1. Introduction

The growing demand for critical raw materials (CRMs) in the electromobility industry and the depletion of high-grade primary ores have resulted in the overdependency of the world on a few CRM-resource-rich countries, such as China, Russia, Australia, the Democratic Republic of Congo, South Africa, and the USA, for the global supply.

The International Energy Agency [

1] estimated that global lithium (Li) demand could increase by up to 40 times by 2040, while Mohr [

2] predicted that annual Li demand could rise by 400 kt by 2050 if there is a complete transition to electric vehicles. According to the World Economic Forum [

3], Australia, Chile, and China alone account for 52%, 25%, and 13% of the world’s Li production, respectively, while more than 70% of the global supply of cobalt is sourced from the Democratic Republic of Congo [

4]. This poses a significant threat to the global CRM supply chain.

Lithium from Australia is extracted from spodumene mineral (hard-rock), while that from Chile is extracted from brines. Chinese lithium is extracted from both hard rock mines and brines, with brines accounting for the more widely distributed source. Due to the hike in the prices of critical metals such as Li and the vulnerability to disruptions in CRM supply, there has been a surge in the urgency in the exploitation of secondary resources such as mine tailings as an alternative source for base metals [

5,

6,

7] and CRMs.

Tailings are residuals left over after the extraction of valuable minerals from primary ores. They often contain significant amounts of valuable minerals [

8,

9] that were not or not fully extracted during initial processing resulting from different target minerals or the inefficiency of the technology used at the time [

10]. Furthermore, they contain minerals that were previously not of commercial interest [

11,

12] but are of a particular value for modern raw material extraction under current conditions. Residual silicate material in tailings can also be valorized for construction applications such as bricks, geopolymers, or cement additives, offering both economic and environmental benefits [

12].

There are countless projects (both lab and commercial scale) worldwide focused on recovering CRMs from historical mine tailings, driven by the rising demand for these materials and the need for sustainable supply chains [

12,

13,

14,

15,

16,

17]. According to [

18], there are over 75 major tailings reprocessing projects worldwide. The European Union (EU) has been at the forefront of metal recovery from tailings, primarily through several policy initiatives such as Horizon 2020 that have funded over 26 CRMs-related projects, with more than EUR 200 million invested. One of the key outcomes of this initiative is the establishment of European Institute of Innovation and Technology (EIT) Raw Materials, the world’s largest raw materials consortium, which supports innovation, education, and entrepreneurship across the sector, significantly advancing sustainable resource recovery in Europe [

19].

Despite this progress in CRM tailings research, Li recovery from mine tailings remains underrepresented in both the global and European literature, particularly from greisen-type Sn–Li systems, where Li is hosted in fine-grained mica-group minerals such as zinnwaldite. Most existing research instead targets brines [

20,

21,

22] or battery recycling [

23,

24,

25,

26,

27], leaving a critical gap in understanding tailings specifically derived from granitic mineralization [

12,

28,

29].

In Germany, the Altenberg region has a 500-year history of tin mining and is home to major tailings deposits such as Tiefenbachhalde and Bielatal. Ref. [

11] assessed the remining potential of the Tiefenbachhalde tailings dump. They found that the total mass of tailings in the Tiefenbachhalde dam was 5.6 Mt, with 2038 t of recoverable SnO

2 and 6.9 wt% zinnwaldite. This study, however, only focused on Sn and no other valuable contents of the tailings [

28]. The Bielatal TSF, which contains over 10.5 Mio m

3 of fine-grained Sn residues, remains systematically uncharacterized, particularly for its lithium (originating from greisen-type granitic systems) and tin remining potential. Therefore, there is no published literature on the reprocessing potential of the Bielatal tailings body, leaving a significant gap in knowledge regarding fine-grained, lithium-bearing tailings formed during historical Sn processing within the Erzgebirge region. Given the site-specific variability in tailings’ mineralogy and composition [

15], comprehensive characterization is essential to assess feasibility and reduce investment risk.

The present study addresses this research gap by conducting a systematic characterization of the Bielatal TSF. Specifically, it aims to evaluate the potential exploitability of lithium and tin, assess their spatial, geochemical, and mineralogical distribution, and investigate the residual silicate matrix for its suitability as a secondary construction material. This work contributes to the growing body of knowledge on tailings reprocessing, particularly in greisen-type granitic systems, and supports the EU’s strategy for CRM supply security and sustainable raw material use. This research not only addresses a major data gap in tailings characterization but also contributes to the EU’s strategic goals of enhancing CRM supply security and sustainable raw material use through the reprocessing of greisen-type tailings.

2. Study Area

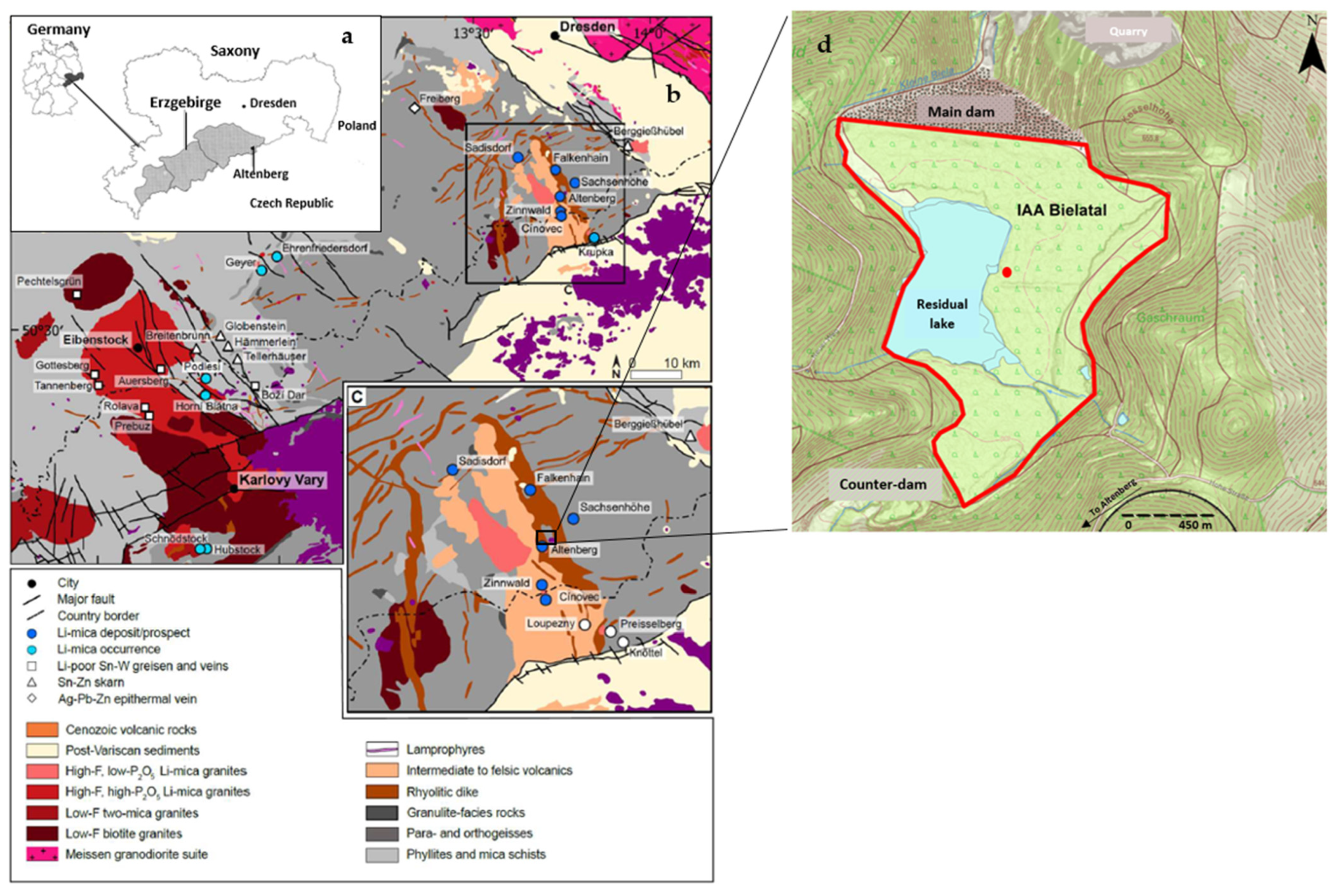

The study area is located in the Eastern Erzgebirge region (Ore Mountain area in Saxony, Germany, located along the border with the Czech Republic), near the town of Altenberg, approximately 35 km south of Dresden [

30] (

Figure 1a). The focus of this study is the Bielatal Tailings Storage Facility (TSF), situated about 1.5 km north of Altenberg, in the Erzgebirge region, historically known for the extraction of Sn, tungsten (W), and, more recently, Li. The facility was constructed in 1967 by the former East German company Volkseigener Betrieb (VEB) Zinnerz Altenberg and remained in operation until 1991, storing residues from the beneficiation of Sn ores mined from the world-class Altenberg greisen deposit [

31].

Geologically, the site lies within the Saxo-Thuringian Zone of the Variscan orogeny, part of the Bohemian Massif [

28,

32] (

Figure 1b). The Altenberg deposit is hosted in highly fractionated, fluorine-rich albite granites, altered through intense greisenisation, a hydrothermal process that replaced primary minerals with assemblages of quartz, zinnwaldite, muscovite, fluorite, topaz, and tourmaline (

Figure 1c). This alteration is responsible for concentrating economically valuable elements such as Li, Sn, W, and niobium (Nb) [

28,

32].

