into their operations and for their customers. The use of this indicator system is fundamental for assessing transport service quality and provides a comprehensive evaluation framework, as it enables an overall analysis of the expected results of satellite monitoring implementation.

The data obtained from logistics monitoring clearly highlight the priority areas for improving the transport process and help to identify the components that have the greatest influence on transport service effectiveness. The next step involves applying Harrington’s generalized desirability function, which allows for the integral evaluation of transport quality based on all key criteria. The Harrington-based evaluation results can directly inform the managerial decisions in transport companies. Notably, this study established that an integrated desirability value

D exceeding 0.63 corresponds to acceptable service quality. Following the standard semantic interpretation of Harrington’s desirability scale [

34], values around D = 0.63 mark the transition from “satisfactory” to “good” quality on the composite index. These specific cut-off values are not arbitrary. They derive from the mathematical formulation of the desirability function (with 0.37 ≈ 1/e and 0.63 ≈ 1 − 1/e). In this study we adopt D ≥ 0.63 as the managerial acceptability threshold; above this level, incremental improvements deliver diminishing perceived gains relative to the operational effort required, whereas values below 0.63 signal underperformance, which is visible to customers and should trigger corrective actions. This threshold becomes a managerial benchmark if the overall service quality index

D for a given period or route falls below 0.63, signaling to management that intervention is needed to address weaknesses in the transport service. Thus, managers can set

D = 0.63 as a target performance indicator (target KPI) in their quality monitoring dashboards—when the index drops into the “unsatisfactory” zone, they may initiate corrective actions such as rescheduling deliveries, retraining staff or fleet maintenance, depending on which criteria are lagging. Conversely, if

D consistently reaches, say, 0.8 (“very good”) or higher for certain divisions, those practices can be recognized as effective, standardized and even used as examples for other departments. In this way, the multi-criteria metric provides a clear quantitative basis for managerial decision making, replacing gut feeling with data-driven triggers. This approach fully aligns with quality management principles and the concept of continuous improvement, which are central to logistics and transport operations [

7].

In a pilot deployment, we evaluated the system’s effectiveness by comparing its alerts and composite outputs with observed operational events. The desirability index consistently flagged a known weakness in one customer segment; low partial desirability for responsiveness (S5) coincided with delays in handling unforeseen incidents. This convergence between system output and field observations increased confidence that the metric set captures meaningful performance issues rather than noise. Management then implemented a focused intervention (a tightened incident response protocol) and we tracked the effect using the same indicators. In subsequent evaluation cycles, the partial score for S5 rose and the composite desirability D for the affected segment moved above the acceptability target of 0.63. This pre/post pattern illustrates how the index can diagnose bottlenecks, guide corrective action and verify improvement over time. In practical terms, monitoring the trajectory of D after interventions serves as the operational test of the evaluation system: if targeted changes are followed by sustained gains in D, the system is functioning as intended. A broader comparative study against alternative evaluation schemes and a longer follow-up horizon remains as future work.

A key benefit of the multi-criteria approach is the insight it offers into which aspect of service quality requires attention. The methodology yields partial desirability scores for each indicator (timeliness, safety, economy, routing, responsiveness), so managers are not only alerted by the aggregate

D value but can also see the breakdown of performance. For instance, if overall

D is low primarily due to a poor desirability score in “routing efficiency”, management can focus on route optimization strategies or better driver navigation training. If “transport safety” has the lowest score, decision makers might invest in vehicle safety systems or stricter compliance with safety protocols. In our results, each criterion’s contribution to the integral quality index is transparent, enabling managerial decisions that are pinpointed—addressing the root cause of quality shortfall rather than treating symptoms. This aligns with the multi-criteria philosophy: by evaluating diverse performance dimensions simultaneously, transport enterprises can prioritize improvements that yield the greatest overall desirability gain. The result is a more efficient allocation of resources; for example, improving a single indicator from “poor” to “good” could raise

D above the 0.63 acceptable threshold, translating into tangible service enhancements perceived by clients. Furthermore, the integral quality indicator can be integrated into the company’s key performance indicator (KPI) system. This facilitates the tracking of progress toward operational objectives and the evaluation of the impact of management decisions and corrective measures over time [

7]. Such an approach provides both strategic and tactical control of transport quality and contributes to improving the company’s overall competitiveness.

