1. Introduction

The evolution of industrial systems has been increasingly shaped by the principles of digitalisation, automation, and sustainability. These shifts, encapsulated by the concept of Industry 4.0, are widely recognised as key enablers of transformation across manufacturing and logistics domains [

1,

2]. At the same time, the imperative to integrate environmental and social responsibility into industrial strategy has grown steadily, reinforcing the relevance of sustainable development in both research and practice [

3]. In particular, Bag et al. [

3] emphasise that the adoption of advanced manufacturing capabilities—rooted in the “10R” framework—can facilitate the alignment of Industry 4.0 implementation with sustainability goals. The convergence of these domains creates new opportunities and challenges, thus calling for integrated frameworks that support strategic decisions under complexity [

4].

Building on this foundation, Vrchota et al. [

1] provide a systematic review of how green process outcomes are linked to Industry 4.0 initiatives in the manufacturing sector, highlighting the measurable impacts of digital transformation on sustainability performance. However, despite these opportunities, several studies underline the existence of persistent organisational and technological barriers that hinder the transition towards more sustainable operations. Kumar et al. [

5], for example, analyse structural impediments and coordination challenges in implementing circular supply chains under Industry 4.0 conditions.

Recent studies have highlighted the importance of balancing technological advancement with economic, environmental, and social considerations when deploying Industry 4.0 solutions. For instance, Bag et al. [

6] propose a strategic roadmap for sustainable supply chain transformation through digital innovation. Other contributions highlight the potential of circular economy principles to reinforce resource efficiency and stakeholder engagement in technologically advanced production systems [

6,

7]. Moreover, interdisciplinary research increasingly recognises the need for systemic approaches to Industry 4.0 planning—ones that integrate resilience, agility, and sustainability [

8,

9]. This perspective reflects a shift from purely efficiency-driven transformation to more inclusive and long-term oriented models of industrial development.

In light of this, a growing body of literature supports the integration of sustainability frameworks and digital technologies within comprehensive decision-making architectures [

10,

11]. However, the current research remains fragmented in terms of how to evaluate and prioritise technologies under sustainability criteria, especially when strategic transformation is expected to address both production and logistics domains simultaneously. This study addresses that gap by proposing a multi-criteria evaluation model that links sustainability perspectives with Industry 4.0 and 5.0 technologies in an integrated decision-support structure.

The review of the existing literature indicates a significant research gap in the application of multi-criteria decision analysis (MCDM) methods to assess and identify issues covering three areas: sustainable development, Industry 4.0—with particular emphasis on production and supply chains—and modern technologies supporting these areas. Existing approaches frequently analyse these issues in a fragmented manner, without identifying the interdependencies and technological hierarchies. This article contributes novel cognitive value by (i) developing an integrated model that simultaneously takes into account, within Industry 4.0, four subspheres of sustainable production, four subspheres of supply chain management, twelve technologies from the area of production, eleven technologies from the area of logistics, and four main areas of sustainable development in enterprises; and (ii) building a ranking of the importance of the elements within the aforementioned domains.

The developed analysis scheme is based on the application of the DEMATEL–PROMETHEE II hybrid decision-making method, which enables both the identification of cause-and-effect relationships between the elements studied and their prioritisation within the decision-making process. The Industry 4.0 philosophy, combined with sustainable production and supply chain management, raises critical questions among both business practitioners and the academic community. To address the research gap, the following research questions have been formulated:

RQ1: Which modern technologies are the most important and should be prioritised by companies striving to implement the Industry 4.0 concept in the area of production and logistics?

RQ2: In what sequence should companies implement selected technologies and key aspects of production and supply chain management to effectively implement the goals of sustainable Industry 4.0?

The remainder of the article is structured as follows:

Section 2 comprises a review of related literature.

Section 3 describes the model of 23 technologies, 8 subspheres of production and logistics within Industry 4.0, and 4 spheres of sustainable development.

Section 4 is the theoretical foundations of the combined DEMATEL and PROMETHEE II methodology.

Section 5 illustrates the application of the proposed methodology to build rankings of model elements.

Section 6 contains a summary, formulates research limitations, and lays out directions for model development.

3. Industry 4.0, Sustainable Production, and Supply Chains

Modern enterprises operate in a rapidly evolving environment, where advanced technologies and increasing sustainability requirements play a pivotal role. The Industry 4.0 paradigm is revolutionising production processes and supply chain management by integrating intelligent systems, automation, and real-time data analysis. The impact of innovative technologies on sustainable production is becoming increasingly evident enabling companies to achieve higher operational efficiency while minimising their environmental footprint. Organisations that can effectively integrate digitalization, supply chain optimisation, and environmental and social responsibility gain a competitive advantage and long-term stability.

Table 1 proposes four subspheres each from the manufacturing (I1–I4) and supply chain and logistics (S1–S4) domains as characteristics of Industry 4.0, along with 23 related modern technologies. They collectively address Research Question 1 (RQ1).

In order to ensure clarity when analysing the relationships and rankings within the model, a consistent coding scheme has been adopted:

Subspheres within manufacturing are denoted by the prefix I (e.g., I1–I4), while subspheres within supply chain and logistics use the prefix S (e.g., S1–S4).

Correspondingly, technologies related to manufacturing are labelled with D (D11–D42), and those related to supply chain and logistics are labelled with G (G11–G43).

This structure enables immediate recognition of the domain to which each component belongs and enhances the interpretability of model outputs, particularly in hierarchical rankings and influence diagrams.

Below are brief characteristics of Industry 4.0 subspheres in manufacturing (I1–I4) and supply chain and logistics (S1–S4).

Digital transformation and intelligent management systems (I1) from the foundation of Industry 4.0. Smart management systems integrating AI, IoT, big data, and blockchain enable process automation, failure prediction, and ongoing production optimisation. As a result, they increase operational efficiency, reduce raw material losses, and support the implementation of a circular economy. Advanced automation and robotics leverage AI (I2), collaborative robots (cobots), and autonomous systems to improve production efficiency. These technologies improve production, reduce costs and resource consumption, increase operational flexibility and improve work safety, while minimising the impact of industry on the environment. Energy optimisation in manufacturing (I3) is achieved through smart energy management systems, which integrate AI, IoT, and Big Data tools. These systems monitor energy consumption in real time, enable the integration of renewable energy sources, and support the transition to low-emission and energy-efficient production. Sustainable materials and green manufacturing processes (I4) play a key role in reducing the environmental footprint of the industry. The use of renewable, biodegradable, and recycled raw materials, combined with clean technologies and AI-supported systems, helps reduce emissions, limit resource consumption, and support environmental and corporate social responsibility (CSR) objectives. Smart logistics and transport optimisation (S1) are based on transportation management systems, which, supported by IoT, GPS, and blockchain, optimise delivery routes, monitor deliveries, and reduce pollutant emissions. The use of autonomous vehicles and logistics drones increases the flexibility and operational efficiency of the entire supply chain. Digital supply chain tracking and transparency (S2) powered by IoT and blockchain ensures real-time visibility into the location and condition of products. These technologies increase process transparency, eliminate the risk of counterfeiting, and enhance the safety and sustainability of logistics. Circular supply chain and the circular economy (S3) focus on the reuse, regeneration and recycling of resources. Through modular product design and new business models, it is possible to extend the life cycle of products, reduce emissions and significantly minimise waste. Smart warehouses and distribution hubs (S4) use AI, IoT and warehouse management systems (WMS) technologies to automate operations, monitor goods and optimise spatial efficiency. These innovations enhance operational performance, reduce losses and support the sustainable development of logistics and the entire supply chain.

