1. Introduction

As human social and economic activities have increased, greenhouse gas (GHG) levels, especially carbon dioxide (CO

2) concentrations, have become a climate change challenge, leading to more frequent and severe weather events, higher sea levels, and ecosystem changes. CO

2 emissions reached nearly 38 billion tons in 2023 [

1], indicating a notable rise in the global understanding of the need to cut CO

2 emissions [

2]. The European Union has committed to at least 50% mitigation in net GHG emissions by 2030, aiming to achieve carbon neutrality by 2050 [

3]. Also, to attain the 2 °C goal outlined in the Paris Agreements, carbon capture, utilization, and storage (CCUS) has emerged as a crucial strategy for mitigating GHG emissions, alongside the employment of cleaner energy sources and technology upgrades [

4]. Moreover, the CCUS is widely acknowledged for its potential to address climate change. In particular, the International Energy Agency asserted that, within the 2 °C situation, the total emission mitigations attributable to the CCUS technique could attain more than 90 Gton [

5]. In fact, CCUS aims to capture massive amounts of CO

2 from significant emission sources or even air, utilize captured CO

2 for different industrial applications, and/or inject it into permanent geological storage [

6]. The scientific and industrial communities agree that CCUS systems not only enable the existing fossil fuel-based plants to continue operating while markedly diminishing their carbon footprint (net emissions) but also offer a gradual pathway to a carbon-negative scenario for the next generation [

7,

8]. The adoption of CCUS also creates opportunities for synthesizing CO

2-based chemicals and fuels and drives demand for skilled workers in manufacturing, operating, and maintaining CCUS technologies [

9]. Consequently, an increasing number of large-scale CCUS projects are globally in operation: 45 in 2024, more than double that in 2014 [

10]. Additionally, 44 facilities currently under construction are projected to yield an extra capture capacity of 51 Mton/year. It is worth noting that CCUS technologies are set to decrease cumulative CO

2 emissions by 7% and achieve an annual mitigation capability of above 2200 Mton by 2040 [

11].

Given the complexity and interconnected elements of the CCUS system, it is essential to consider the comprehensive evaluation of the design and operation of the whole infrastructure, involving emission sources, capture technologies, transportation options, utilization, and storage activities. Furthermore, the current global deployment of CCUS technologies falls well short of the gigatonne scale required to meet the 2030 and 2050 climate targets. One of the primary obstacles to broader adoption is the high cost of implementation. Consequently, the academic community has focused on creating mathematical models capable of efficiently designing and optimizing the cost-efficient CCUS layout.

Technical feasibility is a critical factor, encompassing the maturity of the technology, its compatibility with existing systems, and the additional energy required during the CO

2 mitigation process [

12,

13,

14].

Regarding economic analysis, several research papers have been published recently. CO

2 conversion into chemicals was explored when planning CCUS networks in South Korea, suggesting that energy demand for CO

2 conversion was the primary contributor to the rise in the overall yearly expense of the CCUS system [

15]. Similarly, Leonzio et al. modeled three various CCUS networks in the UK to minimize the total capture costs while synthesizing valuable CO

2-based chemicals [

16]. The findings showed that calcium carbonate was the preferred product to satisfy customers’ needs at a minimum overall cost. The same author created a mathematical approach for CCUS networks in Germany [

17] and Italy [

18] to minimize the overall cost while producing several products such as ethylene, methanol, methane, concrete, urea, polyurethane, wheat, calcium carbonates, etc. The most important finding in these studies is that economic subsidies (such as carbon tax or financial incentives for sustainable production) are needed to have a convenient framework. A stochastic model minimizing the overall total cost was considered by Shirazaki et al. for a CCUS where the captured CO

2 could be used for microalgae cultivation involved in biofuel production [

19]. The results indicated that the cost of producing biodiesel is currently not competitive with diesel prices; however, it can be substantially lowered by enhancing biomass yield. A Mixed Integer Linear Programming (MILP) model was used to maximize the profit of the CCUS systems in Slovenia, finding that the CCUS system is only economically viable if the tax exceeds 110 EUR/ton of emitted CO

2 [

20].

