Advancements in Characterization and Potential Structural Seismic Performance of Alkali-Activated Concrete Incorporating Crumb Rubber: A State-of-the-Art Review

Abstract

1. Introduction

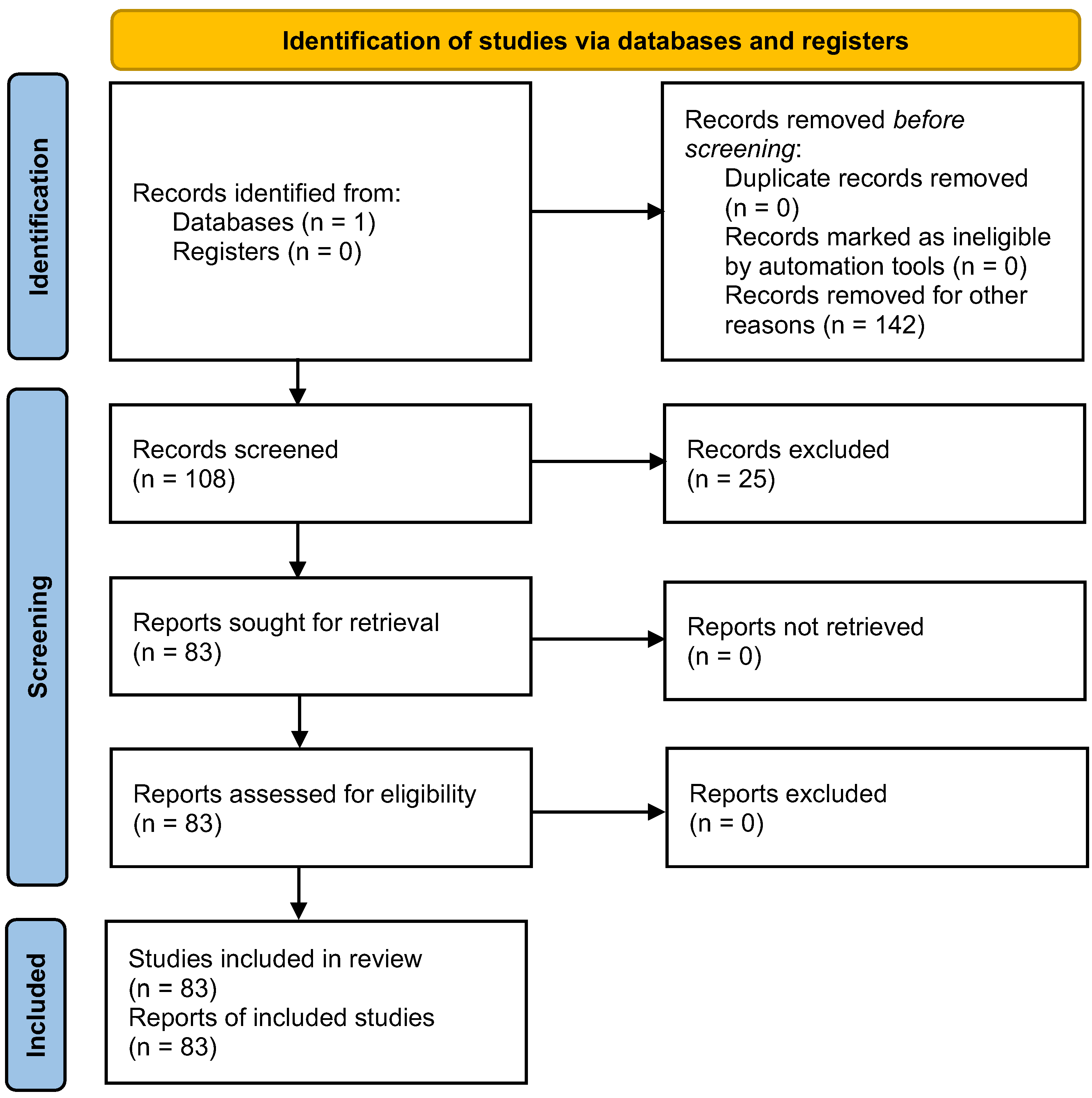

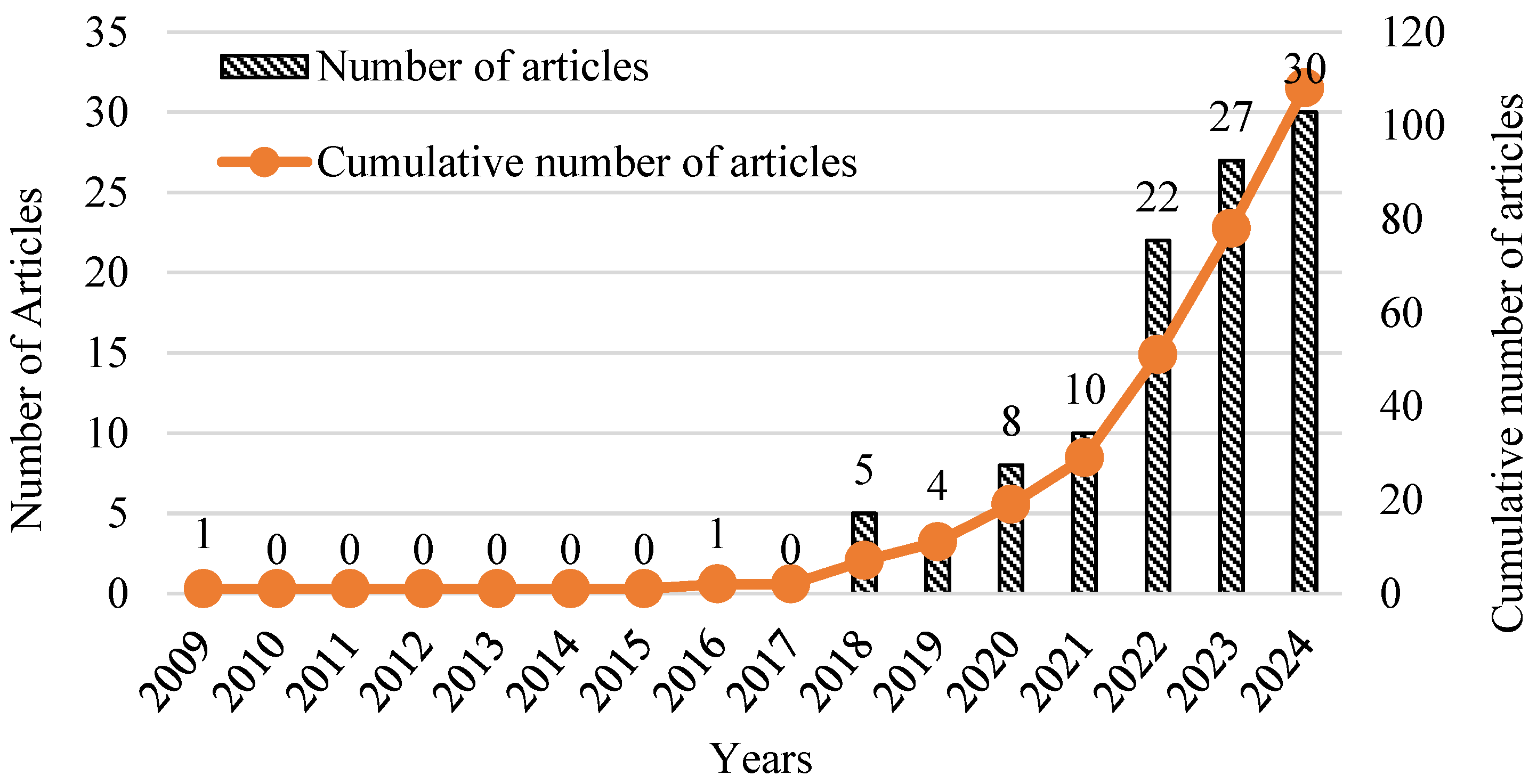

2. Methods and Statistics of Literature Review

2.1. Bibliometric Analysis Overview

2.2. Production and Impact Analysis

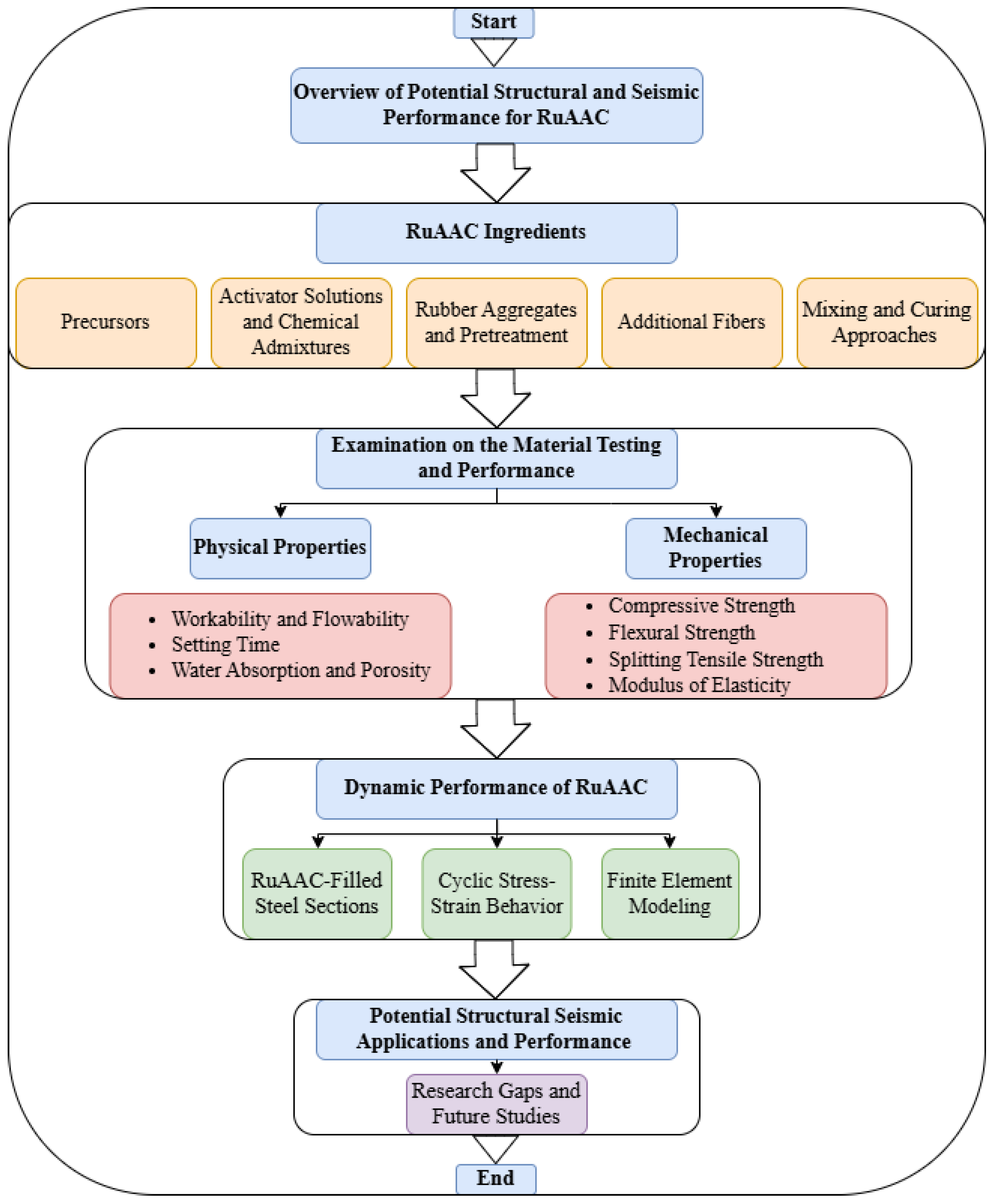

2.3. Review Framework

3. RuAAC Components, Mixing, and Curing

3.1. Precursors

3.2. Activator Solutions and Chemical Admixtures