Twelve technologies (D11–D42) related to production and eleven technologies (G11–G43) related to logistics are characterised within Industry 4.0.

Big data, AI, and machine learning (D11) enable real-time data analysis, production optimisation, failure prediction, and downtime reduction. These technologies enhance quality, flexibility, and operational efficiency, supporting sustainable industrial development. Digital twins (D12) represent physical processes and machines, enabling real-time monitoring, simulation, and optimisation. They support waste reduction, test innovations, extend equipment lifecycles, and achieve sustainable development goals. The Internet of Things (IoT) (D13) provides continuous monitoring of resources and processes, increasing efficiency and reducing losses. Thanks to sensors and data analysis, it supports energy management, predictive maintenance, and logistics optimisation in line with sustainable development. Cybersecurity (D14) ensures the protection of industrial data and systems from attacks, sabotage, and data breaches. It ensures infrastructure protection and business continuity, supporting resilient, sustainable development within Industry 4.0. Collaborative robots (cobots) (D21) operate alongside human workers, performing repetitive tasks using AI, the IoT, and vision systems. They enhance efficiency, reduce waste, and improve ergonomics, supporting flexible and safe manufacturing. Autonomous production systems (D22) continuously monitor and adapt processes in real time. They minimise waste and optimise resource and energy usage, supporting sustainable manufacturing and the circular economy. Robots equipped with vision systems and artificial intelligence (D23) analyse the environment, perform quality control, and flexibly adapt operations. They enhance precision, reduce waste, and enable more efficient resource management. Autonomous mobile robots (AMR) (D24) utilise AI, IoT, and vision systems to independently autonomously transport materials. They optimise internal logistics, reduce energy consumption, and enhance flexibility and operational efficiency. Intelligent energy management systems (EMS), smart grid and digital twins (D31) monitor energy consumption in real time, detect losses, and implement optimizations. They support network management and the integration of renewable energy sources, increasing energy efficiency and system resilience. Integration with renewable energy sources (RES) and storage systems (D32), such as batteries or hydrogen storage, reduces emissions and stabilises power supply. These solutions enable energy consumption optimisation and support the implementation of Industry 4.0 climate goals. Modern, sustainable materials and raw inputs (D41), such as biopolymers, recycled composites, and renewable raw materials, reduce emissions and resource consumption. Supported by AI and 3D printing, they enhance the product durability and facilitate the circular economy. Energy-efficient manufacturing processes (D42) utilising technologies such as 3D printing, CNC, AI, and IoT reduce raw material and energy consumption. They support precise planning, quality control, and material reuse, minimising the overall carbon footprint.

Dynamic route optimisation (G11) based on AI, IoT, and GPS algorithms enables real-time route planning. It reduces empty mileage, CO2 emissions, and fuel consumption, thereby increasing transport efficiency and punctual delivery. Green logistics (G12) incorporates electric- and hydrogen-powered vehicles, low-emission rail, and drones. Integrated with AI and IoT systems, it optimises routes and mitigates emissions and noise, supporting sustainable transport. Blockchain technology in supply chain management (G21) provides full transparency and traceability of products. It monitors the flow of materials, eliminates counterfeiting and supports ethical and ecological supply. IoT and RFID (G22) enable the real-time monitoring of product location and storage conditions. This reduces losses and waste, especially in the cold chain, thereby improving the efficiency of sustainable logistics. ESG and CO2 emissions reporting systems (G23) facilitate real-time tracking and documentation of greenhouse gas emissions. Integrated with blockchain, they enhance data transparency, regulatory compliance, and stakeholder trust. Reverse logistics (G31) enables the recovery, recycling, and repair of products. Through intelligent systems and blockchain, organisations can effectively classify returns, reduce waste and effectively manage resources in a circular economy. Distributed 3D printing (G32) enables on-demand production of components, eliminating the need for warehousing and reducing transportation emissions. When combined with AI and IoT, it supports local, flexible production and promotes the circular economy. Minimising inventory and raw material losses through AI and big data (G33) enables demand forecasting, inventory optimisation, and raw material reutilization. This approach enhances operational efficiency and fosters the development of sustainable logistics. Autonomous warehouse systems—AGV and AMR (G41)—automate internal transport, optimising routes and decreasing energy consumption. Integrated with WMS, they improve efficiency and reduce resource waste. Ecological packaging (G42), composed of biodegradable, compostable, or reusable materials, replaces plastics. Supported by AI, they enable the optimisation of material use and reduction of the supply chain’s carbon footprint. Intelligent warehouse space management (G43) based on AI and Big Data enables dynamic optimisation of goods allocation. Integration with IoT and WMS shortens picking times, reduces energy consumption and promotes efficient logistics.

Then, based on literature research, four perspectives for Sustainable Industry 4.0 have been established. Given the specific characteristics of manufacturing as well as supply chain and logistics domains, an operational perspective was added to the three commonly recognised sustainability dimensions—ecological–environmental, social, and economic–financial (

Table 2).

4. Solution Methodology

Most of the research on MCDA in the concept of Industry 4.0 focuses on individual methods such as AHP, TOPSIS, or ANP. Only a limited number of studies combine approaches like DEMATEL and PROMETHEE II, despite the potential of such integrations to enhance the accuracy of evaluating decision-making factors. There is a noticeable lack of comprehensive MCDA models that account for the dynamic changes in Industry 4.0.

Industry 4.0 is characterised by highly dynamic processes and rapid technological advancements. Current models fail to fully incorporate variable parameters such as adaptive decision algorithms, artificial intelligence, and IoT in making decisions about sustainable production and supply chain management. While the majority of current studies emphasise resource optimisation, relatively few explore how Industry 4.0 technologies can support decisions about the circular economy in the context of MCDM methods. On the one hand, the majority of existing studies are limited to conceptual models and simulations, with a notable lack of research based on real data from companies implementing Industry 4.0 solutions. On the other hand, due to the framework of industry standards, ISO and similar, the possibility of testing MCDA models in industries such as automotive, aviation, pharmaceuticals, or logistics is limited.

