1. Introduction

In the face of the threats posed by global warming and environmental pollution, “low carbon” has become an issue of increasing concern. According to statistics from the World Resources Institute for 186 countries and regions worldwide, carbon dioxide is the largest contributor to climate change among greenhouse gases (GHGs), accounting for 77% of total GHG emissions. Most countries have reached a consensus on reducing CO

2 emissions and begun to explore methods for reducing CO

2 emissions, introducing various policies and regulations to promote the sustainable development of human society through institutional innovations and technological progress. On 22 September 2020, China announced its target of capping its carbon emissions by 2030 and achieving carbon neutrality by 2060, or the “dual-carbon target” [

1]. In 2023, China’s emissions increased by 565 million metric tons, the largest global increment. However, the country also leads in clean energy adoption. Notably, a historic hydropower shortfall contributed to one-third of the 2023 emission growth. China’s per capita emissions are currently 15% higher than those of developed economies [

2]. In response to the challenges of global climate change, the Chinese government has committed to achieving peak CO

2 emissions by 2030 and carbon neutrality by 2060 [

3].

The transport industry has always been the pillar of China’s national economy, and it is also a key area for energy conservation and emission reduction. According to a report from the International Energy Agency (IEA), carbon emissions from the transport sector will account for 21.6% of carbon emissions from the end-use sector in 2022 [

4,

5]. Carbon emissions from China’s transport sector will continue to grow between now and 2030, and it will be more than four times as high in 2030 as it was in 2000 [

6]. According to data released by the Ministry of Transport (MOT) of the People’s Republic of China, the national road maintenance mileage was 5,350,300 km by the end of 2022, accounting for 99.9% of road mileage [

7]. Consequently, China issued the 14th Five-Year Plan for the Development of Highway Maintenance and Management Business in April 2022, proposing the full implementation of the concept that “highway construction is development, and highway maintenance and management are also development, and are sustainable development,” with the goal of strengthening energy conservation and emission reduction efforts to help promote sustainable development [

8].

The life cycle assessment (LCA) methodology has been used in the past two decades for environmental impact assessment in other industries, such as pavement infrastructure, energy, and agriculture [

9,

10,

11]. The LCA serves as a standard methodology for quantitatively analyzing the environmental effects of roads throughout their life cycle by constructing a framework [

12]. At present, many studies have introduced LCA methodologies to comprehensively assess carbon emissions during the road construction, maintenance, and operation phases [

13]. The LCA provides accurate, consistent, and repeatable measurements of the resource consumption and environmental effects of an activity or product [

14,

15], from the production, use, disposal, and recycling (i.e., cradle to grave) of raw materials [

16]. Systems for calculating life cycle emissions can be divided into two broad categories: top-down, i.e., based on input–output LCA analysis, and bottom-up, i.e., based on the process LCA (PLCA) [

17]. The PLCA is well suited for evaluating asphalt pavement maintenance due to its process-level accuracy, despite challenges in comparability [

18,

19]. This study applies the PLCA to quantify unit carbon emissions and identify emission hotspots for Xinjiang’s highway maintenance.

The delineation of model boundaries is crucial for the LCA process. In general, the maintenance and rehabilitation phases of the road LCA typically estimate emissions from construction materials and equipment. The emissions from traffic delays caused by maintenance and rehabilitation work are included [

20], but carbon emissions from transportation vehicles are not fully considered. Emission sources during the operation and use phases of a road typically include fuel consumption over the lifetime of a vehicle, the number of vehicles on a road, and the effects of changes in pavement performance. Road traffic is considered part of road operations, and thus, emissions from the fuel consumption of road vehicles should be considered [

21]. Meanwhile, they considered the life cycle of vehicles, and it was one of the first studies to consider the use phase. However, this approach has faced criticism. Loijos et al. (2013) [

20] attributed traffic emissions solely to the vehicle life cycle, considering only direct road-related factors like surface roughness, albedo, and carbonization. This perspective was corroborated by Fernández-Sánchez et al. (2015) [

22] and Yu and Lu (2012) [

23]. In addition, lighting is rarely considered a source of operational emissions.

Therefore, this study breaks new ground by selecting Xinjiang, China, as a case study and integrating the process-based life cycle assessment (PLCA) method with six cutting-edge technologies specifically tailored for the region’s unique highway maintenance needs. Unlike previous research that often focuses on generic scenarios, this study conducts a granular, region-specific comparison of energy consumption and carbon emissions across different maintenance techniques, deriving precise unit carbon emissions. By meticulously tracing the entire life cycle from material extraction to on-site application, the research uncovers previously overlooked emission hotspots, particularly in the raw material production phase, where cement and asphalt account for 40–60% of the total emissions.

This study’s innovation lies in its three-pronged methodological contribution: First, it establishes a regionalized PLCA framework specifically adapted to Xinjiang’s arid climate, vast transportation distances, and unique economic conditions, enabling precise carbon accounting for road maintenance in extreme environments. Second, it challenges conventional wisdom by demonstrating that preventive maintenance strategies, such as hot asphalt grouting, can reduce carbon emissions by up to 87% compared to reactive methods like milling and resurfacing. Third, by decoupling emission sources across life cycle phases, it pinpoints raw material production (40–60% of emissions, cement/asphalt-dominated) as the critical leverage point, with transport distance and construction efficiency as key modifiable factors. These advances provide, for the first time, emission benchmarks for road maintenance in Xinjiang, replicable models for arid regions, and actionable strategies, i.e., prioritizing preventive measures, optimizing material logistics, and upgrading mixing processes to accelerate the decarbonization process of highway infrastructure. The study has significantly contributed to the greening of the asphalt pavement maintenance sector and set a new benchmark for sustainable infrastructure research.

4. Discussion

In recent years, various industries in China have made sustained efforts to realize the dual-carbon goal. Highway maintenance, as one of the important tasks in the transportation industry, must also accelerate its pace in energy saving and emission reduction and in realizing the goal of green transportation. Therefore, the accounting of carbon emission baseline value for road maintenance is particularly important. At present, the LCA is a commonly used tool for assessing carbon emissions from road maintenance, and its combination with the CEF method of accounting for carbon emissions has been recognized in the industry.

