1. Introduction

Low-carbon liquid fuels are needed for the decarbonization of hard-to-electrify sectors such as aviation, shipping, and long-haul trucking. This decarbonization can be limited by the amount of renewable carbon that is available for production of these fuels. Biomass and municipal solid waste (MSW) gasification represent a promising pathway for producing these fuels. Biomass feedstocks, including agricultural waste, forestry residues, MSW and specially cultivated crops, are key inputs for the biomass-to-liquid (BTL) processes using biomass gasification. However, conventional BTL processes face significant limitations, particularly in terms of carbon conversion efficiency. The primary challenge stems from the hydrogen deficiency inherent in biomass and MSW, which results in low efficiency of renewable carbon to liquid fuel in the process [

1]. This inefficiency is a significant drawback given the limited availability of biomass resources, making it crucial to maximize fuel output from available feedstocks. Enhancing the BTL process to improve conversion efficiency can therefore be critical to increasing the production of methanol and other low-carbon fuels in a resource-constrained context.

Hydrogen-enhanced biomass/MSW gasification has been explored in the literature [

2,

3], and it has been shown that it can increase the amount of liquid fuel per tonne biomass/MSW by a factor of two for methanol [

1,

4,

5] and Fischer–Tropsch synthetic fuel [

6]. However, additional hydrogen should be sourced from low-carbon sources to keep the overall GHG emissions low [

6]. Low-carbon hydrogen could be provided by water electrolysis using renewable electricity from wind, solar, or nuclear power and/or by potential production of hydrogen from pyrolytic conversion of natural gas to hydrogen and elemental carbon. Development of technologies for natural gas pyrolysis is being pursued by many organizations, with some beginning to operate commercial-scale test units [

7,

8]. Hydrogen production from natural gas pyrolysis could potentially provide advantages of being a source of hydrogen when renewable electricity is not available or is too expensive [

1]. An additional option for producing lower-cost hydrogen, albeit one at a very early stage of exploration, is the use of geologic hydrogen [

9].

In addition to conventional gasification, other thermochemical conversion routes have been explored for processing biomass and MSW. These include pyrolysis [

10] and hydrothermal gasification [

11], among others.

In this study, our focus is on the production of methanol, which is a fuel that is most efficiently and easily produced from biomass/MSW feedstocks. Methanol has currently strong commercial interest for ship propulsion and in addition can be converted into dimethyl ether (as a clean substitute for diesel fuel or propane), aviation fuel, or gasoline [

12]. Methanol can also be employed for vehicular propulsion using both spark ignition and compression ignition engines. Biomass feedstocks can also be converted by a different pathway (the Fischer–Tropsch (FT) process) into aviation fuel or diesel fuel [

13]. Methanol is more efficiently produced than FT, but for some applications, such as production of sustainable aviation fuel (SAF), FT is currently used. On the other hand, methanol can also be converted to SAF through the MTSAF process [

14].

While the potential of liquid fuel production from biomass gasification has received considerable attention, the potential use of MSW feedstock remains relatively underexplored [

5]. In addition to producing liquid fuels, the use of MSW can have the benefit of avoiding landfilling and its resulting methane generation [

5]. This is particularly important because of the increased concerns about the near-term impacts of landfill methane release (due to the 20-year methane global warming potential (GWP), which is around 85 times larger than the 20-year GWP of CO

2 [

5]). We show that it is possible to have a net-negative emissions scenario, emphasizing avoided methane emissions from landfills. The comparative emissions impact between pyrolytic hydrogen and electrolytic hydrogen provides valuable insights into real-world decarbonization potential. The use of MSW could also be attractive because there is already an established network for its pickup and transportation to disposal sites. This approach could be particularly suitable for urban and industrial settings.

In this study, we explore the impact of hydrogen-enhancement biomass/MSW gasification on the potential production of methanol in a geographical location. The US was chosen as an illustrative location, and the analysis presented here can be applied to any other location globally. In the literature, studies have taken into account the potential of hydrogen-enhanced biomass gasification in other regions, such as in Europe [

15,

16,

17]. For our analysis, we need to determine the quantity of available biomass and MSW feedstocks. For that purpose, we took into account the recent projections of the potential for the US to produce a billion tonnes/yr of biomass feedstocks based on the 2024 USDOE report [

18]. This report estimated potential liquid biofuel production of 60 billion gallons of diesel energy equivalent fuel per year (which is the energy equivalent of around 120 billion gallons/yr of methanol). Biomass feedstocks include agricultural waste, forestry waste, and specially grown biomass that does not interfere with food production and MSW. In this study, we explore the co-location potential of these feedstocks with natural gas pipelines and renewable energy generation sites. This co-location strategy enhances logistical feasibility, reducing transport costs and optimizing energy system integration, an aspect that is not often addressed in biomass-to-fuel research. Here, we explore the potential impacts of hydrogen-enhanced biomass gasification on the production of low-carbon liquid fuels, taking the US as an illustrative location.

2. Biomass to Methanol Processes

Hydrogen enhancement of the gasification process offers a promising pathway to significantly improve the efficiency and output of syngas conversion into low-carbon fuels such as methanol. By using adjustable hydrogen addition into the gasification syngas, it is possible to adjust the H2 content of the syngas and thereby nearly double methanol production from the same amount of biomass or municipal solid waste while simultaneously reducing CO2 emissions. This enhancement overcomes the hydrogen deficiency in conventional BTL processes, allowing for more efficient carbon utilization and greater fuel yields.