3.3. Rubber Aggregates and Pretreatment of CR

3.4. Fibers

3.5. Mixing and Curing Approaches

4. Physical and Mechanical Characteristics of RuAAC

4.1. Physical Properties

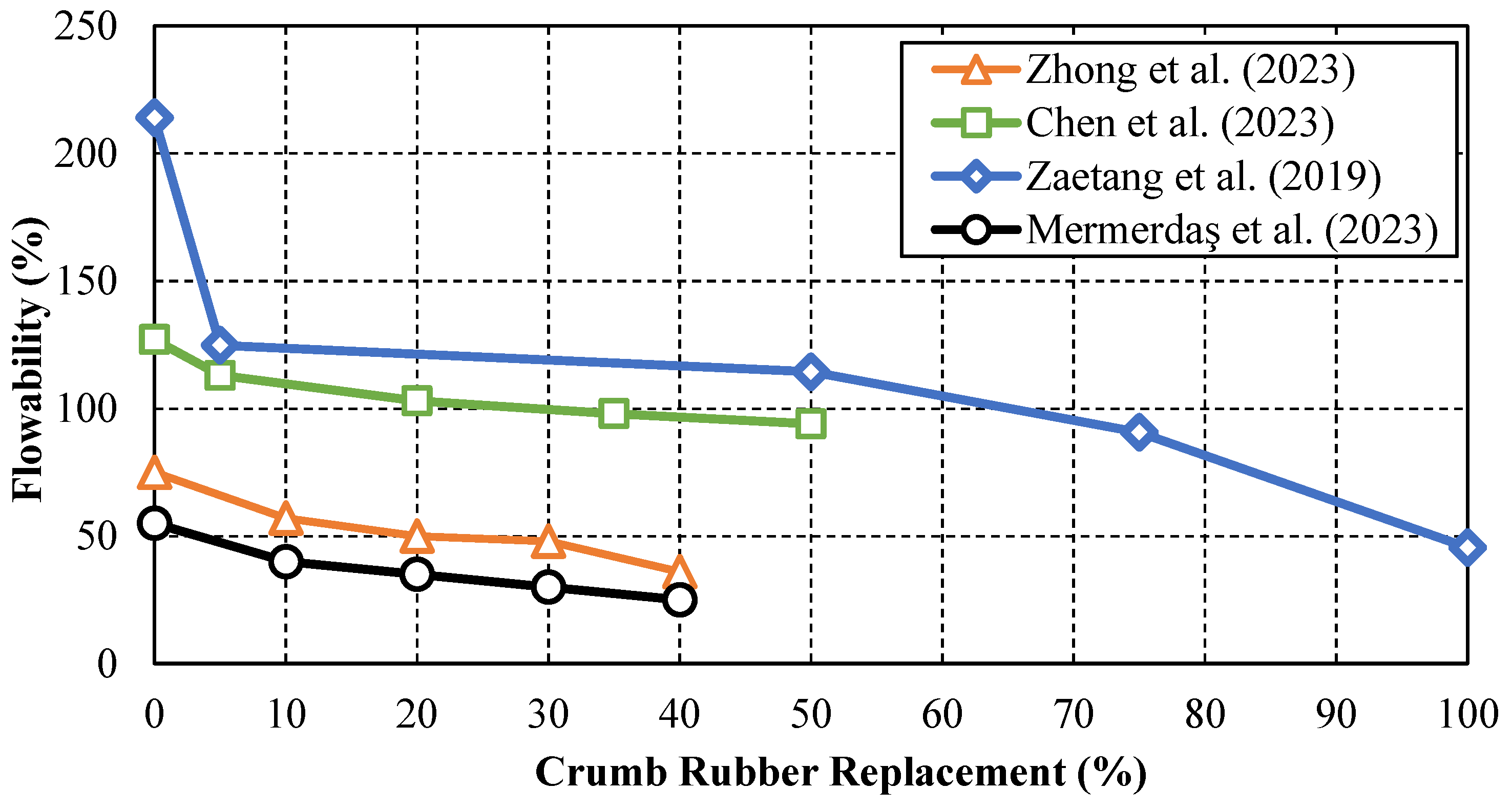

4.1.1. Workability and Flowability

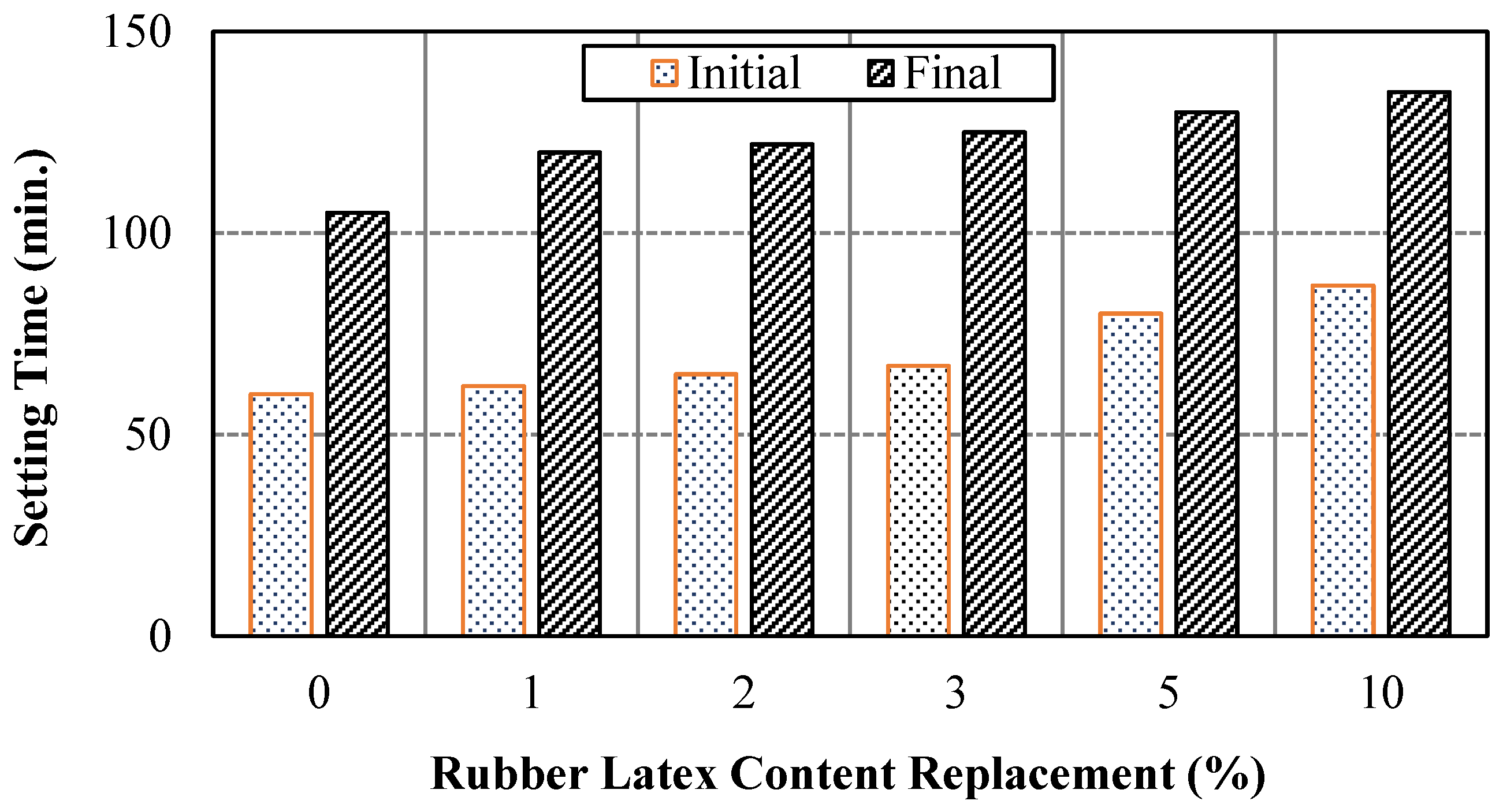

4.1.2. Setting Time

4.1.3. Water Absorption and Porosity

4.2. Mechanical Properties

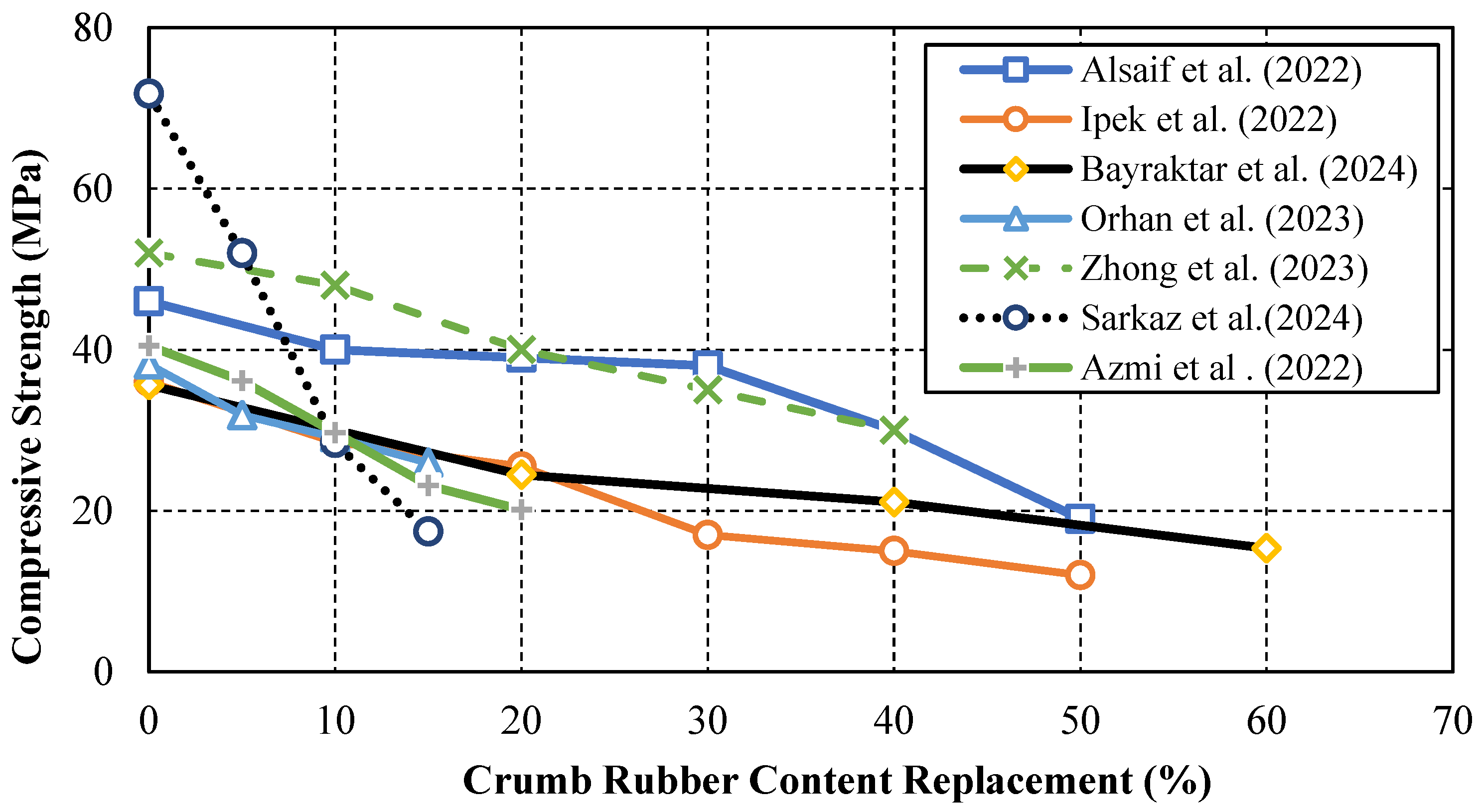

4.2.1. Compressive Strength

- Rubber particles’ lower stiffness and higher deformability compared to natural aggregates decrease the composite’s overall stiffness;

