Analysis of Sewage Sludge Drying Parameters Using Different Additives

Abstract

1. Introduction

2. Materials and Methods

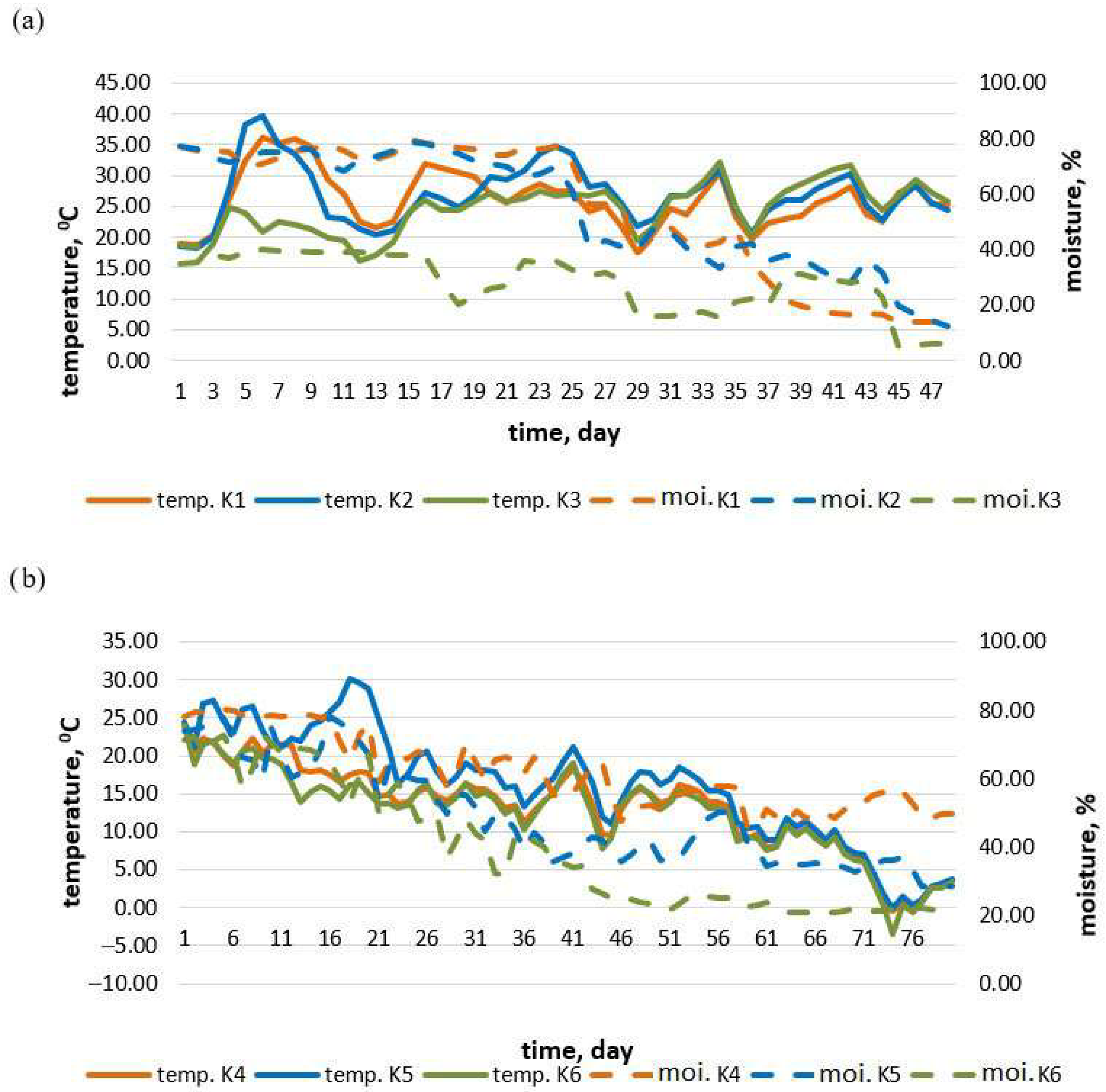

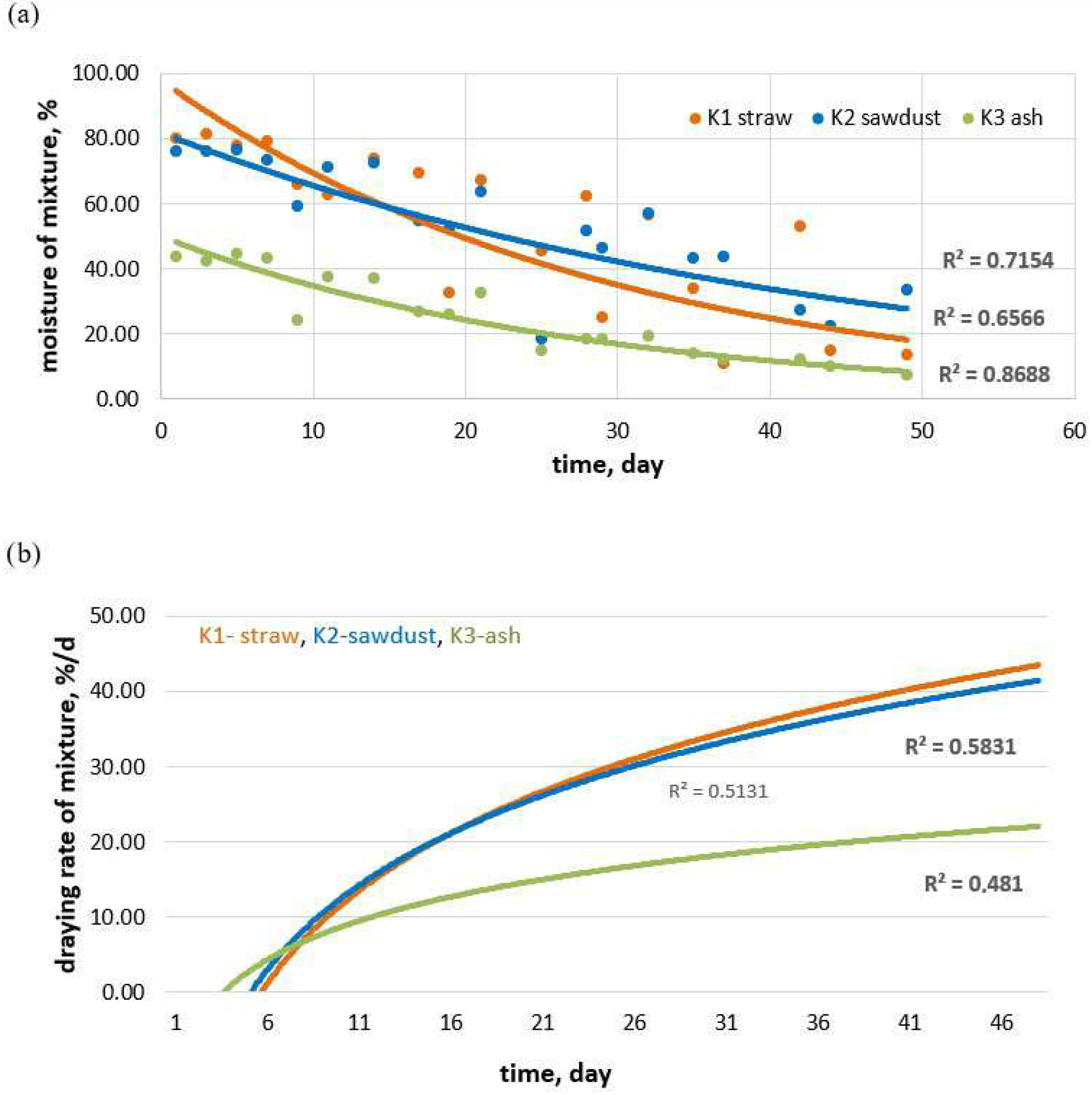