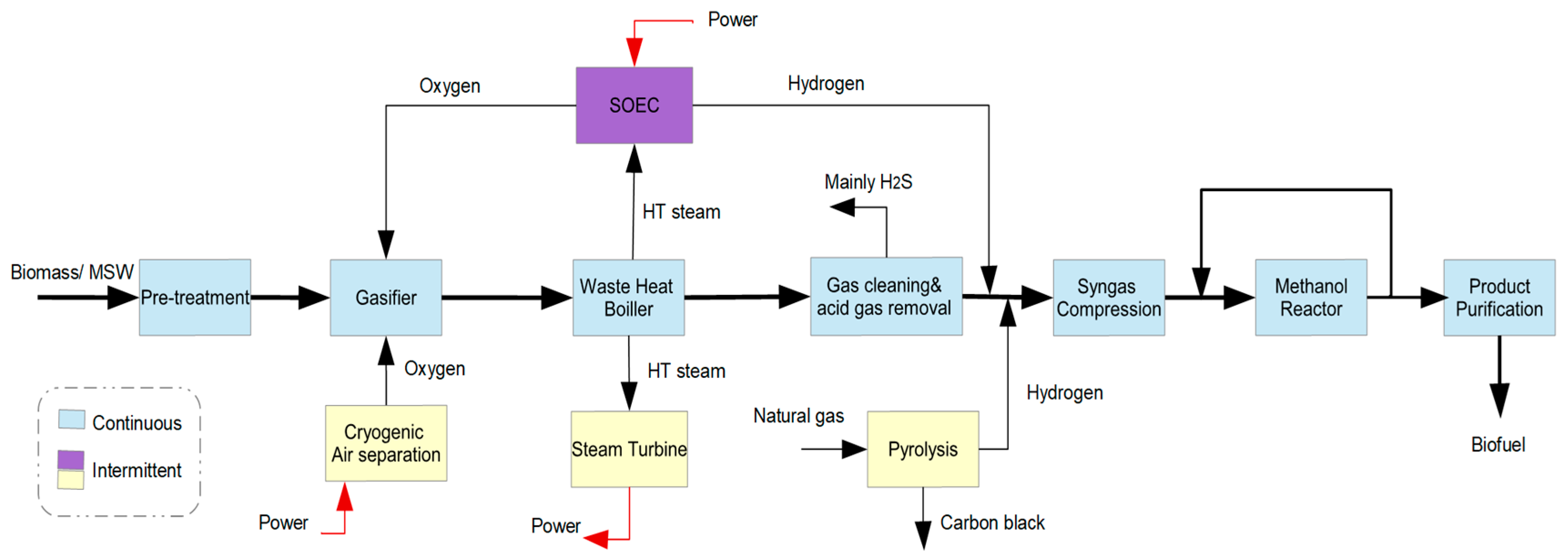

Hydrogen enhancement can be provided by low-carbon hydrogen sources: water electrolysis (using low carbon electricity) or pyrolytic conversion of natural gas. Technoeconomic evaluations suggest that hydrogen produced via natural gas pyrolysis may be more cost-effective than hydrogen from electrolysis, especially under typical natural gas market conditions in the US (however, further developments could reduce the cost of renewable hydrogen from nuclear, wind, or solar power). These two hydrogen sources can be used separately or together. The use of these two hydrogen sources is shown in a flexible hydrogen-enhanced process (

Figure 1) that can use either or both hydrogen sources and can take advantage of varying feedstock costs, such as natural gas and electricity, to optimize both production efficiency and economic viability [

1]. This flexibility allows producers to adjust hydrogen sourcing based on feedstock prices, ensuring cost-efficient methanol production. Depending on the price of input biomass/MSW feedstocks, electricity cost, natural gas cost, and the configuration, methanol can be produced within a wide price range of

$300 to

$1000 per tonne [

1].