Other studies related to the application of CO

2 to enhance oil recovery (CO

2-EOR) also considered the economic aspect. A source-sink matching methodology was employed to assess the possibility of CO

2 sequestration at current coal-fired power plants in China [

21]. The findings indicated that oil and gas fields and saline aquifers are regarded as viable CO

2 sinks, with an estimated mitigation potential of more than 1 billion tons annually. On the other hand, Wei et al. suggested an economical approach to mitigate CO

2 emissions at the global scale with over 3000 emission sources and 400 utilization/storage sites [

22]. Over 30% of CO

2 produced was sent to oil fields to enhance oil recovery, which could help the CCUS system yield profits if the oil price was over 100 USD/bbl. The benefits of utilizing mitigated CO

2 for recovering more oil were also analyzed by Rakhiemah and Xu, who found that a positive net income could be obtained at a minimum oil price of 34 USD/bbl [

23]. An optimum strategy for carbon networks with CO

2-EOR as the only carbon utilization sink was suggested in Turkey [

24]. The authors concluded that when the market demand for EOR is sufficiently high, carbon utilization options are economically favored over storage alternatives.

The enhancement and integration of the models were also taken into account in the economic evaluation of carbon frameworks via mathematical modeling. Zhang et al. improved the source-sink model by adding intermediate points to increase the flexibility of the CCUS structure [

25]. The updated model was applied to minimize the capture costs in China, which reduced the annual transportation and total expenses by 0.08 and 0.09 billion USD, respectively, compared to the base source-sink method. The integration of carbon and hydrogen networks in Germany was conducted to produce jet fuel from renewable sources, with a target of using 2% sustainable aviation fuel in 2030 [

26]. The research indicates that with an electricity cost of 0.05 USD/kWh, fuel production and supply expenses fluctuate between 2052 and 2258 USD/ton. A prior analysis by Ochoa Bique et al. determined that the system is economically viable when the electricity required for renewable hydrogen is provided at no cost [

27]. García-Saravia et al. integrated a CCUS supply chain with one supplier related to hydrogen in order to simultaneously produce hydrogen and recover oil [

28]. The model was developed to maximize the net present value, achieving a desirable value of 2189 million USD. Furthermore, Tang et al. integrated the energy network optimizer into the source-sink model to assess the carbon network design in China, finding the total cost at different reduction levels of CO

2 to be about 50 USD/ton

CO2 in 2050 [

29].

Although numerous studies have substantially advanced the economic aspects of CCUS, they have largely overlooked the environmental dimension. CCUS systems have the capability to mitigate CO

2 emissions, but their operation necessitates substantial energy and raw resources, which emit some pollutants. As a result, the environmental effect of the CCUS has been a significant consideration in the construction of the overall CCUS network in other studies [

30,

31].

Several studies focus on the environmental analysis of supply chains using CO

2 for enhanced oil recovery. The hybrid life cycle assessment (LCA) approach employed in Norway revealed a substantial decrease in emissions for both power facilities and oil production using the CO

2-EOR system [

32]. Also, compared with standard oil production, the GHG emissions from implementing a large-scale CO

2-EOR system on the coast of Norway could be markedly dropped by over 70% [

33]. Hussain et al. investigated the life cycle emissions associated with CO

2-EOR technologies utilizing CO

2 from various sources [

34]. They found that the systems with CO

2 from natural gas, biomass, and coal could be viable options for mitigating GHG emissions. Moreover, negative emissions could be obtained for oil production using the CO

2-EOR method if CO

2 were captured from an ethanol fermentation process in the US [

35]. Abotalib et al. implemented a comparative survey of three CO

2-EOR pathways with CO

2 from different emission sources by combining the LCA method with a geographical system [

36]. The findings suggested that integrating CO

2-EOR and ethanol manufacturing demonstrated considerably higher GHG benefits than other options. A partial LCA approach was implemented to measure energy demand and emissions for a CO

2-EOR network in China [

37]. The results showed that the deployment of CO

2-EOR has significantly mitigated China’s impact on climate change.