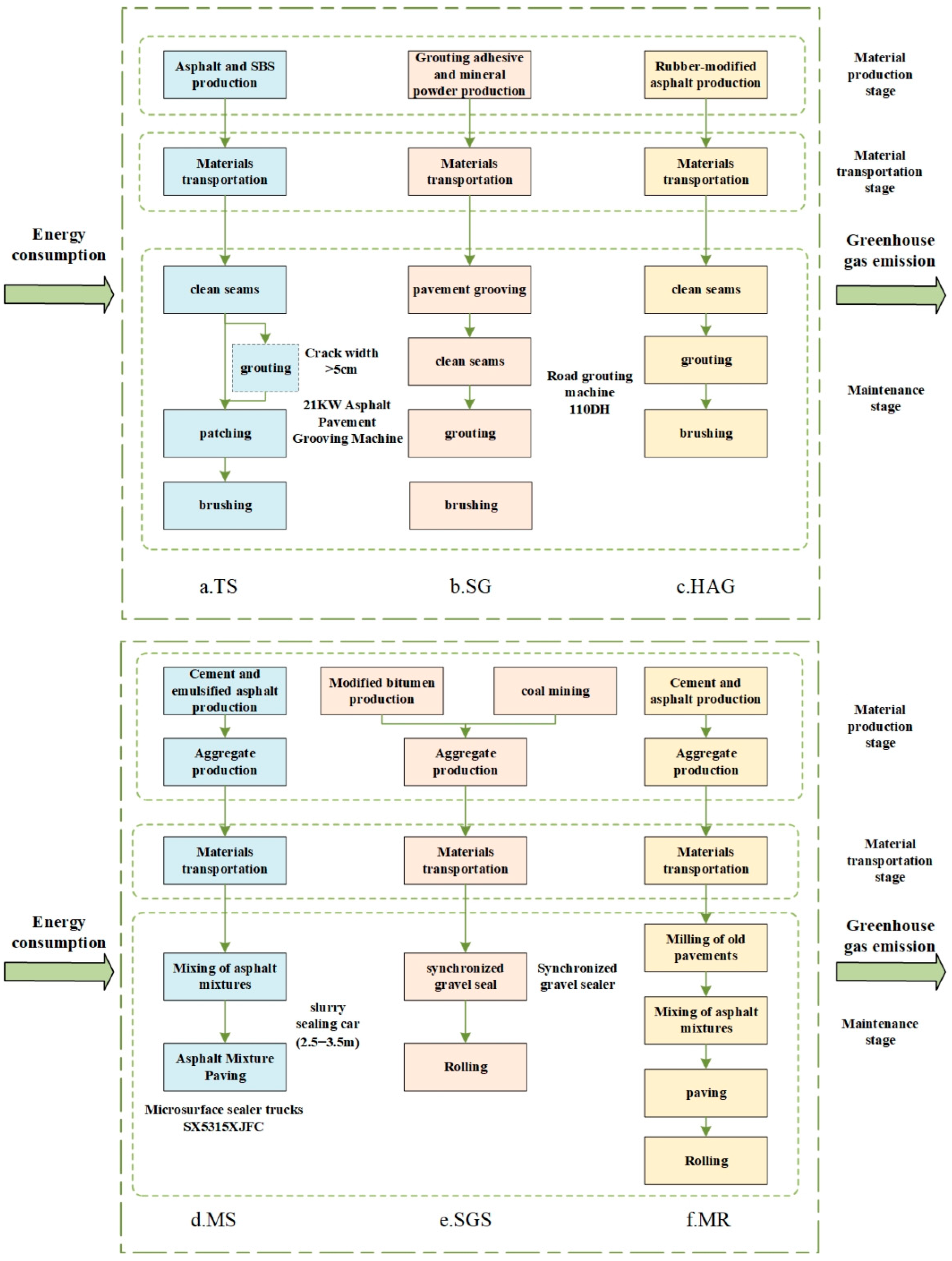

In this study, the unit energy consumption and carbon emissions of six commonly used conservation technologies in Xinjiang were critically assessed from the perspective of the LCA. An assessment framework and calculation model through the PLCA were also designed to measure the energy consumption and carbon emissions of each maintenance material and different maintenance phases. In this manner, the baseline value of the carbon emissions of the six maintenance technologies were accounted for in a more refined manner, laying a solid foundation for finding the typical links of carbon emission reduction and exploring the potential of carbon emission reduction. Moreover, the first step is taken toward realizing the energy-saving, emission-reduction, and dual-carbon goals of Xinjiang’s highway maintenance industry.

