1. Introduction

Over the past four decades, the annual output of edible fungi in China has increased nearly 730 fold, making it the fifth largest agricultural plantation sector after grain, vegetables, fruits, and oil crops, with an annual output value exceeding 400 billion CNY [

1]. Moreover, China is the world’s largest producer and consumer of edible mushrooms [

2]. The edible mushroom industry plays a crucial role in optimizing and restructuring the agricultural sector, promoting the development of the health industry, and contributing to national food security [

3,

4]. With the rapid growth of the industry—particularly the expanding cultivation of high-value varieties such as

Hymenopellis raphanipes (black-skinned chicken matsutake)—strengthening quality and safety management throughout the entire process has become a critical factor to ensure the industry’s sustainable development. On one hand, issues such as opaque information and lax management persist in the production, processing, and distribution stages, necessitating the application of scientific methods to enhance product quality and safety control. On the other hand, establishing a robust traceability system helps to increase consumer confidence in product quality and facilitates accurate and efficient supervision by regulatory authorities. Furthermore, a comprehensive traceability mechanism also contributes to enhancing industrial brand value and promoting the sustainable development of the edible mushroom industry. Therefore, researching and constructing a scientific and efficient quality safety and traceability system holds significant practical importance for modernizing the

Hymenopellis raphanipes industry and improving its market competitiveness.

Food safety and supply chain integrity are critical for high-value edibles like

Hymenopellis raphanipes. Current traceability systems still face challenges in terms of data transparency and tamper resistance. Blockchain technology, with its characteristics of decentralization, immutability, and traceability, holds great promise for achieving end-to-end traceability [

5,

6]. However, challenges related to system scalability and interoperability remain significant barriers to its widespread adoption. This study specifically addresses these critical issues. Zhao [

7] constructed a safe and efficient blockchain traceability model to realize the safe storage of traceability confidentiality data and designed and realized a safe and trustworthy traceability system for ginger product quality. He [

8] and others integrated blockchain technology into traditional seed information traceability and proposed a seed quality traceability model with distributed data storage to achieve accurate traceability and the rapid identification of seed quality. Ren [

9] and others proposed a consensus algorithm based on the reputation supervision mechanism and designed and realized an information traceability platform for the whole industry chain of wheat. In addition, existing studies have involved the construction of quality and safety traceability systems for many types of agricultural and animal products, such as tea [

10],

Agaricus bisporus [

11], millet [

12], fish [

13,

14], fruits and vegetables [

15], and so on. Although previous studies have achieved success in specific domains,

Hymenopellis raphanipes, as an emerging high-value-added fresh edible mushroom, presents unique challenges due to its short shelf life, high perishability, and strong reliance on cold chain logistics. The time span from harvest to consumption is relatively short, placing stringent demands on temperature and humidity control, transportation efficiency, and real-time information synchronization. Existing agricultural traceability systems are often designed for conventional products, characterized by long data acquisition cycles and limited responsiveness. These systems typically lack essential functionalities such as cold chain temperature monitoring, real-time tracking, and multi-source data integration, making them insufficient for the precise traceability and quality control required throughout the entire lifecycle of

Hymenopellis raphanipes. This mismatch significantly hinders the sustainable development of the

Hymenopellis raphanipes industry.

Based on the aforementioned background, this paper focuses on quality management throughout the entire lifecycle of Hymenopellis raphanipes and proposes a comprehensive quality and safety traceability solution applicable to the entire industry chain of the black-skinned chanterelle mushroom. Starting from an analysis of the supply chain’s information characteristics, this study examines data flows and the practical needs of enterprises, progressively constructing a traceability system architecture capable of accommodating multiple stages and stakeholders. To address issues in existing traceability mechanisms—such as unclear granularity, information silos, and insufficient data credibility—this paper designs a hierarchical and highly scalable system framework, combined with a unified coding scheme and information association strategy to enhance the accuracy and consistency of data across the whole chain. To further improve system performance and security, the research introduces a multi-chain collaborative mechanism, establishing a mainchain and sidechain storage model and leveraging on-chain/off-chain cooperation technologies and smart contracts to achieve the automatic verification and closed-loop management of key node information. Finally, the system is deployed and functionally validated on the Hyperledger Fabric platform. To achieve the aforementioned objectives, this study is grounded on the following methodological assumptions: a unified coding system and information association strategy can ensure data consistency and accuracy across multiple stages and stakeholders within the supply chain; a collaborative storage architecture combining main and sidechains, integrated with the Hyperledger Fabric platform, can significantly enhance the system’s scalability and data processing efficiency; and the implementation of smart contracts for the automatic verification and closed-loop management of key node information can improve system security and trustworthiness. This study aims to address existing technical gaps in the Hymenopellis raphanipes industry, particularly in high-frequency data acquisition, cold chain temperature control integration, and end-to-end trustworthy traceability. It seeks to provide a replicable and scalable framework for the intelligent quality management of high-value-added, perishable agricultural products and to offer a theoretical and technical foundation for advancing digital agricultural supervision in China.

This paper is organized as follows:

Section 2 introduces the relevant technologies used for the design of the traceability system for black-skinned chanterelle mushroom, provides an in-depth analysis of the supply chain information, and puts forward the overall system framework and a traceability granularity design scheme.

Section 3 describes in detail the blockchain-based traceability model of black skinned chanterelle mushroom, covering the design of the traceability code, fast query mechanism, smart contract design, and data collection method.

Section 4 describes the specific realization process of the system and the experimental verification studies.

Section 5 discusses the system’s advantages, problems, and future directions for improvement.

Section 6 summarizes the whole paper and predicts future research directions.

2. Design of Blockchain-Based Traceability Scheme for Hymenopellis raphanipes

2.1. Related Technologies

2.1.1. Blockchain Technology

Blockchain is a distributed ledger based technology in which all data is stored in multiple nodes in a decentralized manner and secured by cryptographic algorithms [

15,

16,

17]. Each block contains multiple transaction records and is connected to the previous block by a hash algorithm to form a chain structure, making the data untamperable once written [

18,

19]. This tamperproofing and decentralization [

20,

21] have led to the widespread application of blockchain in the field of food safety and quality traceability. In the quality and safety traceability system of

Hymenopellis raphanipes, blockchain technology can effectively guarantee the authenticity and traceability of the information in each link and enhance the overall transparency and credibility of the system.

2.1.2. Smart Contracts

Smart contracts are self-checking, tamperproof, automated protocols running on the blockchain with the characteristics of determinism, autonomy, decentralization, and automatic execution, meaning they are capable of automatically executing predetermined contract terms when specific conditions are met [

22,

23,

24,

25]. Smart contracts do not require a third-party intermediary and can realize the execution of contracts without human intervention, ensuring the transparency and efficiency of the execution process [

26,

27]. In the quality and safety traceability system of

Hymenopellis raphanipes, a smart contract guarantees the authenticity and integrity of data flow on the chain by automatically verifying the hash value and key information of the production process data.