Overall, the above studies show the environmental benefits of CO

2-EOR inside a carbon supply chain. Other CO

2-based products were investigated in the environmental analysis. In Thonemann and Pizzol, various CO

2-based synthesis technologies were considered to evaluate the influence of global warming [

38]. The outcomes showed that introducing a CCUS system into the chemical sector was advisable from a sustainability perspective. Fernández-Dacosta et al. evaluated the potential of various configurations of the CCUS systems in terms of technology and environment [

39]. The study indicated that the integration of carbon capture and multi-product utilization with storage emerged as the optimal solution for both minimizing CO

2 emissions and attaining economic benefits. To reduce CO

2 emissions by mineralization in Europe, Ostovari et al. designed an optimum CCUS supply chain by conducting a two-step method [

40]. Specifically, a source-sink model was employed in the first step to maximize CO

2 emission reduction before the pipeline network topology was optimized in the second step, providing an annual avoidance of 160 Mton of CO

2 by 2040. Using the LCA, Leonzio et al. found that the annual global warming potential (GWP) for CCUS networks in Italy and Germany is 9.62 × 10

10 kg

CO2eq and 1.94 × 10

11 kg

CO2eq, respectively, which could assist both nations in meeting the CO

2 mitigation targets set by European environmental regulations [

41]. A sensitivity evaluation indicated that storage significantly contributes to decreasing the GWP factor in Germany, whereas this factor is primarily affected by the exploitation of captured CO

2 to make methane using a power-to-gas technique in Italy.

Examining existing papers, it is found that most research concentrates only on either economic or environmental targets. Also, the utilization of captured CO2 often focuses on specific applications like enhanced oil recovery or the synthesis of a single product (e.g., methanol), neglecting a broader exploration of diverse CO2-based chemicals. This study seeks to overcome existing limitations by introducing an innovative CCUS supply chain optimization framework that incorporates the LCA methodology into the source-sink connection model while integrating the geographical storage and various synthesis pathways of CO2 into high-value chemicals. In detail, the objective of this approach is to identify optimal solutions that maximize the overall annual profit and the life cycle emission reduction, subject to a range of crucial operational constraints such as the availability of feedstocks, market demand sizes of products, and the targeted amount of CO2 mitigation. As a result, the proposed model enables a comprehensive assessment of the performance of the whole CCUS infrastructure in terms of both economy and environment. Furthermore, this work offers practical insights into designing effective CCUS supply chains for emission mitigation by analyzing various scenarios optimized using the new framework.

