Sustainable Anodes for Direct Methanol Fuel Cells: Advancing Beyond Platinum Scarcity with Low-Pt Alloys and Non-Pt Systems

Abstract

1. Introduction

CH3OH + 3/2O2 → CO2 + 2H2O E⊖ = 1.21 V

CH3OH + H2O → CO2 + 6H+ + 6e− E⊖ = 0.046 V

3/2O2 + 6H+ + 6e− → 3H2O E⊖ = 1.229 V

CH3OH + 3/2O2 → CO2 + H2O E⊖ = 1.183 V

CH3OH + 6OH− → CO2 + 5H2O + 6e− E⊖ = −0.81 V

3/2O2 + 3H2O + 6e− → 6OH− E⊖ = 0.402 V

2. Platinum-Based Catalysts for DMFC Anodes

2.1. Platinum Catalysts of Different Sizes and Crystalline Surfaces

2.2. Multi-Alloyed Platinum-Based Catalysts

2.3. Platinum-Based Core–Shell Structures

3. Platinum-Free Catalysts for DMFC Anodes

3.1. Palladium-Based Catalysts

3.2. Perovskite-Type Oxide Catalysts

3.3. Metal Carbide Catalysts

3.4. MOF and Its Derivatives

4. Carbon Carriers for DMFC Anode Catalysts

4.1. Single Versus Multiple Carbon Loads

4.2. Doped Heteroatom Carbon Loading and Metal-Oxide-Modified Carbon Loading

4.3. Polymer-Modified Carbon Loading

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, F.; Zhang, J.; Li, X. Energy Security Dilemma and Energy Transition Policy in the Context of Climate Change: A Perspective from China. Energy Policy 2023, 181, 113624. [Google Scholar] [CrossRef]

- Chen, L.; Msigwa, G.; Yang, M.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Strategies to Achieve a Carbon Neutral Society: A Review. Environ. Chem. Lett. 2022, 20, 2277–2310. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Al Labadidi, M.; Hamada, A.T.; Orhan, M.F. Design and Utilization of a Direct Methanol Fuel Cell. Membranes 2022, 12, 1266. [Google Scholar] [CrossRef]

- Santiago, Ó.; Mosa, J.; Escribano, P.G.; Navarro, E.; Chinarro, E.; Aparicio, M.; Leo, T.J.; Del Río, C. 40SiO2–40P2O5–20ZrO2 Sol-Gel Infiltrated sSEBS Membranes with Improved Methanol Crossover and Cell Performance for Direct Methanol Fuel Cell Applications. Int. J. Hydrogen Energy 2020, 45, 20620–20631. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Elsaid, K.; Wilberforce, T.; Kamil, M.; Sayed, E.T.; Olabi, A. Environmental Aspects of Fuel Cells: A Review. Sci. Total Environ. 2021, 752, 141803. [Google Scholar] [CrossRef] [PubMed]

- Al Shouny, A.; Rezk, H.; Sayed, E.T.; Abdelkareem, M.A.; Issa, U.H.; Miky, Y.; Olabi, A.G. Maximization of Power Density of Direct Methanol Fuel Cell for Greener Energy Generation Using Beetle Antennae Search Algorithm and Fuzzy Modeling. Biomimetics 2023, 8, 557. [Google Scholar] [CrossRef] [PubMed]

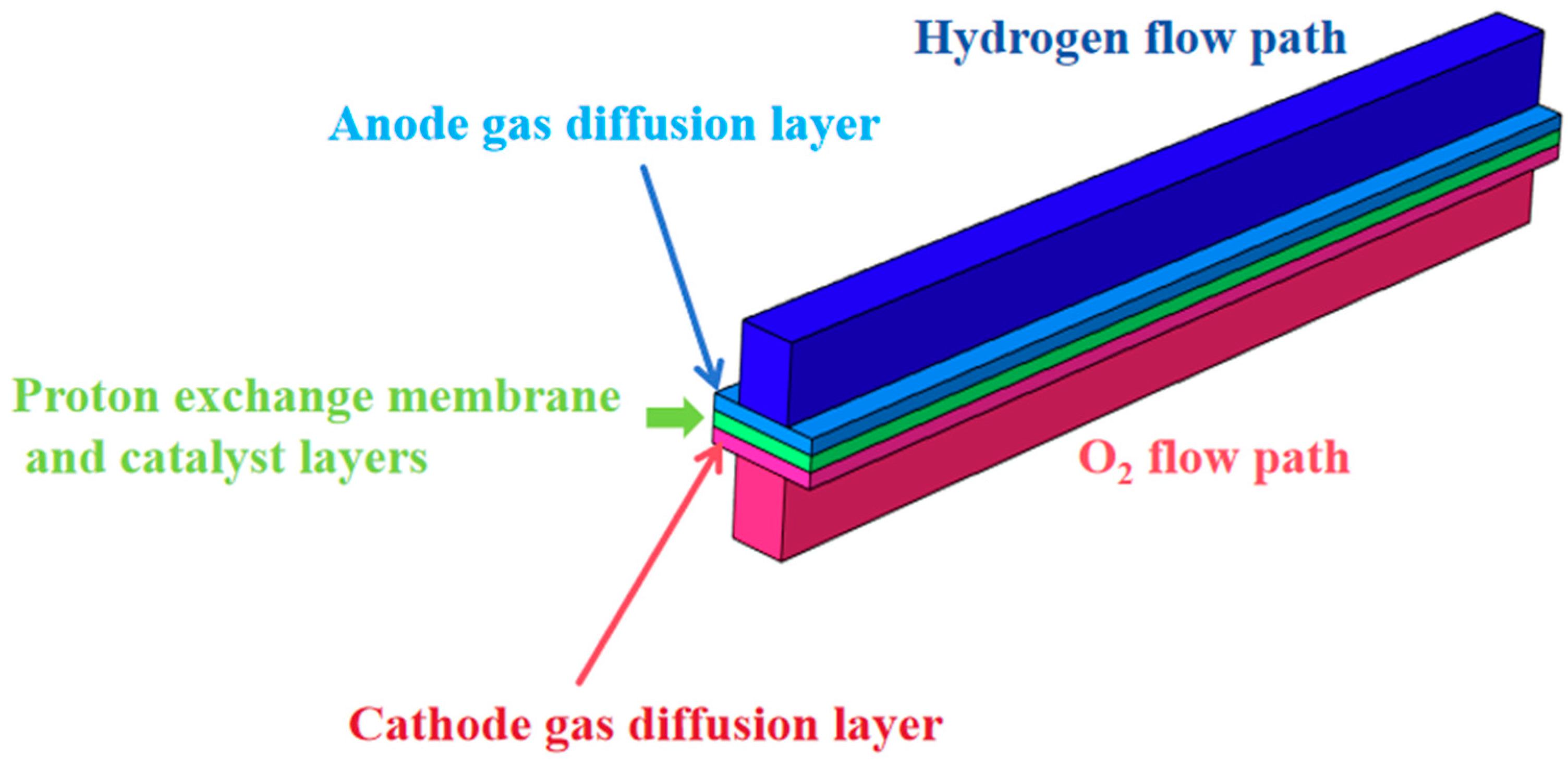

- Wang, Y.; Ruiz Diaz, D.F.; Chen, K.S.; Wang, Z.; Adroher, X.C. Materials, Technological Status, and Fundamentals of PEM Fuel Cells—A Review. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Kumar, P.; Dutta, K.; Das, S.; Kundu, P.P. An Overview of Unsolved Deficiencies of Direct Methanol Fuel Cell Technology: Factors and Parameters Affecting Its Widespread Use: Unsolved Deficiencies of Direct Methanol Fuel Cells. Int. J. Energy Res. 2014, 38, 1367–1390. [Google Scholar] [CrossRef]

