A Connectivity-Based Outlier Factor Method for Rapid Battery Internal Short-Circuit Diagnosis

Abstract

1. Introduction

- (1)

- A COF-based ISC fault diagnosis method is proposed, effectively amplifying the abnormal data in the voltage signal and improving the ability to diagnose early ISC faults.

- (2)

- The voltage sequence is processed to enhance fault characteristics, minimize the effects of voltage fluctuations during battery discharge, and accelerate the fault diagnosis process.

- (3)

- An ISC fault experiment is conducted under urban-dynamometer driving schedule (UDDS) working conditions to verify the effectiveness of the proposed method under different fault severities and varying conditions.

2. Methodology

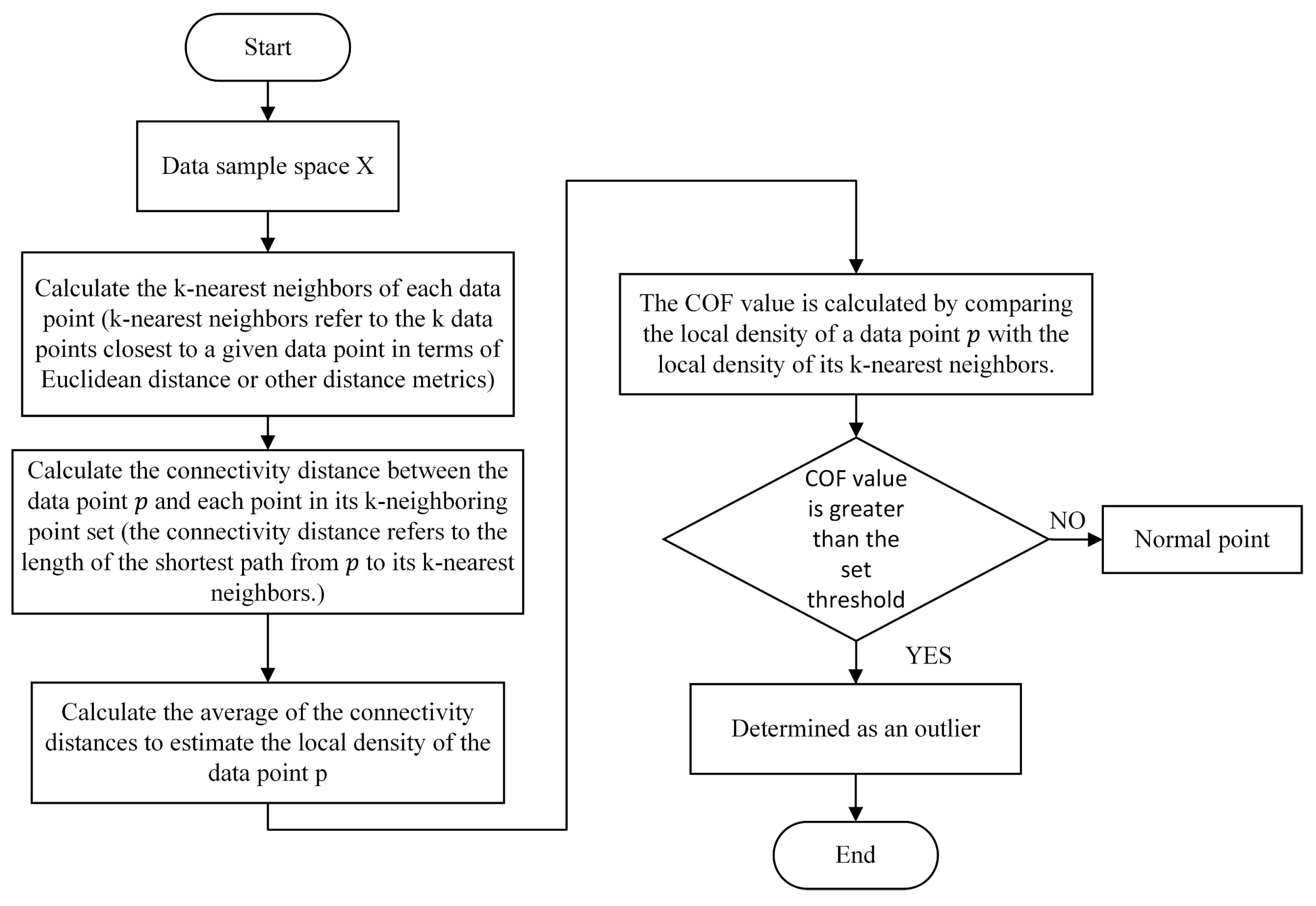

2.1. Connectivity-Based Outlier Factor Algorithm

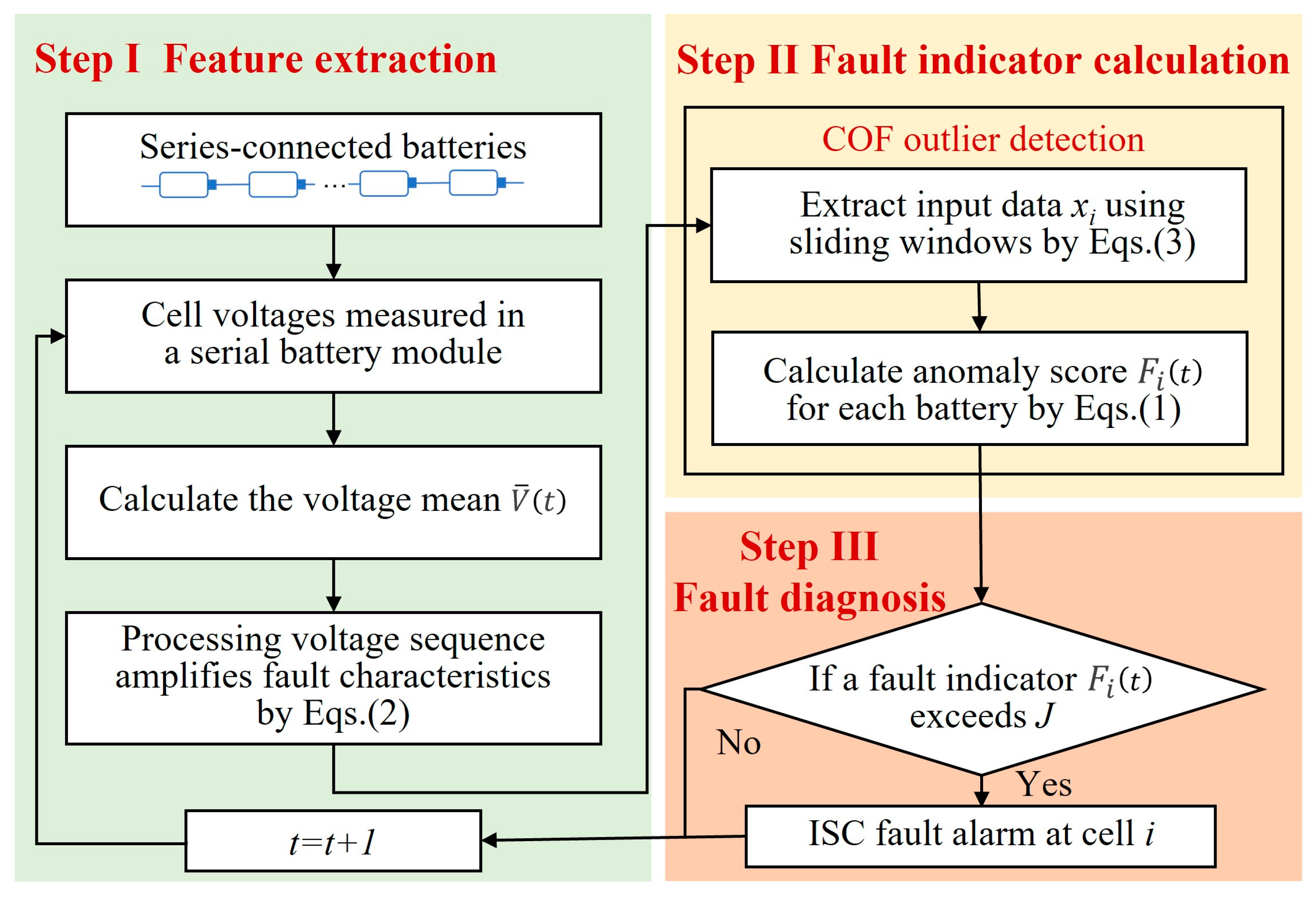

2.2. Fault Diagnosis Scheme

2.2.1. Feature Extraction

2.2.2. Fault Diagnosis

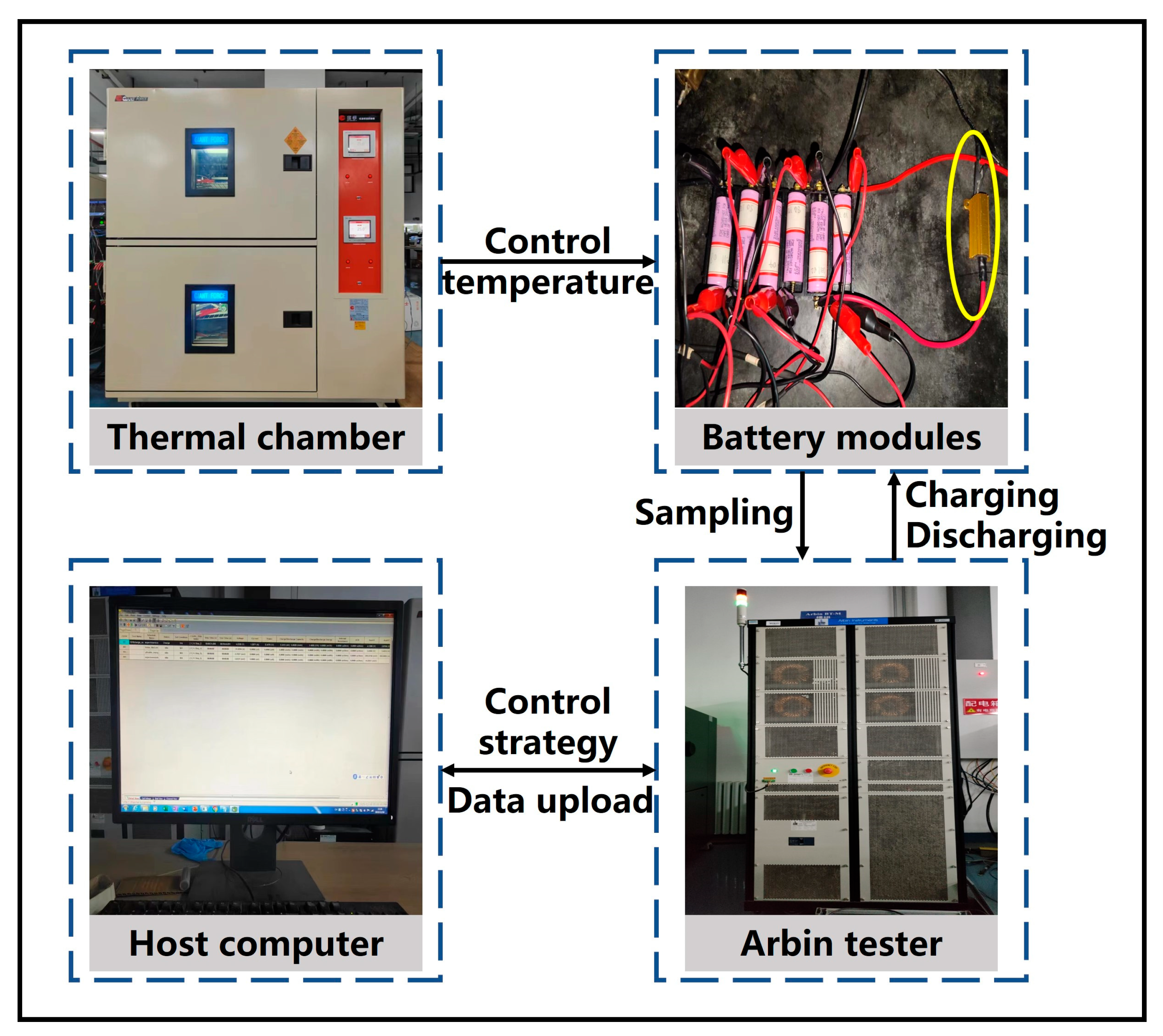

3. Design of Experiment

4. Results and Discussion

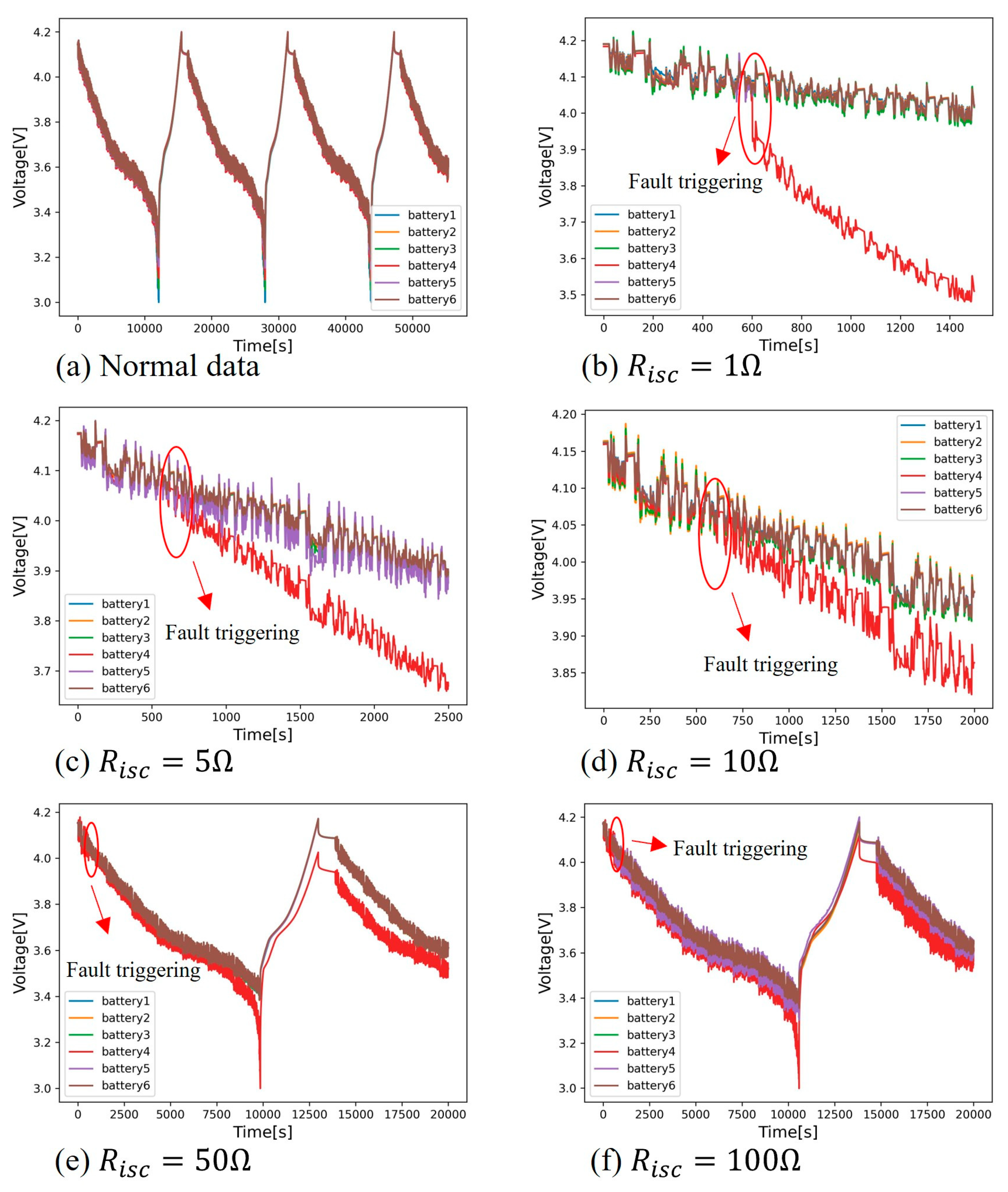

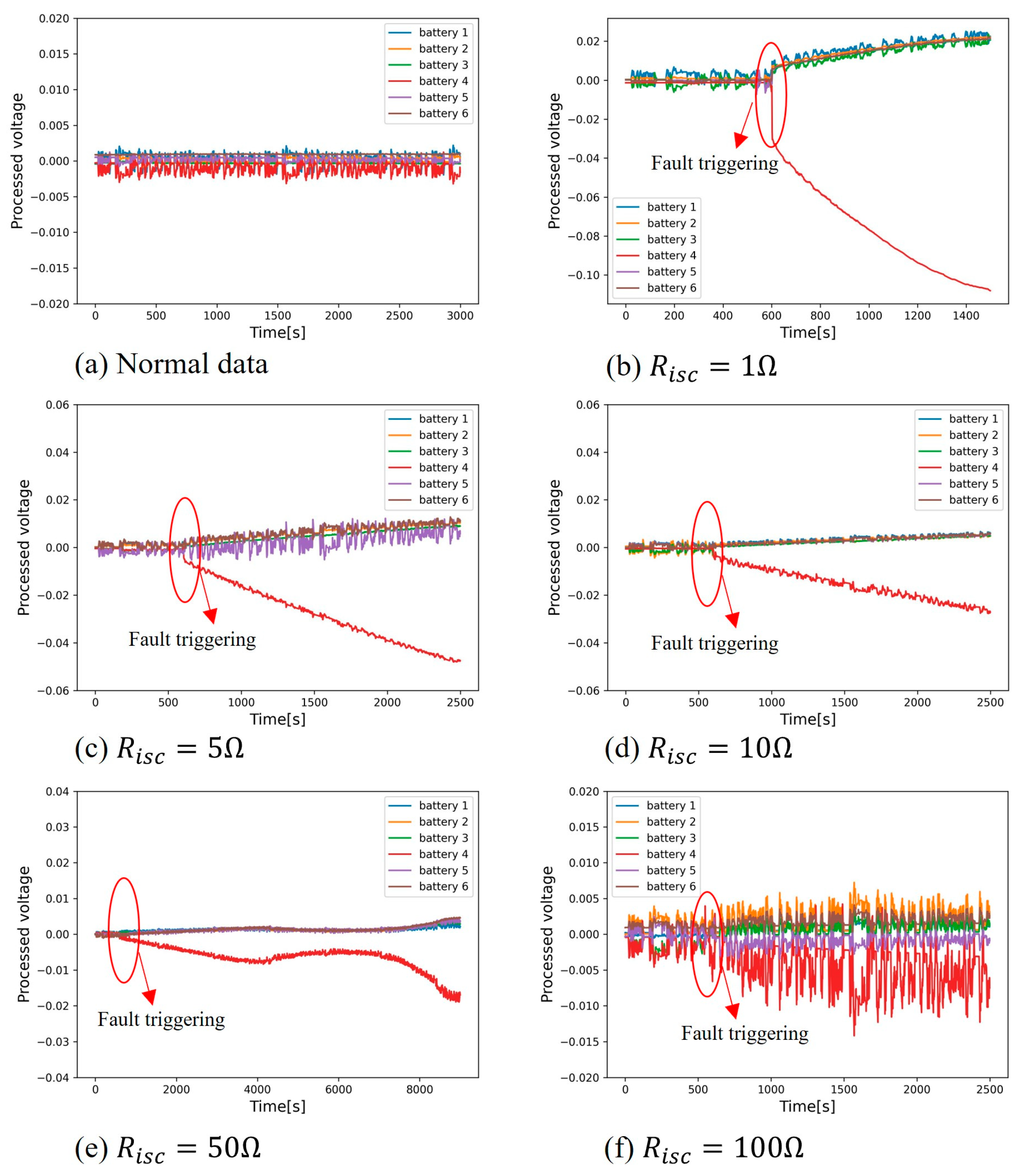

4.1. Fault Experiment Data Results and Processing

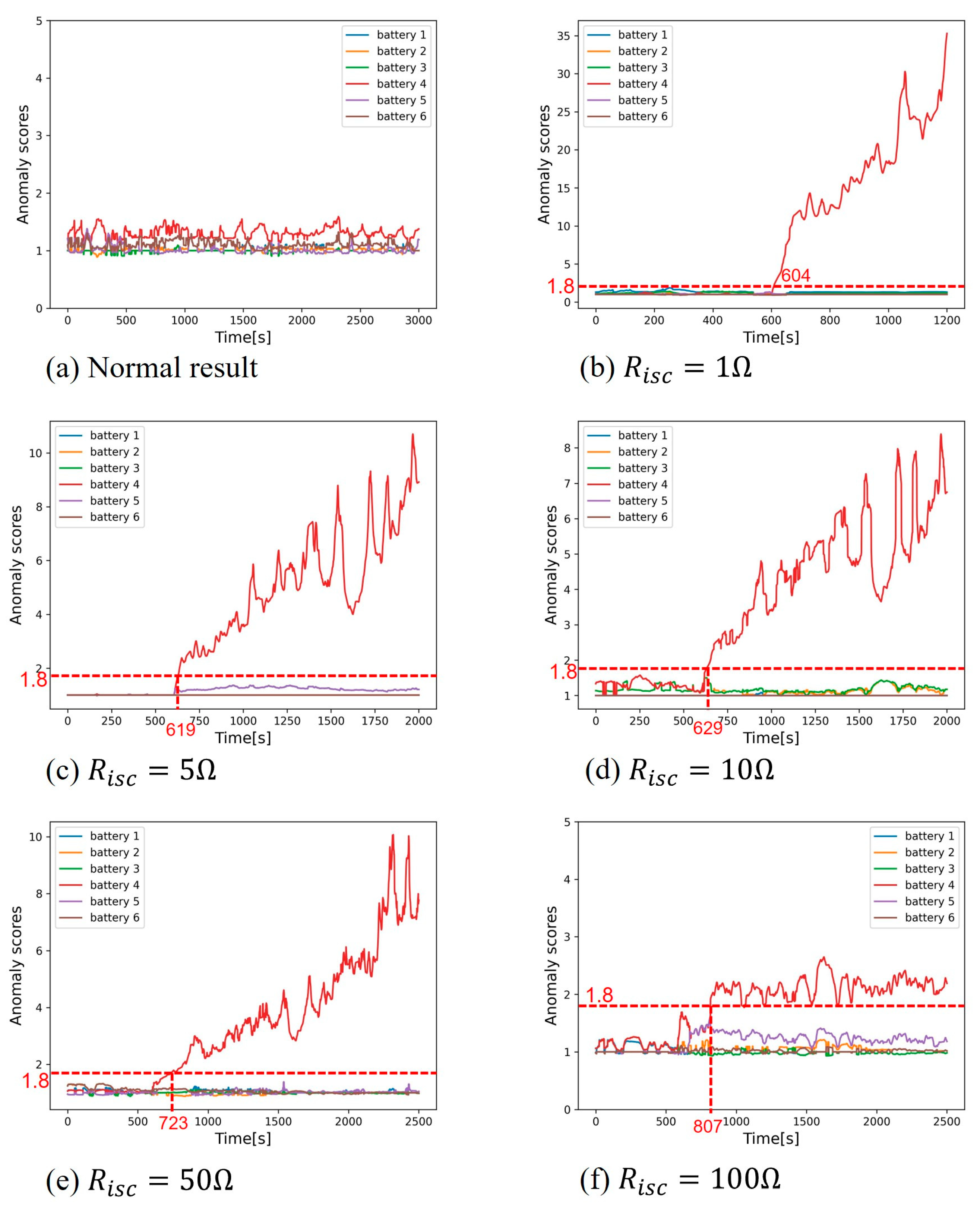

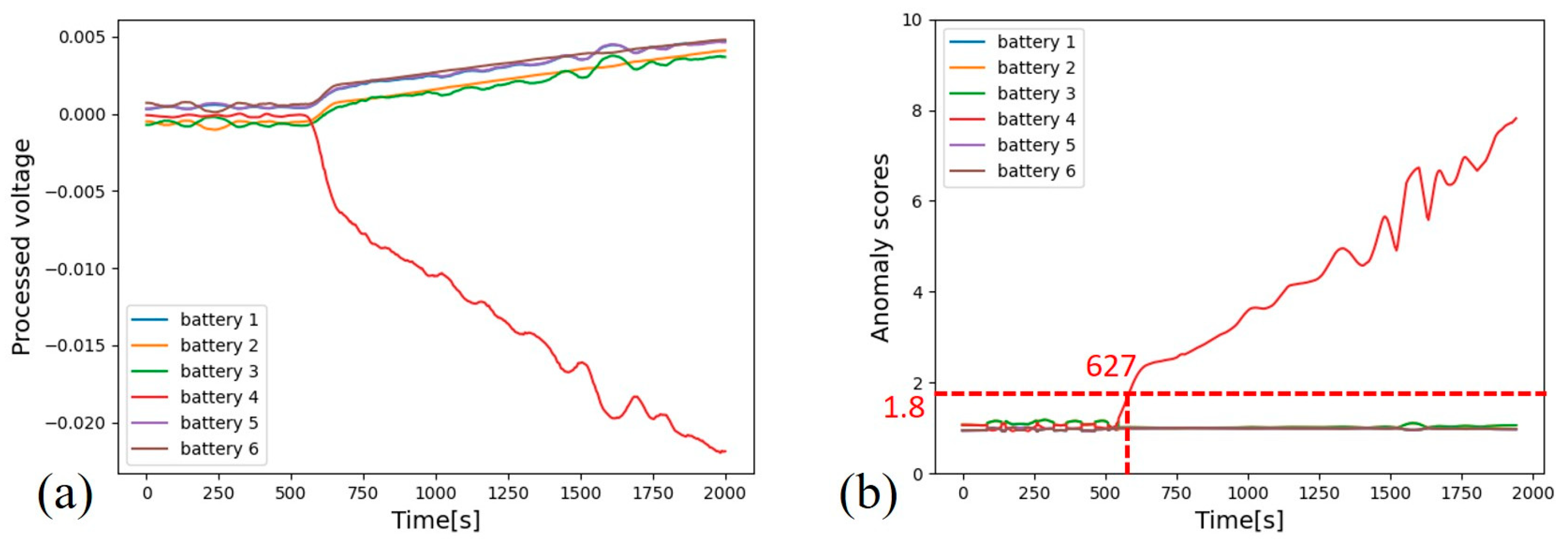

4.2. Fault Diagnosis Results

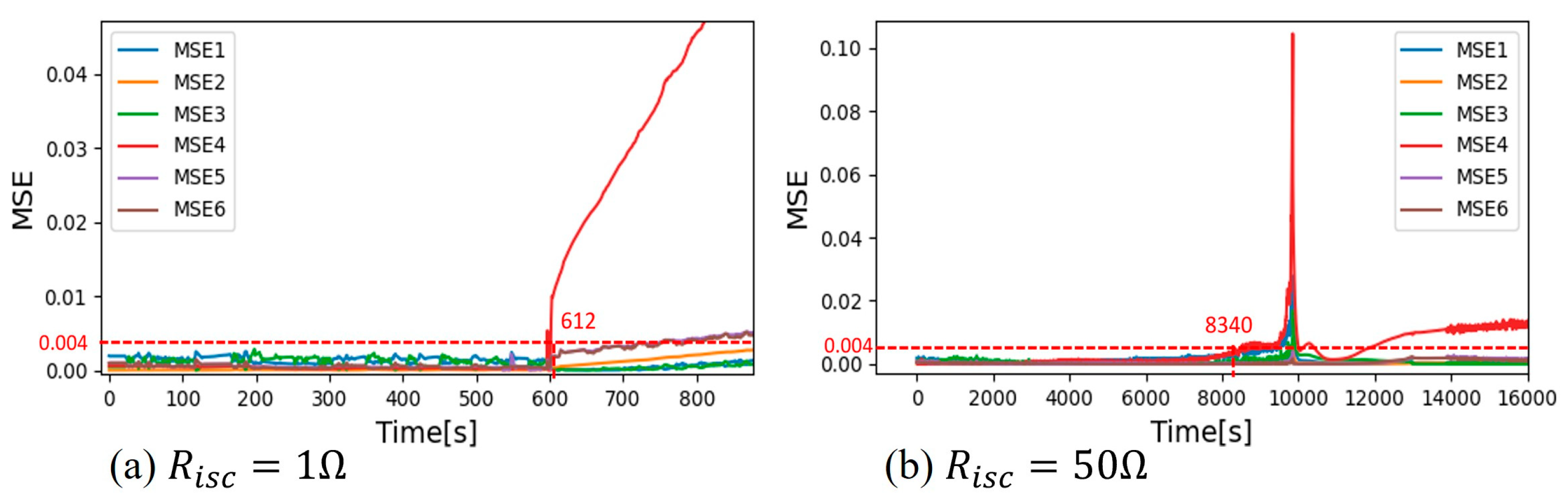

4.3. Comparison with Autoencoder-Based Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Li-ion | Lithium-ion |

