Analysis of the Physical and Thermal Characteristics of Gypsum Panels with Hemp Hurds for Building Insulation

Abstract

1. Introduction

2. Materials and Methods

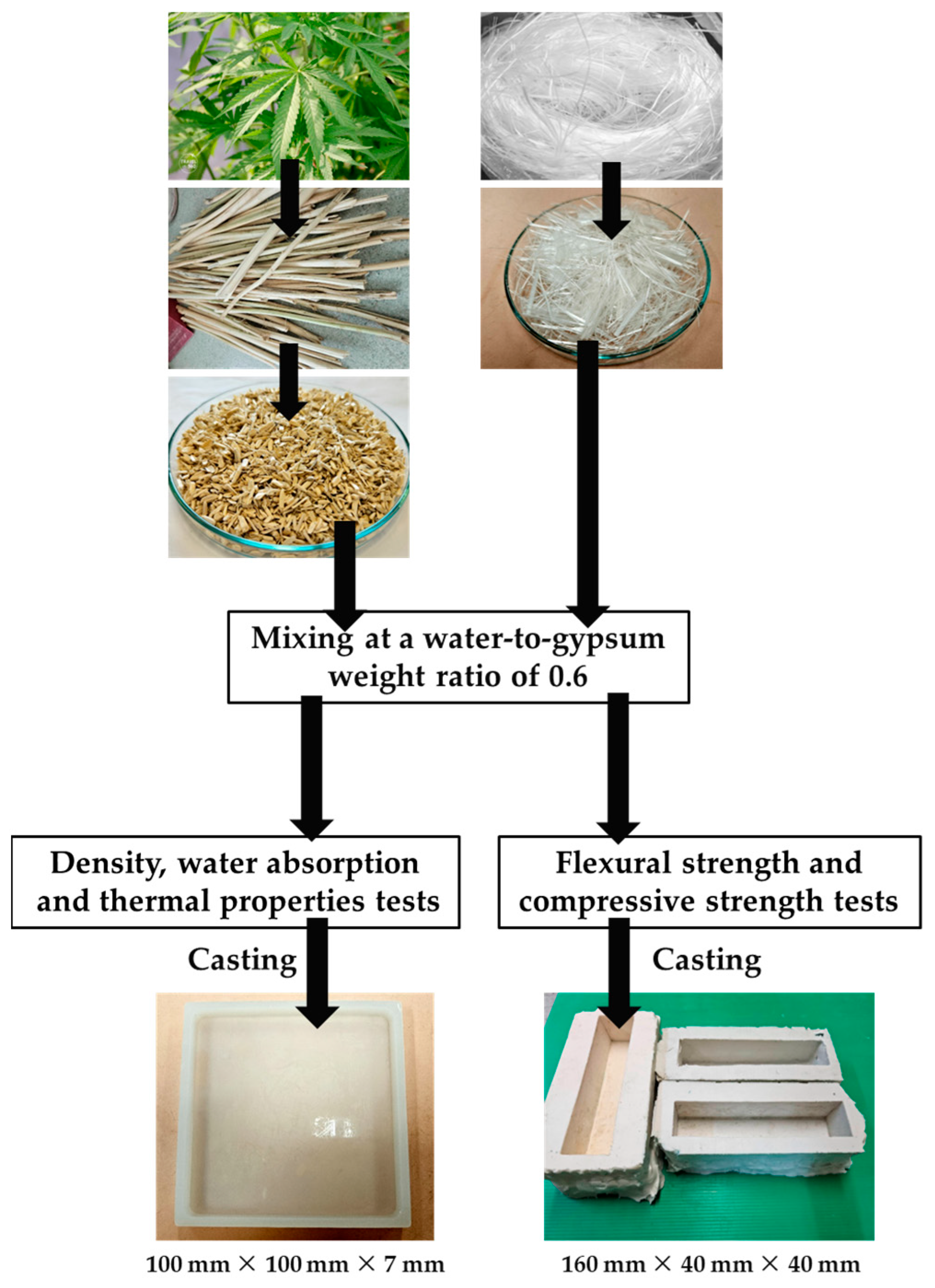

2.1. Raw Materials and Preparation of Gypsum Board

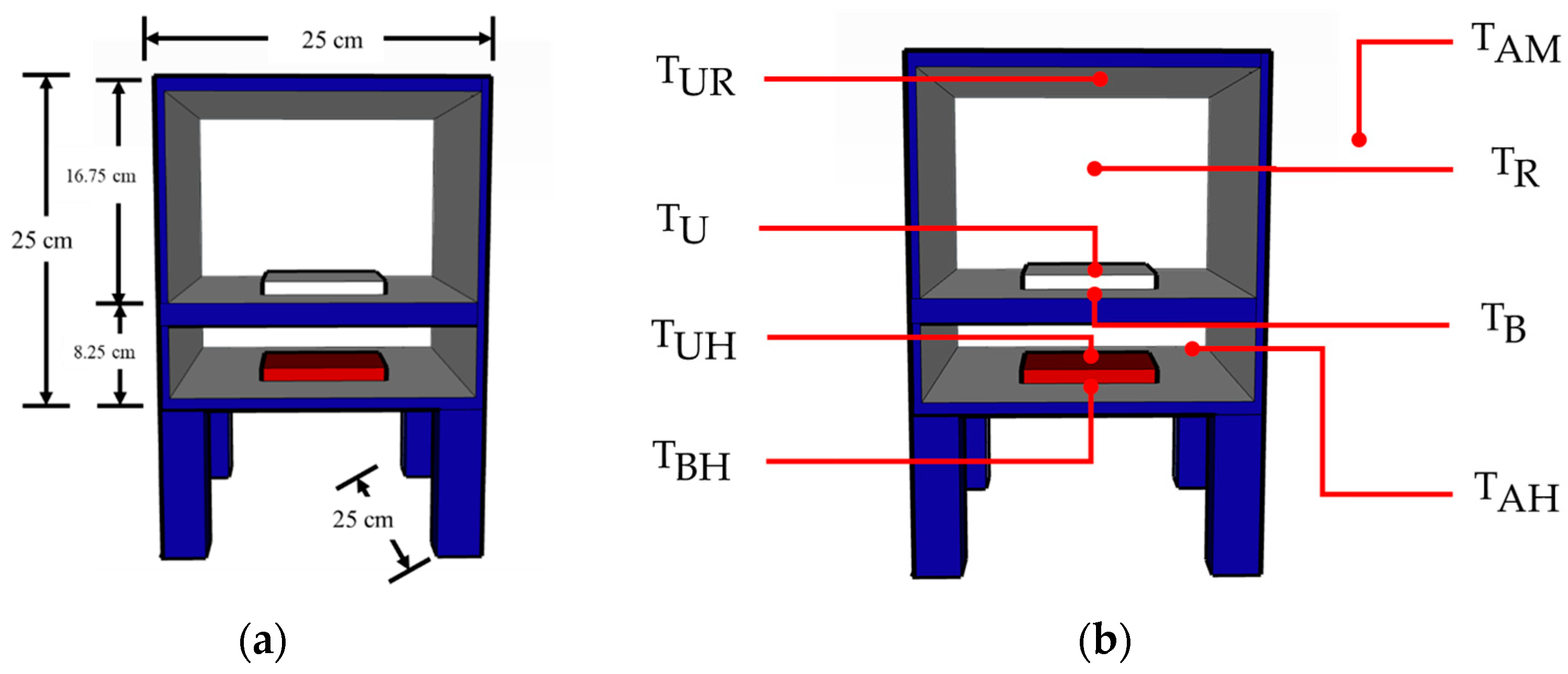

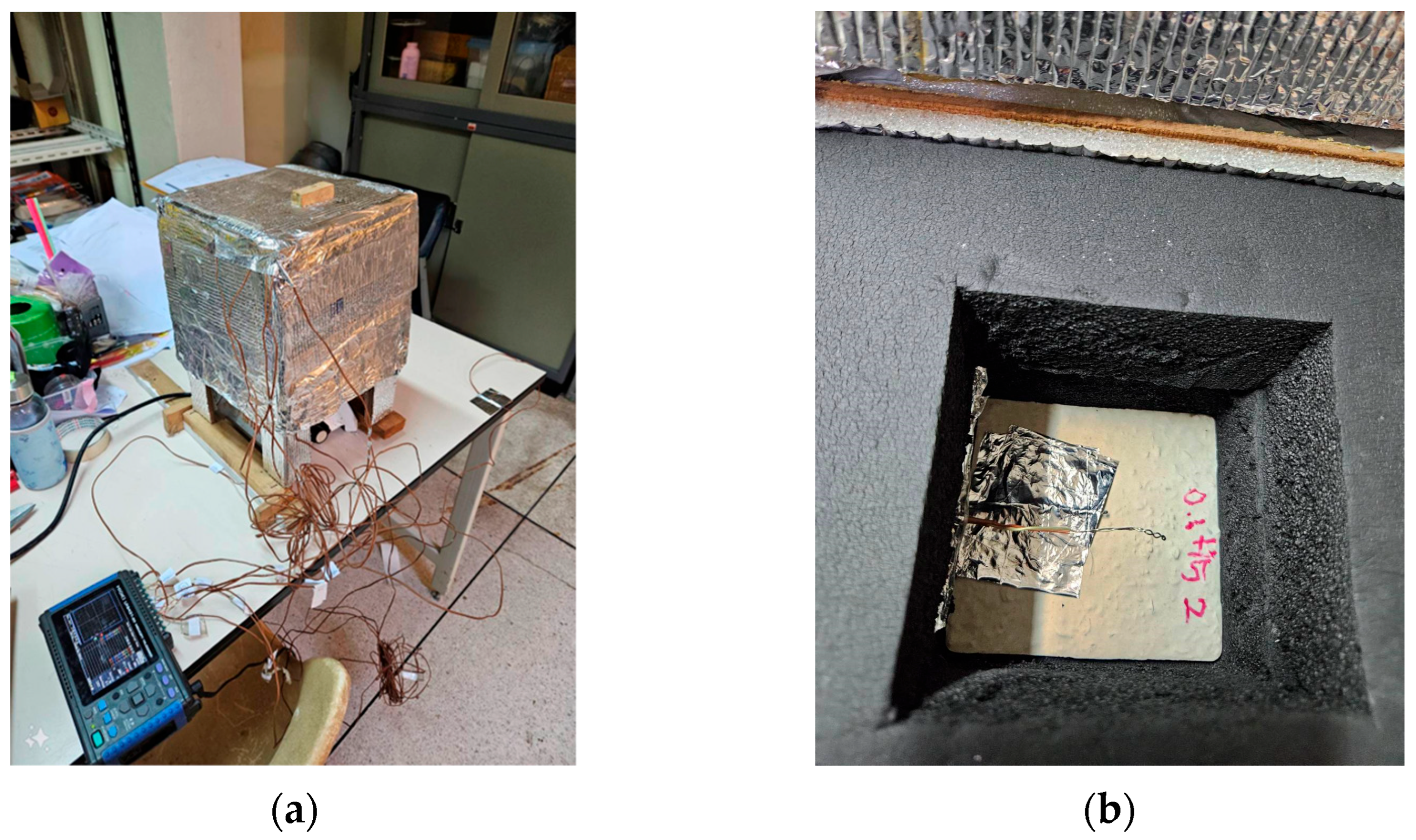

2.2. Measurement of Gypsum Board: Assessing Physical and Thermal Characteristics