- Faghri, A.; Guo, Z. Challenges and Opportunities of Thermal Management Issues Related to Fuel Cell Technology and Modeling. Int. J. Heat Mass Transf. 2005, 48, 3891–3920. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Fan, Y. Techno-Economic Challenges of Fuel Cell Commercialization. Engineering 2018, 4, 352–360. [Google Scholar] [CrossRef]

- Jiao, K.; Xuan, J.; Du, Q.; Bao, Z.; Xie, B.; Wang, B.; Zhao, Y.; Fan, L.; Wang, H.; Hou, Z.; et al. Designing the next Generation of Proton-Exchange Membrane Fuel Cells. Nature 2021, 595, 361–369. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, S.P. Prospects of Fuel Cell Technologies. Natl. Sci. Rev. 2017, 4, 163–166. [Google Scholar] [CrossRef]

- Chen, F.; Sun, Y.; Li, H.; Li, C. Review and Development of Anode Electrocatalyst Carriers for Direct Methanol Fuel Cell. Energy Technol. 2022, 10, 2101086. [Google Scholar] [CrossRef]

- Yaqoob, L.; Noor, T.; Iqbal, N. Recent Progress in Development of Efficient Electrocatalyst for Methanol Oxidation Reaction in Direct Methanol Fuel Cell. Int. J. Energy Res. 2021, 45, 6550–6583. [Google Scholar] [CrossRef]

- Sharma, P.; Pandey, O.P. Proton Exchange Membrane Fuel Cells: Fundamentals, Advanced Technologies, and Practical Applications. In PEM Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–24. ISBN 978-0-12-823708-3. [Google Scholar]

- Ren, X.; Lv, Q.; Liu, L.; Liu, B.; Wang, Y.; Liu, A.; Wu, G. Current Progress of Pt and Pt-Based Electrocatalysts Used for Fuel Cells. Sustain. Energy Fuels 2020, 4, 15–30. [Google Scholar] [CrossRef]

- Tripković, A.V.; Popović, K.D.; Grgur, B.N.; Blizanac, B.; Ross, P.N.; Marković, N.M. Methanol Electrooxidation on Supported Pt and PtRu Catalysts in Acid and Alkaline Solutions. Electrochim. Acta 2002, 47, 3707–3714. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, T.S.; Liu, J.G. Effect of Cell Orientation on the Performance of Passive Direct Methanol Fuel Cells. J. Power Sources 2006, 157, 351–357. [Google Scholar] [CrossRef]

- Hu, X.; Wang, X.; Chen, J.; Yang, Q.; Jin, D.; Qiu, X. Numerical Investigations of the Combined Effects of Flow Rate and Methanol Concentration on DMFC Performance. Energies 2017, 10, 1094. [Google Scholar] [CrossRef]

- Ismail, A.; Kee, Y.W. Investigation on Voltage Loss Mechanism for Direct Methanol Fuel Cell. Energy Rep. 2023, 10, 535–543. [Google Scholar] [CrossRef]

- Goor, M.; Menkin, S.; Peled, E. High Power Direct Methanol Fuel Cell for Mobility and Portable Applications. Int. J. Hydrogen Energy 2019, 44, 3138–3143. [Google Scholar] [CrossRef]

- Ud Din, M.A.; Idrees, M.; Jamil, S.; Irfan, S.; Nazir, G.; Mudassir, M.A.; Saleem, M.S.; Batool, S.; Cheng, N.; Saidur, R. Advances and Challenges of Methanol-Tolerant Oxygen Reduction Reaction Electrocatalysts for the Direct Methanol Fuel Cell. J. Energy Chem. 2023, 77, 499–513. [Google Scholar] [CrossRef]

- Hamnett, A. Mechanism and Electrocatalysis in the Direct Methanol Fuel Cell. Catal. Today 1997, 38, 445–457. [Google Scholar] [CrossRef]

- Yuda, A.; Ashok, A.; Kumar, A. A Comprehensive and Critical Review on Recent Progress in Anode Catalyst for Methanol Oxidation Reaction. Catal. Rev. 2022, 64, 126–228. [Google Scholar] [CrossRef]

- Martinaiou, I.; Monteverde Videla, A.H.A.; Weidler, N.; Kübler, M.; Wallace, W.D.Z.; Paul, S.; Wagner, S.; Shahraei, A.; Stark, R.W.; Specchia, S.; et al. Activity and Degradation Study of an Fe-N-C Catalyst for ORR in Direct Methanol Fuel Cell (DMFC). Appl. Catal. B Environ. 2020, 262, 118217. [Google Scholar] [CrossRef]

- Prapainainar, P.; Du, Z.; Theampetch, A.; Prapainainar, C.; Kongkachuichay, P.; Holmes, S.M. Properties and DMFC Performance of Nafion/Mordenite Composite Membrane Fabricated by Solution-Casting Method with Different Solvent Ratio. Energy 2020, 190, 116451. [Google Scholar] [CrossRef]

- Yaqoob, L.; Noor, T.; Iqbal, N.; Nasir, H.; Zaman, N.; Rasheed, L.; Yousuf, M. Development of an Efficient Non-Noble Metal Based Anode Electrocatalyst to Promote Methanol Oxidation Activity in DMFC. ChemistrySelect 2020, 5, 6023–6034. [Google Scholar] [CrossRef]

- Bai, X.; Geng, J.; Zhao, S.; Li, H.; Li, F. Tunable Hollow Pt@Ru Dodecahedra via Galvanic Replacement for Efficient Methanol Oxidation. ACS Appl. Mater. Interfaces 2020, 12, 23046–23050. [Google Scholar] [CrossRef]

- Cui, R.; Liu, S.; Guo, X.; Huang, H.; Wang, J.; Liu, B.; Li, Y.; Zhao, D.; Dong, J.; Sun, B. N-Doping Holey Graphene TiO2–Pt Composite as Efficient Electrocatalyst for Methanol Oxidation. ACS Appl. Energy Mater. 2020, 3, 2665–2673. [Google Scholar] [CrossRef]

- Alias, M.S.; Kamarudin, S.K.; Zainoodin, A.M.; Masdar, M.S. Active Direct Methanol Fuel Cell: An Overview. Int. J. Hydrogen Energy 2020, 45, 19620–19641. [Google Scholar] [CrossRef]

- Shi, W.; Park, H.-U.; Park, A.-H.; Kwon, Y.-U. Effect of Composition of Pd10−xCux (x = 2, 3, 4, and 5) Alloy Nanoparticles on Their Electrocatalysis for Methanol Oxidation. J. Electroanal. Chem. 2020, 865, 114144. [Google Scholar] [CrossRef]

- Menshchikov, V.; Alekseenko, A.; Guterman, V.; Nechitailov, A.; Glebova, N.; Tomasov, A.; Spiridonova, O.; Belenov, S.; Zelenina, N.; Safronenko, O. Effective Platinum-Copper Catalysts for Methanol Oxidation and Oxygen Reduction in Proton-Exchange Membrane Fuel Cell. Nanomaterials 2020, 10, 742. [Google Scholar] [CrossRef]

- Sayed, E.T.; Abdelkareem, M.A.; Alawadhi, H.; Salameh, T.; Olabi, A.G.; Alami, A.H. Facile and Low-Cost Synthesis Route for Graphene Deposition over Cobalt Dendrites for Direct Methanol Fuel Cell Applications. J. Taiwan Inst. Chem. Eng. 2020, 115, 321–330. [Google Scholar] [CrossRef]

- Raduwan, N.F.; Shaari, N.; Kamarudin, S.K.; Masdar, M.S.; Mohamad Yunus, R.; Wani, A.A. Advances, Progress and Challenges of NiCo2O4-Based Composite Materials for Direct Methanol Fuel Cell Applications: A Critical Review. Int. J. Green Energy 2024, 21, 3391–3413. [Google Scholar] [CrossRef]

