Leveraging Milk-Traceability Technologies for Supply-Chain Performance: Evidence from Saudi Dairy Firms

Abstract

1. Introduction

- RQ. How can Saudi dairy firms leverage traceability technologies and overcome traceability challenges to improve supply chain performance?

- RQ1.1. What are the traceability challenges and barriers they face?

- RQ1.2. What factors determine the intention to adopt dairy traceability technologies in Saudi dairy firms?

- RQ1.3. How can food traceability technologies help improve the supply chain performance for dairy firms?

2. Literature Review

2.1. Saudi Dairy Sector and Its Supply Chain

2.2. Traceability Technologies

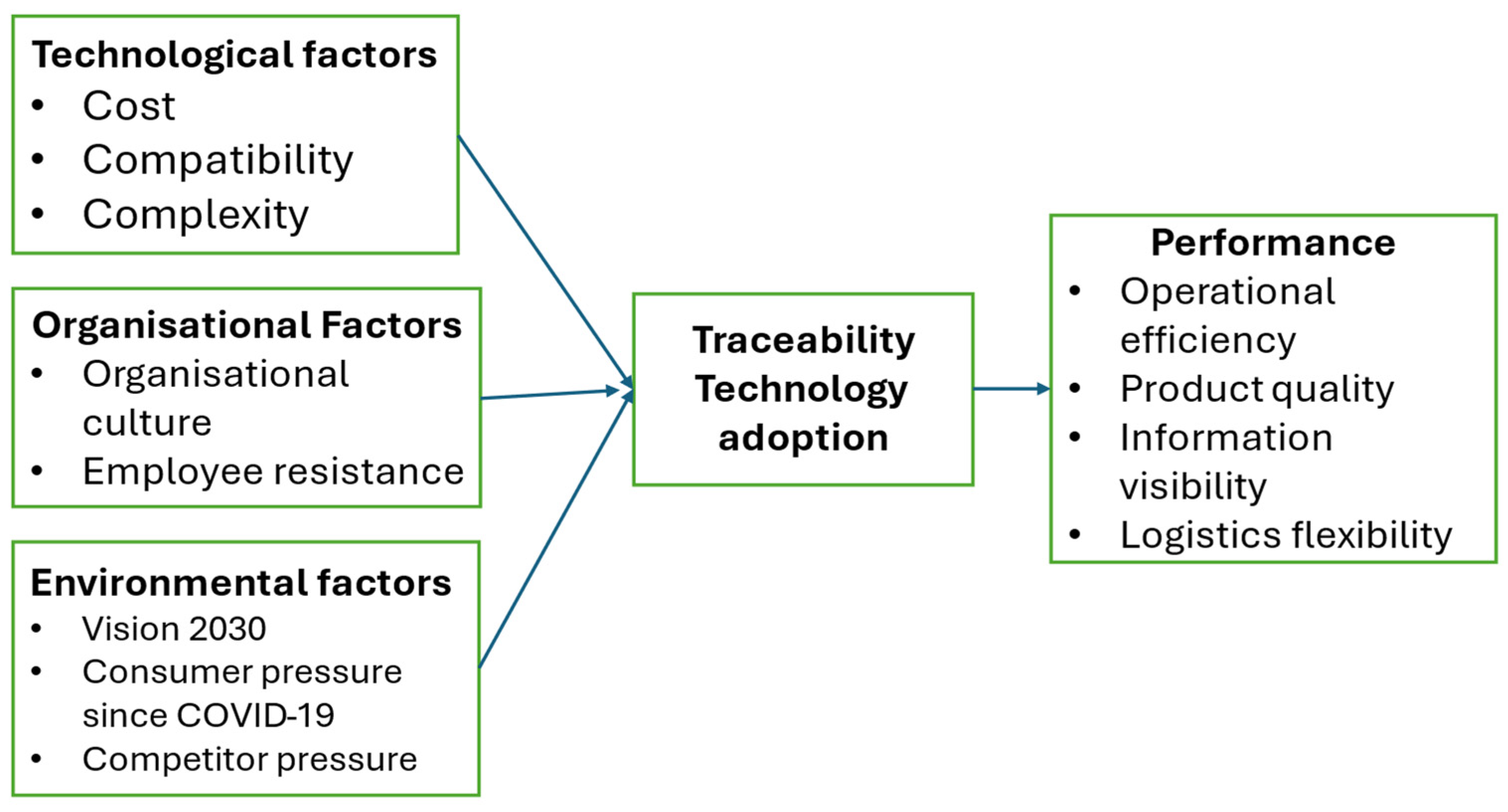

2.3. Technological, Organisational, and Environmental (TOE) Dimensions

2.3.1. Technological Factors

2.3.2. Organisational Factors

2.3.3. Environmental Factors

3. Methodology

3.1. Sampling and Data Collection

3.2. Data Analysis

3.3. Findings

3.4. Reliability and Validity of the Findings

4. Discussion and Implications

4.1. Development of Study Proposition

4.2. Theoretical Contribution

4.3. Practical Implications

5. Conclusions and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DOAJ | Directory of open access journals |

| TLA | Three letter acronym |

| LD | Linear dichroism |

References

- Melatu Samsi, S.Z.; Ibrahim, O.; Tasnim, R. Review on Knowledge Management as a Tool for Effective Traceability System in Halal Food Industry Supply Chain. J. Res. Innov. Inf. Syst. 2012, 1, 78–85. [Google Scholar]

- Zhou, X.; Xu, Z. Traceability in food supply chains: A systematic literature review and future research directions. Int. Food Agribus. Manag. Rev. 2022, 25, 173–196. [Google Scholar] [CrossRef]

- Aiyar, A.; Pingali, P. Pandemics and food systems-towards a proactive food safety approach to disease prevention & management. Food Secur. 2020, 12, 749–756. [Google Scholar] [PubMed]

- Wang, X.; Li, D.; O’brien, C. Optimisation of traceability and operations planning: An integrated model for perishable food production. Int. J. Prod. Res. 2009, 47, 2865–2886. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- Islam, S.; Cullen, J.M. Food traceability: A generic theoretical framework. Food Control 2021, 123, 107848. [Google Scholar] [CrossRef]

- ISO 12875:2011; Traceability of Finfish Products—Specification on the Information to be Recorded in Captured Finfish Distribution Chains. International Organization for Standardization: Geneva, Switzerland, 2011.