2.3. Economic Evaluation

3. Results

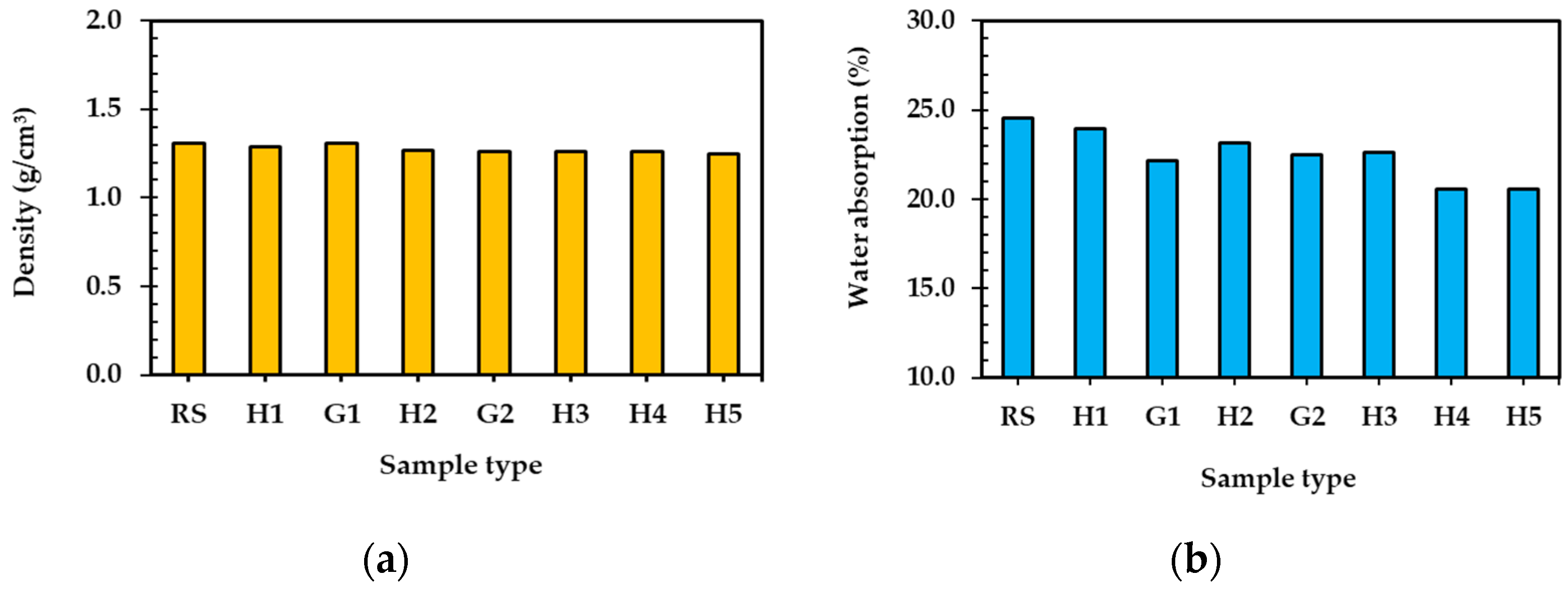

3.1. Density

3.2. Water Absorption

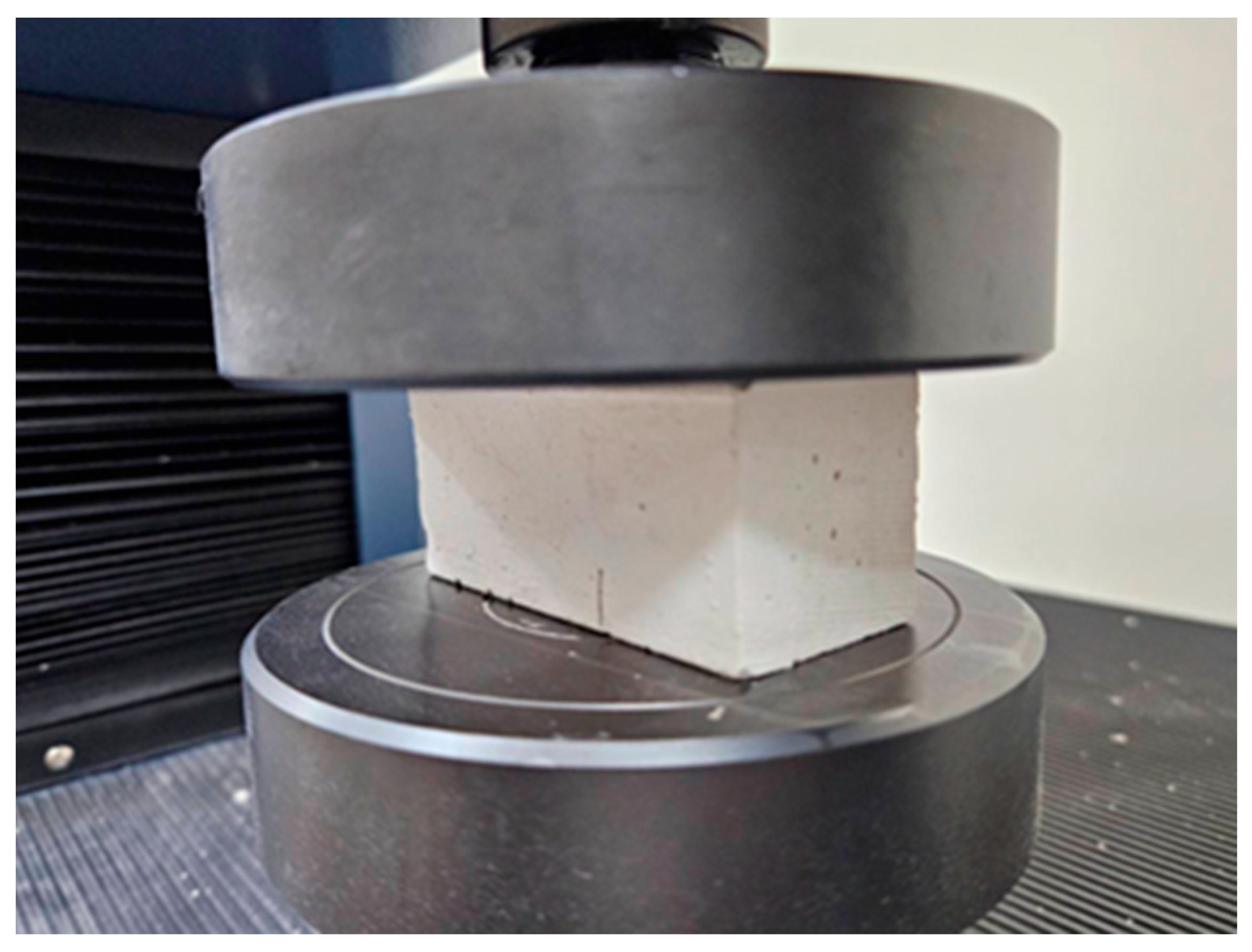

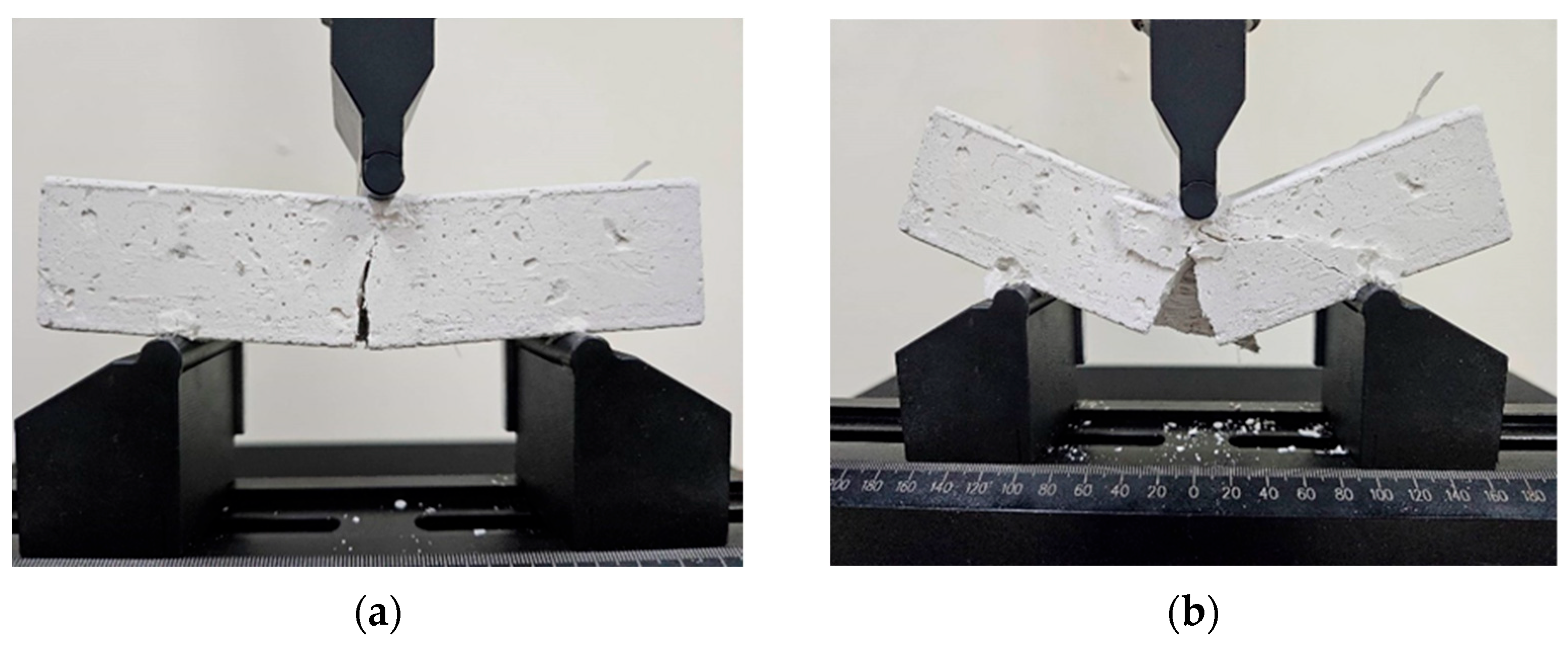

3.3. Flexural Strength Tests

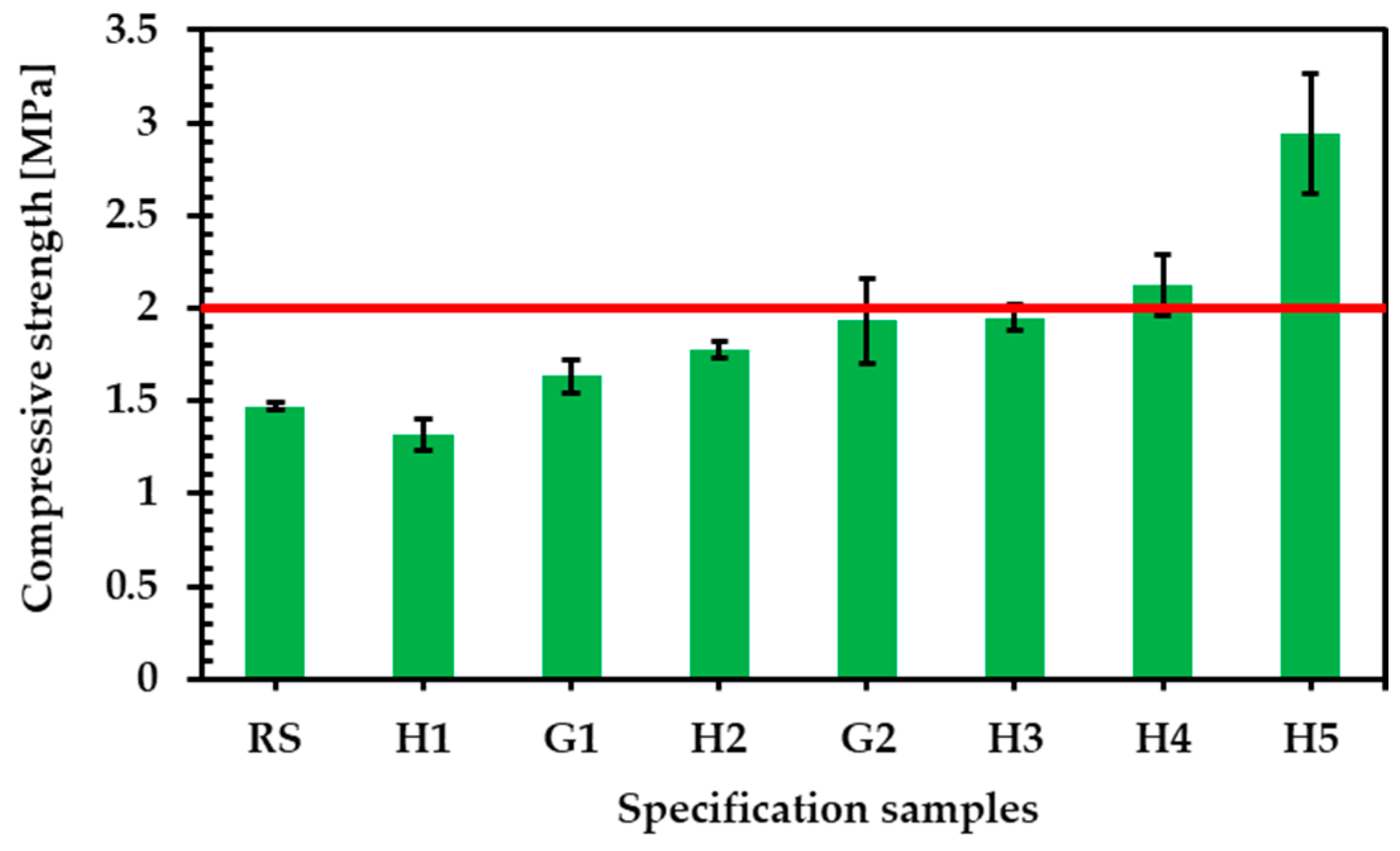

3.4. Compressive Strength Tests

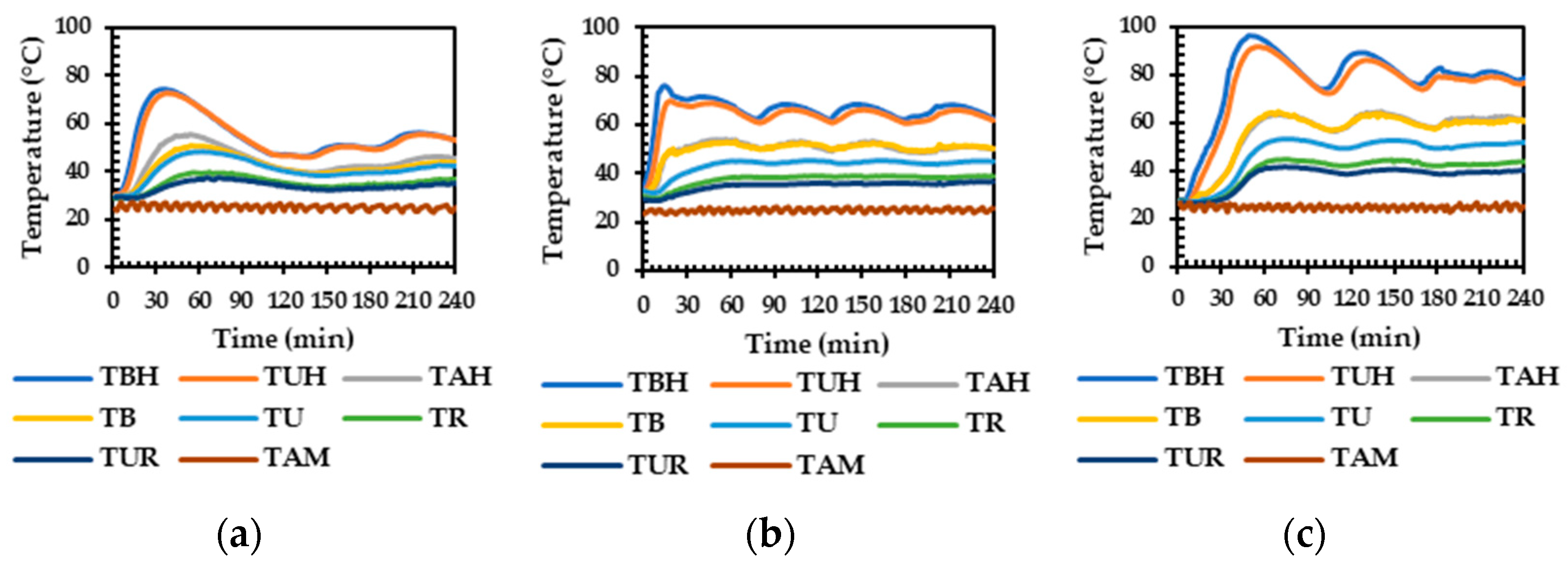

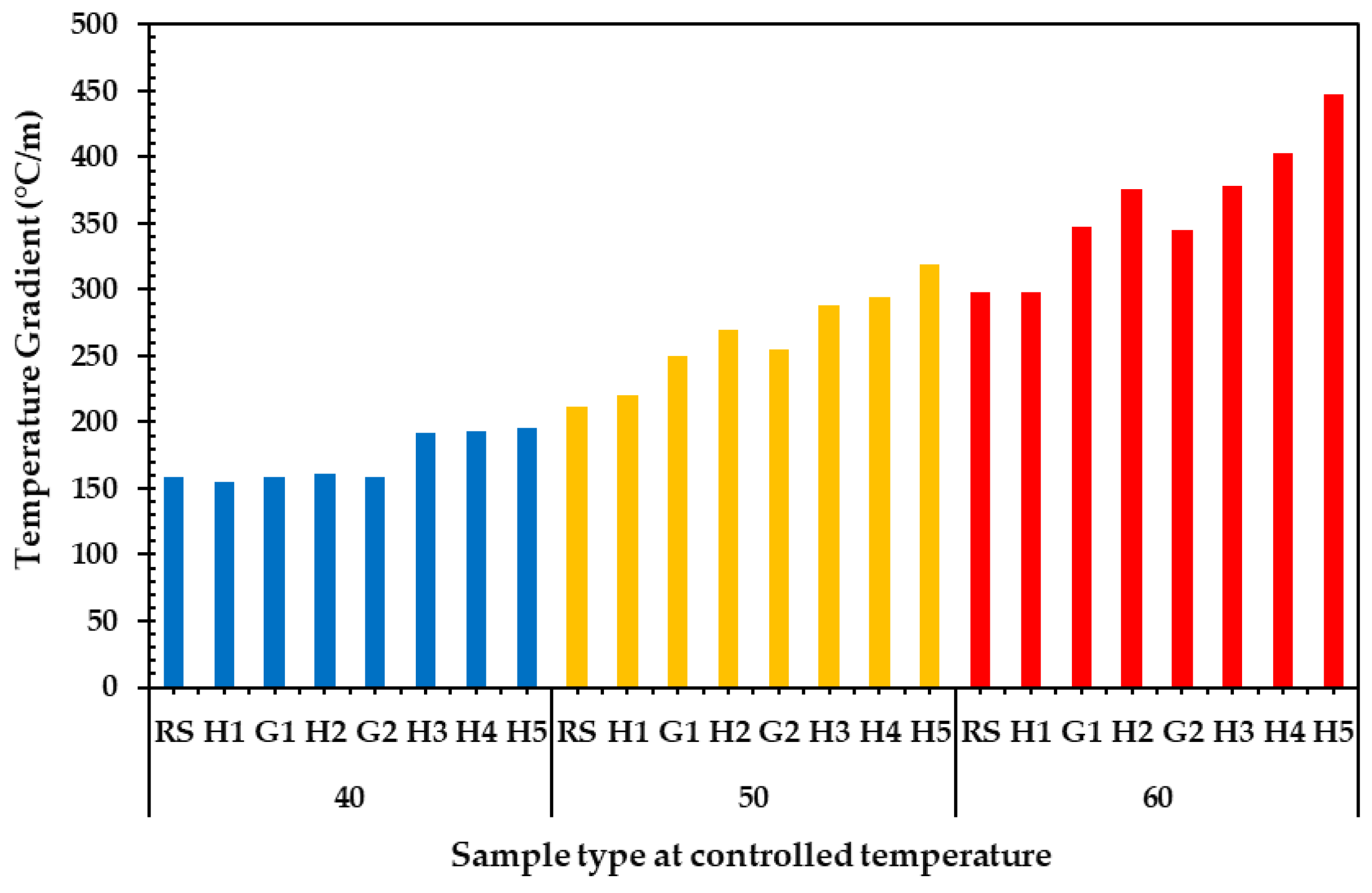

