Global Population, Carrying Capacity, and High-Quality, High-Pressure Processed Foods in the Industrial Revolution Era

Abstract

1. Introduction

2. Materials and Methods

3. Results

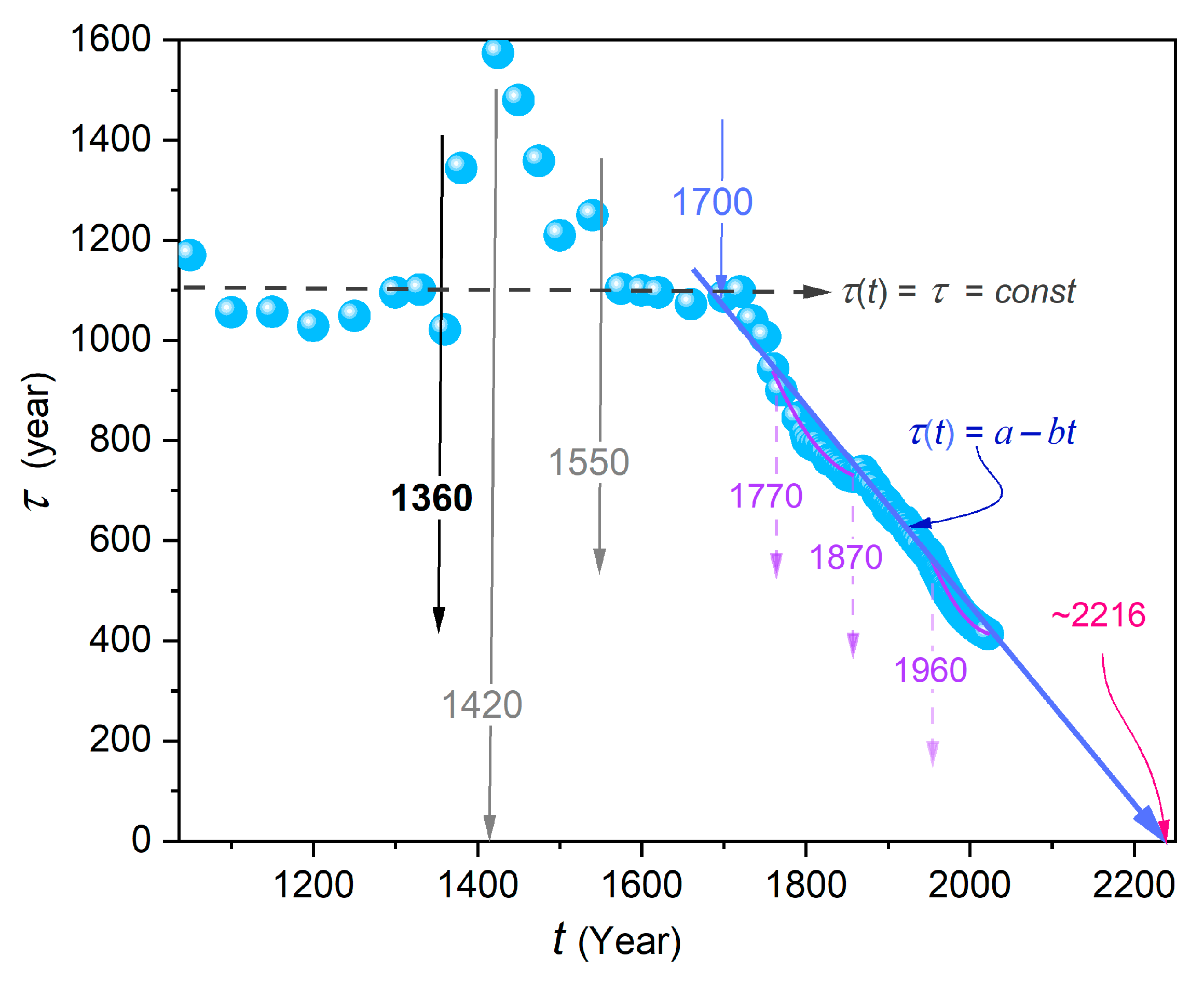

3.1. Global Population, Carrying Capacity, and Condorcet Criterion

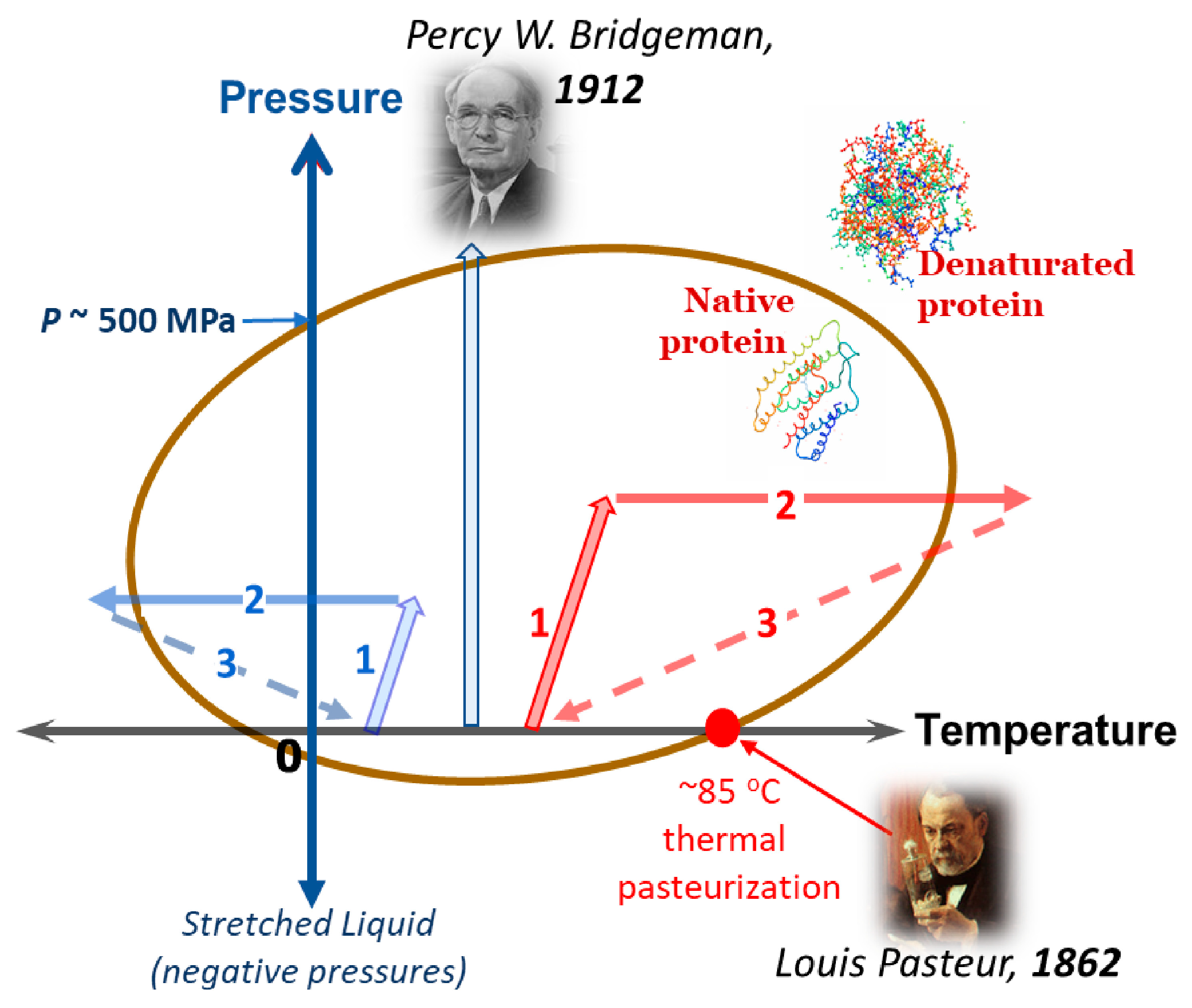

3.2. High-Pressure Preservation/Processing of Food

- ✓

- Thermal pasteurization ensures microbiological safety, but, at the same time, it often reduces the nutritional quality, vitamin content, and bioactivity.

- ✓

- Chemical additives appear to be directly related to obesity, some types of cancer, allergies, skin problems, and intestinal problems;

- ✓

- Cooling and freezing are excellent preservation methods; however, the use of technological solutions can contribute to global warming;

- ✓

- Irradiation can effectively extend shelf lives and improve safety by killing pathogens and insects; however, there are problems related to nutrient degradation and changes in taste and texture. Therefore, it must be limited to dry products such as spices.

- shelf-life extension of up to 180 days;

- high microbiological safety;

- maintenance of the fresh product’s taste, flavor, and texture;

- maintenance of the fresh product’s vitamin composition;

- maintenance of the bioactive and nutritional properties;

- no chemical preservatives;

- activation/deactivation of selected enzymes;

- salt- and sugar-limited/-free products;

- suitability for ‘fluid’ and ‘solid’ foods;

- application to packaged food, reducing the risk of secondary contamination;

- environmentally friendly technology, namely with (i) limited requirements for electric energy, (ii) an almost complete lack of waste during processing, and (iii) a reduction in the quantity of ‘expired products’ and then the disposal problems;

- ‘clean labels’ and innovative technology.

3.3. Compression-Related Sterilization

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Industrial Revolution Review

- First IR—Steam Age;

- Second IR—Electricity Age;

- Third IR—Electronic Technologies and Computers Age;

- Fourth IR—Datafication and Internet Age;

- Fifth IR—New Generation of Energy Sources and Innovative Materials Age, associated with AI-supported implementations.

Appendix A.2. Comments on the Colossal Barocaloric Effect

- The process is based on cheap, widely available, and environmentally neutral materials;

- In applications based on CBE, there is no possibility of ‘escape’ to the atmosphere;

- A power supply is necessary only for a short compression period; consequently, the demand for energy is three times to even ten times smaller than for the ‘standard’, currently used devices.