According to the conducted study, an additional important step involves the sensitivity analysis of the weighting coefficients and their impact on the generalized desirability function. As illustrated in the graphs (

Figure 4), in most cases, a variation of weights by 0.04–0.06 resulted in only minor changes to the final

D value (with deviations ranging from approximately 0.001 to 0.007). However, the analysis demonstrated that the greatest impact on

D is caused by fluctuations in the weights of criteria with the highest initial partial desirability values and higher baseline weights (such as

S1 or

S5). In practical logistics operations, this means that increasing the focus on certain indicators (e.g., timeliness or responsiveness) can significantly “shift” the integral quality assessment, whereas minor adjustments to lower priority criteria (especially those with lower partial desirability values) produce minimal changes in the overall result.

The developed multi-criteria assessment tool functions as a real-time decision support system for transport company managers. The automation of the evaluation process (via the custom software mentioned) dramatically reduces the time and effort required to analyze service quality. This means managers can receive frequent (even continuous) updates on the overall service quality index without burdening staff with extensive manual calculations. In practice, such capability allows for proactive management: managers can respond quickly to degrading performance—for instance, reallocating trucks or adjusting delivery schedules on the same day an issue is detected rather than after monthly or quarterly reviews. The multi-criteria nature of the index also facilitates strategic comparisons: different routes, drivers or business units can be benchmarked by their D scores, introducing a data-driven performance management culture. Over time, tracking the composite desirability index helps in assessing the effectiveness of managerial decisions themselves. If a decision (e.g., introducing a new routing software or a safety training program) is successful, its impact should manifest as a higher D value in subsequent evaluations. The incorporation of Harrington’s multi-criteria desirability function into the company’s monitoring system closes the loop between performance monitoring and managerial decisions. It translates complex operational data into an accessible metric for decision makers, strengthens evidence-based management and supports the continuous improvement of transport service quality.

Recent research in transport logistics strongly supports this study, finding that data-driven multi-criteria evaluation can enhance both service quality and sustainability. For example, Jamkhaneh et al. (2022) point out that logistics service quality is a key driver of corporate sustainability, with advanced “Logistics 4.0” technologies, cost efficiency, safety and human factors identified as essential enablers of value creation [

24]. Their study suggests that integrating modern digital tools into logistics operations improves performance while meeting sustainability challenges. Similarly, Dzemydienė et al. (2021) developed an intelligent decision support system for freight transport that combines real-time smart services with multi-criteria analysis to optimize multi-modal logistics under green development requirements [

20]. This approach, like the ones obtained in this work, underscores how real-time data and MCDM techniques can be harnessed to drive sustainable transport outcomes. This study’s results contribute to this evolving literature by demonstrating a practical desirability-based index that translates complex operational data into a single performance metric. This kind of integrated metric resonates with calls in recent studies to embed sustainability factors into freight transport decision frameworks to remain effective in the modern context. In essence, this study aligns with the broader trend of leveraging IoT-driven monitoring and analytics in transportation. Such approaches enable managers to simultaneously improve service efficiency and advance environmental and social objectives. By quantifying how operational enhancements (e.g., reducing empty runs or improving safety training) raise the overall desirability score, empirical support is provided for the notion that pursuing sustainability can go hand-in-hand with boosting logistics performance, as suggested by current supply chain research [

24].

Crucially, the proposed desirability-based evaluation can be extended to incorporate explicit sustainability metrics, thereby directly linking transport service improvements with specific sustainable development goals. In our research, we focused on traditional service quality criteria (timeliness, reliability, etc.), but the framework readily accommodates additional indicators (e.g., fuel consumption, CO

2 emissions, vehicle load factor) to capture environmental performance. By assigning desirability scores to such sustainability indicators, a transport company can simulate how “greener” practices would affect its overall quality score. For instance, if route optimizations or alternative fuel vehicles lead to higher desirability values, this provides a compelling business case for innovations that also advance sustainability. This outcome directly supports SDG 9, which aims to “build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation” [