The Bielatal TSF was constructed as a valley-fill dam reaching a maximum height of 80 m in height, with a surface area of 73,000 m

2. It includes two submerged internal containment dams and a residual lake that collects runoff and rainfall (

Figure 1d). The tailings with an estimated volume of 10.5 Mio m

3 were produced from gravity and flotation processing of cassiterite-rich ores. Due to process inefficiencies, only about 50% of the tin was recovered, with about 0.1–0.2 wt% Sn and approximately 0.1 wt% Li retained in the tailings [

31]. The Li in the tailings is predominantly associated with mica-group minerals, particularly zinnwaldite, which is also the main Li host in the nearby Zinnwald–Cinovec deposit, one of the largest greisen-hosted Li systems in Europe [

28]. The mineralogical and geochemical characteristics of the tailings reflect the alteration processes and primary granite composition of the primary ore deposit [

33].

The Bielatal TSF is representative of a lesser-studied tailings typology, derived from greisen-altered, Li-Sn-rich granites where lithium is hosted in fine-grained, altered mica phases, unlike the coarser spodumene-bearing tailings typical of pegmatite operations [

29]. Similar tailings bodies in Central Europe, such as Cinovec, have recently been revisited as part of broader efforts to identify secondary sources of critical raw materials, including Li, Sn, and W [

28]. These sites, including Bielatal, are increasingly recognized as valuable within circular economy frameworks focused on resource recovery from historical mining residues.

Figure 1.

(

a) Geographical location of study area (Altenberg) in Erzgebirge (Ore Mountains), Saxony, Germany (modified after [

30]); (

b) geological map of the Erzgebirge region (modified after [

28]); (

c) enlarged map showing the local geology around study area, Altenberg (modified after [

28]); (

d) geographical map of Bielatal tailings dam, with red marking the boundary of the surface of the dam and a red spot showing the sampling area (modified after [

34]).

Figure 1.

(

a) Geographical location of study area (Altenberg) in Erzgebirge (Ore Mountains), Saxony, Germany (modified after [

30]); (

b) geological map of the Erzgebirge region (modified after [

28]); (

c) enlarged map showing the local geology around study area, Altenberg (modified after [

28]); (

d) geographical map of Bielatal tailings dam, with red marking the boundary of the surface of the dam and a red spot showing the sampling area (modified after [

34]).

3. Materials and Methods

Sampling took place in October/November 2023 on the eastern side of the residual lake (

Figure 1d) at 5 sampling points using percussion coring to a depth of 7 m each and approximately 5 m apart. The samples were named RKS1 to RKS5. The selection of this method was primarily based on site-specific conditions: the tailings material is relatively soft and unconsolidated, allowing for efficient penetration without the need for more complex drilling systems. Given the moderate sampling depth and limited site accessibility due to safety and permitting constraints, percussion coring provided a practical and effective solution. For safety reasons, the tailings dam is covered with a geogrid towards the flushing beach and a gravel cover at the upper part of the dam. Sampling took place in the immediate transition area between the geogrid and the gravel cover to ensure minimal disturbance to the dam structure while still allowing for representative subsurface sampling. Although no formal sampling guideline was directly followed, the methodology aligned with common practice in similar environmental sites and geotechnical investigations where logistical, material, and safety considerations determine the approach [

35,

36,

37,

38,

39].

During the sampling, different macroscopic properties (colour, grain size, and fragment) were observed; therefore, a lithological approach/classification of the material in the depth profile was carried out on site, resulting in subsamples from the respective profiles A total of approximately 100 kg of material was sampled, with each drill core accounting for about 20 kg of the total material weight. Aliquot samples were taken from the bulk materials for more detailed characterizations. In order to characterize each sample, the tailing samples were oven dried at 105 °C, deagglomerated, and homogenized with a mortar and pestle for subsequent analysis.

Tailings material from Cinovec, a former tin mining area in the Erzgebirge region on the Czech–German border close to Altenberg, was also sampled for comparison purposes. The reference samples, basic cement (BC), coal fly ash (CFA), and sand (S), used in this study were sourced from [

40].

Particle size distribution was assessed via a laser particle size analyzer and larger particles (>300 µm) were analyzed by means of wet sieving.

The pH, redox potential (Eh), and electrical conductivity (EC) of the tailings were measured in a 1:2 solid–liquid ratio. Mixing of the solution was performed manually with a stirring glass rod for about 2 min. Eh measured values were corrected to the standard hydrogen electrode (SHE) [

41]. The bulk chemical composition was determined via sodium peroxide fusion. Due to the limit of detection (LOD) for Si (<30 wt%) and Na measurement using sodium peroxide fusion, lithium borate fusion/XRF was used to determine the Si and Na content. It should further be noted that the geochemical composition of individual subsamples of each drill hole (profile) was determined by means of X-ray fluorescence (XRF).

A scanning electron microscope (SEM) with energy dispersive X-ray spectroscopy (EDX) operating under high vacuum at 20 kV was used to identify mineral phases. The images were acquired by a backscattered electron (BSE) detector and the chemical composition of the sample was determined by EDX using the ESPRIT Compact Bruker Microanalysis software (QUANTAX 75/80) with an XFlash 5010 detector (Bruker, Billerica, MA, USA). In the first step, SEM was used to identify the presence of different mineral phases in the samples based on the morphology and texture of the grains, as well as their backscattered electron (BSE) intensity. Phases with higher average atomic numbers had a higher BSE intensity and were brighter in the grey-scale images compared to phases with lower average atomic numbers [

42]. In the second step, these different mineral phases were confirmed via analysis with EDX for their element compositions.

To theoretically evaluate the tailings’ properties as potential geopolymer materials, geochemical data/properties of other tailings materials from various literature sources were compiled in relation to the properties for use as geopolymers. A comparison was then made with the properties of the samples taken from the Bielatal tailings body. These properties were further compared to regulations (European standard) for geopolymer production.

4. Results

4.1. Particle Size Distribution

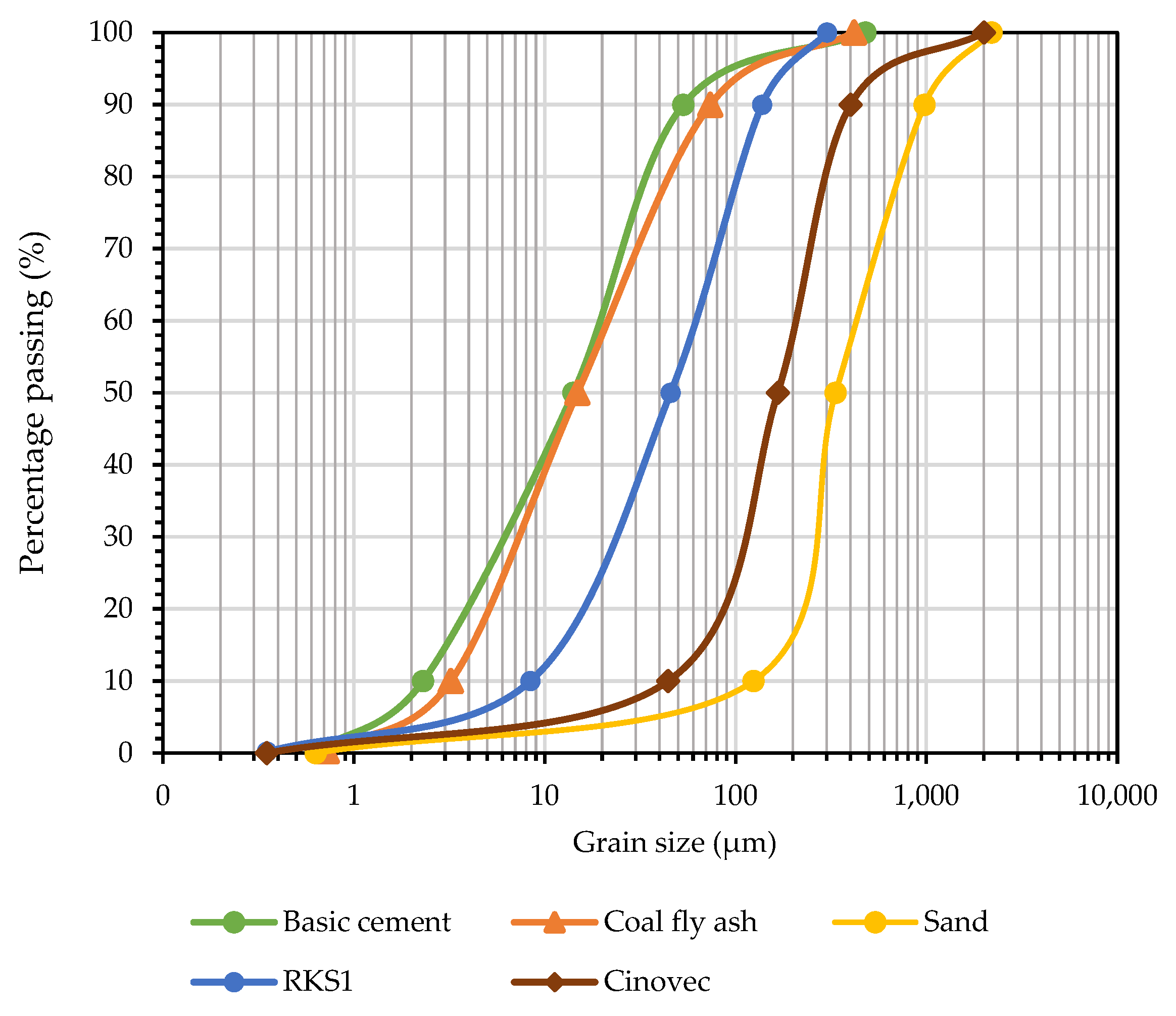

A comparison of the particle size distribution of the RKS tailings samples, Cinovec sample, and the reference samples, coal fly ash (CFA), basic cement (BC) and sand (S), (according to [

40]) is presented in

Figure 2. It should be noted that, due to the relatively similar results (i.e., overlapping particle size distribution curves) of the RKS samples, only RKS1 is shown for simplicity. The RKS tailings sample is composed of particles ranging in size from 0.35 to 300 μm. The RKS sample is very heterogeneous with regard to grain size. The silt fraction represents the highest content (56–60%), with the fine sand and clay content ranging from 30 to 35% and from 8 to 10%, respectively (

Table 1). The d10 value ranges from 6 to 7 μm, the d50 value ranges from 42 to 49 μm, and d90 value ranges from 131 to 146 μm. The RKS sample is more graded, with a clear silt to fine sand content and a small proportion of clay.