- Lin, X.; Chang, S.-C.; Chou, T.-H.; Chen, S.-C.; Ruangkanjanases, A. Consumers’ Intention to Adopt Blockchain Food Traceability Technology towards Organic Food Products. Int. J. Environ. Res. Public Health 2021, 18, 912–931. [Google Scholar] [CrossRef]

- Mattevi, M.; Jones, J.A. Traceability in the food supply chain: Awareness and attitudes of UK small and medium-sized enterprises. Food Control 2016, 64, 120–127. [Google Scholar] [CrossRef]

- Behnke, K.; Janssen, M. Boundary conditions for traceability in food supply chains using blockchain technology. Int. J. Inf. Manag. 2020, 52, 101969. [Google Scholar] [CrossRef]

- Shi, P.; Yan, B. Factors affecting RFID adoption in the agricultural product distribution industry: Empirical evidence from China. SpringerPlus 2016, 5, 2029. [Google Scholar] [CrossRef]

- Vishvakarma, N.K.; Singh, R.K.; Sharma, R. Cluster and DEMATEL analysis of key RFID implementation factors across different organizational strategies. Glob. Bus. Rev. 2022, 23, 176–191. [Google Scholar] [CrossRef]

- Verdouw, C.; Robbemond, R.M.; Wolfert, J. ERP in agriculture: Lessons learned from the Dutch horticulture. Comput. Electron. Agric. 2015, 114, 125–133. [Google Scholar] [CrossRef]

- Jayashankar, P.; Nilakanta, S.; Johnston, W.J.; Gill, P.; Burres, R. IoT adoption in agriculture: The role of trust, perceived value and risk. J. Bus. Ind. Mark. 2018, 33, 804–821. [Google Scholar] [CrossRef]

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldύ, F.X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 2019, 91, 640–652. [Google Scholar] [CrossRef]

- Zhou, X.; Pullman, M.; Xu, Z. The impact of food supply chain traceability on sustainability performance. Oper. Manag. Res. 2021, 15, 93–115. [Google Scholar] [CrossRef]

- Baralla, G.; Pinna, A.; Tonelli, R.; Marchesi, M.; Ibba, S. Ensuring transparency and traceability of food local products: A blockchain application to a Smart Tourism Region. Concurr. Comput. Pract. Exp. 2020, 33, e5857. [Google Scholar] [CrossRef]

- Casino, F.; Kanakaris, V.; Dasaklis, T.K.; Moschuris, S.; Stachtiaris, S.; Pagoni, M.; Rachaniotis, N.P. Blockchain-based food supply chain traceability: A case study in the dairy sector. Int. J. Prod. Res. 2020, 59, 5758–5770. [Google Scholar] [CrossRef]

- Ketokivi, M.; Choi, T. Renaissance of case research as a scientific method. J. Oper. Manag. 2014, 32, 232–240. [Google Scholar] [CrossRef]

- Cimmino, F.; Catapano, A.; Petrella, L.; Villano, I.; Tudisco, R.; Cavaliere, G. Role of Milk Micronutrients in Human Health. Front. Biosci.-Landmark 2023, 28, 41. [Google Scholar] [CrossRef]

- Zhong, Y.; Moon, H.C. Investigating the Impact of Industry 4.0 Technology through a TOE-Based Innovation Model. Systems 2023, 11, 277–298. [Google Scholar] [CrossRef]

- Lopes, B.; Falcão, L.; Canellas, T. Supply-Side: Mapping High Capacity Suppliers of Goods and Services. In Supply Chain and Logistics Management: Concepts, Methodologies, Tools, and Applications; I. R. Management Association: Hershey, PA, USA, 2020; pp. 1246–1264. [Google Scholar]

- de Vass, T.; Shee, H.; Miah, S.J. IoT in supply chain management: A narrative on retail sector sustainability. Int. J. Logist. Res. Appl. 2020, 24, 605–624. [Google Scholar] [CrossRef]

- Ahmed, W.A.; MacCarthy, B.L. Blockchain-enabled supply chain traceability—How wide? How deep? Int. J. Prod. Econ. 2023, 263, 108963. [Google Scholar] [CrossRef]

- Muduli, K.; Raut, R.; Narkhede, B.E.; Shee, H. (Eds.) Blockchain Technology for Enhancing Supply Chain Performance and Reducing the Threats Arising from the COVID-19 Pandemic; MDPI Publication: Basel, Switzerland, 2022; Available online: https://www.mdpi.com/books/pdfview/book/5318 (accessed on 25 June 2025).

