An Attempt to Assess the Implementation of the Circular Economy in the EU-27 as an Important Element of Sustainable Development

Abstract

1. Introduction

- The communication “EUROPE 2020: A strategy for smart, sustainable and inclusive growth” [20];

- The communication “Roadmap for a Resource-Efficient Europe” [21];

- The economic report on the potential of the CLE model “Towards the Circular Economy” [22];

- The communication “Closing the loop—the EU action plan for a circular economy” [23];

- The statement “Manifesto for a resource-efficient Europe” [24].

- Plastics and packaging—Europe’s 2030 strategy addresses reusing or recycling every plastic package, reducing their single-use consumption, and ending the use of microplastics [29].

- Textiles—the EU’s strategy for sustainable, closed-loop textiles by 2030 includes tougher water consumption standards and encourages a shift to quality, durability, longer use, repair, and reuse, among other things [30].

- Electronics—the directive incorporating the Ecodesign Action Plan requires products to be more energy efficient and have a longer life cycle [31].

- Food and water—halving food waste by 2030 as part of a farm-to-table strategy [32].

- Batteries and vehicles—among other things, the materials of all batteries should have a low carbon footprint [33].

- Construction—increasing material reuse and energy renovation rates for buildings [34].

- Waste management—regulations to increase high quality recycling, move away from landfill, and minimize waste incineration [35].

- The product design phase—takes into account resource conservation, ecological design, and the prevention of product obsolescence;

- The production phase—involves the significant reduction of production waste, maximizing the efficiency of technological processes by introducing innovative solutions, monitoring the energy efficiency of machinery and buildings, an eco-management and audit system, and the verification of environmental technologies;

- The use phase—concerns raising public awareness of the rational consumption of goods by, among others, government agencies and entrepreneurs whose expenditures on pro-environmental campaigns can count as tax-deductible expenses;

- The waste management phase—involves the use of various types of solutions that give products a “second life”, i.e., recycling or up cycling, which maximize the usefulness of once-obtained resources.

2. Study Materials

- The sum of the extracted subsets was the same as the set subject to division (adequacy condition);

- The individual typological groups could not contain any common elements (the condition of separability of typological groups);

- Each class contained at least one object;

- Objects in a given group were as similar to each other as possible;

- Objects in different groups were as dissimilar to each other as possible.

3. Research Methodology

- (1)

- The values (xij) of the diagnostic variables formed an n × p observation matrix, X, where

- n = 27 (the number of EU countries), i = 1, 2, …, n.

- p = 18 (the number of diagnostic features), j = 1, 2, …, p.

- (2)

- The values of the X matrix were standardized, that is, transformed into the values (zij) of the Z matrix of dimensions 27 × 18, according to the formula

- —the arithmetic mean calculated for each diagnostic variable on the basis of n = 27.

- sj—the standard deviation calculated for each diagnostic variable, according to the formula

- (3)

- The values of zij were the basis for determining the pattern of development, which was an object with coordinates z01, z02, …, z0j, where z0j = max{zij}. A higher value means a better situation for the object in the case of variables called stimulants, z0j = min{zij}. A lower value means a better situation for the object in the case of variables called destimulants.

- (4)

- The distance from the benchmark (di) was determined for each object, according to the formula

- (5)

- Based on the di index, the values of the relative taxonomic measure of the CLE development (zi) were calculated for each of the studied facilities, according to the formula

- —the arithmetic mean, calculated on the basis of n = 27 di values;

- sd—the standard deviation, calculated on the basis of n = 27 values of di, according to the formula in point 2.

- I group, a very good situation when + < ;

- II group, a good situation when < ≤ +;

- III group, a sufficient situation when − < < ;

- IV group, an insufficient situation when ≤ − .