3. Results and Discussion

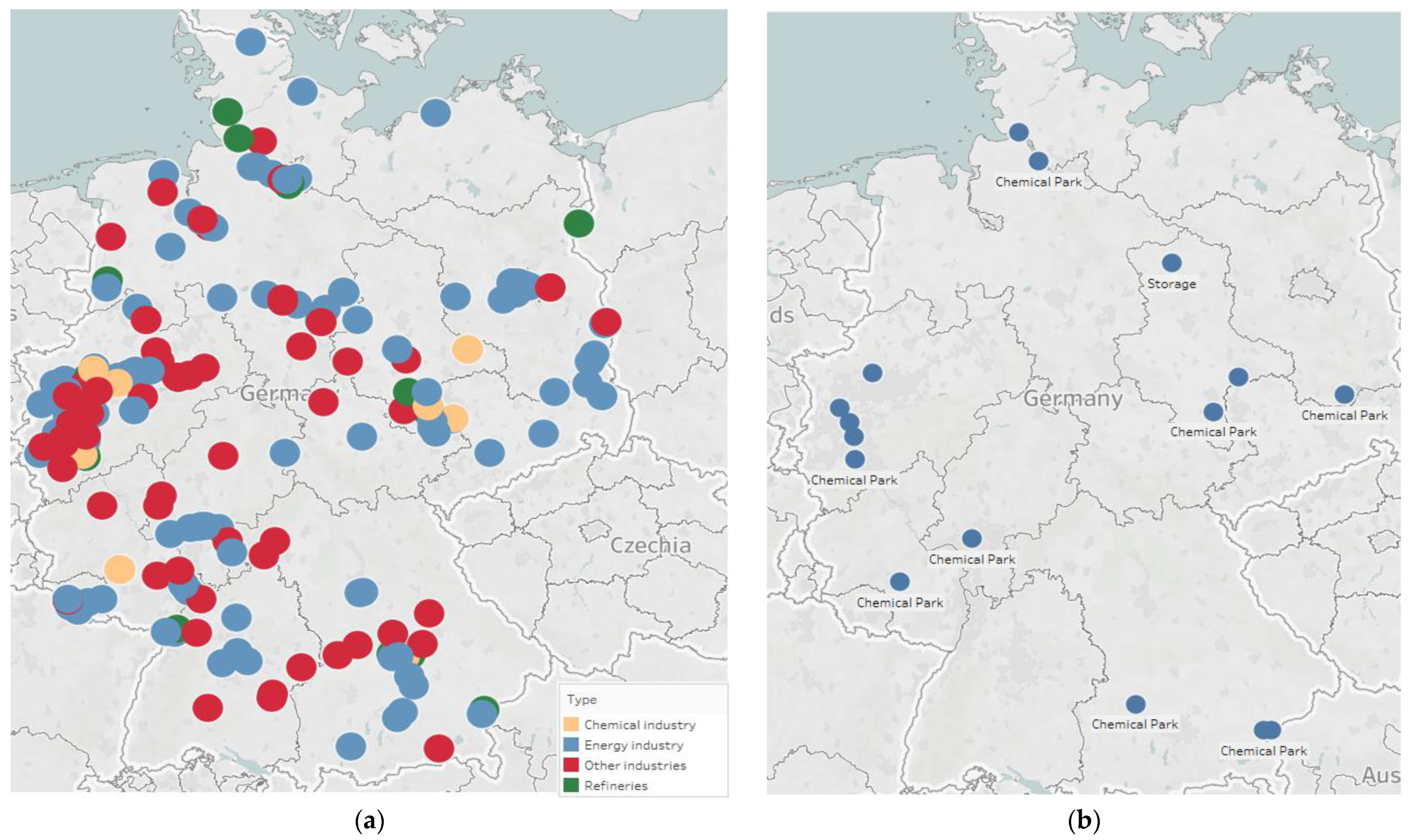

This study employed an optimization model for implementing CCUS networks at a national scale in Germany, considering three scenarios, which were levels of CO2 reduction, product market demand, and hydrogen availability, as discussed below. The model was developed in AIMMS (Version 4.96) and addressed using the CPLEX 22.1 method on a server with an Intel Core i5 CPU at 3.2 GHz with 32 GB of RAM.

3.1. Results for Different Levels of CO2 Reduction

This scenario explored the effect of emission reduction goals on the performance of CCUS infrastructures. Undoubtedly, optimum solutions could vary considerably based on the scale of CO

2 emissions. In addition, it was presumed that all raw materials were entirely accessible, and conventional producers within the country were currently manufacturing all target products. The goal was to maximize the overall annual profit or the reduction of life cycle GHG emissions. The results presented in

Table 3 and

Table 4 provide a complete assessment of the cost- and climate-optimal solutions at various levels of CO

2 reduction (10, 50, and 80%). The production rates of various chemicals for three different levels of CO

2 reduction are presented in

Table 5.

