Experimental Study on the Activation Mechanism of Residual Slag Micro Powder After Recycled Aggregate of Waste Concrete

Abstract

1. Introduction

2. Experimental Section

2.1. Raw Material

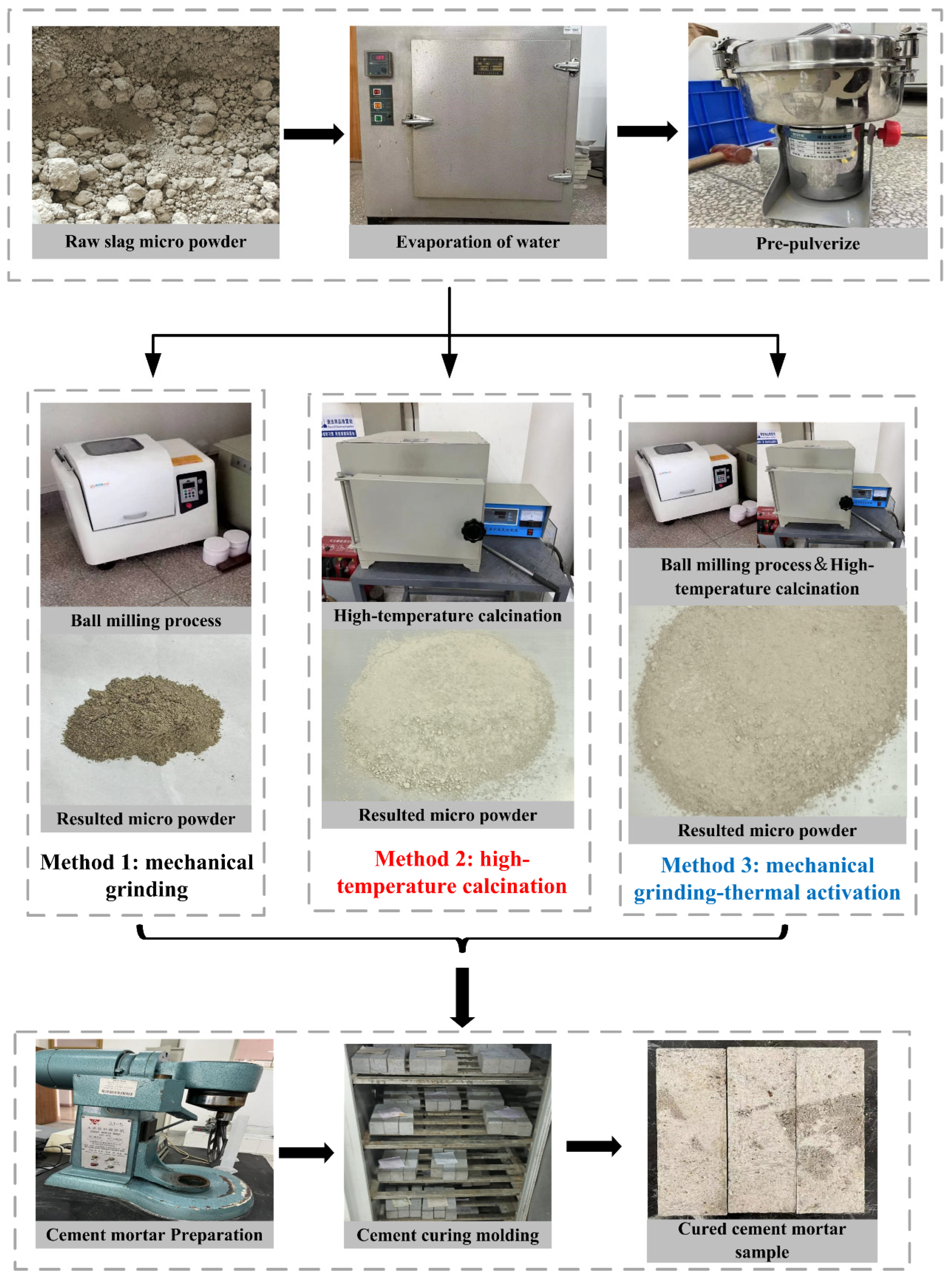

2.2. Experimental Design for Activation of Slag Micro Powder

2.3. Grain Size Analysis

2.4. Determination of Activity Index

2.5. SEM and EDS

3. Results and Discussion

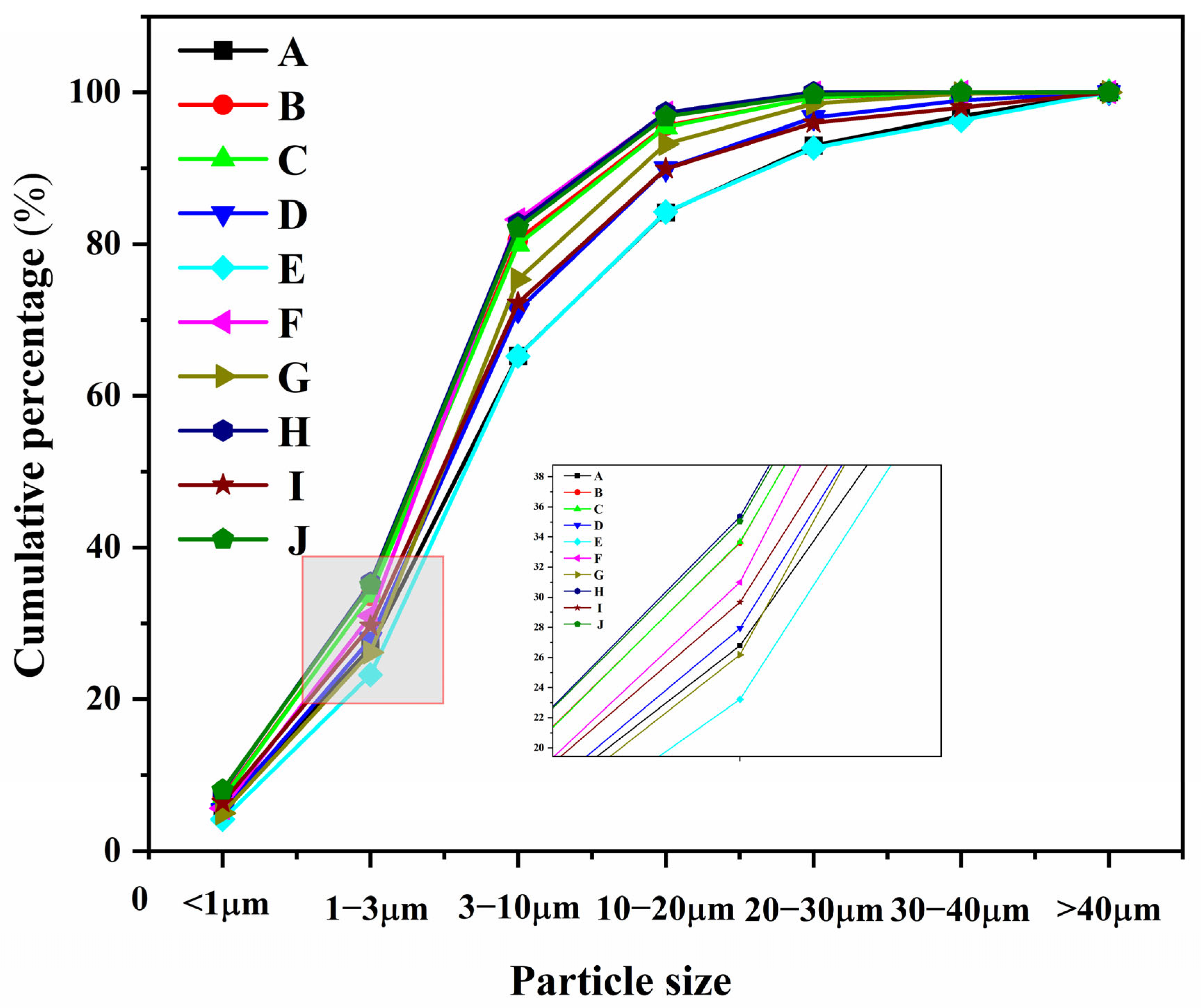

3.1. Particle Characteristics of Activated Slag Micro Powder

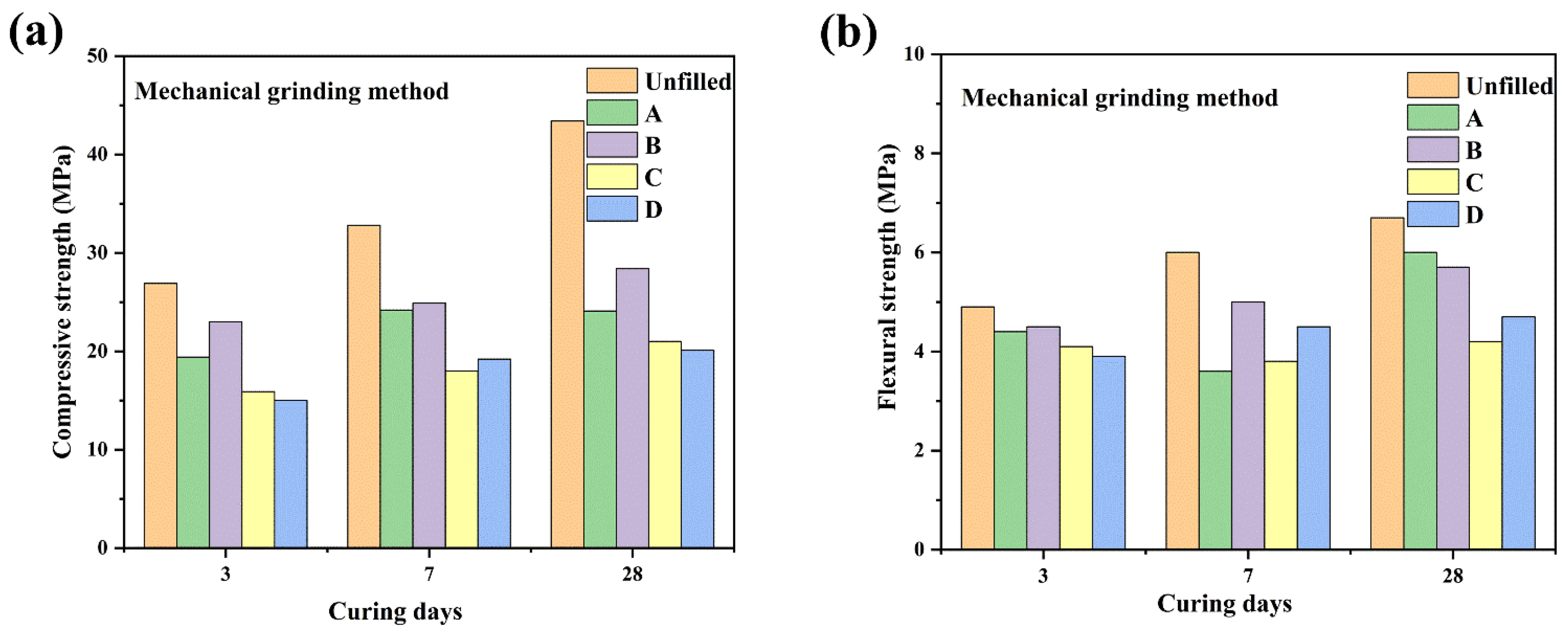

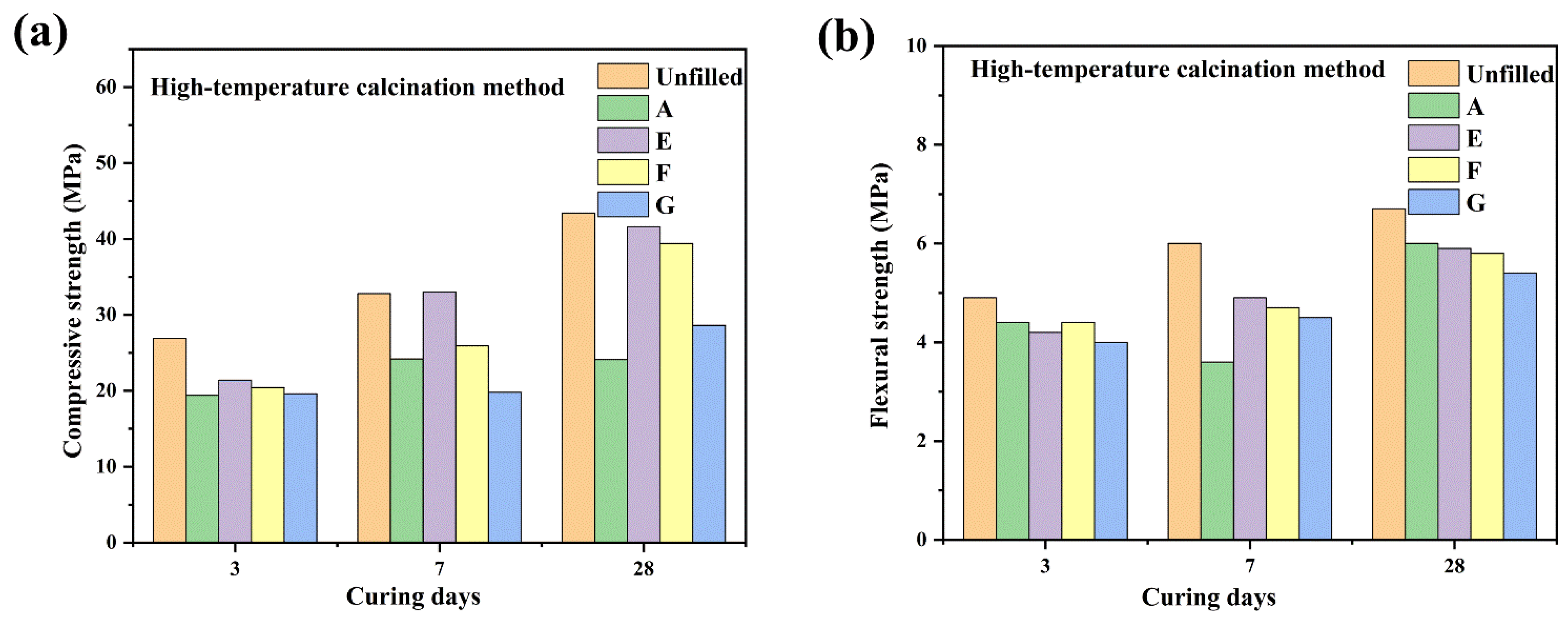

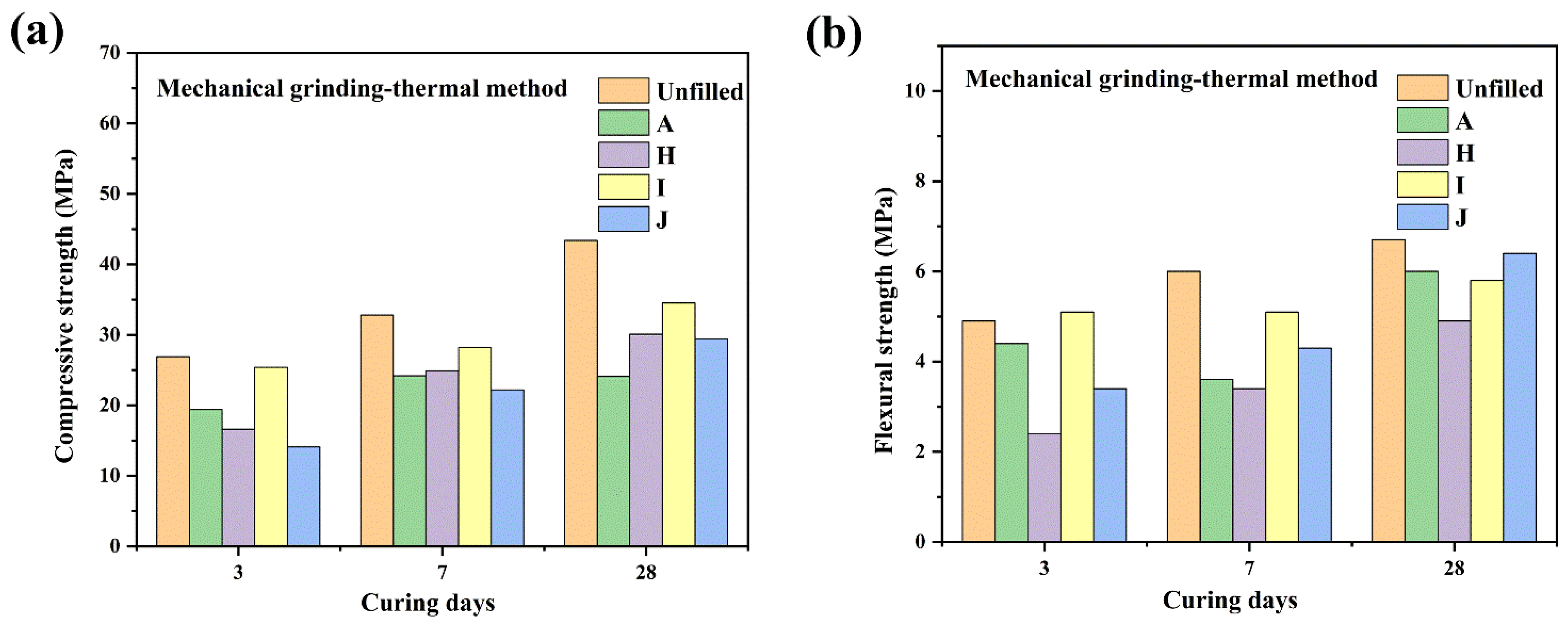