4. Results and Discussion

5. Summary

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarkis, J.; Zhu, H. Information technology and systems in China’s circular economy: Implications for sustainability. J. Syst. Inf. Technol. 2008, 10, 202–217. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2016, 143, 757–768. [Google Scholar] [CrossRef]

- Kortmann, S.; Piller, F. Open business models and closed-loop value chains. Calif. Manag. Rev. 2013, 58, 88–108. [Google Scholar] [CrossRef]

- Velis, C.A. Circular economy and global secondary material supply chains. Waste Manag. Res. 2015, 33, 389–391. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Kok, L.; Wurpel, G.; Ten Wolde, A. Unleashing the Power of the Circular Economy; Report by IMSA Amsterdam for Circle Economy; IMSA Amsterdam: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Heshmati, A. A Review of the Circular Economy and Its Implementation. IZA Discussion Papers. 2015. Available online: https://www.iza.org/publications/dp/9611/a-review-of-the-circular-economy-and-its-implementation (accessed on 20 February 2025).

- Tisserant, A.; Pauliuk, S.; Merciai, S.; Schmidt, J.; Fry, J.; Wood, R.; Tukker, A. Solid waste and the circular economy: A global analysis of waste treatment and waste footprints. J. Ind. Ecol. 2017, 21, 628–640. [Google Scholar] [CrossRef]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Stefanou, M. Environmental impacts in the life cycle of olive oil: A literature review. J. Sci. Food Agric. 2017, 97, 1686–1697. [Google Scholar] [CrossRef]

- Tsarouhas, P.; Achillas, C.; Aidonis, D.; Folinas, D.; Maslis, V. Life Cycle Assessment of olive oil production in Greece. J. Clean. Prod. 2015, 93, 75–83. [Google Scholar] [CrossRef]

- Bartoszczuk, P. Circular economy and its restriction. Econ. Environ. 2023, 86, 469–482. [Google Scholar] [CrossRef]

- Li, P.; Wang, D.; Zafar, Q.; Waheed, H. Strategic resource management for economic sustainability: Assessing the impact of technological advancement and energy efficiency. Resour. Policy 2024, 89, 104631. [Google Scholar] [CrossRef]

- Rossi, D.; Lermen, F.H.; Fernandes, S.d.C.; Echeveste, M.E.S. Exploring business model strategies to achieve a circular bioeconomy from a waste valorization perspective. Environ. Dev. Sustain. 2024, 12, 5223. [Google Scholar] [CrossRef]

- Kluska, M.; Jabłońska, J. Variability and heavy metal pollution levels in water and bottom sediments of the Liwiec and Muchawka Rivers (Poland). Water 2023, 15, 2833. [Google Scholar] [CrossRef]

- Kluska, M.; Jabłońska, J. Pollution Assessment and Spatial Distribution of Heavy Metals in Surface Waters and Bottom Sediments of the Krzna River (Poland). Water 2024, 16, 1008. [Google Scholar] [CrossRef]

- Shrivastava, P.; Stafford Smith, M.; O’Brien, K.; Zsolnai, L. Transforming Sustainability Science to Generate Positive Social and Environmental Change Globally. One Earth 2020, 2, 329–340. [Google Scholar] [CrossRef]

- Nyam, Y.S.; Kotir, J.H.; Jordaan, A.J.; Ogundeji, A.A.; Adetoro, A.A.; Orimoloye, I.R. Towards Understanding and Sustaining Natural Resource Systems through the Systems Perspective: A Systematic Evaluation. Sustainability 2020, 12, 9871. [Google Scholar] [CrossRef]

- Achillas, C.; Moussiopoulos, N.; Karagiannidis, A.; Banias, G.; Perkoulidis, G. The use of multi-criteria decision analysis to tackle waste management problems: A literature review. Waste Manag. Res. 2013, 31, 115–129. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://op.europa.eu/en/publication-detail/-/publication/6a915e39-0aab-491c-8881-147ec91fe88a/language-en (accessed on 27 February 2025).

- Available online: https://www.eea.europa.eu/policy-documents/com-2011-571-roadmap-to (accessed on 28 February 2025).

- Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 25 February 2025).

- Lampridi, M.; Sørensen, C.; Bochtis, D. Agricultural Sustainability: A Review of Concepts and Methods. Sustainability 2019, 11, 5120. [Google Scholar] [CrossRef]

- Available online: https://ec.europa.eu/commission/presscorner/api/files/document/print/en/memo_12_989/MEMO_12_989_EN.pdf (accessed on 20 February 2025).