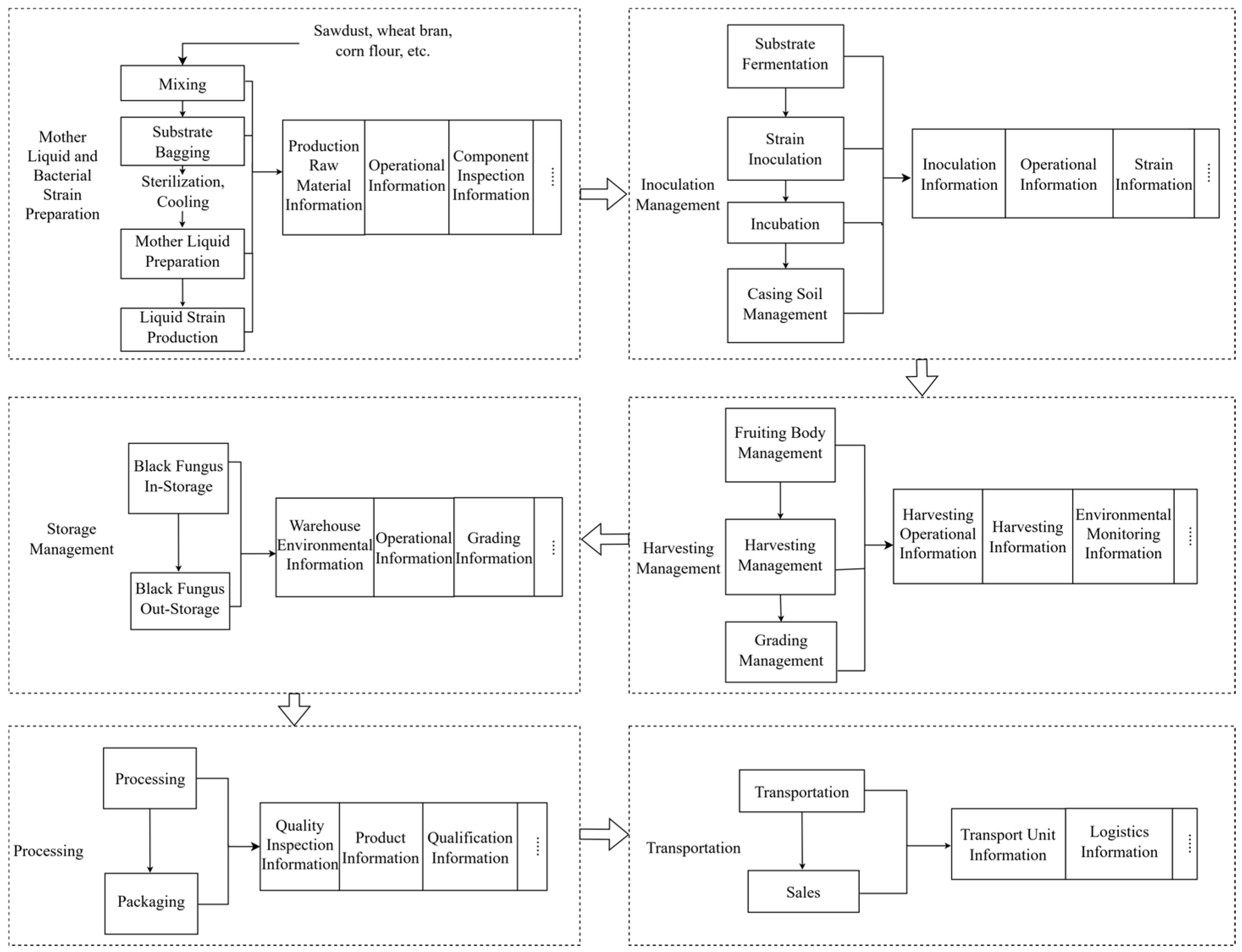

2.2. Supply Chain Information Analysis of Hymenopellis raphanipes

To achieve the quality and safety traceability of

Hymenopellis raphanipes, it is essential to comprehensively record and securely store key product quality and safety information at each stage of the supply chain, ensuring the authenticity and security of information transmission and sharing, thereby obtaining reliable traceability data. The supply chain of

Hymenopellis raphanipes is divided into several stages based on the factory production process, including strain preparation (mixing, the bagging of culture materials, mother liquor preparation, and liquid strain cultivation), mushroom development management (fermentation, inoculation, mushroom growth, and mulching), mushroom production and harvesting (mushroom management, picking, and grading), storage, processing, transportation, and sales. The overall supply chain process is illustrated in

Figure 1.

At each stage of the supply chain, aligned with the practical needs of enterprises, two categories of key information must be simultaneously collected and managed: production material information and operational information. Production material information includes substrate materials and their proportions, strain sources and batches, and related production equipment data. Operational information covers operation records, growth environment monitoring data, daily management logs, harvesting records, product grading and packaging details, and environmental conditions during transportation and storage. Together, these two categories of information form a comprehensive quality management and traceability data support system covering the entire lifecycle.

However, in current enterprise production practices, each stage of the Hymenopellis raphanipes supply chain faces specific quality and safety risks and challenges in information management. At the strain preparation stage, issues include lack of transparency in raw material sources, missing records of culture material ratios, and the inaccurate recording of key parameters such as sterilization temperature and duration. During the germination management stage, the main challenges stem from insufficient environmental control and data recording. High standards for environmental variables such as temperature, humidity, ventilation frequency, and light are required, yet automated monitoring and data retention are often absent, making it difficult to trace the causes of abnormal mushroom stick development and to assign management responsibility. In mushroom production and harvesting, common problems are inconsistent picking standards, the lack of operation process records, and unclear product grading classifications. In storage and processing, issues include substandard cold storage conditions, lax batch labeling management, and the inadequate recording of processing operations. The transportation phase frequently suffers from cold chain interruptions, missing location data, and fragmented, non-communicative transport data, which can lead to serious product spoilage due to temperature control failures, while responsibility remains unclear. The sales stage faces problems such as ineffective binding between packaging information and product batches and ambiguous origin information, preventing consumers from identifying the product source, which undermines brand trust and consumer confidence. In summary, the production and distribution processes within the Hymenopellis raphanipes supply chain exhibit notable weaknesses in quality control, with prominent issues including opaque information, missing data, and unclear responsibility divisions.

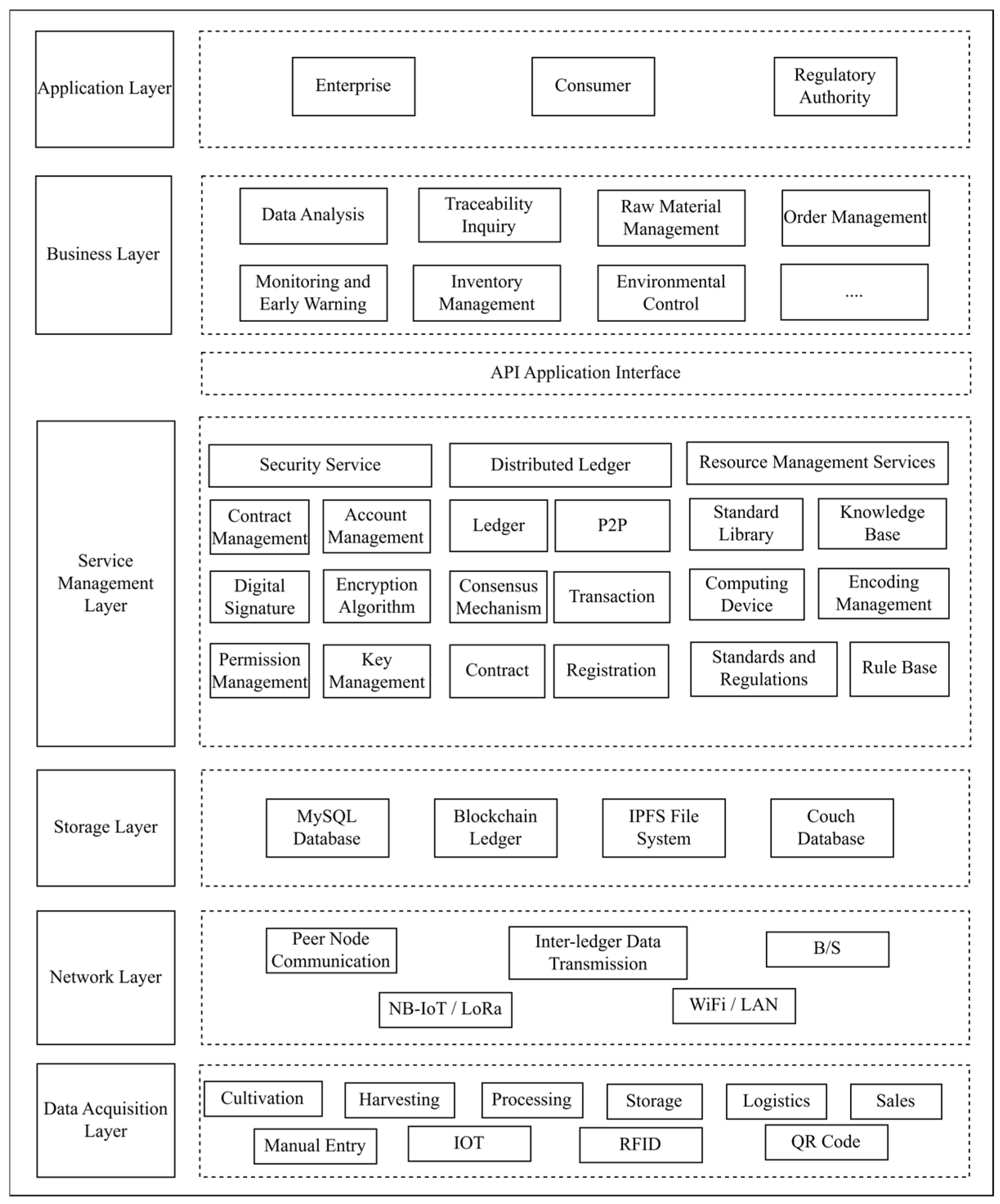

2.3. Overall System Framework

The quality and safety credible traceability system for

Hymenopellis raphanipes adopts a six-layer system architecture comprising the data collection layer, network layer, storage layer, service management layer, business layer, and application layer. The system design architecture is illustrated in

Figure 2.