3.2. Effects of Different Activation Methods on the Mechanical Properties of Cement Mortar Filled with Slag Micro Powder

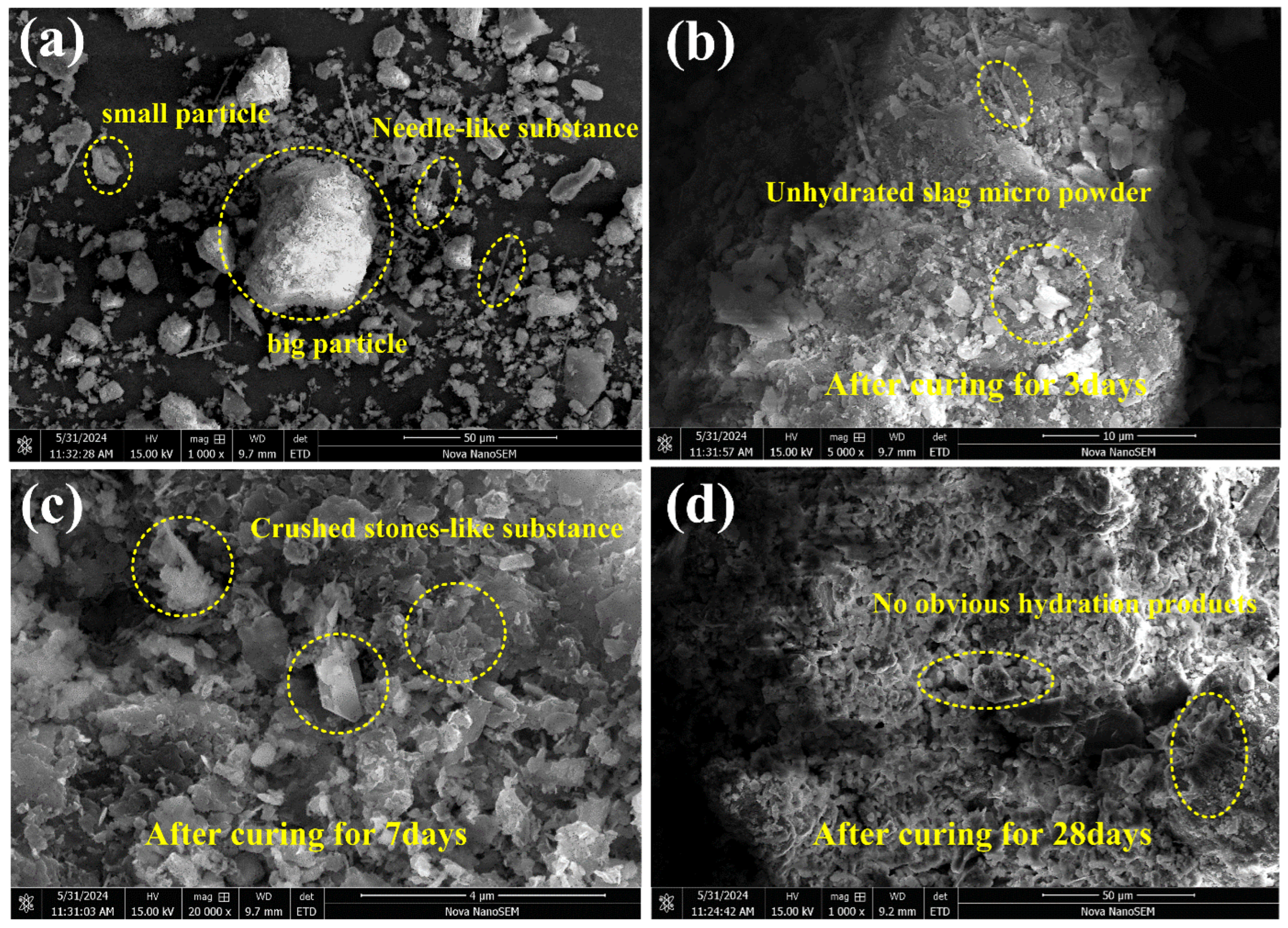

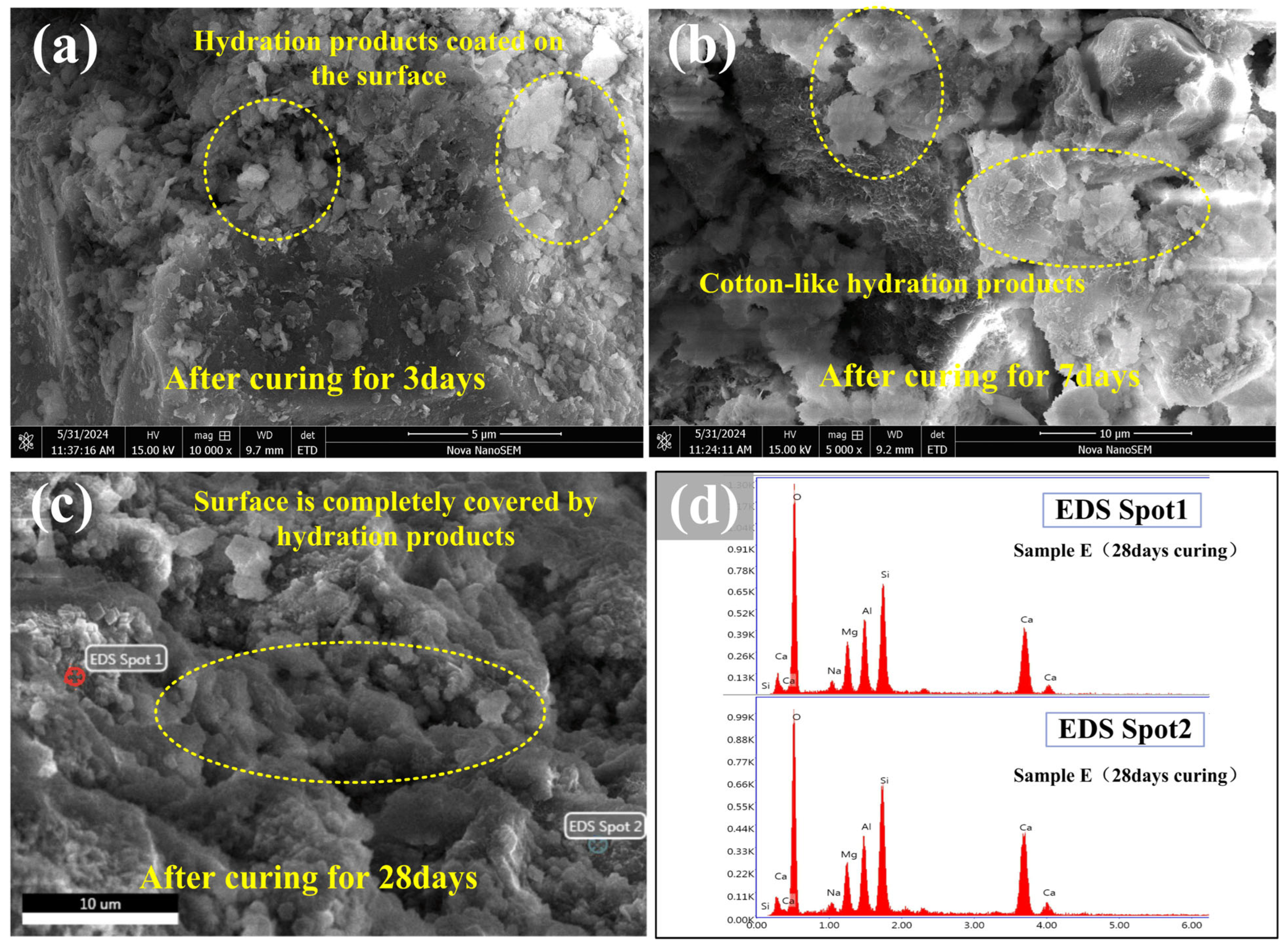

3.3. Micro-Scale Mechanism Analysis

4. Conclusions

- High-temperature calcination emerged as the most effective activation method, achieving a 95.85% activity index by calcining slag micro powder at 750 °C for 10 min. This treatment may release reactive SiO2 and Al2O3 components that participated in volcanic ash reactions, forming hydration products (e.g., C-S-H gel) and significantly improving the compressive strength of cement mortar.