- Andoh, S.; Kawaji, J.; Suzuki, S.; Kuroda, Y.; Mitsushima, S. Heat and Mass Balance Analysis of 130-W Active-Type Direct-Methanol Fuel Cell. Electrochemistry 2022, 90, 017007. [Google Scholar] [CrossRef]

- Coguplugil, Z.K.; Akin, M.; Bayat, R.; Bekmezci, M.; Karimi-Maleh, H.; Javadi, A.; Sen, F. Synthesis and Characterization of Pt/ZnO@SWCNT/Fe3O4 as a Powerful Catalyst for Anodic Part of Direct Methanol Fuel Cell Reaction. Int. J. Hydrogen Energy 2023, 48, 21285–21293. [Google Scholar] [CrossRef]

- Erduran, V.; Bayat, R.; Isik, I.; Bayazit, T.; Şen, F. Production of Sustainable Low-Layer Graphene by Green Synthesis at Room Conditions for Platinum-Based Direct Methanol Fuel Cell. ACS Eng. Au 2023, 3, 537–545. [Google Scholar] [CrossRef]

- Liu, F.; Dang, D.; Tian, X. Platinum-Decorated Three Dimensional Titanium Copper Nitride Architectures with Durable Methanol Oxidation Reaction Activity. Int. J. Hydrogen Energy 2019, 44, 8415–8424. [Google Scholar] [CrossRef]

- Wang, H.; Xue, Y.; Zhu, B.; Yang, J.; Wang, L.; Tan, X.; Wang, Z.; Chu, Y. CeO2 Nanowires Stretch-Embedded in Reduced Graphite Oxide Nanocomposite Support for Pt Nanoparticles as Potential Electrocatalyst for Methanol Oxidation Reaction. Int. J. Hydrogen Energy 2017, 42, 20549–20559. [Google Scholar] [CrossRef]

- Cheng, Y.; Shen, P.K.; Jiang, S.P. Enhanced Activity and Stability of Core–Shell Structured PtRuNi Electrocatalysts for Direct Methanol Fuel Cells. Int. J. Hydrogen Energy 2016, 41, 1935–1943. [Google Scholar] [CrossRef]

- Gizem Güneştekin, B.; Medetalibeyoglu, H.; Atar, N.; Lütfi Yola, M. Efficient Direct-Methanol Fuel Cell Based on Graphene Quantum Dots/Multi-walled Carbon Nanotubes Composite. Electroanalysis 2020, 32, 1977–1982. [Google Scholar] [CrossRef]

- Raveendran, A.; Jeyapriya, M.; Ramalingan, C.; Ramamoorthy, G.; Chandran, M.; Kamalakannan, D.; Prabu, B.; Siddiqui, M.R.; Wabaidur, S.M.; Dhanusuraman, R. Nickel-Modified Poly(Aniline-Co-Pyrrole) as Electrocatalyst for Electrochemical Oxidation of Methanol in Direct Methanol Fuel Cell Application. Ionics 2024, 30, 5577–5595. [Google Scholar] [CrossRef]

- Wu, Z.; Duan, R.; Cui, J.; Ye, C.; Zhang, S.; Yan, S. An Overview of the Pd Based Electrocatalysts Utilized in Direct Alcohol Fuel Cells. Electrocatalysis 2025, 16, 197–223. [Google Scholar] [CrossRef]

- Calderón Gómez, J.; Moliner, R.; Lázaro, M. Palladium-Based Catalysts as Electrodes for Direct Methanol Fuel Cells: A Last Ten Years Review. Catalysts 2016, 6, 130. [Google Scholar] [CrossRef]

- Jeong, H.; Kim, J.W.; Park, J.; An, J.; Lee, T.; Prinz, F.B.; Shim, J.H. Bimetallic Nickel/Ruthenium Catalysts Synthesized by Atomic Layer Deposition for Low-Temperature Direct Methanol Solid Oxide Fuel Cells. ACS Appl. Mater. Interfaces 2016, 8, 30090–30098. [Google Scholar] [CrossRef]

- Mohamed, M.M.; Amer, A.A. Solid Waste-Derived γ-Al2O3 Nanowires Supporting α-Fe2O3 as an Efficient Anodic Direct Methanol Fuel Cell Electrocatalyst. J. Alloys Compd. 2023, 966, 171632. [Google Scholar] [CrossRef]

- Shams-Eldin, R.; Ali, A.A.; Hani, A.; Haikal, R.R.; Fahmy, H.M.; El Nashar, R.M.; Alkordi, M.H. Metal–Organic Framework Mediated Ni-Deposition on MWCNTs for Direct Methanol Fuel Cell Catalysis. SN Appl. Sci. 2023, 5, 166. [Google Scholar] [CrossRef]

- Chen, F.; Wang, L.; Yu, S.; Guo, S.; Zhang, C.; Guo, M.; Li, C. Synergistic CoCu Nanocrystals on N-Doped Carbon Nanofibers with Significant Carbon Monoxide-Resistant in Alkaline Direct Methanol Fuel Cell. Int. J. Hydrogen Energy 2024, 72, 1001–1009. [Google Scholar] [CrossRef]

- Stevanović, S.; Tripković, D.; Gavrilović-Wohlmuther, A.; Rogan, J.; Lačnjevac, U.; Jovanović, V. Carbon Supported PtSn versus PtSnO2 Catalysts in Methanol Oxidation. Int. J. Electrochem. Sci. 2021, 16, 210222. [Google Scholar] [CrossRef]

- Shi, H.; Liao, F.; Zhu, W.; Shao, C.; Shao, M. Effective PtAu Nanowire Network Catalysts with Ultralow Pt Content for Formic Acid Oxidation and Methanol Oxidation. Int. J. Hydrogen Energy 2020, 45, 16071–16079. [Google Scholar] [CrossRef]

- Ordóñez, L.C.; Roquero, P.; Ramírez, J.; Sebastian, P.J. Methanol Electro-Oxidation on Bimetallic PtMo/C Catalysts and Pt/C—Mo/C Mechanical Mixtures. Int. J. Electrochem. Sci. 2016, 11, 5364–5379. [Google Scholar] [CrossRef]

- Zhang, R.; Xia, W.; Kang, W.; Li, R.; Qu, K.; Zhang, Y.; Chen, B.; Wang, H.; Sun, Y.; Li, H. Methanol Oxidation Reaction Performance on Graphene-Supported PtAg Alloy Nanocatalyst: Contrastive Study of Electronic and Geometric Effects Induced from Ag Doping. ChemistrySelect 2018, 3, 3615–3620. [Google Scholar] [CrossRef]

- Men’shchikov, V.S.; Guterman, V.E.; Belenov, S.V.; Spiridonova, O.A.; Rezvan, D.V. De-Alloyed PtCu/C Catalysts of Methanol Electrooxidation. Russ. J. Electrochem. 2020, 56, 850–858. [Google Scholar] [CrossRef]

- Yang, T.; Xue, Q.; Yu, X.; Qi, X.; Wu, R.; Lu, S.; Gu, Z.; Jiang, J.; Nie, Y. DFT Study on Methanol Oxidation Reaction Catalyzed by PtmPdn Alloys. Coatings 2022, 12, 918. [Google Scholar] [CrossRef]

- Ercelik, M.; Ozden, A.; Seker, E.; Colpan, C.O. Characterization and Performance Evaluation of Pt Ru/C TiO2 Anode Electrocatalyst for DMFC Applications. Int. J. Hydrogen Energy 2017, 42, 21518–21529. [Google Scholar] [CrossRef]

- Min, L.; Yuan, L.; Xu, W.J.; Liu, J.-X. Synthesis of DMFC Anode Catalyst Fe3O4@Pt Particles and Catalytic Performance. J. Inorg. Mater. 2017, 32, 916. [Google Scholar] [CrossRef]

