Research on the Configurations and Control Methods of a Hybrid System of Air-Source Heat Pumps and Gas Boilers for Space Heating: Simulation and Comparative Analysis

Abstract

1. Introduction

2. Methodology

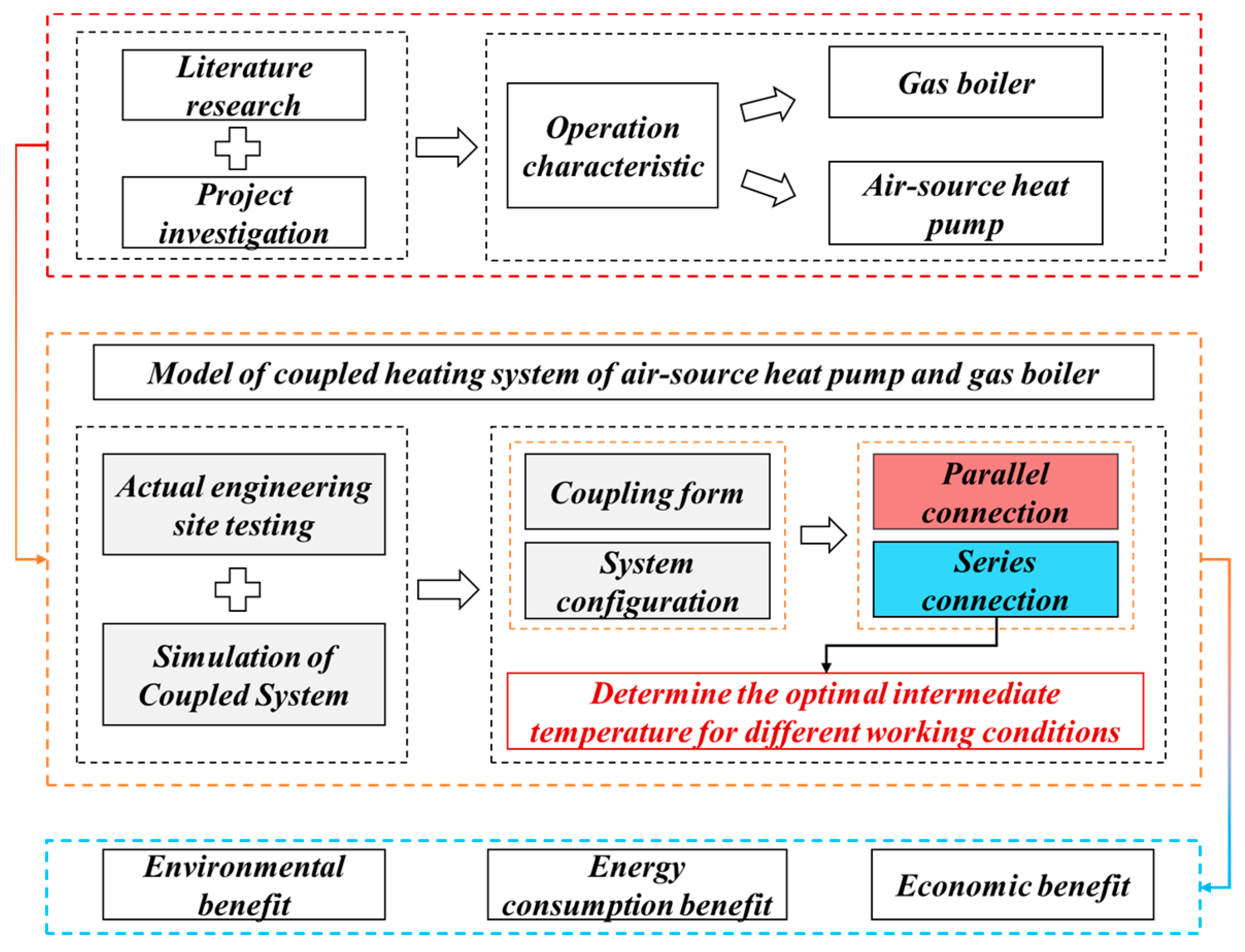

2.1. Research Framework

2.1.1. Research Workflow

2.1.2. Evaluation Indexes

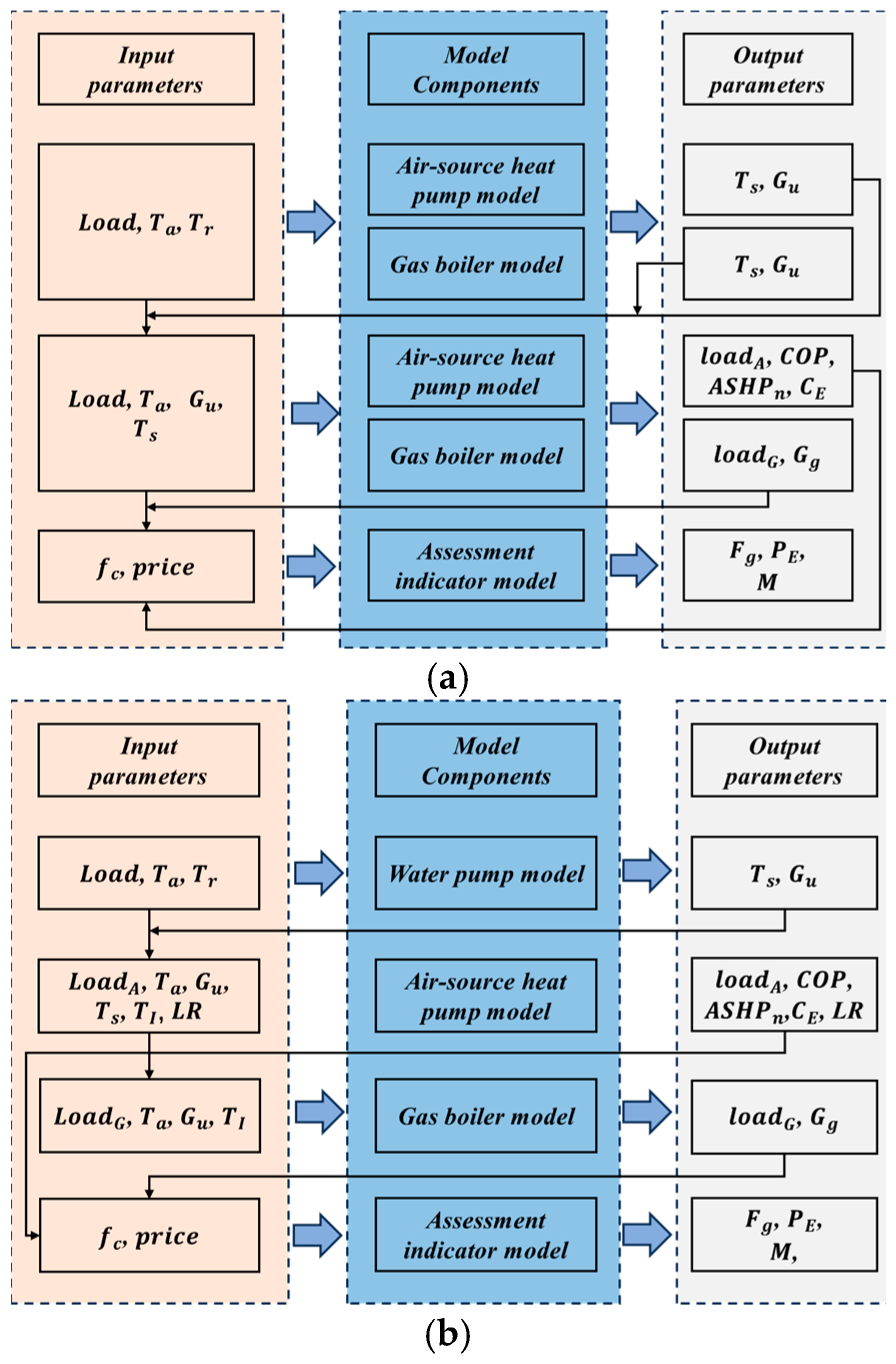

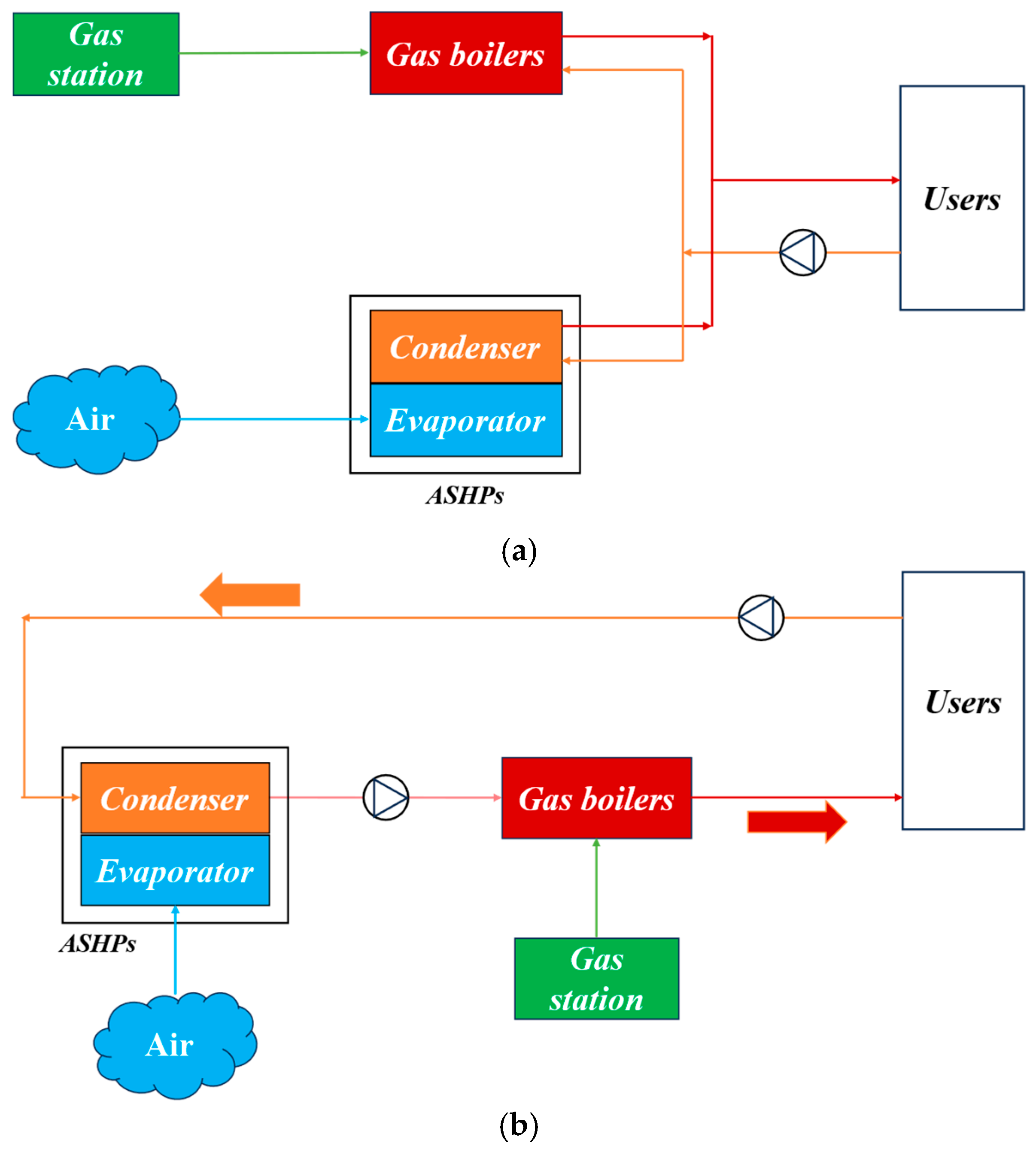

2.2. Simulation Model and Control Strategies for Different Operation Modes

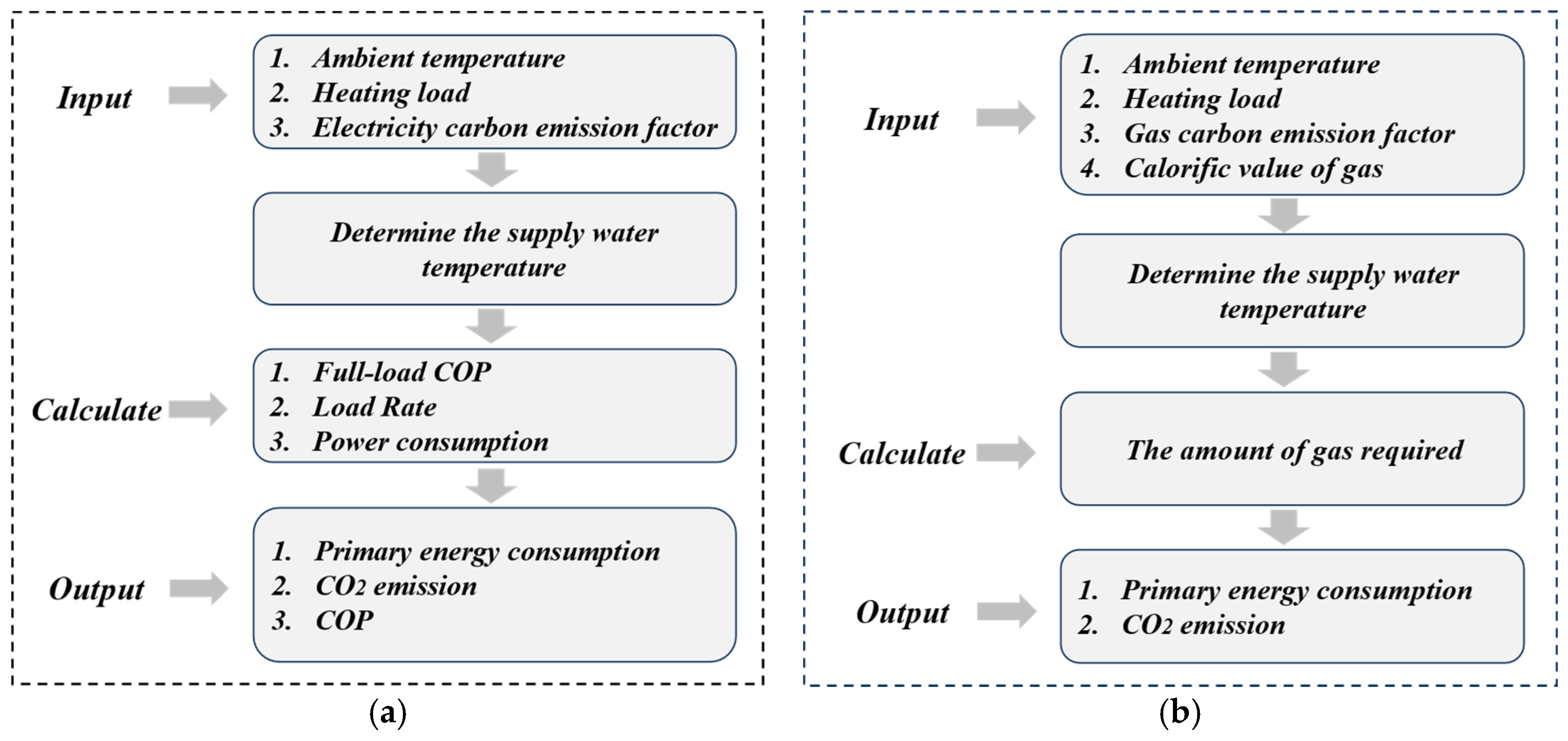

2.2.1. System Model Description

2.2.2. Model Assumption

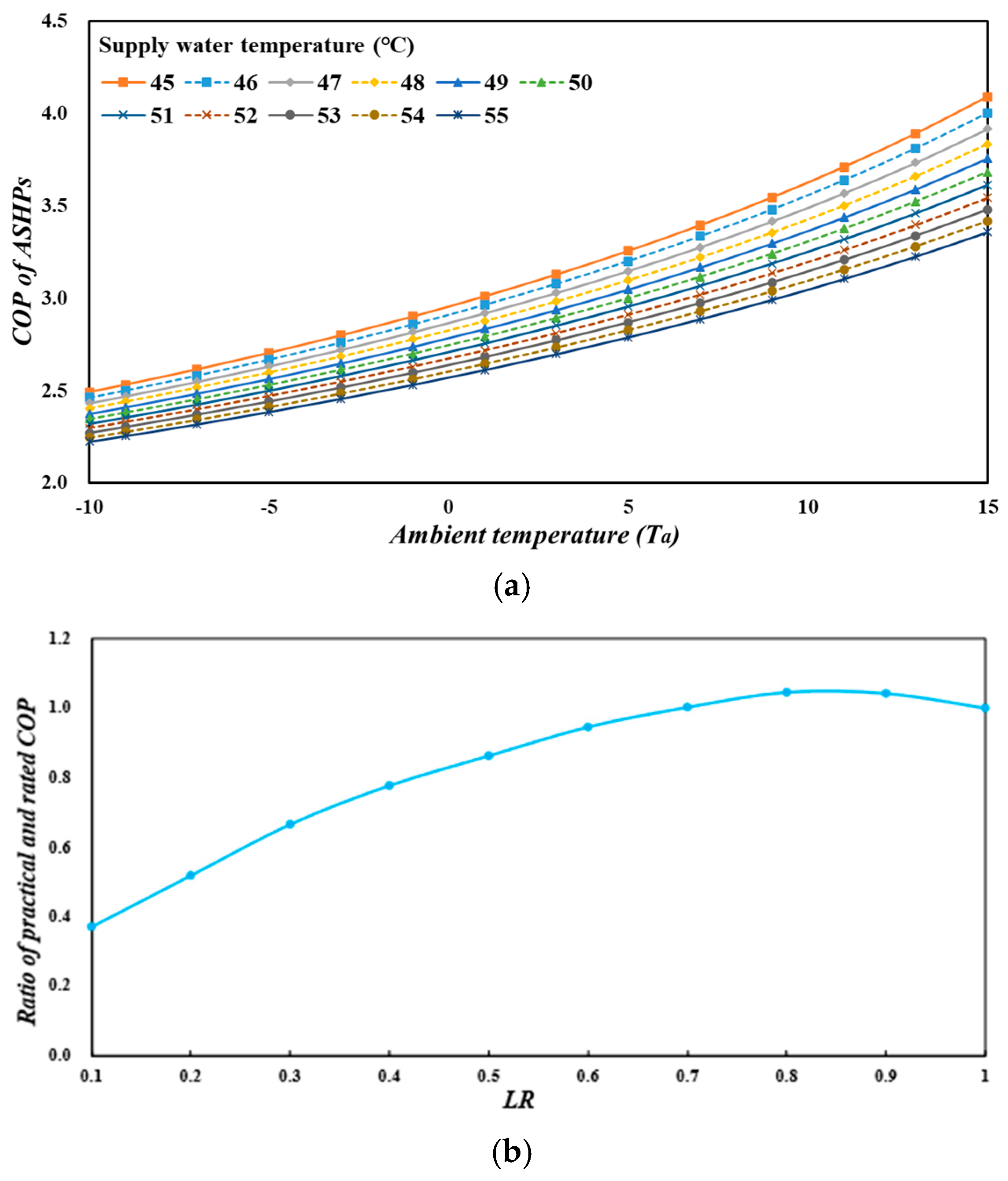

2.2.3. Simulation Models of ASHPs

2.2.4. Control Strategies for Different Operating Modes

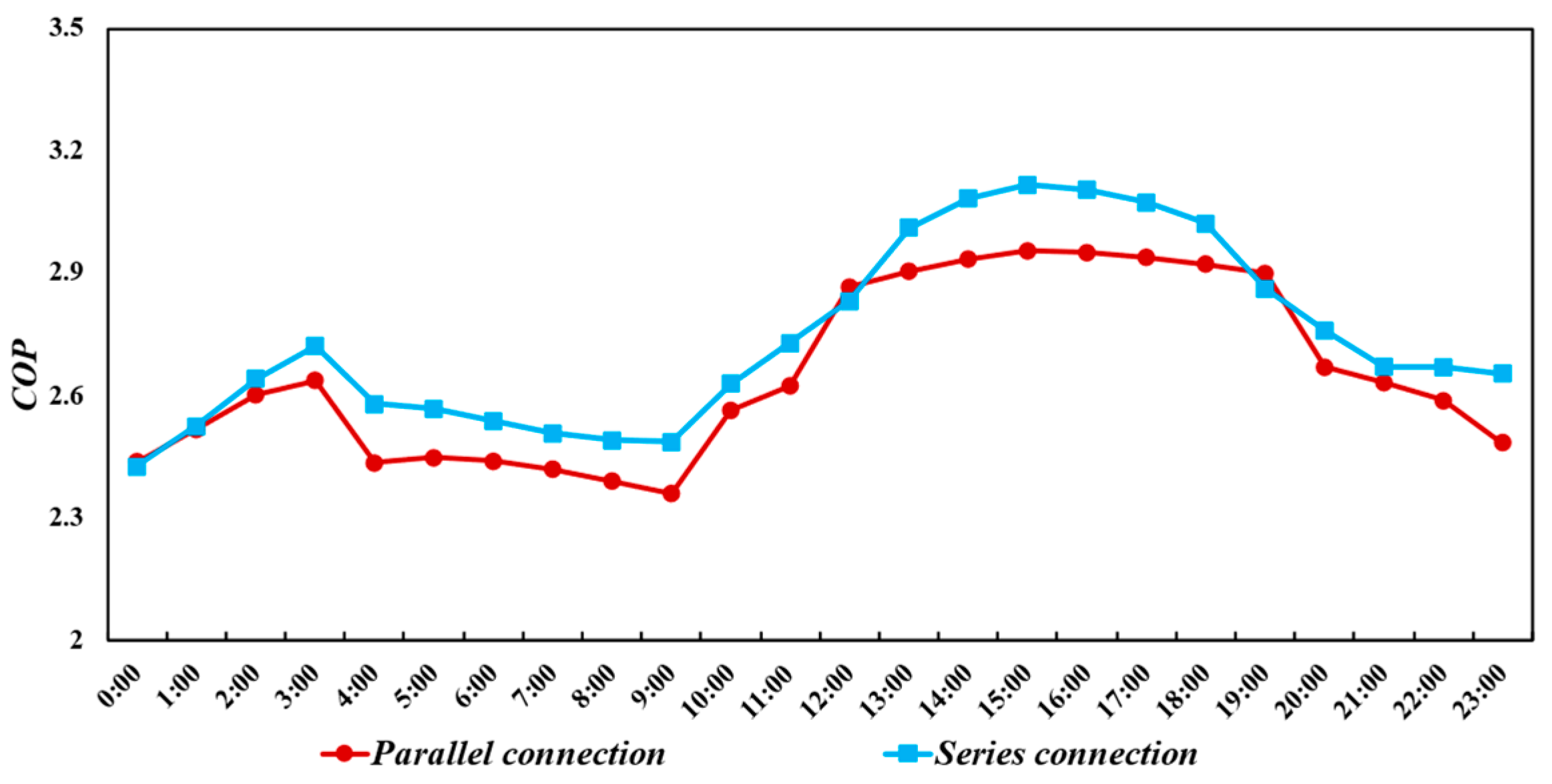

3. Heating System Performance Analysis