3.5. Thermal Performance of Gypsum Board

3.6. Economic and Holistic Sustainability Assessment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ürge-Vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and Cooling Energy Trends and Drivers in Buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Petrichenko, K.; Staniec, M.; Eom, J. Energy Use in Buildings in a Long-Term Perspective. Curr. Opin. Environ. Sustain. 2013, 5, 141–151. [Google Scholar] [CrossRef]

- Chan, A.L.S.; Chow, T.T. Evaluation of Overall Thermal Transfer Value (OTTV) for Commercial Buildings Constructed with Green Roof. Appl. Energy 2013, 107, 10–24. [Google Scholar] [CrossRef]

- Yang, L.J.; Yang, E.H. Energy Performance of Building Envelopes Integrated with Phase Change Materials for Cooling Load Reduction in Tropical Singapore. Appl. Energy 2016, 162, 207–217. [Google Scholar] [CrossRef]

- Levinson, R.; Berdahl, P.; Akbari, H.; Miller, W.; Joedicke, I.; Reilly, J.; Suzuki, Y.; Vondran, M. Methods of Creating Solar-Reflective Nonwhite Surfaces and Their Application to Residential Roofing Materials. Sol. Energy Mater. Sol. Cells 2007, 91, 304–314. [Google Scholar] [CrossRef]