DEMATEL can help with cause–effect analysis and PROMETHEE II can help with ranking alternatives, allowing for better decision evaluation in the dynamic Industry 4.0 environment. This combined approach enables a comprehensive and dynamic analysis of the impact of Industry 4.0 technologies on sustainable production and supply chain management. Using DEMATEL in risk impact analysis and PROMETHEE II to assess resilience strategies can improve supply chain management.

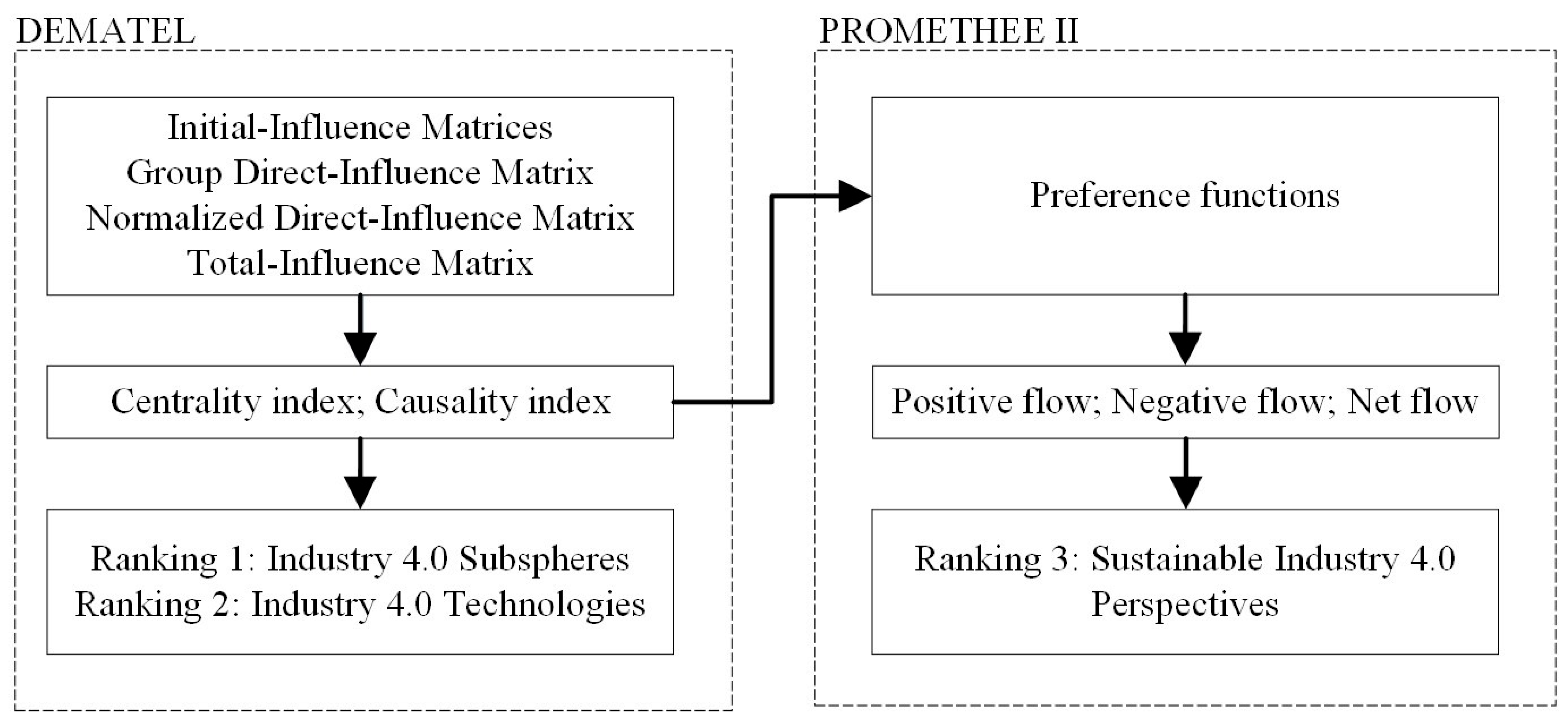

Figure 1 presents a structured overview of the two-phase hybrid methodology integrating DEMATEL and PROMETHEE II.

The left-hand section represents the DEMATEL phase, where the initial matrices are developed, validated, and processed to calculate influence values and determine two rankings: one for Industry 4.0 subspheres and one for technologies. These results are then used as structured input for the PROMETHEE II phase (right-hand side), which involves the evaluation of technologies across sustainability perspectives and the generation of a final ranking. Expert validation is incorporated into both phases. This schematic representation provides a concise visual summary of the proposed hybrid decision-making model.

The DEMATEL (decision-making trial and evaluation laboratory) [

78] methodology is one of the methods of system analysis that allows users

to identify and evaluate cause–effect relationships among factors. This method is mainly used to model complex decision-making systems and analyse the influence of individual factors on each other. In the initial phase,

n experts evaluate the mutual influence of

k criteria on each other, using a scale from, for example, 0 (no influence) to 4 (very strong influence). In this way,

n initial-influence matrices

:

where

denotes expert

m’s assessment of the influence of factor

i on factor

j. To incorporate the perspectives of all experts, the group direct–influence matrix is determined:

The matrix

constructed in this way aggregates expert ratings and represents average influence ratings between factors. To ensure the stability of calculations, the matrix

is normalised, creating normalised direct–influence matrix

The final total-influence matrix

accounts for both direct and indirect influences. It can be represented as an infinite sum of powers of the matrix

:

which leads to the form:

where

is the identity matrix. For the purposes of further analysis, the main indicators for each factor are calculated based on the matrix

. The following are calculated: the total impact

and the received impact

:

The centrality index

indicates the overall significance of a given factor within the system. In contrast, the causality index

reflects whether a factor is a cause

or an effect

. The values of

and

are used as input to PROMETHEE II. Parameters with high values

are key in the analysed system. Factors with high values are classified as causes

and influence other factors. Conversely, factors with low values are classified as effect

and are influenced by other factors. The results can be visualised in a cause–effect diagram (

Using the results of the DEMATEL method, PROMETHEE II [

79] determines the weights of the criteria:

The differences between the alternatives are calculated:

Various forms of preference functions are subsequently applied, including:

which are summed up, taking into account the weights

Next, the positive flow (leaving flow), negative flow (entering flow), and net flow are determined.

A higher net flow value indicates a better evaluation of a given alternative. To assess the internal consistency of expert evaluations used in both methods, Kendall’s coefficient of concordance, denoted as

, was applied. This non-parametric statistic measures the degree of agreement among multiple raters [

80]. The formula is expressed as:

where

is the sum of squared deviations of the sums of ranks from their mean.