- Frelink, T.; Visscher, W.; Van Veen, J.A.R. Particle Size Effect of Carbon-Supported Platinum Catalysts for the Electrooxidation of Methanol. J. Electroanal. Chem. 1995, 382, 65–72. [Google Scholar] [CrossRef]

- Housmans, T.H.M.; Wonders, A.H.; Koper, M.T.M. Structure Sensitivity of Methanol Electrooxidation Pathways on Platinum: An On-Line Electrochemical Mass Spectrometry Study. J. Phys. Chem. B 2006, 110, 10021–10031. [Google Scholar] [CrossRef]

- Jarvi, T.D.; Sriramulu, S.; Stuve, E.M. Reactivity and Extent of Poisoning during Methanol Electro-Oxidation on Platinum (100) and (111): A Comparative Study. Colloids Surf. A Physicochem. Eng. Asp. 1998, 134, 145–153. [Google Scholar] [CrossRef]

- Ferrin, P.; Mavrikakis, M. Structure Sensitivity of Methanol Electrooxidation on Transition Metals. J. Am. Chem. Soc. 2009, 131, 14381–14389. [Google Scholar] [CrossRef]

- Mikita, K.; Nakamura, M.; Hoshi, N. In Situ Infrared Reflection Absorption Spectroscopy of Carbon Monoxide Adsorbed on Pt(S)-[n (100)×(110)] Electrodes. Langmuir 2007, 23, 9092–9097. [Google Scholar] [CrossRef]

- Veizaga, N.S.; Paganin, V.A.; Rocha, T.A.; Scelza, O.A.; De Miguel, S.R.; Gonzalez, E.R. Development of PtGe and PtIn Anodic Catalysts Supported on Carbonaceous Materials for DMFC. Int. J. Hydrogen Energy 2014, 39, 8728–8737. [Google Scholar] [CrossRef]

- Patel, P.P.; Datta, M.K.; Jampani, P.H.; Hong, D.; Poston, J.A.; Manivannan, A.; Kumta, P.N. High Performance and Durable Nanostructured TiN Supported Pt50–Ru50 Anode Catalyst for Direct Methanol Fuel Cell (DMFC). J. Power Sources 2015, 293, 437–446. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, Y.-W.; Jin, Z.; Chen, C.; Li, H.; Cai, W.-B. Alternative Aqueous Phase Synthesis of a PtRu/C Electrocatalyst for Direct Methanol Fuel Cells. Catalysts 2021, 11, 925. [Google Scholar] [CrossRef]

- Muthukumar, V.; Chetty, R. Impregnated Electroreduced Pt on Ru/C as an Anode Catalyst for Direct Methanol Fuel Cells. J. Electrochem. Soc. 2019, 166, F1173–F1179. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, S.; Chen, M.; Zhu, L.; Pei, A.; Wu, F.; Liao, X.; Gao, Q.; Wang, W.; Yang, Z.; et al. Revealing the Mechanism of Bifunctional PtLa Electrocatalyst for Highly Efficient Methanol Oxidation, Hydrogen Evolution, and Coupling Reaction. J. Colloid Interface Sci. 2025, 679, 918–928. [Google Scholar] [CrossRef] [PubMed]

- Eudora Khotseng, L. (Ed.) Electrocatalysis and Electrocatalysts for a Cleaner Environment—Fundamentals and Applications; IntechOpen: London, UK, 2022; ISBN 978-1-83968-127-1. [Google Scholar]

- Petrii, O.A. Pt–Ru Electrocatalysts for Fuel Cells: A Representative Review. J. Solid State Electrochem. 2008, 12, 609–642. [Google Scholar] [CrossRef]

- Wang, H.; Gao, C.; Liu, Z.; Li, B.; Dok Kim, Y.; Feng, J.; Sun, K.; Peng, Z. Pt-Ru Atomic Alloys Confined in Mesoporous Carbon Hollow Spheres for Accelerating Methanol Oxidation. J. Colloid Interface Sci. 2025, 678, 1004–1011. [Google Scholar] [CrossRef]

- Xu, H.; Zheng, D.J.; Iriawan, H.; Fang, J.-H.; Kim, J.; Wang, X.; Román-Leshkov, Y.; Li, J.; Shao-Horn, Y. A Cobalt–Platinum–Ruthenium System for Acidic Methanol Oxidation. Chem. Mater. 2024, 36, 6938–6949. [Google Scholar] [CrossRef]

- Cui, Z.; Liu, C.; Liao, J.; Xing, W. Highly Active PtRu Catalysts Supported on Carbon Nanotubes Prepared by Modified Impregnation Method for Methanol Electro-Oxidation. Electrochim. Acta 2008, 53, 7807–7811. [Google Scholar] [CrossRef]

- Rojas, S.; García-García, F.J.; Järas, S.; Martínez-Huerta, M.V.; Fierro, J.L.G.; Boutonnet, M. Preparation of Carbon Supported Pt and PtRu Nanoparticles from Microemulsion. Appl. Catal. A Gen. 2005, 285, 24–35. [Google Scholar] [CrossRef]

- Schmidt, T.J.; Gasteiger, H.A.; Behm, R.J. Methanol Electrooxidation on a Colloidal PtRu-Alloy Fuel-Cell Catalyst. Electrochem. Commun. 1999, 1, 1–4. [Google Scholar] [CrossRef]

- Caillard, A.; Coutanceau, C.; Brault, P.; Mathias, J.; Léger, J.-M. Structure of Pt/C and PtRu/C Catalytic Layers Prepared by Plasma Sputtering and Electric Performance in Direct Methanol Fuel Cells (DMFC). J. Power Sources 2006, 162, 66–73. [Google Scholar] [CrossRef]

- Jow, J.; Yang, S.; Chen, H.; Wu, M.; Ling, T.; Wei, T. Co-Electrodeposition of Pt–Ru Electrocatalysts in Electrolytes with Varying Compositions by a Double-Potential Pulse Method for the Oxidation of MeOH and CO. Int. J. Hydrogen Energy 2009, 34, 665–671. [Google Scholar] [CrossRef]

- Cai, G.; Hua, C.; Ren, H.; Yu, R.; Xu, D.; Khan, M.A.; Guo, J.; Sun, Y.; Tang, Y.; Qian, H.; et al. Ultrathin Ternary PtNiRu Nanowires for Enhanced Oxygen Reduction and Methanol Oxidation Catalysis via D-Band Center Regulation. J. Colloid Interface Sci. 2025, 678, 599–608. [Google Scholar] [CrossRef]

- Strasser, P.; Fan, Q.; Devenney, M.; Weinberg, W.H.; Liu, P.; Nørskov, J.K. High Throughput Experimental and Theoretical Predictive Screening of Materials—A Comparative Study of Search Strategies for New Fuel Cell Anode Catalysts. J. Phys. Chem. B 2003, 107, 11013–11021. [Google Scholar] [CrossRef]

- Watanabe, M.; Zhu, Y.; Uchida, H. Oxidation of CO on a Pt−Fe Alloy Electrode Studied by Surface Enhanced Infrared Reflection−Absorption Spectroscopy. J. Phys. Chem. B 2000, 104, 1762–1768. [Google Scholar] [CrossRef]

- Jeon, M.K.; Won, J.Y.; Lee, K.R.; Woo, S.I. Highly Active PtRuFe/C Catalyst for Methanol Electro-Oxidation. Electrochem. Commun. 2007, 9, 2163–2166. [Google Scholar] [CrossRef]

- Cai, Z.; Kuang, Y.; Qi, X.; Wang, P.; Zhang, Y.; Zhang, Z.; Sun, X. Ultrathin Branched PtFe and PtRuFe Nanodendrites with Enhanced Electrocatalytic Activity. J. Mater. Chem. A 2015, 3, 1182–1187. [Google Scholar] [CrossRef]