The Cinovec sample is composed of particles ranging in size from 0.35 to 2000 μm. The sand fraction represents the highest content (79%), with a silt and clay content of 20% and 2%, respectively (

Table 1). The d-values (d10, d50, and d90) are as follows; 44 μm, 166 μm, 399 μm. The Cinovec sample has a broader and coarser particle size distribution with sand to silt content.

From the particle size distribution diagram (

Figure 2), it can be seen that coal fly ash and basic cement are generally finer than the tailings samples. However, all the tailings samples show a distribution less than the reference sand sample.

4.2. Millieu Parameters

To access the environmental conditions [

43] of the RKS tailings samples, eluate analysis for the relevant environmental parameters (pH, Eh, and EC) were conducted.

Figure 3 shows the measured pH, Eh, and EC values of the eluates against profile depth. The pH increases gradually with depth from 5.9 to 7.7, indicating weak acidic to neutral conditions in the tailings body. The Eh, on the other hand, decreases with increasing depth from 570 mV to 45 mV, indicating an oxidized condition in the upper part of the tailings body and a more reduced conditions in the lower part of the tailings body. The electrical conductivity fluctuates within the range of 35–115 µS/cm, suggesting relatively low levels of dissolved ions/salts in the tailings.

4.3. Geochemical Composition

4.3.1. General Chemical Characteristics

A summary of the chemical composition of the RKS tailings samples is presented in

Table 2. The result indicates that the main components of the RKS tailings samples are Si (avg. 33 wt%), Al (avg. 8 wt%), Fe (avg. 5 wt%), and K (avg. 2 wt%). The valuable elements are Sn and Li, with average concentrations of 0.12 wt% and 0.1 wt%, respectively. All other elements have an average concentration <0.5 wt%. The result shows that the major environmentally concerning element present in the tailings is arsenic (As), with an average concentration of 0.05 wt%. In comparison to other tailings bodies worldwide, the arsenic content of the Altenberg tailings is notably low [

44]. A study by [

45] reported As levels reaching 3.17 wt% in mine wastes in North-Central Mexico. Ref. [

46] also reported As concentrations exceeding 4 wt% in oxidized tailings at the Long Lake Gold Mine in Canada. Ref. [

47] found an average As concentration of 0.15 wt% in an abandoned mining area in Spain using a combination of geophysical and geochemical methods.

There are no significant differences in the average element concentrations in the RKS tailings from the five different drill cores. In a broader scope, the chemical composition of the Altenberg tailings is compared to other Li-bearing tailings worldwide (

Table 3). It can be seen that the Altenberg tailings analyzed in this study display a Li content of 0.098 wt%, which falls within a similar range to tailings from Cornwall, UK (0.04 wt% Li) [

48] and Guiyang, China (0.098 wt% Li) [

29], but is less than the tailings reported by [

49,

50,

51]. In contrast, some selected fresh Li ore projects worldwide (

Table 4), like Whabouchi (Canada, 0.68 wt% Li) [

52], Pilgangoora (Australia, 0.48 wt% Li) [

53], and Keliber (Finland, 0.52 wt% Li) [

54], boast higher grades; however, they require full-scale mining, crushing, and grinding operations. Tailings, on the other hand, are already ground, which can significantly offset energy and processing costs, enhancing their feasibility as secondary Li resources. Moreover, the Li grade in Altenberg tailings is comparable to the cut-off grades reported in some primary projects, such as 0.17 wt% at Zinnwald Lithium, Germany [

33] and 0.12 wt% at Sonora, Mexico [

55], supporting tailings’ potential for economic reprocessing.

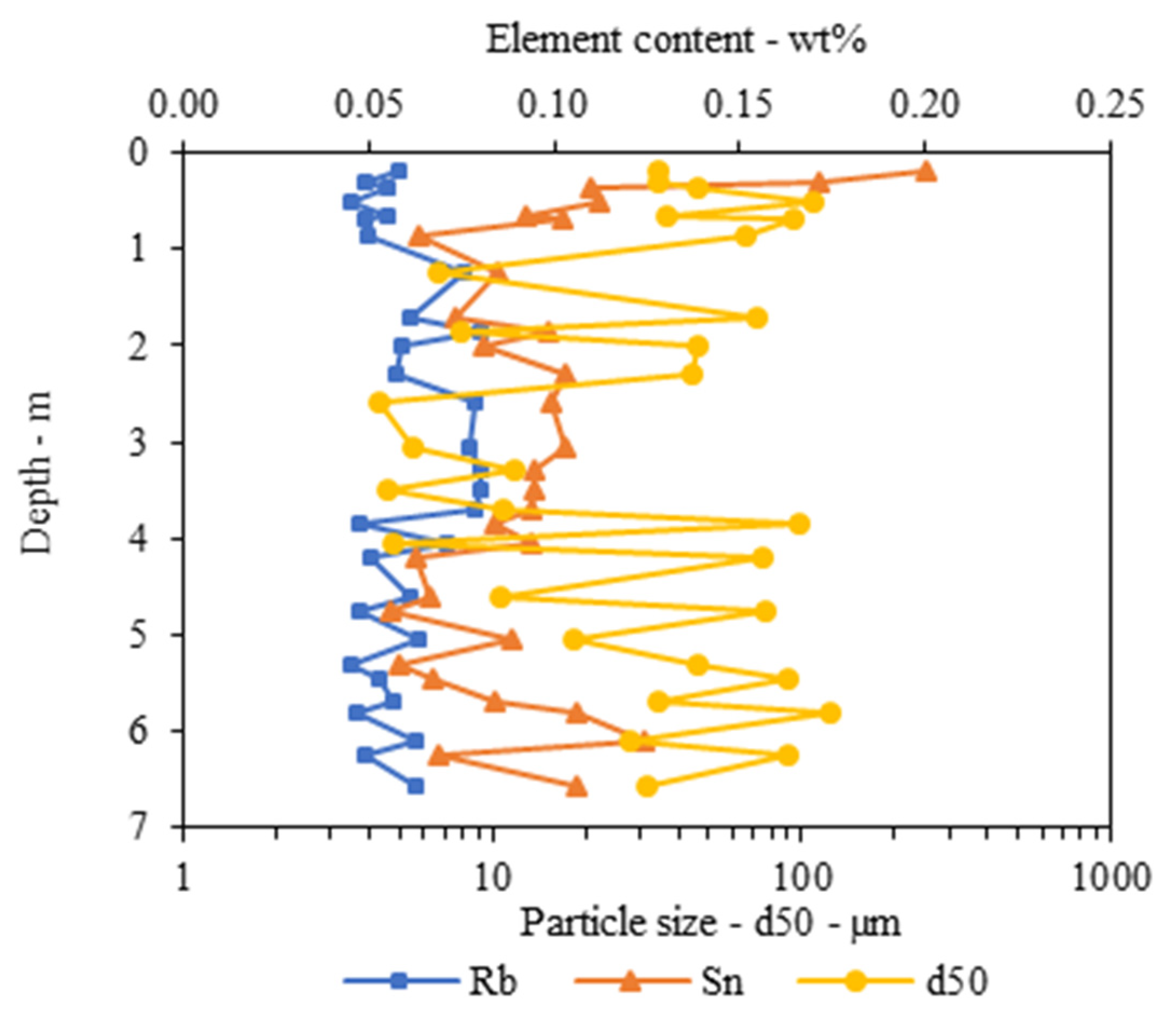

4.3.2. Geochemical Composition (XRF) Related to Particle Size Classes

The geochemical composition of tailings samples is determined by the minerals that remain after ore processing. The multi-stage treatment process affects the grain size, leading to variations in particle size distribution.

Figure 4 shows relevant particle size data (d50) from drill core sample RKS1, in combination with concentration data (XRF analysis) for Rb and Sn. Li is excluded here because it is not measurable by XRF. The proxy element, Rb, is presented instead. A vertical fractionation layered structure is clearly evident in the drill profile. There is an alternating layer structure of coarse and fine-grained materials which results from the tailings deposition process. With regard to the vertical fractionation layered structure, it can be seen that Rb (a proxy element for Li) and Sn are highly enriched in the fine-grained fractions. It could therefore be inferred that Li would also be enriched in the fine-grained fractions.

This is consistent with a study by [

29] which reported that Li and Al concentrations were significantly higher in the finer particle size fractions (<75 μm) of bauxite mine tailings from Guiyang, China. Similarly, Ref. [

11] demonstrated that Sn and other critical elements were preferentially enriched in the finer fractions of historical flotation tailings from Altenberg, Germany, identified through spatially resolved automated mineralogy and geochemical modeling.