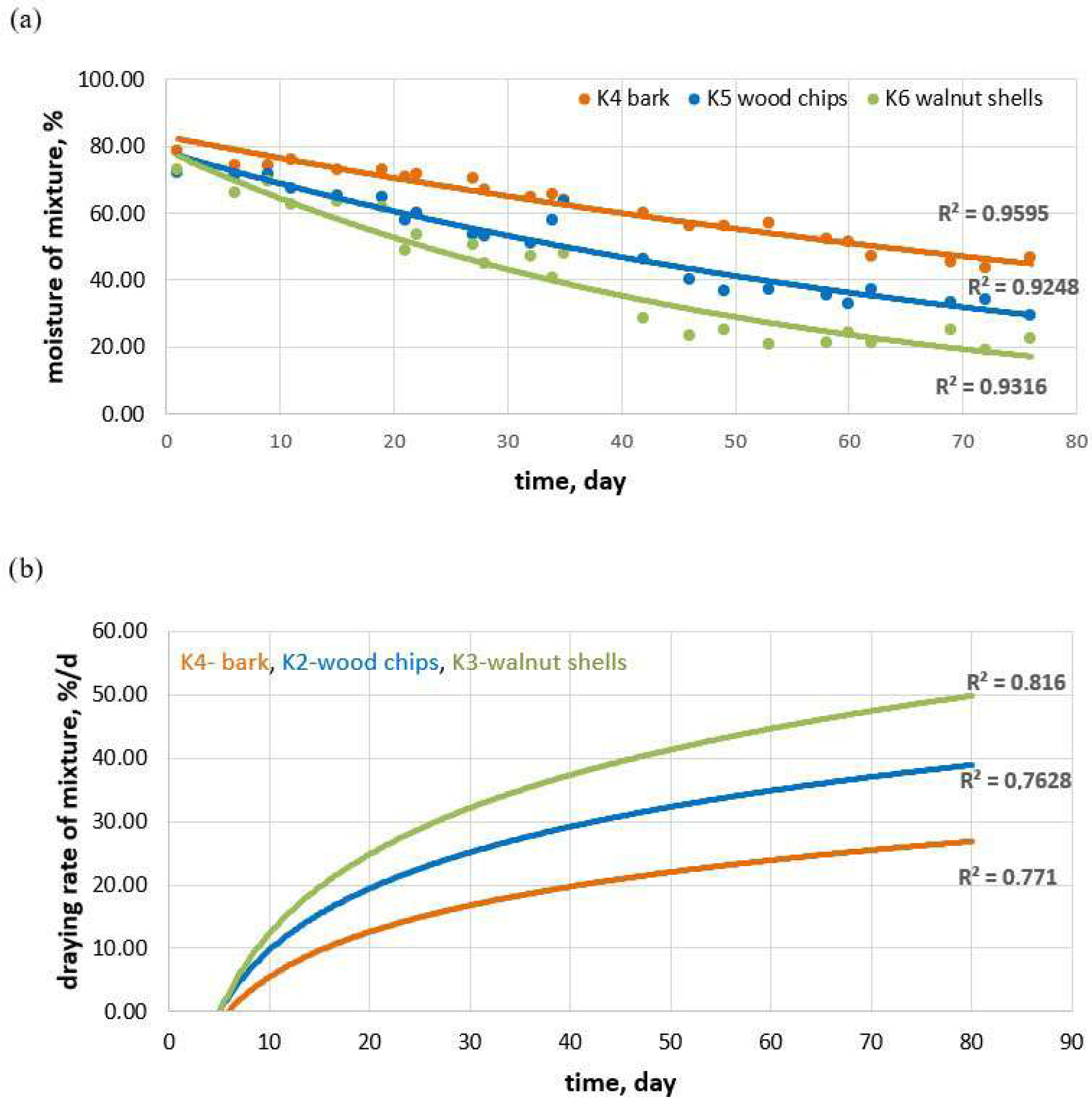

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wolna-Maruwka, A.; Dach, J. Effect of Type and Proportion of Different Structure-Creating Additions on the Inactivation Rate of Pathogenic Bacteria in Sewage Sludge Composting in a Cybernetic Bioreactor. Arch. Environ. Prot. 2009, 35, 87–100. Available online: https://journals.pan.pl/Content/122965/PDF/10_AE_VOL_35_3_2009_Wolna_Maruwka_Effect.pdf (accessed on 14 June 2025).