References

- McCorriston, J.; Field, J. A New Introduction to World Prehistory; Thames & Hudson: London, UK, 2020. [Google Scholar]

- Sojecka, A.A.; Drozd-Rzoska, A. Global population: From Super-Malthus behavior to Doomsday criticality. Sci. Rep. 2024, 14, 9853. [Google Scholar] [CrossRef]

- Sojecka, A.A.; Drozd-Rzoska, A. Verhulst-type equation and the universal pattern for global population growth. PLoS ONE 2025, 20, e0323165. [Google Scholar] [CrossRef]

- Sojecka, A.A.; Drozd-Rzoska, A. Society & Science: Doomsday criticality for the global society. Proc. Socrat. Lect. 2025, 12, 155–165. [Google Scholar] [CrossRef]

- Sokołowska, B.; Skąpska, S.; Niezgoda, J.; Rutkowska, M.; Dekowska, A.; Rzoska, S.J. Inactivation and sublethal injury of Escherichia coli and Listeria innocua by high hydrostatic pressure in model suspensions and beetroot juice. High Press. Res. 2014, 34, 147–155. [Google Scholar] [CrossRef]

- Nema, P.K.; Sehrawat, R.; Ravichandran, C.; Kaur, B.P.; Kumar, A.; Tarafdar, A. Inactivating food microbes by high-pressure processing and combined nonthermal and thermal treatment: A review. J. Food Qual. 2022, 2022, 797843. [Google Scholar] [CrossRef]

- Sojecka, A.A.; Drozd-Rzoska, A.; Rzoska, S.J. Food preservation in the Industrial Revolution epoch: Innovative high pressure processing (HPP, HPT) for the 21st-century sustainable society. Foods 2024, 13, 3028. [Google Scholar] [CrossRef]

- Sojecka, A.A.; Drozd-Rzoska, A. Society & Science: High pressures for innovative pro-health foods. Proc. Socrat. Lect. 2025, 12, 88–100. [Google Scholar] [CrossRef]

- Young, R.M. Malthus and the evolutionists: The common context of biological and social theory. Past Present 1969, 43, 109–145. [Google Scholar] [CrossRef]

- Kooijman, S.A.L.M.; Lika, K.; Starrlight, A.; Nina Marn, N.; Kooi, B.W. The energetic basis of population growth in animal kingdom. Ecol. Model. 2020, 428, 109055. [Google Scholar] [CrossRef]

- Loring, P.A. Coral reefs: Moving beyond Malthus. Curr. Biol. 2022, 32, R569–R571. [Google Scholar] [CrossRef] [PubMed]

- Rzoska, S.J.; Drozd-Rzoska, A.; Mukherjee, P.K.; Lopez, D.O.; Martinez-Garcia, J.C. Distortions-sensitive analysis of pretransional behavior in n-octyloxycyanobiphenyl (8OCB). J. Phys. Condens. Matter 2013, 25, 245105. [Google Scholar] [CrossRef]

- Drozd-Rzoska, A.; Rzoska, S.J.; Zioło, J. Anomalous temperature behavior of nonlinear dielectric effect in supercooled nitrobenzene. Phys. Rev. E 2008, 77, 041501. [Google Scholar] [CrossRef]

- Rzoska, S.J.; Paluch, M.; Drozd-Rzoska, A.; Paluch, M.; Janik, P.; Zioło, J.; Czupryński, K. Glassy and fluidlike behavior of the isotropic phase of mesogens in broad-band dielectric. Eur. Phys. J. E 2001, 7, 387–392. [Google Scholar] [CrossRef] [PubMed]

- Niven, R.K. q-Exponential structure of arbitrary-order reaction kinetics. Chem. Eng. Sci. 2006, 61, 3785–3790. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, P.; Fu, Q.; Ruan, M.; Xu, W. Single-molecule chemical reaction reveals molecular reaction kinetics and dynamics. Nat. Commun. 2014, 5, 4238. [Google Scholar] [CrossRef]

- Akhiezer, A.I.; Belozorov, D.P.; Rofe-Beketov, F.S.; Davydov, L.N.; Spolnik, Z.A. On the theory of propagation of chain nuclear reaction. Phys. A 1999, 273, 272–285. [Google Scholar] [CrossRef]

- Sharon, M.; Sharon, M. Nuclear Chemistry; Springer: Berlin, Germany, 2021. [Google Scholar]

- Pyeon, C.H.; Chiba, G.; Endo, T.; Watanabe, K. Basics of nuclear reactor physics. In Reactor Laboratory Experiments at Kyoto University Critical Assembly; Springer: Singapore, 2025. [Google Scholar]

- Fox, K. The Chain Reaction: Pioneers of Nuclear Science (Lives in Science); Franklin Watts: London, UK, 1998. [Google Scholar]

- Willett, W.; Rockström, J.; Loken, B.; Springmann, M.; Lang, T.; Vermeulen, S.; Garnett, T.; Tilman, D.; DeClerck, F.; Wood, A.; et al. Food in the Anthropocene: The EAT–Lancet Commission on healthy diets from sustainable food systems. Lancet 2019, 393, 447–492. [Google Scholar] [CrossRef]

- Fanzo, J.; Hood, A.; Davis, C. Eating our way through the Anthropocene. Physiol. Behav. 2020, 222, 112929. [Google Scholar] [CrossRef] [PubMed]

- Allen, R.C. The Industrial Revolution: A Very Short Introduction; OUP Oxford: Oxford, UK, 2017. [Google Scholar]