- Tomaszewska, J. Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

- Feleki, E.; Vlachokostas, C.; Achillas, C.; Moussiopoulos, N.; Michailidou, A.V. Involving decision-makers in the transformation of results into urban sustainability policies. Eur. J. Environ. Sci. 2016, 6, 7–10. [Google Scholar] [CrossRef][Green Version]

- Marting Vidaurre, N.A.; Vargas-Carpintero, R.; Wagner, M.; Lask, J.; Lewandowski, I. Social Aspects in the Assessment of Biobased Value Chains. Sustainability 2020, 12, 9843. [Google Scholar] [CrossRef]

- Dieken, S.; Venghaus, S. Potential Pathways to the German Bioeconomy: A Media Discourse Analysis of Public Perceptions. Sustainability 2020, 12, 7987. [Google Scholar] [CrossRef]

- Available online: https://commission.europa.eu/publications/sustainable-europe-2030_en (accessed on 2 April 2025).

- Available online: https://www.europarl.europa.eu/legislative-train/theme-a-european-green-deal/file-eu-textiles-strategy#:~:text=By%202030%2C%20textiles%20on%20the%20EU%20market%20should,an%20environmentally%20friendly%20way%20while%20respecting%20social%20rights (accessed on 3 April 2025).

- Available online: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/ecodesign-sustainable-products-regulation_en (accessed on 10 April 2025).

- Available online: https://food.ec.europa.eu/food-safety/food-waste/eu-actions-against-food-waste_en (accessed on 5 April 2025).

- Available online: https://www.compliancegate.com/batteries-regulation-european-union/ (accessed on 6 April 2025).

- Available online: https://www.eea.europa.eu/publications/building-renovation-where-circular-economy (accessed on 5 April 2025).

- Available online: https://publyon.com/packaging-and-packaging-waste-regulation-is-your-business-ready-for-new-packaging-requirements/#:~:text=Central%20to%20the%20Packaging%20and%20Packaging%20Waste%20Regulation,packaging%20waste%20generated%20each%20year%20in%20the%20EU (accessed on 5 April 2025).

- Purwestri, R.C.; Hájek, M.; Šodková, M.; Jarskỳ, V. How are wood and non-wood forest products utilized in the Czech Republic? A preliminary assessment of a nationwide survey on the bioeconomy. Sustainability 2020, 12, 566. [Google Scholar] [CrossRef]

- Priefer, C.; Meyer, R. One concept, many opinions: How scientists in Germany think about the concept of bioeconomy. Sustainability 2019, 11, 4253. [Google Scholar] [CrossRef]

- Anagnostis, A.; Papageorgiou, E.; Bochtis, D. Application of artificial neural networks for natural gas consumption forecasting. Sustainability 2020, 12, 6409. [Google Scholar] [CrossRef]

- Singh, P.K.; Papageorgiou, K.; Chudasama, H.; Papageorgiou, E.I. Evaluating the effectiveness of climate change adaptations in the world’s largest Mangrove Ecosystem. Sustainability 2019, 11, 6655. [Google Scholar] [CrossRef]

- Fiore, E.; Stabellini, B.; Tamborrini, P. A systemic design approach applied to rice and wine value chains. The case of the innovaecofood project in piedmont (italy). Sustainability 2020, 12, 9272. [Google Scholar] [CrossRef]

- Ovezikoglou, P.; Aidonis, D.; Achillas, C.; Vlachokostas, C.; Bochtis, D. Sustainability assessment of investments based on a multiple criteria methodological framework. Sustainability 2020, 12, 6805. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Busato, P.; Bochtis, D.; Sørensen, C.G.; Zhou, K. Energy savings from optimised in-field route planning for agricultural machinery. Sustainability 2017, 9, 1956. [Google Scholar] [CrossRef]

- Rodias, E.C.; Lampridi, M.; Sopegno, A.; Berruto, R.; Banias, G.; Bochtis, D.D.; Busato, P. Optimal energy performance on allocating energy crops. Biosyst. Eng. 2019, 181, 11–27. [Google Scholar] [CrossRef]

- Marinoudi, V.; Sørensen, C.G.; Pearson, S.; Bochtis, D. Robotics and labour in agriculture. A context consideration. Biosyst. Eng. 2019, 184, 111–121. [Google Scholar] [CrossRef]