35]. The improvements in reliability, efficiency and safety demonstrated by our results contribute to more resilient transport infrastructure (by enhancing service dependability) and reflect innovation in logistics operations (through the use of advanced monitoring and decision tools). In essence, our findings show that boosting day-to-day performance in freight services can yield broader benefits consistent with SDG 9’s industry and infrastructure targets. This integrative perspective aligns with recent studies urging that freight transport decision frameworks incorporate sustainability factors to remain effective in the modern context. By quantifying how operational enhancements (e.g., reduced empty runs or improved safety responses) raise the overall desirability score, the model translates sustainability-oriented improvements into the language of service quality. Thus, each incremental gain in transport service performance doubles as progress toward sustainable infrastructure and innovation, anchoring operational decisions within the 2030 agenda. In practice, companies using this model might find, for example, that routes optimized for minimal fuel consumption score higher in desirability due to cost savings and reliability, thereby reinforcing a shift toward sustainability without sacrificing profitability. This outcome is consistent with the notion that pursuing sustainability can drive enhanced efficiency and stakeholder value in supply chains.

To position our approach within the multi-criteria decision-making canon and to make its managerial value more concrete, we benchmarked it against the AHP method. AHP is a staple multi-criteria method in transport planning because it turns expert judgments into criterion weights via pairwise comparisons and checks for consistency. It has been used to prioritize service attributes such as comfort, accessibility and safety. Its drawbacks are well known. Classical AHP assumes precise inputs, is sensitive to inconsistency and becomes labor-intensive as the number of criteria grow. Fuzzy AHP softens these issues by allowing ratings as ranges or fuzzy numbers, yet it still requires many comparisons and is typically applied to static one-off evaluations rather than to streaming operational contexts.

Our framework is designed for continuous quality control. We derive criterion weights directly from stakeholder importance ratings and historical monitoring data, which reduces cognitive burden and anchors weights in observed preferences. Performance on each indicator is measured with logistics telemetry (GPS/IoT, dispatch logs, incident records), transformed into unit-free desirability scores and combined through Harrington’s function into an absolute index D. Unlike AHP’s relative ranking of alternatives, D is interpretable against fixed benchmarks (e.g., D = 0.63) as the acceptability threshold in our case study, giving managers a clear go/no-go signal independent of a comparison set. Because the pipeline is automated, D and the partial desirability’s update as new data arrive enables near real-time alerts and proactive interventions (route adjustments, incident response escalation, targeted maintenance). A further advantage is diagnostic transparency. The common desirability scale exposes which dimension (timeliness, routing, cost efficiency, safety, responsiveness) is dragging down performance and by how much, while the sensitivity analysis shows how re-weighting priorities would change D before committing resources. In short, AHP is well suited to structured expert-led selection problems. The proposed desirability-based scheme is better aligned with data-rich freight operations, offering automation, absolute thresholds and actionable diagnostics on live data, while remaining compatible with fuzzy extensions if deeper uncertainty modeling is later required.

Despite its contributions, this study has certain limitations that should be acknowledged. First, the customer survey used to weight and evaluate the service quality criteria may carry some bias. The sample of respondents was limited to the clients available in our case study and their subjective perceptions (measured on a five-point scale) could affect the generality of the results. In other words, different or broader customer groups might assign different importance weights to the quality indicators, so the derived weights should be interpreted with caution. Second, the reliability and completeness of the logistics monitoring data could influence the assessment accuracy. Real-world telematics data are prone to issues like missing GPS readings or sensor errors, which might skew certain indicator values if not properly handled. We assumed high-quality data inputs. However, any systematic data gaps or errors in the monitoring system could introduce uncertainty into the desirability scores. Third, our implementation trial focused on a specific transport enterprise, which may limit the immediate generalizability of the findings. Company-specific operational conditions or regional factors could impact the performance of the desirability function approach. Future research should address these limitations by expanding the survey scope, improving data validation and preprocessing steps and testing the proposed model across multiple companies or logistic contexts. Such steps would help verify the consistency of the desirability threshold results, strengthen the reliability of the conclusions and refine the tool for broader application.