- Martin, A. Industry 5.0. Introductory Guide to the 5th Industrial Revolution; Editoriale Delfino: Milano, Italy, 2023. [Google Scholar]

- Hassoun, A.; SJagtap, S.; Trollman, H.; Garcia-Garcia, G.; Abdullah, A.A.; Goksen, G.; Bader, F.; Ozogul, F.; Barba, F.J.; Cropotova, A.; et al. Food processing 4.0: Current and future developments spurred by the fourth industrial revolution. Food Control 2023, 145, 109507. [Google Scholar] [CrossRef]

- Golovianko, M.; Terziyan, V.; Branytskyi, V.; Malyk, D. Industry 4.0 vs. Industry 5.0: Co-existence, transition, or a hybrid. Procedia Comp. Sci. 2023, 217, 102–113. [Google Scholar] [CrossRef]

- Coccia, M. Driving forces of technological change: The relation between population growth and technological innovation. Analysis of the optimal interaction across countries. Technol. Forecast. Soc. Change 2014, 82, 52–65. [Google Scholar] [CrossRef]

- Galor, O. From Malthusian Stagnation to Modern Growth. Am. Econ. Rev. 1999, 89, 150–154. [Google Scholar] [CrossRef]

- Peterson, R. Behind the Curve: Can Manufacturing Provide Inclusive Growth; Peterson Inst. for Int. Economics: Washington, DC, USA, 2024. [Google Scholar]

- Berdegué, J.A.; Trivelli, C.; Vos, R. Employment impacts of agrifood system innovations and policies: A review of the evidence. Glob. Food Secur. 2025, 44, 100832. [Google Scholar] [CrossRef]

- Hunter, N. Louis Pasteur; Raintree Publishers: Oxford, UK, 2014. [Google Scholar]

- Teixeira, A.A. Thermal food preservation techniques (pasteurization, sterilization, canning and blanching). In Conventional and Advanced Food Processing Technologies; Bhattacharya, S., Ed.; Wiley: New York, NY, USA, 2014; Chapter 6. [Google Scholar]

- Msagati, T.A.M. The Chemistry of Food Additives and Preservatives; Wiley-Blackwell: New York, NY, USA, 2012. [Google Scholar]

- Bald, W.B. Food Freezing: Today and Tomorrow; Springer: Berlin, Germany, 2012. [Google Scholar]

- Thomas, M.H. Use of ionizing radiation to preserve food. In Nutritional Evaluation of Food Processing; Karmas, E., Harris, R.S., Eds.; Springer: Dordrecht, The Netherlands, 1988. [Google Scholar]

- Ajibola, O.J. An overview of irradiation as a food preservation technique. Nov. Res. Microbiol. J. 2020, 4, 779–789. [Google Scholar] [CrossRef]

- Rabeja, I.R. Marie Sklodowska Curie: Her Contribution to Science; Lightning Source Inc.: La Vergne, TN, USA, 2017. [Google Scholar]

- Sen, M. Food Chemistry: The Role of Additives, Preservatives and Adulteration; Wiley and Sons: New York, NY, USA, 2022. [Google Scholar]

- Muhsin, N.M.B.; Ghafil, R.A.; Hussein, K.M.; Alasady, D. Review on the Impact of Chemical Preservatives on Health. J. Clin. Trials Regul. 2022, 4, 26–32. [Google Scholar]

- Anand, S.P.; Sati, N. Artificial preservatives and their harmful effects: Looking toward nature for safer alternatives. Int. J. Pharm. Sci. Res. 2013, 7, 2496–2501. [Google Scholar]

- Reardon, S. Food preservatives linked to obesity and gut disease. Nature 2015. [Google Scholar] [CrossRef]

- Kobets, T.; Smith, B.P.C.; Williams, G.M. Food-borne chemical carcinogens and the evidence for human cancer risk. Foods 2022, 11, 2828. [Google Scholar] [CrossRef]

- Simmons, A.L.; Schlezinger, J.J.; Corkey, B.E. What are we putting in our food that is making us fat? Food Additives, contaminants, and other putative contributors to obesity. Curr. Obes. Rep. 2014, 3, 273–285. [Google Scholar] [CrossRef]

- Nyambok, E.; Robinson, C. The role of food additives and chemicals in food allergy. Ann. Food Proces. Preserv. 2016, 1, 1006. [Google Scholar]

- Monteiro, C.A. Reasons to avoid ultra-processed foods. BMJ 2024, 384, 439. [Google Scholar] [CrossRef]

- Nilson, E.A.F.; Delpino, F.M.; Batis, C.; Machado, P.P.; Moubarac, J.-C.; Cediel, G.; Corvalan, C.; Ferrari, G.; Rauber, F.; Martinez-Steele, E.; et al. Premature mortality attributable to ultraprocessed food consumption in 8 countries. Am. J. Prevent. Med. 2025, 25, 1091–1099. [Google Scholar] [CrossRef]

- Food Waste Index Report 2024. Think Eat Save: Tracking Progress to Halve Global Food Waste; UNEP: New York, NY, USA, 2024. [Google Scholar]

- Jeremić, M.; Matkovski, B.; Đokić, D.; Jurjević, Ž. Food loss and food waste along the food supply chain—An international perspective. Prob. Sust. Develop. 2024, 19, 81–90. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Development, Poland (Ministerstwo Rolnictwa i Rozwoju Wsi, Polska): Food Promotion Strategy. 2017; p. 5. Available online: https://www.gov.pl/web/rolnictwo/stanowiska-2017 (accessed on 5 May 2025).