- Nahar, N.M.; Sharma, P.; Purohit, M.M. Performance of Different Passive Techniques for Cooling of Buildings in Arid Regions. Build. Environ. 2003, 38, 109–116. [Google Scholar] [CrossRef]

- Chen, Y.; Xia, B. Building as Major Energy Consumer. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Khalil, A.A.; Tawfik, A.; Hegazy, A.A. Plaster Composites Modified Morphology with Enhanced Compressive Strength and Water Resistance Characteristics. Constr. Build. Mater. 2018, 167, 55–64. [Google Scholar] [CrossRef]

- Kondratieva, N.; Barre, M.; Goutenoire, F.; Sanytsky, M. Study of Modified Gypsum Binder. Constr. Build. Mater. 2017, 149, 535–542. [Google Scholar] [CrossRef]

- Shim, H.; Choi, G.J. Study of Construction Convergence Technology for Performance Improvement in Functional Building Materials. J. Build. Eng. 2017, 11, 108–114. [Google Scholar] [CrossRef]

- Aramwit, P.; Sheng, D.D.C.V.; Moorthy, G.K.; Guna, V.; Reddy, N. Rice Husk and Coir Fibers as Sustainable and Green Reinforcements for High Performance Gypsum Composites. Constr. Build. Mater. 2023, 393, 132065. [Google Scholar] [CrossRef]

- Benchouia, H.E.; Boussehel, H.; Guerira, B.; Sedira, L.; Tedeschi, C.; Becha, H.E.; Cucchi, M. An Experimental Evaluation of a Hybrid Bio-Composite Based on Date Palm Petiole Fibers, Expanded Polystyrene Waste, and Gypsum Plaster as a Sustainable Insulating Building Material. Constr. Build. Mater. 2024, 422, 135735. [Google Scholar] [CrossRef]

- Kehli, K.; Belhadj, B.; Ferhat, A. Development of a New Lightweight Gypsum Composite: Effect of Mixed Treatment of Barley Straws with Hot Water and Bio-Based Phase Change Material on the Thermo-Mechanical Properties. Constr. Build. Mater. 2023, 389, 131597. [Google Scholar] [CrossRef]

- Trociński, A.; Wieruszewski, M.; Bartkowiak, M.; Mirski, R. The Influence of Hemp Fibers (Cannabis sativa L.) on the Mechanical Properties of Fiber–Gypsum Boards Reinforcing the Gypsum Matrix. Polymers 2024, 16, 2644. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Jones, D.; Brischke, C. Performance of Bio-Based Building Materials; Woodhead: Cambridge, UK, 2017. [Google Scholar]

- Aït Oumeziane, Y.; Collet, F.; Lanos, C.; Moujalled, B. Modelling the Hygrothermal Behaviour of Hemp Concrete: From Material to Building; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Pervaiz, M.; Sain, M.M. Carbon Storage Potential in Natural Fiber Composites. Resour. Conserv. Recycl. 2003, 39, 325–340. [Google Scholar] [CrossRef]

- Ingrao, C.; Giudice, A.L.; Bacenetti, J.; Tricase, C.; Dotelli, G.; Fiala, M.; Siracusa, V.; Mbohwa, C. Energy and Environmental Assessment of Industrial Hemp for Building Applications: A Review. Renew. Sustain. Energy Rev. 2015, 51, 29–42. [Google Scholar] [CrossRef]

- Gregoire, M.; De Luycker, E.; Bar, M.; Musio, S.; Amaducci, S.; Ouagne, P. Study of Solutions to Optimize the Extraction of Hemp Fibers for Composite Materials. SN Appl. Sci. 2019, 1, 1293. [Google Scholar] [CrossRef]

- TIS 219-2552; Industrial Standards Institute (TISI). Hot-Rolled Structural Steel Sections. Ministry of Industry: Bangkok, Thailand, 2009.

- Saint-Gobain Gyproc. Gyproc Multi-Purpose Plaster: Product Data Sheet; Saint-Gobain Gyproc: Bangkok, Thailand, 2022. [Google Scholar]

- Saint-Gobain Gyproc. Gyproc Rhinolite Natural Plus: Product Technical Guide; Saint-Gobain Gyproc: Johannesburg, South Africa, 2021. [Google Scholar]

- British Gypsum. Gypsum-Based Plasters: Safety and Technical Properties; British Gypsum: Loughborough, UK, 2020. [Google Scholar]

- Gyproc Thailand. Material Safety Data Sheet: Gypsum Plaster Products; Gyproc Thailand (Saint-Gobain): Bangkok, Thailand, 2021. [Google Scholar]

- Owens Corning. Cem-FIL® 54 AR-Glass Fibre for GRC: Product Data Sheet; Owens Corning: Toledo, OH, USA, 2021. [Google Scholar]

- Owens Corning. Cem-FIL® 54: Declaration of Performance According to Regulation (EU) No. 305/2011; Owens Corning: Chambéry, France, 2020. [Google Scholar]

- Vetrotex Saint-Gobain. Technical Data Sheet: Cem-FIL® Alkali Resistant Glass Fibres; Vetrotex International: Chambéry, France, 2010. [Google Scholar]

- Ejaz, M.F.; Riaz, M.R.; Azam, R.; Hameed, R.; Fatima, A.; Deifalla, A.F.; Mohamed, A.M. Physico-Mechanical Characterization of Gypsum-Agricultural Waste Composites for Developing Eco-Friendly False Ceiling Tiles. Sustainability 2022, 14, 9797. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Aprea, P.; Caputo, D. Evaluation of Bio-Degummed Hemp Fibers as Reinforcement in Gypsum Plaster. Compos. Part B Eng. 2018, 138, 149–156. [Google Scholar] [CrossRef]

- UNE-EN 13279-2; Gypsum Binders and Gypsum Plasters: Part 1: Definitions and Requirements. European Committee for Standardization: Brussels, Belgium, 2006.