- Mishra, D.; Muduli, K.; Raut, R.; Narkhede, B.E.; Shee, H.; Jana, S.K. Challenges Facing Artificial Intelligence Adoption during COVID-19 Pandemic: An Investigation into the Agriculture and Agri-Food Supply Chain in India. Sustainability 2023, 15, 6377. [Google Scholar] [CrossRef]

- Tóth, Z.; Sklyar, A.; Kowalkowski, C.; Sörhammar, D.; Tronvoll, B.; Wirths, O. Tensions in digital servitization through a paradox lens. Ind. Mark. Manag. 2022, 102, 438–450. [Google Scholar] [CrossRef]

- Lechler, S.; Canzaniello, A.; Roßmann, B.; von der Gracht, H.A.; Hartmann, E. Real-time data processing in supply chain management: Revealing the uncertainty dilemma. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 1003–1019. [Google Scholar] [CrossRef]

- Legenvre, H.; Hameri, A.-P. The emergence of data sharing along complex supply chains. Int. J. Oper. Prod. Manag. 2024, 44, 292–297. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J. The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australas. J. Inf. Syst. 2018, 22, 1–10. [Google Scholar] [CrossRef]

- Abad, E.; Palacio, F.; Nuin, M.; de Zárate, A.G.; Juarros, A.; Gómez, J.; Marco, S. RFID smart tag for traceability and cold chain monitoring of foods: Demonstration in an intercontinental fresh fish logistic chain. J. Food Eng. 2009, 93, 394–399. [Google Scholar] [CrossRef]

- Mainetti, L.; Patrono, L.; Stefanizzi, M.L.; Vergallo, R. An innovative and low-cost gapless traceability system of fresh vegetable products using RF technologies and EPCglobal standard. Comput. Electron. Agric. 2013, 98, 146–157. [Google Scholar] [CrossRef]

- Feng, J.; Fu, Z.; Wang, Z.; Xu, M.; Zhang, X. Development and evaluation on a RFID-based traceability system for cattle/beef quality safety in China. Food Control 2013, 31, 314–325. [Google Scholar] [CrossRef]

- Corallo, A.; Latino, M.E.; Menegoli, M.; Pontrandolfo, P. A systematic literature review to explore traceability and lifecycle relationship. Int. J. Prod. Res. 2020, 58, 4789–4807. [Google Scholar] [CrossRef]

- Pigini, D.; Conti, M. NFC-Based Traceability in the Food Chain. Sustainability 2017, 9, 1910. [Google Scholar] [CrossRef]

- El Matbouly, H.; Nikbakhtnasrabadi, F.; Dahiya, R. RFID Near-field Communication (NFC)-Based Sensing Technology in Food Quality Control. In Biosensing and Micro-Nano Devices: Design Aspects and Implementation in Food Industries; Chandra, P., Ed.; Springer Nature: Singapore, 2022; pp. 219–241. [Google Scholar]

- Ruiz-Garcia, L.; Lunadei, L.; Barreiro, P.; Robla, J.I. A Review of Wireless Sensor Technologies and Applications in Agriculture and Food Industry: State of the Art and Current Trends. Sensors 2009, 9, 4728–4750. [Google Scholar] [CrossRef]

- Xiao, X.; He, Q.; Li, Z.; Antoce, A.O.; Zhang, X. Improving traceability and transparency of table grapes cold chain logistics by integrating WSN and correlation analysis. Food Control 2017, 73, 1556–1563. [Google Scholar] [CrossRef]

- Kim, W.R.; Aung, M.M.; Chang, Y.S.; Makatsoris, C. Freshness Gauge based cold storage management: A method for adjusting temperature and humidity levels for food quality. Food Control 2015, 47, 510–519. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Andoni, M.; Robu, V.; Flynn, D.; Abram, S.; Geach, D.; Jenkins, D.; McCallum, P.; Peacock, A. Blockchain technology in the energy sector: A systematic review of challenges and opportunities. Renew. Sustain. Energy Rev. 2019, 100, 143–174. [Google Scholar] [CrossRef]

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Ølnes, S.; Ubacht, J.; Janssen, M. Blockchain in government: Benefits and implications of distributed ledger technology for information sharing. Gov. Inf. Q. 2017, 34, 355–364. [Google Scholar] [CrossRef]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture—Tuscany (IOT Tuscany), Tuscany, Italy, 8–9 May 2018. [Google Scholar]

- Surasak, T.; Wattanavichean, N.; Preuksakarn, C.; Huang, S.C. Thai agriculture products traceability system using blockchain and Internet of Things. Int. J. Adv. Comput. Sci. Appl. 2019, 10, 578–583. [Google Scholar] [CrossRef]

- Demestichas, K.; Peppes, N.; Alexakis, T.; Adamopoulou, E. Blockchain in Agriculture Traceability Systems: A Review. Appl. Sci. 2020, 10, 4113. [Google Scholar] [CrossRef]

- Compagnucci, L.; Lepore, D.; Spigarelli, F.; Frontoni, E.; Baldi, M.; Di Berardino, L. Uncovering the potential of blockchain in the agri-food supply chain: An interdisciplinary case study. J. Eng. Technol. Manag. 2022, 65, 101700. [Google Scholar] [CrossRef]

- Žurbi, T.; Gregor-Svetec, D. Use of QR code in dairy sector in Slovenia. SAGE Open 2023, 13, 21582440231177028. [Google Scholar] [CrossRef]

- Saurabh, S.; Dey, K. Blockchain technology adoption, architecture, and sustainable agri-food supply chains. J. Clean. Prod. 2021, 284, 124731. [Google Scholar] [CrossRef]

- Wang, N.; Li, Z. Wireless sensor networks (WSNs) in the agricultural and food industries. In Robotics and Automation in the Food Industry; Caldwell, D.G., Ed.; Woodhead Publishing: Sawston, UK, 2013; pp. 171–199. [Google Scholar]

- IFIF/FAO. Manual on Good Practices for the Feed Sector—Implementing the Codex Alimentarius Code of Practice on Good Animal Feeding; FAO: Rome, Italy, 2020; Available online: https://ifif.org/our-work/project/ifif-fao-feed-manual/ (accessed on 2 December 2024).