- de Schutter, L.; Giljum, S.; Häyhä, T.; Bruckner, M.; Naqvi, A.; Omann, I.; Stagl, S. Bioeconomy Transitions through the Lens of Coupled Social-Ecological Systems: A Framework for Place-Based Responsibility in the Global Resource System. Sustainability 2019, 11, 5705. [Google Scholar] [CrossRef]

- Duquet, B.; Brunelle, C. Subcentres as Destinations: Job Decentralization, Polycentricity, and the Sustainability of Commuting Patterns in Canadian Metropolitan Areas, 1996. Sustainability 2020, 12, 9966. [Google Scholar] [CrossRef]

- EEA. Signals 2014, Our Well-Being Depends on a Resource-Efficient, Circular Economy. Available online: https://www.eea.europa.eu/highlights/signals-2014-our-well-being (accessed on 12 April 2025).

- Ramanauske, N.; Balezentis, T.; Streimikiene, D. Biomass use and its implications for bioeconomy development: A resource efficiency perspective for the European countries. Technol. Forecast. Soc. Chang. 2023, 193, 122628. [Google Scholar] [CrossRef]

- Biogas System, S.A. Biogas Plant Calculator. 2024. Available online: https://biogas-system.com/kalkulator-biogazu/ (accessed on 14 April 2025).

- Hertwich, E.G. Consumption and the Rebound Effect: An industrial ecology perspective. J. Ind. Ecol. 2005, 9, 85–98. [Google Scholar] [CrossRef]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Giurco, D.; Littleboy, A.; Boyle, T.; Fyfe, J.; White, S. Circular economy: Questions for responsible minerals, additive manufacturing and recycling of metals. Resources 2014, 3, 432–453. [Google Scholar] [CrossRef]

- Naustdalslid, J. Circular economy in China—The environmental dimension of the harmonious society. Int. J. Sustain. Dev. World Ecol. 2014, 21, 303–313. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Barragán-Ocaña, A.; Silva-Borjas, P.; Olmos-Peña, S.; Polanco-Olguín, M. Biotechnology and Bioprocesses: Their Contribution to Sustainability. Processes 2020, 8, 436. [Google Scholar] [CrossRef]

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van Der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Preston, F. A Global Redesign? Shaping the Circular Economy; Chatham House: London, UK, 2012; pp. 1–20. [Google Scholar]

- Webster, K. What might we say about a circular economy? Some temptations to avoid if possible. World Futures 2013, 69, 542–554. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The emergence of circular economy: A new framing around prolonging resource productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Bonviu, F. The European economy: From a linear to a circular economy. Rom. J. Eur. Aff. 2014, 14, 78–91. [Google Scholar]

- Hobson, K. Closing the loop or squaring the circle? Locating generative spaces for the circular economy. Prog. Hum. Geogr. 2016, 40, 88–104. [Google Scholar] [CrossRef]

- Available online: https://www.europarl.europa.eu/doceo/document/E-9-2022-003327_EN.html (accessed on 6 March 2025).

- Pialot, O.; Millet, D.; Bisiaux, J. “Upgradable PSS”: Clarifying a new concept of sustainable consumption/production based on upgradability. J. Clean. Prod. 2017, 141, 538–550. [Google Scholar] [CrossRef]

- Aguiar, A.P.D.; Collste, D.; Harmáčková, Z.V.; Pereira, L.; Selomane, O.; Galafassi, D.; Van Vuuren, D.; Van Der Leeuw, S. Co-designing global target-seeking scenarios: A cross-scale participatory process for capturing multiple perspectives on pathways to sustainability. Glob. Environ. Chang. 2020, 65, 102198. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy 3—Accelerating the Scale-Up across Global Supply Chains; Ellen MacArthur Foundation: Cowes, UK, 2014; Available online: https://www3.weforum.org/docs/WEF_ENV_TowardsCircularEconomy_Report_2014.pdf (accessed on 12 June 2017).