| ISC | Internal short-circuit |

| MDM | Mean difference model |

| SOC | State of charge |

| COF | Connectivity-based outlier factor |

| UDDS | Urban dynamometer driving schedule |

References

- Naresh, G.; Praveenkumar, T.; Madheswaran, D.K.; Varuvel, E.G.; Pugazhendhi, A.; Thangamuthu, M.; Muthiya, S.J. Battery fault diagnosis methods for electric vehicle Lithium-ion batteries: Correlating codes and battery management system. Process Saf. Environ. Prot. 2025, 196, 106919. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, W.; Xu, S.; Yan, Y.; Huang, L.; Wang, J.; Hao, W.; Yang, Z. Electric vehicle lithium-ion battery fault diagnosis based on multi-method fusion of big data. Sustainability 2023, 15, 1120. [Google Scholar] [CrossRef]

- Liu, K.; Liu, Y.; Peng, Q.; Cui, N.; Zhang, C. Interpretable Data-Driven Learning with Fast Ultrasonic Detection for Battery Health Estimation. IEEE/CAA J. Autom. Sin. 2025, 12, 267–269. [Google Scholar] [CrossRef]

- Kong, Y.; Yuan, L.; Liao, Y.; Shao, Y.; Hao, S.; Huang, Y. Efficient separation and selective Li recycling of spent LiFePO4 cathode. Energy Mater. 2023, 3, 300053. [Google Scholar] [CrossRef]

- Xu, Y.; Ge, X.; Guo, R.; Shen, W. Recent advances in model-based fault diagnosis for lithium-ion batteries: A comprehensive review. Renew. Sustain. Energy Rev. 2025, 207, 114922. [Google Scholar] [CrossRef]