5. Results and Discussion

Below, we present a practical application of the proposed methodology to assess three interconnected domains: (i) sustainable development of the Industry 4.0 area, (ii) modern technologies (iii) in the spheres of production and supply chain. Drawing upon a comprehensive literature review, a template was proposed that simultaneously included: four subspheres of production with twelve modern technologies, and four subspheres of the supply chain with eleven modern technologies that support the implementation of four areas of sustainable development in enterprises operating in the Industry 4.0 paradigm. Eleven invited specialists participated in the assessment process. Six experts from this group were experienced practitioners from manufacturing companies, five participants were responsible for supply chain and logistics (SC&L) issues in companies. All declared at least good knowledge of the Industry 4.0 sphere. Experts assessed the degree of influence of one factor on another, using a scale of 0–4. The reliability of expert input used in the DEMATEL method was evaluated using Kendall’s coefficient of concordance (14), denoted as , which measures the degree of agreement among raters. The calculation was performed based on the total outgoing influence values per technology. For experts and technologies, the resulting coefficient was with . This indicates a satisfactory level of internal consistency in the assessments of causal relationships between technologies. The reliability findings are complemented by validity measures, discussed later in the PROMETHEE II section.

The initial-influence matrices

were created (1), which were aggregated (2) into the group direct-influence matrix

(

Table A1 in

Appendix A) and normalised (3) to the normalised direct-influence matrix

(

Table A2 in

Appendix A). Following additional transformations (5), the final total-influence matrix

was obtained (

Table A3 in

Appendix A). Subsequently, based on (6), the centrality

and causality indices

were determined within Industry 4.0 for four production subspheres I1–I4 and twelve related modern technologies D11–D42, as well as for four supply chain and logistics (SC&L) spheres S1–S4 and eleven related modern technologies G11–G43. The results are presented in

Table 3. Centrality indicators

have the highest value for digital transformation and intelligent management systems (I1) and for sustainable materials and ecological production processes (I4) within Manufacturing Industry 4.0. In turn, in the supply chain and logistics part, centrality indicators

have the highest value for digital supply chain tracking and transparency (S2) and circular supply chain and closed-loop economy (S3). These findings suggest that these technology groups are the most influential within the Industry 4.0 framework. Simultaneously, the value of I1 is greater than S2, suggesting that production-related domains hold greater significance than logistics-related ones within the context of Industry 4.0.

Moving on to the centrality indicators

for individual Industry 4.0 technologies, the greatest value in the manufacturing section is attributed to cybersecurity (D14), ecological and energy-efficient production processes that reduce the consumption of raw materials (D42), autonomous production systems (D22), and big data and AI and machine learning (D11). These technologies and the previously mentioned technology groups should be prioritised by company management when developing and implementing Industry 4.0 strategies. The remaining technologies in this set—namely D31, D13, D12, D24, D21, D32, D41, and D23—are therefore of comparatively lesser importance. In terms of centrality indicators

in the supply chain and logistics section, the greatest value is attributed to IoT and RFID for monitoring the status of products in real time (G22), minimising warehouse and raw material losses using AI and big data (G33), intelligent warehouse space management (G43), and autonomous warehouse systems (AGV and AMR) (G41). These technologies should, likewise, be incorporated into companies’ strategic plans to transition toward Industry 4.0. As before, the remaining technologies in this group, G21, G11, G42, G31, G12, G32, and G23, are of lesser importance. In contrast, the causality indicator

allows for the formulation of a cause–effect relationship. A value greater than zero indicates that the parameter influences other criteria. With a value less than zero, the parameter is an “effect”, i.e., it is influenced by other parameters.

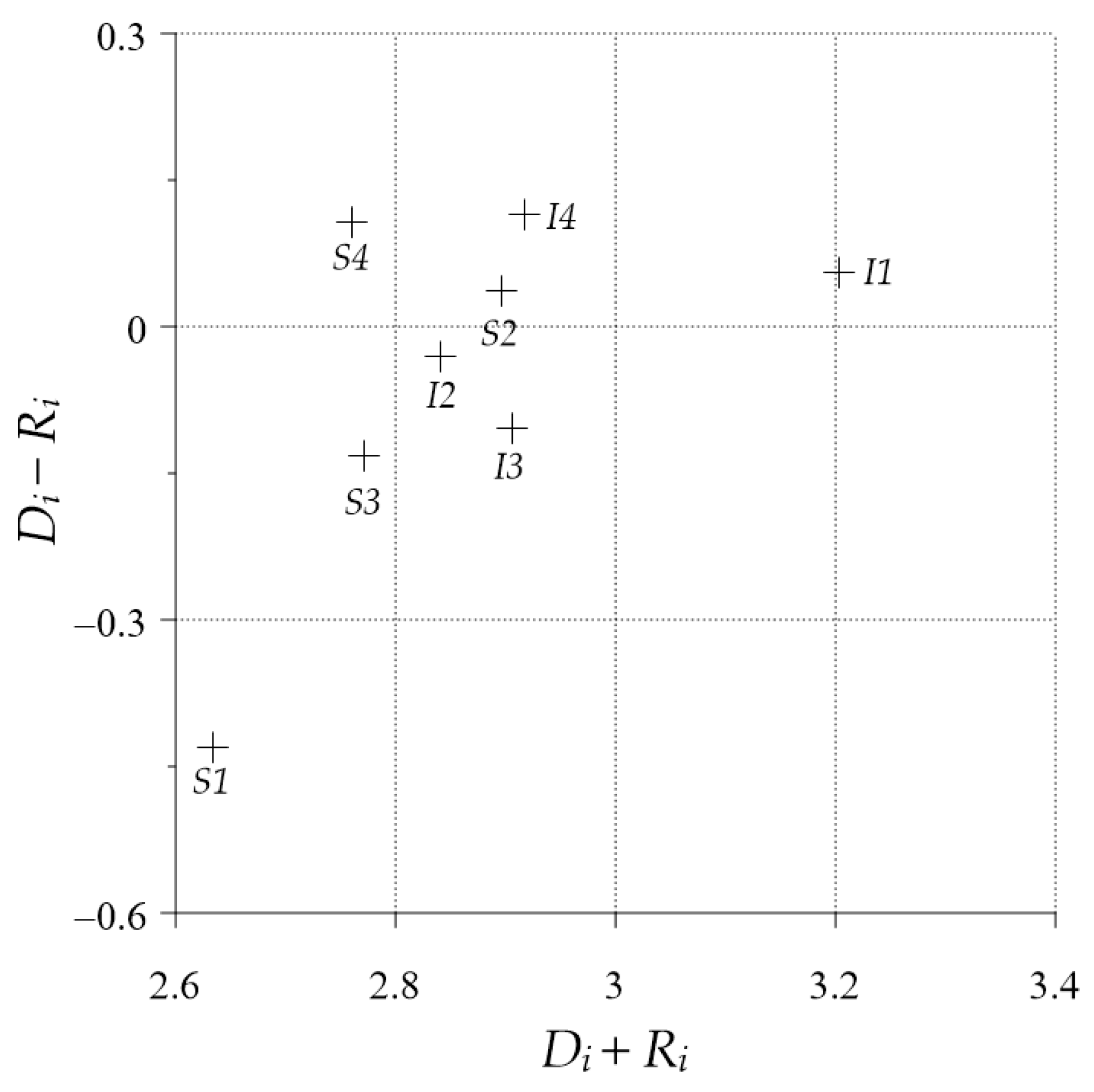

Figure 2 presents a cause–effect graph (

for eight subspheres of manufacturing and supply chain and logistics in the Industry 4.0 sphere.