The data acquisition layer is responsible for the real-time collection of environmental and equipment data during the production process of Hymenopellis raphanipes and transmitting it to the system backend for processing. This layer integrates IoT devices such as temperature and humidity sensors and RFID tags, enabling precise monitoring and environmental optimization via WiFi, LAN, and other communication protocols, with data compression applied to enhance transmission efficiency. The network layer, based on blockchain technology, adopts peer nodes and a browser/server (B/S) architecture, ensuring secure data transmission and storage through access control and attribute-based encryption mechanisms, thereby safeguarding the immutability of supply chain information and supporting credible traceability and accurate tracking. The service management layer integrates smart contract functionalities through API interfaces, handling data recording, management, and verification across all supply chain stages. It writes information into the blockchain using a decentralized storage model and implements automatic verification and querying via smart contracts to guarantee data authenticity and integrity, providing reliable traceability support for consumers, enterprises, and regulatory bodies.

The storage layer comprises data storage, access, and management modules, utilizing distributed databases and IPFS technology to achieve high data availability and security through on-chain and off-chain collaborative storage. It also implements granular privilege management based on role-based access control policies, balancing transparency with privacy protection. The business layer supports various functional modules, including traceability queries, supply chain management, and procurement management, catering to the diverse needs of consumers, enterprises, and regulators: consumers can access product lifecycle information via the traceability query module, enterprises can optimize quality control through the supply chain management module, and regulators can conduct risk early warning and compliance checks via the regulatory module. The application layer serves all users by providing interactive interfaces for web and mobile platforms, supporting query, statistical analysis, and data export functions. It combines strict access control and encryption mechanisms to ensure data security while enhancing user experience and traceability reliability.

2.4. Traceability Granularity Design

In food quality and safety traceability systems, “traceability granularity” refers to the minimum identifiable management unit within the traceability process—namely, the smallest unit that can be independently identified, recorded, and traced. The granularity design directly influences the system’s tracking accuracy, data processing cost, and operational efficiency. An overly coarse granularity may obscure the attribution of responsibilities, while an excessively fine granularity can result in increased storage demands and maintenance overhead. Therefore, the determination of traceability granularity should adopt a phased and strategic approach, balancing traceability requirements with the enterprise’s production processes, distribution of risk points, and data collection capabilities.

The supply chain of Hymenopellis raphanipes encompasses multiple stages including mushroom stick production, inoculation, cultivation, warehousing, logistics, and sales, in which data isolation at each link may cause information discontinuities. To address the practical production needs of enterprises, the system employs a batch management mechanism, assigning a unique traceability identification code to each product batch to accurately correlate data from raw material warehousing to final sales, ensuring the continuity and integrity of the information chain. Furthermore, integrating blockchain technology, smart contracts automatically verify the temporal consistency and logical integrity of key information such as hash values uploaded at each stage, effectively preventing data tampering and enhancing the credibility and supervisability of the entire traceability system.

In response to management challenges such as unclear batch tracking and the difficulty in defining quality responsibility, as well as traceability requirements in enterprise production, the system adopts a hierarchical traceability granularity strategy. Appropriate tracking units are established according to the process logic and risk levels at different stages: during the preparation stage of mushroom sticks, the incoming batch of raw materials is taken as the granularity unit, grouping raw materials by arrival time and quality standards to address the sources of quality variation in the mushroom sticks; at the inoculation stage, collections of sticks from the same strain batch serve as the granularity unit to ensure strain consistency and facilitate the identification of contamination risks; during cultivation, the mushroom room is used as the granularity unit, leveraging physical isolation and consistent environmental parameters to reduce data redundancy and improve environmental monitoring efficiency; at the warehousing stage, a combination of storage location and the product batch is adopted as the tracking unit to enhance the management efficiency of the warehouse’s in-and-out information; in the logistics stage, the transportation task number serves as the granularity unit, integrating cold chain temperature control and GPS positioning data to support cold chain process tracking; finally, to satisfy consumer trust and accountability demands, the sales and after-sales stages use product batches as the granularity unit, enabling transparent consumer queries and facilitating after-sales responsibility tracing.

The granularity design effectively balances data processing costs and system operational efficiency while ensuring traceability accuracy, thereby enhancing the practicality and cost-effectiveness of the traceability system. However, high-frequency data collection depends heavily on the performance of IoT devices; sensor failures or inadequate calibration may result in data loss, necessitating increased equipment redundancy and regular maintenance [

28]. Additionally, the computational overhead associated with blockchain validation can increase system latency [

29]. Future work may focus on optimizing data collection frequency and validation algorithms to reduce costs and latency.

3. Results of the Blockchain-Based Traceability System for Hymenopellis raphanipes

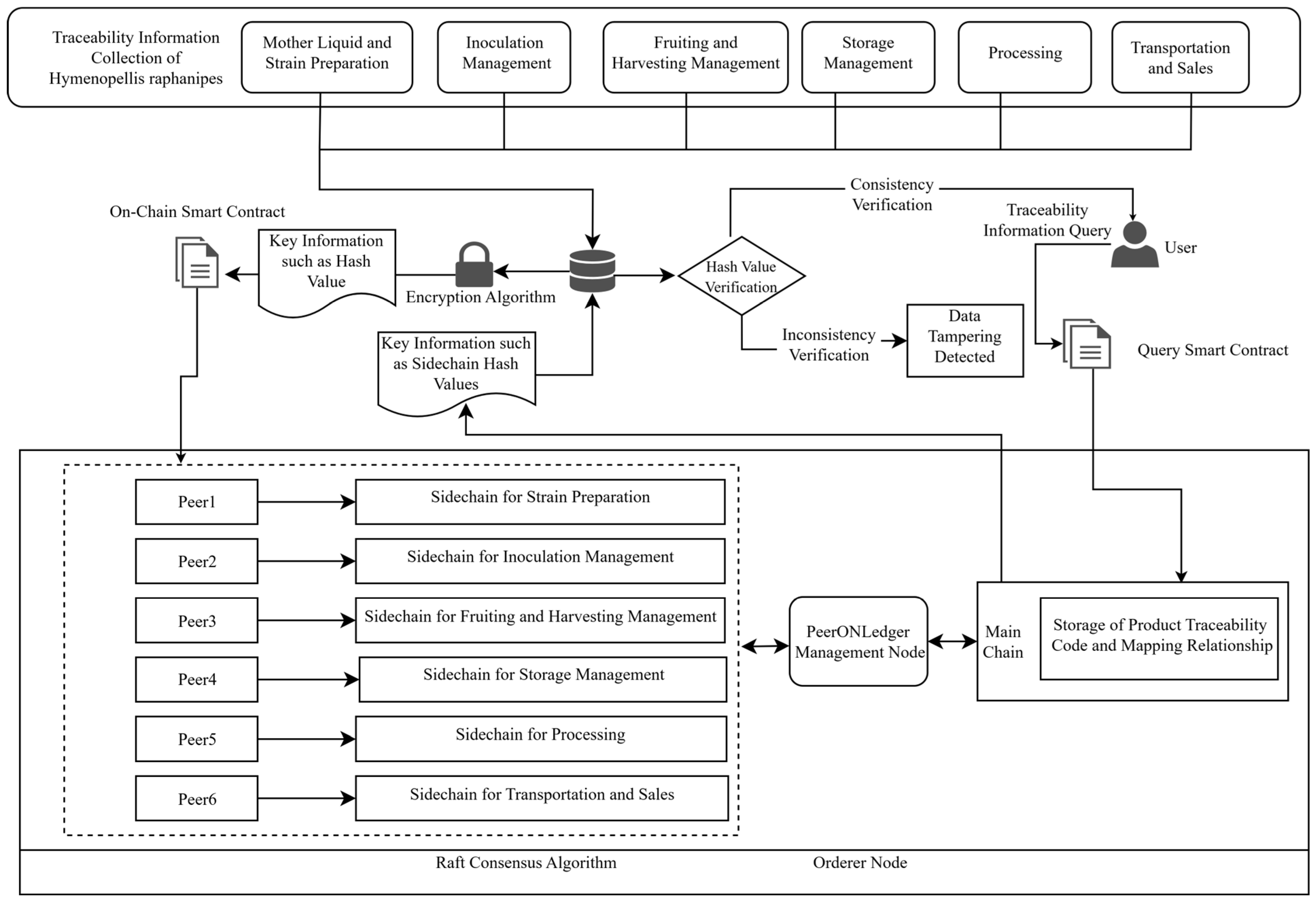

3.1. Blockchain-Based Traceability Model of Hymenopellis Raphanipes

The supply chain of

Hymenopellis raphanipes covers multiple links, and the data volume is large and presents heterogeneous characteristics from multiple sources [

30], To meet the demand for efficient traceability, a hierarchical storage architecture featuring a mainchain and multiple sidechains is established, complemented by an on-chain and off-chain collaborative management mechanism. This approach alleviates issues such as high data storage pressure on blockchain nodes, low query efficiency, and network congestion during data uploads within the traceability blockchain network. The mainchain functions as a global index, recording transaction data for each product’s traceability code and the associated sidechains.