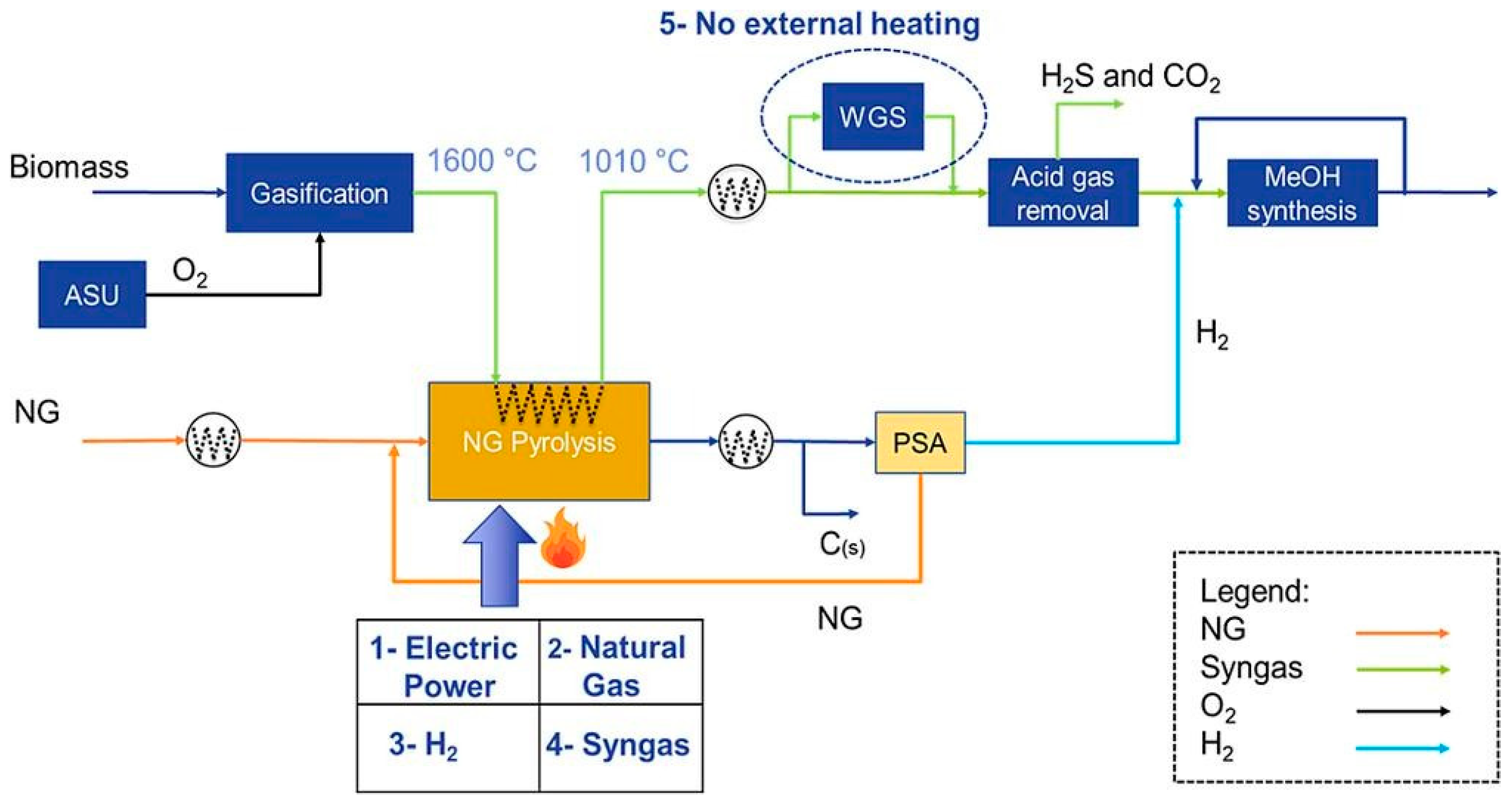

Taking the US as an illustrative location, hydrogen produced via natural gas pyrolysis is potentially more cost-effective than hydrogen from electrolysis. With a focus on the endothermic nature of natural gas pyrolysis, we developed an integrated framework [

4] for analyzing the combination of pyrolytic hydrogen with biomass gasification for methanol production, aiming to enhance both economic viability and low greenhouse gas (GHG) emissions.

Five different integration options were evaluated for an illustrative biomass to methanol process using an illustrative combination of an entrained flow gasifier (EFG) and a molten media natural gas pyrolysis unit, as shown in

Figure 2 [

4]. For an illustrative process that produces 48.4 tonne methanol per hour, technoeconomic analysis showed that for a molten material-based pyrolysis process, the production cost of methanol ranges from approximately

$440 to

$470 per tonne, assuming the sale of carbon byproduct at

$100 per tonne. In scenarios where the carbon byproduct is not sold, methanol production costs increase to about

$475 to

$500 per tonne. In case of no revenue from selling carbon and instead assuming a cost of

$40 per tonne of produced carbon for waste disposal of elemental carbon, this results in an illustrative cost range of around

$490 to

$510 per tonne methanol. This cost is in the present cost range of US production of natural-gas-based methanol [

19]. It may be possible for the performance of the biomass gasifier to be improved by adding small amounts of the carbon produced from the methane pyrolysis. The key benefits include enhanced reaction kinetics [

20], due to the large surface area of carbon, and more homogeneous temperature in the gasifier, due to carbon’s high thermal conductivity and radiative properties. However, carbon addition slightly increases the carbon intensity of the produced methanol.

The net GHG emissions associated with natural gas pyrolysis can be strongly influenced by the level of natural gas fugitive emissions, which are methane leaks that occur during natural gas extraction, processing, and transportation to the end user. While the pyrolysis process itself generates hydrogen with minimal direct CO2 emissions, high levels of fugitive methane emissions could substantially increase the overall carbon footprint. Therefore, ensuring a low-emission natural gas supply chain is necessary for achieving the environmental benefits of this process.