- Kakati, N.; Maiti, J.; Oh, J.Y.; Yoon, Y.S. Study of Methanol Oxidation of Hydrothermally Synthesized PtRuMo on Multi Wall Carbon Nanotubes. Appl. Surf. Sci. 2011, 257, 8433–8437. [Google Scholar] [CrossRef]

- Park, S.-H.; Jung, H.-M.; Um, S.; Song, Y.-W.; Kim, H.-S. Rapid Synthesis of Pt-Based Alloy/Carbon Nanotube Catalysts for a Direct Methanol Fuel Cell Using Flash Light Irradiation. Int. J. Hydrogen Energy 2012, 37, 12597–12604. [Google Scholar] [CrossRef]

- Li, Z.; Yu, K.; Leng, Y.; Chen, Z. Platinum-Nickel Bimetallic Nanowire Electrocatalyst Enables Methanol Oxidation. J. Electroanal. Chem. 2025, 980, 118989. [Google Scholar] [CrossRef]

- Li, L.; Gao, W.; Wan, X.; Wen, D. Pt Nanoparticles Dispersed on Ni/C Nanoflowers as Stable Electrocatalysts for Methanol Oxidation and Oxygen Reduction. ACS Appl. Nano Mater. 2021, 4, 10960–10968. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, H.; Tian, Z.; Zhu, X.; Wang, X.; Yi, B. Synthesis and Structure−Activity Relationship Exploration of Carbon-Supported PtRuNi Nanocomposite as a CO-Tolerant Electrocatalyst for Proton Exchange Membrane Fuel Cells. J. Phys. Chem. B 2006, 110, 7828–7834. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Q.; Gu, L.; Xu, S.; Wang, P.; Liu, J.; Ding, Y.; Yao, Y.F.; Nan, C.; Zhao, M.; et al. Ruthenium–Platinum Core–Shell Nanocatalysts with Substantially Enhanced Activity and Durability towards Methanol Oxidation. Nano Energy 2016, 21, 247–257. [Google Scholar] [CrossRef]

- Ren, Y.; Chen, K.; Zhang, Y.; Shi, D.; Wu, Q.; Liang, D.; Hu, C.; Li, H. N-Doped Carbon Confined CoFe@Pt Nanoparticles with Robust Catalytic Performance for the Methanol Oxidation Reaction. J. Mater. Chem. A 2022, 10, 13345–13354. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, J.S.; Göhl, D.; Paciok, P.; Gonçalves, D.S.; Lim, H.; Zanchet, D.; Heggen, M.; Shao-Horn, Y.; Ledendecker, M.; et al. Platinum/Tantalum Carbide Core–Shell Nanoparticles with Sub-Monolayer Shells for Methanol and Oxygen Electrocatalysis. Adv. Energy Mater. 2024, 14, 2304092. [Google Scholar] [CrossRef]

- El Sawy, E.N.; Birss, V.I. Nanoengineered Ircore @Ptshell Nanoparticles with Controlled Pt Shell Coverages for Direct Methanol Electro-Oxidation. ACS Appl. Mater. Interfaces 2018, 10, 3459–3469. [Google Scholar] [CrossRef]

- Gawande, M.B.; Goswami, A.; Asefa, T.; Guo, H.; Biradar, A.V.; Peng, D.-L.; Zboril, R.; Varma, R.S. Core–Shell Nanoparticles: Synthesis and Applications in Catalysis and Electrocatalysis. Chem. Soc. Rev. 2015, 44, 7540–7590. [Google Scholar] [CrossRef]

- Cao, K.; Zhu, Q.; Shan, B.; Chen, R. Controlled Synthesis of Pd/Pt Core Shell Nanoparticles Using Area-Selective Atomic Layer Deposition. Sci. Rep. 2015, 5, 8470. [Google Scholar] [CrossRef]

- Xue, Y.; Chen, L.; Zhang, L.; Zheng, G.; Zhang, X.; Zhou, Z. Activity and Stability Origin of Core–Shell Catalysts: Unignorable Atomic Diffusion Behavior. Chem. Sci. 2025, 16, 3323–3328. [Google Scholar] [CrossRef]

- Wu, Y.-N.; Liao, S.-J.; Liang, Z.-X.; Yang, L.-J.; Wang, R.-F. High-Performance Core–Shell PdPt@Pt/C Catalysts via Decorating PdPt Alloy Cores with Pt. J. Power Sources 2009, 194, 805–810. [Google Scholar] [CrossRef]

- Cheng, Y.; Shen, P.K.; Saunders, M.; Jiang, S.P. Core–Shell Structured PtRuCox Nanoparticles on Carbon Nanotubes as Highly Active and Durable Electrocatalysts for Direct Methanol Fuel Cells. Electrochim. Acta 2015, 177, 217–226. [Google Scholar] [CrossRef]

- Strasser, P.; Koh, S.; Anniyev, T.; Greeley, J.; More, K.; Yu, C.; Liu, Z.; Kaya, S.; Nordlund, D.; Ogasawara, H.; et al. Lattice-Strain Control of the Activity in Dealloyed Core–Shell Fuel Cell Catalysts|Nature Chemistry. Nature Chem. 2010, 2, 454–460. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-J.; Liu, Y.-T.; Chen, I.-L.; Yang, Y.-W.; Yeh, T.-K.; Lee, C.H.; Hu, C.-C.; Wen, T.-C.; Chen, T.-Y.; Lin, T.-L. Near-Monolayer Platinum Shell on Core–Shell Nanocatalysts for High-Performance Direct Methanol Fuel Cell. J. Phys. Chem. C 2014, 118, 2253–2262. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, Z.; Jia, Y.; Wang, M.; Qi, W.; Pang, Y.; Yi, J.; Zhang, Y.; Li, Z.; Zhang, Z. Unique Cu@CuPt Core–Shell Concave Octahedron with Enhanced Methanol Oxidation Activity. ACS Appl. Mater. Interfaces 2017, 9, 36817–36827. [Google Scholar] [CrossRef]

- Erlebacher, J.; Aziz, M.J.; Karma, A.; Dimitrov, N.; Sieradzki, K. Evolution of Nanoporosity in Dealloying. Nature 2001, 410, 450–453. [Google Scholar] [CrossRef]

- Singh, B.; Seddon, B.; Dempsey, E.; Redington, W.; Dickinson, C. Porous Core-Shell Platinum-Silver Nanocatalyst for the Electrooxidation of Methanol. Electroanalysis 2015, 27, 135–143. [Google Scholar] [CrossRef]

- Sarkar, A.; Murugan, A.V.; Manthiram, A. Synthesis and Characterization of Nanostructured Pd−Mo Electrocatalysts for Oxygen Reduction Reaction in Fuel Cells. J. Phys. Chem. C 2008, 112, 12037–12043. [Google Scholar] [CrossRef]

- Sikeyi, L.L.; Ntuli, T.D.; Maxakato, N.W.; Coville, N.J.; Maubane-Nkadimeng, M.S. Highly Active Bimetallic Nanocatalysts (Pd/Ag and Pd/ZnO) Decorated Nitrogen-Doped Onion-like Carbon Nanoparticles for Enhanced Methanol Oxidation in Alkaline Media. J. Power Sources 2024, 613, 234802. [Google Scholar] [CrossRef]

- Yao, C.; Li, M.; Xue, Z.; Yang, Z.; He, K.; Chen, Q.; Cheng, B.; Wang, R.; Cai, S.; Qiao, X.; et al. Three-Dimensional MXene-Based Pd/Ni/Cu Electrocatalyst for Methanol Oxidation Reaction with Efficient Performance. ACS Appl. Nano Mater. 2024, 7, 19628–19636. [Google Scholar] [CrossRef]