- Gangwar, H.; Date, H.; Ramaswamy, R. Understanding determinants of cloud computing adoption using an integrated TAM-TOE model. J. Enterp. Inf. Manag. 2015, 28, 107–130. [Google Scholar] [CrossRef]

- Gharaibeh, M.K.; Gharaibeh, N.K.; De Villiers, M.V. A Qualitative Method to Explain Acceptance of Mobile Health Application: Using Innovation Diffusion Theory. Int. J. Adv. Sci. Technol. 2020, 29, 3426–3432. [Google Scholar]

- Kalaitzi, D.; Jesus, V.; Campelos, I. Determinants of blockchain adoption and perceived benefits in food supply chains. In Logistics Research Network (LRN); University of Northampton: Northampton, UK, 2019. [Google Scholar]

- Tornatzky, L.G.; Fleischer, M. The Processes of Technological Innovation; Lexington, D.C. Heath & Company: Lexington, MA, USA, 1990. [Google Scholar]

- Shee, H.; Miah, S.; De Vass, T. Impact of smart logistics on smart city sustainable performance: An empirical investigation. Int. J. Logist. Manag. 2021, 32, 821–845. [Google Scholar] [CrossRef]

- Awa, H.O.; Ukoha, O.; Emecheta, B.C. Using T-O-E theoretical framework to study the adoption of ERP solution. Cogent Bus. Manag. 2016, 3, 1196571. [Google Scholar] [CrossRef]

- Gökalp, E.; Gökalp, M.O.; Çoban, S. Blockchain-based supply chain management: Understanding the determinants of adoption in the context of organizations. Inf. Syst. Manag. 2020, 39, 100–121. [Google Scholar] [CrossRef]

- Nam, K.; Dutt, C.S.; Chathoth, P.; Daghfous, A.; Khan, M.S. The adoption of artificial intelligence and robotics in the hotel industry: Prospects and challenges. Electron. Mark. 2020, 31, 553–574. [Google Scholar] [CrossRef]

- Orji, I.J.; Kusi-Sarpong, S.; Huang, S.; Vazquez-Brust, D. Evaluating the factors that influence blockchain adoption in the freight logistics industry. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 102025. [Google Scholar] [CrossRef]

- Siew, E.-G.; Rosli, K.; Yeow, P.H. Organizational and environmental influences in the adoption of computer-assisted audit tools and techniques (CAATTs) by audit firms in Malaysia. Int. J. Account. Inf. Syst. 2020, 36, 100445. [Google Scholar] [CrossRef]

- Clohessy, T.; Acton, T. Investigating the influence of organizational factors on blockchain adoption. Ind. Manag. Data Syst. 2019, 119, 1457–1491. [Google Scholar] [CrossRef]

- Zadeh, A.; Akinyemi, B.; Jeyaraj, A.; Zolbanin, H.M. Cloud ERP Systems for Small-and-Medium Enterprises: A Case Study in the Food Industry. J. Cases Inf. Technol. 2018, 20, 53–70. [Google Scholar] [CrossRef]

- Verma, S.; Bhattacharyya, S.S. Perceived strategic value-based adoption of Big Data Analytics in emerging economy. J. Enterp. Inf. Manag. 2017, 30, 354–382. [Google Scholar] [CrossRef]

- Battini, D.; Berti, N.; Finco, S.; Zennaro, I.; Das, A. Towards industry 5.0: A multi-objective job rotation model for an inclusive workforce. Int. J. Prod. Econ. 2022, 250, 108619. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 4th ed.; The Free Press: Los Angeles, CA, USA, 2010. [Google Scholar]

- Luomala, H.; Jokitalo, M.; Karhu, H.; Hietaranta-Luoma, H.-L.; Hopia, A.; Hietamäki, S. Perceived health and taste ambivalence in food consumption. J. Consum. Mark. 2015, 32, 290–301. [Google Scholar] [CrossRef]

- Chang, S.E.; Chen, Y.-C.; Lu, M.-F. Supply chain re-engineering using blockchain technology: A case of smart contract based tracking process. Technol. Forecast. Soc. Change 2019, 144, 1–11. [Google Scholar] [CrossRef]

- Hong, J.; Zhang, Y.; Ding, M. Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. J. Clean. Prod. 2018, 172, 3508–3519. [Google Scholar] [CrossRef]

- Jain, L.; Bhardwaj, S. Enterprise cloud computing: Key considerations for adoption. Int. J. Eng. Inf. Technol. Dev. 2010, 2, 113–117. [Google Scholar]

- Calisir, F.; Altin Gumussoy, C.; Bayram, A. Predicting the behavioral intention to use enterprise resource planning systems: An exploratory extension of the technology acceptance model. Manag. Res. News 2009, 32, 597–613. [Google Scholar] [CrossRef]

- Chen, H.; Tian, Z.; Xu, F. What are cost changes for produce implementing traceability systems in China? Evidence from enterprise A. Appl. Econ. 2018, 51, 687–697. [Google Scholar] [CrossRef]

- Peng, R.; Xiong, L.; Yang, Z. Exploring Tourist Adoption of Tourism Mobile Payment: An Empirical Analysis. J. Theor. Appl. Electron. Commer. Res. 2012, 7, 21–33. [Google Scholar] [CrossRef]

- Au, A.K.; Enderwick, P. A cognitive model on attitude towards technology adoption. J. Manag. Psychol. 2000, 15, 266–282. [Google Scholar]

- Sonnenwald, D.H.; Maglaughlin, K.L.; Whitton, M.C. Using innovation diffusion theory to guide collaboration technology evaluation: Work in progress. In Proceedings of the Tenth IEEE International Workshop on Enabling Technologies: Infrastructure for Collaborative Enterprises, WET ICE 2001, Cambridge, MA, USA, 20–22 June 2001. [Google Scholar]

- Chau, P.Y.; Hu, P.J.H. Information technology acceptance by individual professionals: A model comparison approach. Decis. Sci. 2001, 32, 699–719. [Google Scholar] [CrossRef]

- Parveen, F.; Sulaiman, A. Technology complexity, personal innovativeness and intention to use wireless internet using mobile devices in Malaysia. Int. Rev. Bus. Res. Pap. 2008, 4, 1–10. [Google Scholar]

- Lian, J.-W. Critical factors for cloud based e-invoice service adoption in Taiwan: An empirical study. Int. J. Inf. Manag. 2015, 35, 98–109. [Google Scholar] [CrossRef]

- Aldraehim, M.S.A. Cultural Impact on e-Service Use in Saudi Arabia. Ph.D. Thesis, Queensland University of Technology, Brisbane City, Australia, 2013. Available online: https://eprints.qut.edu.au/60899/3/Majid_Saad_Aldraehim_Thesis.pdf (accessed on 18 June 2025).