- Guo, F.; Wu, X.; Liu, L.; Ye, J.; Wang, T.; Fu, L.; Wu, Y. Prediction of remaining useful life and state of health of lithium batteries based on time series feature and Savitzky-Golay filter combined with gated recurrent unit neural network. Energy 2023, 270, 126880. [Google Scholar] [CrossRef]

- Hossain, M.I.; Shafiullah, M.; Abido, M.A. Battery power control strategy for intermittent renewable energy integrated modular multilevel converter-based high-voltage direct current network. Sustainability 2023, 15, 2626. [Google Scholar] [CrossRef]

- Liu, K.; Peng, Q.; Liu, Z.; Li, W.; Cui, N.; Zhang, C. Adaptive battery thermal management systems in unsteady thermal application contexts. J. Energy Chem. 2024, 97, 650–668. [Google Scholar] [CrossRef]

- Hu, J.; He, H.; Wei, Z.; Li, Y. Disturbance-immune and aging-robust internal short circuit diagnostic for lithium-ion battery. IEEE Trans. Ind. Electron. 2021, 69, 1988–1999. [Google Scholar] [CrossRef]

- Xu, Y.; Ge, X.; Shen, W. Multi-objective nonlinear observer design for multi-fault detection of lithium-ion battery in electric vehicles. Appl. Energy 2024, 362, 122989. [Google Scholar] [CrossRef]

- Qiu, Y.; Dong, T.; Lin, D.; Zhao, B.; Cao, W.; Jiang, F. Fault diagnosis for lithium-ion battery energy storage systems based on local outlier factor. J. Energy Storage 2022, 55, 105470. [Google Scholar] [CrossRef]