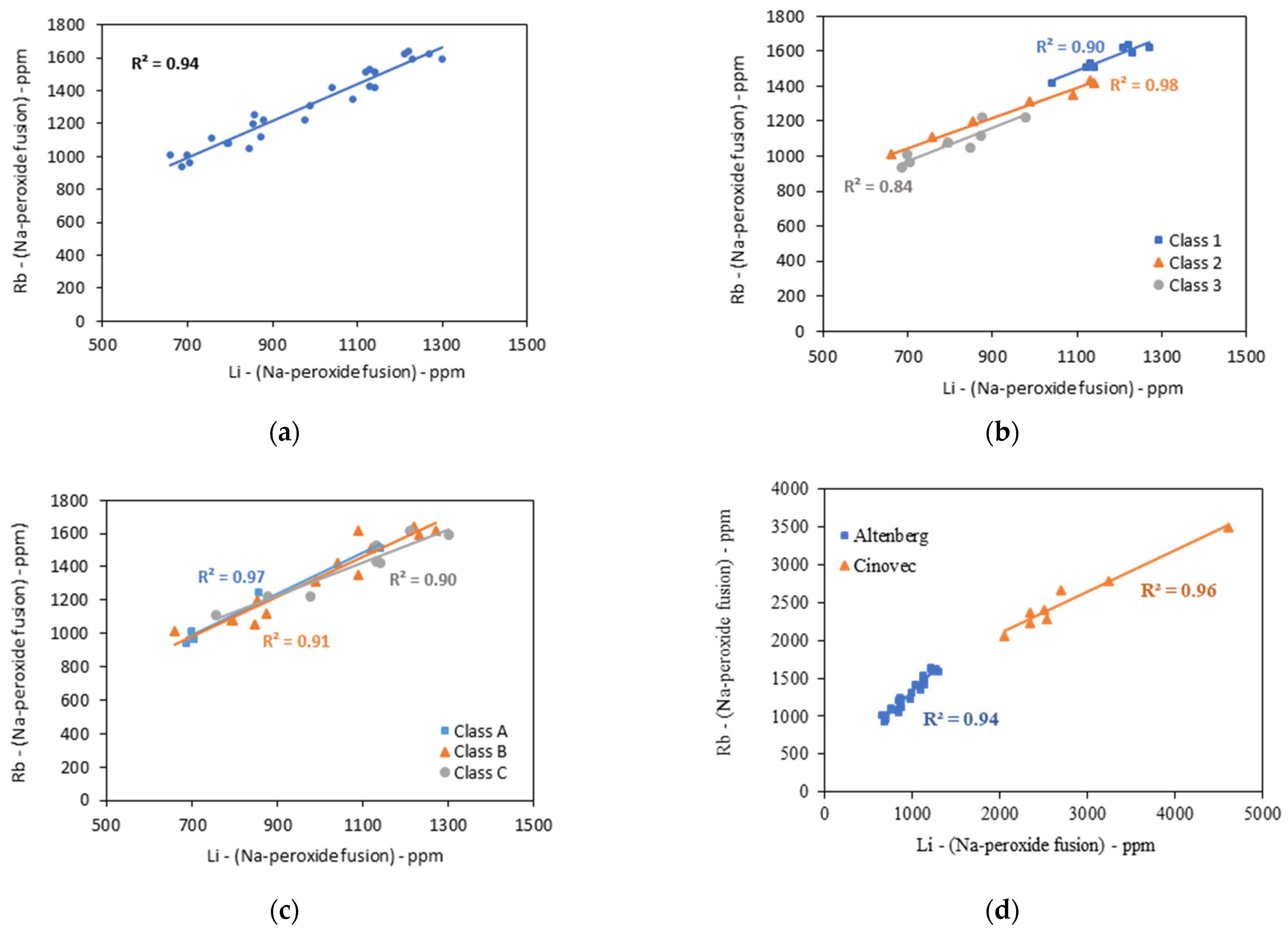

4.3.3. Correlation of Rb-Li in the Bulk Sample (RKS), Different Particle Sizes, Redox Classes, and Neighbouring Tailings Material (Cinovec)

Traditional lithogeochemical techniques often involve delays between sample collection and laboratory analysis, creating a gap between data acquisition and its practical application [

56]. Therefore, XRF can be applied as a tool for fast, but not 100% accurate, measurements in the field to speed up the logging process and provide better determination for subsampling for geochemical analysis during early-stage exploration. The application of XRF in this context optimizes the process and reduces analytical costs. While XRF cannot directly measure Li, a correlation between Li and Rb can be utilized to estimate/approximate Li concentrations. Establishing a robust correlation equation based on this relationship has the potential to significantly reduce analytical delays and lower costs, particularly in large-scale sampling campaigns.

Figure 5a shows the correlation between Rb and Li in the RKS tailings samples, indicating a strong correlation (R

2 = 0.94) between Rb and Li. This means that the samples with higher Rb enrichment are also enriched in Li. The RKS tailings were further classified into various groups based on their particle sizes and redox conditions.

Table 5 shows the different classification groups and their criteria for grouping. It was therefore imperative to test the Rb–Li correlation for these different classification groups.

The redox state condition was determined in relation to the rH value, a dimensionless number that represents the relative electron activity of the tailings system calculated using Equations (1) and (2), where pE is electron activity and Eh is the redox potential in volts at 25 °C.

Figure 5b,c, show the correlation of Rb and Li in different grain sizes and redox classes. It can be seen that a strong Rb–Li correlation exists within the different grain size and redox state classes, with an improved correlation in the redox classes. Similar behavior is evident in the Cinovec sample (

Figure 5d), with a high Rb–Li correlation (R

2 = 0.96) like that in the Altenberg samples.

4.4. Mineralogical Composition (SEM-EDX)

The Bielatal tailings material was previously described by [

31], with the quantitative mineralogical information presented in

Table 6. The tailings consist mainly of quartz, mica, topaz, and alkali feldspars, with minor hematite and clay minerals resulting from feldspar alterations [

57]. The mineralogical composition of the tailings reflects the greisen nature of the primary host rock [

31]. SEM-EDX analysis was conducted to further confirm the presence of the different mineral phases in the RKS tailings samples in BSE mode. The BSE mode in relation to the different grey scales (brightness) immediately allows a conclusion to be drawn about the distinction between different mineral phases/valuable elements.

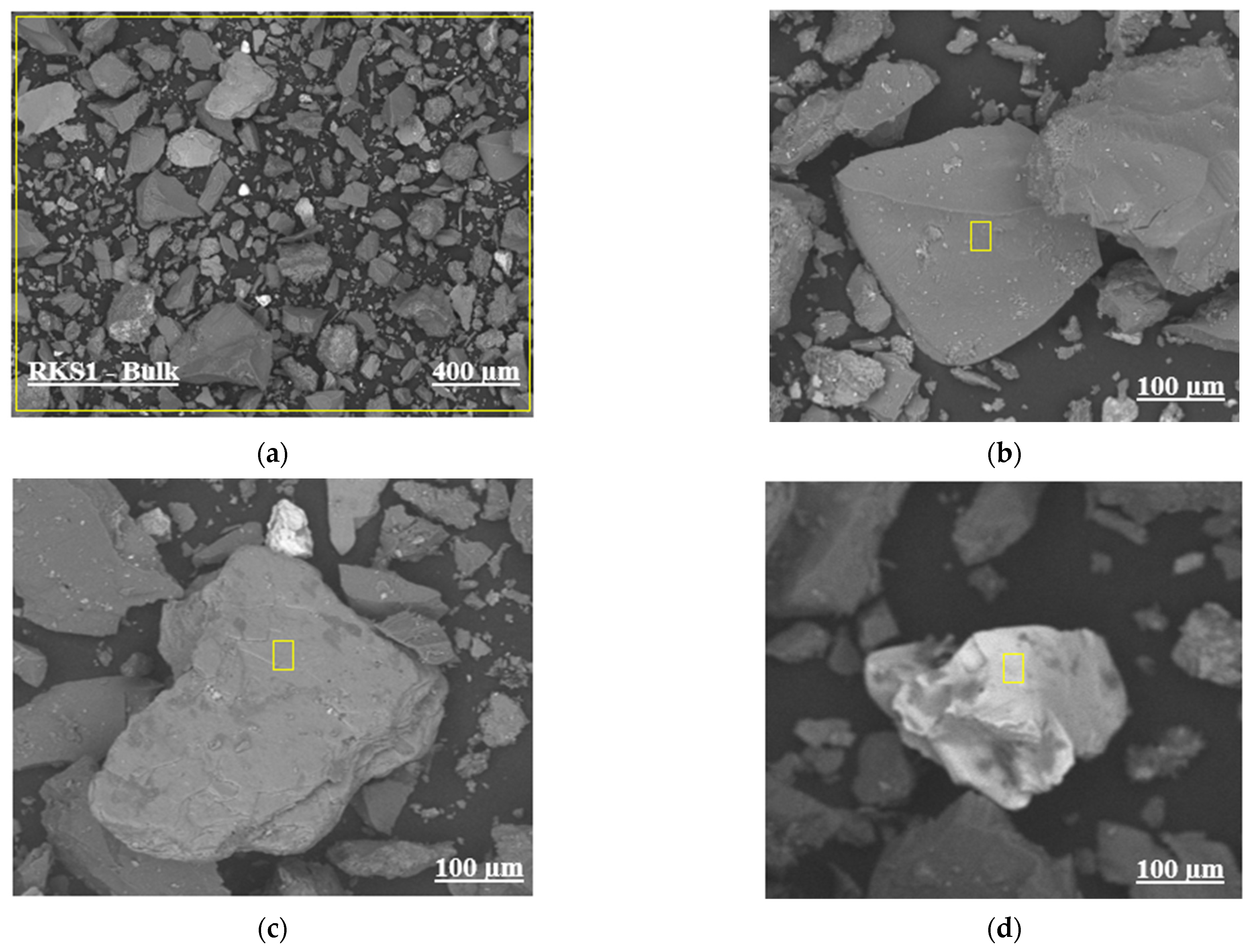

From

Table 7, it can be seen that the main elements distributed in the sample are Si, K, Al, Fe, F, Na, Ca, Mg, and Ti. In agreement with [

31], the following mineral phases are relevant (as seen

Figure 6) and identified for the tailings material: quartz (SiO

2) (

Figure 6b); topaz ((Al

2SiO

4)(F,OH)

2); feldspar (i.e., orthoclase (KAlSi

3O

8), albite (NaAlSi

3O

8), and plagioclase ((NaCa)((Si,Al)(AlSi

2)O

8)); mica (i.e., zinnwaldite (KLiFeAl(AlSi

3))O

10(F,OH)

2); biotite (K(Mg,Fe)

3AlSi

3O

10(OH,F)

2); and muscovite (KAl

2(AlSi

3O

10)(OH)

2)) (

Figure 6c); and clay mineral kaolinite (Al

2(Si

2O

5)(OH)

4). Tin is bound to the strongly bright, discrete particles in the BSE mode and is associated with cassiterite phases (SnO

2) (

Figure 6d). Fe may also be association with sulfur and arsenic, which could indicate the probable presence of pyrite and/or arsenopyrite. This needs to be further investigated to differentiate between hematite, pyrite, and/or arsenopyrite phases in the tailing samples.