- AlBar, A.M.; Hoque, M.R. Factors affecting the adoption of information and communication technology in small and medium enterprises: A perspective from rural Saudi Arabia. Inf. Technol. Dev. 2019, 25, 715–738. [Google Scholar] [CrossRef]

- Alqahtani, A.S.; Goodwin, R.; de Vries, D. Cultural factors influencing e-commerce usability in Saudi Arabia. Int. J. Adv. Appl. Sci. 2018, 5, 1–10. [Google Scholar] [CrossRef]

- AlGhamdi, R.; Drew, S.; Al-Ghaith, W. Factors Influencing e-commerce Adoption by Retailers in Saudi Arabia: A qualitative analysis. Electron. J. Inf. Syst. Dev. Ctries. 2011, 47, 1–23. [Google Scholar] [CrossRef]

- Eid, M.I. Determinants of e-commerce customer satisfaction, trust, and loyalty in Saudi Arabia. J. Electron. Commer. Res. 2011, 12, 78–94. [Google Scholar]

- Ameen, N.; Willis, R. The effect of cultural values on technology adoption in the Arab countries. Int. J. Inf. Syst. 2015, 2, 1–7. [Google Scholar]

- Abunadi, I. Influence of Culture on e-Government Acceptance in Saudi Arabia. Ph.D. Thesis, Griffith University, Brisbane City, Australia, 2013. [Google Scholar] [CrossRef]

- Al-Ghaith, W.A. Applying decomposed theory of planned behaviour towards a comprehensive understanding of social network usage in Saudi Arabia. Int. J. Inf. Technol. Comput. Sci. 2016, 8, 52–72. [Google Scholar] [CrossRef]

- Gangwar, H.; Date, H.; Raoot, A. Review on IT adoption: Insights from recent technologies. J. Enterp. Inf. Manag. 2014, 27, 488–502. [Google Scholar] [CrossRef]

- Low, C.; Chen, Y.; Wu, M. Understanding the determinants of cloud computing adoption. Ind. Manag. Data Syst. 2011, 111, 1006–1023. [Google Scholar] [CrossRef]

- Salwani, M.I.; Marthandan, G.; Norzaidi, M.D.; Chong, S.C. Information Management & Computer Security. E-commerce usage and business performance in the Malaysian tourism sector: Empirical analysis. Inf. Manag. Comput. Secur. 2009, 17, 166–185. [Google Scholar]

- Ramdani, B.; Kawalek, P.; Lorenzo, O.; Dwivedi, Y.K. Predicting SMEs’ adoption of enterprise systems. J. Enterp. Inf. Manag. 2009, 22, 10–24. [Google Scholar] [CrossRef]

- Teo, T.S.; Lin, S.; Lai, K.-H. Adopters and non-adopters of e-procurement in Singapore: An empirical study. Omega 2009, 37, 972–987. [Google Scholar] [CrossRef]

- Wang, Y.-M.; Wang, Y.-S.; Yang, Y.-F. Understanding the determinants of RFID adoption in the manufacturing industry. Technol. Forecast. Soc. Change 2010, 77, 803–815. [Google Scholar] [CrossRef]

- Li, W.; Bhutto, T.A.; Nasiri, A.R.; Shaikh, H.A.; Samo, F.A. Organizational innovation: The role of leadership and organizational culture. Int. J. Public Leadersh. 2017, 14, 33–47. [Google Scholar] [CrossRef]

- Schillewaert, N.; Ahearne, M.J.; Frambach, R.T.; Moenaert, R.K. The adoption of information technology in the sales force. Ind. Mark. Manag. 2005, 34, 323–336. [Google Scholar] [CrossRef]

- Rizou, M.; Galanakis, I.M.; Aldawoud, T.M.; Galanakis, C.M. Safety of foods, food supply chain and environment within the COVID-19 pandemic. Trends Food Sci. Technol. 2020, 102, 293–299. [Google Scholar] [CrossRef]

- Liu, R.; Gao, Z.; Nayga, R.M., Jr.; Snell, H.A.; Ma, H. Consumers’ valuation for food traceability in China: Does trust matter? Food Policy 2019, 88, 101768. [Google Scholar] [CrossRef]

- Lusk, J.L.; Tonsor, G.T.; Schroeder, T.C.; Hayes, D.J. Effect of government quality grade labels on consumer demand for pork chops in the short and long run. Food Policy 2018, 77, 91–102. [Google Scholar] [CrossRef]

- Matias, J.B.; Hernandez, A.A. Cloud Computing Adoption Intention by MSMEs in the Philippines. Glob. Bus. Rev. 2019, 22, 612–633. [Google Scholar] [CrossRef]

- Hsu, P.-F.; Ray, S.; Li-Hsieh, Y.-Y. Examining cloud computing adoption intention, pricing mechanism, and deployment model. Int. J. Inf. Manag. 2014, 34, 474–488. [Google Scholar] [CrossRef]

- Ifinedo, P. Internet/e-business technologies acceptance in Canada’s SMEs: An exploratory investigation. Internet Res. 2011, 21, 255–281. [Google Scholar] [CrossRef]

- Reid, G.; O’Beirne, N.; Gibson, N. How Companies Can Reshape Results and Plan for a COVID-19 Recovery. EY. 2020. Available online: https://www.esba-europe.org/wp-content/uploads/2020/09/HowCompaniescanreshaperesultsandplanforaCOVID-19recovery-EY.pdf (accessed on 25 June 2025).