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Man; Urban Development Series Knowledge Papers; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Zeng, H.; Chen, X.; Xiao, X.; Zhou, Z. Institutional pressures, sustainable supply chain management, and circular economy capability: Empirical evidence from Chinese eco-industrial park firms. J. Clean. Prod. 2017, 155, 54–65. [Google Scholar] [CrossRef]

- Liu, Q.; Li, H.M.; Zuo, X.L.; Zhang, F.F.; Wang, L. A survey and analysis on public awareness and performance for promoting circular economy in China: A case study from Tianjin. J. Clean. Prod. 2009, 17, 265–270. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Sharmina, M.; Gallego-Schmid, A.; Heyes, G.; Azapagic, A. Integrating Backcasting and Eco-Design for the Circular Economy: The BECE Framework. J. Ind. Ecol. 2017, 21, 526–544. [Google Scholar] [CrossRef]

- Xue, B.; Chen, X.P.; Geng, Y.; Guo, X.J.; Lu, C.P.; Zhang, Z.L.; Lu, C.Y. Survey of officials’ awareness on circular economy development in China: Based on municipal and county level. Resour. Conserv. Recycl. 2010, 54, 1296–1302. [Google Scholar] [CrossRef]

- Ababneh, H.; Hameed, B.H. Electrofuels as emerging new green alternative fuel: A review of recent literature. Energy Convers. Manag. 2022, 254, 115213. [Google Scholar] [CrossRef]

- Jarosch, L.; Zeug, W.; Bezama, A.; Finkbeiner, M.; Thrän, D. A Regional Socio-Economic Life Cycle Assessment of a Bioeconomy Value Chain. Sustainability 2020, 12, 1259. [Google Scholar] [CrossRef]

- Krekel, D.; Samsun, R.C.; Peters, R.; Stolten, D. The separation of CO2 from ambient air—A techno-economic assessment. Appl. Energy 2018, 218, 361–381. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G.; Busato, P.; Berruto, R. Benefits from optimal route planning based on B-patterns. Biosyst. Eng. 2013, 115, 389–395. [Google Scholar] [CrossRef]

- Wu, H.Q.; Shi, Y.; Xia, Q.; Zhu, W.D. Effectiveness of the policy of circular economy in China: A DEA-based analysis for the period of 11th five-year-plan. Resour. Conserv. Recycl. 2014, 83, 163–175. [Google Scholar] [CrossRef]

- Aid, G.; Eklund, M.; Anderberg, S.; Baas, L. Expanding roles for the Swedish Waste Management sector in inter-organizational resource management. Resour. Conserv. Recycl. 2017, 124, 85–97. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, Y. An exploration of firms’ awareness and behavior of developing circular economy: An empirical research in China. Resour. Conserv. Recycl. 2014, 87, 145–152. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Prendeville, S.; Cherim, E.; Bocken, N. Circular cities: Mapping Six Cities in Transition. Environ. Innov. Soc. Trans. 2018, 26, 171–194. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Available online: https://ec.europa.eu/eurostat/web/main/data/database (accessed on 27 March 2025).

| Nr | Name of the Objective | Impact of a Closed Circuit Economy | Power |

|---|---|---|---|

| 6. | Clean water and sanitary sanitation | The reduction of waste and negative externalities throughout the product life cycle. Reducing waste and increasing recycling and reuse. The development of technology and the sustainable management of water resources. Keeping raw material in circulation for as long as possible. | strong |

| 7. | Clean and accessible energy | The use of renewable energy sources and increasing their share in the energy mix. Reducing negative effects, e.g., CO2 emissions. | strong |

| 9. | Innovation, industry, infrastructure | Improving material and energy efficiency (cogeneration). Cooperation between enterprises in the management of waste generated in the production process. Increasing innovation. | strong |

| 11. | Sustainable cities and communities | Reducing excessive consumerism. The use of public transport. | strong |

| 12. | Responsible consumption and production | The extension of the product life cycle, the reduction of waste, reuse, and the rational management of scarce natural resources. | strong |

| 13. | Climate action | The closed cycle of raw materials, the reduction of waste, the introduction of RES. The reduction of the impact of human activities on climate change and the environment. | strong |

| 14. | Life under water | The reduction of marine pollution levels. The reduction of food waste going into the sea. The sustainable use of water resources. | strong |

| 15. | Life on land | The protection and enhancement of plant and animal diversity in the ecosystem. Improving the quality of forest areas and increasing their size. The sustainable management of forests and the use of terrestrial ecosystems. | strong |