- Mandal, K.; Bhattacharjee, D.; Roy, P.S.; Bhattacharya, S.K.; Dasgupta, S. Room Temperature Synthesis of Pd–Cu Nanoalloy Catalyst with Enhanced Electrocatalytic Activity for the Methanol Oxidation Reaction. Appl. Catal. A Gen. 2015, 492, 100–106. [Google Scholar] [CrossRef]

- Mansor, M.; Timmiati, S.N.; Wong, W.Y.; Mohd Zainoodin, A.; Lim, K.L.; Kamarudin, S.K. NiPd Supported on Mesostructured Silica Nanoparticle as Efficient Anode Electrocatalyst for Methanol Electrooxidation in Alkaline Media. Catalysts 2020, 10, 1235. [Google Scholar] [CrossRef]

- Tan, Q.; Shu, C.; Abbott, J.; Zhao, Q.; Liu, L.; Qu, T.; Chen, Y.; Zhu, H.; Liu, Y.; Wu, G. Highly Dispersed Pd-CeO2 Nanoparticles Supported on N-Doped Core–Shell Structured Mesoporous Carbon for Methanol Oxidation in Alkaline Media. ACS Catal. 2019, 9, 6362–6371. [Google Scholar] [CrossRef]

- Gao, Z.; Li, A.; Liu, X.; Peng, M.; Yu, S.; Wang, M.; Ge, Y.; Li, C.; Wang, T.; Wang, Z.; et al. Shielding Pt/γ-Mo2N by Inert Nano-Overlays Enables Stable H2 Production. Nature 2025, 638, 690–696. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, V.; Kumari, N.; Kaur, G.A.; Saha, A.; Thakur, S.; Shandilya, M. Recent Advances in Perovskite Materials: Exploring Multifaceted Properties for Energy Harvesting Applications. Ionics 2024, 30, 5159–5188. [Google Scholar] [CrossRef]

- Li, L.; Tan, S.; Salvatore, K.L.; Wong, S.S. Nanoscale Perovskites as Catalysts and Supports for Direct Methanol Fuel Cells. Chem. A Eur. J 2019, 25, 7779–7797. [Google Scholar] [CrossRef]

- Singh, R.N.; Sharma, T.; Singh, A.; Anindita, R.; Mishra, D.; Tiwari, S.K. Perovskite-Type La2−xSrxNiO4 (0≤x≤1) as Active Anode Materials for Methanol Oxidation in Alkaline Solutions. Electrochim. Acta 2008, 53, 2322–2330. [Google Scholar] [CrossRef]

- Prince, A.G.; Durai, L.; Badhulika, S. Solid State Synthesis of a RuNiO3 Perovskite Nanomaterial as an Electro-Catalyst for Direct Alcohol (Ethanol, Methanol and Ethylene Glycol) Fuel Cell Applications. New J. Chem. 2023, 47, 3870–3879. [Google Scholar] [CrossRef]

- Ekrami-Kakhki, M.-S.; Yavari, Z.; Saffari, J.; Ekrami-Kakhki, S.A. Perovskite-Type LaFeO3 and LaFeO3-CNTs Nanocrystals as Active Anode for Methanol Oxidation in Alkaline Solutions. J. Electr. Eng. 2016, 4, 88–99. [Google Scholar] [CrossRef]

- Stottlemyer, A.L.; Weigert, E.C.; Chen, J.G. Tungsten Carbides as Alternative Electrocatalysts: From Surface Science Studies to Fuel Cell Evaluation. Ind. Eng. Chem. Res. 2011, 50, 16–22. [Google Scholar] [CrossRef]

- Antolini, E.; Gonzalez, E.R. Tungsten-Based Materials for Fuel Cell Applications. Appl. Catal. B Environ. 2010, 96, 245–266. [Google Scholar] [CrossRef]

- Can, F.; Courtois, X.; Duprez, D. Tungsten-Based Catalysts for Environmental Applications. Catalysts 2021, 11, 703. [Google Scholar] [CrossRef]

- Elezovic, N.R.; Zabinski, P.; Ercius, P.; Wytrwal, M.; Radmilovic, V.R.; Lačnjevac, U.Č.; Krstajic, N.V. High Surface Area Pd Nanocatalyst on Core-Shell Tungsten Based Support as a Beneficial Catalyst for Low Temperature Fuel Cells Application. Electrochim. Acta 2017, 247, 674–684. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, S.; Marinkovic, N.; Kattel, S.; Shao, M.; Yang, B.; Chen, J.G. Insight into the Synergistic Effect between Nickel and Tungsten Carbide for Catalyzing Urea Electrooxidation in Alkaline Electrolyte. Appl. Catal. B Environ. 2018, 232, 365–370. [Google Scholar] [CrossRef]

- Zhou, W.; Wachs, I.E.; Kiely, C.J. Nanostructural and Chemical Characterization of Supported Metal Oxide Catalysts by Aberration Corrected Analytical Electron Microscopy. Curr. Opin. Solid State Mater. Sci. 2012, 16, 10–22. [Google Scholar] [CrossRef]

- Del Angel, P.; Hernandez-Pichardo, M.L.; Montoya De La Fuente, J.A. Aberration-Corrected HRTEM Study of Mn-Doped Tungstated Zirconia Catalysts. Catal. Today 2013, 212, 201–205. [Google Scholar] [CrossRef]

- Hou, G.; Shen, Z.; Tang, Y.; Chen, Q.; Cao, H.; Zhang, H.; Zheng, G.; Zhang, J. Ni-WC Nanoparticles/Carbon Aerogel Electrocatalytic Electrode for Methanol and Urea Electrooxidation. Int. J. Hydrogen Energy 2023, 48, 991–1000. [Google Scholar] [CrossRef]

- Kelly, T.G.; Stottlemyer, A.L.; Ren, H.; Chen, J.G. Comparison of O–H, C–H, and C–O Bond Scission Sequence of Methanol on Tungsten Carbide Surfaces Modified by Ni, Rh, and Au. J. Phys. Chem. C 2011, 115, 6644–6650. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Brooks, R.M.; El-Halwany, M.M.; Yousef, A.; Nafady, A.; Hameed, R.M.A. CoCr7C3-like Nanorods Embedded on Carbon Nanofibers as Effective Electrocatalyst for Methanol Electro-Oxidation. Int. J. Hydrogen Energy 2018, 43, 9943–9953. [Google Scholar] [CrossRef]

- Zhou, H.-C.; Long, J.R.; Yaghi, O.M. Introduction to Metal–Organic Frameworks. Chem. Rev. 2012, 112, 673–674. [Google Scholar] [CrossRef]

- Liu, C.; Wang, J.; Wan, J.; Yu, C. MOF-on-MOF Hybrids: Synthesis and Applications. Coord. Chem. Rev. 2021, 432, 213743. [Google Scholar] [CrossRef]

- Ding, M.; Cai, X.; Jiang, H.-L. Improving MOF Stability: Approaches and Applications. Chem. Sci. 2019, 10, 10209–10230. [Google Scholar] [CrossRef] [PubMed]

- Chai, L.; Pan, J.; Hu, Y.; Qian, J.; Hong, M. Rational Design and Growth of MOF-on-MOF Heterostructures. Small 2021, 17, 2100607. [Google Scholar] [CrossRef]

- Yu, J.; Mu, C.; Yan, B.; Qin, X.; Shen, C.; Xue, H.; Pang, H. Nanoparticle/MOF Composites: Preparations and Applications. Mater. Horiz. 2017, 4, 557–569. [Google Scholar] [CrossRef]

- Zhou, W.-Q.; Xi, B.-J.; Chang, X.-W.; Wang, B.; Wu, X.-Q.; Li, S.; Wu, Y.-P.; Li, D.-S. Facile in Situ Transformation of NiOOH into MOF-74(Ni)/NiO OH Heterogeneous Composite for Enchancing Electrocatalytic Methanol Oxidation. Molecules 2022, 27, 2113. [Google Scholar] [CrossRef] [PubMed]