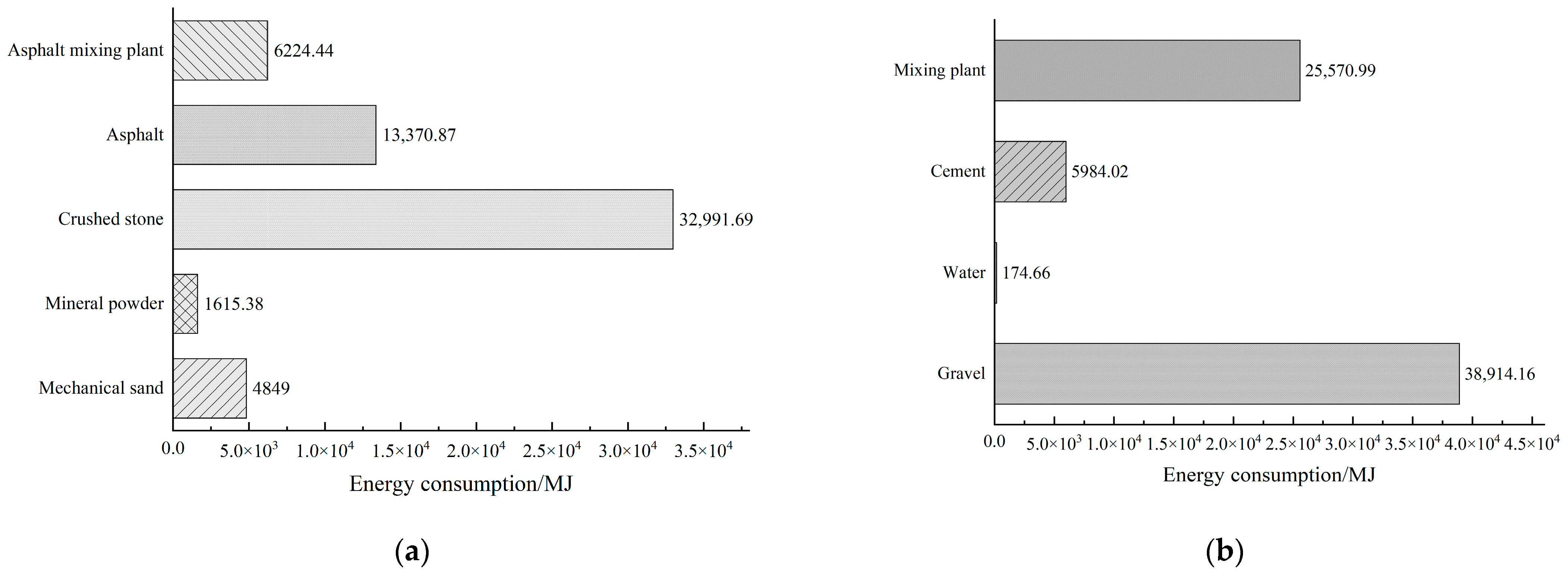

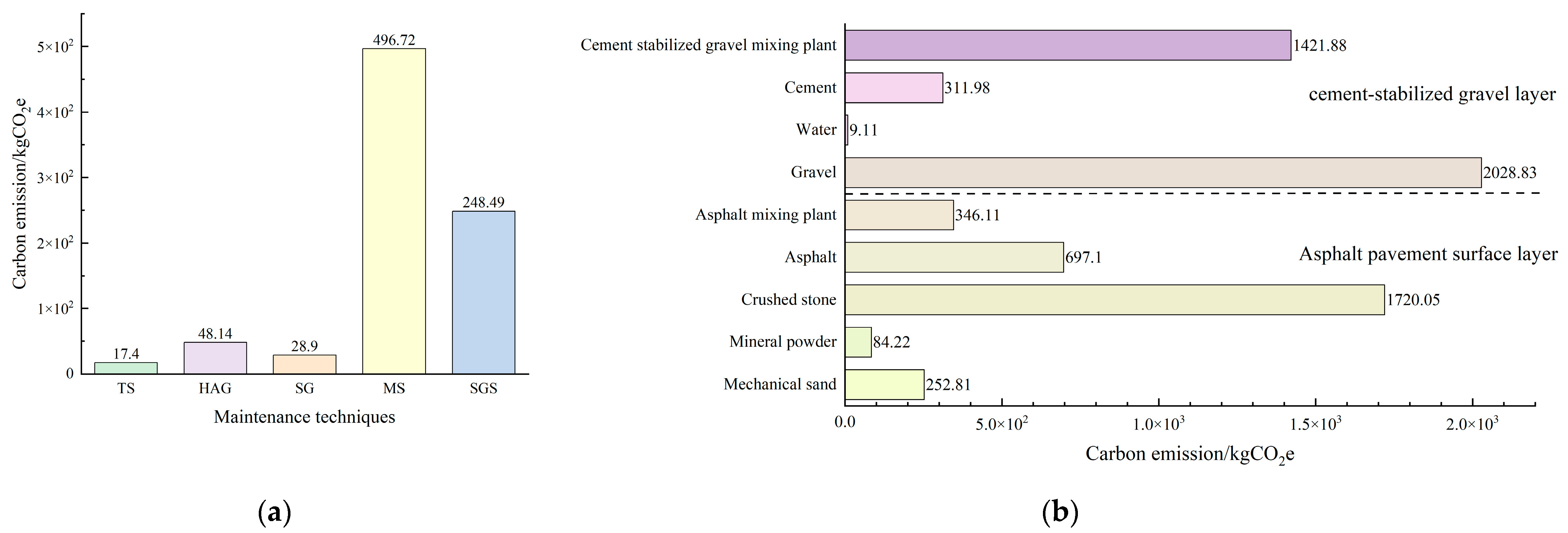

At the raw material production phase, the six types of conservation technologies have the highest levels of combined energy consumption and carbon emissions; this result is basically consistent with the research viewpoints of Liu et al. (2022) [

40] and coincides with the ideas of Ma et al. (2021) [

24]. Although the grouting type of technology during the raw material production phase of carbon emissions is not high, the use of polymer grouting repair technology in highway maintenance projects can significantly reduce CO

2 emissions per km by 76.1% and 87.3%, respectively [

41]. In addition, an interesting phenomenon is that some materials that are used in small quantities, such as cement, produce high emissions. The study is also precisely in line with Liu et al. (2019) [

42]. Furthermore, the researchers found that incorporating phosphogypsum into cement-stabilized asphalt pavement base layers resulted in significant material production benefits: a 48.0% reduction in energy consumption and a 67.5% reduction in carbon emissions. The optimized formulation achieved a synergistic reuse of recycled asphalt pavement (RAP) and phosphogypsum, reducing the need for mineral aggregates by 44.3% and petroleum asphalt by 6.9%, while reducing the landfill footprint by 16.859 m

2 [

43]. This finding highlights the considerable advantages and potential of optimized material selection in terms of carbon reduction.