- Mechanical grinding alone demonstrated limited benefits. While it reduced particle size and increased the specific surface area, thereby promoting partial pozzolanic reactivity, the improvement in compressive strength was marginal, and flexural strength even decreased due to particle agglomeration and stress concentration. However, compared with untreated slag, as long as the cost loss of mechanical grinding is low enough, this method can still be easily used to improve the activity of slag micro powder.

- The combined mechanical grinding–thermal activation method produced negative synergistic effects, likely due to over-densification of the particle structure or conflicting activation pathways, which reduced the reactivity of the slag micro powder. In the future, different grinding times and temperatures can be attempted for activation treatment, which may further enhance the activity of slag micro powder.

- A microstructural analysis via SEM–EDS confirmed that calcined slag micro powder exhibited dense hydration product coverage after 28 days of curing, in contrast to the inert state of untreated slag micro powder. This highlights the critical role of thermal activation in enhancing slag micro powder’s reactivity and cementitious performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, J.; Ye, X.; Cui, H. Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability 2025, 17, 2636. [Google Scholar] [CrossRef]

- Poon, C.S.; Shen, P.; Jiang, Y.; Ma, Z.; Xuan, D. Total recycling of concrete waste using accelerated carbonation: A review. Cem. Concr. Res. 2023, 173, 107284. [Google Scholar] [CrossRef]

- Xiao, J.; Hao, L.; Cao, W.; Ye, T. Influence of recycled powder derived from waste concrete on mechanical and thermal properties of foam concrete. J. Build. Eng. 2022, 61, 105203. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Liu, X.; Cai, Y.; Zhang, Y. Orthogonal experimental design for compressive strength of recycled coarse aggregate concrete with silica fume-slag-fly ash hybrid micro-powders. Constr. Build. Mater. 2023, 408, 133669. [Google Scholar] [CrossRef]