- Qiao, D.; Wang, X.; Lai, X.; Zheng, Y.; Wei, X.; Dai, H. Online quantitative diagnosis of internal short circuit for lithium-ion batteries using incremental capacity method. Energy 2022, 243, 123082. [Google Scholar] [CrossRef]

- Yu, Q.; Wang, C.; Li, J.; Xiong, R.; Pecht, M. Challenges and outlook for lithium-ion battery fault diagnosis methods from the laboratory to real world applications. ETransportation 2023, 17, 100254. [Google Scholar] [CrossRef]

- Lai, X.; Jin, C.; Yi, W.; Han, X.; Feng, X.; Zheng, Y.; Ouyang, M. Mechanism, modeling, detection, and prevention of the internal short circuit in lithium-ion batteries: Recent advances and perspectives. Energy Storage Mater. 2021, 35, 470–499. [Google Scholar] [CrossRef]

- Pan, Y.; Feng, X.; Zhang, M.; Han, X.; Lu, L.; Ouyang, M. Internal short circuit detection for lithium-ion battery pack with parallel-series hybrid connections. J. Clean. Prod. 2020, 255, 120277. [Google Scholar] [CrossRef]

- Song, Y.; Park, S.; Kim, S.W. Model-free quantitative diagnosis of internal short circuit for lithium-ion battery packs under diverse operating conditions. Appl. Energy 2023, 352, 121931. [Google Scholar] [CrossRef]

- Sun, J.; Chen, S.; Xing, S.; Guo, Y.; Wang, S.; Wang, R.; Wu, Y.; Wu, X. A battery internal short circuit fault diagnosis method based on incremental capacity curves. J. Power Sources 2024, 602, 234381. [Google Scholar] [CrossRef]

- Liu, K.; Fang, J.; Zhao, S.; Liu, Y.; Dai, H.; Ye, L.; Peng, Q. Battery state-of-health estimation: An ultrasonic detection method with explainable AI. Energy 2025, 319, 134923. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, L.; Deng, Z.; Xie, Y.; Couture, J.; Lin, X.; Hu, X. An Early Soft Internal Short-Circuit Fault Diagnosis Method for Lithium-Ion Battery Packs in Electric Vehicles. IEEE/ASME Trans. Mechatron. 2023, 28, 644–655. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, X.; Tang, X.; Zhu, J.; Chen, S.; Dai, H. Internal short circuit mechanisms, experimental approaches and detection methods of lithium-ion batteries for electric vehicles: A review. Renew. Sustain. Energy Rev. 2021, 141, 110790. [Google Scholar] [CrossRef]

- Shang, Y.; Wang, S.; Tang, N.; Fu, Y.; Wang, K. Research progress in fault detection of battery systems: A review. J. Energy Storage 2024, 98, 113079. [Google Scholar] [CrossRef]

- Lan, J.; Wei, R.; Huang, S.; Li, D.; Zhao, C.; Yin, L.; Wang, J. In-depth bibliometric analysis on research trends in fault diagnosis of lithium-ion batteries. J. Energy Storage 2022, 54, 105275. [Google Scholar] [CrossRef]

- Meng, J.; Boukhnifer, M.; Delpha, C.; Diallo, D. Incipient short-circuit fault diagnosis of lithium-ion batteries. J. Energy Storage 2020, 31, 101658. [Google Scholar] [CrossRef]

- Hu, J.; Wei, Z.; He, H. An online adaptive internal short circuit detection method of lithium-ion battery. Automot. Innov. 2021, 4, 93–102. [Google Scholar] [CrossRef]

- Cao, R.; Zhang, Z.; Lin, J.; Lu, J.; Zhang, L.; Xiao, L.; Liu, X.; Yang, S. Reliable online internal short circuit diagnosis on lithium-ion battery packs via voltage anomaly detection based on the mean-difference model and the adaptive prediction algorithm. Batteries 2022, 8, 224. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, J.; Zhao, X.; Zhang, K.; Meng, D.; Jiao, Z. Fault diagnosis of early internal short circuit for power battery systems based on the evolution of the cell charging voltage slope in variable voltage window. Appl. Energy 2024, 376, 124310. [Google Scholar] [CrossRef]

- Lin, T.; Chen, Z.; Zheng, C.; Huang, D.; Zhou, S. Fault diagnosis of lithium-ion battery pack based on hybrid system and dual extended Kalman filter algorithm. IEEE Trans. Transp. Electrif. 2020, 7, 26–36. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, W.; Yu, Q.; Sun, F. Research progress, challenges and prospects of fault diagnosis on battery system of electric vehicles. Appl. Energy 2020, 279, 115855. [Google Scholar] [CrossRef]

- Wang, G.; Yang, J.; Jiao, J. Voltage correlation-based principal component analysis method for short circuit fault diagnosis of series battery pack. IEEE Trans. Ind. Electron. 2022, 70, 9025–9034. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, X.; Meng, X.; Shen, W.; Sun, F. Advancing fault diagnosis in next-generation smart battery with multidimensional sensors. Appl. Energy 2024, 364, 123202. [Google Scholar] [CrossRef]

- Li, C.; Zeng, K.; Li, B.; Li, G.; Yang, H.; Li, S. Internal Short-Circuit Fault Diagnosis for Batteries of Energy Storage Stations Based on Multivariate Multiscale Sample Entropy. IEEE Trans. Ind. Electron. 2024, 72, 2068–2077. [Google Scholar] [CrossRef]