- Hahn, S.M. Pandemic Challenges Highlight the Importance of the New Era of Smarter Food Safety. 2020. Available online: https://www.food-safety.com/articles/6691-pandemic-challenges-highlight-the-importance-of-the-new-era-of-smarter-food-safety (accessed on 25 June 2025).

- Galanakis, C.M.; Rizou, M.; Aldawoud, T.M.S.; Ucak, I.; Rowan, N.J. Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends Food Sci. Technol. 2021, 110, 193–200. [Google Scholar] [CrossRef]

- Gao, Z.; Schroeder, T.C. Effects of label information on consumer willingness-to-pay for food attributes. Am. J. Agric. Econ. 2009, 91, 795–809. [Google Scholar] [CrossRef]

- Wongprawmas, R.; Canavari, M. Consumers’ willingness-to-pay for food safety labels in an emerging market: The case of fresh produce in Thailand. Food Policy 2017, 69, 25–34. [Google Scholar] [CrossRef]

- Marchant-Forde, J.N.; Boyle, L.A. COVID-19 effects on livestock production: A one welfare issue. Front. Vet. Sci. 2020, 7, 585787. [Google Scholar]

- Dandage, K.; Badia-Melis, R.; Ruiz-García, L. Indian perspective in food traceability: A review. Food Control 2017, 71, 217–227. [Google Scholar] [CrossRef]

- Jin, S.; Zhou, L. Consumer interest in information provided by food traceability systems in Japan. Food Qual. Prefer. 2014, 36, 144–152. [Google Scholar] [CrossRef]

- Wu, L.; Wang, H.; Zhu, D.; Hu, W.; Wang, S. Chinese consumers’ willingness to pay for pork traceability information—The case of Wuxi. Agric. Econ. 2016, 47, 71–79. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Wamba, S.F. A conceptual framework of RFID adoption in retail using TOE framework. In Technology Adoption and Social Issues: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, 2018; pp. 69–102. [Google Scholar]

- NILDP. National Industrial Development and Logistics Program. 2025. Available online: https://www.vision2030.gov.sa/en/explore/programs/national-industrial-development-and-logistics-program (accessed on 25 June 2025).

- Taboada, I.; Shee, H. Understanding 5G technology for future supply chain management. Int. J. Logist. Res. Appl. 2020, 24, 392–406. [Google Scholar] [CrossRef]

- Alshuaibi, A. Technology as an important role in the implementation of Saudi Arabia’s vision 2030. Int. J. Bus. Humanit. Tchnology 2017, 7, 52–62. [Google Scholar]

- Asharq, A.-A. Saudi Dairy Industry Produces 7 Million Liters per Day. Saudi 24 News. 2021. Available online: https://english.aawsat.com/home/article/2876816/saudi-dairy-industry-produces-7-million-liters-daily?_wrapper_format=html&page=7 (accessed on 25 June 2025).

- Creswell, W. Research Design, Qualitative, Quantitave, and Mixed Methods Approaches, 4th ed.; Knight, V., Ed.; SAGE Publications Inc.: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Kallio, H.; Pietilä, A.; Johnson, M.; Kangasniemi, M. Systematic methodological review: Developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 2016, 72, 2954–2965. [Google Scholar] [CrossRef]

- Denzin, N.; Lincoln, Y. The Landscape of Qualitative Research: Theories and Issues; SAGE Publications Inc.: Thousand Oaks, CA, USA, 1998; Volume 1, Available online: https://library.wur.nl/WebQuery/titel/938654 (accessed on 25 June 2025).

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; SAGE Publications Inc.: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Fereday, J.; Muir-Cochrane, E. Demonstrating rigor using thematic analysis: A hybrid approach of inductive and deductive coding and theme development. Int. J. Qual. Methods 2006, 5, 80–92. [Google Scholar] [CrossRef]

- Nitaqat. Nitaqat Mutawar Program. 2024. Available online: https://www.hrsd.gov.sa/en/knowledge-centre/decisions-and-regulations/regulation-and-procedures/832742 (accessed on 5 January 2024).

- Yin, R.K. Case Study Research and Applications Design and Methods, 6th ed.; SAGE Publications Inc.: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Simpson, D.; Segrave, M.; Quarshie, A.; Kach, A.; Handfield, R.; Panas, G.; Moore, H. The role of psychological distance in organizational responses to modern slavery risk in supply chains. J. Oper. Manag. 2021, 67, 989–1016. [Google Scholar] [CrossRef]

- Leonard-Barton, D. A dual methodology for case studies: Synergistic use of a longitudinal single site with replicated multiple sites. Organ. Sci. 1990, 1, 248–266. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M. Qualitative Data Analysis: A Sourcebook of New Methods; SAGE Publications Inc.: Thousand Oaks, CA, USA, 1984. [Google Scholar]

- Wong, L.-W.; Leong, L.-Y.; Hew, J.-J.; Tan, G.W.-H.; Ooi, K.-B. Time to seize the digital evolution: Adoption of blockchain in operations and supply chain management among Malaysian SMEs. Int. J. Inf. Manag. 2020, 52, 101997. [Google Scholar] [CrossRef]