- Nicula, L.M.; Manea, D.L.; Simedru, D.; Cadar, O.; Becze, A.; Dragomir, M.L. The Influence of Blast Furnace Slag on Cement Concrete Road by Microstructure Characterization and Assessment of Physical-Mechanical Resistances at 150/480 Days. Materials 2023, 16, 3332. [Google Scholar] [CrossRef]

- Huo, W.; Zhu, Z.; Sun, H.; Gao, Q.; Zhang, J.; Wan, Y.; Zhang, C. Reaction kinetics, mechanical properties, and microstructure of nano-modified recycled concrete fine powder/slag based geopolymers. J. Clean. Prod. 2022, 372, 133715. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Toulabi, H.M.; Hosseini, S.A.; Najafi, L.H. Investigating the effect of using recycled waste concrete powder (RWCP) on the performance of thin layer surface treatment: Microsurfacing. Constr. Build. Mater. 2023, 400, 132734. [Google Scholar] [CrossRef]

- Lin, Y.; He, T.; Da, Y.; Yang, R.; Zheng, D. Effects of recycled micro-powders mixing methods on the properties of recycled concrete. J. Build. Eng. 2023, 80, 107994. [Google Scholar] [CrossRef]

- Qing, L.; Chuanming, L.; Huili, S.; Junxiang, W.; Xianjun, L. Use of activated quartz powder as an alkaline source for producing one-part Ca-rich slag based cementitious materials: Activation mechanism, strength, and hydration reaction. J. Build. Eng. 2023, 64, 105586. [Google Scholar] [CrossRef]

- Liang, G.; Liu, T.; Li, H.; Wu, K. Shrinkage mitigation, strength enhancement and microstructure improvement of alkali-activated slag/fly ash binders by ultrafine waste concrete powder. Compos. Part B Eng. 2022, 231, 109570. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, G.; Wang, C.; Zhang, Y.; Wang, P.; Yan, N. Activation effects and micro quantitative characterization of high-volume ground granulated blast furnace slag in cement-based composites. Cem. Concr. Compos. 2020, 109, 103556. [Google Scholar] [CrossRef]

- Caron, R.; Patel, R.A.; Dehn, F. Activation kinetic model and mechanisms for alkali-activated slag cements. Constr. Build. Mater. 2022, 323, 126577. [Google Scholar] [CrossRef]

- Sun, B.; Ye, G.; de Schutter, G. A review: Reaction mechanism and strength of slag and fly ash-based alkali-activated materials. Constr. Build. Mater. 2022, 326, 126843. [Google Scholar] [CrossRef]

- Bai, W.; Ye, D.; Ye, S.; Yuan, C.; Guan, J.; Yang, G.; Xie, C. Study on mechanical properties and damage mechanism of alkali-activated slag concrete. J. Build. Eng. 2024, 96, 110357. [Google Scholar] [CrossRef]

- Allahverdi, A.; Ahmadnezhad, S. Mechanical activation of silicomanganese slag and its influence on the properties of Portland slag cement. Powder Technol. 2014, 251, 41–51. [Google Scholar] [CrossRef]

- Sajedi, F. Mechanical activation of cement–slag mortars. Constr. Build. Mater. 2012, 26, 41–48. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, Z.; Liu, X.; Sheng, M.; Li, H.; Xu, X.; Ai, L.; Yan, Q.; Yang, Y. Preparation of composite micro-slag based on the application of tailings slag in cement and concrete. Constr. Build. Mater. 2022, 322, 126515. [Google Scholar] [CrossRef]

- Abdulkareem, O.M.; Ben Fraj, A.; Bouasker, M.; Khouchaf, L.; Khelidj, A. Microstructural investigation of slag-blended UHPC: The effects of slag content and chemical/thermal activation. Constr. Build. Mater. 2021, 292, 123455. [Google Scholar] [CrossRef]

- Jiang, Y.; Duan, X.; Li, B.; Lu, S.; Liu, T.; Li, Y. Synergistic activation of electric furnace ferronickel slag by mechanical grinding and chemical activators to prepare cementitious composites. Materials 2024, 17, 1247. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, S.; Huang, B.; Yang, Q.; Li, J. Comparison of mechanical, chemical, and thermal activation methods on the utilisation of recycled concrete powder from construction and demolition waste. J. Build. Eng. 2022, 61, 105295. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Cao, Y.; Wuhrer, R.; Murphy, T. Compressive strength and microstructure of alkali-activated fly ash/slag binders at high temperature. Cem. Concr. Compos. 2018, 86, 9–18. [Google Scholar] [CrossRef]

- Xie, Y.; Zhou, H.; Wang, J.; Meng, H.; Wei, S.; Sun, J.; Hu, Y. Enhancing autoclaved aerated concrete performance via replacement of fly ash with granite stone powder and steel slag: Critical role of Ca/Si ratio. Constr. Build. Mater. 2025, 477, 141360. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, D.; Jin, Q.; Li, S.; Liu, X. Effect of Steel Slag Fine Aggregate on the Seismic Behavior of Reinforced Concrete Columns with Steel Slag Sand. Buildings 2025, 15, 1769. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Lakhiar, M.T.; Wang, J. Eco-friendly cement mortar production using rice husk ash and oyster seashell powder: A comprehensive study of mechanical, durability and life cycle properties. Constr. Build. Mater. 2025, 481, 141590. [Google Scholar] [CrossRef]

- Herki, B.M.A.; Ali, A.I.; Smail, Y.S.; Omer, K.M. An Innovative Approach to Enhancing Concrete Sustainability: Utilising Unprocessed Steel Slag with Low CaO and High SiO2 Content. Buildings 2025, 15, 1514. [Google Scholar] [CrossRef]