- Kuqo, A.; Mai, C. Mechanical Properties of Lightweight Gypsum Composites Comprised of Seagrass Posidonia oceanica and Pine (Pinus sylvestris) Wood Fibers. Constr. Build. Mater. 2021, 282, 122714. [Google Scholar] [CrossRef]

- Asan, H. Effects of Wall’s Insulation Thickness and Position on Time Lag and Decrement Factor. Energy Build. 1998, 28, 299–305. [Google Scholar] [CrossRef]

- Sonnier, R.; Belkhane, O.; Ferry, L.; Aprin, L.; Delot, P.; Garcia, C.; de Menibus, A.H.; Lenormand, H.; Potin, M. Fire behaviour of hemp, clay and gypsum-based light biobased concretes and renders. Constr. Build. Mater. 2022, 331, 127230. [Google Scholar] [CrossRef]

- Thongtha, A.; Maneewan, S.; Fazlizan, A. Enhancing thermal performance of autoclaved aerated concrete (AAC) incorporating sugar sediment waste and recycled AAC with phase change material-coated applications for sustainable energy conservation in building. Sustainability 2023, 15, 14226. [Google Scholar] [CrossRef]

- Mano, C.; Thongtha, A.; Maneewan, S.; Punlek, C. Improvement of the thermal efficiency of autoclaved aerated concrete by black powder. ScienceAsia 2021, 47, 76–82. [Google Scholar] [CrossRef]

- Vontetsianou, A. The Effectiveness of Hempcrete in the Reduction of the Environmental and Financial Costs of Residences (A Case Study in The Netherlands. Master’s Thesis, School of Civil Engineering and Geo-sciences, Delft, Netherlands, 2023. [Google Scholar]

- Sutton, A.; Black, D.; Pete, W. Hemp lime: An introduction to low-impact building materials. In BRE Information Papers; HIS BRE Press: Bath, England, 2011. [Google Scholar]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp-lime wall constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Pretot, S.; Collet, F.; Garnier, C. Life cycle assessment of a hemp concrete wall: Impact of thickness and coating. Build. Environ. 2014, 72, 223–231. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Jiang, Y. Hygrothermal and mechanical characterisation of novel hemp shiv-based thermal insulation composites. Constr. Build. Mater. 2019, 212, 561–568. [Google Scholar] [CrossRef]

- Al-Tamimi, A.S.; Qasem, N.A.A.; Bindiganavile, V. Thermal performance evaluation of hempcrete masonry walls for energy storage in cold weather. Appl. Therm. Eng. 2024, 248, 123304. [Google Scholar] [CrossRef]

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavic, M. Mechanical, thermal, and moisture buffering properties of novel insulating hemp-lime composite building materials. Materials 2020, 13, 5000. [Google Scholar] [CrossRef]

- Brzyski, P.; Gładecki, M.; Rumińska, M.; Pietrak, K.; Kubiś, M.; Łapka, P. Influence of hemp shives size on hygro-thermal and mechanical properties of a hemp-lime composite. Materials 2020, 13, 5383. [Google Scholar] [CrossRef]

- Pantawee, S.; Sinsiri, T.; Jaturapitakkul, C.; Chindaprasirt, P. Utilization of hemp concrete using hemp shiv as coarse aggregate with aluminium sulfate [Al2(SO4)3] and hydrated lime [Ca(OH)2] treatment. Constr. Build. Mater. 2017, 156, 435–442. [Google Scholar] [CrossRef]

- Arehart, J.H.; Nelson, W.S.; Srubar, W.V. On the theoretical carbon storage and carbon sequestration potential of hempcrete. J. Clean. Prod. 2020, 266, 121846. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melia, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Sinka, M.; Van den Heede, P.; De Belie, N.; Bajare, D.; Sahmenko, G.; Korjakins, A. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resour. Conserv. Recycl. 2018, 133, 288–299. [Google Scholar] [CrossRef]

- Tronet, P.; Lecompte, T.; Picandet, V.; Baley, C. Study of lime hemp concrete (LHC)—Mix design, casting process and mechanical behaviour. Cem. Concr. Compos. 2016, 67, 60–72. [Google Scholar] [CrossRef]

- AfricaNews. World’s tallest hemp hotel set to open in June in South Africa. AfricaNews, 3 May 2023.

- Aukett, S. Adnams Distribution Centre. 2023. Available online: https://www.aukettswanke.com/projects/adnams-distribution-centre/ (accessed on 21 October 2024).

| Conditions | Composite Mix Ratios | |||||||

|---|---|---|---|---|---|---|---|---|

| RS | H1 | G1 | H2 | G2 | H3 | H4 | H5 | |

| Water/gypsum weight ratio [g/g] | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Hemp hurds [wt.%] | - | 1 | - | 2 | - | 3 | 4 | 5 |

| Glass fiber [wt.%] | - | - | 1 | - | 2 | - | - | - |

| Test | Dimensions of Test Specimen |

|---|---|

| Density, water absorption | 100 mm × 100 mm × 7 mm |

| Flexural strength | 160 mm × 40 mm × 40 mm |

| Thermal properties | 100 mm × 100 mm × 7 mm |

| Specification Samples | Percentage Proportions | Flexural Loading Limit [N] | [N·mm−2] | [N·mm−2] | [N·mm−2] | ||

|---|---|---|---|---|---|---|---|

| Plaster [%] | Hemp Hurds [%] | Glass Fiber [%] | |||||

| 329.99 | 0.77 | ||||||

| 100 | 0 | 0 | 218.78 | 0.51 | 0.58 | 0.17 | |

| 198.18 | 0.46 | ||||||

| 205.87 | 0.48 | ||||||

| 99 | 1 | 0 | 218.03 | 0.51 | 0.50 | 0.02 | |

| 220.00 | 0.51 | ||||||

| 1077.38 | 2.52 | ||||||

| 99 | 0 | 1 | 772.17 | 1.81 | 2.31 | 0.44 | |

| 1115.29 | 2.61 | ||||||

| 409.65 | 0.96 | ||||||

| 98 | 2 | 0 | 307.08 | 0.72 | 0.83 | 0.12 | |

| 341.76 | 0.80 | ||||||

| 1238.80 | 2.90 | ||||||

| 98 | 0 | 2 | 1470.46 | 3.44 | 3.16 | 0.27 | |

| 1338.98 | 3.13 | ||||||

| 394.16 | 0.92 | ||||||

| 97 | 3 | 0 | 346.80 | 0.81 | 0.88 | 0.06 | |

| 386.23 | 0.90 | ||||||

| 430.17 | 1.01 | ||||||

| 96 | 4 | 0 | 470.55 | 1.10 | 1.05 | 0.05 | |

| 448.13 | 1.05 | ||||||

| 664.13 | 1.55 | ||||||

| 95 | 5 | 0 | 645.36 | 1.51 | 1.53 | 0.02 | |

| 655.84 | 1.53 | ||||||

| Specification Samples | Percentage Proportions | Compressive Loading [N] | [N·mm−2] | [N·mm−2] | [N·mm−2] | ||