- Alsheddi, A. The Impact of Socio-Cultural and Religious Values on the Adoption of Technological Innovation: A Case Study of Saudi Arabia. Ph.D. Thesis, University of Canberra, Canberra, Australia, 2020. [Google Scholar]

- Hu, H.; Hu, P.J.-H.; Al-Gahtani, S.S. User acceptance of computer technology at work in Arabian culture: A model comparison approach. In Technology Adoption and Social Issues: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, 2018; pp. 1521–1544. [Google Scholar]

| Technologies | Purpose | Example | Features and Observations |

|---|---|---|---|

| Near Field Communication (NFC) | Identification | [35] |

|

| Barcode | Identification | [48] |

|

| Radio Frequency Identification (RFID) | Identification | [11] |

|

| Blockchain | Data Integration | [49] |

|

| Internet of Things (IoT) | Data Integration | [30] |

|

| Wireless Sensor Network (WSN) | Data Integration | [50] |

|

| Sl. No | Authors | Study Focus | Technological Factors | Organisational Factors | Environmental Factors |

|---|---|---|---|---|---|

| 1 | [21] | Industry 4.0 Technology | Compatibility, cost | Top management support, employee capability | Competitive pressure |

| 2 | [58] | Blockchain technology | Complexity, relative advantage compatibility, trust, and scalability. | Organisations’ IT resources, top management support, size, financial resources | Competitive pressure, trading partner pressure, government policy and regulations, inter-organisational trust |

| 3 | [59] | Artificial intelligence and robotics | Internal and External IT expertise, relative advantage, complexity. | Market position, financial justification, resistance by employees | Customer readiness, and expectation, competition, legal issues |

| 4 | [60] | Blockchain technology | Infrastructural facility, complexity, availability of specific blockchain tools perceived benefits, privacy, compatibility, security | Presence of training facilities, top management support, firm size, capability of human resources, perceived costs, organisational culture | Government policies, competitive pressure, institutional-based trust, market turbulence, stakeholder pressure |

| 5 | [61] | Computer-assisted audit tools and techniques (CAATTs) | n/a | Firm size, top management commitment, employee IT competency | Complexity of clients’ accounting information systems, level of support of professional accounting bodies |

| 6 | [62] | Blockchain technology | n/a | Top management support, organisational readiness, organisation size | n/a. |

| 7 | [63] | Cloud computing | Compatibility, relative advantage, complexity, ease of use, trialability, technology integration | Firm size | Competitive intensity, regulatory support |

| 8 | [64] | Big data analytics | Complexity, compatibility, IT assets. | Top management support, organisation data environment, perceived costs | External pressure, industry type |

| 9 | [57] | Enterprise resource planning (ERP) software | Technical know-how, compatibility, value, security, technology infrastructure | demographic composition, size, scope of business operations, subjective norms | Competitive pressure, external support, trading partners’ readiness |

| Code | Work Exp. | Job Title | Firm Size | First Adopted FTT |

|---|---|---|---|---|

| A | 32 | Head of quality | Large | 2002 |

| B | 14 | Supply chain manager | Large | 2011 |

| C | 21 | Senior director of manufacturing | Large | 2010 |

| D | 19 | Head of Production | Large | 2013 |

| E | 26 | Supply chain manager | Medium | 2019 |

| F | 21 | The CEO | Medium | Not yet—adopted |

| G | 20 | Supply chain manager | Medium | 2014 |

| H | 17 | Plant manager | Small | Not yet—adopted |

| J | 18 | Manufacturing Manager | Small | Not yet—adopted |

| Code | Age | Gender | Citizenship | Job Role | Experience (Years) | Firm Size | Location | Traceability Technologies Adopted |

|---|---|---|---|---|---|---|---|---|

| P1 | 52 | Male | Non-citizen | Head of quality | 32 | Large | Riyadh | 2002 |

| P2 | 37 | Male | Citizen | Supply chain manager | 14 | Large | Alahsa | 2011 |

| P3 | 46 | Male | Citizen | Senior director of manufacturing | 21 | Large | Riyadh | 2010 |

| P4 | 45 | Male | Citizen | Head of production | 19 | Large | Jeddah | 2013 |

| P5 | 50 | Male | Non-citizen | Supply chain manager | 26 | Medium | Alahsa | 2019 |

| P6 | 46 | Male | Citizen | The CEO | 21 | Medium | Alqassim | Not yet—adopted |

| P7 | 47 | Male | Non-citizen | Supply chain manager | 20 | Medium | Alahsa | 2014 |

| P8 | 43 | Male | Non-citizen | Plant manager | 17 | Small | Alqassim | Not yet—adopted |

| P9 | 41 | Male | Citizen | Manufacturing manager | 18 | Small | Jeddah | Not yet—adopted |

| Themes | P2 | P9 | P5 | P3 | P4 | P6 | P8 | P7 | P1 |

|---|---|---|---|---|---|---|---|---|---|

| Technology adoption | 21.06 | 12.06 | 10.96 | 13.67 | 9.1 | 7.97 | 7.19 | 8.39 | 9.6 |

| Environment | 29.53 | 13.32 | 12.68 | 16.85 | 8.99 | 2.73 | 4.65 | 4.98 | 6.26 |

| Competitors | 4.25 | 20.4 | 15.01 | 27.2 | 3.4 | 4.82 | 8.22 | 5.67 | 11.05 |

| Consumer pressure | 62.59 | 4.07 | 9.63 | 3.33 | 16.3 | 0 | 0 | 4.07 | 0 |

| Consumer Awareness | 62.59 | 4.07 | 9.63 | 3.33 | 16.3 | 0 | 0 | 4.07 | 0 |

| Government Support | 24.04 | 11.86 | 16.67 | 10.26 | 8.97 | 11.54 | 8.01 | 4.49 | 4.17 |