- Mao, Z.; Gu, X.; Li, J.; Liu, K.; Wang, T.; Shang, Y. An applicable minor short-circuit fault diagnosis method for automotive lithium-ion batteries based on extremum sample entropy. IEEE Trans. Power Electron. 2023, 39, 4636–4644. [Google Scholar] [CrossRef]

- Wu, X.; Wei, Z.; Wen, T.; Du, J.; Sun, J.; Shtang, A.A. Research on short-circuit fault-diagnosis strategy of lithium-ion battery in an energy-storage system based on voltage cosine similarity. J. Energy Storage 2023, 71, 108012. [Google Scholar] [CrossRef]

- Zheng, Y.; Luo, Q.; Cui, Y.; Dai, H.; Han, X.; Feng, X. Fault identification and quantitative diagnosis method for series-connected lithium-ion battery packs based on capacity estimation. IEEE Trans. Ind. Electron. 2021, 69, 3059–3067. [Google Scholar] [CrossRef]

- Gotz, J.D.; Neto, J.E.M.; Galvão, J.R.; Marques, T.M.B.; Siqueira, H.V.; Viana, E.R.; Marinho, M.H.N.; Mohamed, M.A.; Ilinca, A.; Corrêa, F.C.; et al. Studying abuse testing on lithium-ion battery packaging for energy storage systems. Sustainability 2023, 15, 11545. [Google Scholar] [CrossRef]

- Cui, Y.; Li, C.; Lu, Y.; Ma, L.; Cheng, L.; Cao, L.; Yu, S.; Jiang, T. Multimodal Connectivity-based Individual Parcellation and Analysis for Humans and Rhesus Monkeys. IEEE Trans. Med. Imaging 2024, 43, 3343–3353. [Google Scholar] [CrossRef] [PubMed]

- Alghushairy, O.; Alsini, R.; Soule, T.; Ma, X. A review of local outlier factor algorithms for outlier detection in big data streams. Big Data Cogn. Comput. 2020, 5, 1. [Google Scholar] [CrossRef]

- Yuan, H.; Cui, N.; Li, C.; Cui, Z.; Chang, L. Early stage internal short circuit fault diagnosis for lithium-ion batteries based on local-outlier detection. J. Energy Storage 2023, 57, 106196. [Google Scholar] [CrossRef]

- Li, P.; Pei, Y.; Li, J. A comprehensive survey on design and application of autoencoder in deep learning. Appl. Soft Comput. 2023, 138, 110176. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, P.; Lin, N.; Zhang, Z.; Wang, Z. A novel battery abnormality detection method using interpretable Au-toencoder. Appl. Energy 2023, 330, 120312. [Google Scholar] [CrossRef]

| Method Type | ||

|---|---|---|

| Model-Based Approach | Data-Driven Approach | Proposed Method |

| Relies on accurate battery modeling, which is complex and susceptible to noise and actual operating conditions. | Poses difficulties in accurately identifying early ISC features and is easily affected by noise | Does not require building complex models, strong early ISC identification capabilities. |

| Battery Type | Nominal Voltage (V) | Nominal Capacity (Ah) | Charge Cutoff Voltage (V) | Discharge Cutoff Voltage (V) |

|---|---|---|---|---|

| INR18650-2P | 3.7 | 2000 | 4.2 | 2.5 |

| Experiment Number | Fault Type | Fault Parameters | Start Time |

|---|---|---|---|

| 01 | No fault status | None | 0 s |

| 02 | ISC fault | 1 Ω | 600 s |

| 03 | ISC fault | 5 Ω | 600 s |

| 04 | ISC fault | 10 Ω | 600 s |

| 05 | ISC fault | 50 Ω | 600 s |

| 06 | ISC fault | 100 Ω | 600 s |

| Fault Trigger Time | Diagnosis Time (s) | ||||

|---|---|---|---|---|---|

| 1 Ω | 5 Ω | 10 Ω | 50 Ω | 100 Ω | |

| 600 s | 604 s | 619 s | 629 s | 723 s | 807 s |

| Method | Fault Trigger Time | Diagnosis Time (s) | |

|---|---|---|---|

| 1 Ω | 50 Ω | ||

| Proposed method | 600 s | 604 s | 723 s |

| Autoencoder | 600 s | 612 s | 8340 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Z.; Li, G.; Xie, F.; Zhao, S.; Ji, X.; Tian, M.; Liu, K. A Connectivity-Based Outlier Factor Method for Rapid Battery Internal Short-Circuit Diagnosis. Sustainability 2025, 17, 5147. https://doi.org/10.3390/su17115147

Dong Z, Li G, Xie F, Zhao S, Ji X, Tian M, Liu K. A Connectivity-Based Outlier Factor Method for Rapid Battery Internal Short-Circuit Diagnosis. Sustainability. 2025; 17(11):5147. https://doi.org/10.3390/su17115147

Chicago/Turabian StyleDong, Zhiguo, Gongqiang Li, Fengxiang Xie, Shiwen Zhao, Xiaofan Ji, Mofan Tian, and Kailong Liu. 2025. "A Connectivity-Based Outlier Factor Method for Rapid Battery Internal Short-Circuit Diagnosis" Sustainability 17, no. 11: 5147. https://doi.org/10.3390/su17115147

APA StyleDong, Z., Li, G., Xie, F., Zhao, S., Ji, X., Tian, M., & Liu, K. (2025). A Connectivity-Based Outlier Factor Method for Rapid Battery Internal Short-Circuit Diagnosis. Sustainability, 17(11), 5147. https://doi.org/10.3390/su17115147