- Weak interfacial bonding between rubber particles and the geopolymer matrix leads to stress concentrations and early crack initiation;

- The hydrophobic nature of rubber particles can entrap air and increase the porosity of the geopolymer matrix, reducing its density and strength;

- Replacing stiffer natural aggregates with softer rubber particles alters the stress distribution within the matrix, resulting in a less efficient load transfer mechanism.

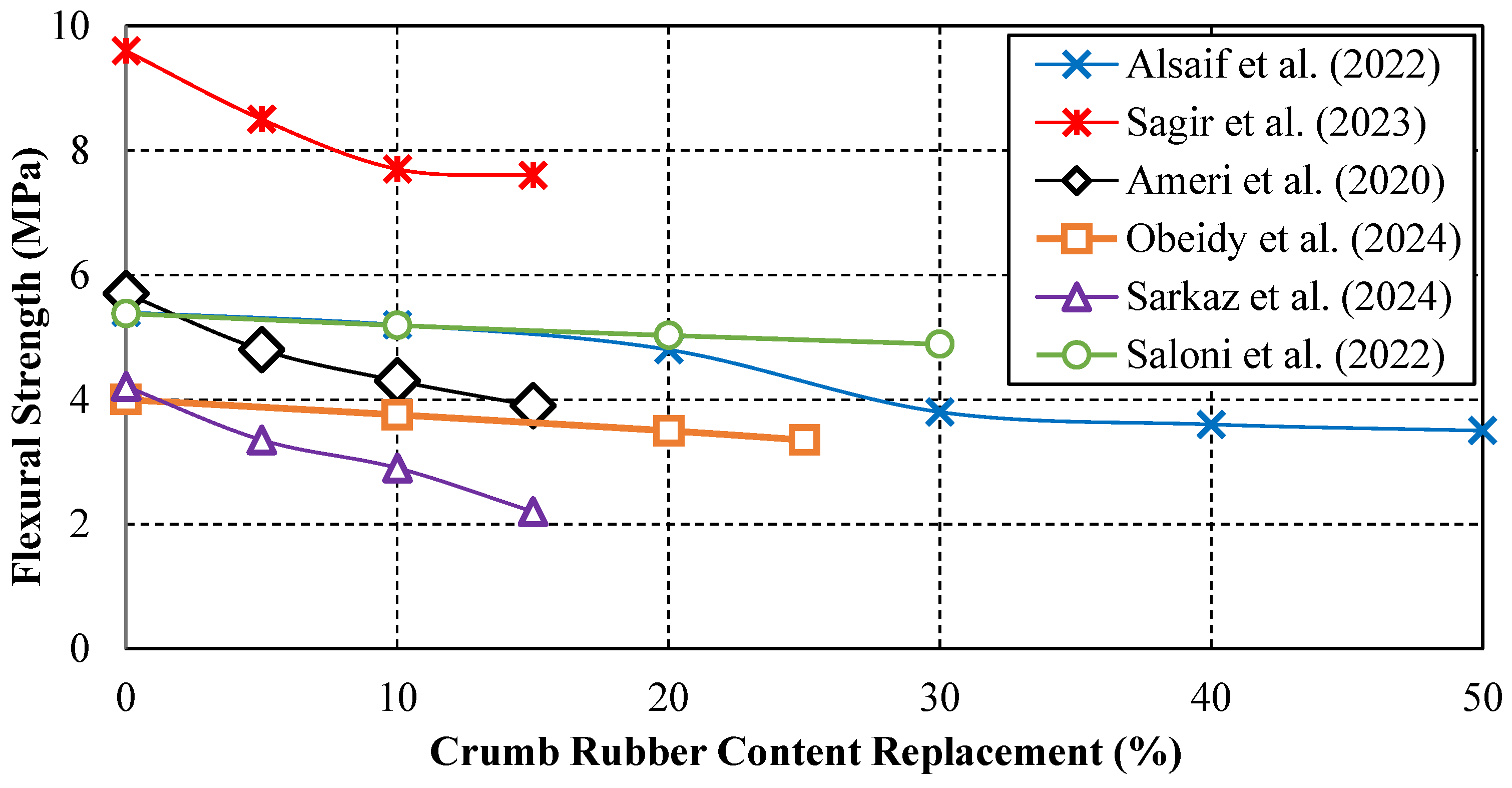

4.2.2. Flexural Strength

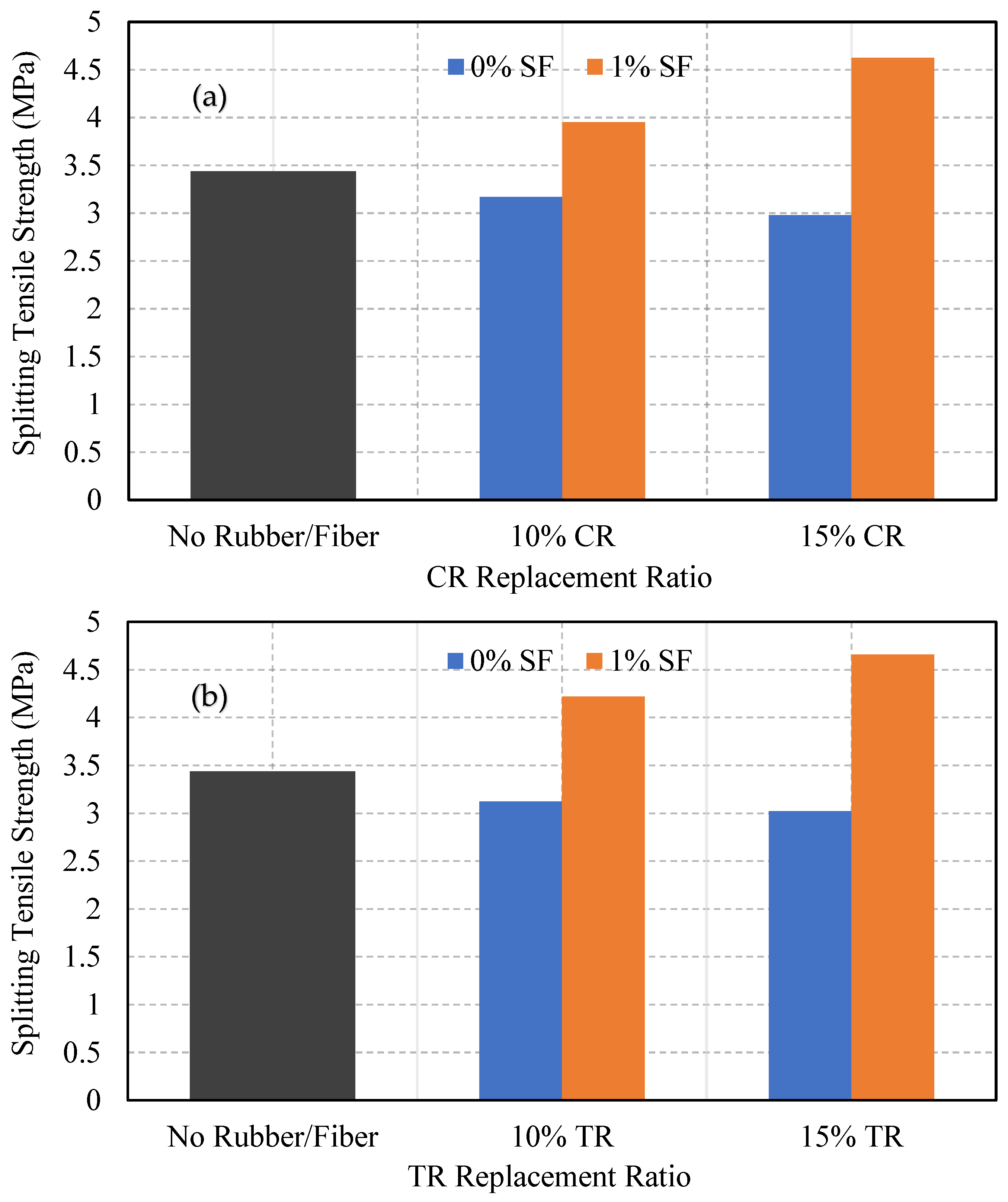

4.2.3. Splitting Tensile Strength

4.2.4. Modulus of Elasticity and Stress–Strain Relationship

5. Seismic Performance of RuAAC and Rubberized Concrete

5.1. Seismic Performance of RuAAC

5.1.1. RuAAC-Filled Steel Sections

5.1.2. Monotonic and Cyclic Stress–Strain Behavior

5.1.3. Finite Element Modeling of Damping Characteristics

5.2. Seismic Performance of Rubberized Concrete

6. Conclusions

6.1. Summary and Key Findings

- Material Components: FA and GGBFS serve as the main aluminosilicate precursors with NaOH and Na2SiO3 solutions as activators. Interface bonding improves through pretreatment methods like NaOH immersion and cement slurry coating.

- Fresh Properties: CR content affects mixtures by reducing workability/flowability and extending setting times. Both initial and final setting times increase with higher CR content.

- Physical Properties: Higher CR content consistently leads to increased water absorption and porosity in the hardened material.

- Mechanical Properties:

- ⚬

- Most mechanical properties decline with CR addition;

- ⚬

- Compressive strength shows major reduction (up to 63.2% at 50% CR);

- ⚬

- Flexural strength decreases more gradually than compressive strength;

- ⚬

- Elastic modulus typically decreases except for small improvements at 5% CR;

- ⚬

- Splitting tensile strength varies, with possible gains of up to 10% CR content.

- Dynamic Performance: CR enhances dynamic behavior through improved energy dissipation and damping. Analysis shows 10% rubber content optimizes damping, while yielding better seismic performance through reduced peak accelerations and enhanced deformability, which suggests potential applications such as in bridge bearings or seismic isolation layers.