- Lakhiar, M.T.; Mohamad, N.; Jhatial, A.A.; Sohu, S.; Oad, M. Mechanical properties of concrete containing river indus sand and recyclable concrete aggregate. Civ. Eng. J. 2018, 4, 1869–1876. [Google Scholar] [CrossRef]

- Herki, B.M.A. Strength and Absorption Study on Eco-Efficient Concrete Using Recycled Powders as Mineral Admixtures under Various Curing Conditions. Recycling 2024, 9, 99. [Google Scholar] [CrossRef]

- Xu, L.; Huifeng, Z.; Bo, G.; Zhe, W.; Sida, Z. Investigation on Mechanical Properties of Loess-based Cemented Paste Backfill and Numerical Back-Analysis. Nonferrous Met. Eng. 2023, 13, 108. [Google Scholar]

- Ma, J.; Wang, Y.; Zhang, L.; Zeng, L.; Wang, X.; Dang, J. Influence of geometric shape, pore structure and surface modification of recycled fine aggregate on the rheology behaviour and strength development of mortar. J. Build. Eng. 2024, 91, 109604. [Google Scholar] [CrossRef]

- He, T.; Xu, Z.; Li, Z.; Zhao, X.; Zhao, S.; Liu, Y. Study on the relationship between the particle size distribution characteristics of ground granulated blast furnace slag and its mortar properties. Front. Mater. 2022, 9, 962279. [Google Scholar] [CrossRef]

- Yang, H.M.; Zhang, S.M.; Wang, L.; Chen, P.; Shao, D.K.; Tang, S.W.; Li, J.Z. High-ferrite Portland cement with slag: Hydration, microstructure, and resistance to sulfate attack at elevated temperature. Cem. Concr. Compos. 2022, 130, 104560. [Google Scholar] [CrossRef]

- Zhang, S.; Ghouleh, Z.; Mucci, A.; Bahn, O.; Provençal, R.; Shao, Y. Production of cleaner high-strength cementing material using steel slag under elevated-temperature carbonation. J. Clean. Prod. 2022, 342, 130948. [Google Scholar] [CrossRef]

- Chen, X.; Guo, J.; Yu, H.; Zhang, G.; Kang, Y.; Zhang, M.; Hao, T.; Du, Q. Impact of calcination temperatures on lithium magnesium slag for enhanced magnesium phosphate cement properties. Constr. Build. Mater. 2024, 451, 138766. [Google Scholar] [CrossRef]

- Duque-Redondo, E.; Bonnaud, P.A.; Manzano, H. A comprehensive review of CSH empirical and computational models, their applications, and practical aspects. Cem. Concr. Res. 2022, 156, 106784. [Google Scholar] [CrossRef]

- Zheng, Q.; Li, C.; Song, F.; He, B.; Li, W.; Jiang, Z. Autogenous self-healing of ultra-high-performance fiber-reinforced concrete with varying silica fume dosages: Secondary hydration and structural regeneration. Cem. Concr. Compos. 2023, 137, 104905. [Google Scholar] [CrossRef]

- Zhang, R.; Tao, Z.; Xiong, Y.; He, M. Experimental analysis and prediction of flexural performance in high-ductility UHTCC concrete beams reinforced with NPR materials. Structures 2025, 77, 109084. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, J.; Chen, S.; Shi, H.; Hu, Q.; Tang, Y. Evaluation of slag and tannery sludge based geopolymer after thermal exposure: Properties, phase transformation and Cr leaching behavior. J. Clean. Prod. 2025, 512, 145716. [Google Scholar] [CrossRef]

- Cai, R.; Ye, H. Clinkerless ultra-high strength concrete based on alkali-activated slag at high temperatures. Cem. Concr. Res. 2021, 145, 106465. [Google Scholar] [CrossRef]

- Chen, B.; Pang, L.; Zhou, Z.; Chang, Q.; Fu, P. Study on the activation mechanism and hydration properties of gold tailings activated by mechanical-chemical-thermal coupling. J. Build. Eng. 2022, 48, 104014. [Google Scholar] [CrossRef]

- Chen, L.; Wei, M.; Lei, N.; Li, H. Effect of chemical–thermal activation on the properties of recycled fine powder cementitious materials. Case Stud. Constr. Mater. 2024, 20, e02956. [Google Scholar] [CrossRef]

- Baldassari, M.; Monaco, A.; Sapora, A.; Cornetti, P. Size effect on flexural strength of notched and un-notched concrete and rock specimens by Finite Fracture Mechanics. Theor. Appl. Fract. Mech. 2023, 125, 103787. [Google Scholar] [CrossRef]

- Karlina, A.I.; Karlina, Y.I.; Gladkikh, V.A. Analysis of experience in the use of micro-and nanoadditives from silicon production waste in concrete technologies. Minerals 2023, 13, 1525. [Google Scholar] [CrossRef]

| Slag Micro Powder | Color | Fineness (cm2/g) | Clay Content (wt.%) | Loss on Ignition (wt.%) |

|---|---|---|---|---|

| performance index | off-white | 1593 | 15% | 2.5% |

| Sample Type | Grinding Time/min | Content of Slag Micro Powder | Cement Weight/g | Standard Sand Weight/g | Water Weight/g |

|---|---|---|---|---|---|

| Unfilled | - | - | 450 | 1350 | 225 |

| A | - | 15% | 380 | 1350 | 225 |

| B | 30 | 15% | 380 | 1350 | 225 |

| C | 60 | 15% | 380 | 1350 | 225 |

| D | 120 | 15% | 380 | 1350 | 225 |

| Sample Type | High-Temperature Calcination Time/min | Temperature/°C | Content of Slag Micro Powder | Cement Weight/g | Standard Sand Weight/g | Water Weight/g |