The causality indicator

has the highest value for sustainable materials and ecological production processes (I4), smart warehouses and distribution hubs (S4), digital transformation and intelligent management systems (I1), and digital supply chain tracking and transparency (S2). These are the groups of technologies that have the greatest impact on other technologies. The remaining four have a negative value of this indicator, which means that other groups have an impact on them. Among them, smart logistics and transport optimisation (S1) is the largest recipient of the impact from others. In a similar effect–cause pattern (

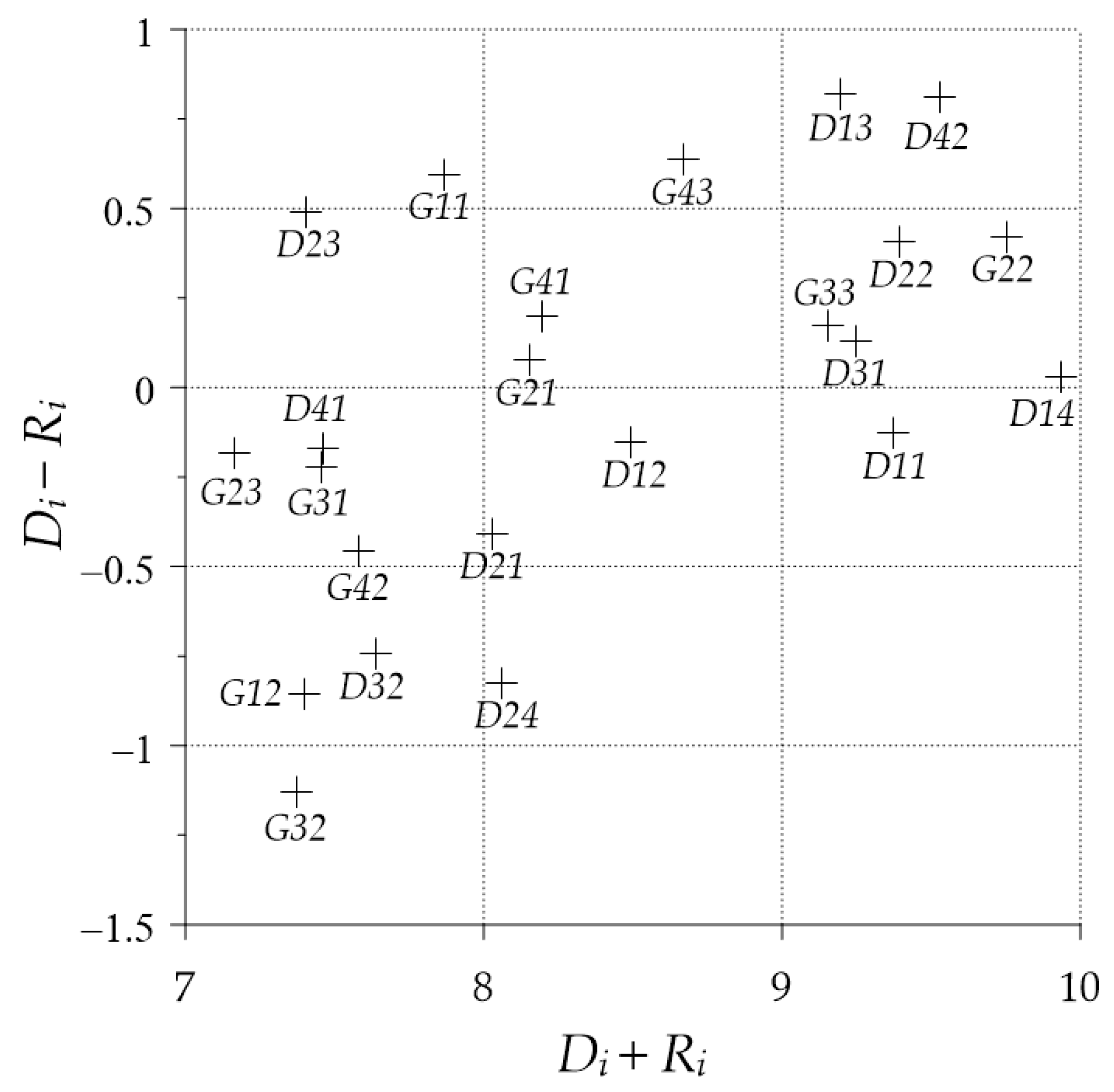

, 23 Industry 4.0 technologies were presented (

Figure 3).

Within this group, the causality indicator

has the highest positive value for Internet of Things—IoT (D13), ecological and energy-efficient production processes reducing the consumption of raw materials (D42), intelligent warehouse space management (G43), and dynamic optimisation of transport routes (G11). These technologies represent the most influential components within the Industry 4.0 framework, exerting a strong impact on other technologies. Conversely, the four technologies exhibiting the highest negative value of this indicator, which means that other groups have an impact on them, are 3D printing in distribution (G32), green logistics (G12), autonomous mobile robots—AMR (D24), and integration with renewable energy sources and energy storage (D32). The above values

and

obtained using the DEMATEL methodology serve as input data for the subsequent application of PROMETHEE II methodology, in which a ranking of four Industry 4.0 sustainable perspectives outlined in

Table 2 will be determined. First, (7) elements of the vector

that creates the Industry 4.0 technology ranking are determined (

Table 4).

Subsequently, experts rate the impact of technology on individual Industry 4.0 sustainable perspectives options on a scale of 1–5 (where 1 represents the least favourable option). Aggregated results are presented in

Table 5. The reliability of expert input used in the PROMETHEE II method was also assessed using (14) Kendall’s coefficient of concordance

. The calculation was based on the impact scores of each technology on the four sustainability perspectives. For the same group of

experts and

technologies, the resulting coefficient was:

with

. This result reflects a high level of agreement among experts when evaluating sustainability impacts. In addition to internal consistency, the validity of the expert input is supported by the use of two independent evaluation sheets: one for causal relationships (DEMATEL) and one for sustainability alignment (PROMETHEE II). This dual structure enables triangulation and strengthens the robustness of the overall findings.