| Areas of the CLE Monitoring | Monitoring Sub-Indicators the CLE | Unit |

|---|---|---|

| Production and consumption | X1—material footprint | t/person |

| X2—resource productivity | Euro/kg | |

| X3—waste generation per capita | kg/person | |

| X4—waste generation excluding mineral waste per unit of GDP | kg/thousand euro | |

| X5—municipal waste generation per capita | kg/person | |

| X6—food waste | kg/person | |

| X7—generation of packaging waste per capita | kg/person | |

| X8—waste generation per capita of plastic packaging | kg/person | |

| Waste management | X9—recycling rate of municipal waste | % |

| X10—recycling rate for all waste excluding major mineral waste | % | |

| X11—recycling rate of packaging waste by type | % | |

| X12—WEEE recycling rate of waste electrical equipment | % | |

| Secondary raw materials | X13—use of materials in a closed loop | % |

| X14—share of recycled materials in raw materials demand—end-of-life recycling rates (EOL-RIR) | % | |

| X15—trade in recyclable raw materials | million t | |

| Competitiveness and innovation | X16—private investment and gross value added in the CLE sectors | million Euro |

| X17—people employed in the CLE sectors | thousand FTE | |

| X18—patents related to recycling and recyclable raw materials | per million people | |

| Global sustainability and resilience | X19—consumption footprint | % |

| X20—greenhouse gas emissions from production activities | kg/person | |

| X21—dependence on imported materials | % | |

| X22—EU self-sufficiency in raw materials | % |

| Circular Economy Indicators | Selected Characteristics | ||||

|---|---|---|---|---|---|

| Me | V% | Xmin (Country) | Xmax (Country) | ||

| X1—Material footprint | 19.3 | 16.9 | 45.8 | 8.3 The Netherlands | 50.6 Finland |

| X2—Resource productivity * | 1.9 | 1.6 | 59.9 | 0.3 Bulgaria | 4.7 The Netherlands |

| X3—Waste generation per capita | 6291 | 4604 | 82.6 | 1330.0 Latvia | 19,950 Finland |

| X4—Waste generation excluding mineral waste per unit of GDP | 98.7 | 70 | 114 | 20 Ireland | 500 Bulgaria |

| X5—Municipal waste generation per capita | 533.3 | 488 | 23.6 | 303.0 Romania | 803 Austria |

| X7—Generation of packaging waste per capita | 138.2 | 163.2 | 26.1 | 78.8 Bulgaria | 2333.8 Ireland |

| X8—Waste generation per capita of plastic packaging | 33.2 | 31.8 | 27.6 | 19.3 Croatia | 66.8 Ireland |

| X9—Recycling rate of municipal waste * | 41.1 | 41.2 | 36.9 | 12.3 Romania | 69.2 Germany |

| X11—Recycling rate of packaging waste by type * | 62.2 | 64.9 | 18.4 | 31.8 Malta | 80.4 Belgium |

| X12—Recycling rate of waste electrical equipment * | 80.7 | 81.8 | 10.1 | 56.6 Portugal | 92.8 Czechia |

| X13—Closed-cycle material use * | 10.3 | 8.8 | 67.9 | 1.3 Romania | 30.6 The Netherlands |

| X15—Trade in recyclable raw materials * in million t | 1.5 | 0.9 | 112.2 | 0.003 Malta | 5.8 The Netherlands |

| X16—Private investment and gross value added in the CLE sectors * | 4176.5 | 1081 | 168.3 | 51.0 Cyprus | 31,507 Germany |

| X17—People employed in the circular economy sectors * in thousand | 154.8 | 66.3 | 124 | 8.1 Malta | 771.8 Germany |

| X18—Patents related to recycling and secondary raw materials * | 8.0 | 4 | 139.7 | 0.0 Slovakia, Malta, Cyprus | 46 Germany |

| X19—Consumption footprint | 111.2 | 108 | 10.4 | 90.0 Ireland | 144 Malta |

| X20—Greenhouse gas emissions from production activities | 7183 | 6841 | 33.2 | 3971 Sweden | 12,913 Denmark |

| X21—Dependence on imports of materials | 39.9 | 36.8 | 48 | 9.9 Romania | 90 Luxemburg |