From

Table 8, it can be seen that the different types of tailings explored for the potential recovery of Li have different mineralogical composition. The samples exhibit diverse mineral assemblages, reflecting influences from host rock geology, regional geological evolution, processing technologies, ore beneficiation methods, and hydrothermal alteration histories. Despite this variability, a key observation is that the Altenberg tailings and the other tailings are consistently dominated by quartz, feldspars, and mica-group minerals such as muscovite, biotite, zinnwaldite, and lepidolite. With the exception of tailings from La Corne (Canada) [

49] and Guiyang (China) [

29], the primary lithium-bearing phases in all the tailings (including the Altenberg tailings) samples are predominantly associated with mica-group minerals, zinnwaldite, and lepidolite. Though there are principal similarities among these tailings, it is important to note that the specific mineralogical trends are highly site-dependent. Recognizing these distinctions is critical for assessing the reprocessing potential of Li, since the recovery of Li is strongly influenced by the host mineralogy and its response to metallurgical treatment.

4.5. Evaluation of the Potential of Mine Tailings as Geopolymer Materials—Chemical Characteristics

The chemical composition of mine tailings plays a crucial role in determining their suitability for geopolymer production [

58,

59,

60,

61,

62,

63,

64,

65].

Table 9 shows the chemical composition of eight mine tailing samples that have previously been used in the application of geopolymer production in comparison to the chemical composition of the Altenberg samples.

Table 10 shows the chemical composition of some selected reference samples (basic cement, coal fly ash and sand) and European standard requirements for the use of coal fly ash and cement in comparison to the chemical composition of Altenberg tailings sample (RKS samples).

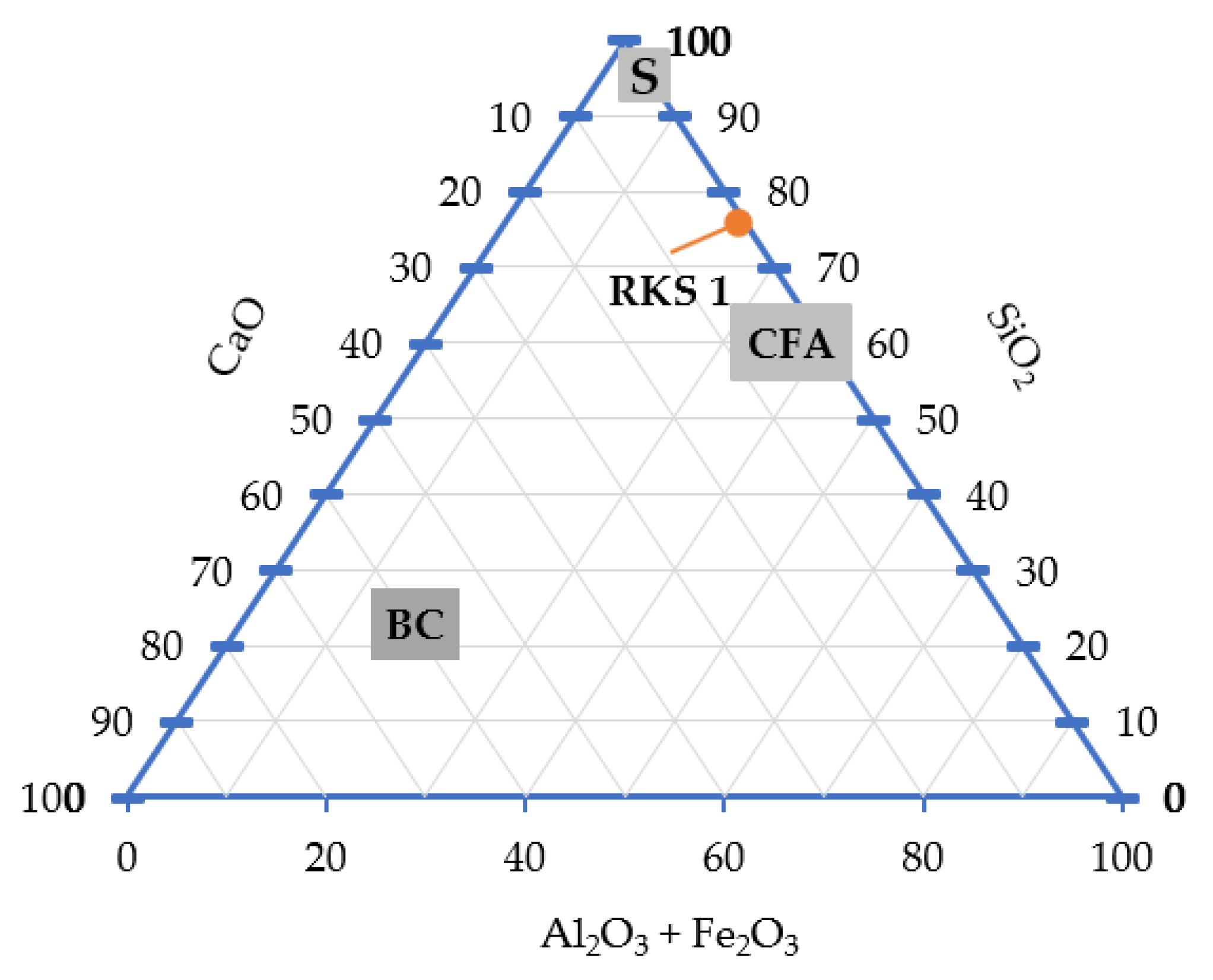

The relative chemical composition of the Altenberg tailing samples is presented in a CaO-SiO

2-Al

2O

3 + Fe

2O

3 ternary phase diagram (

Figure 7) to assess the cementitious and pozzolanic properties of the tailing materials.