6.2. Future Recommendations and Research Gaps

- Lack of studies on the effect of different types of fibers on RuAAC: While various rubber types have been studied in RuAAC, there is a notable absence of research investigating the incorporation of various types of fibers, such as steel, basalt, and carbon fibers, in RuAAC.

- Insufficient comparative studies of CR pretreatment effects on RuAAC: Comparative studies examining different rubber pretreatment methods and their influence on bond characteristics and mechanical and long-term performance remain scarce.

- Limited studies on the structural applications of RuAAC: While numerous studies have investigated the mechanical properties of RuAAC at the material level, there is a lack of research on its performance in structural-level elements such as beams, columns, slabs, and beam–column connections.

- Insufficient research on the seismic performance of RuAAC structural members: While extensive research highlighted the seismic behavior of rubberized concrete structures, the combination of these two materials (rubber + AAC) has not been adequately investigated in the context of seismic performance. Further studies are recommended to validate the energy dissipation of RuAAC structural members under cyclic loading.

- Limited experimental testing of large-scale RuAAC structural systems: The testing programs conducted previously for rubberized concrete structural systems, such as cyclic loading and shake table testing, have not been widely adopted for RuAAC. There is a pressing need for comprehensive experimental investigations to assess the structural behavior and seismic performance of RuAAC structural systems, particularly under actual earthquake loading.

- Impacts of construction technology and cost on RuAAC practical structural applications: Further studies are needed to verify the relative impacts of different construction technologies and related costs on RuAAC practical structural applications.

- Lack of standardized experimental protocols: The experimental conditions across different studies reviewed in the present study could be a limitation when conducting comparative analysis. Several measures were taken in the present study to address this issue, including comparing studies that use similar mix quantities in terms of CR content, sizes, and curing conditions, and focusing on percentage changes and trends rather than absolute values for mechanical property evaluation. However, standardized experimental protocols across the research community should be developed and adopted to enhance data comparability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| RuAAC | Rubberized alkali-activated concrete |

| CR | Crumb rubber |

| FA | Fly ash |

| GGBFS | Ground granulated blast furnace slag |

| NaOH | Sodium hydroxide |

| Na2SiO3 | Sodium silicate |

| AAC | Alkali-activated concrete |

| GPC | Geopolymer concrete |

| OPC | Ordinary Portland cement |

| CO2 | Carbon dioxide |

| UAE | United Arab Emirates |

| SS/SH | The ratio of Na2SiO3 to NaOH |

| Ca(OH)2 | Calcium hydroxide |

| BaCl2 | Barium chloride |

| KOH | Potassium hydroxide |

| K2SiO3 | Potassium silicate |

| UFS | Ultra-fine slag |

| CSH | Calcium silicate hydrate |

| SF | Steel fiber |

| TR | Tire rubber chips |

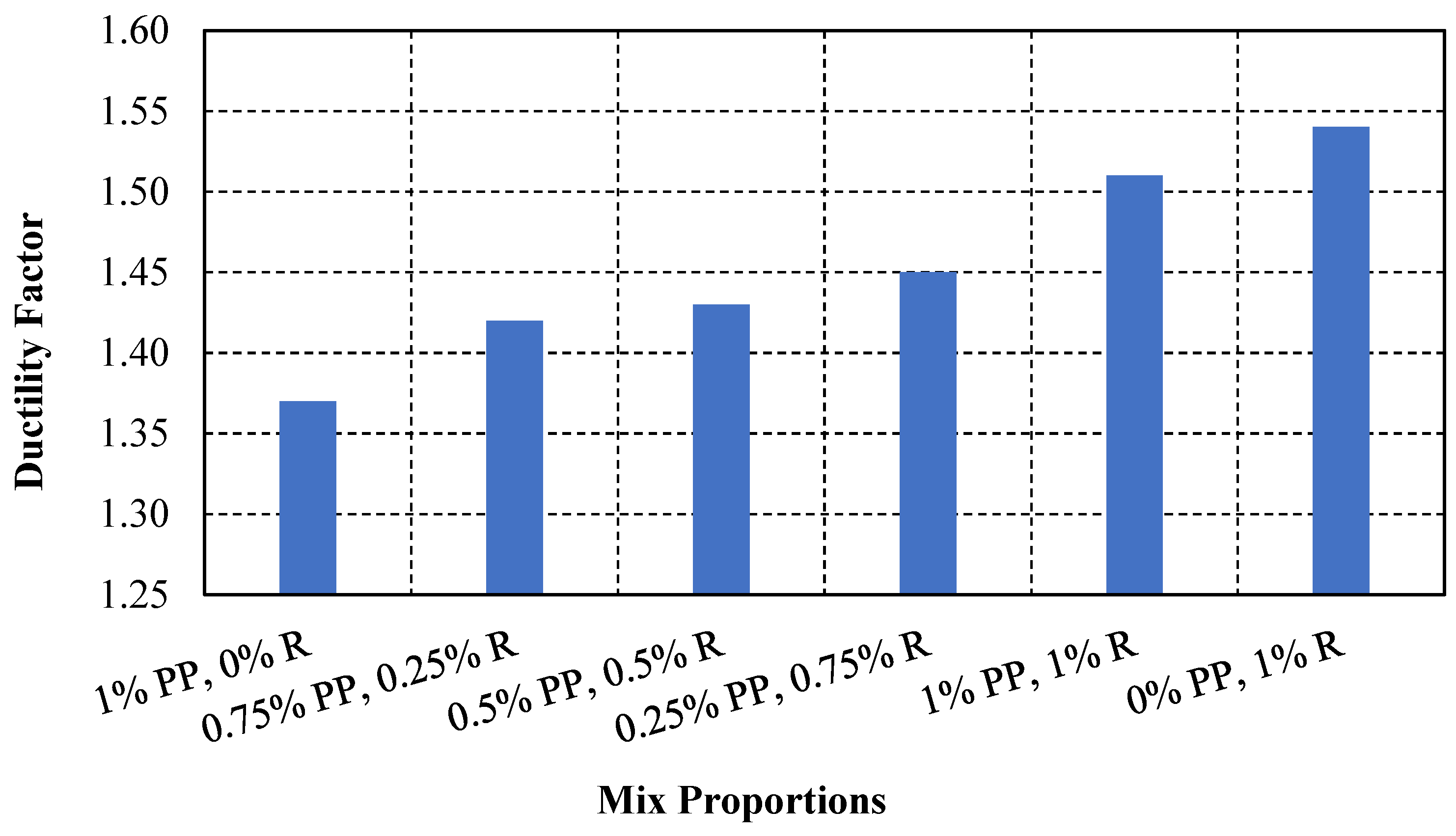

| PP | Polypropylene fiber |

| R | Rubber fiber |

| UN | United Nations |

| SDGs | Sustainable Development Goals |

References

- Zhang, G.-Y.; Wang, X.-Y. Carbon Peaking and Carbon Neutrality in the Cement-Based Materials. Materials 2023, 16, 4705. [Google Scholar] [CrossRef] [PubMed]

- Ślosarczyk, A.; Fořt, J.; Klapiszewska, I.; Thomas, M.; Klapiszewski, Ł.; Černý, R. A Literature Review of the Latest Trends and Perspectives Regarding Alkali-Activated Materials in Terms of Sustainable Development. J. Mater. Res. Technol. 2023, 25, 5394–5425. [Google Scholar] [CrossRef]

- Elbaz, Y.; Arab, M.G.; Omar, M. Effect of Macro-Synthetic Fibers on Treated Sandy Soil with Alkali Activated Binders. In Proceedings of the Geo-Congress 2022, Charlotte, NC, USA, 20–23 March 2022; American Society of Civil Engineers: Reston, VA, USA, 2022; pp. 615–623. [Google Scholar]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean Production and Properties of Geopolymer Concrete; A Review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A State-of-the-Art Review on the Durability of Geopolymer Concrete for Sustainable Structures and Infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Zhao, R.; Yuan, Y.; Cheng, Z.; Wen, T.; Li, J.; Li, F.; Ma, Z.J. Freeze-Thaw Resistance of Class F Fly Ash-Based Geopolymer Concrete. Constr. Build. Mater. 2019, 222, 474–483. [Google Scholar] [CrossRef]

- Han, B.; Kumar, D.; Pei, Y.; Norton, M.; Adams, S.D.; Khoo, S.Y.; Kouzani, A.Z. Sustainable Transformation of End-of-Life Tyres into Value-Added Products Using Thermochemical Processes. Carbon Res. 2024, 3, 73. [Google Scholar] [CrossRef]

- Grammelis, P.; Margaritis, N.; Dallas, P.; Rakopoulos, D.; Mavrias, G. A Review on Management of End of Life Tires (ELTs) and Alternative Uses of Textile Fibers. Energies 2021, 14, 571. [Google Scholar] [CrossRef]

- Formela, K. Sustainable Development of Waste Tires Recycling Technologies—Recent Advances, Challenges and Future Trends. Adv. Ind. Eng. Polym. Res. 2021, 4, 209–222. [Google Scholar] [CrossRef]

- Hamdi, A.; Abdelaziz, G.; Farhan, K.Z. Scope of Reusing Waste Shredded Tires in Concrete and Cementitious Composite Materials: A Review. J. Build. Eng. 2021, 35, 102014. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Preparation and Properties of Rubberised Geopolymer Concrete: A Review. Constr. Build. Mater. 2021, 313, 125504. [Google Scholar] [CrossRef]

- Niş, A.; Eren, N.A.; Çevik, A. Effects of Recycled Tyre Rubber and Steel Fibre on the Impact Resistance of Slag-Based Self-Compacting Alkali-Activated Concrete. Eur. J. Environ. Civ. Eng. 2023, 27, 519–537. [Google Scholar] [CrossRef]

- Che, W.; Li, L.; Chen, Z.; Liang, D.; Guo, Y. Impact Resistance of Rubberized Alkali-Activated Concrete Incorporating Recycled Aggregate and Recycled Steel Fiber. Buildings 2024, 14, 322. [Google Scholar] [CrossRef]

- Assaggaf, R.A.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Properties of Concrete with Untreated and Treated Crumb—A Review. J. Mater. Res. Technol. 2021, 11, 1753–1798. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, J.; Wu, J.; Zhao, C.; Zhang, B. Workability, Compressive Strength, and Microstructures of One-Part Rubberized Geopolymer Mortar. J. Build. Eng. 2023, 68, 106088. [Google Scholar] [CrossRef]

- Alsaif, A.; Albidah, A.; Abadel, A.; Abbas, H.; Al-Salloum, Y. Development of Metakaolin-Based Geopolymer Rubberized Concrete: Fresh and Hardened Properties. Arch. Civ. Mech. Eng. 2022, 22, 144. [Google Scholar] [CrossRef]

- Giri, Y.G.A.P.; Mohammed, B.S.; Liew, M.S.; Zawawi, N.A.W.A.; Abdulkadir, I.; Singh, P.; Ravindran, G. Mechanical and Microstructural Properties of Rubberized Geopolymer Concrete: Modeling and Optimization. Buildings 2023, 13, 2021. [Google Scholar] [CrossRef]