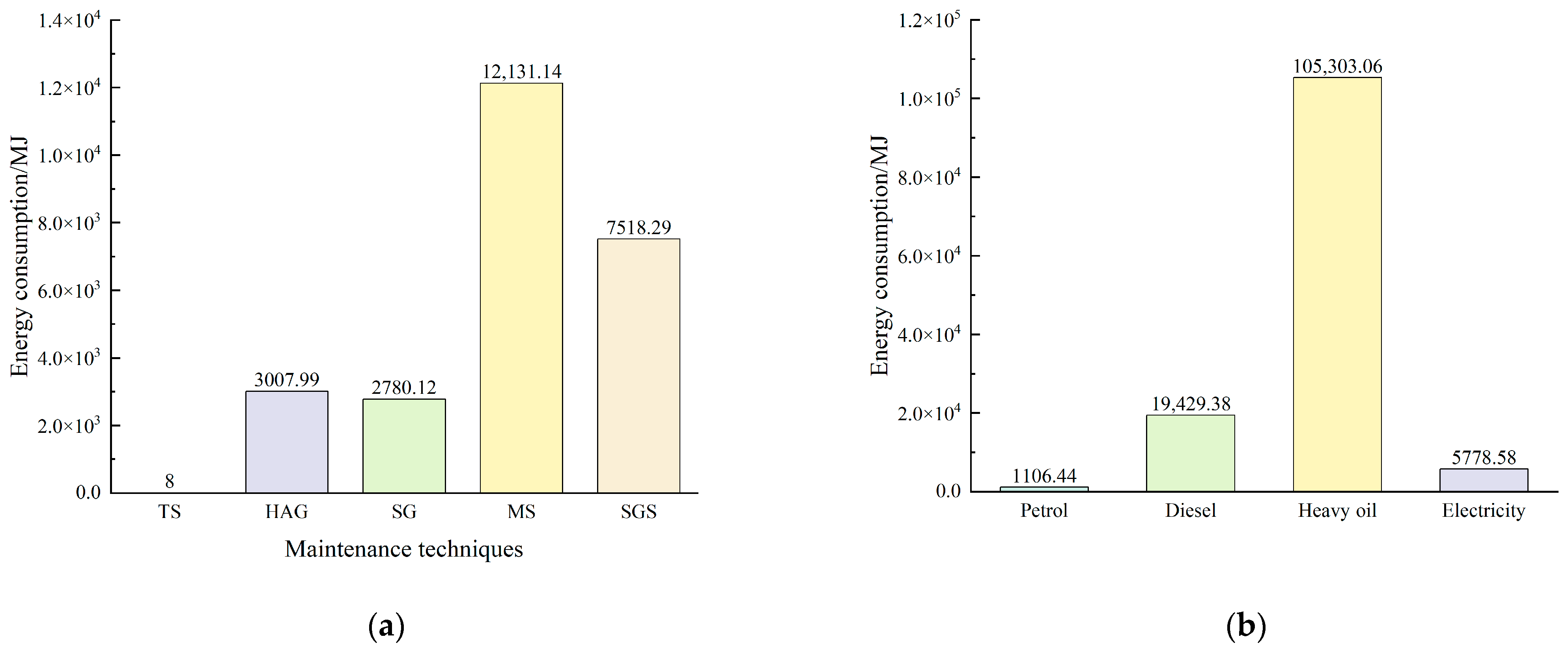

Transportation contributed the lowest emissions, primarily influenced by material volume and distance, with a strong positive correlation between these factors and carbon emissions. Currently, the promotion of alternative power systems, such as hybrid, electric, and fuel cell vehicles, provides a broad opportunity to reduce fuel consumption and greenhouse gas emissions [

44]. Although new energy vehicles have been rapidly developed in recent years, transportation vehicles still use fossil energy as their most important power source. Therefore, improving the transportation efficiency and shortening the transportation distance are the keys to reduce carbon emissions. For the Xinjiang region, promoting the construction of local asphalt modification plants (e.g., Karamay, Dushanzi) and aggregate processing bases in Xinjiang can shorten the transportation distance to 100–300 km and reduce the transportation carbon emissions by 12–37%.

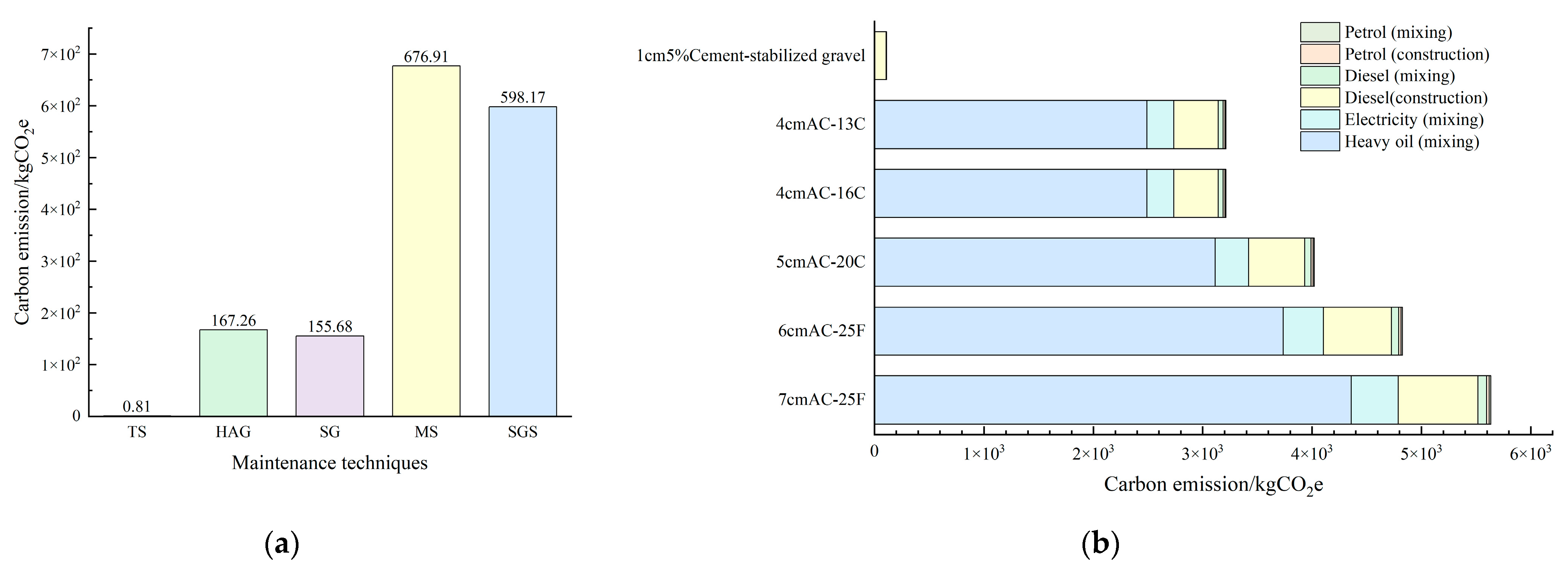

The construction phase ranked second among the three phases in terms of overall energy consumption and carbon emissions. Compared with the material production and transportation phases, the construction phase has a higher feasibility of emission reduction techniques and a greater potential to reduce carbon emissions. Carbon emission reduction in the conservation and construction phase can start from optimizing the construction process, improving the efficiency of construction machinery, and making reasonable construction planning. At the same time, the recycling process has been proven as a technology for achieving sustainable development in infrastructure construction. Recycled hot mix asphalt (HMA) mixtures that contain RAP are considered environment-friendly materials for the base and binder layers of highways; they are capable of reducing CO

2 emissions by 28–39% during the production cycle [

45]. Furthermore, waste plastics serve as a low-carbon asphalt mix additive, and the addition of polyethylene terephthalate (PET) to pavements can reduce life cycle costs and carbon emissions by 26.2% [

46]. Finally, carbon reductions can also be achieved by increasing the use of clean energy in the heating and mixing phases of asphalt mixtures, optimizing pavement design and machinery maintenance.