|---|---|---|---|---|---|---|

| E | 10 | 750 | 15% | 380 | 1350 | 225 |

| F | 20 | 750 | 15% | 380 | 1350 | 225 |

| G | 30 | 750 | 15% | 380 | 1350 | 225 |

| Sample Type | Grinding Time/min | High-Temperature Calcination Time/min | Temperature/°C | Content of Slag Micro Powder | Cement Weight/g | Standard Sand Weight/g | Water Weight/g |

|---|---|---|---|---|---|---|---|

| H | 60 | 20 | 300 | 15% | 380 | 1350 | 225 |

| I | 60 | 20 | 500 | 15% | 380 | 1350 | 225 |

| J | 60 | 20 | 750 | 15% | 380 | 1350 | 225 |

| Sample Type | <1 μm | 1–3 μm | 3–10 μm | 10–20 μm | 20–30 μm | 30–40 μm | >40 μm | Cumulative Percentage (%) |

|---|---|---|---|---|---|---|---|---|

| A | 5.8 | 20.99 | 38.45 | 18.94 | 8.78 | 3.91 | 3.13 | 100 |

| B | 7.01 | 26.61 | 46.95 | 15.01 | 3.68 | 0.68 | 0.05 | 99.99 |

| C | 6.83 | 26.84 | 46.26 | 15.48 | 3.91 | 0.65 | 0 | 99.97 |

| D | 5.36 | 22.57 | 43.36 | 18.62 | 6.76 | 2.25 | 1.06 | 99.98 |

| E | 4.16 | 19.06 | 42 | 19.02 | 8.42 | 3.63 | 3.69 | 99.98 |

| F | 5.64 | 25.36 | 52.24 | 14.03 | 2.65 | 0.08 | 0 | 100 |

| G | 4.99 | 21.19 | 49.13 | 17.89 | 5.32 | 1.31 | 0.18 | 100.01 |

| H | 7.88 | 27.47 | 47.34 | 14.65 | 2.67 | 0.02 | 0 | 100.03 |

| I | 6.38 | 23.29 | 42.57 | 17.69 | 6.02 | 2.04 | 2 | 99.99 |

| J | 8.02 | 27.02 | 47.08 | 14.69 | 2.9 | 0.29 | 0 | 100 |

| Sample Type | BET Surface Area/m2·kg−1 | D10/μm | D50/μm | D90/μm | R80/μm |

|---|---|---|---|---|---|

| A | 1595 | 1.52 | 6.82 | 26.9 | 0 |

| B | 1923 | 1.36 | 4.74 | 15.9 | 0 |

| C | 1912 | 1.37 | 4.76 | 16.1 | 0 |

| D | 1642 | 1.55 | 5.96 | 21.3 | 0.14 |

| E | 1431 | 1.79 | 7.05 | 27.1 | 0 |

| F | 1814 | 1.51 | 4.83 | 14.3 | 0 |

| G | 1617 | 1.65 | 5.8 | 18.4 | 0 |

| H | 2022 | 1.28 | 4.53 | 14.5 | 0 |

| I | 1741 | 1.43 | 5.76 | 21.3 | 0 |

| J | 2016 | 1.27 | 4.62 | 14.8 | 0 |

| Sample Type | Compressive Strength (MPa) | Flexural Strength (MPa) | Activity Index H |

|---|---|---|---|

| Unfilled | 43.4 ± 3.9 | 6.7 ± 0.5 | 100% |

| A | 24.1 ± 2.5 | 6.0 ± 0.2 | 55.50% |

| B | 28.4 ± 3.1 | 5.7 ± 0.4 | 65.59% |

| C | 21.0 ± 2.4 | 4.2 ± 0.5 | 48.39% |

| D | 20.1 ± 2.2 | 4.7 ± 0.6 | 46.31% |

| E | 41.6 ± 3.2 | 5.9 ± 0.3 | 95.85% |

| F | 39.4 ± 3.1 | 5.8 ± 0.3 | 90.78% |

| G | 28.6 ± 2.4 | 5.4 ± 0.4 | 65.90% |

| H | 30.1 ± 2.7 | 4.9 ± 0.5 | 69.35% |

| I | 34.5 ± 2.9 | 5.8 ± 0.6 | 79.49% |

| J | 29.4 ± 2.3 | 6.4 ± 0.7 | 67.74% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Zhang, K.; Liu, S.; Gao, L.; Wang, J.; Wang, X.; Cui, M.; Guo, L. Experimental Study on the Activation Mechanism of Residual Slag Micro Powder After Recycled Aggregate of Waste Concrete. Sustainability 2025, 17, 6046. https://doi.org/10.3390/su17136046

Zhou S, Zhang K, Liu S, Gao L, Wang J, Wang X, Cui M, Guo L. Experimental Study on the Activation Mechanism of Residual Slag Micro Powder After Recycled Aggregate of Waste Concrete. Sustainability. 2025; 17(13):6046. https://doi.org/10.3390/su17136046

Chicago/Turabian StyleZhou, Shengbo, Kai Zhang, Shengjie Liu, Li Gao, Jian Wang, Xiaojie Wang, Mengyao Cui, and Lu Guo. 2025. "Experimental Study on the Activation Mechanism of Residual Slag Micro Powder After Recycled Aggregate of Waste Concrete" Sustainability 17, no. 13: 6046. https://doi.org/10.3390/su17136046

APA StyleZhou, S., Zhang, K., Liu, S., Gao, L., Wang, J., Wang, X., Cui, M., & Guo, L. (2025). Experimental Study on the Activation Mechanism of Residual Slag Micro Powder After Recycled Aggregate of Waste Concrete. Sustainability, 17(13), 6046. https://doi.org/10.3390/su17136046