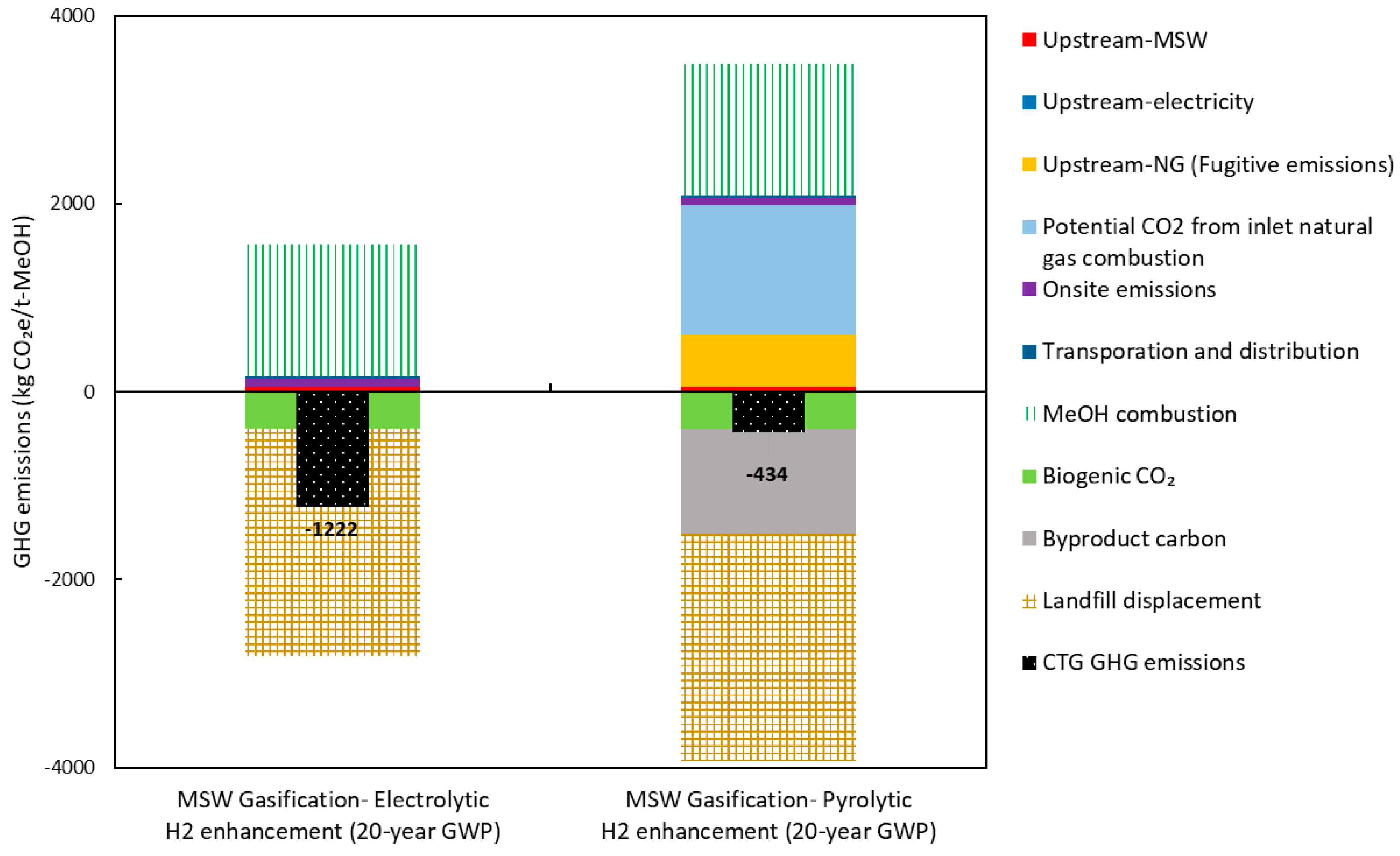

Converting MSW to fuel could offer additional environmental benefits, particularly in terms of reducing net GHG emissions [

5]. The life cycle GHG emissions of converting MSW to methanol with electrolytic and pyrolytic hydrogen enhancement are shown in

Figure 3. Electrolytic hydrogen enhancement could be provided by wind, solar, or nuclear power [

4].

Figure 3 shows that this process has the potential for net-negative life cycle emissions, as shown in the black bars for electrolytic and pyrolytic hydrogen enhancement. This potential advantage is due to the avoidance of methane emissions from landfills, which are a major contributor to short-term global warming potential (GWP), especially over a 20-year time frame.

As an illustrative case of using MSW gasification with hydrogen enhancement, conversion of 50% US landfilled MSW annually, that is, the use of 66 million tonnes of MSW, could potentially produce around 28 billion gallons of methanol, which is energy equivalent to 12.6 billion gallons of diesel [

5]. This amount of diesel accounts for approximately 40% of the annual diesel consumption by long-haul heavy-duty trucks in the US [

21]. If this methanol were used to replace fossil-based diesel fuel, it would result in an annual GHG reduction of 162 million tonnes of CO

2e compared with the current practices of diesel use and MSW landfilling [

5].

3. Feedstock Availability

As a case study, we looked at potential expansion of US low-carbon fuel production using hydrogen-enhanced biomass/MSW gasification. The study considered the US as an illustrative location, and the analysis presented here can be applied to any other location globally.

3.1. Potential Biomass/MSW Resources in the US

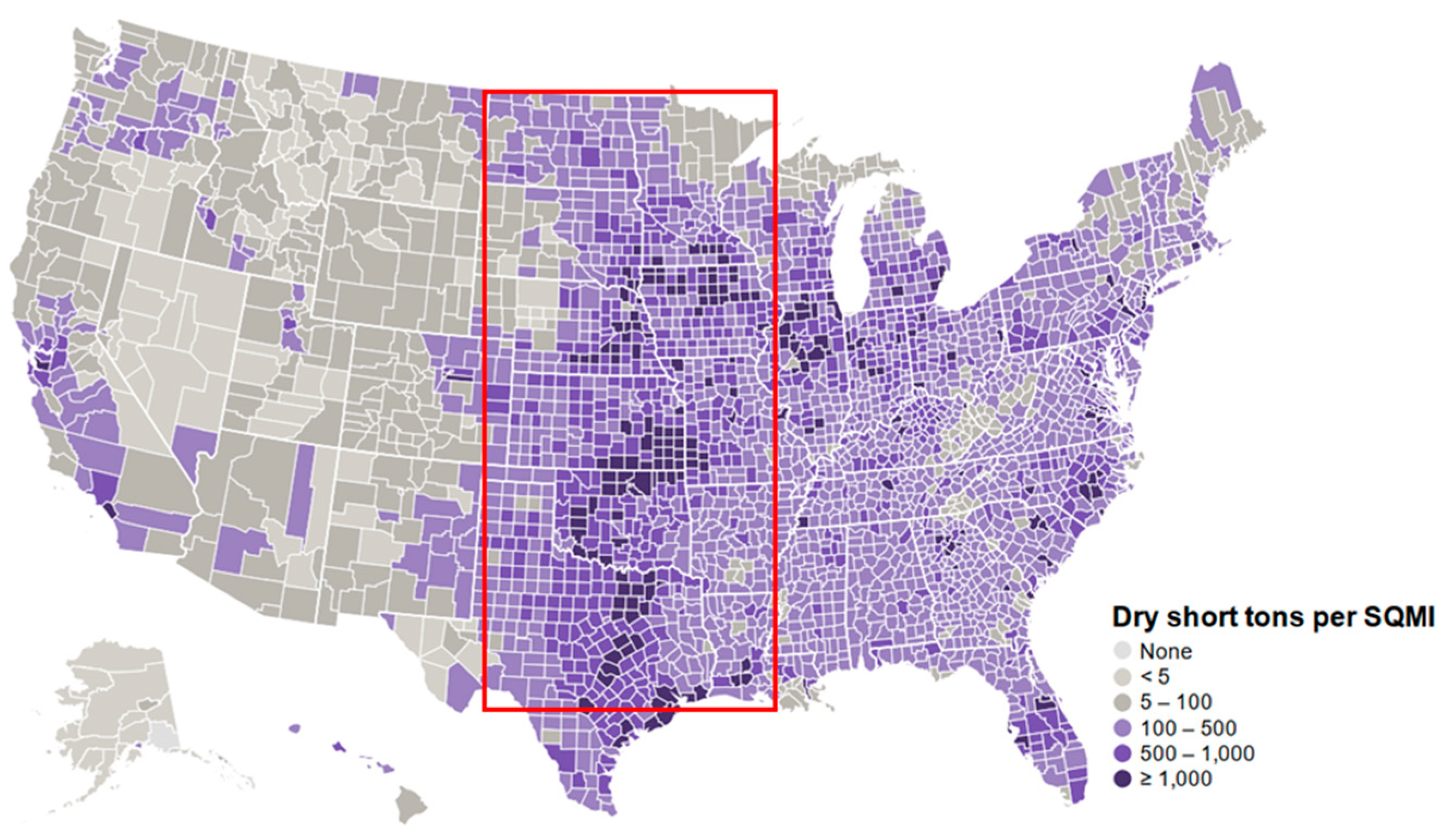

The spatial distribution of untapped biomass resources across the US, as illustrated in