- Jóźwiakowski, K.; Marzec, M.; Fiedurek, J.; Kamińska, A.; Gajewska, M.; Wojciechowska, E.; Wu, S.; Dach, J.; Marczuk, A.; Kowalczyk-Juśko, A. Application of H2O2 to Optimize Ammonium Removal from Domestic Wastewater. Sep. Purif. Technol. 2017, 173, 357–363. [Google Scholar] [CrossRef]

- Li, L.; Li, H.; Tong, L.; Lv, Y. Sustainable Agriculture Practices: Utilizing Composted Sludge Fertilizer for Improved Crop Yield and Soil Health. Agronomy 2024, 14, 756. [Google Scholar] [CrossRef]

- Dai, J.; Xu, M.; Chen, J.; Yang, X.; Ke, Z. PCDD/F, PAH and heavy metals in the sewage sludge from six wastewater treatment plants in Beijing, China. Chemosphere 2007, 66, 353–361. [Google Scholar] [CrossRef] [PubMed]

- Gusiatin, M.Z. Advantages of Co-Pyrolysis of Sewage Sludge with Agricultural and Forestry Waste. Energies 2024, 17, 5736. [Google Scholar] [CrossRef]

- Cao, B.; Zhang, T.; Zhang, W.; Wang, D. Enhanced technology based for sewage sludge deep dewatering: A critical review. Water Res. 2021, 189, 116650. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhang, Q.; Xu, J.; Sun, X.; Chen, H. Study on Drying of Municipal Sludge and Pollutants Release Characteristics. Processes 2025, 13, 53. [Google Scholar] [CrossRef]

- Tsybina, A.; Wuensch, C. Analysis of sewage sludge thermal treatment methods in the context of circular economy. Detritus 2018, 2, 3–15. [Google Scholar] [CrossRef]

- Qi, S.; Hong, G. Discussion on the co-incineration process with municipal sludge in the waste to energy process. Water Wastewater Eng. 2023, 49, 50–55. [Google Scholar]

- Wang, Z.; Li, X.; Liu, H.; Mou, J.; Khan, S.J.; Lin, C.; Wang, Q. Evaluating energy balance and environmental footprint of sludge management in BRICS countries. Water Res. 2024, 25, 100255. [Google Scholar] [CrossRef] [PubMed]

- Płonka, I.; Kudlek, E.; Pieczykolan, B. Municipal Sewage Sludge Disposal in the Republic of Poland. Appl. Sci. 2025, 15, 3375. [Google Scholar] [CrossRef]

- Boniecki, P.; Dach, J.; Nowakowski, K.; Jakubek, A. Neural Image Analysis of Maturity Stage during Composting of Sewage Sludge. In Proceedings of the 2009 International Conference on Digital Image Processing, Bangkok, Thailand, 7–9 March 2009; pp. 200–203. [Google Scholar] [CrossRef]

- Sołowiej, P.; Pochwatka, P.; Wawrzyniak, A.; Łapiński, K.; Lewicki, A.; Dach, J. The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process. Energies 2021, 14, 1183. [Google Scholar] [CrossRef]

- Kozłowski, K.; Dach, J.; Lewicki, A.; Malińska, K.; Do Carmo, I.E.P.; Czekała, W. Potential of Biogas Production from Animal Manure in Poland. Arch. Environ. Prot. 2019, 45, 99–108. [Google Scholar] [CrossRef]