- Youssf, O.; Elchalakani, M.; Hassanli, R.; Roychand, R.; Zhuge, Y.; Gravina, R.J.; Mills, J.E. Mechanical Performance and Durability of Geopolymer Lightweight Rubber Concrete. J. Build. Eng. 2022, 45, 103608. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of Rubberized Geopolymer Concrete: Strength and Durability Studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Nicolaides, D.; Gupta, R. Durability Performance Evaluation of Rubberized Geopolymer Concrete. Sustainability 2021, 13, 5969. [Google Scholar] [CrossRef]

- Pham, T.M.; Liu, J.; Tran, P.; Pang, V.-L.; Shi, F.; Chen, W.; Hao, H.; Tran, T.M. Dynamic Compressive Properties of Lightweight Rubberized Geopolymer Concrete. Constr. Build. Mater. 2020, 265, 120753. [Google Scholar] [CrossRef]

- Yesilata, B.; Isıker, Y.; Turgut, P. Thermal Insulation Enhancement in Concretes by Adding Waste PET and Rubber Pieces. Constr. Build. Mater. 2009, 23, 1878–1882. [Google Scholar] [CrossRef]

- Arunkumar, K.; Muthukannan, M.; Suresh kumar, A.; Chithambar Ganesh, A. Mitigation of Waste Rubber Tire and Waste Wood Ash by the Production of Rubberized Low Calcium Waste Wood Ash Based Geopolymer Concrete and Influence of Waste Rubber Fibre in Setting Properties and Mechanical Behavior. Environ. Res. 2021, 194, 110661. [Google Scholar] [CrossRef]

- Su, H.; Yang, J.; Ling, T.-C.; Ghataora, G.S.; Dirar, S. Properties of Concrete Prepared with Waste Tyre Rubber Particles of Uniform and Varying Sizes. J. Clean. Prod. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Sathish Kumar, V.; Ganesan, N.; Indira, P.V.; Murali, G.; Vatin, N.I. Flexural Behaviour of Hybrid Fibre-Reinforced Ternary Blend Geopolymer Concrete Beams. Sustainability 2022, 14, 5954. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Praveen, B.; Kandasami, S.; Lubloy, E.; Naser, M.Z. Physical Characteristics and Mechanical Properties of a Sustainable Lightweight Geopolymer Based Self-Compacting Concrete with Expanded Clay Aggregates. Dev. Built Environ. 2023, 13, 100115. [Google Scholar] [CrossRef]

- El-Seidy, E.; Sambucci, M.; Chougan, M.; Al-Kheetan, M.J.; Biblioteca, I.; Valente, M.; Ghaffar, S.H. Mechanical and Physical Characteristics of Alkali- Activated Mortars Incorporated with Recycled Polyvinyl Chloride and Rubber Aggregates. J. Build. Eng. 2022, 60, 105043. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nematollahi, B.; Sanjayan, J.; Chindaprasirt, P. Mechanical and Thermal Properties of Lightweight Geopolymer Mortar Incorporating Crumb Rubber. J. Clean. Prod. 2018, 195, 1069–1080. [Google Scholar] [CrossRef]

- Arunkumar, K.; Sureshkumar, A.; Ganesh, A.C.; Parthiban, L.; Premkumar, V. Optimization of Hybrid Fibre Reinforced Geopolymer Concrete Using Hardened and Durability Properties. Res. Eng. Struct. Mater. 2023, 9, 113–130. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, D.; Xu, W.; Sun, J. Modeling of Damping Characteristics of Rubber Geopolymer Concrete Based on Finite Element Simulation. Buildings 2022, 12, 2142. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. One Part Alkali Activated Materials: A State-of-the-Art Review. J. Build. Eng. 2022, 57, 104871. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Shirkouh, A.H.; Soliman, A. Rubberized Alkali-Activated Concrete—A Review. In Canadian Society of Civil Engineering Annual Conference; Springer Nature: Singapore, 2023; pp. 561–570. [Google Scholar]

- Singh, R.J.; Raut, A. Insulation Effects of a Roof System Developed from Waste-Incorporated Geopolymer Concrete. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2023, 47, 3259–3276. [Google Scholar] [CrossRef]

- Raut, A.N.; Adamu, M.; Singh, R.J.; Ibrahim, Y.E.; Murmu, A.L.; Ahmed, O.S.; Janga, S. Investigating Crumb Rubber-Modified Geopolymer Composites Derived from Steel Slag for Enhanced Thermal Performance. Eng. Sci. Technol. Int. J. 2024, 59, 101880. [Google Scholar] [CrossRef]

- Dheyaaldin, M.H.; Bayraktar, O.Y.; Öz, A.; Kaplan, G. Sustainable Use of Waste Tire Rubbers in Eco-Friendly and Lightweight Alkali-Activated Slag–Silica Fume Mortars. J. Mater. Civ. Eng. 2024, 36, 04024432. [Google Scholar] [CrossRef]

- İpek, S.; Mermerdaş, K. Engineering Properties and SEM Analysis of Eco-Friendly Geopolymer Mortar Produced with Crumb Rubber. J. Sustain. Constr. Mater. Technol. 2022, 7, 95–107. [Google Scholar] [CrossRef]

- Rahman, S.H.A.; Farhan, S.A.; Sazali, Y.A.; Shafiee, L.H.; Husna, N.; Hamid, A.I.A.; Shafiq, N.; Zulkarnain, N.N.; Habarudin, M.F. Effect of Elastomeric Expandable Additive on Compressive Strength and Linear Expansion of Fly-Ash-Based Strength-Enhanced Geopolymer Cement for Shrinkage-Resistant Oil-Well Cementing. Appl. Sci. 2022, 12, 1897. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Ridtirud, C. High Calcium Fly Ash Geopolymer Containing Natural Rubber Latex as Additive. Int. J. GEOMATE 2020, 18, 124–129. [Google Scholar] [CrossRef]

- Sağır, M.A.; Karakoç, M.B.; Özcan, A.; Ekinci, E.; Yolcu, A. Effect of Silica Fume and Waste Rubber on the Performance of Slag-Based Geopolymer Mortars under High Temperatures. Struct. Concr. 2023, 24, 6690–6708. [Google Scholar] [CrossRef]

- Lương, Q.H.; Nguyễn, H.H.; Choi, J.I.; Kim, H.K.; Lee, B.Y. Effects of Crumb Rubber Particles on Mechanical Properties and Sustainability of Ultra-High-Ductile Slag-Based Composites. Constr. Build. Mater. 2021, 272, 121959. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Benli, A.; Bodur, B.; Öz, A.; Kaplan, G. Performance Assessment and Cost Analysis of Slag/Metakaolin Based Rubberized Semi-Lightweight Geopolymers with Perlite Aggregate: Sustainable Reuse of Waste Tires. Constr. Build. Mater. 2024, 411, 134655. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Reza Musaeei, H.; Alireza Zareei, S.; Cheah, C.B. Partial Replacement of Copper Slag with Treated Crumb Rubber Aggregates in Alkali-Activated Slag Mortar. Constr. Build. Mater. 2020, 256, 119468. [Google Scholar] [CrossRef]

- Al Obeidy, N.F.; Khalil, W.I. Properties of Modified Metakaolin-Based Geopolymer Concrete with Crumbed Rubber Waste from Damaged Car Tires. Res. Eng. Struct. Mater. 2024, 10, 209–231. [Google Scholar] [CrossRef]

- dos Reis Ferreira, R.A.; Gratão, L.S.; de Castro Motta, L.A. Evaluation and Optimization of the Replacement of Fine Aggregate by Waste Tire Rubber in Geopolymer Mortar with Metakaolin. Mech. Compos. Mater. 2024, 59, 1223–1238. [Google Scholar] [CrossRef]

- Iqbal, H.W.; Hamcumpai, K.; Nuaklong, P.; Jongvivatsakul, P.; Likitlersuang, S.; Pothisiri, T.; Chintanapakdee, C.; Wijeyewickrema, A.C. Enhancing Fire Resistance in Geopolymer Concrete Containing Crumb Rubber with Graphene Nanoplatelets. Constr. Build. Mater. 2024, 426, 136115. [Google Scholar] [CrossRef]

- John, S.K.; Nadir, Y.; Cascardi, A.; Arif, M.M.; Girija, K. Effect of Addition of Nanoclay and SBR Latex on Fly Ash-Slag Geopolymer Mortar. J. Build. Eng. 2023, 66, 105875. [Google Scholar] [CrossRef]

- Eren, N.A.; Çevik, A. Effects of Tire Crumb Rubber and Steel Fiber on Punching Shear Behavior of Two-Way Alkali-Activated Concrete Flat Slabs. Period. Polytech. Civ. Eng. 2024, 68, 248–259. [Google Scholar] [CrossRef]

- Abdelmonim, A.; Bompa, D.V. Mechanical and Fresh Properties of Multi-Binder Geopolymer Mortars Incorporating Recycled Rubber Particles. Infrastructures 2021, 6, 146. [Google Scholar] [CrossRef]

- Orhan, T.Y.; Karakoç, M.B.; Özcan, A. Durability Characteristics of Slag Based Geopolymer Concrete Modified with Crumb Rubber. Constr. Build. Mater. 2023, 404, 132851. [Google Scholar] [CrossRef]

- Yolcu, A.; Karakoç, M.B.; Ekinci, E.; Özcan, A.; Sağır, M.A. Effect of Binder Dosage and the Use of Waste Rubber Fiber on the Mechanical and Durability Performance of Geopolymer Concrete. J. Build. Eng. 2022, 61, 105162. [Google Scholar] [CrossRef]

- Zhong, H.; AlHuwaidi, A.; Zhang, Y.; Zhang, M. Effect of Crumb Rubber on Engineering Properties of Fly Ash-Slag Based Engineered Geopolymer Composites. Constr. Build. Mater. 2023, 409, 133878. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Elchalakani, M.; Mills, J.E.; Tayeh, B.A.; Saad Agwaa, I. Punching Shear Behaviour and Repair Efficiency of Reinforced Eco-Friendly Lightweight Concrete Slabs. Eng. Struct. 2023, 281, 115805. [Google Scholar] [CrossRef]

- Dong, M.; Elchalakani, M.; Karrech, A.; Yang, B. Strength and Durability of Geopolymer Concrete with High Volume Rubber Replacement. Constr. Build. Mater. 2021, 274, 121783. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.P.; Chen, Y.W.; Lin, J.X.; Lao, W.J.; Guo, Y.C.; Chen, Z.B.; Lan, X.W. Development of High Performance Geopolymer Concrete with Waste Rubber and Recycle Steel Fiber: A Study on Compressive Behavior, Carbon Emissions and Economical Performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Bayraktar, O.Y.; Tayeh, B.A.; Öz, A.; Özkan, İ.G.M.; Kaplan, G. Impact of Rice Husk Ash on Physico-Mechanical, Durability and Microstructural Features of Rubberized Lightweight Geopolymer Composite. Constr. Build. Mater. 2024, 427, 136265. [Google Scholar] [CrossRef]