Traceability data from different stages of the supply chain are stored in their respective sidechains, facilitating classified management and parallel processing. The mainchain acts as a global index, recording the mapping between each product’s traceability code and the transaction addresses of traceability data on the sidechains, enabling rapid data retrieval. Instead of storing original sensitive data directly on the sidechains, core information such as the hash value index of sensitive traceability data and transaction addresses—encrypted using the SHA–256 algorithm—is stored. Off-chain, a local database or trusted cloud database is deployed to store original data such as link information, images, and environmental parameters, thereby reducing on-chain storage costs and network bandwidth pressure.

During the data traceability query stage, consumers enter the traceability code through the

Hymenopellis raphanipes traceability system to perform a query. The client node first verifies the validity of the traceability code and transmits it to the blockchain network. The query process begins by invoking the mainchain’s mapping contract to locate the transaction address of the corresponding sidechain, then simultaneously retrieves hash summary records from each sidechain in parallel, and accesses the off-chain database to extract the original data as needed. To ensure data integrity and prevent tampering, the system recalculates the SHA–256 hash of the original information retrieved off-chain and compares it with the summary stored on the sidechains. If the hashes match, the data is considered untampered and the query results are reliable; if not, the system alerts the user that the data is abnormal. The system consolidates traceability information from each stage into a complete product lifecycle record and presents it to users via graphical visualization. This design not only achieves the efficient and tamper-resistant traceability of

Hymenopellis raphanipes quality and safety data, but also effectively protects user privacy and enhances system scalability by isolating private hashes on sidechains and storing original data off-chain. The trusted traceability model of

Hymenopellis raphanipes quality and safety is illustrated in

Figure 3.

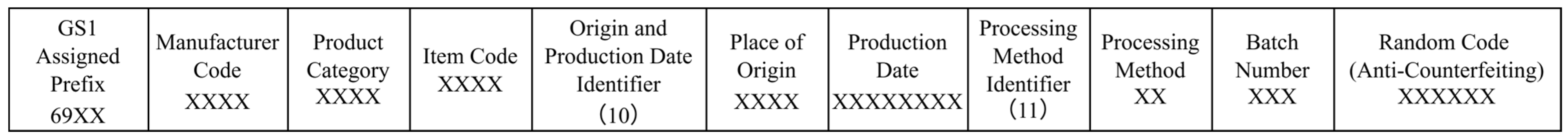

3.1.1. Traceability Code Design

Based on the actual business needs of the enterprise and a systematic analysis of the various links in the

Hymenopellis raphanipes supply chain, the GS1–128 code was selected. Due to its international universality and high coding capacity, GS1–128 can meet the traceability requirements across the entire

Hymenopellis raphanipes supply chain. Accordingly, a 42-bit traceability code tailored to the characteristics of

Hymenopellis raphanipes was designed, and its structure is shown in

Figure 4.

In the design of the traceability code for Hymenopellis raphanipes, the 69X prefix is the identification code assigned to China by the International Article Numbering Association (EAN), and the subsequent components contain multi-level information. First, in the design of the traceability code for Hymenopellis raphanipes, the prefix code “69X” is the identification assigned to China by the International Article Numbering Association (EN). The subsequent components encode information at multiple levels. The last four digits represent the enterprise identification code, specifying the production entity, followed by a four-digit variety identification code distinguishing different types of Hymenopellis raphanipes. The identifier (10) field contains a four-digit origin code and an eight-digit harvest date (formatted as YYYYMMDD), corresponding to the raw material granularity during the mushroom stick preparation stage. The identifier (11) field includes a two-digit processing method code, differentiating fresh from processed products, and a three-digit batch number reflecting batch management in the inoculation and cultivation stages. Finally, a combination of a four-digit individual code and a six-digit random code further ensures code uniqueness and supports item-level traceability in sales and after-sales processes.

The traceability code, serving as the primary key for data association throughout the supply chain, is generated at the mushroom stick production stage and persists through the entire product lifecycle. The system parses the code structure and, together with the interface design, enables automatic mapping between collected data and code fields, thereby establishing a chain granularity mapping relationship spanning raw materials, inoculation, cultivation, warehousing, logistics, and sales. This ensures precise data binding and continuous tracking at each stage. On the consumer side, consumers can scan the QR code on the product packaging or enter the traceability code to access comprehensive information covering raw material sources, production environment, processing methods, and transportation conditions.

The advantage of this coding scheme lies in its standardization and international compatibility, which facilitates future collaboration and data sharing across upstream and downstream segments of the industry chain, while also enhancing the ease of cross-regional regulation and market expansion [

31]. Furthermore, the comprehensive design of the coding fields supports multi-level granularity management, meeting the need for fine-grained traceability in complex supply chains. However, the scheme has certain limitations: the relatively long code length may increase the complexity of data entry and scanning, placing higher demands on the compatibility of hardware devices and information systems. Additionally, the complexity of the coding design may raise initial deployment costs for enterprises and pose challenges for employee training [

32]. Therefore, it is essential to continuously optimize the coding structure and system interfaces based on feedback from real-world operations to improve usability and adaptability.

3.1.2. Fast Query Mechanism

When a user initiates a traceability query request, the system first quickly locates the addresses of multiple data nodes associated with the product identifier through a mapping mechanism. Then, an asynchronous parallel approach using multi-threading or coroutines is employed to simultaneously send query requests to all data nodes, thereby improving retrieval efficiency and reducing response latency.

At the data service interface layer, each node provides an aggregated interface supporting batch queries, enabling the system to retrieve data summaries and metadata related to the current session in a single request, which significantly reduces network round trips and avoids performance bottlenecks caused by sequential communication. After obtaining the summary information, the system accesses the corresponding local or off-chain databases in parallel based on the returned indexes, recalculates the hash values of the original data, and compares them with the registered data summaries to verify information integrity and consistency. This process is supported by underlying trusted mechanisms, including hash verification and signature authentication, ensuring the tamper-proof nature of traceability data throughout its lifecycle. Upon completing data verification, the system extracts the original business data associated with each link, and finally, the query result aggregation module consolidates information from multiple nodes according to the product lifecycle timeline, generating a comprehensive traceability record covering production, processing, circulation, and other key aspects of

Hymenopellis raphanipes, thereby enhancing information transparency and query credibility. The traceability data query process is illustrated in

Figure 5.