Figure 4, highlights the significant potential for expanding low-carbon fuel production. According to the 2024 Department of Energy (DOE) report [

18], more than 1 billion tons of additional biomass per year could be harnessed for fuel production. Based on the report, this biomass could support the annual production of up to 60 billion gallons of diesel energy equivalent fuel. With the integration of hydrogen-enhanced gasification, this figure could potentially double, reaching up to 120 billion gallons of diesel energy equivalent fuel per year, significantly boosting the US’s capacity for producing low-carbon fuels. For hydrogen enhancement, it is necessary to have low-carbon-sourced hydrogen. Pyrolytic H

2 requires natural gas, while electrolytic H

2 depends on renewable electricity, as discussed in the following sections.

While the potential biomass and MSW feedstock availability in the U.S. is substantial, practical deployment for fuel production may face limitations due to accessibility at their location and competition for other uses (e.g., electricity generation, and pulp production). For use of MSW, challenges include the variability in moisture and composition of waste streams, and siting or permitting constraints for new facilities.

It is important to recognize that biomass and especially MSW are heterogeneous, and characterization is needed to determine their suitability for gasification such as moisture content, ash content, and calorific value. MSW, on the other hand, often requires preprocessing to produce refuse-derived fuel (RDF) [

5], which concentrates the organic and combustible fractions while removing materials such as metals and glass.

3.2. Natural Gas Potential for Pyrolytic Production of Hydrogen in the US

The United States has significant natural gas reserves, particularly in shale formations such as the Marcellus, Utica, Permian, and Haynesville basins. It also has an extensive and well-developed natural gas pipeline network that spans the country (

Figure 5). When we overlay the biomass resources (

Figure 4) and natural gas pipeline network (

Figure 5), there is a significant geographical overlap between major natural gas reserves and areas of high biomass and MSW production, particularly in the central regions of the US, as shown in

Figure 5. This proximity enhances the potential for integrating natural gas pyrolysis with biomass/MSW gasification to produce hydrogen-enhanced low-carbon fuels, reducing both logistical costs and emissions.

3.3. US Solar and Wind Potential for Producing Hydrogen

Renewable power is needed for electrolytic hydrogen production. Solar and wind are two main sources of renewable power generation that are discussed in this section. The inherent intermittency of solar power along with seasonal and diurnal variability can affect electrolyzer utilization rates. While photovoltaic (PV) systems are the dominant solar technology because of their lower costs and modularity, concentrated solar power (CSP) may be helpful in supplying thermal energy storage and enable dispatchable electricity generation or provision of heat for high-temperature electrolysis. CSP may be particularly viable in regions with direct normal irradiance (DNI) and available land, although current capital costs remain higher than PV. Similarly, wind power is an important contributor to the renewable energy mix, and wind power tends to complement solar by producing power at night and during different seasons, improving overall renewable electricity availability.