- Ayilara, M.; Olanrewaju, O.; Babalola, O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Marks, S.; Dach, J.; Morales, F.J.F.; Mazurkiewicz, J.; Pochwatka, P.; Gierz, Ł. New Trends in Substrates and Biogas Systems in Poland. J. Ecol. Eng. 2020, 21, 19–25. [Google Scholar] [CrossRef]

- Wawrzyniak, A.; Pochwatka, A.; Lewicki, A.; Sołowiej, P.; Czekała, W. Database system for estimating the biogas potential of cattle and swine feces in Poland. J. Ecol. Eng. 2021, 22, 111–120. [Google Scholar] [CrossRef]

- Khawer, M.; Naqvi, S.R.; Ali, I.; Arshad, M.; Juchelková, D.; Anjum, M.W.; Naqvi, M. Anaerobic digestion of sewage sludge for biogas & biohydrogen production: State-of-the-art trends and prospects. Fuel 2022, 329, 125416. [Google Scholar] [CrossRef]

- Collard, F.X.; Blin, J. A review on pyrolysis of biomass constituents: Mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew. Sustain. Energy Rev. 2014, 38, 594–608. [Google Scholar] [CrossRef]

- Bennamoun, L. Solar drying of wastewater sludge: A review. Renew. Sustain. Energy Rev. 2012, 16, 1061–1073. [Google Scholar] [CrossRef]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of Ashes from Biomass Combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). IEA Energy Technology Essentials ETE03: Biomass for Power Generation and CHP. 2007. Available online: https://iea.blob.core.windows.net/assets/1028bee0-2da1-4d68-8b0a-9e5e03e93690/essentials3.pdf (accessed on 4 July 2025).

- Internet System of Legal Acts. Ustawa z Dnia 14 Grudnia 2012 r. o Odpadach (The Act of 14th December 2012 on the Waste). Dz.U. 2020 Poz. 797. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20200000797 (accessed on 4 July 2025).

- Boldyryev, S.; Maljković, D.; Kirasić, E.; Krajačić, G. Assessment of product composition and energy output of sewage sludge gasification by simulation model. Energy 2025, 321, 135476. [Google Scholar] [CrossRef]

- Wasserman, M.; Moretti, A.; Goi, D.; Mainardis, M. Integrating renewable energy in sewage sludge treatment through greenhouse solar drying: A review. Sci. Total Environ. 2025, 965, 178634. [Google Scholar] [CrossRef] [PubMed]

- Yusuf, H.H.; Roddick, F.; Jegatheesan, V.; Gao, L.; Pramanik, B.K. Tackling fat, oil, and grease (FOG) build-up in sewers: Insights into deposit formation and sustainable in-sewer management techniques. Sci. Total Environ. 2023, 904, 166761. [Google Scholar] [CrossRef] [PubMed]

- Cesaro, A.; Pirozzi, F.; Zafırakou, A.; Alexandraki, A. Microplastics in sewage sludge destined to anaerobic digestion: The potential role of thermal pretreatment. Chemosphere 2022, 309, 136669. [Google Scholar] [CrossRef] [PubMed]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances. full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Mehrdadi, N.; Joshi, S.G.; Nasrabadi, T.; Hoveidi, H. Aplication of solar energy for drying of sludge from pharmaceutical industrial waste water and probable reuse. Int. J. Environ. Res. 2007, 1, 42–48. [Google Scholar]

- Boguniewicz-Zablocka, J.; Klosok-Bazan, I.; Capodaglio, A.G. Sustainable management of biological solids in small treatment plants: Overview of strategies and reuse options for a solar drying facility in Poland. Environ. Sci. Pollut. Res. Int. 2021, 2819, 24680. [Google Scholar] [CrossRef] [PubMed]

- Kelessidis, A.; Stasinakis, A.S. Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries: A review. Waste Manag. 2012, 32, 1186–1195. [Google Scholar] [CrossRef] [PubMed]

- Castro-Fernandez, A.; Taboada-Santos, A.; Balboa, S.; Lema, J.M. Thermal hydrolysis pre-treatment has no positive influence on volatile fatty acids production from sewage sludge. Bioresour. Technol. 2023, 376, 128839. [Google Scholar] [CrossRef] [PubMed]