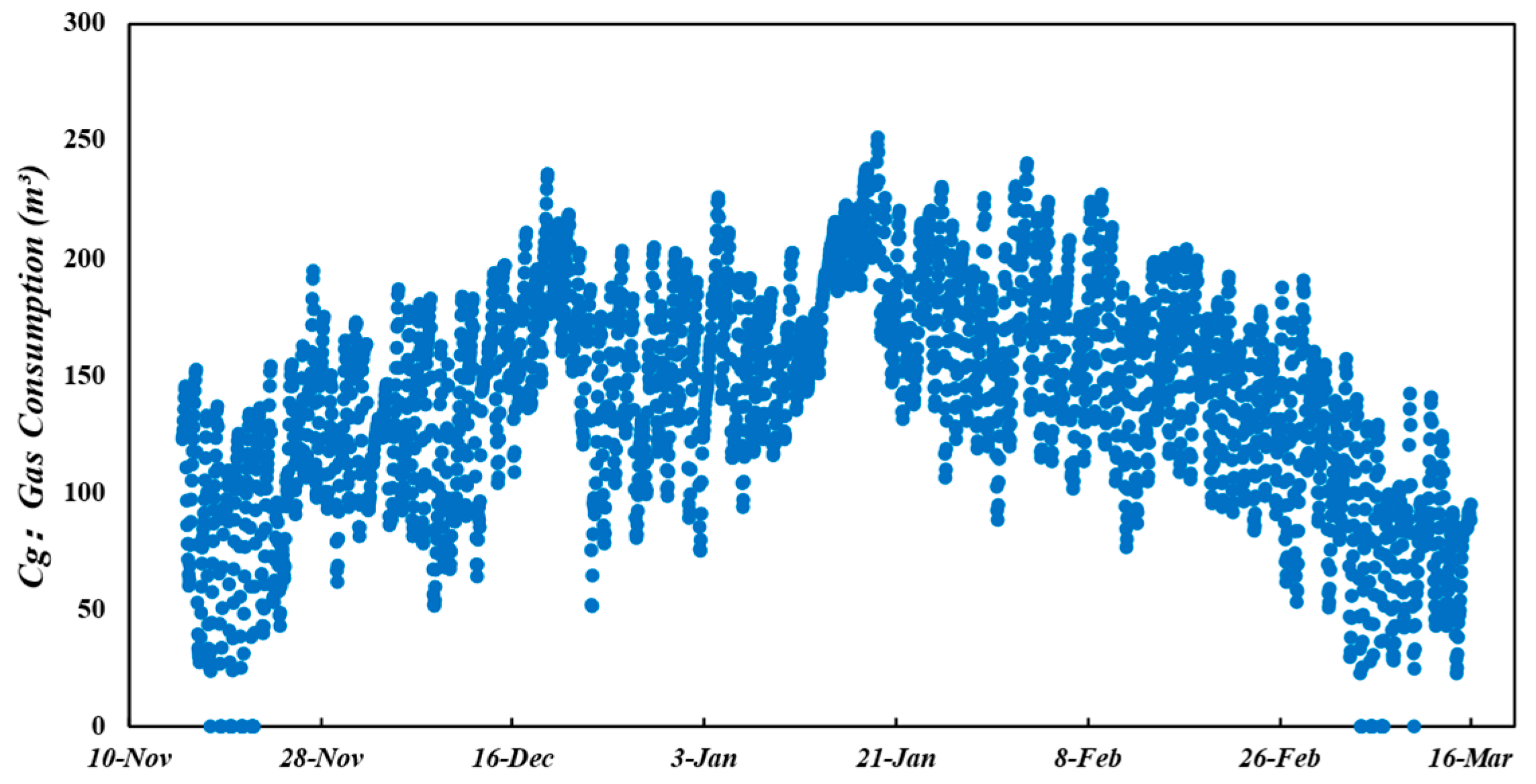

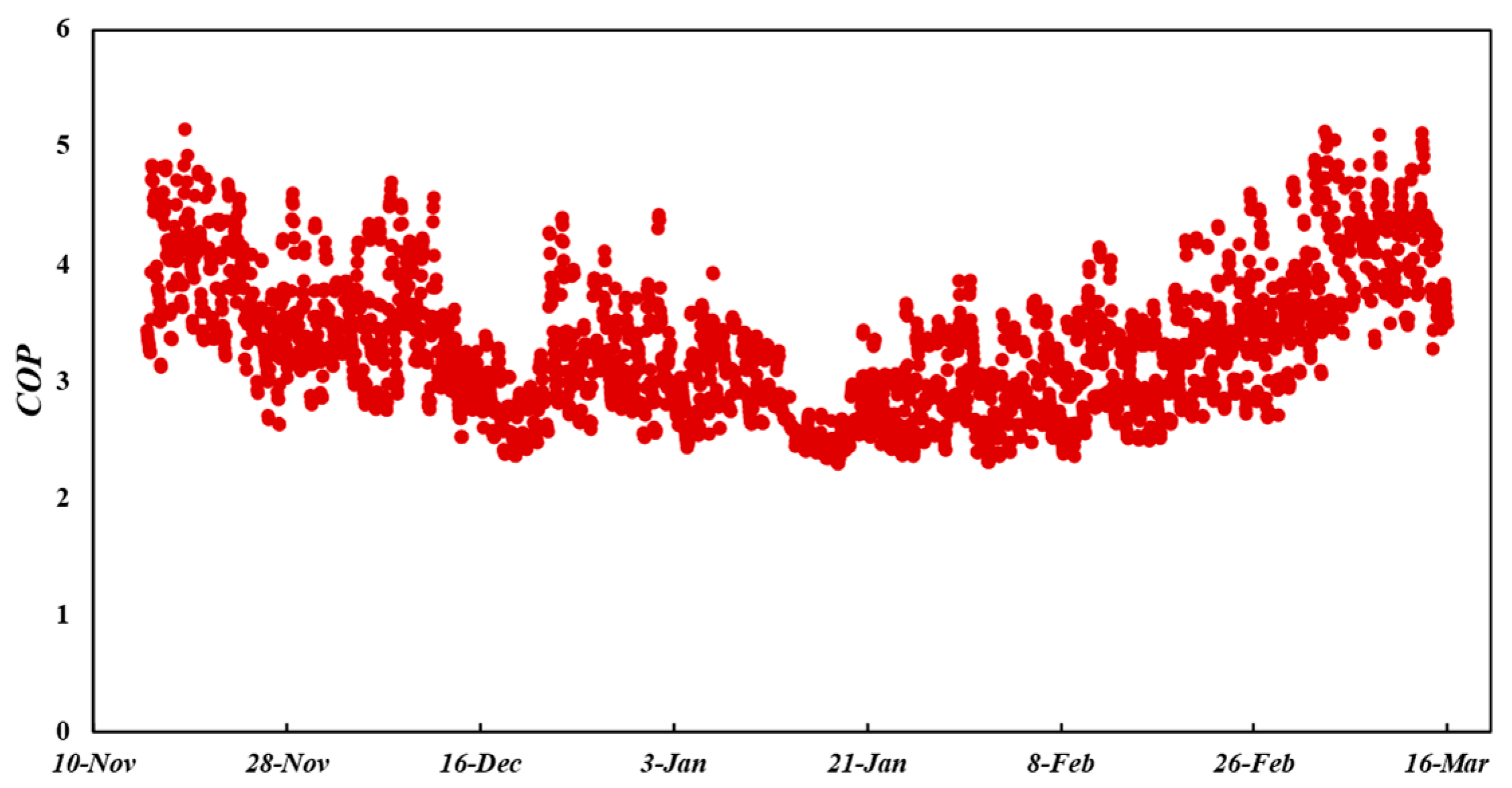

3.1. Analysis of Heating Performance of Conventional Systems

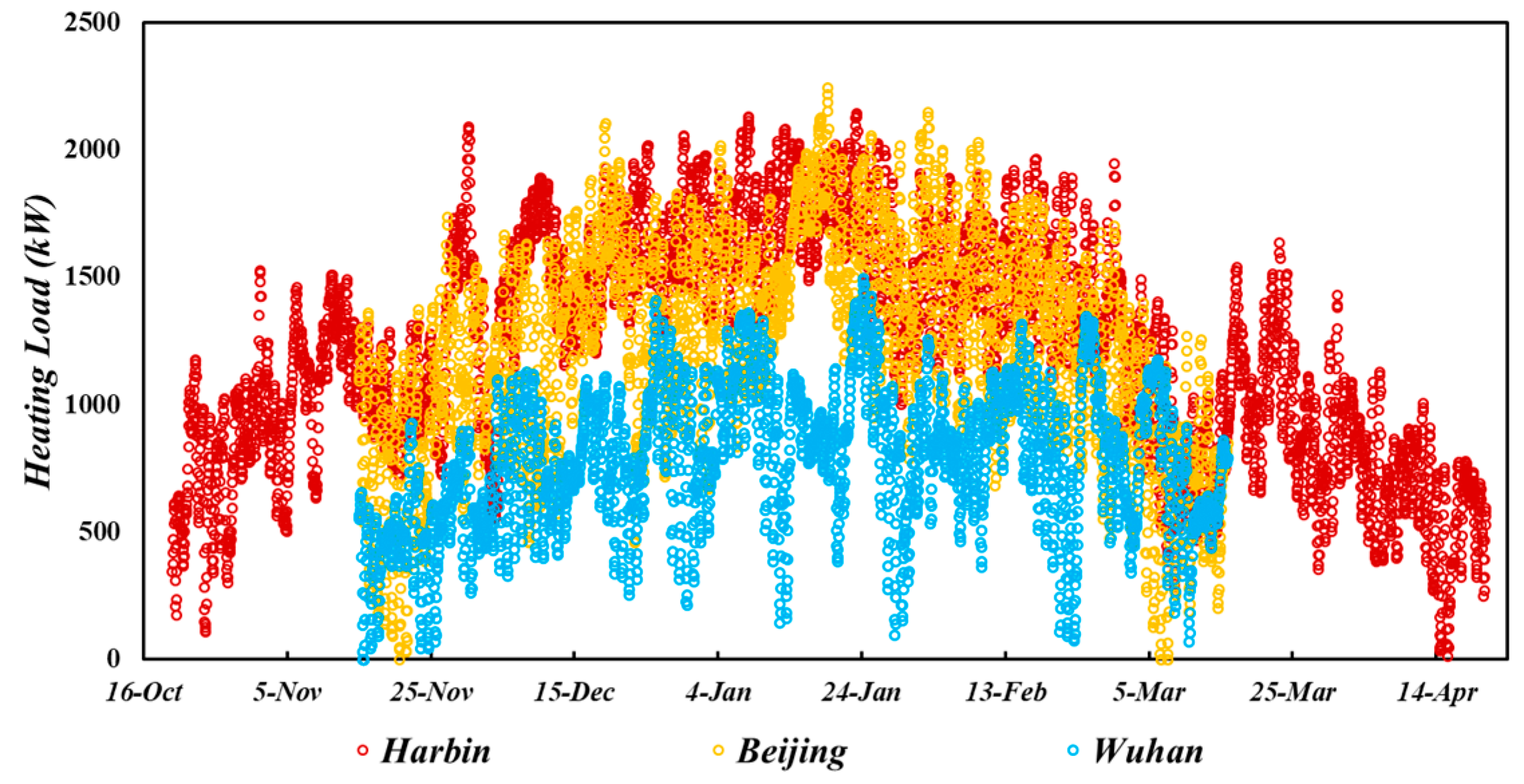

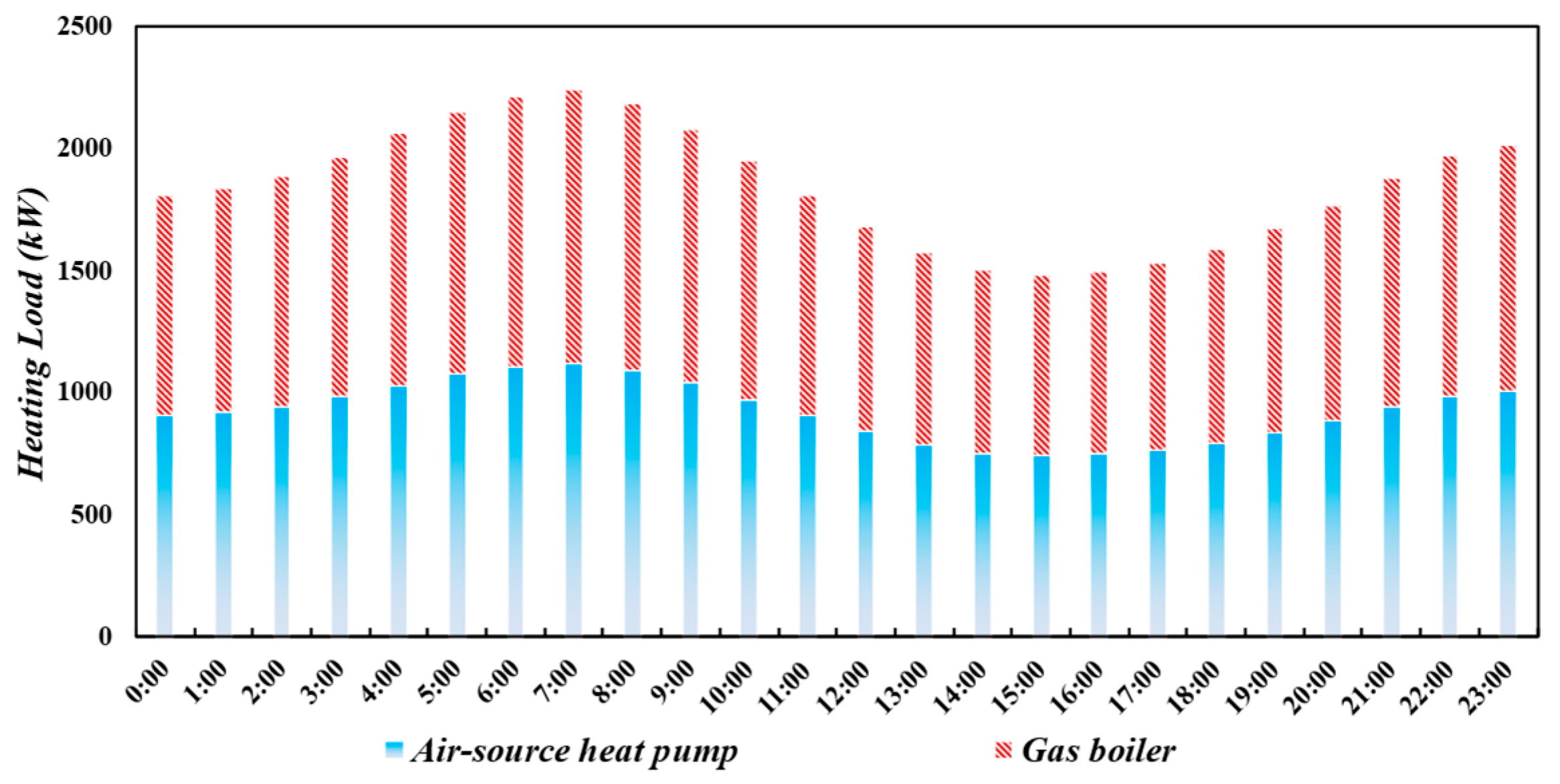

3.1.1. Analysis of Space Heating Load

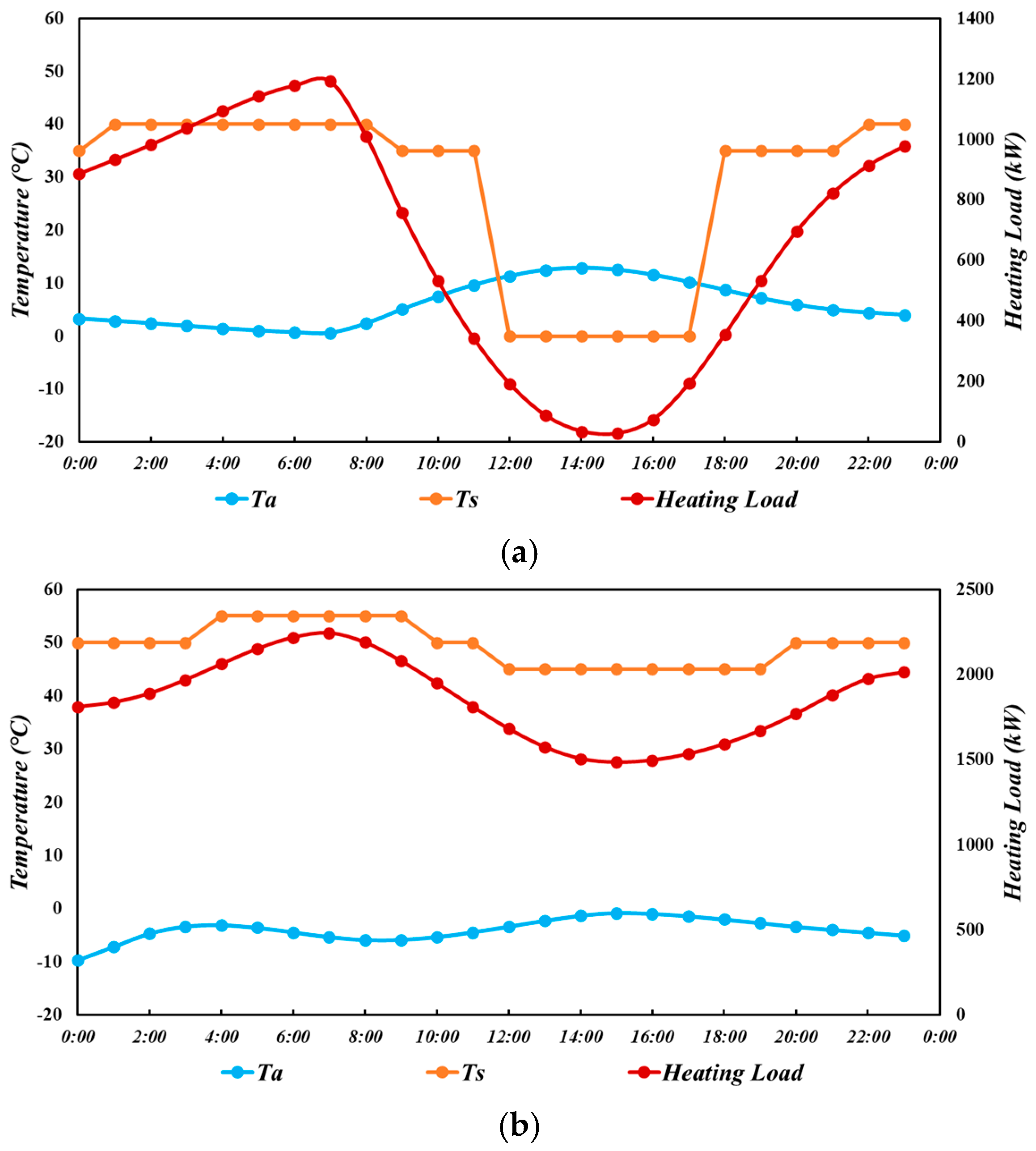

3.1.2. Analysis of Heating Demand on Typical Days

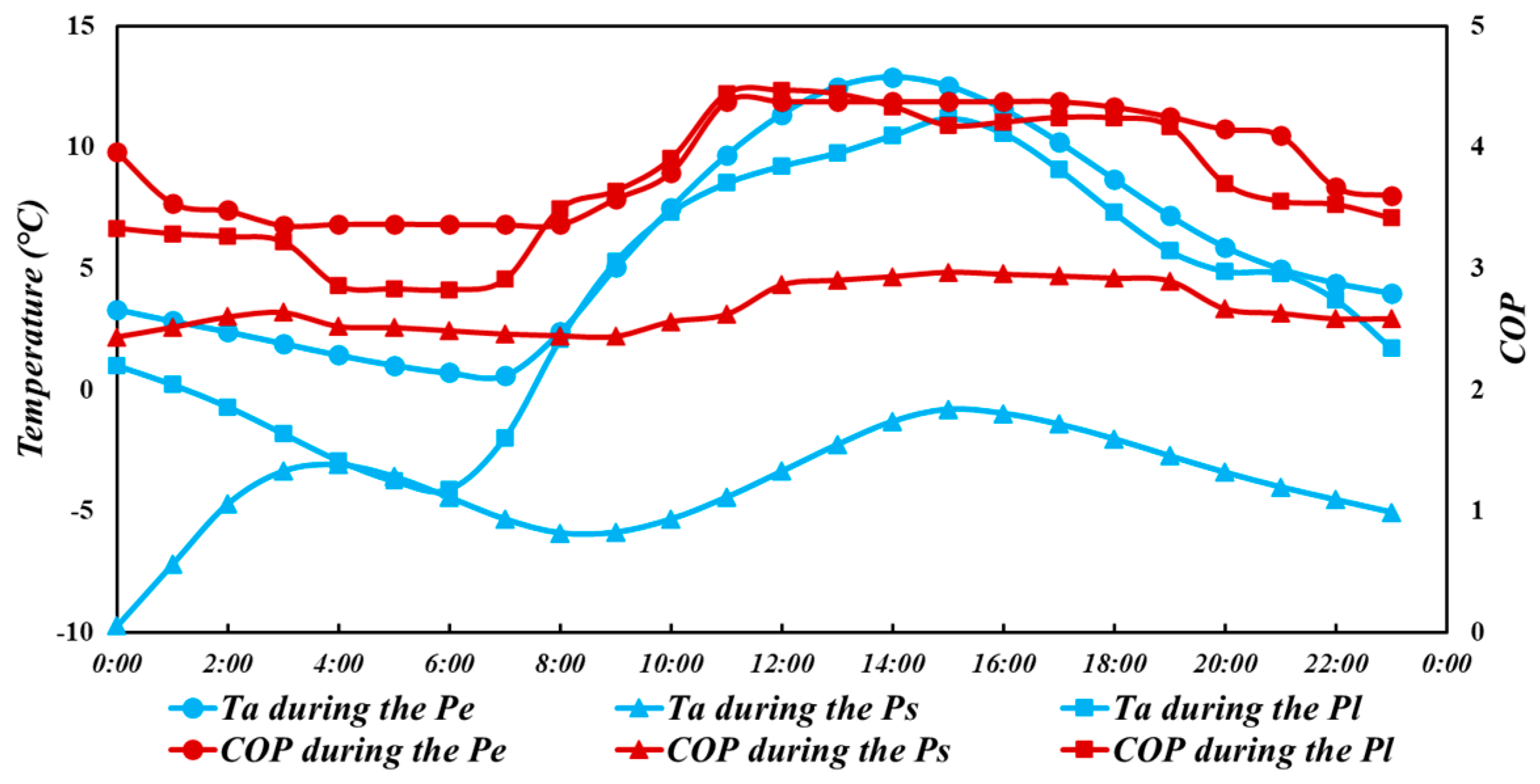

3.1.3. Analysis of Heating Performance of Air-Source Heat Pump and Gas Boiler Systems

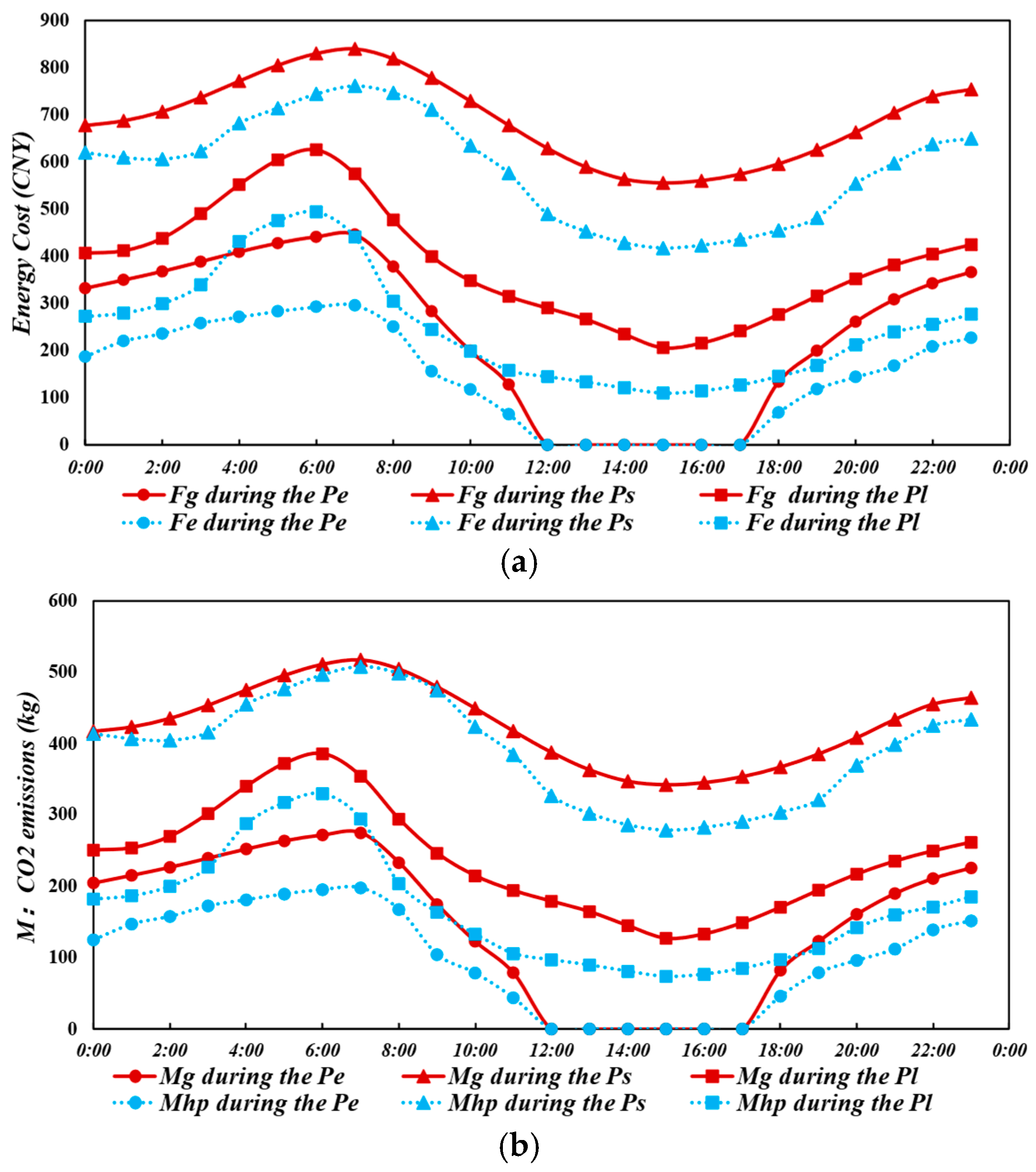

3.1.4. Analysis of Heating Performance During the Heating Season

3.2. Analysis fn Heating Performance of Hybrid Systems

3.3. Comprehensive Comparison of Various Schemes

4. Discussion

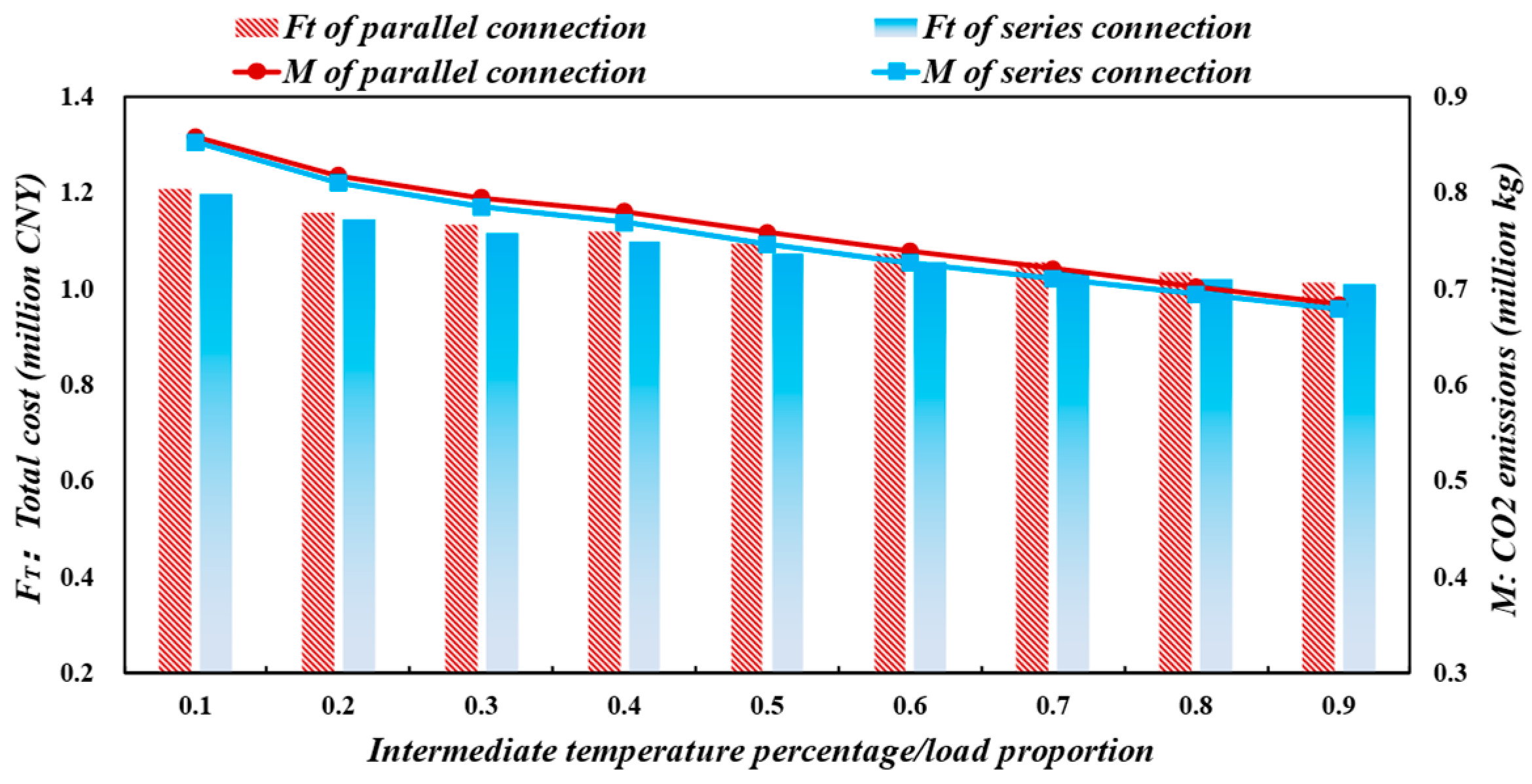

4.1. Comparative Analysis of the Operation Performance of Different Load Distribution Ratios