| Mandatory SFDA | 17.49 | 4.96 | 12.29 | 23.4 | 28.84 | 5.91 | 0 | 0 | 7.09 |

| Vision 2030 | 50 | 0 | 0 | 23.08 | 0 | 21.37 | 0 | 0 | 5.56 |

| Future challenges | 12.96 | 14.2 | 5.86 | 13.27 | 7.41 | 27.47 | 6.17 | 3.4 | 9.26 |

| Organisation | 10.33 | 13.09 | 8.01 | 20.84 | 14.87 | 7.39 | 14.16 | 4.81 | 6.5 |

| Organisational culture | 0 | 0 | 11.11 | 64.05 | 11.11 | 0 | 13.73 | 0 | 0 |

| Saudisation-OC | 10.99 | 10.64 | 17.38 | 10.28 | 12.77 | 7.8 | 11.35 | 5.32 | 13.48 |

| Top Management support | 16.25 | 19.11 | 9.29 | 14.11 | 7.5 | 9.11 | 13.39 | 0.71 | 10.54 |

| Training and development | 18.29 | 7.62 | 4 | 10.86 | 20.57 | 6.1 | 15.43 | 9.52 | 7.62 |

| Technology factors | 22.07 | 10.71 | 11.72 | 12.29 | 8.07 | 7.93 | 6.25 | 10.57 | 10.4 |

| Compatibility | 16.26 | 21.54 | 10.16 | 0 | 9.35 | 3.66 | 26.02 | 8.54 | 4.47 |

| Complexity | 9.12 | 20.85 | 14.33 | 9.12 | 11.73 | 14.66 | 15.31 | 4.89 | 0 |

| Employees’ resistance | 14.94 | 20.12 | 17.84 | 19.09 | 7.88 | 5.19 | 7.88 | 7.05 | 0 |

| Future technology | 23.62 | 20.09 | 7.95 | 9.05 | 8.39 | 16.56 | 5.52 | 6.62 | 2.21 |

| Technology advantages | 32.28 | 2.11 | 13.18 | 14.76 | 10.41 | 5.67 | 4.61 | 3.69 | 13.31 |

| SC performance | 9.33 | 18.48 | 23.43 | 5.71 | 7.62 | 12.57 | 8.95 | 6.48 | 7.43 |

| Current traceability technologies | 20.51 | 5.9 | 9.2 | 10.32 | 6.59 | 6.96 | 3.92 | 18.46 | 18.15 |

| Traceability technologies adoption motivation | 33.8 | 7.18 | 16.2 | 17.13 | 3.94 | 5.09 | 8.33 | 3.7 | 4.63 |

| COVID-19 | 21.73 | 8.25 | 14.08 | 10.26 | 9.96 | 12.37 | 5.23 | 2.31 | 15.79 |

| TOE Factors | Main Theme | Subtheme 1 | Subtheme 2 | Subtheme 3 | Subtheme 4 |

|---|---|---|---|---|---|

| Technology | Existence of traceability technologies in Saudi dairy sector (p1,p2,p3,p4,p5,p8) | - | - | - | - |

| Technology and organisation | Traceability technology adoption challenges and barriers (p1,p2, p3, p6, p8,p9) | Employee’s resistance (P2,P6,P3) | Compatibility considerations (P2,P4,P6,P7) | Complexity in the adoption process (P6,P1,P7,P2,P3) | - |

| Organisation | Role of organisational culture and top management support in the adoption process (p2,p3,p6) | Role of organisational culture(P2, P6) | Role of pop management support (P3,P2,P6) | - | - |

| Technology and organisation | Impact of food traceability technologies on supply chain performance (p1,p2,p3,p4,p5,p6,p7, p8,p9) | Efficiency: cost, profit, time, effort (P1,P2,P3,P5, P7,P8) | Flexibility (P5) | Food quality (P1,P2,P5) | Transparency, information availability, and accuracy(P7) |

| Environment | Impact of COVID-19 and post-COVID-19 period on technology investment (p1,p2,p3,p5,p7,p8) | - | - | - | - |

| Environment | Impact of consumer pressure on food traceability technology adoption (p1,p2,p3,p9) | Consumer awareness (P2) | - | - | - |

| Environment | Influence of competitor pressure (p1,p2,p3,p4,p5,p6, p7,p8,p8) | - | - | - | - |

| Environment, technology | Role of government policy in influencing FTT adoption (P1,P2,P3,P4,P7,P8) | Vision 2030 initiative (P1,P2,P3) | Technology investment (P1,P4,P7,P8) | - | - |

| Organisation | Importance of employee training in technology adoption (P1,P2,P4) | - | - | - | - |

| Environment | Workforce localisation initiative (Saudisation) (P1,P2P6,P9) | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alessa, A.; Shee, H.; De Vass, T. Leveraging Milk-Traceability Technologies for Supply-Chain Performance: Evidence from Saudi Dairy Firms. Sustainability 2025, 17, 5902. https://doi.org/10.3390/su17135902

Alessa A, Shee H, De Vass T. Leveraging Milk-Traceability Technologies for Supply-Chain Performance: Evidence from Saudi Dairy Firms. Sustainability. 2025; 17(13):5902. https://doi.org/10.3390/su17135902

Chicago/Turabian StyleAlessa, Afyaa, Himanshu Shee, and Tharaka De Vass. 2025. "Leveraging Milk-Traceability Technologies for Supply-Chain Performance: Evidence from Saudi Dairy Firms" Sustainability 17, no. 13: 5902. https://doi.org/10.3390/su17135902

APA StyleAlessa, A., Shee, H., & De Vass, T. (2025). Leveraging Milk-Traceability Technologies for Supply-Chain Performance: Evidence from Saudi Dairy Firms. Sustainability, 17(13), 5902. https://doi.org/10.3390/su17135902