5. Discussion

5.1. Characterization of Bielatal Tailings Dam

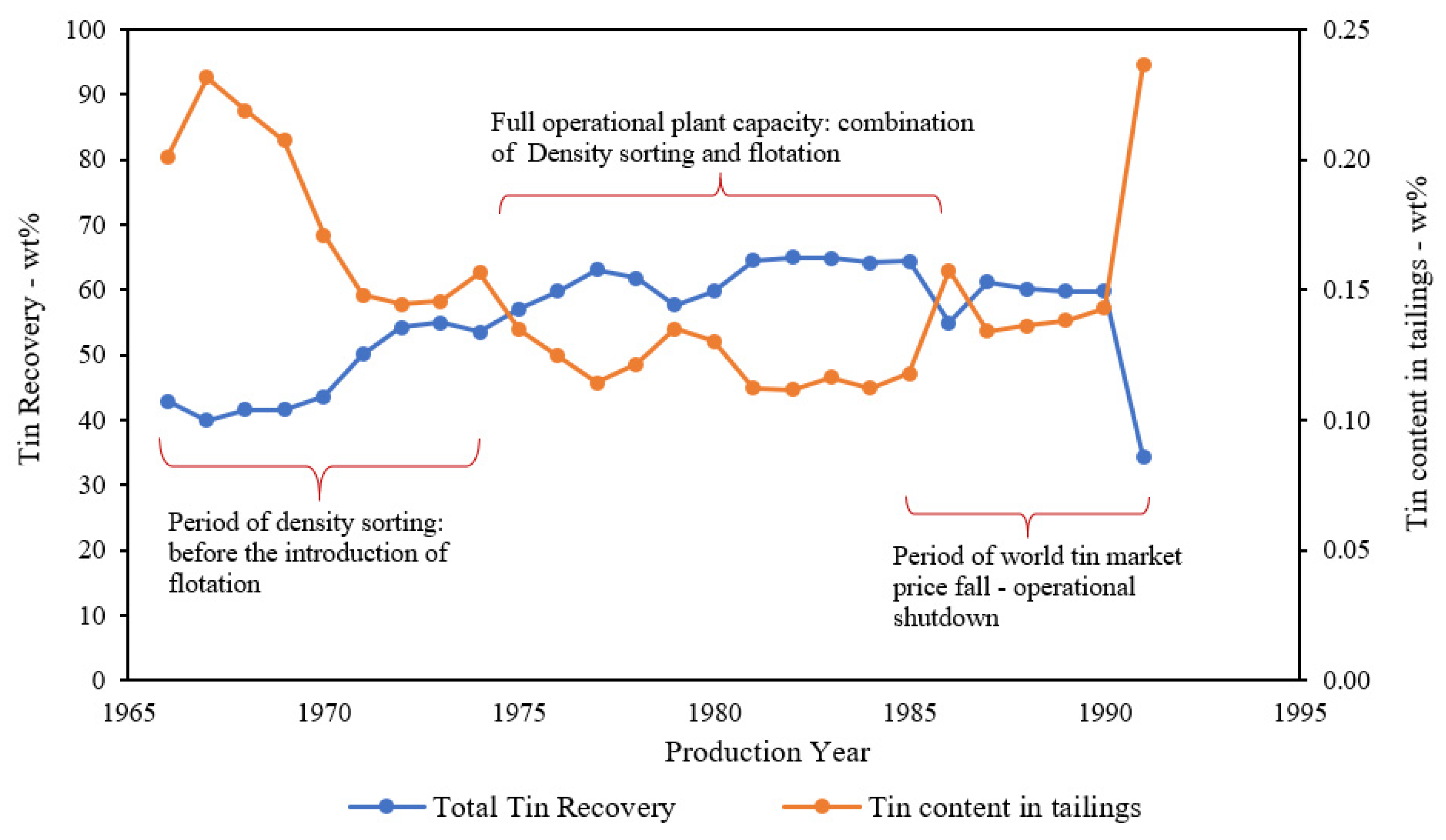

5.1.1. Processing Technology Influence on Value Element (Sn) Spatial Distribution in Tailings Body

Different processing techniques produce tailings with varying physical and chemical properties. The processing history provides insights into the types of materials and their element content deposited in the dam over time and any layering effects. In the framework of Bielatal tailings dam, the dam hosts residues from both density sorting and flotation. During the period of density sorting processing, the company produced a tin concentrate with a total Sn yield of 35–40%. The German Democratic Republic (GDR) government’s fundamental decision to increase pure Sn production (dry ore throughput of 1 million t/a and total tin yield of 70%) in such a way that imports were completely replaced resulted in the investigation into Sn losses. Analysis of the processing tailings showed that the greatest tin losses occurred in the fine grain fraction, which resulted in the introduction of flotation process to recover tin from this fraction (<100 µm). The combined process of density sorting and flotation resulted in an increased average Sn yield of 66%. The fall in the world Sn market price from 1985 to 1990 and the political change in the region affected the efficiency and production of Sn concentrate. During the final years up to the shutdown of the mine, the recovery rate dropped from 66% to 34%. This resulted in a higher Sn content in the tailings materials. This is clearly seen in

Figure 8, with an average Sn recovery rate of 34%, resulting in an average Sn tailings content of 0.24 wt%. This explains why there is a higher Sn content in the upper tailings body, as seen in the drill profile (

Figure 4).

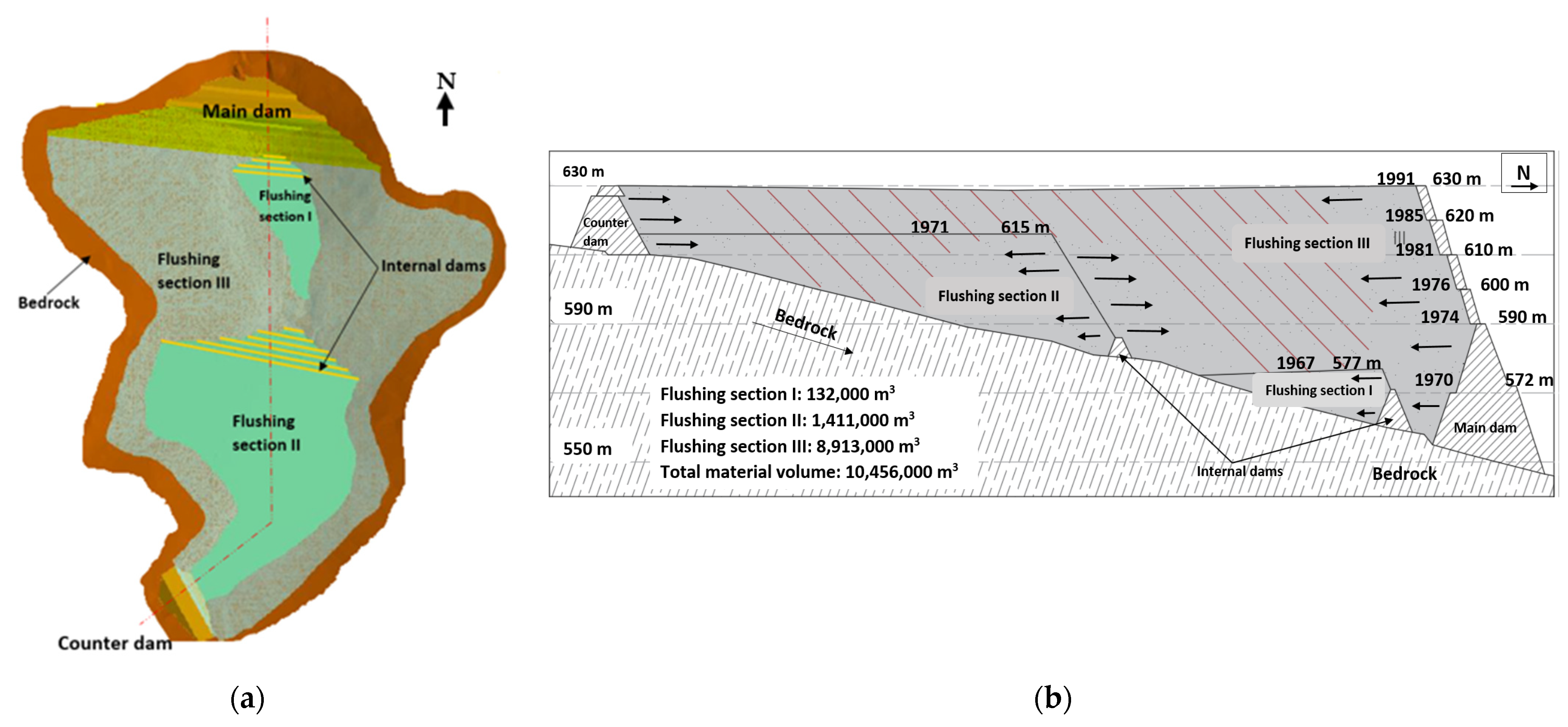

5.1.2. Tailings Dam Structure in Relation to Flushing Technology and Position of Tailings Material

It is important to note that every TSF has its own unique internal structure, leading to a unique depositional history and exact positioning of the tailings material. Examining a tailings dam structure and its depositional history is essential to ensuring the best possible target-oriented sampling for resource recovery investigations [

69], factors that will reduce cost and time. Furthermore, a detailed examination also helps to identify any weaknesses or potential failure points [

70] in the tailings structure.

Figure 9 shows a 3D model of the aerial view of the Bielatal tailings dam and a cross-sectional view with the three flushing sections and periods of tailings deposition, along with dam heights and the volumes of tailing materials deposited, while arrows indicate the direction of discharge and areas with expectedly small grain sizes are shaded in red.

From

Figure 9b, it can be seen that the Bielatal tailings dam is formed by a valley-side main dam in the north, about 590 m above sea level, and a counter dam to the south (approximately 627 m above sea level). Due to an earlier waste deposition than planned, temporary flushing sections (flushing sections I and II) were built in between the main dam and the counter dam to host the tailing materials. Two small internal dams (now submerged), one in the northern part and the other in the middle closer to the southern counter dam, were constructed in this regard (

Figure 9a). This resulted in three flushing sections in the Bielatal tailings dam. The flooding of these flushing sections was performed in succession in the order of flushing sections I, II, and III. After the overflooding of flushing section I (final height of 577 m above sea level), residues were occasionally discharged from both the main dam and flushing section II. Counter-flushing was carried out between the main and counter dam after the overflooding of flushing section II (around 400 m from the main dam and a final height of 616 m above sea level) until operations stopped in 1991. It is worth noting that there were also several uncontrolled flushings from the turbid tunnel on the eastern slope of the valley. Flushing section III reached a final height of 629 m above sea level. After operations ceased, two-thirds of the dump surface was covered with a gritty, insufficiently cultivable material with a layer thickness of about 35 to 50 cm to prevent wind erosion. Currently, the maximum height of the dam is approximately 631 m above sea level, and hence a current covering layer of about 1.50 to 2 m is expected.

Longitudinal flushing via pipes from the dam shoulders was used in the deposition of the tailing wastes into the dam. The slurry ran unpressurised and was distributed over a large area at the main dam crest, washed out, and flowed freely over the inclined flushing beach into the rinsing lake. Due to the fractionation of the material during flushing, the coarser fractions settled mainly in the upper, more accessible area of the flushing beach, while the finer fractions flowed further into the flushing lake. According to the flushing history and technology, it could be expected that a fine layer of silty sand would be deposited in the upper, more accessible area of the dam. Furthermore, red silty mud layers could be expected on the central and western slope of the tailings body towards the flushing lake area. This is confirmed by the particle size distribution of the RKS samples with a clear higher content of silt to fine sand and a small proportion of clay owing to their sampling position on the dam.

From

Figure 4, coupled with the depositional history, the content of Sn and Li is expected to increase significantly with the distance from the main and counter dam. It could therefore be inferred that Li and Sn would be enriched in the fine-grained fraction. It is worth noting that the layered thicknesses are technically not ideal for the possible selective mining/excavation of Li- and Sn-enriched fine-grained fractions.

5.2. Correlation of Li and Rb in Tailings Samples: Implications for Rapid Exploration and Resource Assessment

A key objective of this study was to develop an efficient method for approximating Li concentrations in fine-grained tailings, where conventional analysis is limited by the inability of XRF to detect low-atomic-weight elements like Li. By investigating the correlation between Rb and Li, this study offers an alternative approach to Li quantification through a measurable proxy, enhancing both the speed and cost-efficiency of field and laboratory workflows.

The results show a strong positive correlation between Rb and Li across the bulk Bielatal tailings samples (R

2 = 0.94), aligning with previous findings by [

31], who identified the co-association of Li and Rb within mica-group minerals in the Altenberg primary ore. These data suggest that Rb can reliably indicate Li concentrations in secondary tailings material, which retains the mineralogical properties of its source granite.