- United Nations, FAO. Sustainable Food System. Concept and Framework; Food and Agriculture Organization of the United Nations: Rome, Italy. Available online: https://openknowledge.fao.org/ (accessed on 2 June 2025).

- European Union. Knowledge Centre for Food Fraud and Quality. Available online: https://knowledge4policy.ec.europa.eu/food-fraud-quality/topic/food-quality_en (accessed on 5 May 2025).

- Houška, M.; Silva, F.V.M.; Evelyn; Buckow, R.; Terefe, N.S.; Tonello, C. High pressure processing applications in plant foods. Foods 2022, 11, 223. [Google Scholar] [CrossRef]

- Amsasekar, A.; Mor, R.S.; Kishore, A.; Singh, A.; Sid, S. Impact of high pressure processing on microbiological, nutritional and sensory properties of food: A review. Nutr. Food Sci. 2022, 52, 996–1017. [Google Scholar] [CrossRef]

- Nath, K.G.; Pandiselvam, R.; Sunil, C.K. High-pressure processing: Effect on textural properties of food- a review. J. Food Eng. 2023, 351, 111521. [Google Scholar] [CrossRef]

- Silva, F.V.M.; Evelyn. Pasteurization of food and beverages by high pressure processing (HPP) at room temperature: Inactivation of Staphylococcus aureus, Escherichia coli, Listeria monocytogenes, Salmonella, and other microbial pathogens. Appl. Sci. 2023, 13, 1193. [Google Scholar] [CrossRef]

- Lim, S.H.; Chin, N.L.; Sulaiman, A.; Tay, C.H.; Wong, T.H. Microbiological, physicochemical and nutritional properties of fresh cow milk treated with industrial high-pressure processing (HPP) during storage. Foods 2023, 12, 592. [Google Scholar] [CrossRef]

- Goraya, R.K.; Singla, M.; Kaura, R.; Singh, C.B.; Singh, A. Exploring impact of high pressure processing on the characteristics of processed fruit and vegetable products: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2024, 65, 3856–3879. [Google Scholar] [CrossRef]

- Xiao, T.; Li, Y.; Hu, L.; Zhu, S.; Ramaswany, H.S.; Yu, Y. High pressure sub-zero concept for improving microbial safety and maintaining food quality: Background fundamentals, equipment issues and applications. Food Rev. Int. 2024, 40, 1–21. [Google Scholar] [CrossRef]

- Keyata, E.O.; Bikila, A.M. Effect of high-pressure processing on nutritional composition, microbial safety, shelf life and sensory properties of perishable food products: A review. J. Agric. Food. Nat. Res. 2024, 2, 69–78. [Google Scholar]

- Waghmare, R. High pressure processing of fruit beverages: A recent trend. Food Humanit. 2024, 2, 100232. [Google Scholar] [CrossRef]

- Gazda, P.; Glibowski, P. Advanced technologies in food processing—Development perspective. Appl. Sci. 2024, 14, 3617. [Google Scholar] [CrossRef]

- Yang, P.; Liao, X. High pressure processing plus technologies: Enhancing the inactivation of vegetative microorganisms. Adv. Food Nutr. Res. 2024, 110, 145–195. [Google Scholar]

- Zuo, H.; Wang, B.; Zhang, J.; Zhong, Z.; Tang, Z. Research progress on bacteria-reducing pretreatment technology of meat. Foods 2024, 13, 2361. [Google Scholar] [CrossRef]

- Gauch, H.G. Scientific Method in Brief; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Anstey, P.R. The methodological origins of Newton’s queries. Stud. Hist. Phil. Sci. Part A 2004, 35, 247–269. [Google Scholar] [CrossRef]

- Brewster, D. The Life of Sir Isaac Newton; Diamond Publishers: Croydon, UK, 2017. [Google Scholar]

- Malthus, T. An Essay on the Principle of Population. In Rethinking the Western Tradition; Stimson, S.C., Ed.; de Gruyter: Amsterdam, The Netherlands, 2013. First published 1798. [Google Scholar]

- Macfarlane, A. The Malthusian Trap. In The Savage Wars of Peace; Palgrave Macmillan: London, UK, 2003. [Google Scholar]

- Markert, J. The Malthusian fallacy: Prophecies of doom and the crisis of social security. Soc. Sci. J. 2005, 42, 555–568. [Google Scholar] [CrossRef]

- Valenze, D. The Invention of Scarcity: Malthus and the Margins of History; Yale University Press: New Heaven, CT, USA, 2023. [Google Scholar]

- Verhulst, P.F. Deuxieme Memoire sur la loi D’accroissement de la Population; Memoires de l’Academie Royale des Sciences, des Lettres et des Beaux-Arts de Belgique 1847; EuDML: Online, 2022; Volume 20, pp. 1–32. [Google Scholar]