- Sheikhi, S.; Jalali, F. Copper Selenide—Porous Carbon Derived from Metal-Organic Frameworks as an Efficient Electrocatalyst for Methanol Oxidation. Int. J. Hydrogen Energy 2024, 55, 864–874. [Google Scholar] [CrossRef]

- Rajpure, M.M.; Jadhav, H.S.; Kim, H. Advanced LDH-MOF Derived Bimetallic NiCoP Electrocatalyst for Methanol Oxidation Reaction. Colloids Surf. A Physicochem. Eng. Asp. 2022, 654, 130062. [Google Scholar] [CrossRef]

- Khan, M.E. State-of-the-Art Developments in Carbon-Based Metal Nanocomposites as a Catalyst: Photocatalysis. Nanoscale Adv. 2021, 3, 1887–1900. [Google Scholar] [CrossRef]

- Trogadas, P.; Fuller, T.F.; Strasser, P. Carbon as Catalyst and Support for Electrochemical Energy Conversion. Carbon 2014, 75, 5–42. [Google Scholar] [CrossRef]

- Wildgoose, G.G.; Banks, C.E.; Compton, R.G. Metal Nanoparticles and Related Materials Supported on Carbon Nanotubes: Methods and Applications. Small 2006, 2, 182–193. [Google Scholar] [CrossRef]

- Karczmarska, A.; Adamek, M.; El Houbbadi, S.; Kowalczyk, P.; Laskowska, M. Carbon-Supported Noble-Metal Nanoparticles for Catalytic Applications—A Review. Crystals 2022, 12, 584. [Google Scholar] [CrossRef]

- Huang, H.; Wang, X. Recent Progress on Carbon-Based Support Materials for Electrocatalysts of Direct Methanol Fuel Cells. J. Mater. Chem. A 2014, 2, 6266–6291. [Google Scholar] [CrossRef]

- Xiong, J.; Wang, Y.; Yang, C.; Yang, L.; Zhang, C.; Jiang, Q.; He, H.; Ying, G.; Huang, H. Confining Rhodium Nanocrystals into Polyaniline Nanorod-Embedded MXene Nanoarchitectures Enables Efficient Methanol Electrooxidation. J. Colloid Interface Sci 2025, 695, 137809. [Google Scholar] [CrossRef] [PubMed]

- Belenkov, E.A.; Greshnyakov, V.A. Classification of Structural Modifications of Carbon. Phys. Solid State 2013, 55, 1754–1764. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Avouris, P. (Eds.) Carbon Nanotubes: Synthesis, Structure, Properties, and Applications; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2001; ISBN 978-3-540-41086-7. [Google Scholar]

- Hirsch, A. Functionalization of Single-Walled Carbon Nanotubes. Angew. Chem. Int. Ed. 2002, 41, 1853. [Google Scholar] [CrossRef]

- Zhang, J.; Terrones, M.; Park, C.R.; Mukherjee, R.; Monthioux, M.; Koratkar, N.; Kim, Y.S.; Hurt, R.; Frackowiak, E.; Enoki, T.; et al. Carbon Science in 2016: Status, Challenges and Perspectives. Carbon 2016, 98, 708–732. [Google Scholar] [CrossRef]

- Ramli, Z.A.C.; Kamarudin, S.K. Platinum-Based Catalysts on Various Carbon Supports and Conducting Polymers for Direct Methanol Fuel Cell Applications: A Review. Nanoscale Res. Lett. 2018, 13, 410. [Google Scholar] [CrossRef]

- Wissler, M. Graphite and Carbon Powders for Electrochemical Applications. J. Power Sources 2006, 156, 142–150. [Google Scholar] [CrossRef]

- Zainoodin, A.M.; Kamarudin, S.K.; Daud, W.R.W. Electrode in Direct Methanol Fuel Cells. Int. J. Hydrogen Energy 2010, 35, 4606–4621. [Google Scholar] [CrossRef]

- Cao, R.; Lee, J.; Liu, M.; Cho, J. Recent Progress in Non-Precious Catalysts for Metal-Air Batteries. Adv. Energy Mater. 2012, 2, 816–829. [Google Scholar] [CrossRef]

- Antolini, E. Carbon Supports for Low-Temperature Fuel Cell Catalysts. Appl. Catal. B Environ. 2009, 88, 1–24. [Google Scholar] [CrossRef]

- Liu, Y.; Ji, C.; Gu, W.; Jorne, J.; Gasteiger, H.A. Effects of Catalyst Carbon Support on Proton Conduction and Cathode Performance in PEM Fuel Cells. J. Electrochem. Soc. 2011, 158, B614–B621. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Hu, Y.H. Recent Advances in Graphene-based Materials for Fuel Cell Applications. Energy Sci. Eng. 2021, 9, 958–983. [Google Scholar] [CrossRef]

- Choi, S.M.; Seo, M.H.; Kim, H.J.; Kim, W.B. Synthesis of Surface-Functionalized Graphene Nanosheets with High Pt-Loadings and Their Applications to Methanol Electrooxidation. Carbon 2011, 49, 904–909. [Google Scholar] [CrossRef]

- Chen, W.-F.; Wang, J.-P.; Hsu, C.-H.; Jhan, J.-Y.; Teng, H.; Kuo, P.-L. Nanostructured Coral-like Carbon as Pt Support for Fuel Cells. J. Phys. Chem. C 2010, 114, 6976–6982. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, X.; Liu, S.; Fan, H.-L.; Ju, W.; Wang, Q.-C.; Ma, J. Vertically Aligned Carbon Nanotubes/Carbon Fiber Paper Composite to Support Pt Nanoparticles for Direct Methanol Fuel Cell Application. J. Phys. Chem. Solids 2017, 102, 99–104. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Y.; Matson, D.W.; Li, J.; Lin, Y. Nitrogen-Doped Graphene and Its Application in Electrochemical Biosensing. ACS Nano 2010, 4, 1790–1798. [Google Scholar] [CrossRef]

- Pan, C.; Qiu, L.; Peng, Y.; Yan, F. Facile Synthesis of Nitrogen-Doped Carbon–Pt Nanoparticle Hybrids via Carbonization of Poly([Bvim][Br]-Co-Acrylonitrile) for Electrocatalytic Oxidation of Methanol. J. Mater. Chem. 2012, 22, 13578. [Google Scholar] [CrossRef]

- Forootan Fard, H.; Khodaverdi, M.; Pourfayaz, F.; Ahmadi, M.H. Application of N-Doped Carbon Nanotube-Supported Pt-Ru as Electrocatalyst Layer in Passive Direct Methanol Fuel Cell. Int. J. Hydrogen Energy 2020, 45, 25307–25316. [Google Scholar] [CrossRef]

- Lee, E.; Manthiram, A. One-Step Reverse Microemulsion Synthesis of Pt–CeO2 /C Catalysts with Improved Nanomorphology and Their Effect on Methanol Electrooxidation Reaction. J. Phys. Chem. C 2010, 114, 21833–21839. [Google Scholar] [CrossRef]

- Ito, Y.; Takeuchi, T.; Tsujiguchi, T.; Abdelkareem, M.A.; Nakagawa, N. Ultrahigh Methanol Electro-Oxidation Activity of PtRu Nanoparticles Prepared on TiO2-Embedded Carbon Nanofiber Support. J. Power Sources 2013, 242, 280–288. [Google Scholar] [CrossRef]

- Park, K.-W.; Han, S.-B.; Lee, J.-M. Photo(UV)-Enhanced Performance of Pt–TiO2 Nanostructure Electrode for Methanol Oxidation. Electrochem. Commun. 2007, 9, 1578–1581. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, W.; Du, Y.; Yang, P.; Wang, C.; Xu, J. Enhanced Electrocatalytic Performance for Methanol Oxidation on Pt–TiO2/ITO Electrode under UV Illumination. Int. J. Hydrogen Energy 2010, 35, 13290–13297. [Google Scholar] [CrossRef]