Further subdivision of the Bielatal tailings into grain size and redox condition classes reinforced the robustness of this correlation. While both subsets showed strong Li–Rb relationships, redox-based groupings yielded even higher correlation coefficients. This may indicate that, beyond particle size sorting, oxidation conditions influence Li retention or release in secondary mineral phases. Although mica minerals are the primary hosts, this suggests potential minor associations with feldspars or altered phases under oxidative conditions. This needs to be further investigated.

Comparative analysis with tailings from the neighbouring Cinovec site (on the Czech Republic side of the Erzgebirge region) revealed similar geochemical behavior. Despite textural and processing differences, with the Cinovec samples being coarser and likely produced from gravity separation, they also exhibited high Li–Rb correlations (R

2 = 0.96). This suggests a shared mineralogical or geological control over Li and Rb distribution in the greisen-type ore systems of the Erzgebirge region [

28]. However, an important distinction is the higher Li concentrations in Cinovec (0.21–0.46 wt%) compared to Bielatal (0.09–0.1 wt%). While this does not invalidate the proxy relationship, it underscores the importance of the site-specific calibration of Rb–Li models. The strong and consistent correlations across both locations support the broader applicability of this method, but they must be locally validated for quantitative use in exploration or metallurgical contexts.

From a methodological standpoint, the use of Rb as a proxy for Li in XRF-based field screening can significantly reduce turnaround time for geochemical logging, facilitate real-time subsampling decisions, and lower analytical costs in large-scale reprocessing projects. Nonetheless, this approach should be applied in other lithologies and across wider environmental conditions to assess its universality and operational thresholds.

5.3. Evaluation of Mine Tailings’ Potential Use in Silicatic Products

Table 9 shows that tailings materials with a wide range of elemental compositions have already been utilized as geopolymer materials. A material that would later be relevant for utilization as a geopolymer would of course change in its material composition due to the “removal” of the Li-mica and Sn components. It can be seen that the Altenberg tailings are somewhat richer in Al and poorer in Mg and Na compared to the other nine mine tailings samples. On the basis of the distribution of the tailings in the CaO-SiO

2-Al

2O

3 + Fe

2O

3 ternary phase diagram combined with the proportions of chemical components (

Table 9), the Altenberg tailings samples were identified as silicon-rich and are located in the right side of the diagram, ranging from the middle of the SiO

2 axes to the apex. They also contain higher fractions of Al

2O

3 + Fe

2O

3 and consequently very low fractions of CaO and may display pozzolanic characteristics. The RKS tailings show relatively similar composition to those of CFA, as they fall into the coal fly ash range in the diagram.

According to European Standards (EN 450-1 or EN 197-1), some conditions must be met for materials to be suitable for use as fly ash in concrete or cement. Therefore, the properties of the Altenberg tailings are compared to regulations (European standard) for geopolymer production (

Table 10). Geopolymer materials should have pozzolanic properties; therefore, the minimum total content of primary oxides (i.e., SiO

2, Al

2O

3, and Fe

2O

3) should be at least 70% by mass. Furthermore, the reactive CaO content in the sample should not exceed 10 wt%. The MgO content should be below 4 wt%. The expansive nature of MgO could lead to instability in the volume of the final geopolymer product if expansion is delayed [

73]. To avoid an alkali–silica overreaction, it is important to keep the alkali content (expressed as Na

2O equivalent) below 5 wt%. Negative expansion could also be caused by high levels of calcium sulphate (gypsum). This is of course an essential boundary condition for many mining waste materials, as gypsum is often present as a secondary mineral resulting from sulphide phase weathering. Therefore, the SO

3 content in the sample material should not exceed 3 wt%. The loss on ignition at a temperature of 550 °C (LOI550), translating into the organic content of the material, should not exceed 5 wt%. A high content of organic substances in the sample material can have a retarding effect on the setting and hardening of concrete. This is caused by the high porosity resulting from the decomposition of the organic substances. It should be noted that the temperature used in this study was 1000 °C instead of 550 °C. At first glance, no specific values are defined for Al

2O

3, Fe

2O

3, CaCO

3 in detail, so there should be no problem here. The same applies to the pH value; however, it is clear that highly acidic materials should not be considered, as this could result in corrosion in concretes. For tailing materials used as partial replacements for cement, the material should have a high hydraulic activity, i.e., hydration of calcium silicates. This is characterized by the total content of CaO and SiO

2 in the material, which should be at least 50 wt%.

It is imperative to note that the Altenberg mine tailings exhibit chemical compositions and properties that effectively meet all of the requirements for use as “fly ash substitute” in concrete production or basic cement according to the European standards EN 450-1 and EN 197-1. However, the question of how active the tailings are is important and should be further investigated. This is of great significance, as a replacement for coal fly ash is urgently needed in the medium term due to the restructuring of the energy supply, as this material will then no longer be produced. It should be noted that the tailings samples do not have the same activity as coal fly ash in their basic state. A preliminary test conducted on the tailings samples showed a poorer reactivity and that the possibility of activation [

61,

62] needs to be further investigated. An ongoing test is being performed to assess the materials’ potential as alkali-activated bricks. A partner institute is intensely investigating the possible use of the Altenberg tailings in the production of glass as well.

From the particle size distribution diagram (

Figure 2), it can be seen that coal fly ash and basic cement are generally fine. The average grain size distribution of the Altenberg tailings is not as fine as basic cement and coal fly ash. However, none of the tailing samples were as coarse as sand, and they all exhibit generally good fineness (d50 < 100 µm), which is considered to enhance pozzolanic reactions.

From the SEM analysis, the tailings exhibit a mixture of angular sheet-like particles and irregular porous shapes. This angular nature could improve cement and aggregate interface bonds, thereby enhancing concreate strength [

74]. However, the irregular porous particles could reduce workability by increasing the internal friction, resulting in an increased water demand [

40].

6. Conclusions

This study provides a comprehensive geochemical, mineralogical, and spatial characterization of the Bielatal tailings dam in Altenberg, Germany, with a focus on lithium and tin distribution and the potential for residual silicate valorization. The results underscore the importance of integrating historical depositional practices, particle size distribution, and geochemical and mineralogical characterization in assessing the reprocessing feasibility of legacy tailings.

The spatial differentiation within the tailings body, with coarse-grained material concentrated near injection points and finer-grained, element-enriched zones towards the dam’s central and western sections, reflects the influence of historical flushing technologies. These textural controls significantly affect the distribution of Li and Sn, with fine fractions showing notable Li and Sn enrichment, supporting selective recovery strategies. The variation in tin content across depth intervals further reflects the impact of historical shifts in mineral processing efficiency, notably the adoption of flotation.

Furthermore, this study confirmed a strong and consistent correlation between rubidium (Rb) and lithium (Li), validating Rb as a reliable proxy for Li quantification using XRF under varying grain sizes, redox states, and geological contexts. This finding holds significant operational value, offering a cost-effective approach to guide subsampling and rapid process control decisions in Li recovery from fine-grained tailings.

Milieu parameter analyses revealed that the Bielatal tailings present a low risk for acid mine drainage, with the pH and redox conditions indicating relatively stable geochemical behavior. From a circular economy standpoint, the high silica content and geochemical similarity to pozzolanic materials suggest potential for the partial substitution of coal fly ash in geopolymer production. However, the low reactivity of the raw tailings highlights the need for pre-treatment to enhance their suitability for industrial applications.

This work contributes to the growing literature on CRM recovery from fine-grained, greisen-type tailings, a class of secondary resources that remains underexplored despite its relevance to the EU raw material strategy and supply chain resilience. By establishing both the elemental recovery potential and the valorization of non-metallic components, this study supports a dual-resource recovery model that aligns with sustainable resource use.

A key limitation of this study is the restricted spatial and vertical sampling coverage, with drill core samples obtained only from shallow depths (up to 7 m) and a limited area of the tailings dam. As the tailings body exceeds 20 m in thickness and varies laterally, more extensive and deeper sampling is required to generate a fully representative resource model and better understand vertical and lateral heterogeneity. Additionally, while lithium quantification was performed via external laboratory analysis, reliance on such off-site methods introduces delays in process optimization. Future studies should aim to expand in situ Rb–Li calibration models across broader datasets and diverse tailings settings. Furthermore, the geopolymer potential of Bielatal material warrants further mechanical testing and pilot-scale production to assess performance parameters under industrial conditions.

Author Contributions

Conceptualization, data curation, formal analysis, investigation, methodology, validation, visualization, writing—original draft, writing—review and editing, K.M.; conceptualization, funding acquisition, project administration, resources, supervision, writing—review and editing, N.H.; supervision, writing—review and editing, M.R.; investigation, writing—review and editing, F.K.; writing—review and editing, J.M.V.; funding acquisition, project administration, C.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry for Education and Research (BMBF), grant number 03WIR1912C.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to confidentiality.

Acknowledgments

The authors are sincerely grateful to the site (Bielatal tailings dam) owner, LMBV, for providing permission and their cooperation in material sampling. The authors further extend their appreciation to Gitta Schneider, Institute of Geology, TU Bergakademie Freiberg, Germany, for performing the particle size distribution analysis (laser). Furthermore we want to thank for the discussion and contributions in the project provided by the project partners BEAK GmbH, UVR-FIA GmbH, ERZLABOR GmbH, and Zinnwald Lithium GmbH.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| XRF | X-ray fluorescence |

| CRMs | Critical raw materials |

| TSF | Tailings storage facility |

| VEB | Volkseigener Betrieb |

| RKS | Rammkernsondierung |

| BC | Basic cement |

| CFA | Coal fly ash |

| S | Sand |

| EC | Electrical conductivity |

| SHE | Standard hydrogen electrode |

| LOD | Limit of detection |

| SEM | Scanning electron microscope |

| EDX | Energy dispersive X-ray spectroscopy |

| BSE | Backscattered electron |

| LOI | Loss on ignition |

| GDR | German Democratic Republic |

| EN | Europäische Norm |

| EU | European Union |

| EIT | European Institute of Innovation and Technology |

References

- International Energy Agency (IEA). The Role of Critical Minerals in Clean Energy Transitions; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions (accessed on 5 May 2023).