- Pearl, R. The growth of populations. Q. Rev. Biol. 1927, 2, 532–548. [Google Scholar] [CrossRef]

- Pearl, R.; Reed, L. On the rate of growth of the population of the United States since 1790 and its mathematical representation. Proc. Natl. Acad. Sci. USA 1920, 6, 275–288. [Google Scholar] [CrossRef]

- Kapitza, S.P. On the theory of global population growth. Phys. Uspekhi 2010, 53, 1287–1337. [Google Scholar] [CrossRef]

- Bacaër, N. A Short History of Mathematical Population Dynamics; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- von Foerster, H.; Mora, P.M.; Amiot, L.W. Doomsday: Friday 13 November, A.D. 2026. Science 1960, 132, 1291–1295. [Google Scholar] [CrossRef]

- Taagepera, R. People, skills, and resources: An interaction model for world population growth. Technol. Forecast. Soc. Changes 1979, 13, 13–30. [Google Scholar] [CrossRef]

- Volterra, V. Variations and fluctuations of the number of individuals in animal species living together. ICES J. Mar. Sci. 1928, 3, 3–51. [Google Scholar] [CrossRef]

- Cohen, J.E. Population growth and Earth’s human carrying capacity. Science 1995, 269, 341–346. [Google Scholar] [CrossRef]

- Kendall, B.E.; Fox, G.A.; Fujiwara, M.; Nogeire, T.M. Demographic heterogeneity, cohort selection, and population growth. Ecology 2011, 92, 1985–1995. [Google Scholar] [CrossRef]

- Lima, M.; Berryman, A.A. Positive and negative feedbacks in human population dynamics: Future equilibrium or collapse? Oikos 2011, 120, 1301–1310. [Google Scholar] [CrossRef]

- Lueddeke, G.R. Global Population Health and Well-Being in The 21st Century: Toward New Paradigms, Policy, and Practice; Springer: Berlin, Germany, 2015. [Google Scholar]

- Dias, A.; D’Hombres, M.; Ghisetti, B.; Pontarollo, C.; Dijkstra, N. The Determinants of Population Growth: Literature Review an Empirical Analysis; Working Papers-10; Joint Research Centre, European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Herrington, G. Update to limits to growth: Comparing the World3 model with empirical data. J. Ind. Ecol. 2020, 25, 614–626. [Google Scholar] [CrossRef]

- Bystroff, C. Footprints to Singularity: A global population model explains late 20th century slow-down, and predicts peak within ten years. PLoS ONE 2021, 16, e0247214. [Google Scholar] [CrossRef]

- Galor, O. Population, Technology, and growth: From Malthusian stagnation to the demographic transition and beyond. Am. Econ. Rev. 2000, 90, 816–828. [Google Scholar] [CrossRef]

- Dea, M. The Malthus effect: Population and the liberal government of life. Econ. Soc. 2015, 44, 18–39. [Google Scholar] [CrossRef]

- Weil, D.N.; Wilde, J. How relevant is Malthus for economic development today? Am. Econ. Rev. 2010, 100, 378–382. [Google Scholar] [CrossRef]

- Kaack, L.H.; Katul, G.G. Fifty years to prove Malthus right. Proc. Natl. Acad. Sci. USA 2013, 110, 4161–4416. [Google Scholar] [CrossRef]

- Smith, P. Malthus is still wrong: We can feed a world of 9–10 billion, but only by reducing food demand. Proc. Nutr. Soc. 2015, 74, 187–190. [Google Scholar] [CrossRef]

- Zheng, Y. Malthus’ Population Theory Is Still Wrong. Chin. Sci. Bull. 2017, 62, 233–2345. [Google Scholar] [CrossRef][Green Version]

- Kallis, G. Limits: Why Malthus Was Wrong and Why Environmentalists Should Care; Stanford University Press: Stanford, CA, USA, 2019. [Google Scholar]

- Montano, B.; Garcia-López, M.S. Malthusianism of the 21st century. Environ. Sustain. Indic. 2020, 6, 100032. [Google Scholar] [CrossRef]

- Urdal, H. People vs. Malthus: Population pressure, environmental degradation, and armed. Conflict revisited. J. Peace Res. 2005, 42, 417–434. [Google Scholar] [CrossRef]

- Walker, J.; Gaffney, V.; Fitch, S.; Muru, M.; Fraser, A.; Bates, M.; Bates, R. A great wave: The Storegga tsunami and the end of Doggerland? Antiquity 2020, 94, 1409–1425. [Google Scholar] [CrossRef]

- Bowman, A.; Wilson, A. Quantifying the Roman Economy: Methods and Problems; Oxford University Press: Oxford, UK, 2009. [Google Scholar]

- Garnsey, P. The Roman Empire: Economy, Society and Culture; University of California Press: Los Angeles, CA, USA, 2014. [Google Scholar]

- Pliny (the Elder). Naturalis Historia; Legare Street Press: Hungerford, UK, 2022. [Google Scholar]

- Malanima, P. When did England overtake Italy? Medieval and early modern divergence in prices and wages. Eur. Rev. Econ. Hist. 2013, 17, 45–70. [Google Scholar] [CrossRef]