As shown in

Table 5, big data and AI and machine learning (D11) technology exerts the greatest impact on the economic and financial (L3) perspective, the weakest on the ecological–environmental (L1) perspective. For example, cybersecurity (D14) technology also has the greatest impact on the L3 perspective, and this impact exceeds that of D11 technology. Next, (8) the differences between the individual sustainable Industry 4.0 perspectives are identified (

Table A4 in

Appendix A).

Table A4 in

Appendix A illustrates the extent to which sustainable Industry 4.0 perspectives are beneficial for specific Industry 4.0 technologies. For example, for big data and AI and machine learning (D11) and digital twin (D12) technologies, the L4-L1 score is positive, and higher for D11. This indicates that for both technologies, the L4 perspective is more beneficial than the L1. Moreover, since the L4-L1 score is greater for D11, the L4 perspective is more beneficial for D11 than for D12. In the next step, (9) preference functions, preference function classes, preference parameters and the relationship to sustainable Industry 4.0 perspectives are introduced (

Table 6).

The assignment of preference function types, unit definitions, function classes, and parameter values presented in

Table 6 was conducted by the author based on a review of relevant literature and consultations with the expert panel involved in the study. These design choices were made to ensure methodological transparency while enhancing the interpretability and managerial applicability of the PROMETHEE II model in real industrial contexts.

Each technology was assigned either a qualitative or a quantitative type of preference function depending on its characteristics. For technologies assigned quantitative preference functions, operationally meaningful units were proposed for the ‘unit of the preference function’. These units are intended to support managerial interpretation by offering measurable indictors that are practical and easy to determine within companies. For example, for the ‘Internet of Things (IoT)’ technology, the proposed unit is ‘number of sensors’, which represents a concrete and observable metric. This allows decision-makers to assess the degree of IoT implementation in their operations.

Several classes of preference functions have been proposed in the literature [

81]. The most commonly used include: class 1—a function without a threshold value, class 2—a function with a boundary value, and class 3 with a linear distribution of the function. The type of preference function (qualitative or quantitative) affects the value of the parameter for the preference function (

Table A5 in

Appendix A). Parameter 0 for the preference function indicates a low probability of using a given Industry 4.0 perspectives for a given Industry 4.0 Technologies, parameter 2 indicates a high probability of such application.

In the last step of PROMETHEE II, as outlined in (11–13), three essential parameters of this methodology are calculated: positive flow (also known as the leaving flow), negative flow (also known as the entering flow), and net flow. These parameters serve as the foundation for constructing the ranking of sustainable Industry 4.0 parameter alternatives (

Table 7).

The positive flow (also referred to as the leaving flow) quantifies the degree to which a given alternative over all others. In practical terms, this means that the greater the positive flow, the more alternatives are “worse” than a given alternative. In other words, it indicates how preferred a given alternative is to others. In this analysis, the economic and financial perspective (L3) has the highest value of positive flow, which means that it dominates (is the best) compared to the other perspectives in the analysis. The second perspective in this division plane is the operational perspective (L4). Conversely, the negative flow (also known as the entering flow) measures the extent to which other alternatives dominate the given alternative. In practice, this means that the greater the negative flow, the more alternatives outperform a given alternative. It shows how weak a given alternative is in relation to others. In this analysis, the ecological–environmental (L1) perspective has the highest value entering flow, which indicates that the other perspectives are “better” than it. Next in this approach is the social (L2) perspective. These partial parameters are integrated to determine net flow, which is the difference between domination and being dominated. In practice, this is the parameter used to establish the final and unambiguous ranking of alternatives in PROMETHEE II, i.e., the higher the net flow, the better the alternative. In this analysis, the economic and financial perspective (L3) with the highest net flow is the best overall because it dominates the others and at the same time is not dominated by the others. Second place is occupied by the operational perspective (L4), third by the social perspective (L2), and the last place is taken by the ecological–environmental perspective (L1). The above analysis provides strategic guidance for companies aiming to implement a sustainable development strategy in the spheres of production and supply chain for the sequence of actions and implementations of modern technologies of the Industry 4.0 sphere. At the same time, it directly addresses RQ2.

Within the highest-ranked economic and financial (L3) perspective, the key technologies are D42, D22, G33, D12, D21, and G32. In the production sector, companies should prioritise the adoption of technologies that support sustainable development and increase the autonomy and flexibility of manufacturing processes. Ecological and energy-efficient manufacturing processes, designed to reduce the consumption of raw materials and energy, are the basis for a modern approach to environmentally responsible production. Their implementation allows not only to mitigate the negative impact of industrial activity on the environment, but also to reduce operating costs through better resource management. Autonomous manufacturing systems enable independent planning, monitoring, and optimisation of operations in real time, minimising human involvement in the process and increasing efficiency. Digital twin technology provides virtual representations of physical objects and production processes, which enables their analysis, testing, and improvement without interfering with the actual production environment. An important element of modern production are also collaborative robots (cobots), which operate alongside employees, supporting them in tasks requiring precision, repeatability, or lifting weights, while increasing work safety and ergonomics. Within the supply chain, technologies that support operational efficiency and reduce resource waste are key. Minimising warehouse and raw material losses using artificial intelligence (AI) and big data analytics allows for precise demand forecasting, reduction in surpluses, and optimisation of inventory management, yielding both economic and environmental benefits. Three-dimensional printing in distribution, in turn, introduces new opportunities for decentralised production on demand, enabling faster adaptation to customer needs, shortening delivery times and reducing costs and emissions related to the transport and storage of spare parts or components.

The operational perspective (L4) ranks second. The ranking of technologies in this perspective is D14, G22, D11, D13, G43, G11, D32, G31, and D23. In the production domain, companies should implement advanced technological solutions that enable increased efficiency, flexibility, and security of industrial operations. Cybersecurity constitutes the foundation for the safe operation of enterprises in the digital era, protecting industrial infrastructure from external attacks and ensuring data integrity. Big data, artificial intelligence (AI), and machine learning enable advanced analysis of production data in real time, supporting decision-making, failure forecasting, and process optimisation. The Internet of Things (IoT) enables continuous monitoring and control of machines and production systems, creating a network of interconnected devices that communicate autonomously. Another important aspect is integration with renewable energy sources and energy storage, which supports the implementation of sustainable development goals, reduces operating costs, and reduces dependency on conventional energy supplies. Finally, vision systems and artificial intelligence in robotics increase the precision and quality of production operations, enabling the automation of inspection, assembly, and manipulation tasks in a more flexible and adaptive way. Within the supply chain companies should prioritise the implementation of solutions that enable intelligent and agile management of the flow of goods and information. IoT and RFID technology enable monitoring the location and condition of products in real time, which increases the transparency of the supply chain and allows for a quick response in the event of irregularities. Intelligent warehouse space management is based on the use of optimisation algorithms and automation, which translates into better use of available space and shorter order picking times. Dynamic optimisation of transport routes, based on the analysis of weather data, traffic intensity or order levels, allows for a reduction in logistics costs and a reduction in CO2 emissions. In turn, reverse logistics enables the recovery of products, components, and materials, thus supporting the circular economy strategy and increasing operational efficiency.