- Đurđević, D.; Žiković, S.; Blecich, P. Sustainable Sewage Sludge Management Technologies Selection Based on Techno-Economic-Environmental Criteria: Case Study of Croatia. Energies 2022, 15, 3941. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhai, Y.; Li, S.; Liu, X.; Wang, B.; Liu, X.; Fan, Y.; Shi, H.; Li, C.; Zhu, Y. Thermal treatment of sewage sludge: A comparative review of the conversion principle. recovery methods and bioavailability-predicting of phosphorus. Chemosphere 2022, 291, 133053. [Google Scholar] [CrossRef] [PubMed]

- VijayaVenkataRaman, S.; Iniyan, S.; Goic, R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Li, J.; Yan, J.G.; Wang, Y.F.; Yang, K.; Shao, Y.Y.; Shao, Y.Q.; Wang, Q.C.; Zhu, Y. Influencing factors of the drying rate of sludge for solar drying chamber. IOP Conf. Ser. Earth Environ. Sci. 2021, 626, 012024. [Google Scholar] [CrossRef]

- Wzorek, M. Solar drying of granulated waste blends for dry biofuel production. Environ. Sci. Pollut. Res. 2021, 2826, 34290–34299. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Shrivastava, V.; Kumar, A. Recent developments in greenhouse solar drying: A review. Renew. Sustain. Energy Rev. 2018, 82, 3250–3262. [Google Scholar] [CrossRef]

- Berroug, F.; Lakhal, E.K.; El Omari, M.E.; Ouazzani, N.; Mandi, L.; Nouh, F.A.; Hejjaj, A.; Bellaziz, Y.; Idlimam, A.; Boukhattem, L. Simulation of sewage sludge drying under climate of solar greenhouse. In Proceedings of the 6th International Congress on Thermal Sciences, Khouribga, Morocco, 1–2 December 2020; Volume 2345. [Google Scholar] [CrossRef]

- Patil, P.; Sharara, M. Simulation model for swine lagoon sludge drying in solar-assisted greenhouse systems. Environ. Technol. Innov. 2025, 37, 104057. [Google Scholar] [CrossRef]

- Srivastava, A.; Sharma, A.; Kumar, A. Performance evaluation of indirect solar drying system for potato slices: Comparative analysis with open-sun drying method. Sol. Energy 2025, 285, 113114. [Google Scholar] [CrossRef]

- Kujawiak, S.; Makowska, M.; Waliszewska, B.; Janczak, D.; Brózdowski, J.; Czekała, W.; Zyffert, A. The Influence of Drying Sewage Sludge with the Addition of Walnut Shells on Changes in the Parameters and Chemical Composition of the Mixture. Energies 2024, 17, 4701. [Google Scholar] [CrossRef]

- Kujawiak, S.; Makowska, M.; Janczak, D.; Czekała, W.; Krzesiński, W.; Antonowicz, A.; Kupryaniuk, K. An Analysis of the Physicochemical and Energy Parameters of Briquettes Manufactured from Sewage Sludge Mixtures and Selected Organic Additives. Energies 2024, 17, 4573. [Google Scholar] [CrossRef]

- Qiu, J.; Tian, Q.; Wei, Z.; Zhou, M. Research advances in municipal sludge drying. Ecol. Environ. 2007, 16, 667–671. [Google Scholar]

- Czekała, W.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kwiatkowska, A.; Kozłowski, K. Influence of maize straw content with sewage sludge on composting process. J. Water Land Dev. 2016, 301, 43–49. [Google Scholar] [CrossRef]

- Dach, J.; Czekała, W.; Boniecki, P.; Lewicki, A.; Piechota, T. Specialised Internet Tool for Biogas Plant Modelling and Marked Analysing. Adv. Mat. Res. 2014, 909, 305–310. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-1; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture—Reference Method. Polski Komitet Normalizacyjny: Warszawa, Poland, 2016.