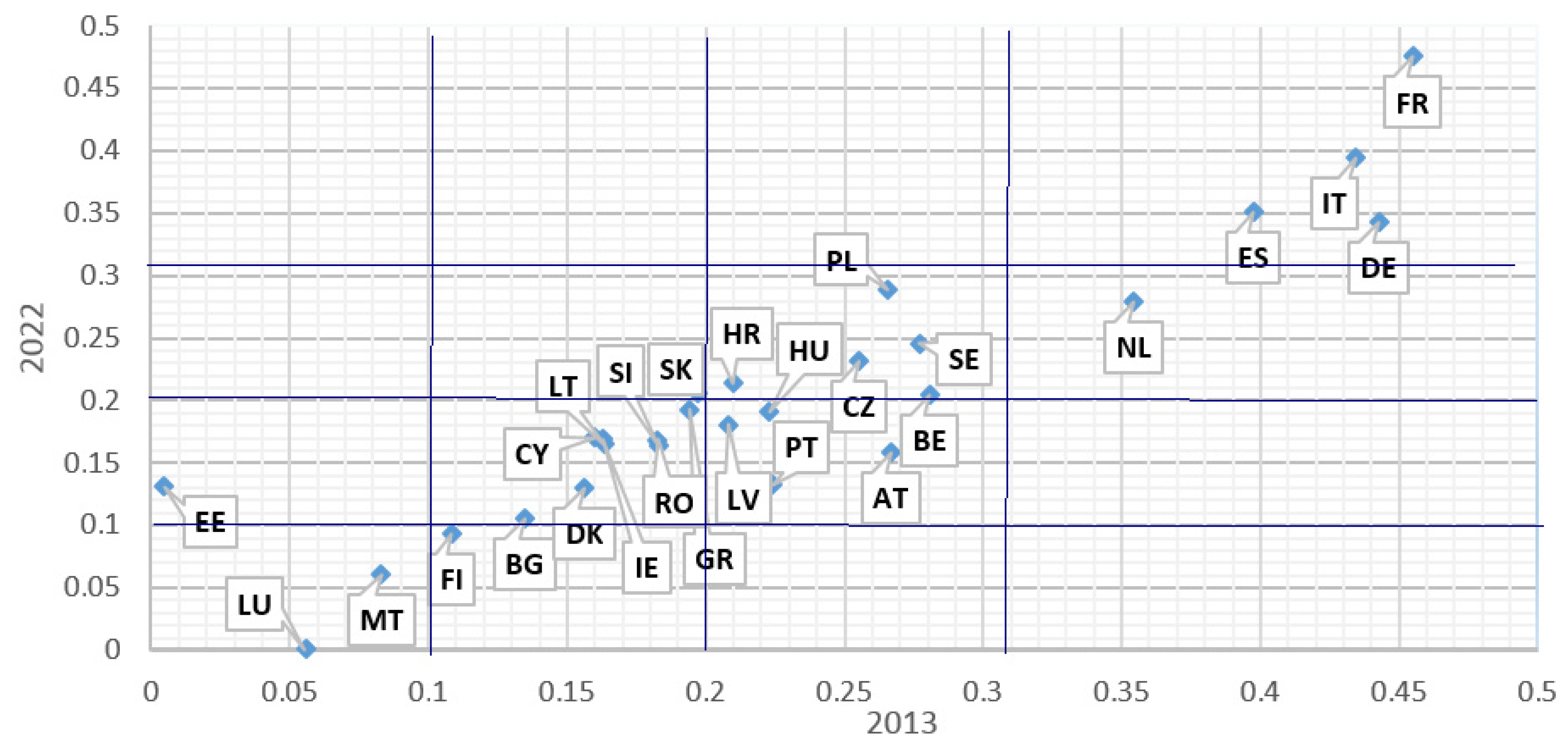

| Development Level | Indicator Value zi (2013) | Indicator Value zi (2022) |

|---|---|---|

| Very good | France (0.455), Germany (0.443), Italy (0.434), Spain (0.397), The Netherlands (0.354) | France (0.475), Italy (0.394), Spain (0.351), Germany (0.343) |

| Good | Belgium (0.281), Sweden (0.277), Austria (0.267), Poland (0.266), Czech Republic (0.255) | Poland (0.289), The Netherlands (0.279), Sweden (0.246), Czech Republic (0.232), Croatia (0.214), Slovakia (0.206), Belgium (0.205) |