- Zhou, C.; Peng, F.; Wang, H.; Yu, H.; Peng, C.; Yang, J. Development of Stable PtRu Catalyst Coated with Manganese Dioxide for Electrocatalytic Oxidation of Methanol. Electrochem. Commun. 2010, 12, 1210–1213. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, H.; Peng, F.; Liang, J.; Yu, H.; Yang, J. MnO2/CNT Supported Pt and PtRu Nanocatalysts for Direct Methanol Fuel Cells. Langmuir 2009, 25, 7711–7717. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Vogel, W.; Chu, P.P.-J. Nanostructure and Surface Composition of Pt and Ru Binary Catalysts on Polyaniline-Functionalized Carbon Nanotubes. Langmuir 2011, 27, 14654–14661. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xia, G.; Huang, C.; Wang, Y. Preparation and Characterization of Pt Nanoparticles Supported on Modified Graphite Nanoplatelet Using Solution Blending Method. Int. J. Hydrogen Energy 2013, 38, 8909–8913. [Google Scholar] [CrossRef]

- Rajendra Prasad, K.; Munichandraiah, N. Electrooxidation of Methanol on Polyaniline without Dispersed Catalyst Particles. J. Power Sources 2002, 103, 300–304. [Google Scholar] [CrossRef]

- Niu, L.; Li, Q.; Wei, F.; Chen, X.; Wang, H. Electrochemical Impedance and Morphological Characterization of Platinum-Modified Polyaniline Film Electrodes and Their Electrocatalytic Activity for Methanol Oxidation. J. Electroanal. Chem. 2003, 544, 121–128. [Google Scholar] [CrossRef]

- Zhiani, M.; Rezaei, B.; Jalili, J. Methanol Electro-Oxidation on Pt/C Modified by Polyaniline Nanofibers for DMFC Applications. Int. J. Hydrogen Energy 2010, 35, 9298–9305. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhan, L.; Tian, J.; Nie, S.; Ning, Z. Enhanced Electrocatalytic Oxidation of Methanol on Pd/Polypyrrole–Graphene in Alkaline Medium. Electrochim. Acta 2011, 56, 1967–1972. [Google Scholar] [CrossRef]

- Luo, B.; Yan, X.; Xu, S.; Xue, Q. Polyelectrolyte Functionalization of Graphene Nanosheets as Support for Platinum Nanoparticles and Their Applications to Methanol Oxidation. Electrochim. Acta 2012, 59, 429–434. [Google Scholar] [CrossRef]

| No. | Author and Time | Refs | Catalyst Preparation Method or Calculation Method | Metals | Catalyst Size or Catalyst Crystal Spacing of Interest | Catalyst Performance or Key Findings |

|---|---|---|---|---|---|---|

| 1 | Sanja Stevanović1 et al., 2021 | [49] | Microwave-assisted polyol process | Pt, Sn | PtSnO2/C: <2 nm SnO2: ~2 nm PtSn/C: ~2 nm Pt3Sn: ~3 nm | The methanol oxidation activity on PtSn/C was increased by about two times compared to that on Pt/C catalysts. |

| 2 | Huixian Shi et al., 2020 | [50] | Silicon monoxide reduction process | Pt, Au | Pt intergranular spacing: 0.226 nm, corresponding to the Pt(111) crystal plane | Pt0.05AuNWNs with a Pt content of 1 wt% were used as catalysts for MOR, with mass activities as high as 2282.3 mA·mgpt−1. |

| 3 | L. C. Ordóñez et al., 2016 | [51] | Metal carbonyl pyrolysis | Pt, Mo | Microcrystalline size of PtMo/C: 4.7~9.3 nm, Pt/C: ~5.4 nm | In the PtMo/C series, the low molybdenum content had the greatest promoter effect on the electro-oxidation of methanol. |

| 4 | Rui Zhang et al., 2018 | [52] | Electro-substitution reaction method | Pt, Ag | The d(111)-spacing for PtAg is 0.228 nm | PtAg/graphene demonstrated superior specific/plasmonic activity and CO tolerance versus Pt/C. |

| 5 | V.S.Men’shchikova et al., 2020 | [53] | Prepared by multi-stage reduction of metal precursors with sodium borohydride | Pt, Cu | The specific activity of this catalyst was 5–7 times higher than that of commercial Pt/C catalysts. | |

| 6 | Tingting Yang et al., 2022 | [54] | Using Density Functional Theory (DFT) | Pt, Pd | PtPd alloys can effectively improve the catalytic efficiency of single metals and also reduce CO poisoning. | |

| 7 | Mustafa Ercelik et al., 2017 | [55] | Sol–gel-synthesized TiO2 was integrated into commercial PtRu/C with controlled loadings (5, 15, 25 wt%). | Pt, Ru | Incorporating 5 wt% polyvinyl alcohol stabilized the polymer, while commercial TiO2 addition to Pt-Ru/C enhanced catalyst durability. | |

| 8 | Li Min et al., 2017 | [56] | Hydrothermal method | Pt, Fe | The particle size of Fe3O4@Pt is 200~300 nm | The peak current density of the prepared Fe3O4@Pt catalyst was about 1.1 times that of the pure Pt catalyst. |

| Catalyst Name | Refs | Mass Activity (Baseline) | Mass Activity (Novel) | Key Improvements/Mechanisms |

|---|---|---|---|---|

| PtRuFe/C (2:1:1) | [79] | 2.28 A/g catal | 5.67 A/g catal | 2.5× higher mass activity; Fe2O3 induces Pt electron deficiency, enhancing CO oxidation. |

| PtRuFe nanodendrites | [80] | 0.19 A/mg Pt (Pt/C) | 1.14 A/mg Pt | 6× mass activity vs. Pt/C; ultrathin branches and ternary synergy improve CO tolerance. |

| PtRuMo/MWCNT | [81] | 12.6 A/cm2·mg (PtRu/C) | 15 A/cm2·mg | Enhanced ECSA (138 vs. 134 m2/g); Mo promotes water activation and reduces CO adsorption. |

| Pt43-Ru43-Mo14/MWCNT | [82] | 0.19 A/mg Pt (Pt/C) | 1.14 A/mg Pt | 6× mass activity vs. Pt/C; flash synthesis improves dispersion; Mo enhances CO tolerance. |

| PtRuNi/C | [85] | 30.6 m2/g EAS (PtRu/C) | 40.7 m2/g EAS | CO oxidation peak decline; Ni(OH)2 enables H-spillover and proton conduction; high stability. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Jiang, Y. Sustainable Anodes for Direct Methanol Fuel Cells: Advancing Beyond Platinum Scarcity with Low-Pt Alloys and Non-Pt Systems. Sustainability 2025, 17, 5086. https://doi.org/10.3390/su17115086

Zhao L, Jiang Y. Sustainable Anodes for Direct Methanol Fuel Cells: Advancing Beyond Platinum Scarcity with Low-Pt Alloys and Non-Pt Systems. Sustainability. 2025; 17(11):5086. https://doi.org/10.3390/su17115086

Chicago/Turabian StyleZhao, Liangdong, and Yankun Jiang. 2025. "Sustainable Anodes for Direct Methanol Fuel Cells: Advancing Beyond Platinum Scarcity with Low-Pt Alloys and Non-Pt Systems" Sustainability 17, no. 11: 5086. https://doi.org/10.3390/su17115086

APA StyleZhao, L., & Jiang, Y. (2025). Sustainable Anodes for Direct Methanol Fuel Cells: Advancing Beyond Platinum Scarcity with Low-Pt Alloys and Non-Pt Systems. Sustainability, 17(11), 5086. https://doi.org/10.3390/su17115086