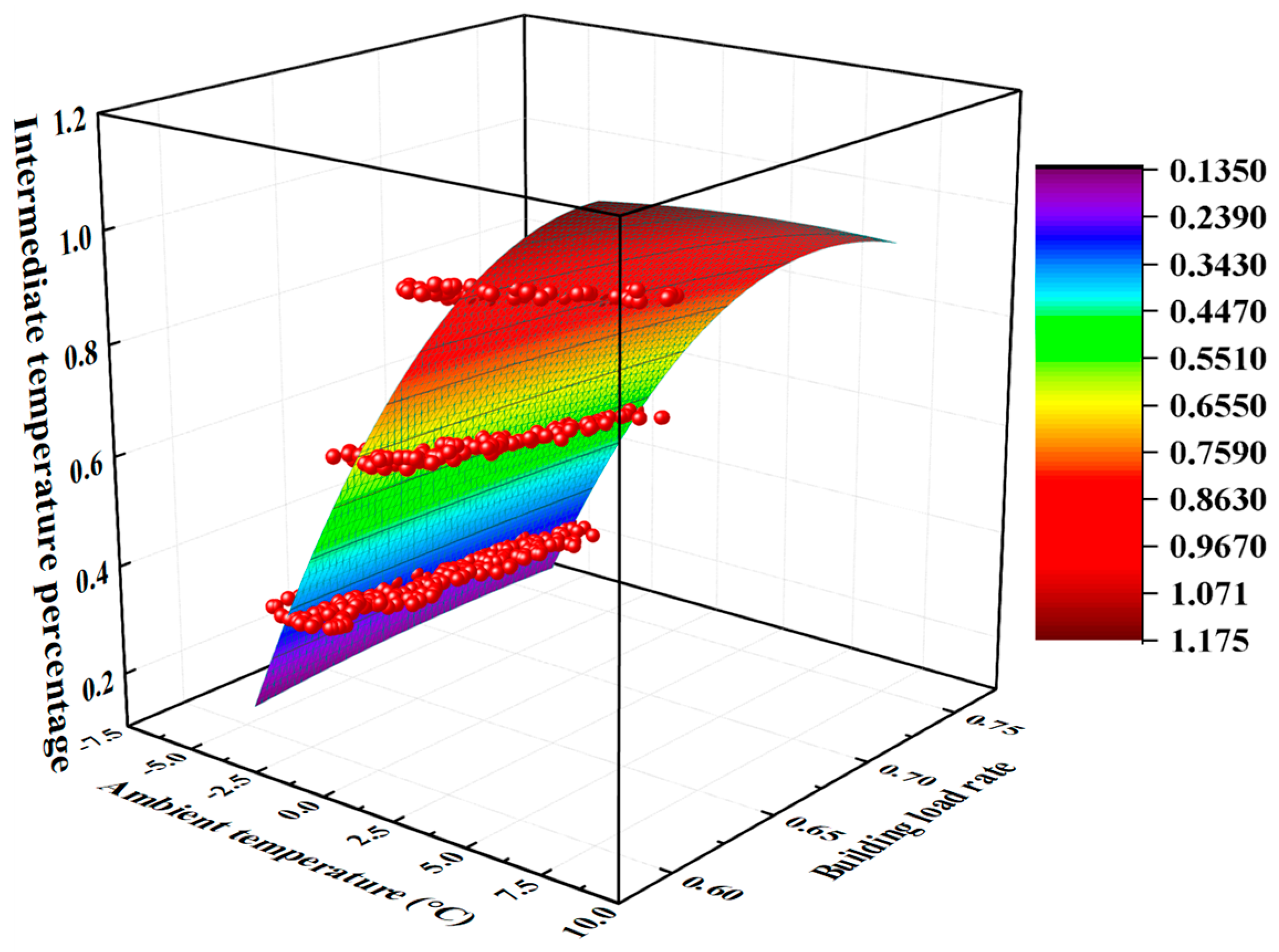

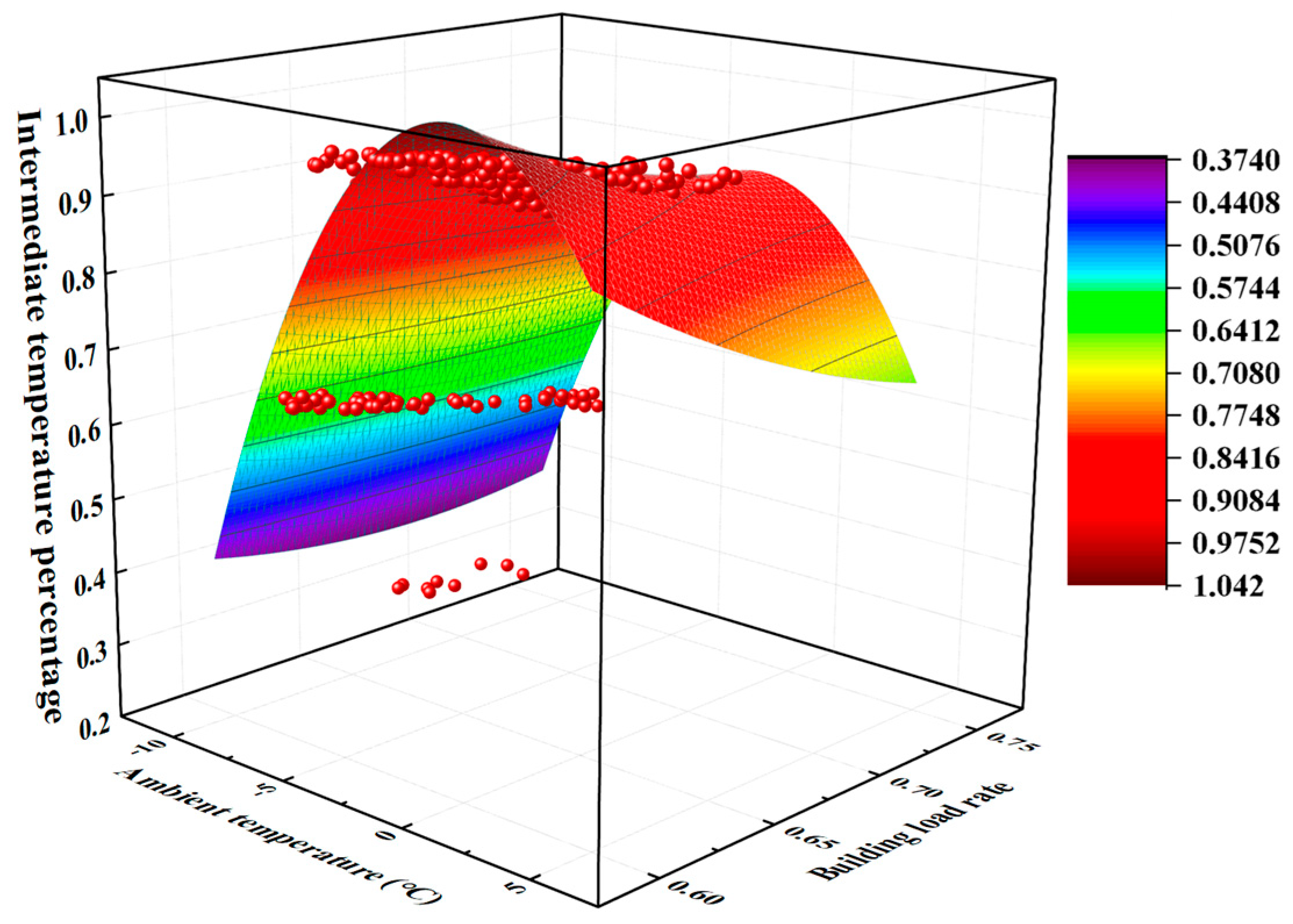

4.2. Analysis of the Optimal Intermediate Temperature in Series Mode

4.2.1. The Optimal Intermediate Temperature Ratio Considering Economic Effect

4.2.2. The Optimal Intermediate Temperature Percentage Considering CO2 Emissions

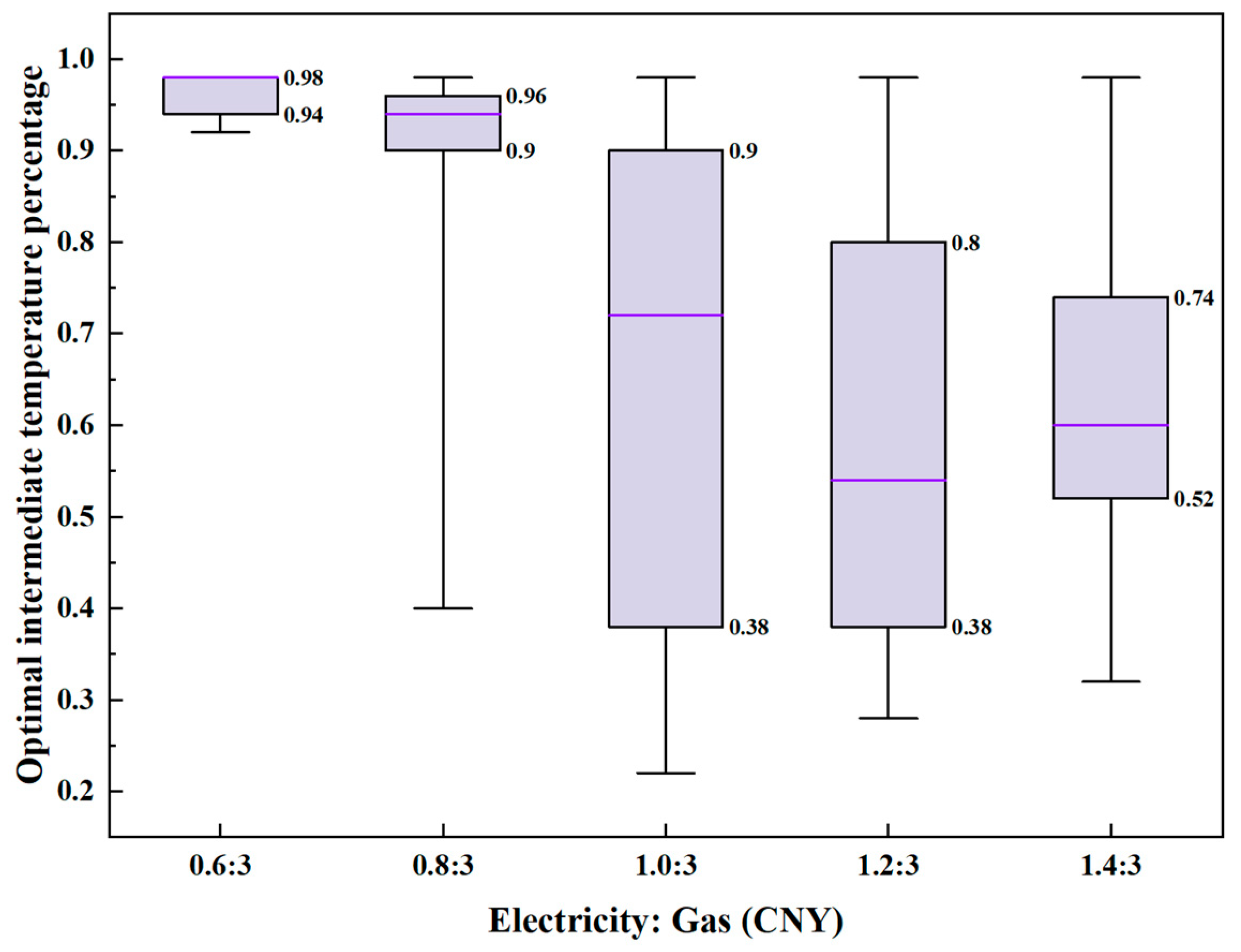

4.2.3. The Optimal Intermediate Temperature Percentage Considering Energy Prices

4.2.4. Optimal Intermediate Temperature Multi-Factor Fitting

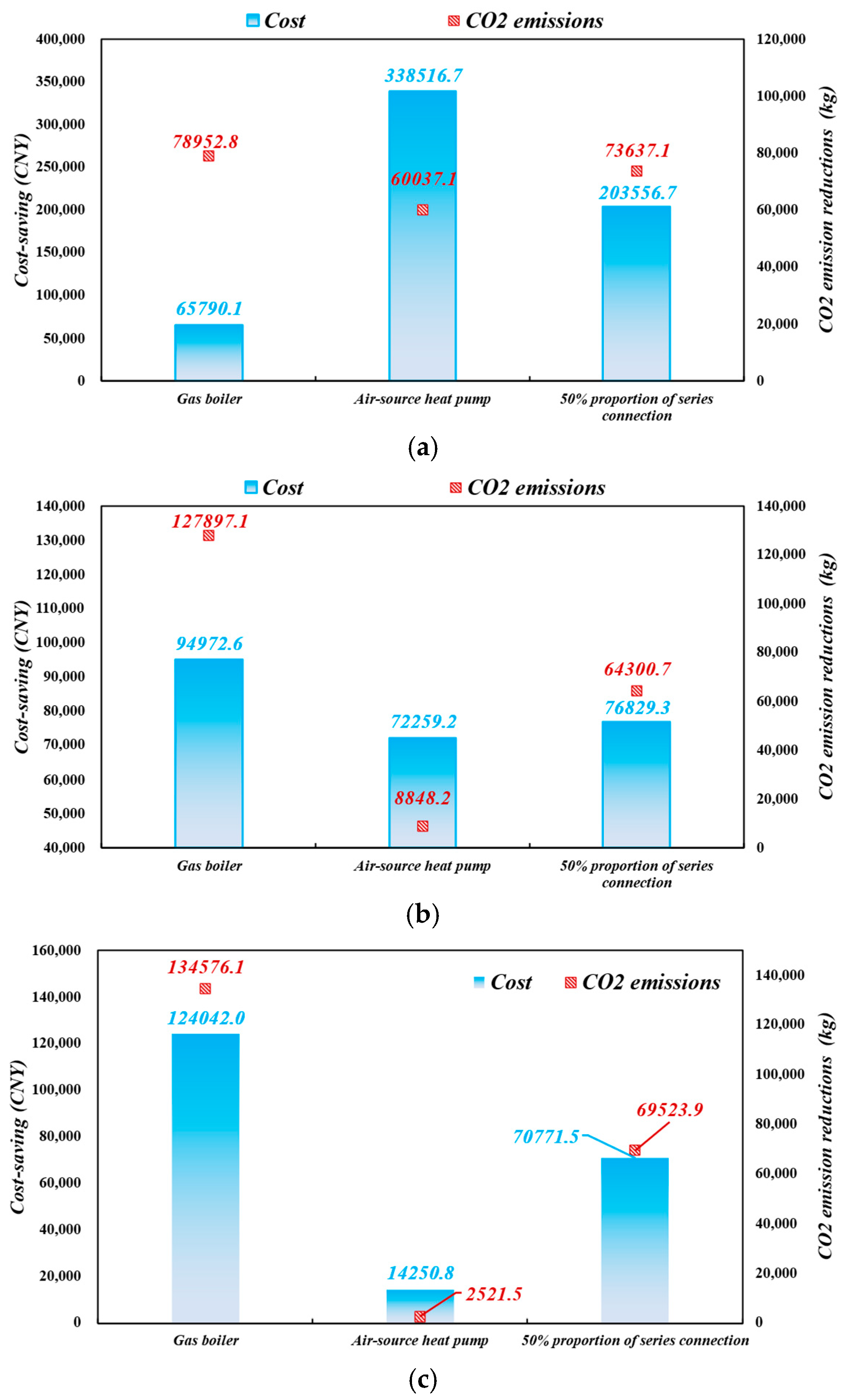

4.3. Analysis of the Cost-Saving and Emission-Reduction Benefits

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nie, Y.Z.; Deng, M.S.; Shan, M.; Yang, X.D. Clean and low-carbon heating in the building sector of China: 10-Year development review and policy implications. Energy Policy 2023, 179, 113659. [Google Scholar] [CrossRef]