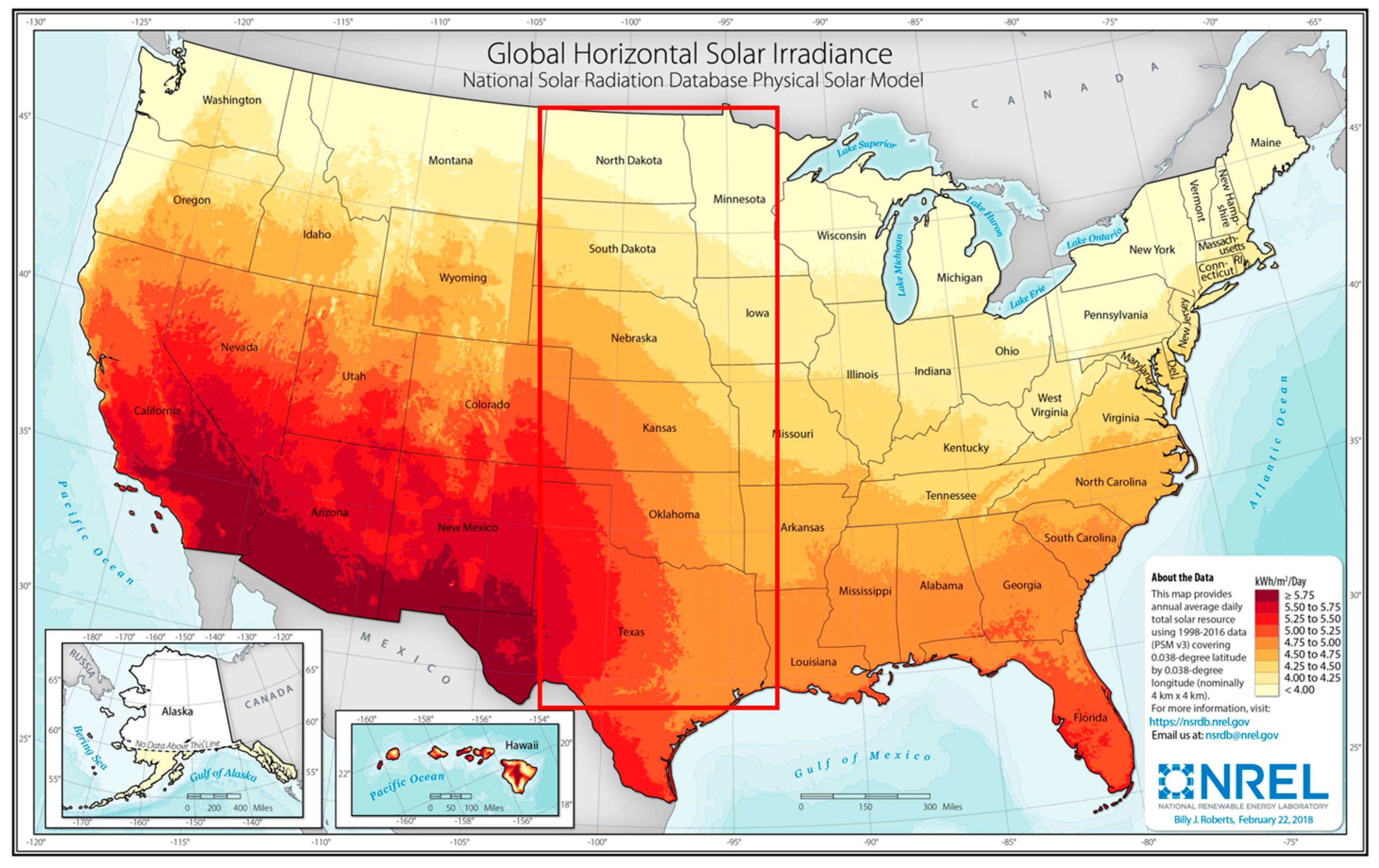

3.3.1. Solar Potential for Renewable Power in the US

The US has extensive potential for solar renewable power generation, with the highest-potential areas primarily concentrated in Arizona, Nevada, New Mexico, and California (as shown in

Figure 6). These regions benefit from abundant solar radiation and large desert areas, making them ideal for large-scale solar energy projects. Moderate-potential areas are also found in the southern plains’ states, such as Texas, Oklahoma, and Kansas, as well as parts of the Midwest. These regions could provide a strong foundation for integrating solar power into low-carbon liquid fuel production.

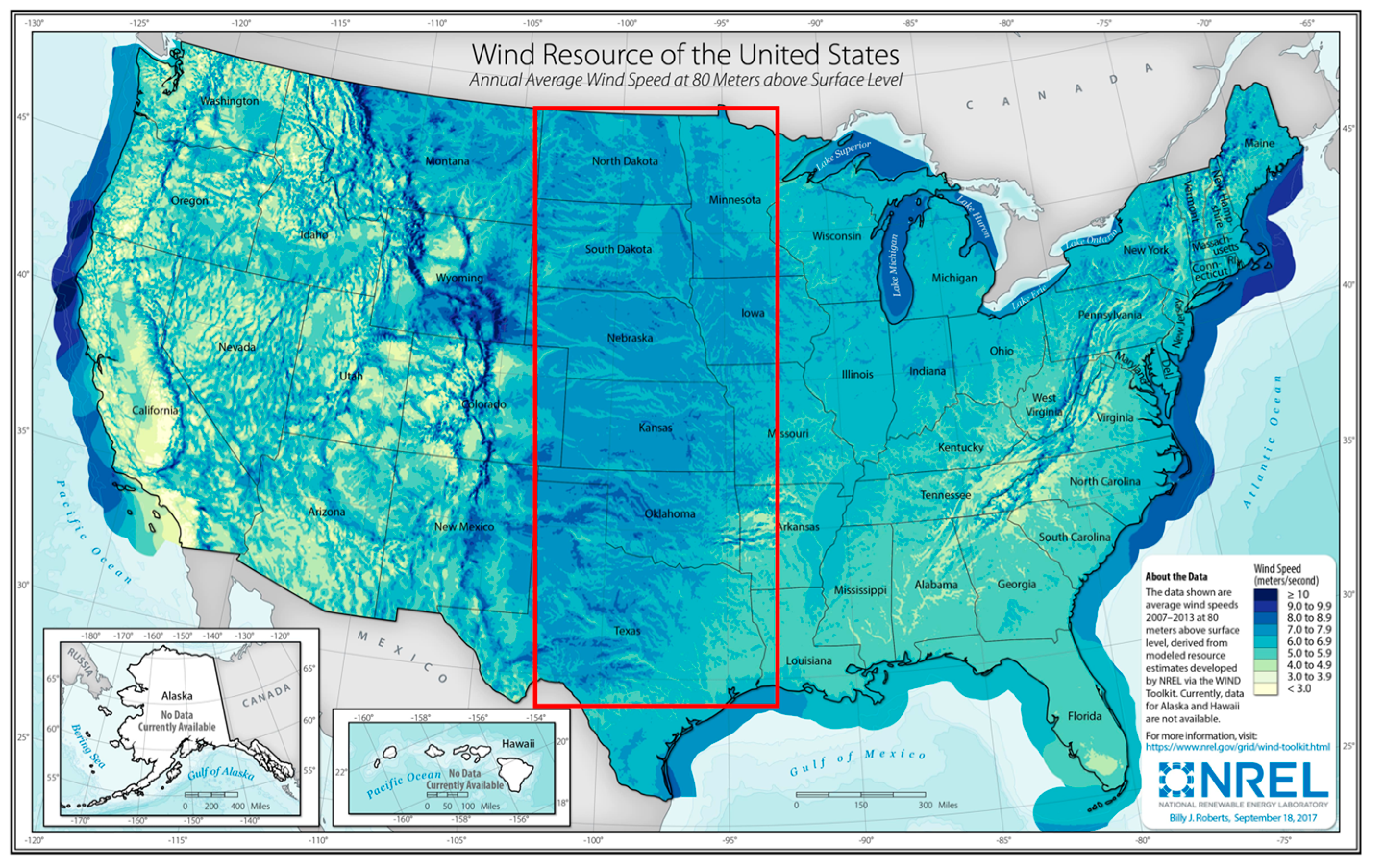

3.3.2. Wind Potential for Renewable Power in the US

The US has significant wind potential for renewable power generation (as shown in

Figure 7), particularly in the central region, which includes states such as Texas, Oklahoma, Kansas, Nebraska, and North Dakota. This area benefits from consistent and strong wind speeds, making it one of the most productive wind energy regions in the country. In addition, substantial wind resources are also present in the Great Lakes region and along the Pacific Northwest coast, where favorable wind conditions further enhance the potential for expanding renewable wind power generation.