- PN-EN ISO 12880:2004; Characterization of Sewage Sludge—Determination of Dry Residue and Water Content. Polski Komitet Normalizacyjny: Warszawa, Poland, 2004.

- PN-EN ISO 21663:2021-06; Solid Recovered Fuels—Determination of Total Content of Carbon. Hydrogen and Nitrogen. Polski Komitet Normalizacyjny: Warszawa, Poland, 2021.

- PN-EN ISO 1097-3:2000; Determination of Bulk Density and Voids. Polski Komitet Normalizacyjny: Warszawa, Poland, 2000.

- PN-EN ISO 933-2:1999; Marking of Grain Composition. Polski Komitet Normalizacyjny: Warszawa, Poland, 1999.

- Ferrentin, R.; Langone, M.; Fiori, L.; Andreottola, G. Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption. Water 2023, 15, 615. [Google Scholar] [CrossRef]

- Gizaw, D.G.; Periyasamy, S.; Redda, Z.T.; John, B.I.; Mengstie, H.B.; Asaithambi, P. A comprehensive review on sewage sludge as sustainable feedstock for bioenergy production. Environ. Qual. Manag. 2023, 33, 223–238. [Google Scholar] [CrossRef]

- Nunes, N.; Ragonezi, C.; Gouveia, C.S.S.; Pinheiro de Carvalho, M.A.A. Review of Sewage Sludge as a Soil Amendment in Relation to Current International Guidelines: A Heavy Metal Perspective. Sustainability 2021, 13, 2317. [Google Scholar] [CrossRef]

- da Silva, B.P.; Saccol, F.; Caetano, N.R.; Pedrazzi, C.; Caetano, N.R. Technical and Economic Viability for the Briquettes Manufacture. Defect Diffus. Forum 2017, 380, 218–226. [Google Scholar] [CrossRef]

| Mix Component | Mixture Symbol | Moisture [%] | Dry Organic Matter Content [% DM org] | Carbon Content [% DM] | Nitrogen Content [% DM] | Bulk Density, [kg/dm3] | Dimensions [mm] | Duration of the Series [Day] |

|---|---|---|---|---|---|---|---|---|

| Sewage sludge | - | 60.74 | 87.08 | 37.08 | 6.57 | 1.07 | - | 63 |

| Straw chaff | K1 | 7.97 | 92.92 | 45.98 | 1.22 | 0.4 | 3–50 | 49 |

| Tree sawdust | K2 | 7.73 | 97.83 | 52.82 | 1.56 | 0.15 | 3–10 | 49 |

| Ash | K3 | 7.61 | 2.44 | 2.84 | 0 | 0.95 | 0.2–0.5 | 49 |

| Pine bark | K4 | 52.05 | 65.01 | 50.06 | 1.13 | 0.15 | 10–20 | 76 |

| Beech–alder wood chips | K5 | 8.47 | 73.74 | 48.19 | 0.73 | 0.32 | 10–16 | 76 |

| Walnut shells | K6 | 10.67 | 70.11 | 49.89 | 0.83 | 0.31 | 26–39 | 76 |

| Survey Methodology | - | PN-EN ISO 18134-1 [47] | PN-EN ISO 12880:2004 [48] | PN-EN ISO 21663:2021-0 6 [49] | PN-EN ISO 21663:2021-06 [49] | PN-EN ISO 1097-3:2000 [50] | PN-EN ISO 933-2:1999 [51] | - |

| Serie | SERIE 1 | SERIE 2 | |||||

|---|---|---|---|---|---|---|---|

| Mixture | K1 | K2 | K3 | K4 | K5 | K6 | |

| Insolation, MJ/m2 | Min. | 2.57 | 0.65 | ||||

| Max. | 24.11 | 12.9 | |||||

| Outside temp., °C | Min. | 10.67 | −3.73 | ||||

| Max. | 29 | 19.81 | |||||

| Inside temp., °C | Min. | 8.1 | −1.29 | ||||

| Max. | 33.4 | 24.2 | |||||

| Outside humidity, % | Min. | 34.25 | 17.99 | ||||

| Max. | 99.5 | 100 | |||||

| Temp. of mixture, °C | Initial | 19.05 | 18.47 | 15.7 | 24.19 | 24.34 | 24.05 |