In the cost-optimal scenarios, the CCUS network continuously allocated almost all captured CO

2 (>99.9%) to the utilization option rather than the storage option at all reduction levels. This approach attained significant annual profits, maintaining stability around approximately 2013–2022 EUR/ton

CO2 across different scales. Using a limited range of cost-effective technologies, primarily adsorption-based methods (due to choosing sources with moderate and high CO

2 compositions) and relying on a high-revenue product like gasoline (due to exploiting cheap raw materials), enabled this economic success. However, this configuration was environmentally detrimental. Specifically, the life cycle GHG emissions related to these networks tended to be substantially negative, indicating an overall increase in emissions, worsening dramatically from −175 Mt

CO2eq/year at 10% to −1399 Mt

CO2eq/year at 80% of CO

2 emission reduction. This can be explained by the fact that producing traditional gasoline from Path 1 based on the methane reforming technologies with very high emissions contributed the largest share of at least 99% of the total emissions (249, 1243, and 1989 Mton

CO2eq/year at 10, 50, and 80% of CO

2 emission reduction, respectively) [

54]. Remarkably, the production and sale of gasoline (Path 1) represented the principal contributors to costs, accounting for over 96% of all cases, and the profit, the single revenue source.

In contrast, aiming for optimal life cycle GHG reduction revealed a different scenario. Clearly, the network tended to favor pathways that exhibited superior GHG reduction efficiency in this situation. The production of acetic acid (Path 6), DMC (Path 12), and formic acid (Path 14) remained stable at 24, 1.55, and 1.3 Mton/year, regardless of the GHG reduction target. As the GHG reduction target increased to 50 and 80%, new production routes emerged, such as methanol (Path 5) (99 and 136 Mton/year at 50 and 80%, respectively) and gasoline (Path 2) (up to 15 Mton/year). Also, although utilization still accounted for the highest CO2 consumption, a larger proportion of CO2 was designated for storage. This shift, along with a broader range of CO2-based products synthesized from low-emission paths, mitigated emissions related to the utilization phase and fostered positive net GHG reductions of 32, 52, and 51 MtonCO2eq/year for the 10, 50, and 80% targets, respectively. On the other hand, climate-optimal networks employed a more diverse set of capture technologies, including a wider array of absorbents, adsorbents, and membranes. These changes led to a notable rise in the number of sources used (241 sources for all cases) and a greater amount of CO2 directed to storage, albeit at a higher economic cost. As a consequence, these strategies incurred significant financial losses, especially at elevated reduction levels, with net profit losses of −66 and −104 billion EUR/year at 50 and 80%, respectively, although the 10% scenario still shows a profit (5.93 billion EUR/year or 146 EUR/tonCO2). The results are justified because while total CCUS costs remained high, a considerable downturn in revenues compared to the most cost-effective solutions was the primary factor contributing to the overall financial penalty in these cases.

3.2. Results for Different Levels of Product Market Demand

This scenario explored the influence of diverse market demands on the performance of the CCUS network. Obviously, producing the full chemical capacity for the entire world is, in reality, impractical. Consequently, production volume was assumed not to surpass 100, 50, 25, 10, or 5% of the worldwide market demand in 2030. Also, all raw materials and target products were accessible in this case. The aim was to maximize the overall annual profit or life cycle GHG reduction by mitigating 203 Mton

CO2/year. While

Table 6 and

Table 7 examine the costs and environmental effects of two objectives,

Table 8 presents the production rates of various chemicals at different market demands.

Table 6 indicates that at a fixed target of emission reduction, the majority of mitigated CO

2 was directed to the utilization sector. In contrast, only minimal mitigated CO

2 was sent to the storage location. This could be attributed to the national demand for CO

2-based products that needed to be met, so utilization was preferred over storage options. The cost-optimal strategy showed strong financial performance even under severe market constraints, with constant profits of 409 billion EUR/year at 50 and 25% of the global product market demand before sharply declining to 339 and 159 billion EUR/year at 10 and 5%, respectively. The profitability was maintained by favoring high-profit chemicals, which included gasoline (Path 1) and diesel (Path 3). Specifically, the manufacture of gasoline (Path 1) dominated at 50 and 25% with 211 Mton/year. However, at 5%, the largest product was diesel (Path 3), with 76 Mton/year, while gasoline (Path 1) dropped to only 12 Mton/year. This economic focus, however, directly resulted in adverse environmental consequences. Notably, the cost-optimal solution yielded considerable negative life cycle GHG reductions, varying from −874 to −493 Mton

CO2eq/year between 50 and 5%, indicating significant net increases in emissions. The outcome is explained by the intrinsically poor GHG reduction performance of the selected pathways, combined with minimal CO

2 storage implementation (0.02 Mton

CO2/year). Importantly, while the carbon network still focused on being economically favorable at 5%, a considerable reduction in life cycle GHG emissions by more than 50% compared to higher demands was found. The result is justifiable due to the product mix transitions toward low-emission chemicals such as gasoline (Path 2), methanol (Path 5), and acetic acid (Path 6) in this case.