Finally, although the LCA methodology itself is not the first of its kind in this study, the core innovation of this work lies in the fact that the empirical calibration for Xinjiang (e.g., modification of long-distance transportation parameters, introduction of localized material production data) and the proposal of a synergistic multi-technology emission reduction pathway provide actionable decision support for the low-carbon transition of pavement maintenance in arid and cold regions.

5. Conclusions

In this study, the life cycle analysis (PLCA) method was introduced into the carbon emission measurement and accounting of asphalt pavement maintenance, and the energy consumption and carbon emissions of six commonly used asphalt pavement maintenance technologies (TS, HAG, SG, MS, SGS, and MR) in Xinjiang were comprehensively accounted for and analyzed. The study not only establishes a carbon emissions accounting model based on the PLCA method, calculates and derives the baseline value of carbon emission per unit for the six maintenance technologies, but also clearly elucidates the sources of energy consumption and carbon emission characteristics of each maintenance technology in the phases of raw material production, transportation, and construction. Finally, based on the results of the study, some suggestions are made on how to reduce the carbon emissions at each phase. The main conclusions are as follows:

- (1)

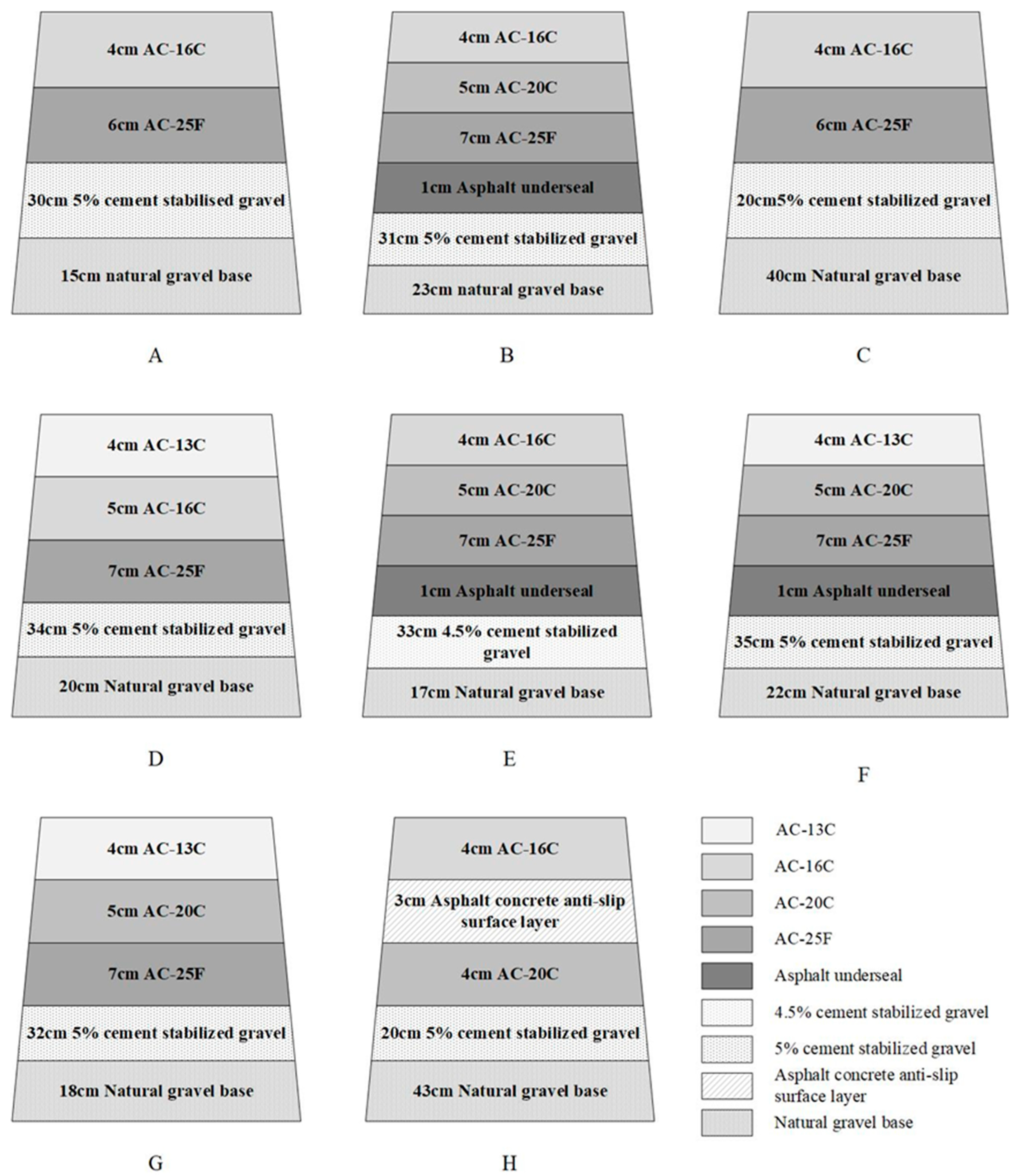

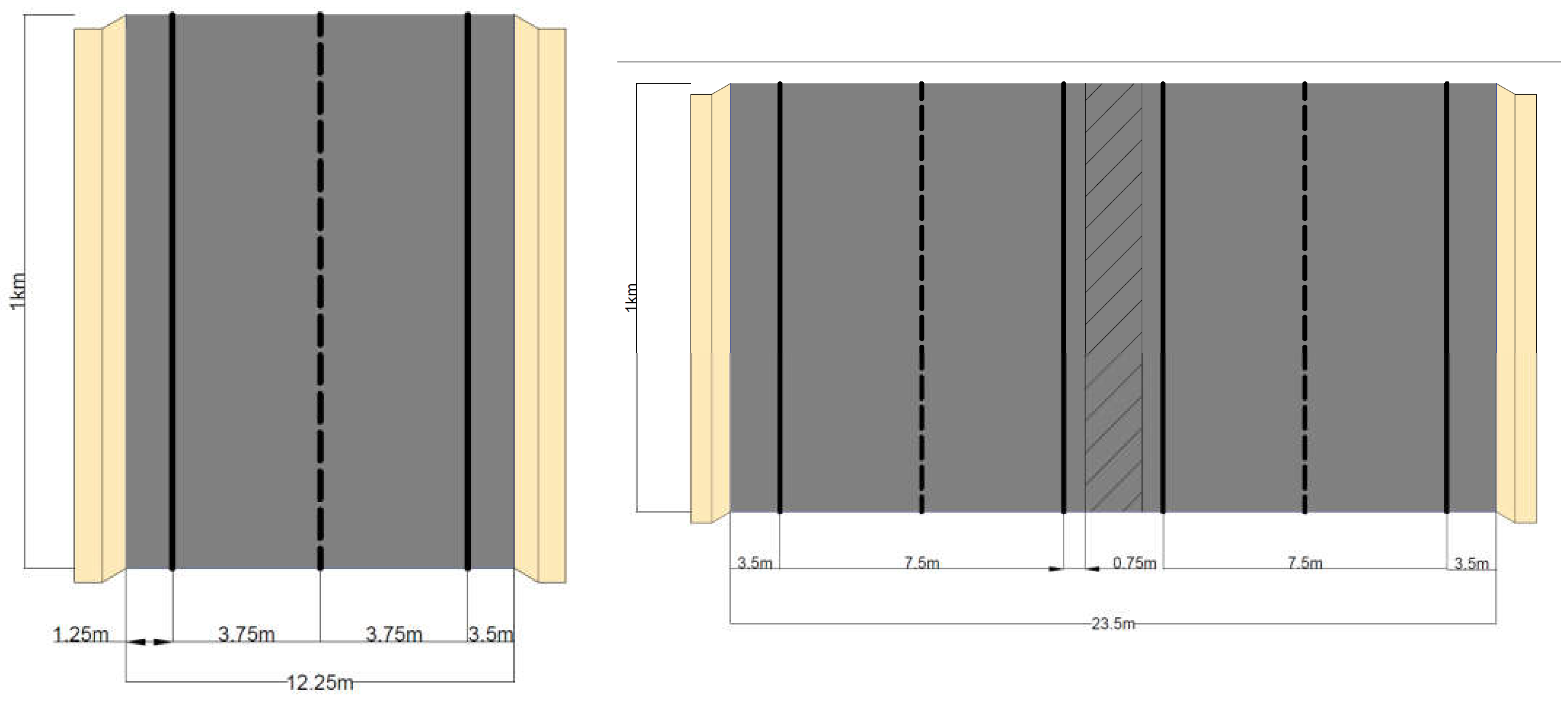

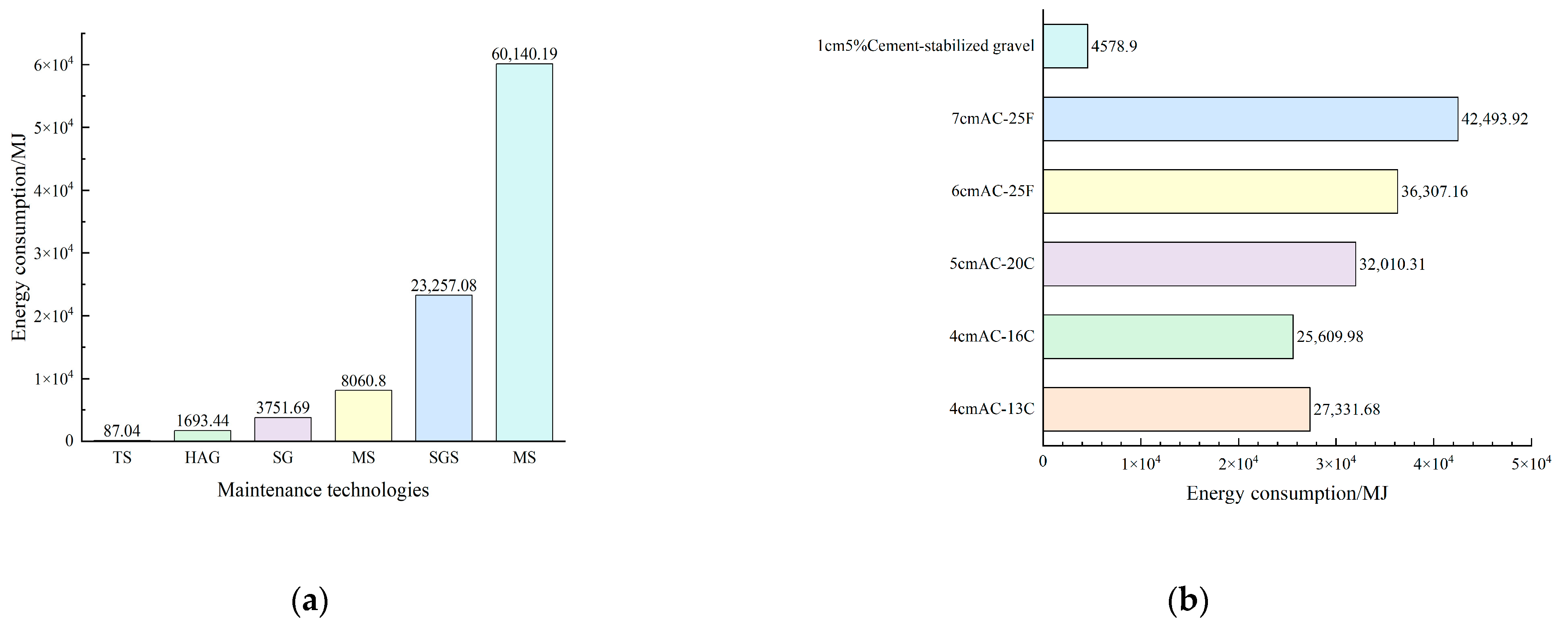

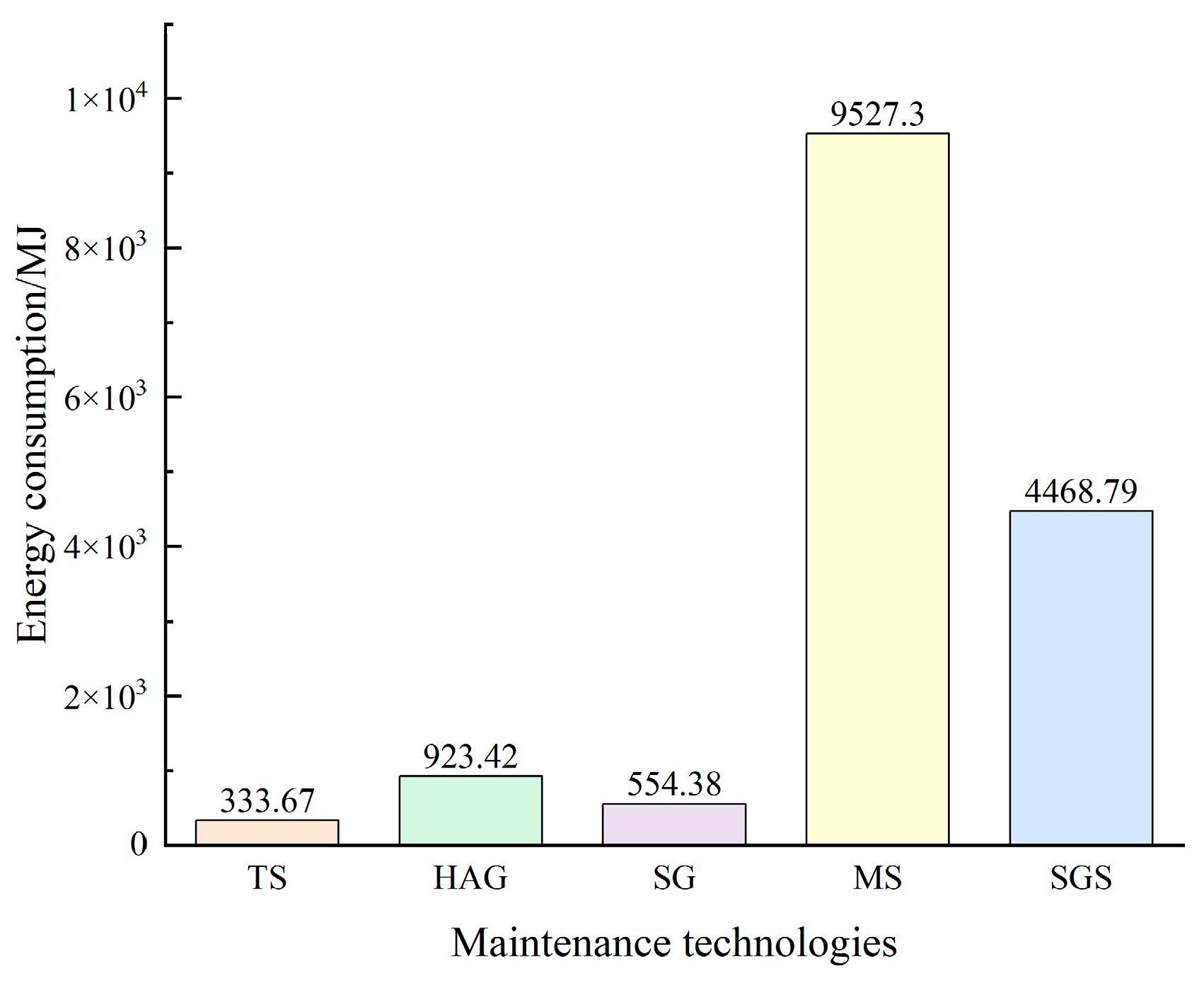