The third perspective is social (L2) with D31, G41, G21, and D24 technologies. In the production sector, solutions that facilitate effective energy management and automation of operations in a dynamic, digital industrial environment are becoming increasingly important. Intelligent energy monitoring and management systems (EMS) and smart grid technologies enable continuous tracking of energy consumption, the identification of inefficiencies, and the optimisation of energy costs by aligning usage to external and internal conditions. Integration with an intelligent energy network (smart grid) additionally enables interaction with distributed energy sources, thereby enhancing the flexibility and energy resilience of production plants. Digital twins support predictive maintenance and optimisation of energy consumption at the level of machines, production lines, or entire facilities, through real-time modelling and simulation. In turn, autonomous mobile robots (AMR), as elements of flexible automation, enable autonomous transport of materials and components within production halls, minimising downtime and improving the fluidity of material flow. In the area of logistics, companies should focus on technologies that allow for increased autonomy and transparency of warehouse operations and the supply chain. Autonomous warehouse systems based on AGV robots (automated vehicle) and AMR, enable the independent movement of goods in warehouses without human intervention, which translates into increased efficiency, reduced errors, and improved work safety. These solutions are complemented by blockchain technology in the supply chain, which guarantees transparency, immutability, and full traceability of goods and data flow, enabling more effective risk management and increased trust between supply chain participants.

The fourth perspective is ecological–environmental (L1) with the technology sequence G42, D41, G12, and G23. In the context of manufacturing, the pursuit of reducing the environmental footprint at the stage of material selection is becoming increasingly important. The modern, ecological materials and raw materials area is a fundamental component of sustainable production—they are designed with renewable, biodegradable, or reusable features in mind. Their implementation not only reduces greenhouse gas emissions and the consumption of natural resources, but also fits into the assumptions of a closed-loop economy, where waste becomes a valuable resource again. In the field of logistics and supply chains, the significance of practices aligned with the idea of environmental and social responsibility is growing. Ecological packaging, composed of recycled or easy-to-process materials, not only reduces the amount of waste, but can also reduce transport weight, contributing to lower fuel consumption and emissions. Green logistics encompasses initiatives aimed at minimising the negative impact of logistics processes on the environment—including the use of low-emission means of transport, route optimisation and reduction in energy consumption in warehouses. A comprehensive approach to sustainable management is supported by ESG (environmental, social, governance) systems and CO2 emission reporting tools, which allow companies to monitor, analyse, and transparently present the impact of their activities on the environment, which is becoming an important assessment criterion in the eyes of investors, business partners, and consumers.

The prioritisation of Industry 4.0 technologies identified in this study aligns with findings from recent research. For instance, Ozdemir [

82] applied a hybrid SF-AHP–WSM model to assess Industry 4.0 performance in SMEs, highlighting the significance of IoT and cybersecurity—findings that closely parallel those of the present study. Similarly, Wang et al. [

39] utilised a multi-criteria decision model in the textile industry, emphasising the role of advanced technologies in supplier selection. Kandakoglu et al. [

40] conducted a comprehensive review of MCDA methods for sustainable development, underscoring their applicability in Industry 4.0 contexts. Furthermore, Beyaz and Yildirim [

41] demonstrated the effectiveness of MCDA in evaluating digital transformation within the automotive supplier industry, identifying key Industry 4.0 technologies.

Kumar et al. [

83] applied a hybrid MCDM approach to identify strategies for overcoming barriers in Industry 4.0 implementation, emphasising the role of top management commitment. Similarly, Albayrak and Erkayman [

84] utilised F-BWM and CoCoSo methods to assess critical success factors, highlighting vertical integration as a key technology. Singh et al. [

85] prioritised enablers for Industry 4.0 adoption in manufacturing, underscoring the importance of data analytics and cybersecurity. Furthermore, He et al. [

86] developed a deep reinforcement learning-based decision support system for optimising textile manufacturing processes, demonstrating the effectiveness of integrating AI with MCDM techniques.

These studies corroborate our findings and reinforce the relevance of MCDA approaches in prioritising Industry 4.0 technologies. Despite being conducted in diverse industrial contexts, they consistently highlight the high priority of cybersecurity, IoT, and AI-based technologies within sustainable transformation strategies.

6. Conclusions

In the era of dynamic market changes, companies from the production and logistics sector are constantly looking for market niches and ways to build a lasting competitive advantage. One of the key directions of development that responds to these business needs is the implementation of Industry 4.0 solutions, while taking into account the principles of sustainable development. In practice, this means that management must choose the appropriate implementation methodology, which will, on the one hand, increase the probability of digital transformation success, and on the other, will allow for reducing costs and implementation time. In the context of growing uncertainty in the external environment, the decision to change operational or investment strategy is becoming particularly difficult. Company boards face a dilemma: whether to maintain current priorities, counting on the stability and resilience of the adopted model, or decide to redefine them, taking the risk associated with implementing innovative technological solutions.

The aim of this article is to present a tool supporting management staff in the decision-making process regarding the transformation towards Industry 4.0. The presented approach can be a practical guide increasing the chances of effectively meeting business needs through accurate identification and implementation of adequate technologies and management models. From the perspective of research value and novelty, this article presents an original framework for simultaneous assessment of sustainable development, Industry 4.0, and advanced technologies in the area of production and logistics. The proposed methodology addresses a clearly identified research gap by integrating four key areas of manufacturing activity and four logistics areas with twenty-three technologies characteristic of the Industry 4.0 concept. In addition, four levels of sustainable development have been taken into account, adapted to the needs of production and logistics enterprises. Another significant innovation is the application of a hybrid MCDM approach (multi-criteria decision-making), which enables a comprehensive evaluation and construction of a ranking of elements contained in the developed scheme. In the first phase of the study, using the DEMATEL (Decision-Making Trial and Evaluation Laboratory) method, centrality and causality indicators were identified and ranked for eight subspheres (four production and four logistics), as well as for twenty-three Industry 4.0 technologies. The obtained results served as input data in the second stage, in which the PROMETHEE II (Preference Ranking Organisation Method for Enrichment Evaluation) method was applied, enabling the creation of a ranking of four dimensions of sustainable development.