The climate-optimal approach, in contrast, focused on minimizing GHG emissions, leading to consistent financial deficits, which increased from −57 billion EUR/year at 50% to −34 billion EUR/year at 5% of global product market demand. The financial penalty was linked to the selection of synthesis routes, which were advantageous in GHG reduction but had poor economic profiles. It is interesting to note that a marked shift in production capacity was observed as the percentage demand diminished from 50 to 5%. Gasoline (Path 2) significantly rose from 17 to 46 Mton/year. At the same time, there was a sharp drop of above 10 and 60 Mton/year in the production of acetic acid (Path 6) and methanol (Path 5), respectively. In addition, DME (Path 8) was integrated at moderate levels of demand but eliminated at the lowest level. As a result, along with significant and consistent CO2 storage allocations (0.54 MtonCO2/year across all scenarios), this selection initially achieved positive overall GHG reductions, yielding 52 and 21 MtonCO2eq/year at 100 and 50%, respectively. However, a critical threshold emerged as market constraints intensified: the net life cycle GHG reduction turned negative (ranging from −1.44 to −20 MtonCO2eq/year between 25 and 5%), indicating that even optimized pathway selection became insufficient to maintain environmental benefits under fluctuating levels of market demand.

3.3. Results for Different Levels of Hydrogen Availability

This scenario attempted to analyze the impact of diverse levels of hydrogen availability on the performance of the CCUS network. Statistics indicate that renewable hydrogen constitutes less than 1% of worldwide hydrogen production [

55]. Also, the practice of using low-emission hydrogen in CCUS networks has been limited. As a consequence, it was assumed that hydrogen consumption could not exceed 100, 50, 25, 10, or 1% of the global renewable hydrogen potential in 2030. Also, all raw materials (except hydrogen) and target products (with full market demand) were accessible in this case. It is essential to highlight that the only objective function in this case was the life cycle GHG reduction for capturing 203 Mton

CO2/year. The reason for this was that since renewable hydrogen-based conversion routes were not employed to improve profitability, the limitation of hydrogen supply did not influence the optimal profit-based cases.

Table 9 and

Table 10 present a complete examination of the costs and environmental effects, while the production rates of various chemicals are shown in

Table 11 under different hydrogen supply levels.

A notable deterioration in environmental performance was observed as the hydrogen supply decreased from 100 to 1%, leading to an increase in life cycle GHG emissions. Despite a constant CO

2 capture potential of 203 Mton

CO2/year across all hydrogen scenarios, the overall life cycle GHG reduction showed a dramatic decrease. The network initially attained a GHG decline of 52 Mton

CO2eq/year at full hydrogen availability, but this benefit quickly diminished and turned negative at lower levels, with −48, −327, −497, and −599 Mton

CO2eq/year at 50, 25, 10, and 1%, respectively. The reason for this was that notable shifts in the production strategy drove the increase in net GHG emissions under stricter hydrogen limitations [

54]. Moreover, this environmental degradation coincided with a significant improvement in total annual profit, escalating from a loss of −66 billion EUR/year at 100% to a net gain of 196 billion EUR/year at 1%.