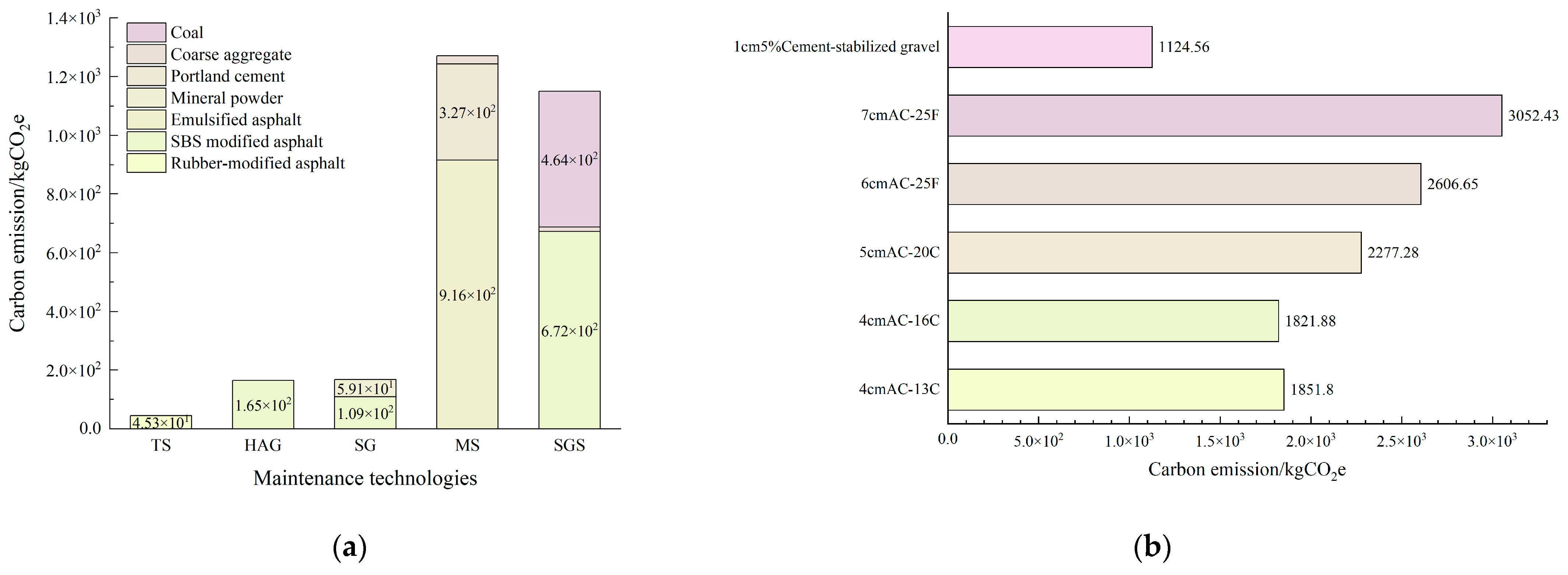

Substantial variations exist in energy and carbon emission intensity across the six techniques: The rankings of energy consumption and carbon emissions per unit of the six asphalt pavement maintenance techniques, as measured by the PLCA method, were as follows: TS (428.17 MJ/km, 63.53 kgCO2e/km) < HAG (5624.85 MJ/km, 378.98 kgCO2e/km) < SG (7086.19 MJ/km, 352.39 kgCO2e/km) < MS (29,719.24 MJ/103 m2, 2444.42 kgCO2e/103m2) < SGS (35,244.16 MJ/103m2, 1997.2 kgCO2e/103m2) ≪ MR (250,809 MJ/103m2, 15,095.67 kgCO2e/103 m2). Taking the whole life cycle of a 20 km highway as an example, the total energy consumption reaches 135,212,302.6 MJ, and the total carbon emissions are 10,558.4 tCO2e, which provides data support for the low-carbon maintenance strategy of highways in Xinjiang.