|---|---|---|---|---|---|---|---|

| Plaster [%] | Hemp Hurds [%] | Glass Fiber [%] | |||||

| 4773.41 | 1.49 | ||||||

| 100 | 0 | 0 | 4666.91 | 1.46 | 1.47 | 0.020 | |

| 4662.99 | 1.46 | ||||||

| 4016.86 | 1.26 | ||||||

| 99 | 1 | 0 | 4527.96 | 1.41 | 1.32 | 0.086 | |

| 4088.85 | 1.28 | ||||||

| 5244.71 | 1.64 | ||||||

| 99 | 0 | 1 | 4916.06 | 1.54 | 1.63 | 0.092 | |

| 5504.32 | 1.72 | ||||||

| 5759.37 | 1.80 | ||||||

| 98 | 2 | 0 | 5517.83 | 1.72 | 1.77 | 0.04 | |

| 5761.54 | 1.80 | ||||||

| 6868.22 | 2.15 | ||||||

| 98 | 0 | 2 | 6289.13 | 1.97 | 1.93 | 0.23 | |

| 5405.01 | 1.69 | ||||||

| 6304.60 | 1.97 | ||||||

| 97 | 3 | 0 | 6406.78 | 2.00 | 1.95 | 0.07 | |

| 5975.86 | 1.87 | ||||||

| 7367.39 | 2.30 | ||||||

| 96 | 4 | 0 | 6318.11 | 1.97 | 2.13 | 0.16 | |

| 6750.35 | 2.11 | ||||||

| 10,606.73 | 3.31 | ||||||

| 95 | 5 | 0 | 8735.46 | 2.73 | 2.94 | 0.33 | |

| 8881.43 | 2.78 | ||||||

| Controlled Temperature (°C) | Specification Samples | Temperatures at Different Positions (°C) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| TBH | TUH | TAH | TB | TU | TR | TUR | TAM | ||

| 40 | RS | 53.2 | 51.1 | 43.4 | 41.8 | 40.9 | 35.6 | 34.7 | 24.6 |

| H1 | 52.3 | 51.3 | 43.0 | 41.3 | 40.9 | 35.5 | 34.1 | 25.2 | |

| G1 | 52.7 | 52.1 | 42.1 | 40.2 | 39.2 | 34.5 | 32.7 | 24.8 | |

| H2 | 50.9 | 50.2 | 41.3 | 40.2 | 39.0 | 34.1 | 32.8 | 24.6 | |

| G2 | 52.9 | 50.9 | 42.9 | 41.8 | 40.5 | 35.7 | 34.5 | 25.1 | |

| H3 | 55.3 | 54.2 | 44.8 | 42.6 | 40.4 | 35.7 | 33.4 | 24.5 | |

| H4 | 48.2 | 47.8 | 40.0 | 41.0 | 37.8 | 33.7 | 32.0 | 24.3 | |

| H5 | 47.7 | 47.2 | 40.1 | 40.5 | 37.3 | 33.2 | 31.4 | 24.4 | |

| 50 | RS | 67.0 | 65.7 | 53.3 | 50.1 | 48.9 | 42.0 | 40.4 | 25.1 |

| H1 | 64.9 | 63.8 | 52.7 | 50.1 | 49.3 | 41.5 | 40.2 | 25.9 | |

| G1 | 68.8 | 67.6 | 53.2 | 50.1 | 48.1 | 40.8 | 38.4 | 25.0 | |

| H2 | 67.1 | 65.6 | 51.1 | 50.6 | 47.8 | 40.1 | 38.3 | 25.7 | |

| G2 | 67.7 | 66.2 | 53.6 | 50.6 | 48.1 | 40.6 | 39.2 | 24.8 | |

| H3 | 67.0 | 65.9 | 52.0 | 50.1 | 45.8 | 39.6 | 36.5 | 25.6 | |

| H4 | 64.6 | 63.4 | 50.2 | 50.3 | 45.0 | 39.1 | 36.7 | 24.7 | |

| H5 | 64.0 | 62.8 | 49.9 | 50.5 | 44.6 | 38.4 | 35.9 | 25.1 | |

| 60 | RS | 81.0 | 79.3 | 65.0 | 59.9 | 58.1 | 48.4 | 46.4 | 25.8 |

| H1 | 78.9 | 77.6 | 63.1 | 59.8 | 58.4 | 48.2 | 46.2 | 26.0 | |

| G1 | 82.1 | 80.4 | 63.2 | 58.7 | 55.4 | 45.8 | 42.5 | 25.5 | |

| H2 | 84.2 | 82.3 | 63.1 | 59.8 | 56.1 | 45.6 | 42.4 | 24.9 | |

| G2 | 81.1 | 80.2 | 64.9 | 60.7 | 56.8 | 47.4 | 45.0 | 25.2 | |

| H3 | 81.3 | 79.8 | 62.9 | 61.1 | 54.6 | 46.0 | 44.4 | 25.2 | |

| H4 | 82.0 | 80.3 | 61.5 | 61.1 | 54.1 | 45.6 | 42.8 | 25.3 | |

| H5 | 79.2 | 77.0 | 61.1 | 60.4 | 51.3 | 43.3 | 39.9 | 24.8 | |

| Controlled Temperature (°C) | Time Lag at Different Sample Type (min) | |||||||

|---|---|---|---|---|---|---|---|---|

| RS | H1 | G1 | H2 | G2 | H3 | H4 | H5 | |

| 40 | 6 | 8 | 7 | 9 | 10 | 10 | 16 | 16 |

| 50 | 4 | 8 | 7 | 9 | 7 | 9 | 16 | 16 |

| 60 | 2 | 6 | 5 | 6 | 6 | 6 | 6 | 7 |

| Type of Samples | Material Cost (USD/m2) | Additional Investment (USD) |

|---|---|---|

| Commercial ceiling | 1.32 | 0.00 |

| 0.6 G1 | 3.66 | 2.35 |

| 0.6 H1 | 3.49 | 2.18 |

| 0.6 G2 | 3.79 | 2.48 |

| 0.6 H2 | 3.47 | 2.15 |

| 0.6 H3 | 3.47 | 2.15 |

| 0.6 H4 | 3.40 | 2.08 |

| 0.6 H5 | 3.36 | 2.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaimongkol, C.; Ross, S.; Kealkaew, D.; Thongtha, A. Analysis of the Physical and Thermal Characteristics of Gypsum Panels with Hemp Hurds for Building Insulation. Sustainability 2025, 17, 6801. https://doi.org/10.3390/su17156801

Chaimongkol C, Ross S, Kealkaew D, Thongtha A. Analysis of the Physical and Thermal Characteristics of Gypsum Panels with Hemp Hurds for Building Insulation. Sustainability. 2025; 17(15):6801. https://doi.org/10.3390/su17156801

Chicago/Turabian StyleChaimongkol, Chatpon, Sukunya Ross, Dachaphon Kealkaew, and Atthakorn Thongtha. 2025. "Analysis of the Physical and Thermal Characteristics of Gypsum Panels with Hemp Hurds for Building Insulation" Sustainability 17, no. 15: 6801. https://doi.org/10.3390/su17156801

APA StyleChaimongkol, C., Ross, S., Kealkaew, D., & Thongtha, A. (2025). Analysis of the Physical and Thermal Characteristics of Gypsum Panels with Hemp Hurds for Building Insulation. Sustainability, 17(15), 6801. https://doi.org/10.3390/su17156801