Based on the analysis, key recommendations can be formulated regarding priority directions for implementing Industry 4.0 solutions and sustainable development in manufacturing and logistics companies. The results clearly indicate that enterprises should concentrate their efforts on the following areas first:

The economic and financial (L3) perspective within the concept of sustainable development should be the foundation for transformation initiatives, due to its importance for the stability and long-term competitiveness of the organisation.

In the production sphere, Industry 4.0 assigns the highest priority to the area of digital transformation and intelligent management systems (I1), which enable integrated management of production processes based on real-time data.

In the context of logistics in Industry 4.0, the area of digital supply chain tracking and transparency (S2) has become crucial, supporting the efficiency, security, and transparency of logistics operations throughout the supply chain.

Industry 4.0 technologies used in production, the most important element was cybersecurity (D14), which is the foundation for the safe and reliable operation of integrated digital systems.

In the field of Industry 4.0 logistics technologies, particular priority is given to the Internet of Things (IoT) and RFID technology for real-time product status monitoring (G22), enabling continuous asset tracking and dynamic supply chain management.

These conclusions constitute the basis for further work on implementation models and tools facilitating strategic decision-making in the context of Industry 4.0 integration and the principles of sustainable development.

It should be noted that the empirical analysis was based on a single round of evaluations from qualified experts. While a larger panel could further increase robustness, the current results have been statistically validated using concordance measures and are grounded in input from a sufficiently diverse and competent panel. This limitation has been considered when interpreting the findings.

To ensure the robustness of the expert-based evaluation process, both reliability and validity were verified. Reliability was confirmed using Kendall’s coefficient of concordance , with the results indicating satisfactory consistency for DEMATEL and high consistency for PROMETHEE II. Additionally, the validity of the results was supported by a dual-questionnaire structure, which enabled triangulation of expert opinions across different methodological dimensions. This approach reinforces the credibility of the findings and supports their practical applicability.

Methodologically, the scientific contribution of this study lies in the integration of the DEMATEL and PROMETHEE II methods into a unified evaluation framework specifically tailored to the context of sustainable Industry 4.0 transformation. Unlike previous studies that focus solely on either causal analysis or ranking, the proposed approach enables both the identification of cause–effect relationships between technologies and operational domains, such as production and logistics, and the development of consistent rankings across sustainability dimensions. Moreover, the model is applied concurrently to both production and supply chain and logistics areas, while addressing four distinct sustainability perspectives (ecological–environmental, social, economic–financial, and operational). This dual application broadens the scope of analysis and delivers a more comprehensive decision-support tool, which remains unexplored in the current literature.

It should be emphasised that the evaluation framework used in this study produces three complementary rankings: (1) a ranking of technological subspheres (i.e., domains within manufacturing and supply chain and logistics), (2) a ranking of individual Industry 4.0 technologies, and (3) a ranking of sustainable Industry 4.0 perspectives (L1–L4). Each of these layers supports a distinct type of strategic decision-making.

The recommendation to prioritise the economic and financial perspective (L3) is based on the highest net flow score in

Table 7. Technologies most strongly associated with this dimension were identified by cross-referencing

Table 4 and

Table 6 such as D42, D22, G33, D12, D21, and G32, and their relevance has been explained in detail in the discussion following

Table 7. Similarly, if a company wishes to focus on environmental (L1) or social (L2) dimensions, it may use the same rationale—selecting technologies linked to these perspectives in

Table 6, and considering their relative importance from the technology ranking in

Table 4.

This layered structure enables flexible, goal-oriented interpretation of the results, depending on the transformation priorities of a given enterprise.

The presented research model assumes simultaneous analysis of three key areas: (i) sustainable development, (ii) application of the Industry 4.0 concept in the production and logistics sector, and (iii) advanced technologies supporting the digital transformation of enterprises. This approach allows for a comprehensive approach to the assessment of innovative solutions implemented within the industry of the future.

The priorities identified in this article and the proposed assessment scheme constitute a starting point for further, in-depth analyses, and research. Potential directions for future scientific work include, in particular:

Validation of the model in a real environment—testing the proposed methodology in specific manufacturing, service (logistics) enterprises to verify the usability, effectiveness, and practical application of the proposed decision-making scheme.

Extending the model to the trade sector—developing the assessment structure to include the specifics of trade enterprises, taking into account characteristic technologies (e.g., intelligent sales systems, advanced CRM systems, e-commerce platforms, inventory management automation) and new dimensions of sustainable development, such as ethical supply chains, packaging management, and impact on the end-consumer. This adaptation may significantly enhance its universality and application usefulness.

Extending the model with emerging technologies—taking into account solutions characteristic of the Industry 5.0 concept, such as production personalization, human–machine cooperation, and technologies supporting employee well-being.

Integration with ERP and MES decision-making systems—embedding the model in digital enterprise management environments, which will enable its automation and continuous updating of decision-making data.

Application of advanced MCDM and machine learning methods—exploration of alternative approaches to multi-criteria evaluation (e.g., ANP, TOPSIS, AHP fuzzy) and integration of the model with artificial intelligence algorithms for dynamic adaptation of weights and preferences.

Development of visualisation tools and user interfaces—development of interactive dashboards and applications supporting company management in scenario analysis and rapid interpretation of model outcomes.

Sensitivity and strategic scenario analysis—execution of comprehensive sensitivity analyses for various configurations of decision parameters, which will allow for a better understanding of the model’s resilience to changes in the business and technological environment.

The implementation of the aforementioned research directions may contribute to the further development of integrated decision-making models supporting digital transformation in alignment with the principles of sustainable development in various economic sectors.

The significant limitations of the proposed approach include the currently limited form of visualisation of results. To enhance its practical applicability, especially for management staff, it is recommended to develop more intuitive and interactive data presentation tools that allow for easier interpretation and use of results in decision-making processes. Additionally, the potential impact of subjectivity of expert assessments, which may affect the credibility of the obtained results, should be taken into account. It is therefore important to ensure a high-quality expert process by selecting a diverse, interdisciplinary, and representative group of experts and by using methods that minimise the risk of bias.

Another important limitation concerns the choice of methodological tools. While the model proposed in this study relies on a hybrid DEMATEL–PROMETHEE II approach for identifying relationships and priorities, future research could explore Structural Equation Modelling (SEM) or other formal inference techniques to enhance internal validation. Although SEM offers strong analytical capabilities, it also requires strict assumptions and extensive data, which may limit its applicability for managerial applications. As Ziemba et al. [

87] highlight, excessive methodological complexity can hinder the adoption of decision-support tools in real-world industrial practice.

Similarly, more advanced causal inference methods, such as Bayesian or counterfactual approaches, may provide deeper insight into causal mechanisms or uncertainty propagation. However, due to their computational and interpretative complexity, they are not easily applicable in managerial contexts. Therefore, the choice of methods in this study reflects an deliberate balance between scientific rigour and practical relevance, ensuring that the results remain accessible and actionable for decision-makers.