4. Conclusions

This study has developed a comprehensive methodology for evaluating the quality of transport services provided by freight transportation companies using logistics monitoring system data and Harrington’s generalized desirability function. Key quality indicators for transport services were identified (timeliness of delivery, route optimization, cost efficiency, safety and responsiveness) and a mathematical framework was developed to convert them into a single integrated quality index. By employing Harrington’s desirability function, we developed an integrated metric that captures the complex trade-offs among performance indicators in automotive transport. The enhanced strategic orientation of this evaluation means that managers and planners can directly use the results to guide long-term decisions, ensuring that each incremental improvement in service quality also advances the company’s sustainability agenda. In essence, the proposed approach turns quality assessment into a form of strategic appraisal, highlighting where investments or policy changes will yield the greatest overall benefit across economic, customer service and environmental dimensions. This is particularly relevant as the transport industry navigates the transition towards greener and smarter logistics in line with global sustainability commitments. The proposed methodology not only enabled quantitative assessment of transport service quality but also allowed for adaptation of the evaluation process to support enterprise-level management decision making.

The practical value of the model was validated through an implementation trial, which demonstrated its capability to promptly detect weaknesses in the transport management system and provide management with relevant data for formulating corrective actions. Specifically, it was established that an integrated desirability value exceeding 0.63 can be considered a target threshold for high-quality service. The developed software application automates the quality assessment process, substantially reducing the time and resource demands associated with transport operation analysis and managerial decision-making processes. From a managerial perspective, the composite desirability index gives a single yardstick for benchmarking at the route, fleet and client level and supports target setting in KPI dashboards. The built-in sensitivity analysis shows in advance how rebalancing priorities, such as putting more weight on safety or responsiveness, will move the overall score, which lowers the risk of costly misallocation.

The main scientific contribution of this study lies in the integration of real-time monitoring systems with multi-criteria analysis methodology through the application of the desirability function. This work advances the field in three concrete ways. First, it turns high-resolution logistics monitoring into a single decision-ready indicator by operationalizing Harrington’s desirability function on real operational data rather than laboratory settings. Second, it delivers a six-stage algorithm with an executable Python/PySpark pipeline that can be deployed alongside existing IT without refactoring. Third, it adds a weight-sensitivity procedure that shows how shifts in managerial priorities change the composite score and reveal the highest-leverage interventions. Together these elements connect routine monitoring with strategic performance steering and provide an auditable benchmark for quality improvement.

However, the research also has certain limitations. The proposed model is primarily oriented toward indicators available within monitoring systems and does not fully account for social and environmental criteria, which are important for a more holistic assessment of sustainability in logistics operations. Future research will aim to extend the model by incorporating fuzzy evaluations and machine learning techniques to automatically determine weighting coefficients, as well as by integrating data on corporate social responsibility and the carbon footprint of transport operations. This will allow for the creation of a universal framework for comprehensive quality assessment of transport services, combining technical, operational, economic, social and environmental aspects. Such a framework will serve as a valuable managerial decision support tool for transport companies operating in the dynamic environment of the logistics services market. Future work can build on this foundation by incorporating a broader array of sustainability indicators and exploring the model’s applicability in diverse transport contexts, but the following core message remains: quality-driven strategic planning in transportation can and should be harnessed for sustainability, ensuring that progress in service performance goes with progress towards a more sustainable future.

Beyond its theoretical and practical contributions to logistics management, this study has clear implications for SDG 9 (industry, innovation and infrastructure). The developed approach—using real-time data and multi-criteria desirability analysis—actively promotes resilient infrastructure in the transport sector by identifying and reinforcing reliability and efficiency in freight services. Each quality improvement measured by our integrated index (e.g., faster delivery times, cost savings or safer operations) corresponds to strengthening the performance of transportation infrastructure, which is a core target of SDG 9. Moreover, the implementation of a logistics monitoring system and a data-driven decision support tool exemplifies innovation in industry practices, echoing SDG 9’s call to “foster innovation” in operational processes [

35]. In sum, by adopting this Harrington’s function-based evaluation, transport enterprises can align their service enhancements with global sustainability objectives. The methodology does more than improve corporate performance, it provides a pathway for companies to contribute to sustainable industrialization and modern infrastructure development, as envisaged in the UN 2030 agenda. This alignment with SDG 9 highlights the broader significance of our findings: improvements in logistics service efficiency at the firm level can cumulatively support national and global progress towards more inclusive and sustainable industries and infrastructure.