| Final | 25.43 | 24.38 | 25.86 | 3.66 | 3.81 | 3.39 | |

| Min. | 17.56 | 18.24 | 15.7 | −0.34 | −0.06 | −3.46 | |

| Max. | 36.12 | 39.63 | 32.26 | 24.19 | 30.16 | 24.05 | |

| Humidity of mixture, % | Initial | 77.27 | 77.12 | 41.84 | 78.23 | 73.78 | 78.28 |

| Final | 13.68 | 12.46 | 6.23 | 49.5 | 28.6 | 21.93 | |

| Min. | 13.68 | 12.46 | 5.05 | 45.63 | 28.55 | 20.75 | |

| Max. | 79.67 | 78.99 | 41.84 | 80.14 | 78.16 | 72.61 | |

| Insolation | Outside Temp. | Inside Temp. | Inside Humidity | Temp. of Mixture | ||

|---|---|---|---|---|---|---|

| Outside temp. | 0.4768 | |||||

| Inside temp. | 0.6044 | 0.9477 | ||||

| Inside humidity | −0.7661 | −0.4081 | −0.3931 | |||

| Humidity of mixture | K1 | −0.6777 | −0.5732 | 0.1445 | 0.2961 | |

| K2 | −0.6984 | −0.6039 | 0.0768 | 0.0916 | ||

| K3 | −0.5005 | −0.4681 | 0.0316 | −0.4665 | ||

| Insolation | Outside Temp. | Inside Temp. | Inside Humidity | Temp. of Mixture | ||

|---|---|---|---|---|---|---|

| Outside temp. | 0.6241 | |||||

| Inside temp. | 0.7537 | 0.9080 | ||||

| Inside humidity | −0.5842 | −0.2500 | −0.1506 | |||

| Humidity of mixture | K4 | 0.4817 | 0.7385 | −0.2351 | 0.7394 | |

| K5 | 0.5585 | 0.7898 | −0.2262 | 0.8277 | ||

| K6 | 0.5313 | 0.7749 | −0.1774 | 0.7073 | ||

| Factor | Series 1 | Series 2 | ||||

|---|---|---|---|---|---|---|

| K1 | K2 | K3 | K4 | K5 | K6 | |

| Insolation | +++ | +++ | +++ | ++ | ++ | ++ |

| Outside temperature | +++ | +++ | ++ | ++ | ++ | ++ |

| Inside temperature | ++ | ++ | ++ | +++ | +++ | +++ |

| Inside Humidity | + | + | + | + | + | + |

| Temperature of mixture | + | + | ++ | +++ | +++ | +++ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makowska, M.; Kujawiak, S.; Janczak, D.; Miler, P.; Czekała, W. Analysis of Sewage Sludge Drying Parameters Using Different Additives. Sustainability 2025, 17, 6500. https://doi.org/10.3390/su17146500

Makowska M, Kujawiak S, Janczak D, Miler P, Czekała W. Analysis of Sewage Sludge Drying Parameters Using Different Additives. Sustainability. 2025; 17(14):6500. https://doi.org/10.3390/su17146500

Chicago/Turabian StyleMakowska, Małgorzata, Sebastian Kujawiak, Damian Janczak, Patryk Miler, and Wojciech Czekała. 2025. "Analysis of Sewage Sludge Drying Parameters Using Different Additives" Sustainability 17, no. 14: 6500. https://doi.org/10.3390/su17146500

APA StyleMakowska, M., Kujawiak, S., Janczak, D., Miler, P., & Czekała, W. (2025). Analysis of Sewage Sludge Drying Parameters Using Different Additives. Sustainability, 17(14), 6500. https://doi.org/10.3390/su17146500