3.1.3. Smart Contract Design

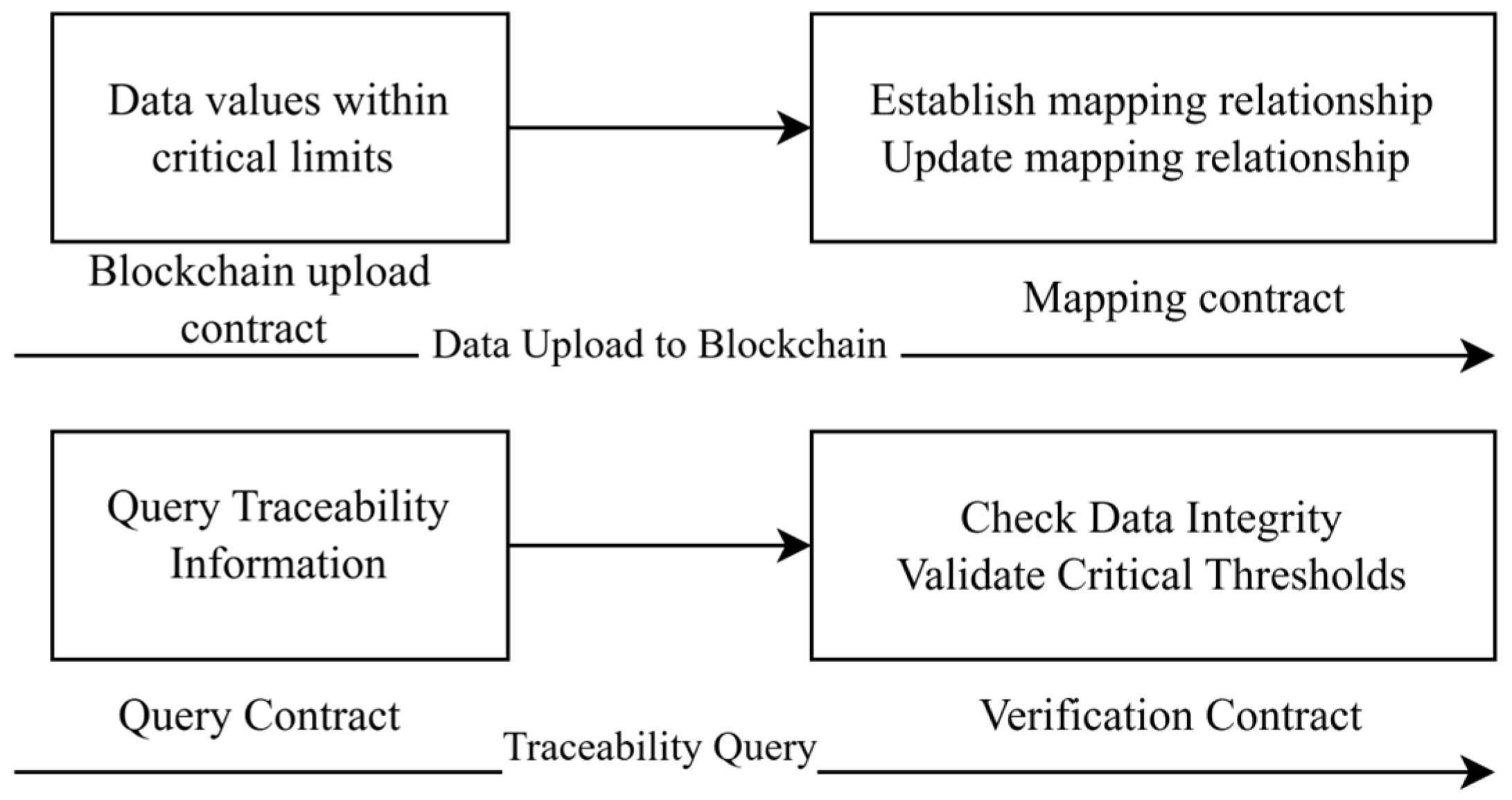

Under the Hyperledger architecture, smart contracts trigger function executions based on preset conditions to enable data uploading and verification across each link of the supply chain. The system defines a unified data structure model tailored to the data types of different links, with each sidechain storing data as key-value pairs according to its business standards, in which the key consists of the original traceability code and transaction address, and the value contains the sidechain’s transaction address or the data hash summary. Each organization invokes the smart contract via its node to hash local data and upload it on-chain, extracting batch numbers and link identification codes to synchronize with the mainchain; if the batch number already exists on the mainchain, the corresponding link information is automatically updated. To enhance modularity and maintainability, smart contracts are divided into three categories: (1) the data uploading contract, responsible for receiving and verifying data summaries from each sidechain, performing field validation, and synchronizing information; (2) the data mapping contract, which maintains the mapping relationships between the main- and sidechains and establishes queryable indexes by batch number and link identifier; and (3) the data validation contract, which checks the consistency of hash values and key information to prevent forgery or redundant data from entering the system, thereby improving data credibility. The supply chain traceability smart contract for

Hymenopellis raphanipes is illustrated in

Figure 6.

3.2. Data Acquisition

In the quality and safety traceability system of Hymenopellis raphanipes, data acquisition serves as a fundamental link for realizing the visualization, verification, and credible on-chain uploading of information across each supply chain stage. It plays a critical role in ensuring the integrity of the information chain and the consistency of the traceability path. The system integrates the actual production processes with the design of traceability granularity to establish a multi-source data collection mechanism that encompasses raw material warehousing, mushroom stick preparation, inoculation and cultivation, warehousing management, logistics and transportation, as well as sales and circulation. Leveraging a combination of IoT devices and manual data entry, the system builds an information collection network characterized by vertical continuity and horizontal collaboration.

In supply chain links in which automated data collection is feasible, the system deploys devices such as sensors, QR codes, RFID tags, and edge computing gateways to enable the real-time sensing and acquisition of data, including environmental parameters, operation times, equipment status, and location information. Each IoT device adopts a unified interface protocol and undergoes regular calibration and testing to ensure data accuracy and stability. For information that cannot be automatically sensed, such as quality inspection results, personnel operation records, and raw material sources, the system utilizes standardized form templates for manual data entry and review via mobile terminals or web interfaces. All manually entered information is bound to the operator’s identity and timestamp, with smart contracts performing on-chain verification and recording to ensure data authenticity and traceability.

Data collected at each supply chain stage is uniformly formatted and mapped according to traceability granularity and coding standards. Combined with technologies such as hash value summaries and digital signatures, this ensures on-chain certification. Throughout data collection, transmission, processing, and uploading, strict access control and encrypted transmission mechanisms are enforced to guarantee the consistency and security of both on-chain and off-chain data. The data collection methods for each supply chain link are detailed in

Table 1.

At the same time, taking into account the realities of the weak network infrastructure, unstable power supply, and limited computing capabilities of terminal devices in agricultural settings, the system incorporates edge computing nodes into its architecture to enable local data caching, preliminary processing, and fault tolerance for anomalies. Data collected by various sensors and terminal devices is first transmitted to the edge nodes for real-time processing and format conversion, and then uploaded to the blockchain network when network conditions permit. This architecture effectively reduces reliance on network bandwidth and continuous connectivity, while enhancing the robustness of data transmission and ensuring the continuity of on-chain verification. Additionally, the system implements a breakpoint retransmission mechanism and a data replenishment strategy to guarantee the complete recording and restoration of traceability data on the blockchain even in the event of network fluctuations or interruptions.

4. System Implementation

This system has been successfully deployed based on Hyperledger Fabric 1.4.6 within the context of the Chinese agricultural environment, fully validating the platform’s feasibility and stability for practical applications in complex supply chain scenarios. The Fabric platform was developed using Java SDK 1.8 and deployed on a cloud server. The front end is developed with the Vue.js framework 2.6.14, while the back end utilizes the Spring Boot framework 2.1.9. For on-chain distributed data management, the system employs CouchDB 3.1.1 and LevelDB 1.20, with MySQL 5.7 serving as the supplementary and backup database for off-chain data storage.

Hyperledger Fabric provided the chain code to realize business logic control, including data uploading, authentication, rights management, history records queries, and other functions. The chain code was developed in the Go language and deployed to each node, and all operations were confirmed by the consensus mechanism before it was written, which further ensures the non-tamperability and transparency of data. For different participants, such as farmers, processors, transporters, and consumers, the system designs a user permission model based on Fabric’s access control policy, thus realizing the hierarchical management of data access. In terms of on-chain data storage, the system adopts LevelDB as the default state database for the management of book state information and at the same time is combined with CouchDB to provide rich query support for on-chain data, so that users can quickly retrieve the target information through multi-dimensional conditions. The off-chain data management module uses MySQL as the core for storing auxiliary information and redundant data, such as user behavior records, system logs, and non-critical traceability fields, to improve the overall operational efficiency and data persistence of the system.

To accommodate different participants—such as farmers, processors, transporters, and consumers—the system designs a user permission model based on Fabric’s access control policies, enabling the hierarchical management of data access. For on-chain data storage, LevelDB serves as the default state database for managing ledger state information, complemented by CouchDB, which provides rich query capabilities to allow users to quickly retrieve target data using multi-dimensional conditions. The off-chain data management module centers on MySQL to store auxiliary information and redundant data, including user behavior records, system logs, and non-critical traceability fields, thereby improving overall system efficiency and data persistence.