As the hydrogen availability decreased, synthesis paths with high GHG reduction potential but significant hydrogen requirements were reduced or eliminated. Methanol (Path 5) and DME (Path 8) saw a decrease in production from 99 and 6.88 Mton/year at 100%, respectively, to zero at 25% hydrogen availability and below. Similarly, gasoline (Path 2) peaked at 16 Mton/year at 25% before phasing out at lower levels, while formic acid (Path 14) maintained marginal production (1.3 Mton/year) at 10% and disappeared at 1%. Meanwhile, the CCUS network increased production in pathways that offered economic advantages with lower hydrogen demands. Methanol (Path 4) emerged as the primary product as hydrogen supply decreased, considerably increasing from 69 Mton/year at 50% to 136 Mton/year at 25% and below. Furthermore, diesel (Path 3) was heavily utilized in all cases below 25%, showing a sharp rise in production from zero at 100% to 32 Mton/year at 25% before reaching 80 Mton/year at 1%.

4. Conclusions

This study offers critical insights into applying carbon capture, utilization, and storage networks at the national level under different targeted criteria, addressing a considerable gap in the simultaneous evaluation of economic and environmental aspects. In detail, the novelty of this research is that it formulated and implemented an integrated optimization framework that combined a comprehensive superstructure model with life cycle assessment to explore the optimal configuration and performance of CCUS networks, balancing two competing objectives: overall annual profit versus life cycle GHG reduction. Similar studies have not been conducted before.

This paper introduced an innovative framework to demonstrate the deployment of CCUS systems in Germany as a case study. The results show the trade-off between annual profit and life cycle GHG reduction. In other words, pursuing profit-driven strategies leads to increased GHG emissions, while environmental strategies suffer substantial financial costs despite creating considerable environmental benefits. In detail, cost-optimal cases focused on high-profit utilization routes (e.g., gasoline through methane reforming) and cost-effective capture technologies, creating significant profitability (up to 2022 EUR/tonCO2 captured) but resulting in a notable net rise in life cycle GHG emissions (up to −1399 MtonCO2eq/year). In contrast, climate-optimal approaches required diversification, integrating CO2 storage with conversion pathways that exhibited lower emissions (e.g., gasoline, acetic acid, methanol through CO2 hydrogenation). As a result, the CCUS systems could attain a net positive reduction of GHG emission (up to 52 MtonCO2eq/year) while resulting in significant financial penalties (losses reaching −104 billion EUR/year), especially when aiming for ambitious CO2 mitigation targets (e.g., 80%).

In this research, three scenarios were examined to assess the impact of key constraints on optimum solutions. Levels of CO2 reduction, market demand for CO2-based products, and the availability of renewable hydrogen emerged as primary factors in shaping both the economic feasibility and the environmental performance of CCUS systems. For example, if market demand for CO2-based products is insufficient, this not only limits potential profits but can also reduce or even cancel out the climate advantages of CCUS networks. Also, having enough renewable hydrogen is crucial for making CCUS networks environmentally friendly. A shortage of hydrogen complicates the utilization of the low-emission methods, forcing a switch to alternatives that produce higher emissions. This significantly reduces or eliminates the environmental benefits while unexpectedly increasing profits because alternative methods use cheaper raw materials.

The optimization framework presented here was demonstrated through its application to stationary CO2 sources in Germany; nevertheless, its methodology is intentionally designed for broad applicability without limitation by this geographical scope. Given reliable and comprehensive data on CO2 sources and other parameters (e.g., process parameters of CO2 storage and utilization, market demands, and costs of CO2-based products), the framework can be effectively deployed to construct CCUS networks at various levels, from individual locations to regions, states, or entire countries. On the other hand, a key consideration is the assumptions, which include constant prices, demand profiles, and CO2 source availability over a 30-year horizon. In reality, such systems are subject to significant temporal dynamics of factors such as market uncertainty, fluctuating economic conditions, and technical evolution. The development of a multi-stage stochastic optimization model would enable the explicit integration of uncertainty in key parameters, yielding investment strategies that are more robust and resilient to market volatility. Consequently, the results, with a necessary simplification, should be interpreted as an initial estimate for assessing the fundamental techno-economic feasibility of the proposed infrastructure before the profound impacts of dynamic and stochastic factors can be quantified in subsequent analyses.

Future research should enhance capture and conversion techniques with cost-effective and low-emission capabilities and investigate utilization paths that depend less on limited resources. Additionally, the effect of implementing CCUS technologies on local communities should be examined.