- Hawa, A.; Salaemae, P.; Abdulmatin, A.; Ongwuttiwat, K.; Prachasearee, W. Properties of Palm Oil Ash Geopolymer Containing Alumina Powder and Field Para Rubber Latex. Civ. Eng. J. 2023, 9, 1271–1288. [Google Scholar] [CrossRef]

- Rath, B.; Praveenkumar, T.R.; Misgana, D.; Deo, S. Porosity of Calcined Clay-Based Geopolymer Concrete Incorporating Natural Rubber Latex. Innov. Infrastruct. Solut. 2022, 7, 163. [Google Scholar] [CrossRef]

- Zaetang, Y.; Wongsa, A.; Chindaprasirt, P.; Sata, V. Utilization of Crumb Rubber as Aggregate in High Calcium Fly Ash Geopolymer Mortars. Int. J. GEOMATE 2019, 17, 158–165. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Borges, P.H.R.; De Andrade Silva, F. Evaluation of Fiber–Matrix Bond in the Mechanical Behavior of Geopolymer Composites Reinforced with Natural Fibers. Adv. Civ. Eng. Mater. 2019, 8, 361–375. [Google Scholar] [CrossRef]

- Eisa, M.S.; Fahmy, E.A.; Basiouny, M.E. Using Metakaolin-Based Geopolymer Concrete in Concrete Pavement Slabs. Innov. Infrastruct. Solut. 2022, 7, 1. [Google Scholar] [CrossRef]

- Pradhan, S.S.; Mishra, U.; Biswal, S.K.; Jangra, P.; Pham, T.M.; Arora, S.; Lim, Y.Y. Effects of Crumb Rubber Inclusion on Strength, Permeability, and Acid Attack Resistance of Alkali-Activated Concrete Incorporating Different Industrial Wastes. Struct. Concr. 2022, 23, 3616–3630. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Experimental Assessment and Constitutive Modelling of Rubberised One-Part Alkali-Activated Concrete. Constr. Build. Mater. 2022, 353, 129161. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Reducing the Emission of Climate-Altering Substances in Cementitious Materials: A Comparison between Alkali-Activated Materials and Portland Cement-Based Composites Incorporating Recycled Tire Rubber. J. Clean. Prod. 2022, 333, 130013. [Google Scholar] [CrossRef]

- Arunkumar, K.; Muthukannan, M.; Kumar, A.S.; Ganesh, A.C.; Devi, R.K. Hybrid Fibre Reinforced Eco-Friendly Geopolymer Concrete Made with Waste Wood Ash: A Mechanical Characterization Study. Eng. Appl. Sci. Res. 2022, 49, 235–247. [Google Scholar] [CrossRef]

- Park, Y.; Abolmaali, A.; Kim, Y.H.; Ghahremannejad, M. Compressive Strength of Fly Ash-Based Geopolymer Concrete with Crumb Rubber Partially Replacing Sand. Constr. Build. Mater. 2016, 118, 43–51. [Google Scholar] [CrossRef]

- Gill, P. Parveen Development of Detailed Mix Design Methodology for Low Calcium Fly Ash Based Geopolymer Concrete Incorporating OPC and Crumb Rubber. Infrastructures 2022, 7, 149. [Google Scholar] [CrossRef]

- Goaiz, H.A.; Shamsaldeen, H.A.; Abdulrehman, M.A.; Al-Gasham, T.S. Evaluation of Steel Fiber Reinforced Geopolymer Concrete Made of Recycled Materials. Int. J. Eng. Trans. A Basics 2022, 35, 2018–2026. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.S.; Kohail, M.; Nasr, E.S.A.R. Performance of Geopolymer Concrete Containing Recycled Rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Iqbal, H.W.; Hamcumpai, K.; Nuaklong, P.; Jongvivatsakul, P.; Likitlersuang, S.; Chintanapakdee, C.; Wijeyewickrema, A.C. Effect of Graphene Nanoplatelets on Engineering Properties of Fly Ash-Based Geopolymer Concrete Containing Crumb Rubber and Its Optimization Using Response Surface Methodology. J. Build. Eng. 2023, 75, 107024. [Google Scholar] [CrossRef]

- Sarkaz, A.M.H.; Danish, A.; Memiş, S.; Yaprak, H.; Gencel, O.; Ozbakkaloglu, T. Performance Assessment and Economic and Ecological Analysis of Carbon-Negative Recycled Crumb Rubber-Based Geopolymers. J. Clean. Prod. 2024, 434, 139842. [Google Scholar] [CrossRef]

- Kuang, F.; Long, Z.; Kuang, D.; Guo, R.; Sun, J. Experimental Study on Preparation and Properties of Low Content Rubberized Geopolymer Mortar. Constr. Build. Mater. 2022, 352, 128980. [Google Scholar] [CrossRef]

- Mohana, R.; Bharathi, S.M.L. Eggshell Catalysed Rubber Aggregates for the Sustainable Green Mortar Constructions. Constr. Build. Mater. 2024, 420, 135475. [Google Scholar] [CrossRef]

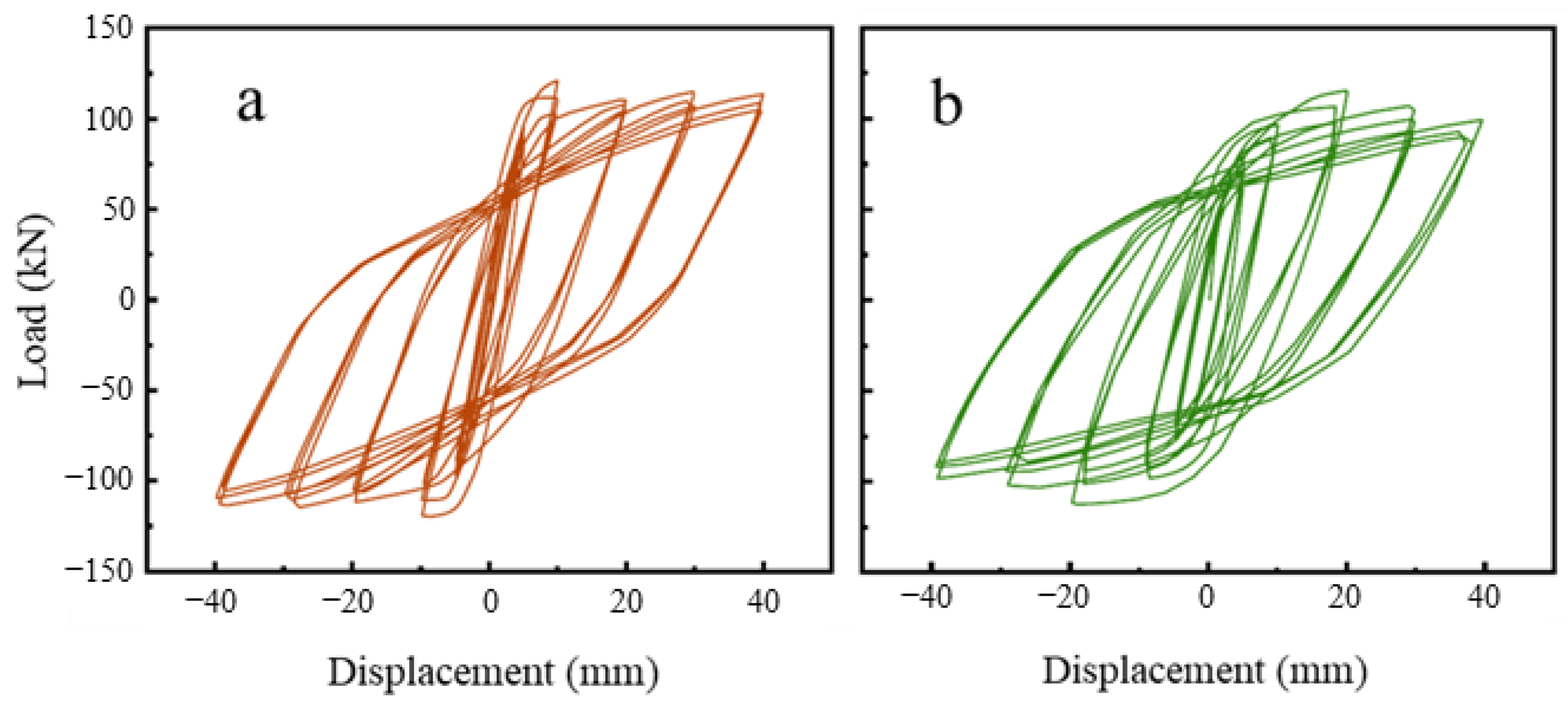

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Monotonic and Cyclic Constitutive Behaviour of Rubberised One-Part Alkali-Activated Concrete. Constr. Build. Mater. 2023, 368, 130414. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Compressive Behaviour of FRP-Confined Rubberised Alkali-Activated Concrete. Constr. Build. Mater. 2023, 409, 134110. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, Y.; Xie, J.; Lai, D.; Yu, T.; Huang, D. Rubberized Geopolymer Concrete: Dependence of Mechanical Properties and Freeze-Thaw Resistance on Replacement Ratio of Crumb Rubber. Constr. Build. Mater. 2021, 310, 125248. [Google Scholar] [CrossRef]

- Chaudhary, D.; Liu, H. Influence of High Temperature and High Acidic Conditions on Geopolymeric Composite Material for Steel Pickling Tanks. J. Mater. Sci. 2009, 44, 4472–4481. [Google Scholar] [CrossRef]

- Gill, P.; Jangra, P.; Roychand, R.; Saberian, M.; Li, J. Effects of Various Additives on the Crumb Rubber Integrated Geopolymer Concrete. Clean. Mater. 2023, 8, 100181. [Google Scholar] [CrossRef]

- Li, L.; Chen, Z.; Che, W.; Cheng, C.; Chen, Y.; Li, D.; Liu, L.; Guo, Y. Ultra-High-Performance Alkali-Activated Concrete: Effect of Waste Crumb Rubber Aggregate Proportions on Tensile and Flexural Properties. Buildings 2024, 14, 1088. [Google Scholar] [CrossRef]

- El-Yamany, H.E.; El-Salamawy, M.A.; El-Assal, N.T. Microstructure and Mechanical Properties of Alkali-Activated Slag Mortar Modified with Latex. Constr. Build. Mater. 2018, 191, 32–38. [Google Scholar] [CrossRef]

- Idrees, M.; Ameen, A.; Shi, J.; Saeed, F.; Gencel, O. Preparation and Performance Optimization of Eco-Friendly Geopolymers Prepared from Coarser Lignite-Based Waste Fly Ash. Constr. Build. Mater. 2023, 391, 131804. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Compressive and Splitting Tensile Impact Properties of Rubberised One-Part Alkali-Activated Concrete. J. Build. Eng. 2023, 71, 106596. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Creep Response of Rubberized Alkali-Activated Concrete. J. Mater. Civ. Eng. 2023, 35. [Google Scholar] [CrossRef]

- Rajendran, M.; Akasi, M. Performance of Crumb Rubber and Nano Fly Ash Based Ferro-Geopolymer Panels under Impact Load. KSCE J. Civ. Eng. 2020, 24, 1810–1820. [Google Scholar] [CrossRef]

- Sharkawi, A.; Taman, M.; Afefy, H.M.; Hegazy, Y. Efficiency of Geopolymer vs. High-Strength Grout as Repairing Material for Reinforced Cementitious Elements. Structures 2020, 27, 330–342. [Google Scholar] [CrossRef]