4. Potential Areas for Co-Locating Biomass Feedstocks with Renewable Electricity and/or Natural Gas Networks

High potential for co-locating biomass feedstocks, renewable electricity, and natural gas availability in the US exists in regions with abundant biomass/MSW resources, wind and solar power, and well-established natural gas pipeline infrastructure. These regions include:

The Midwest (Corn Belt): States such as Iowa, Illinois, and Nebraska benefit from a strong agricultural base, providing ample biomass from crop residues. These states also possess significant wind energy capability, potentially making the region especially well-suited for integrating renewable energy with biomass and natural gas infrastructure.

Texas: In addition to its large wind and solar resources and extensive natural gas infrastructure, Texas also has significant agricultural residues for biomass. This combination could position Texas as a promising region for the production of low-carbon liquid fuel from hydrogen-enhanced gasification of biomass/MSW.

California: The Central Valley’s extensive agricultural activity generates large amounts of biomass, while the state’s abundant solar resources and established natural gas networks offer high potential for synergistic renewable energy development.

Southeast (Georgia, North Carolina): Rich forestry biomass, a growing solar industry, and a well-developed natural gas network make this region a promising candidate for renewable power and biomass co-location.

Great Plains (North and South Dakota): These states are home to significant wind resources and agricultural biomass, supported by natural gas infrastructure and integration.

5. Technological and Economic Challenges

Although there is promising potential for hydrogen-enhanced biomass/MSW gasification to produce the low-carbon liquid fuels needed to meet greenhouse gas reduction goals, a number of challenges must be addressed to achieve large-scale commercial deployment. Producing affordable liquid fuel requires affordable capital and operating costs and high operational reliability. Our illustrative costs of around

$500 per tonne for production of low-carbon methanol using hydrogen from natural gas pyrolysis (and assuming high availability) are around the same as the present cost per tonne of methanol produced from US natural gas [

19]. Use of hydrogen produced from electrolysis using renewable electricity could result in considerably higher costs unless renewable electricity costs are sufficiently low [

1].

A particularly challenging requirement is the demonstration at scale of the high availability of the equipment used in the gasification facilities. Frequent maintenance or operational disruptions could increase costs and hinder the commercial viability.

In addition, the commercial viability of producing hydrogen from pyrolytic conversion of natural gas to hydrogen has not yet been commercially demonstrated. Moreover, access to natural gas with low fugitive emissions is needed for meeting GHG reduction goals. High levels of methane leakage during natural gas extraction and transport could negate the environmental benefits of hydrogen-enhanced biomass conversion. As with most emerging technologies for reducing GHG (e.g., electric vehicles), government support will likely be needed to meet goals for initial deployment of commercial units using hydrogen-enhanced biomass gasification to produce low-carbon liquid fuels at scale

6. Conclusions

Hydrogen-enhanced biomass/MSW gasification could present a transformative opportunity to greatly expand production of low-carbon liquid fuel such as methanol. By addressing the hydrogen deficiency in conventional biomass gasification, this approach enables a substantial increase in methanol yields while reducing overall carbon intensity. The integration of flexible hydrogen sources, such as water electrolysis and natural gas pyrolysis, enhances the viability and scalability of the process. Hydrogen enhancement at scale could potentially be provided by water electrolysis using low-cost renewable electricity from wind, solar or nuclear power. Another option is the potential use of significantly lower-cost hydrogen through natural gas pyrolysis. A further potential option is the use of geologic hydrogen, which is at a very early stage of exploration.

We considered the US as an illustrative location to explore the impact of hydrogen enhancement, but the analysis presented here could be applied to any other location globally. We took into account recent projections of the potential for the US to produce a billion tonnes/yr of biomass feedstocks based on a 2024 USDOE report [

18]. On one end of the spectrum, if the biomass feedstock availability is lower than expected, the use of hydrogen enhancement could provide additional certainty of reaching the production level of 60 billion gallons of diesel energy equivalent fuel per year discussed in the DOE report (the energy equivalent of around 120 billion gallons of methanol/yr). On the other and most optimistic end, it could potentially enable a production level of low-carbon liquid fuel that has an energy equivalent of 120 billion gallons of diesel energy equivalent fuel per year and substantially boost US low-carbon liquid fuel capacity. Future work is needed on optimizing the process, reducing fugitive methane emissions from natural gas supply chains, and conducting pilot-scale demonstrations to validate economic assumptions.

By identifying high-potential U.S. regions with overlapping biomass/MSW availability, renewable power resources, and natural gas infrastructure, this work could potentially be used in regional siting decisions. This could be beneficial in prioritizing investment in co-located projects using hydrogen sources and scalable gasification technologies.

Author Contributions

Conceptualization, M.O., D.R.C., G.Z. and L.B.; methodology, M.O., D.R.C., G.Z. and L.B.; software, M.O.; validation, M.O., D.R.C., G.Z. and L.B.; formal analysis, M.O., D.R.C., G.Z. and L.B.; investigation, M.O., D.R.C., G.Z. and L.B.; resources, M.O., D.R.C., G.Z. and L.B.; writing—original draft preparation, M.O. and D.R.C.; writing—review and editing, M.O., D.R.C., G.Z. and L.B.; visualization, M.O.; supervision, D.R.C. and L.B.; project administration, D.R.C. and L.B.; funding acquisition, D.R.C. and L.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Eni S.p.A.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors gratefully acknowledge Eni S.p.A. for funding this research through the MIT Energy Initiative. This paper is an extension of our presentation at 2024 MIT–Harvard A+B conference [

25].