- Yuan, M.; Mathiesen, B.V.; Schneider, N.; Xia, J.J.; Zheng, W.; Sorknæs, P.; Lund, H.; Zhang, L. Renewable energy and waste heat recovery in district heating systems in China: A systematic review. Energy 2024, 294, 130788. [Google Scholar] [CrossRef]

- Li, W.; Zhang, S.H.; Lu, C. Exploration of China’s net CO2 emissions evolutionary pathways by 2060 in the context of carbon neutrality. Sci. Total Environ. 2022, 831, 154909. [Google Scholar] [CrossRef]

- Wang, H.Y.; Gao, L.; Jia, Y. The predicament of clean energy technology promotion in China in the carbon neutrality context: Lessons from China’s environmental regulation policies from the perspective of the evolutionary game theory. Energy Rep. 2022, 8, 4706–4723. [Google Scholar]

- Deng, J.W.; Su, Y.Y.; Peng, C.W.; Qiang, W.B.; Cai, W.L.; Wei, Q.P.; Zhang, H. How to improve the energy performance of mid-deep geo-thermal heat pump systems: Optimization of heat pump, system configuration and control strategy. Energy 2023, 285, 129537. [Google Scholar] [CrossRef]

- Cui, P.; Yang, W.B.; Zhang, W.K.; Zhu, K.; Spitler, J.D.; Yu, M. Advances in ground heat exchangers for space heating and cooling: Review and perspectives. Energy Built Environ. 2024, 5, 255–269. [Google Scholar] [CrossRef]

- Wei, Z.; Calautit, J. Evaluation of model predictive control (MPC) of solar thermal heating system with thermal energy storage for buildings with highly variable occupancy levels. Build. Simul. 2023, 16, 1915–1931. [Google Scholar] [CrossRef]