- De Zwart, P. The long-run evolution of global real wages. J. Econ. Surv. 2025, 99, 489–516. [Google Scholar] [CrossRef]

- Clark, G. The Condition of the Working Class in England, 1209–2004. J. Political Econ. 2005, 113, 1307–1340. [Google Scholar] [CrossRef]

- Lehman, C.; Loberg, S.; Wilson, M.; Girham, E. Ecology of the Anthropocene signals hope for consciously managing the planetary ecosystem. Proc. Natl. Acad. Sci. USA 2021, 118, e2024150118. [Google Scholar] [CrossRef]

- Huxley, A. Brave New World; Penguin Random House: London, UK, 2004. [Google Scholar]

- Andrews, P.; Martin, L. Hominoid dietary evolution. Philos. Trans. R. Soc. London. Ser. B Biol. Sci. 1991, 334, 199–209. [Google Scholar]

- MacDonald, K.; Sherrjon, F.; van Vee, E.; Roebroeks, W. Middle Pleistocene fire use: The first signal of widespread cultural diffusion in human evolution. Proc. Natl. Acad. Sci. USA 2021, 118, e2101108118. [Google Scholar] [CrossRef]

- Craig, O.; Saul, H.; Lucquin, A.; Nishida, Y.; Taché, K.; Clarke, L.; Thompson, A.; Altoft, D.T.; Uchiyama, J.; Ajimoto, M.; et al. Earliest evidence for the use of pottery. Nature 2013, 496, 351–354. [Google Scholar] [CrossRef]

- Akhila, P.P.; Sunooj, K.V.; Aaliya, B.; Navaf, M.M. Historical developments in food science and technology. J. Nutr. Res. 2022, 10, 36–41. [Google Scholar] [CrossRef]

- Alt, K.W.; Al-Ahmed, A.; Woelber, J.P. Nutrition and health in human evolution–past to present. Nutrients 2022, 14, 3594. [Google Scholar] [CrossRef]

- Bridgeman, P.W. The coagulation of albumen by pressure. J. Biol. Chem. 1912, 19, 511–512. [Google Scholar] [CrossRef]

- Bridgeman, P.W. General Survey of Certain Results in the Field of High-Pressure Physics. Nobel Prize in Physics Lecture. 1946. Available online: https://www.nobelprize.org/uploads/2018/06/bridgman-lecture.pdf (accessed on 20 June 2024).

- Clapeyron, M.C. Mémoire sur la puissance motrice de la chaleur. J. l’École Polytech. 1834, 23, 153–190. [Google Scholar]

- Clausius, R. Ueber die bewegende Kraft der Wärme und die Gesetze, welche sich daraus für die Wärmelehre selbst ableiten lassen [On the motive power of heat and the laws which can be deduced therefrom regarding the theory of heat]. Ann. Der Phys. 1850, 155, 500–524. [Google Scholar] [CrossRef]

- Debenedetti, P.G. Metastable Liquids: Concepts and Principles; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Imre, A.R.; Drozd-Rzoska, A.; Horvath, A.; Kraska, T.; Rzoska, S.J. Solid-fluid phase transitions under extreme pressures including negative ones. J. Non-Cryst. Solids 2008, 354, 4157–4162. [Google Scholar] [CrossRef]

- Smeller, L.; Heremans, K. Some thermodynamic and kinetic consequences of the phase diagram of protein denaturation. In High Pressure Research in Bioscience and Biotechnology; Heremans, K., Ed.; Leuven University Press: Leuven, Belgium, 1997; pp. 55–58. [Google Scholar]

- Heremans, K.; Smeller, L. Proteins in structure and dynamics at high pressure. Biochim. Biophys. Acta (BBA) Protein Struct. Molec. Enzymol. 1998, 1386, 353–370. [Google Scholar] [CrossRef]

- Govaris, A.; Pexara, A. Inactivation of foodborne viruses by high-pressure processing (HPP). Foods 2021, 10, 215. [Google Scholar] [CrossRef]

- Hyperbaric Company: HPP Blog. High Pressure Thermal Processing (HPTP). 2014. Available online: https://www.hiperbaric.com/en/high-pressure-thermal-processing-hptp/ (accessed on 10 June 2024).

- Li, B.; Kawakita, Y.; Ohira-Kawamura, S.; Sugahara, T.; Wang, H.; Wang, J.; Chen, Y.; Kawaguchi, S.I.; Kawaguchi, S.; Ohara, K.; et al. Colossal barocaloric effects in plastic crystals. Nature 2019, 567, 506–510. [Google Scholar] [CrossRef]

- Lloveras, P.; Aznar, A.; Barrio, M.; Negrier, P.; Popescu, C.; Planes, A.; Manosa, L.; Stern-Taulats, E.; Avramenko, A.; Mathur, N.D.; et al. Colossal barocaloric effects near room temperature in plastic crystals of neopentylglycol. Nat. Commun. 2019, 10, 1803. [Google Scholar] [CrossRef]

- Miliante, C.M.; Christmann, A.M.; Soares, R.P.; Bocca, J.R.; Alves, C.S.; Carvalho, A.M.G.; Muniz, A.R. On the colossal barocaloric effect in higher n-alkanes. J. Mat. Chem. A 2022, 10, 8344–8355. [Google Scholar] [CrossRef]