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BTL | Conventional biomass to liquid (i.e., methanol) process |

| CO2e | CO2-equivalent emissions |

| DOE | Department of Energy in the US |

| FT | Fischer–Tropsch |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| MSW | Municipal solid waste |

| PSA | Pressure swing adsorption |

| SAF | Sustainable aviation fuel |

| WGS | Water–gas shift |

References

- Ostadi, M.; Bromberg, L.; Cohn, D.R.; Gençer, E. Flexible methanol production process using biomass/municipal solid waste and hydrogen produced by electrolysis and natural gas pyrolysis. Fuel 2023, 334, 126697. [Google Scholar] [CrossRef]

- Poluzzi, A.; Guandalini, G.; Guffanti, S.; Elsido, C.; Moioli, S.; Huttenhuis, P.; Rexwinkel, G.; Martelli, E.; Groppi, G.; Romano, M.C. Flexible Power & Biomass-to-Methanol plants: Design optimization and economic viability of the electrolysis integration. Fuel 2022, 310, 122113. [Google Scholar] [CrossRef]

- Butera, G.; Jensen, S.H.; Gadsbøll, R.Ø.; Ahrenfeldt, J.; Clausen, L.R. Flexible biomass conversion to methanol integrating solid oxide cells and TwoStage gasifier. Fuel 2020, 271, 117654. [Google Scholar] [CrossRef]

- Ostadi, M.; Zang, G.; Bromberg, L.; Cohn, D.R.; Gençer, E. Enhancing Biomass-to-Liquid Conversion Through Synergistic Integration of Natural Gas Pyrolysis: Process Options and Environmental Implications. Energy Convers. Manag. 2024, 302, 118142. [Google Scholar] [CrossRef]

- Ostadi, M.; Cohn, D.R.; Zang, G.; Bromberg, L. CH4 and CO2 Reductions from Methanol Production Using Municipal Solid Waste Gasification with Hydrogen Enhancement. Sustainability 2024, 16, 8649. [Google Scholar] [CrossRef]

- Ostadi, M.; Rytter, E.; Hillestad, M. Hillestad Boosting carbon efficiency of the biomass to liquid process with hydrogen from power: The effect of H2/CO ratio to the Fischer-Tropsch reactors on the production and power consumption. Biomass Bioenergy 2019, 127, 105282. [Google Scholar] [CrossRef]

- Lázaro, I. Hazer Group’s Commercial Demonstration Plant Operated for 240 Hours Continuously. Available online: https://inspenet.com/en/noticias/commercial-demonstration-plant-hazer-group/ (accessed on 9 February 2025).

- Monolith Inc. Available online: https://en.wikipedia.org/wiki/Monolith_Inc (accessed on 9 February 2025).

- Musa, M.; Hosseini, T.; Sander, R.; Frery, E.; Sayyafzadeh, M.; Haque, N.; Kinaev, N. Techno-economic assessment of natural hydrogen produced from subsurface geologic accumulations. Int. J. Hydrogen Energy 2024, 93, 1283–1294. [Google Scholar] [CrossRef]

- Zadeh, Z.E.; Abdulkhani, A.; Aboelazayem, O.; Saha, B. Recent Insights into Lignocellulosic Biomass. Processes 2020, 8, 799. [Google Scholar] [CrossRef]

- Kruse, A. Hydrothermal biomass gasification. J. Supercrit. Fluids 2009, 47, 391–399. [Google Scholar] [CrossRef]

- Goeppert, A.; Czaun, M.; Jones, J.P.; Prakash, G.S.; Olah, G.A. Recycling of carbon dioxide to methanol and derived products-closing the loop. Chem. Soc. Rev. 2014, 43, 7995–8048. [Google Scholar] [CrossRef] [PubMed]

- Hillestad, M.; Ostadi, M.; Serrano, G.A.; Rytter, E.; Austbø, B.; Pharoah, J.G.; Burheim, O.S. Improving carbon efficiency and profitability of the biomass to liquid process with hydrogen from renewable power. Fuel 2018, 234, 1431–1451. [Google Scholar] [CrossRef]

- Eyberg, V.; Dieterich, V.; Bastek, S.; Dossow, M.; Spliethoff, H.; Fendt, S. Fendt Techno-economic assessment and comparison of Fischer–Tropsch and Methanol-to-Jet processes to produce sustainable aviation fuel via Power-to-Liquid. Energy Convers. Manag. 2024, 315, 118728. [Google Scholar] [CrossRef]

- Dietrich, R.U.; Adelung, S.; Habermeyer, F.; Maier, S.; Philippi, P.; Raab, M.; Weyand, J. Technical, economic and ecological assessment of European sustainable aviation fuels (SAF) production. CEAS Aeronaut. J. 2024, 15, 161–174. [Google Scholar] [CrossRef]

- Hannula, I. Hydrogen enhancement potential of synthetic biofuels manufacture in the European context: A techno-economic assessment. Energy 2016, 104, 199–212. [Google Scholar] [CrossRef]

- Koponen, K.; Hannula, I. GHG emission balances and prospects of hydrogen enhanced synthetic biofuels from solid biomass in the European context. Appl. Energy 2017, 200, 106–118. [Google Scholar] [CrossRef]

- U.S. Department of Energy. 2023 Billion-Ton Report: An Assessment of U.S. Renewable Carbon Resources; U.S. Department of Energy: Washington, WA, USA, 2024. [Google Scholar]

- Blumberg, T.; Tsatsaronis, G.; Morosuk, T. On the economics of methanol production from natural gas. Fuel 2019, 256, 115824. [Google Scholar] [CrossRef]

- Zhang, Y.; Wan, L.; Guan, J.; Xiong, Q.A.; Zhang, S.; Jin, X. A Review on Biomass Gasification: Effect of Main Parameters on Char Generation and Reaction. Energy Fuels 2020, 34, 13438–13455. [Google Scholar] [CrossRef]

- Alternative Fuels Data Center. Available online: https://afdc.energy.gov/data (accessed on 9 February 2025).

- US Natural Gas Pipelines and Pipeline Boarder Crossings. Available online: https://www.eia.gov/energyexplained/natural-gas/natural-gas-pipelines.php (accessed on 9 February 2025).

- US Solar Resource Map. Available online: https://www.nrel.gov/gis/solar-resource-maps.html (accessed on 9 February 2025).

- US Wind Resource Map. Available online: https://www.nrel.gov/gis/wind-resource-maps.html (accessed on 9 February 2025).

- MIT A+B Conference 2024. Available online: https://applied-energy.org/mitab2024/program (accessed on 9 February 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).