- (2)

The raw material production phase is the main source of carbon emissions: it contributes 40–60% to the carbon emissions of the six technologies, with the production of cement (735 kgCO2e/t) and asphalt (270–412 kgCO2e/t) being the key links. For example, although the amount of cement used in MS technology is only 20% of emulsified asphalt, its carbon emissions account for 25.7%, and the carbon emissions from the production of modified bitumen in SGS technology account for 58.4%. In addition, the MR technology, which involves the milling of a cement-stabilized gravel layer, can have five times the carbon emissions of an asphalt surface layer.

- (3)

The influence factors of carbon emissions in the transportation and construction phases are clear: the carbon emissions in the transportation phase are positively correlated with the amount of materials used and the transportation distance, e.g., the transportation carbon emissions of MR technology are 6.24 times that of MS, and if the transportation distance is optimized to 100–300 km, the carbon emissions can be reduced by 12–37%. The construction phase has the highest energy consumption per unit and potential for emission reduction, and optimizing the efficiency of construction processes and equipment can significantly reduce emissions. The mixing process (e.g., MR accounts for 87% of construction emissions) is a key target for optimization.

- (4)

Preventive maintenance technologies have significant low-carbon advantages: compared with MR, TS, HAG, and other preventive maintenance technologies can reduce carbon emissions by 76–87%. In terms of the whole life cycle, MS and SGS, due to their wide range of application scenarios, have a total energy consumption ranking of MS > SGS > HAG > SG > TS, but even so, the life cycle energy consumption of MS is only 10% that of MR. This suggests that promoting preventive maintenance is a core strategy to realize low-carbon maintenance of highways. It is suggested to match maintenance techniques with the phase of pavement distress (TS and HAG for early phase, MS and GS for middle phase, and MR for late phase) to maximize the benefits of emission reduction.

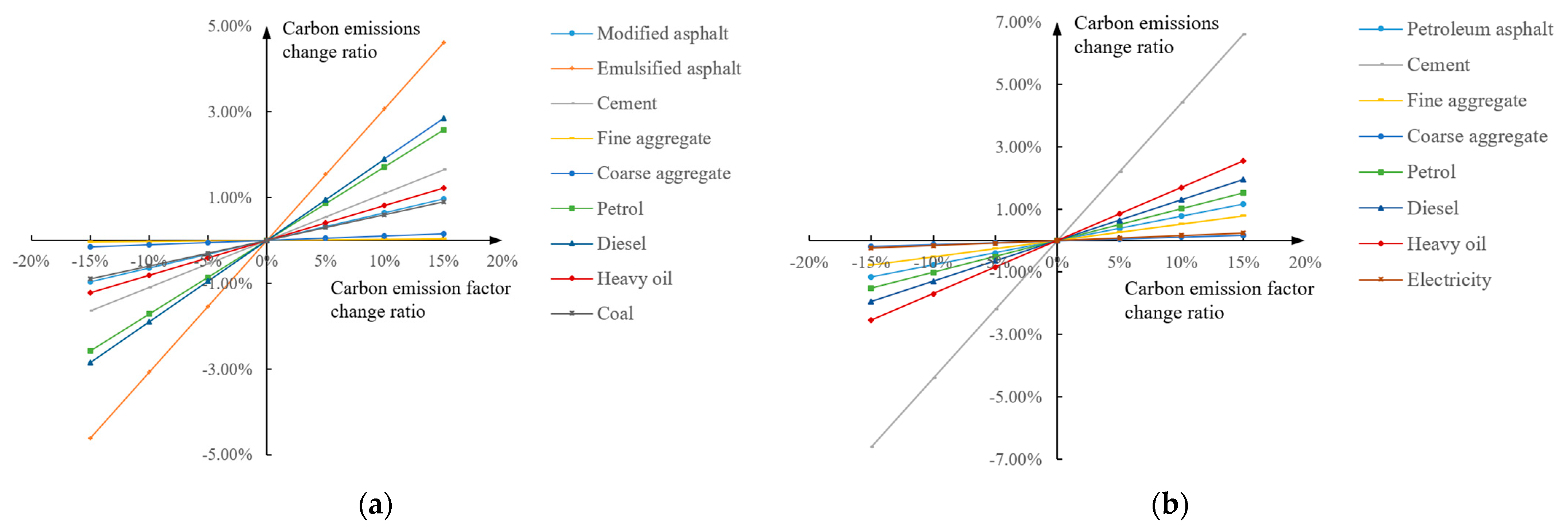

- (5)

Material optimization and process improvement are the key paths to emission reduction; sensitivity analysis reveals that the carbon emission factors of cement and emulsified asphalt have the greatest overall impact. It is suggested that the use of phosphogypsum to replace cement (which reduces carbon emissions by 67.5%), the use of recycled asphalt materials (which reduces emissions by 28–39%), as well as the promotion of electric construction equipment and optimization of mixing plant sites can reduce transportation emissions by 37.7%. In addition, the use of skeleton void structures to reduce the amount of asphalt used is also effective in reducing whole-life carbon emissions.

In conclusion, this study accounts for and analyzes the energy consumption and carbon emissions of the most representative maintenance techniques in Xinjiang, and finally proposes strategies to reduce carbon emissions, including optimizing material composition, using low-emission asphalt binder, avoiding the use of high-emission fillers, and adopting a skeleton void structure to reduce the demand for binder and aggregate. In this study, a PLCA accounting framework adapted to the geographical characteristics of Xinjiang was constructed for the first time, solving the problem of missing conservation data in cold and arid areas. And for the first time, it quantitatively compares the differences in whole life cycle carbon emissions of six typical maintenance technologies under Xinjiang conditions, and improves the applicability of the model in the western region through localized parameter validation The research result not only provides a scientific basis and practical guidance for the Xinjiang highway asphalt pavement maintenance industry in the selection of materials, optimization of construction technology, and formulation of the low-carbon maintenance strategy, but also has important theoretical and practical significance for promoting the realization of energy saving, emission reduction, and green transportation in the region, and even in the country. However, this study’s findings are region-specific to Xinjiang, China, and their generalizability may be limited by omitted life cycle phases (e.g., machinery production) and reliance on aggregated data. Future research should expand to diverse regions, integrate real-time monitoring for dynamic assessments, and explore emerging technologies (e.g., bio-binders, electric equipment), while addressing uncertainties through stochastic modeling and policy-aligned frameworks to advance sustainable pavement maintenance globally.