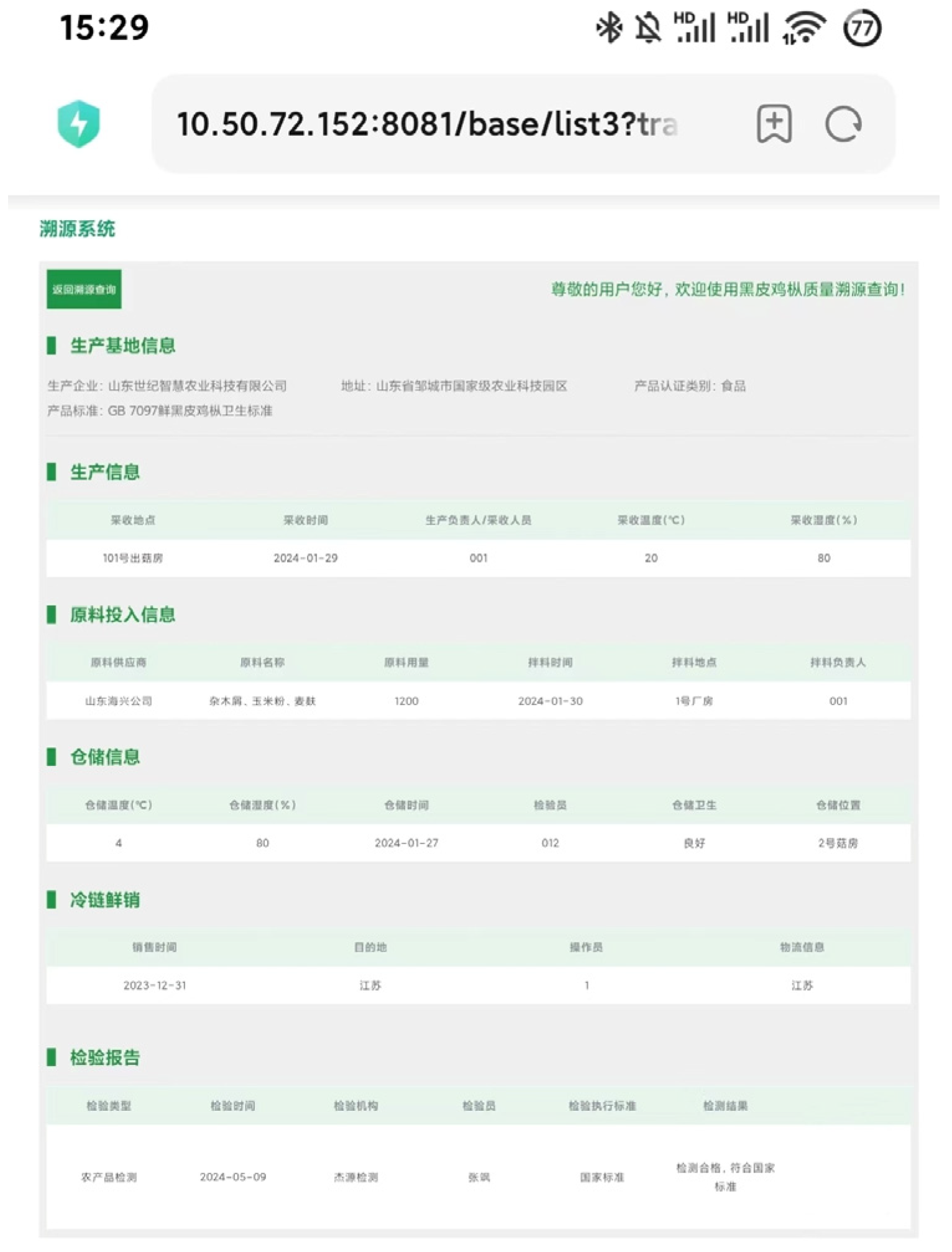

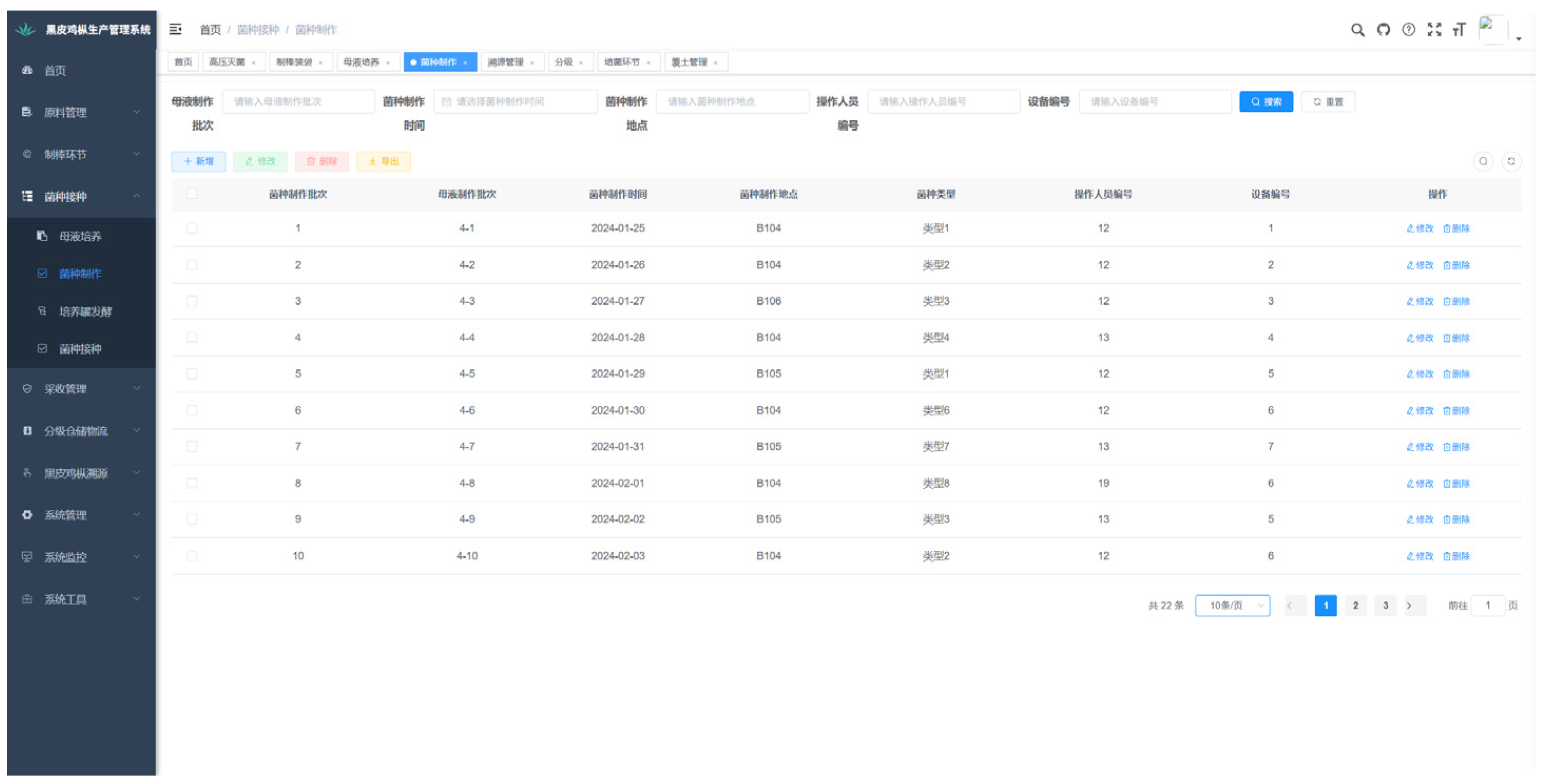

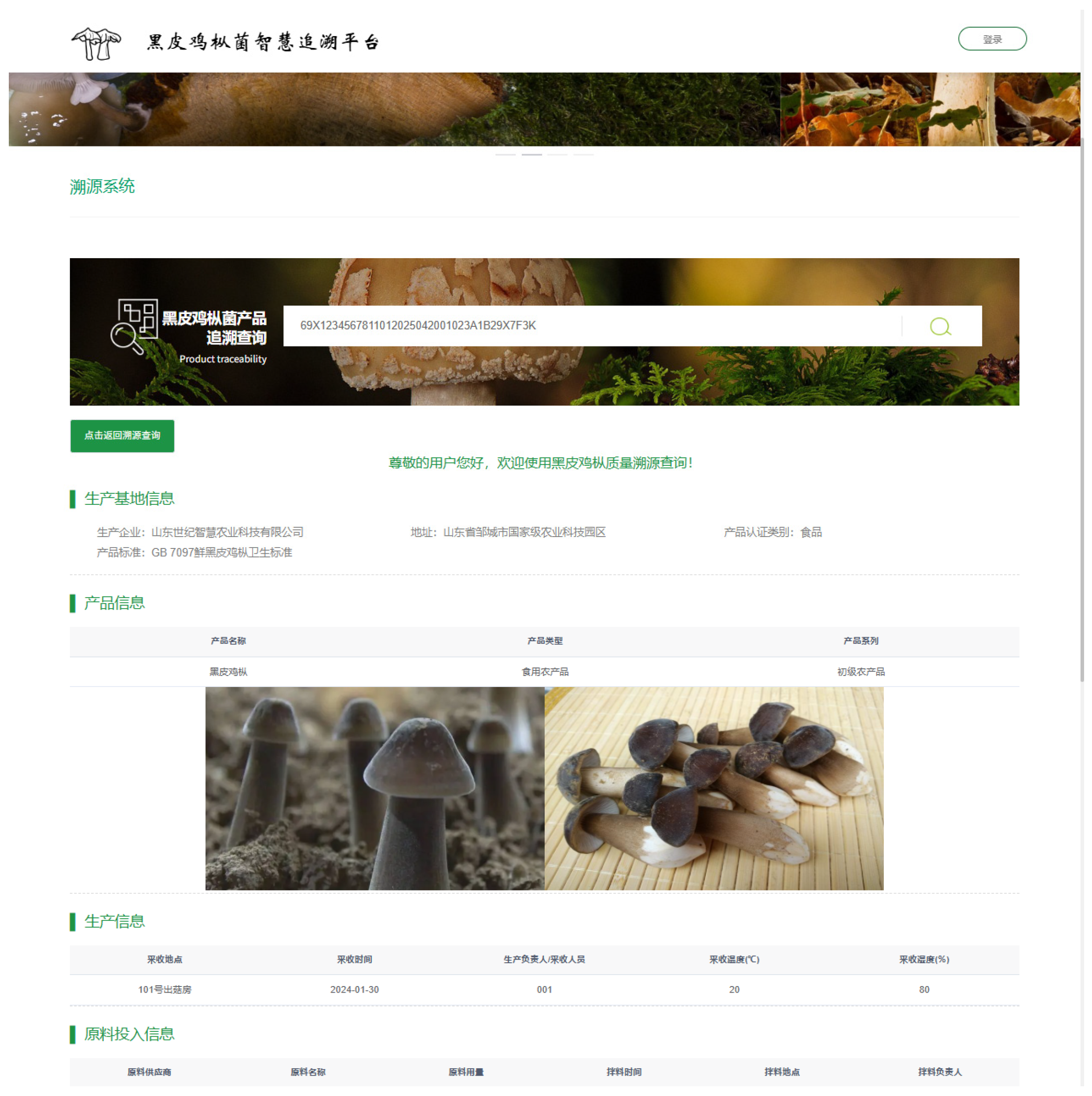

Additionally, the system adopts a multi-chain storage model and is divided into three subsystems: management, web, and mobile, which work collaboratively to ensure data transparency, trustworthiness, and an efficient flow. The management subsystem serves participants across the planting, processing, and logistics stages of the industry chain, supporting the collection and management of information, such as agricultural records, processing techniques, quality testing results, and cold chain transportation data. The web subsystem enables consumers to query the entire lifecycle information of

Hymenopellis raphanipes—from planting environment to logistics—by entering the traceability code via a computer. The mobile subsystem provides a QR code-based traceability query function, allowing consumers to use their smartphones to access traceability data through an API. It visually presents traceability details such as planting environment, processing information, and quality inspection reports, enabling consumers to intuitively understand the origin and flow path of the agricultural product, thereby enhancing consumer trust and brand recognition. The quality and safety traceability system for

Hymenopellis raphanipes is illustrated in

Figure 7,

Figure 8 and

Figure 9.