- Da, J.; Li, M.; Li, G.; Wang, Y.; Zhang, Y. Simulation and experiment of a photovoltaic—Air source heat pump system with thermal energy storage for heating and domestic hot water supply. Build. Simul. 2023, 16, 1897–1913. [Google Scholar] [CrossRef]

- Deng, J.W.; Peng, C.W.; Su, Y.Y.; Qiang, W.B.; Cai, W.L.; Wei, Q.P. Research on the heat storage characteristic of deep borehole heat exchangers under intermittent operation mode: Simulation analysis and comparative study. Energy 2023, 282, 128938. [Google Scholar] [CrossRef]

- Deng, J.W.; Wang, Y.H.; Su, Y.Y.; Wang, Y.G.; Chen, Y.; Ma, M.H.; Peng, C.W.; Cai, W.L.; Li, J.; Wei, Q.P. Research on the natural circulation characteristic of deep borehole heat exchanger and the influences on the water circulation resistance. Build. Simul. 2024, 17, 2213–2232. [Google Scholar] [CrossRef]

- Wei, W.Z.; Ni, L.; Li, S.Y.; Wang, W.; Yao, Y.; Xu, L.; Yang, Y. A new frosting map of variable-frequency air source heat pump in severe cold region considering the variation of heating load. Renew. Energy 2020, 161, 184–199. [Google Scholar] [CrossRef]

- Huang, Y.; Ezeh, C.I.; Deng, W.; Hong, S.H.; Peng, Z.; Tang, Y. Correlation between building characteristics and associated energy consumption: Prototyping low-rise office buildings in Shanghai. Energy Build. 2020, 217, 109959. [Google Scholar] [CrossRef]

- Wang, X.N.; Li, W.G.; Luo, Z.Y.; Wang, K.; Shah, S.P. A critical review on phase change materials (PCM) for sustainable and energy efficient building: Design, characteristic, performance and application. Energy Build. 2022, 260, 111923. [Google Scholar] [CrossRef]