- Lin, J.; Tong, P.; Zhang, K.; Tao, K.; Lu, W.; Wang, X.; Zhang, X.; Song, W.; Sun, Y. Colossal and reversible barocaloric effect in liquid-solid-transition materials n-alkanes. Nat. Commun. 2022, 13, 596. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, K.; Li, S.; Song, R.; Yu, D.; Wang, Y.; Wang, J.; Kawaguchi, S.; Zhang, Z.; Yu, C.; et al. Thermal batteries based on inverse barocaloric effect. Sci. Adv. 2023, 9, eadd0374. [Google Scholar] [CrossRef]

- Peters, J.; Schmidt, K.; Dietrich, O.; Pöllath, N. Göbekli Tepe: Agriculture and Domestication. In Encyclopedia of Global Archaeology; Smith, C., Ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Knitter, D.; Braun, R.; Clare, L.; Nykamp, M.; Schütt, B. Göbekli Tepe: A Brief Description of the Environmental Development in the Surroundings of the UNESCO World Heritage Site. Land 2019, 8, 72. [Google Scholar] [CrossRef]

- Global Growth Insight. High Pressure Processing (HPP) Food Market Size by 2032. Available online: https://www.globalgrowthinsights.com/market-reports/high-pressure-processing-hpp-food-market-100548 (accessed on 6 May 2025).

- Rzoska, S.J.; Musiał, F.; Rutkowska, M.; Fonberg-Broczek, M.; Sokołowska, B.; Drozd-Rzoska, A.; Nowakowska, J. Simultaneous impact of high pressures and pulsed electric field on Saccharomyces cerevisiae model system. J. Food Process. Technol. 2015, 6, 1000518. [Google Scholar]

- Prempeh, N.Y.A.; Nunekpeku, X.; Murugesan, A.; Li, H. Ultrasound in the food industry: Mechanisms and applications for non-invasive texture and quality analysis. Foods 2025, 14, 2057. [Google Scholar] [CrossRef]

- Rzoska, S.J.; Drozd-Rzoska, A. Criticality-related fundamental bases for new generations of gas-liquid, liquid-liquid, and liquid (LE) extraction technologies. Eur. Phys. J. E 2022, 45, 67. [Google Scholar] [CrossRef] [PubMed]

- Tchonkouang, R.D.; Lima, A.R.; Quintino, A.C.; Cristofoli, N.L.; Vieira, M.C. UV-C Light: A promising preservation technology for vegetable-based nonsolid food products. Foods 2023, 12, 3227. [Google Scholar] [CrossRef] [PubMed]

- Harikrishna, S.; Anil, P.P.; Shams, R.; Dash, K.K. Cold plasma as an emerging nonthermal technology for food processing: A comprehensive review. J. Agric. Food Res. 2023, 14, 100747. [Google Scholar] [CrossRef]

- Mandal, R.; Mohammadi, X.; Wiktor, A.; Singh, A.; Singh, A.P. Applications of Pulsed Light Decontamination Technology in Food Processing: An Overview. Appl. Sci. 2020, 10, 3606. [Google Scholar] [CrossRef]

- Habiba, U.; Bajpai, A.; Shafi, Z.; Pandey, V.; Singh, R. Advancing sustainability through modified atmosphere packaging (MAP) for fresh food preservation: A critical review. J. Stored Prod. Res. 2025, 112, 102657. [Google Scholar] [CrossRef]

- Pattnaik, R.; Panda, S.K.; Biswas, S.; De, S.; Satahrada, S.; Kumar, S. Prospects and challenges of nanomaterials in sustainable food preservation and packaging: A review. Discov. Nano 2024, 19, 178. [Google Scholar] [CrossRef] [PubMed]

- Adams, F. On Ancient Medicine, Hippocrates of Kos; Dalcassian Publishing Company: Glasgow, UK, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sojecka, A.A.; Drozd-Rzoska, A.; Rzoska, S.J. Global Population, Carrying Capacity, and High-Quality, High-Pressure Processed Foods in the Industrial Revolution Era. Sustainability 2025, 17, 6827. https://doi.org/10.3390/su17156827

Sojecka AA, Drozd-Rzoska A, Rzoska SJ. Global Population, Carrying Capacity, and High-Quality, High-Pressure Processed Foods in the Industrial Revolution Era. Sustainability. 2025; 17(15):6827. https://doi.org/10.3390/su17156827

Chicago/Turabian StyleSojecka, Agata Angelika, Aleksandra Drozd-Rzoska, and Sylwester J. Rzoska. 2025. "Global Population, Carrying Capacity, and High-Quality, High-Pressure Processed Foods in the Industrial Revolution Era" Sustainability 17, no. 15: 6827. https://doi.org/10.3390/su17156827

APA StyleSojecka, A. A., Drozd-Rzoska, A., & Rzoska, S. J. (2025). Global Population, Carrying Capacity, and High-Quality, High-Pressure Processed Foods in the Industrial Revolution Era. Sustainability, 17(15), 6827. https://doi.org/10.3390/su17156827