| Sufficient | Hungary (0.223), Croatia (0.210), Latvia (0.208), Slovakia (0.197), Greece (0.194), Slovenia (0.183), Romania (0.168), Ireland (0.163), Lithuania (0.163), Cyprus (0.160), Denmark (0.156), Bulgaria (0.135), Portugal (0.133) | Denmark (0.129), Ireland (0.169), Estonia (0.131), Greece (0.193), Cyprus (0.171), Portugal (0.133), Latvia (0.181), Austria (0.159), Lithuania (0.165), Romania (0.168), Slovenia (0.143), Hungary (0.191) |

| Unsatisfactory | Finland (0.108), Malta (0.083), Luxembourg (0.055), Estonia (0.005) | Bulgaria (0.106), Finland (0.092), Malta (0.060), Luxembourg (0.001) |

| Circular Economy Indicators | Group I | Group II | Group III | Group IV | Total |

|---|---|---|---|---|---|

| Material footprint t/person | 12.3 | 15.6 | 20.4 | 29.4 | 19.3 |

| Resource productivity * euro/kg | 3.1 | 2.1 | 1.5 | 2.0 | 1.9 |

| Waste generation kg/person | 3843 | 5803 | 4928 | 13,681 | 6291 |

| Waste generation excluding mineral waste per unit GDP kg/thousand euro | 53.7 | 83.3 | 103.5 | 156.0 | 98.7 |

| Generation of municipal waste kg/person | 523.3 | 492.4 | 535.8 | 587.3 | 533.3 |

| Generation of packaging waste kg/person | 207.7 | 137.9 | 154.9 | 153.6 | 138.2 |

| Generation of plastic packaging waste kg/person | 39.0 | 28.8 | 35.2 | 28.9 | 33.2 |

| Recycling rate of municipal waste * % | 50.6 | 45.7 | 37.6 | 33.9 | 41.1 |

| Packaging waste recycling rate * % | 69.3 | 67.4 | 58.7 | 56.8 | 62.2 |

| WEEE recycling rate of waste electrical equipment * % | 79.0 | 83.3 | 78.7 | 83.7 | 80.7 |

| Closed-loop material use * % recycling rate | 15.2 | 13.9 | 6.8 | 9.3 | 10.3 |

| Trade in raw materials for recycling * million t | 3.9 | 1.9 | 0.83 | 0.1 | 1.5 |

| Private investment and gross value added in the CLE sectors * million euro | 17,611 | 3417 | 1366 | 504 | 4176 |

| People employed in the CLE sectors * thousands FTE | 561.2 | 133.1 | 69.8 | 41.7 | 156.8 |

| Patents related to recycling and secondary raw materials * per 1 million people | 28.9 | 6.8 | 2.1 | 4.3 | 8.0 |

| Consumption footprint % | 107.5 | 112.6 | 107.4 | 124.0 | 111.2 |

| Greenhouse gas emissions kg/person | 5612 | 6844 | 7378 | 8764 | 7183 |

| Material import dependency % | 41.9 | 45.5 | 32.9 | 48.8 | 39.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marciniuk-Kluska, A.; Kluska, M. An Attempt to Assess the Implementation of the Circular Economy in the EU-27 as an Important Element of Sustainable Development. Sustainability 2025, 17, 4942. https://doi.org/10.3390/su17114942

Marciniuk-Kluska A, Kluska M. An Attempt to Assess the Implementation of the Circular Economy in the EU-27 as an Important Element of Sustainable Development. Sustainability. 2025; 17(11):4942. https://doi.org/10.3390/su17114942

Chicago/Turabian StyleMarciniuk-Kluska, Anna, and Mariusz Kluska. 2025. "An Attempt to Assess the Implementation of the Circular Economy in the EU-27 as an Important Element of Sustainable Development" Sustainability 17, no. 11: 4942. https://doi.org/10.3390/su17114942

APA StyleMarciniuk-Kluska, A., & Kluska, M. (2025). An Attempt to Assess the Implementation of the Circular Economy in the EU-27 as an Important Element of Sustainable Development. Sustainability, 17(11), 4942. https://doi.org/10.3390/su17114942