- Vassiliades, C.; Agathokleous, R.; Barone, G.; Forzano, C.; Giuzio, G.F.; Palombo, A.; Buonomano, A.; Kalogirou, S. Building integration of active solar energy systems: A review of geometrical and architectural characteristics. Renew. Sustain. Energy Rev. 2022, 164, 112482. [Google Scholar] [CrossRef]

- Ma, R.; Mao, C.; Shan, M.; Zhang, L.; Yang, X. Occupant control patterns of low temperature air-to-air heat pumps in Chinese rural households based on field measurements. Energy Build. 2017, 154, 157–165. [Google Scholar] [CrossRef]

- Xu, Z.W.; Li, H.; Xu, W.; Shao, S.Q.; Wang, Z.; Gou, X.; Zhao, M.; Li, J. Investigation on the efficiency degradation characterization of low ambient temperature air source heat pump under partial load operation. Int. J. Refrig. 2022, 133, 99–110. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Ma, Q.; Li, B.X.; Fan, X.; Fu, Z. Application of an air source heat pump (ASHP) for heating in Harbin, the coldest provincial capital of China. Energy Build. 2017, 138, 96–103. [Google Scholar] [CrossRef]

- Xu, S.X.; Ma, G.Y.; Liu, Q.; Liu, Z.L. Experiment study of an enhanced vapor injection refrigeration/heat pump system using R32. Int. J. Therm. Sci. 2013, 68, 103–109. [Google Scholar]

- Aikins, K.A.; Lee, S.H.; Choi, J.M. Technology review of two-stage vapor compression heat pump system. Int. J. Air-Cond. Refrig. 2013, 21, 1330002. [Google Scholar] [CrossRef]

- Gschwend, A.; Menzi, T.; Caskey, S.; Groll, E.A.; Bertsch, S.S. Energy consumption of cold climate heat pumps in different climates—Comparison of single-stage and two-stage systems. Int. J. Refrig. 2016, 62, 193–206. [Google Scholar] [CrossRef]

- Liang, S.M.; Wang, H.; Bai, X.X.; Wang, G.; Gao, X.; Tian, X. A field study on the impacts of cold island effect on operating performances of air source heat pump array for space heating. J. Build. Eng. 2024, 82, 108266. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Q.N.; Huang, K.L.; Wu, Y.; Liang, C.; Cao, H.; Wei, J. Operating characteristics and evaluation of air source heat pumps in cold regions during heating season in China. Energy Built Environ. 2025, 6, 645–654. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, L.; Nie, J.; Li, Y. Techno-economic analysis of air source heat pump applied for space heating in northern China. Appl. Energy 2017, 207, 533–542. [Google Scholar] [CrossRef]

- Kelly, N.J.; Cockroft, J. Analysis of retrofit air source heat pump performance: Results from detailed simulations and comparison to field trial data. Energy Build. 2011, 43, 239–245. [Google Scholar] [CrossRef]

- Huang, S.F.; Wang, L.B.; Xie, L.Y.; Liu, J.; Zhang, X.S. Energetic, economic and environmental analyses of frost-free air-source heat pump in multi-type buildings and different locations. J. Build. Eng. 2023, 80, 108060. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Jeong, J.W. Energy saving potential of radiant floor heating assisted by an air source heat pump in residential buildings. Energies 2021, 14, 1321. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, W.; Luo, X.; Wang, D.; Hu, X.; Hu, L. Design and operation optimization of multi-source complementary heating system based on air source heat pump in Tibetan area of Western Sichuan, China. Energy Build. 2021, 242, 110979. [Google Scholar] [CrossRef]

- Xu, Y.C.; Guo, Z.W.; Yuan, C.Q. Feasibility study of an integrated air source heat pump water heater/chillers and exhaust gas boiler heating system for swimming pool on luxury cruise ship. Energy Rep. 2022, 8, 1260–1282. [Google Scholar] [CrossRef]

- Olympios, A.V.; Pantaleo, A.M.; Sapin, P.; Markides, C.N. On the value of combined heat and power (CHP) systems and heat pumps in centralised and distributed heating systems: Lessons from multi-fidelity modelling approaches. Appl. Energy 2020, 274, 115261. [Google Scholar] [CrossRef]

- Bagarella, G.; Lazzarin, R.; Noro, M. Annual simulation, energy and economic analysis of hybrid heat pump systems for residential buildings. Appl. Therm. Eng. 2016, 99, 485–494. [Google Scholar] [CrossRef]

- Zhang, Z.B.; Cao, Y.; Qin, S.Y.; Wang, Z.; Gao, W.; Jia, G.; Jin, L. Optimization of design parameters and operation conditions of solar-air source heat pump coupled system for rural buildings in cold and severe cold regions. Sol. Energy 2025, 286, 113147. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Jin, Y.P.; Zhou, J.; Yang, Y.; Xu, F.; Liu, H. A novel dynamic operation method for solar assisted air source heat pump systems: Optimization control and performance analysis. Energy 2025, 316, 134535. [Google Scholar] [CrossRef]

- Wang, N.; Chu, S.L.; Cheng, C.; Zhang, H.; Chen, H.; Gao, D. Performance research and multi-objective optimization of concentrating photovoltaic/thermal coupled air source heat pump heating system. Energy 2024, 296, 131008. [Google Scholar] [CrossRef]

- Lin, Z.; Li, X.L.; Lin, M.S.; Zhang, T.H.; Qiang, G.; Lin, L. Analysis of carbon emission associated with composite air source heat pumps in buildings. Case Stud. Therm. Eng. 2025, 69, 106033. [Google Scholar]

- GB/T 51161-2016; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Building Energy Consumption of Urban Buildings. China Architecture & Building Press: Beijing, China, 2016.

- Ministry of Ecology and Environment of the People’s Republic of China. Announcement on Releasing the 2022 Electricity Carbon Dioxide Emission Factors (Annex: 2022 Electricity Carbon Dioxide Emission Factors). Available online: https://www.mee.gov.cn (accessed on 26 December 2024).

- Wang, Y.; Deng, J.; Su, Y.; Peng, C.; Ma, M.; Chen, Y.; Fan, L.; Chen, M.; Wei, Q.; Zhang, H. Research on Configuration Optimization and Control Methods for Mid-Deep Geothermal Heat Pumps Coupled with Air-Source Heat Pump Systems for Space Heating in Residential Buildings. Buildings 2025, 15, 1938. [Google Scholar] [CrossRef]

- Yan, D.; Zhou, X.; An, J.J.; Kang, X.Y.; Bu, F.; Chen, Y.; Pan, Y.; Gao, Y.; Zhang, Q.; Zhou, H.; et al. DeST 3.0: A new-generation building performance simulation platform. Build. Simul. 2022, 15, 1849–1868. [Google Scholar] [CrossRef]

| Coefficients | R2 | ||||||

| Values | 0.00097 | 0.001 | −0.002 | 0.1487 | −0.1378 | 7.1892 | 0.9928 |

| Coefficients | R2 | ||||||

| Values | −1.1147 | 1.9529 | 0.1783 | 0.9987 |

| Peak Heating Load (kW) | Total Heating Load (Million kWh) | Total Heating Load Per Unit Area (kWh/m2) | Average Outdoor Temperature During Heating Season (°C) | |

|---|---|---|---|---|

| Harbin | 2141.80 | 5.42 | 108.34 | −10 |

| Beijing | 2244.40 | 3.61 | 72.23 | 0 |

| Wuhan | 1494.68 | 2.27 | 45.43 | 5 |

| Air-Source Heat Pump | Gas Boiler | ||

|---|---|---|---|

| Heating capacity (kW) | 500 | 500 | |

| The number of units required for a parallel coupling system | Harbin | 6 | 6 |

| Beijing | 6 | 6 | |

| Wuhan | 4 | 4 | |

| The number of units required for a series coupling system | Harbin | 6 | 6 |

| Beijing | 6 | 6 | |

| Wuhan | 4 | 4 | |

| (°C) | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 35 | −0.0004 | 13.7607 | −0.0130 | 0.0010 | −10.2905 | 2.5670 |

| 40 | −0.0032 | 20.6421 | 0.2176 | −0.0710 | −20.4306 | 5.8951 |

| 45 | −0.0049 | −2.0010 | −0.1389 | 0.1818 | 2.1784 | 0.1226 |

| 50 | 0.0390 | 6.8374 | 0.4685 | −0.4039 | −11.5774 | 5.1132 |

| (°C) | a | b | c | d | e | f |

|---|---|---|---|---|---|---|

| 35 | −0.00005 | 18.9189 | 0.0169 | −0.0035 | −13.0687 | 2.9642 |

| 40 | −0.0007 | 27.0535 | 0.1409 | −0.0572 | −26.5387 | 7.4216 |

| 45 | −0.0058 | 4.6630 | −0.0923 | 0.0488 | −7.4020 | 3.8047 |

| 50 | 0.0090 | −4.1911 | −0.0318 | 0.2188 | 6.5154 | −1.2863 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Ma, M.; Chen, S.; Zhan, H.; Yuan, Y.; Wang, Y.; Deng, J.; Peng, C. Research on the Configurations and Control Methods of a Hybrid System of Air-Source Heat Pumps and Gas Boilers for Space Heating: Simulation and Comparative Analysis. Sustainability 2025, 17, 6173. https://doi.org/10.3390/su17136173

Mao Y, Ma M, Chen S, Zhan H, Yuan Y, Wang Y, Deng J, Peng C. Research on the Configurations and Control Methods of a Hybrid System of Air-Source Heat Pumps and Gas Boilers for Space Heating: Simulation and Comparative Analysis. Sustainability. 2025; 17(13):6173. https://doi.org/10.3390/su17136173

Chicago/Turabian StyleMao, Yangyang, Minghui Ma, Shenxin Chen, Huajian Zhan, Yuwei Yuan, Yanhui Wang, Jiewen Deng, and Chenwei Peng. 2025. "Research on the Configurations and Control Methods of a Hybrid System of Air-Source Heat Pumps and Gas Boilers for Space Heating: Simulation and Comparative Analysis" Sustainability 17, no. 13: 6173. https://doi.org/10.3390/su17136173

APA StyleMao, Y., Ma, M., Chen, S., Zhan, H., Yuan, Y., Wang, Y., Deng, J., & Peng, C. (2025). Research on the Configurations and Control Methods of a Hybrid System of Air-Source Heat Pumps and Gas Boilers for Space Heating: Simulation and Comparative Analysis. Sustainability, 17(13), 6173. https://doi.org/10.3390/su17136173