- Aslani, F.; Deghani, A.; Asif, Z. Development of Lightweight Rubberized Geopolymer Concrete by Using Polystyrene and Recycled Crumb-Rubber Aggregates. J. Mater. Civ. Eng. 2020, 32. [Google Scholar] [CrossRef]

- Lu, S.; Yang, J.; Wang, J.; Huang, L.; Wang, L. Behavior of Steel Tubed Rubberized Geopolymer Concrete Columns under Axial Compression: Experimental Study and Analytical Modeling. Eng. Struct. 2024, 302, 117389. [Google Scholar] [CrossRef]

- Hamidi, F.; Valizadeh, A.; Aslani, F. The Effect of Scoria, Perlite and Crumb Rubber Aggregates on the Fresh and Mechanical Properties of Geopolymer Concrete. Structures 2022, 38, 895–909. [Google Scholar] [CrossRef]

- Youssf, O.; Roychand, R.; Elchalakani, M.; Tahwia, A.M. Assessment of the Efficiency of Eco-Friendly Lightweight Concrete as Simulated Repair Material in Concrete Joints. Buildings 2024, 14, 37. [Google Scholar] [CrossRef]

- Saloni; Parveen; Lim, Y.Y.; Pham, T.M.; Negi, P. Performance Enhancement of Rubberised-Alkali-Activated-Concrete Utilising Ultra-Fine Slag and Fly Ash. Clean. Mater. 2022, 4, 100080. [Google Scholar] [CrossRef]

- Mohana, R.; Bharathi, S.M.L. Sustainable Approach of Promoting Impact Resistant Rubberized Geopolymer by Reducing the Embodied Emission Rate of Climate Changing Substances. Structures 2023, 57, 105241. [Google Scholar] [CrossRef]

- Xiao, R.; Shen, Z.; Si, R.; Polaczyk, P.; Li, Y.; Zhou, H.; Huang, B. Alkali-Activated Slag (AAS) and OPC-Based Composites Containing Crumb Rubber Aggregate: Physico-Mechanical Properties, Durability and Oxidation of Rubber upon NaOH Treatment. J. Clean. Prod. 2022, 367, 132896. [Google Scholar] [CrossRef]

- Saloni; Parveen; Pham, T.M.; Lim, Y.Y.; Malekzadeh, M. Effect of Pre-Treatment Methods of Crumb Rubber on Strength, Permeability and Acid Attack Resistance of Rubberised Geopolymer Concrete. J. Build. Eng. 2021, 41, 102448. [Google Scholar] [CrossRef]

- Liu, J.; Tran, P. Cement Mortar Containing Crumb Rubber Coated with Geopolymer: From Microstructural Properties to Compressive Strength. Constr. Build. Mater. 2023, 383, 131284. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Huang, Z.; Chen, W.; Ngo, T.T.; Hao, H.; Elchalakani, M. Effect of Fibre Reinforcements on Shear Capacity of Geopolymer Concrete Beams Subjected to Impact Load. Int. J. Impact. Eng. 2022, 159, 104056. [Google Scholar] [CrossRef]

- Dashti, P.; Ranjbar, S.; Ghafari, S.; Ramezani, A.; Nejad, F.M. RSM-Based and Environmental Assessment of Eco-Friendly Geopolymer Mortars Containing Recycled Waste Tire Constituents. J. Clean. Prod. 2023, 428, 139365. [Google Scholar] [CrossRef]

- Eren, N.A.; Alzeebaree, R.; Çevik, A.; Niş, A.; Mohammedameen, A.; Gülşan, M.E. The Effects of Recycled Tire Rubbers and Steel Fibers on the Performance of Self-Compacting Alkali Activated Concrete. Period. Polytech. Civ. Eng. 2021, 65, 890–900. [Google Scholar] [CrossRef]

- Shijagurumayum, C.; Singh, N.S.; Thokchom, S. Fibre Reinforced Alkali Activated Composites Exposed to Elevated Temperature. Eng. Appl. Sci. Res. 2022, 49, 593–602. [Google Scholar] [CrossRef]

- Zhong, H.; Poon, E.W.; Chen, K.; Zhang, M. Engineering Properties of Crumb Rubber Alkali-Activated Mortar Reinforced with Recycled Steel Fibres. J. Clean. Prod. 2019, 238, 117950. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M. Behavior of Alkali-Activated Slag Pastes Blended with Waste Rubber Powder under the Effect of Freeze/Thaw Cycles and Severe Sulfate Attack. Constr. Build. Mater. 2020, 265, 120716. [Google Scholar] [CrossRef]

- Zakeremamreza, A.; Kianifar, M.E.; Chibuisi, C.; Ahmadi, E.; Salami, M.R. A High-Performance Rubberised Alkali-Activated Mortar for Repair of RC Beams. Constr. Build. Mater. 2023, 400, 132610. [Google Scholar] [CrossRef]

- Yahya, Z.; Abdullah, M.M.A.B.; Ramli, S.N.H.; Minciuna, M.G.; Abd Razak, R. Durability of Fly Ash Based Geopolymer Concrete Infilled with Rubber Crumb in Seawater Exposure. In IOP Conference Series: Materials Science and Engineering; Sandu, A.V., Sandu, I., Abdullah, M.M.A.B., Vizureanu, P., Ghazali, C.M.R., Eds.; Institute of Physics Publishing: Bristol, UK, 2018; Volume 374. [Google Scholar] [CrossRef]

- Nurruddin, M.F.; Sani, H.; Mohammed, B.S.; Sha’aban, I. Methods of Curing Geopolymer Concrete: A Review. Int. J. Adv. Appl. Sci. 2018, 5, 31–36. [Google Scholar] [CrossRef]

- Muhammad, N.; Baharom, S.; Amirah Mohamed Ghazali, N.; Asiah Alias, N. Effect of Heat Curing Temperatures on Fly Ash-Based Geopolymer Concrete. Int. J. Eng. Technol. 2019, 8, 15–19. [Google Scholar] [CrossRef]

- Mermerdaş, K.; İpek, S.; Işıker, Y.; Rasool, H. Effect of Waste Tire Aggregate on Thermal and Strength Characteristics of Fly Ash–Based Geopolymer Composites Produced at Various Binder Contents. J. Mater. Civ. Eng. 2023, 35. [Google Scholar] [CrossRef]

- Yahya Mohammed Al-Fasih, M.; Fahim Huseien, G.; Syahrizal bin Ibrahim, I.; Rahman Mohd Sam, A.; Amer Algaifi, H.; Alyousef, R. Synthesis of Rubberized Alkali-Activated Concrete: Experimental and Numerical Evaluation. Constr. Build. Mater. 2021, 303, 124526. [Google Scholar] [CrossRef]

- Deng, Z.; Yang, Z.; Pan, X. Synergetic Effects of Recycled Crumb Rubber and Glass Cullet on the Engineering Properties of Geopolymer Mortar. Cem. Concr. Compos. 2023, 137, 104907. [Google Scholar] [CrossRef]

- Bostanci, L. Synergistic Effect of a Small Amount of Silica Aerogel Powder and Scrap Rubber Addition on Properties of Alkali-Activated Slag Mortars. Constr. Build. Mater. 2020, 250, 118885. [Google Scholar] [CrossRef]

- Azmi, A.A.; Al Bakri Abdullah, M.M.; Ruzaidi Ghazali, C.M.; Ahmad, R.; Jaya, R.P.; Abd Rahim, S.Z.; Almadani, M.A.; Wysłocki, J.J.; Śliwa, A.; Sandu, A.V. Crumb Rubber Geopolymer Mortar at Elevated Temperature Exposure. Arch. Civ. Eng. 2022, 68, 87–105. [Google Scholar] [CrossRef]

- Mucsi, G.; Szenczi, Á.; Nagy, S. Fiber Reinforced Geopolymer from Synergetic Utilization of Fly Ash and Waste Tire. J. Clean. Prod. 2018, 178, 429–440. [Google Scholar] [CrossRef]

- Charkhtab Moghaddam, S.; Madandoust, R.; Jamshidi, M.; Nikbin, I.M. Mechanical Properties of Fly Ash-Based Geopolymer Concrete with Crumb Rubber and Steel Fiber under Ambient and Sulfuric Acid Conditions. Constr. Build. Mater. 2021, 281, 122571. [Google Scholar] [CrossRef]

- Kuang, F.; Long, Z.; Kuang, D.; Guo, R.; Sun, J. Experimental Study on High Temperatures Performance of Rubberized Geopolymer Mortar. J. Build. Eng. 2023, 76, 107091. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Thermal Resistance of Fly Ash Based Rubberized Geopolymer Concrete. J. Build. Eng. 2018, 19, 420–428. [Google Scholar] [CrossRef]

- Thomas, R.J.; Peethamparan, S. Alkali-Activated Concrete: Engineering Properties and Stress–Strain Behavior. Constr. Build. Mater. 2015, 93, 49–56. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Li, L.; Cheng, B.; Zhang, Y.; Wei, Y. The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression. Materials 2020, 13, 4291. [Google Scholar] [CrossRef]

- Strukar, K.; Kalman Šipoš, T.; Dokšanović, T.; Rodrigues, H. Experimental Study of Rubberized Concrete Stress-Strain Behavior for Improving Constitutive Models. Materials 2018, 11, 2245. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.T.; Pham, T.M.; Hao, H. Rectangular Stress-Block Parameters for Fly-Ash and Slag Based Geopolymer Concrete. Structures 2019, 19, 143–155. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Axial Compressive Behaviour of Composite Steel Elements Incorporating Rubberised Alkali-Activated Concrete. J. Constr. Steel Res. 2024, 212, 108276. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.; Elghazouli, A. Axial Behaviour of Steel Tubes Infilled with Rubberised Alkali-activated Concrete. ce/papers 2023, 6, 154–159. [Google Scholar] [CrossRef]

- Elghazouli, A.Y.; Elzeadani, M.; Bompa, D.V. Inelastic Cyclic Behaviour of Steel Tubes Infilled with Rubberised Alkali-Activated Concrete. Eng. Struct. 2025, 325, 119490. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E. Experimental Investigation of Crumb Rubber Concrete Columns under Seismic Loading. Structures 2015, 3, 13–27. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Experimental Investigations of Reinforced Rubberized Concrete Structural Members. J. Build. Eng. 2017, 10, 149–165. [Google Scholar] [CrossRef]

- Ahmed, M.; Mohamed, H.-A.; Hassan, H.; Zaghlal, M. Rubberized Reinforced Concrete Columns under Axial and Cyclic Loading. Frat. Integrità Strutt. 2024, 18, 286–309. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, M.; Liu, B.; Geng, G.; Lin, B. Multi-Scale Study on the Crack Resistance and Energy Dissipation Mechanism of Modified Rubberized Concrete. Constr. Build. Mater. 2024, 457, 139448. [Google Scholar] [CrossRef]

- Khan, I.; Shahzada, K.; Bibi, T.; Ahmed, A.; Ullah, H. Seismic Performance Evaluation of Crumb Rubber Concrete Frame Structure Using Shake Table Test. Structures 2021, 30, 41–49. [Google Scholar] [CrossRef]