Experimental Verification

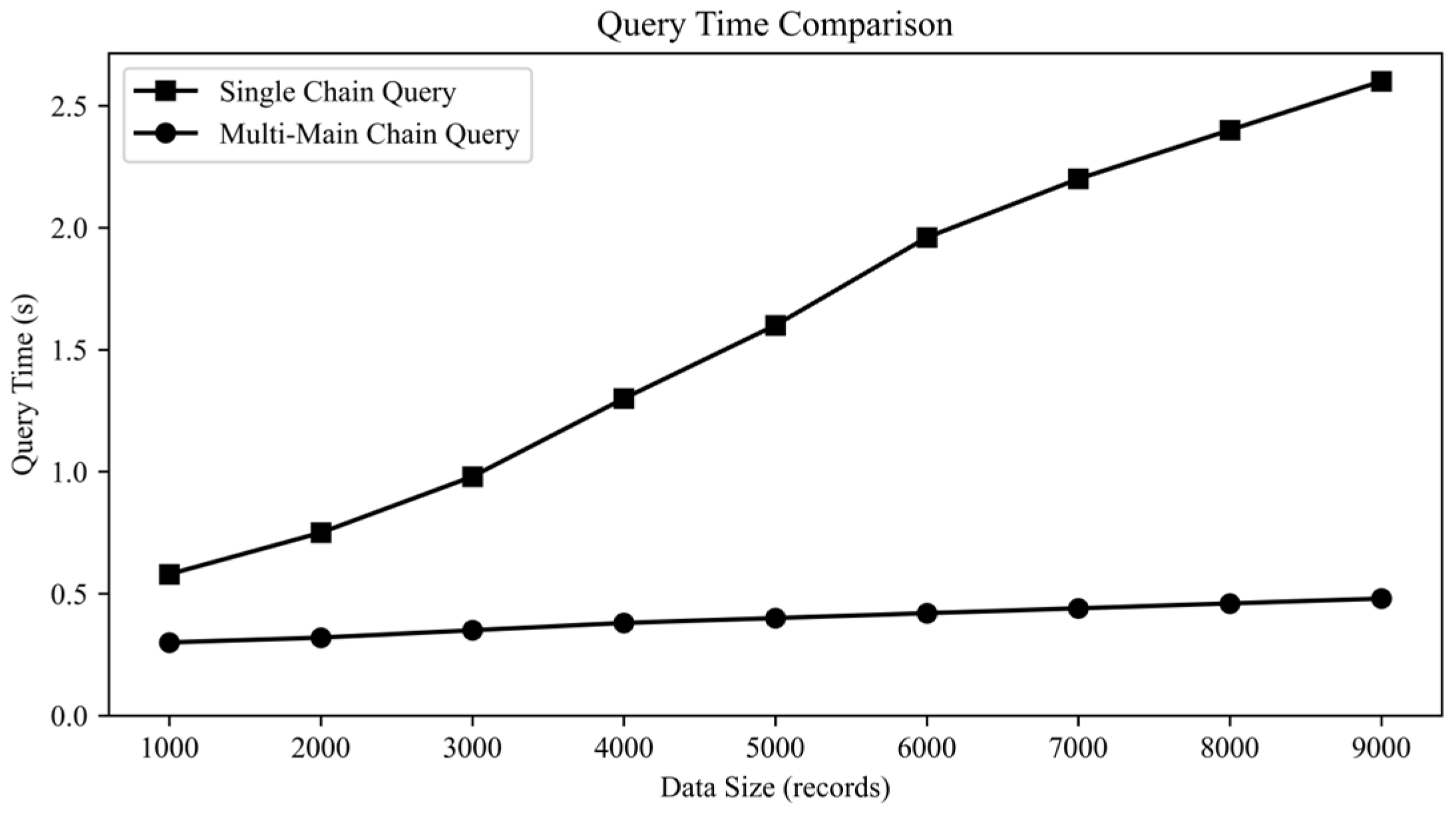

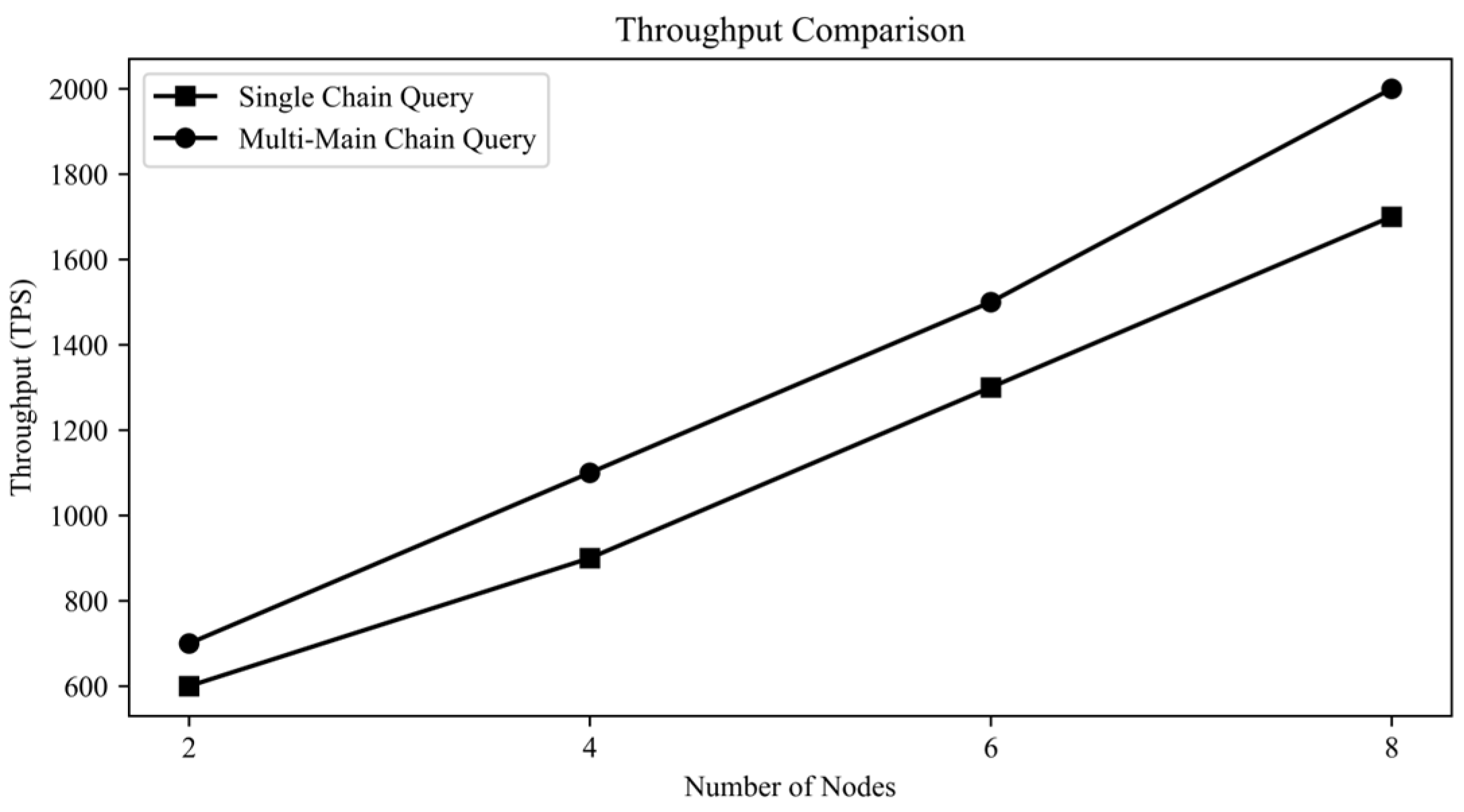

To verify the advantages of the proposed multi-masterchain model in terms of query efficiency and throughput, this study conducts a comparative performance analysis between the traditional single-chain storage model and the multi-masterchain storage model, with a focus on differences in query time and throughput. The experimental environment consists of multiple blockchain nodes deployed within the same network setting. The tests were performed on Ubuntu 20.04, using Hyperledger Fabric version 1.4.6 and Docker version 20.10.18 to ensure a stable and efficient environment. The blockchain benchmarking tool Caliper was employed for comparative testing. The data query time was tested with varying data volumes, and the results are shown in

Figure 10. The throughput was evaluated by varying the number of nodes, and as the number of nodes increased, the system throughput improved accordingly. The throughput test results are presented in

Figure 11.

The experimental results demonstrate that, compared to the traditional single-chain model, the multi-masterchain storage model offers significant advantages in query efficiency, system throughput, and storage optimization. By employing split-chain storage and parallel processing, the multi-masterchain model effectively reduces the mainchain’s load, alleviates system bottlenecks, and significantly lowers data access latency. These performance improvements make it particularly well-suited for large-scale quality and safety traceability systems for Hymenopellis raphanipes, substantially enhancing the efficiency and reliability of food traceability while providing robust technical support for the modernization and development of the rare edible mushroom industry.

5. Discussion

This study addresses the quality and safety traceability requirements for Hymenopellis raphanipes. Based on a detailed analysis of the supply chain information flow, a comprehensive traceability solution suitable for the entire industrial chain of Hymenopellis raphanipes was proposed. The overall system architecture comprises six layers: data acquisition, network transmission, storage management, service management, business functionality, and application interaction, ensuring system scalability and maintainability. Building upon this, a multi-chain collaborative traceability model was developed, employing a mainchain–sidechain storage mechanism combined with on-chain and off-chain coordination. By integrating blockchain technology, the system achieves the efficient management of traceability data with a high degree of transparency, effectively alleviating storage pressure and latency issues commonly found in traditional systems. The functional validation demonstrates that the system successfully balances data credibility and user experience, fulfilling the diverse requirements of consumers, enterprises, and regulatory bodies. The one-click QR code query feature greatly enhances product information accessibility and transparency, reinforcing brand credibility and contributing to the socio-economic sustainability of local specialty agriculture.

Currently, the system is deployed at the pilot scale within a single enterprise. Future work should focus on multi-stakeholder collaboration across organizations to test interoperability in heterogeneous information integration, cross-chain communication, and regulatory interactions, laying the groundwork for large-scale adoption and digital transformation of green agriculture. In addition, the system faces several challenges and limitations that cannot be overlooked. Firstly, the procurement and maintenance costs of IoT equipment may impose a significant financial burden on small- and medium-sized agricultural enterprises, thereby limiting the system’s large-scale adoption. Secondly, although a consortium blockchain architecture has been adopted to reduce energy consumption, blockchain technology still demands ongoing computational resources. This energy consumption may partially conflict with the principles of “low-carbon and environmentally friendly” green agriculture. Future research should prioritize optimizing energy efficiency—such as through the design and deployment of lightweight nodes—and conduct comprehensive cost–benefit analyses of system construction and maintenance to support the sustainable development of digital agricultural infrastructure.

Although this study centers on the traceability of Hymenopellis raphanipes as a core application scenario, the proposed system architecture, coding scheme, and multi-chain coordination mechanism exhibit strong generalizability. When extending the system to other agricultural products, it is essential to consider differences in production processes, quality standards, and supply chain structures. Accordingly, the traceability granularity, coding rules, IoT device selection, and smart contract logic must be dynamically adjusted to ensure system adaptability and traceability accuracy. Future research will focus on tailoring the system to different agricultural product workflows, conducting multi-scenario validations across regions and categories, and further assessing its practical scalability and industrial support capabilities.

Based on the research outcomes, work could be further extended in the following areas in the future.

To meet the demands for real-time responsiveness and system stability in large-scale green agricultural supply chains, blockchain sharding and parallel consensus mechanisms can be introduced to improve processing efficiency and concurrency. Additionally, future research may leverage tools such as Hyperledger Caliper to conduct scalability and performance benchmarking under larger-scale deployments, enabling a systematic evaluation of system behavior in complex and dynamic environments.

While ensuring data availability and sharing, the system should further strengthen its capabilities to protect sensitive information. Integrating privacy-preserving technologies such as zero-knowledge proofs, homomorphic encryption, and federated learning can facilitate secure and compliant data collaboration among stakeholders throughout the supply chain, thereby reducing the risk of data leakage.

Establishing interoperability mechanisms between multiple blockchain platforms and agricultural standards is crucial for supporting the traceability of diverse agricultural products and promoting coordinated development within sustainable agricultural value chains. Through cross-institutional collaboration, the system can explore the application of privacy-enhancing technologies—such as zero-knowledge proofs—in cross-chain communication, ensuring secure and efficient data exchange across different blockchain networks. This will lay a solid technical foundation for extending the system to additional agricultural traceability scenarios.

6. Conclusions

To address the quality and safety management requirements across the entire supply chain of Hymenopellis raphanipes, this study proposes and implements a comprehensive blockchain-based traceability solution, encompassing the construction of a traceability model, the design of a layered system architecture, and the application of key technologies. The system ensures data consistency and traceability throughout planting, harvesting, processing, cold chain logistics, and retail by adopting a unified coding scheme and information association strategy. Leveraging a collaborative storage architecture that integrates mainchains and sidechains, along with coordinated on-chain and off-chain management techniques, the system significantly enhances scalability and data processing efficiency. Moreover, smart contracts are employed to automatically verify and record information at critical nodes, thereby improving data credibility and overall system security.

In the actual deployment process, the system still faces certain challenges in the standardization of data collection, the security management of the off-chain database and the participation of multiple subjects in synergy. For example, the data collection terminals of different production subjects have different standards, leading to differences in the front-end information structure and affecting the efficiency of data fusion; the security strategy and access rights of the off-chain database need to be further optimized to ensure data integrity and privacy. In addition, some farmers are not familiar enough with the operation of the system, which increases the cost of training and promotion. In view of the above problems, it is suggested to focus on strengthening three aspects of work in the promotion process: first, to establish a unified data collection interface and standard template to improve data quality and compatibility; second, to introduce better access control and auditing mechanisms to improve the security and protection of the data under the chain; and third, to strengthen the training and incentive mechanism for users, and to promote the active participation of upstream and downstream subjects in the industry chain in the construction and operation of the system.

This study, based on the Hyperledger Fabric platform, deployed and validated the system within the real-world context of China’s agricultural supply chain, demonstrating the practicality and feasibility of the proposed solution. The research results have effectively enhanced the environmental, economic, and social sustainability of the Hymenopellis raphanipes industry, improved its management level and market competitiveness, and provided a valuable reference for building trustworthy traceability systems for other agricultural products.

With ongoing advances in blockchain technology and agricultural digitalization, this system holds strong potential for broader application. It is expected to support green agricultural transformation and modernization, enhancing food safety assurance and promoting the achievement of sustainable development goals.