- Xue, J.; Shinozuka, M. Rubberized Concrete: A Green Structural Material with Enhanced Energy-Dissipation Capability. Constr. Build. Mater. 2013, 42, 196–204. [Google Scholar] [CrossRef]

- Moustafa, A.; Gheni, A.; ElGawady, M.A. Shaking-Table Testing of High Energy–Dissipating Rubberized Concrete Columns. J. Bridge Eng. 2017, 22. [Google Scholar] [CrossRef]

- Chao, L.; Li, A.; Wang, Y.; Deng, Y. Experimental Study on Seismic Performance of Crumb Rubber Aeolian Sand Concrete Columns. Structures 2024, 61, 105970. [Google Scholar] [CrossRef]

- Turatsinze, A.; Measson, M.; Faure, J.-P. Rubberised Concrete: From Laboratory Findings to Field Experiment Validation. Int. J. Pavement Eng. 2018, 19, 883–892. [Google Scholar] [CrossRef]

| Property | Traditional Concrete | RuAAC | Reference |

|---|---|---|---|

| Environmental Impact | High CO2 emissions | Reduced emissions from replacing cement with waste materials + waste tire utilization | [29] |

| Energy Absorption | Limited | Significantly enhanced | [13] |

| Thermal Insulation | Low | Enhanced | [30] |

| Compressive, Flexural, and Tensile Strength | High | Moderate (trade-off) | [30] |

| Ductility | Brittle | Enhanced flexibility | [31] |

| Seismic Performance | Standard | Excellent energy dissipation | [32] |

| Title | Year | Research Objective | Study Description |

|---|---|---|---|

| Scope of reusing waste shredded tires in concrete and cementitious composite materials: A review [11] | 2021 | To assess the feasibility of adding shredded tire CR waste to concrete and evaluate its environmental impact | Assessed the feasibility of incorporating shredded tire CR in concrete through a critical review of rheological, static/dynamic, mechanical, and durability properties. |

| Preparation and properties of rubberized geopolymer concrete: A review [12] | 2021 | To explore the integration of CR into AAC and evaluate its potential benefits | Examined compatibility between CR particles and alkali-activation matrix, highlighting limited studies on alternative aluminosilicate precursors as sustainable FA replacements. |

| One part alkali activated materials: A state-of-the-art review [33] | 2022 | To evaluate advancements in one-part AAMs incorporating CR aggregates | Highlighted the need for more comprehensive studies on the structural-level properties of one-part alkali-activated materials (AAMs) when incorporating CR and emphasized the lack of performance-based design standards for one-part AAMs. |

| Advancements in Characterization and Potential Structural Seismic Performance of Alkali-Activated Concrete Incorporating Crumb Rubber: A State-of-the-Art Review (Current Review) | 2025 | To examine RuAAC from material science to structural applications with a focus on seismic performance | This study examines RuAAC from material science to structural applications, with an emphasis on seismic performance. It explores recent research, identifies knowledge gaps, and offers recommendations for future studies. |

| Main information about the data | Sources (Journals) | 36 |

| Number of documents | 108 | |

| Average citations per document | 25 | |

| Documents’ contents | Keywords | 838 |

| Author’s keywords | 382 | |

| Authors’ information | Number of authors | 374 |

| Co-Authors per document | 4.47 | |

| Authors’ collaboration | International co-authorships % | 38 |

| Single-authored documents | 2 |

| Precursor Type | Percentage Range | Primary Role | References |

|---|---|---|---|

| Fly Ash (Class F) | 40–100% | Primary binder | [31,39,48,49,61] |

| GGBFS | 10–100% | Primary or secondary binder | [44,50,51,52,53] |

| Metakaolin | Up to 100% | Primary precursor | [18,47,62,63] |

| Rice Husk Ash | 15–30% | Supplementary precursor | [31,58,64] |

| Palm Oil Fly Ash | 10–30% | Partial precursor replacement | [36,59] |

| Silica Fume | - | Supplementary precursor | [20,42,65,66] |

| Calcined Clay | - | Supplementary precursor | [60] |

| Wood Ash | 10–30% | Partial precursor replacement | [25,31,67] |

| Activator Solutions | References |

|---|---|

| Sodium hydroxide (NaOH) | [18,48,50,57,63,68,69,72,73] |

| Sodium silicate (Na2SiO3) | [40,56,68,71,74] |

| Potassium hydroxide (KOH) | [75] |

| Potassium silicate (K2SiO3) | [75] |

| Anhydrous sodium metasilicate | [17,65,76,77] |

| Calcium hydroxide (Ca(OH)2) | [43] |

| Calcium silicate gel | [60] |

| Admixtures and Additives | Primary Role | References |

|---|---|---|

| Superplasticizers | Additive | [21,39,50,54,64,68,69,75,79,80] |

| Barium chloride (BaCl2) | Retarder | [17,57,78,81] |

| Styrene-butadiene rubber latex | Polymer additive | [82] |

| Polyvinyl alcohol | Polymer additive | [54] |

| Ethylene-vinyl acetate | Polymer additive | [83] |

| Borax | Admixture | [65,76,77,84,85] |

| NaHCO3, NaCl, C12H22O11 | Chemical additives | [83] |

| Additional water | Additive | [47,63,74,79,86,87] |

| Pretreatment Techniques | References |

|---|---|

| Water washing | [93,95] |

| NaOH immersion | [45,56,78,80,93,94,95] |

| Cement slurry coating | [93,95] |

| Ultra-fine slag (UFS) paste coating | [93,95] |

| Thermal pretreatment | [93] |

| Oxidation and sulphonation | [93] |

| Sulphuric acid treatment | [93] |

| Eggshell catalyzation | [75,93] |

| Geopolymer paste coating | [93,96] |

| Type of Fiber | Volume (%) | Length/Diameter | References |

|---|---|---|---|

| Hook-end steel fiber | 1 | 30 mm × 0.75 mm | [13,99] |

| Hooked-end steel fibers | 0.25, 0.5 | - | [100] |

| New hooked-end steel fiber | 0.5, 1.0, 1.5 | 25 mm × 0.5 mm | [70] |

| Polyvinyl alcohol fibers | 0.5, 1.0, 1.5 | - | [49,54] |

| Polypropylene fibers | 0, 0.5, 1, 1.5, 2 | 24 mm × 0.3 mm | [31] |

| Polypropylene fibers | 0.25, 0.5 | ~32.06 μm | [100] |

| Recycled steel fiber from tires | 0.5, 1.0, 1.5 | - | [14,57,101] |

| Micro steel fibers | 0.25, 0.5 | ~237.8 μm | [100] |

| Polyethylene fibers | 1.75 | - | [43] |

| Waste tire textile fibers | 0–0.4 | - | [98] |

| Waste tire steel fibers | 0–0.4 | - | [98] |

| Straight steel fibers | 2 | 13 mm × 0.2 mm | [57] |

| Glass fibers | 0.15, 0.30, 0.45 | - | [80] |

| Steel fibers | 0.5, 1.0, 1.5 | - | [80] |

| Recycled steel fibers | 2 | 9.92 mm × 0.3 mm | [57] |

| Property | Influencing Factor | Specific Effects on RuAAC | References |

|---|---|---|---|

| Workability and Flowability | CR content |

| [18,39,41,44,45,46,51,54,57,61,64,67,74,90,92,99,101,107] |

| CR particle size |

| ||

| CR surface treatment |

| ||

| Fiber content |

| ||

| Binder content |

| ||

| Activator concentration |

| ||

| Water-to-binder ratio |

| ||

| Setting Time | CR content |

| [25,41] |

| Water Absorption and Porosity | CR content |

| [31,46,47,56,61,64,74,103] |

| CR particle size |

| ||

| Curing time and temperature |

|

| Property | Influencing Factor | Specific Effects on RuAAC | References |

|---|---|---|---|

| Compressive Strength | CR particle size |

| [14,18,39,42,44,52,54,68,73,80,88,92,98,102,108,109,110,111] |

| CR surface treatment |

| ||

| NaOH molarity |

| ||

| Fiber content |

| ||

| CR content |

| ||

| Flexural Strength | CR particle size |

| [13,19,31,39,41,46,50,51,58,61,65,67,70,71,99,112] |

| CR surface treatment |

| ||

| Fiber content |

| ||

| CR content |

| ||

| Splitting Tensile Strength | Fiber content |

| [19,21,31,36,42,46,49,53,56,65,67,70,71,78,84,90,99,107,108,109,113] |

| CR content |

| ||

| Modulus of Elasticity | CR surface treatment |

| [14,18,21,36,64,65,76,78,85,90,92,95,96] |

| Fiber content |

| ||

| GGBFS content |

| ||

| CR content |

|

| Study | Experiment Type | Scope | Composition | Main Findings |

|---|---|---|---|---|

| Khan et al. [113] | Shake table testing |

| 15% CR |

|

| Xue et al. [114] | Free vibration and shaking table testing |

| 0%, 5%, 10%, 15%, 20% CR |

|

| Moustafa et al. [115] | Shake table testing |

| 20% CR |

|

| Chao et al. [116] | Cyclic loading tests |

| 10% CR and 30% aeolian sand |

|

| Kalman Šipoš et al. [117] | Cyclic loading tests |

| 10% and 15% CR | For Columns:

|

| Youssf et al. [123] | Axial compression and cyclic loading |

| 20% CR |

|

| Hassanli et al. [124] | Cyclic loading, eccentrically applied monotonic axial loading, free vibration tests (for beams) and finite element analysis |

| 0%, 6%, 12%, 18% CR | Beam Testing:

|

| Mohamed et al. [125] | Numerical analysis for cyclic loading, axial loading |

| 0%, 10%, and 15% CR |

|

| Zhang et al. [126] | Cyclic loading test |

|

| Enhanced damping properties:

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elbaz, Y.; Mwafy, A.; El-Hassan, H.; El-Maaddawy, T. Advancements in Characterization and Potential Structural Seismic Performance of Alkali-Activated Concrete Incorporating Crumb Rubber: A State-of-the-Art Review. Sustainability 2025, 17, 6043. https://doi.org/10.3390/su17136043

Elbaz Y, Mwafy A, El-Hassan H, El-Maaddawy T. Advancements in Characterization and Potential Structural Seismic Performance of Alkali-Activated Concrete Incorporating Crumb Rubber: A State-of-the-Art Review. Sustainability. 2025; 17(13):6043. https://doi.org/10.3390/su17136043

Chicago/Turabian StyleElbaz, Yousef, Aman Mwafy, Hilal El-Hassan, and Tamer El-Maaddawy. 2025. "Advancements in Characterization and Potential Structural Seismic Performance of Alkali-Activated Concrete Incorporating Crumb Rubber: A State-of-the-Art Review" Sustainability 17, no. 13: 6043. https://doi.org/10.3390/su17136043

APA StyleElbaz, Y., Mwafy, A., El-Hassan, H., & El-Maaddawy, T. (2025). Advancements in Characterization and Potential Structural Seismic Performance of Alkali-Activated Concrete Incorporating Crumb Rubber: A State-of-the-Art Review. Sustainability, 17(13), 6043. https://doi.org/10.3390/su17136043