- Mohr, S.H.; Mudd, G.M.; Giurco, D. Lithium Resources and Production: Critical Assessment and Global Projections. Minerals 2012, 2, 65–84. [Google Scholar] [CrossRef]

- World Economic Forum. Available online: https://www.weforum.org/agenda/2023/01/chart-countries-produce-lithium-world/ (accessed on 27 August 2024).

- European Commission. Critical Raw Materials for Strategic Technologies and Sectors in the EU: A Foresight Study; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- Pan, H.; Cheng, Z.; Zhou, G.; Yang, R.; Sun, B.; He, L.; Zeng, D.; Wang, J. Geochemical and Mineralogical Characterization of Tailings of the Dexing Copper Mine, Jiangxi Province, China. Geochem. Explor. Environ. Anal. 2017, 17, 334–344. [Google Scholar] [CrossRef]

- Modabberi, S. Mineralogical and Geochemical Characterization of Mining Wastes: Remining Potential and Environmental Implications, Muteh Gold Deposit, Iran. Environ. Monit. Assess. 2018, 190, 734. [Google Scholar] [CrossRef] [PubMed]

- Weng, R.; Chen, G.; Huang, X.; Tian, F.; Ni, L.; Peng, L.; Liao, D.; Xi, B. Geochemical Characteristics of Tailings from Typical Metal Mining Areas in Tibet Autonomous Region. Minerals 2022, 12, 697. [Google Scholar] [CrossRef]

- Anawar, H.M. Sustainable rehabilitation of mining waste and acid mine drainage using geochemistry, mine type, mineralogy, texture, ore extraction and climate knowledge. J. Environ. Manag. 2015, 158, 111–121. [Google Scholar] [CrossRef] [PubMed]

- Lottermoser, B.G. Mine Wastes: Characterization, Treatment and Environmental Impacts, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; p. 400. [Google Scholar]

- Jamieson, E.; Walker, S.R.; Parsons, M.B. Mineralogical Characterization of Mine Waste. Appl. Geochem. 2015, 57, 85–105. [Google Scholar] [CrossRef]

- Büttner, P.; Osbahr, I.; Zimmermann, R.; Leißner, T.; Satge, L.; Gutzmer, J. Recovery potential of flotation tailings assessed by spatial modelling of automated mineralogy data. Min. Eng. 2018, 116, 143–151. [Google Scholar] [CrossRef]

- Sarker, S.K.; Haque, N.; Bhuiyan, M.; Bruckard, W.; Pramanik, B.K. Recovery of Strategically Important Critical Minerals from Mine Tailings. J. Environ. Chem. Eng. 2022, 10, 107622. [Google Scholar] [CrossRef]

- Butu, A.; Morais, P.V.; Butu, M.; Avram, S.; Rodino, S. Recovery of Critical Metals from Mine Tailings. In Constraints and Opportunities in Shaping the Future: New Approaches to Economics and Policy Making. ESPERA 2022; Chivu, L., Ioan-Franc, V., Georgescu, G., De Los Ríos Carmenado, I., Andrei, J.V., Eds.; Springer Proceedings in Business and Economics; Springer: Cham, Switzerland, 2024; pp. 293–300. [Google Scholar] [CrossRef]

- Araya, N.; Kraslawski, A.; Cisternas, L.A. Towards Mine Tailings Valorization: Recovery of Critical Materials from Chilean Mine Tailings. J. Clean. Prod. 2020, 263, 121555. [Google Scholar] [CrossRef]

- Figueiredo, J.; Vila, M.C.; Fiúza, A.; Góis, J.; Futuro, A.; Dinis, M.L.; Martins, D. A Holistic Approach in Re-mining Old Tailings Deposits for the Supply of Critical-Metals: A Portuguese Case Study. Minerals 2019, 9, 638. [Google Scholar] [CrossRef]

- Rosario-Beltré, A.J.; Sánchez-España, J.; Rodríguez-Gómez, V.; Fernández-Naranjo, F.J.; Bellido-Martín, E.; Adánez-Sanjuán, P.; Arranz-González, J.C. Critical Raw Materials Recovery Potential from Spanish Mine Wastes: A National-Scale Preliminary Assessment. J. Clean. Prod. 2023, 407, 137163. [Google Scholar] [CrossRef]

- Babel, B.; Penz, M.; Schach, E.; Boehme, S.; Rudolph, M. Reprocessing of a southern Chilean Zn tailing by flotation—A case study. Minerals 2018, 8, 295. [Google Scholar] [CrossRef]

- Van Zyl, D.; Shields, D.; Agioutantis, Z.; Joyce, S. Waste Not, Want Not—Rethinking the Tailings and Mine Waste Issue. In Proceedings of the Tailings and Mine Waste Management for the 21st Century, Sydney, Australia, 27–28 July 2015; The Australasian Institute of Mining and Metallurgy (AusIMM): Melbourne, Australia, 2015; pp. 7–10. [Google Scholar]

- Bobba, S.; Claudiu, P.; Huygens, D.; Alves Dias, P.; Gawlik, B.; Tzimas, E.; Wittmer, D.; Nuss, P.; Grohol, M.; Saveyn, H.; et al. Report on Critical Raw Materials and the Circular Economy; European Commission: Luxembourg, 2018; Available online: https://data.europa.eu/doi/10.2873/167813 (accessed on 7 March 2025).

- Flexer, V.; Fernando, C.; Claudia, B.; Galli, I. Li Recovery from Brines: A Vital Raw Material for Green Energies with a Potential Environmental Impact in Its Mining and Processing. Sci. Total Environ. 2018, 639, 1188–1204. [Google Scholar] [CrossRef]

- Xu, P.; Hong, J.; Qian, X.; Xu, X.; Xia, H.; Tao, X.; Xu, Z.; Ni, Q. Materials for Li Recovery from Salt Lake Brine. J. Mater. Sci. 2021, 56, 16–63. [Google Scholar] [CrossRef]

- Yoshizuka, K.; Nishihama, S.; Takano, M.; Asano, S. Li Recovery from Brines with Novel λ-MnO2 Adsorbent Synthesized by Hydrometallurgical Method. Solvent Extr. Ion Exch. 2021, 39, 604–621. [Google Scholar] [CrossRef]

- Meshram, P.; Pandey, B.D.; Mankhand, T.R. Extraction of Lithium from Primary and Secondary Sources by Pre-treatment, Leaching and Separation: A Comprehensive Review. Hydrometallurgy 2014, 150, 192–208. [Google Scholar] [CrossRef]

- Gerold, E.; Luidold, S.; Antrekowitsch, H. Separation and Efficient Recovery of Li from Spent Li-Ion Batteries. Metals 2021, 11, 1091. [Google Scholar] [CrossRef]

- Liang, L.; Cai, C.; Peng, G.; Hu, J.; Hou, H.; Liu, B.; Liang, S.; Xiao, K.; Yuan, S.; Yang, J. Hydrometallurgical Recovery of Spent Li-Ion Batteries: Environmental Strategies and Sustainability Evaluation. ACS Sustain. Chem. Eng. 2021, 9, 5750–5767. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Zheng, X.; Cao, H.; He, M.; Zhang, Y.; Yu, H.; Sun, Z. Selective Recovery of Li from Spent Li-Ion Batteries by Coupling Advanced Oxidation Processes and Chemical Leaching Processes. ACS Sustain. Chem. Eng. 2020, 8, 5165–5174. [Google Scholar] [CrossRef]

- Urbańska, W. Recovery of Co, Li, and Ni from Spent Li-Ion Batteries by the Inorganic and/or Organic Reducer Assisted Leaching Method. Minerals 2020, 10, 555. [Google Scholar] [CrossRef]

- Burisch, M.; Leopardi, D.; Guilcher, M.; Šešulka, V.; Dittrich, T.; Lehmann, B. Greisen-Hosted Lithium Resources of the Erzgebirge/Krušné Hory Province (Germany and Czech Republic). Econ. Geol. 2025, 120, 1–35. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Wu, L.; Tan, L.; Xie, F.; Cheng, J. Extraction of Lithium and Aluminium from Bauxite Mine Tailings by Mixed Acid Treatment without Roasting. J. Hazard. Mater. 2021, 404, 124044. [Google Scholar] [CrossRef] [PubMed]

- Benabdellah, B.; Albrecht, K.F.; Pomaz, V.L.; Denisenko, E.A.; Logofet, D.O. Markov Chain Models for Forest Successions in the Erzgebirge, Germany. Ecol. Model. 2003, 159, 145–160. [Google Scholar] [CrossRef]

- Weinhold, G. Bergbau in Sachsen-Die Zinnerzlagerstätte Altenberg/Osterzgebirge; Sächsisches Oberbergamt Sächsisches Landesamt für Umwelt und Geologie: Freiberg, Germany, 2002. [Google Scholar]

- Qiao, S.; John, T.; Loges, A. Formation of Topaz-Greisen by a Boiling Fluid: A Case Study from the Sn-W-Li Deposit, Zinnwald/Cínovec. Econ. Geol. 2024, 119, 805–828. [Google Scholar] [CrossRef]

- Snowden Optiro. Pre-Feasibility Study Report—Executive Summary: Zinnwald Lithium Project, Saxony, Germany, Report No. 167-RPT-GEN-019 Rev0; Zinnwald Lithium plc & Zinnwald Lithium GmbH: Perth, Australia, 2025. [Google Scholar]

- GEOS Ingenieurgesellschaft mbH. Herstellung der dauerhaften Stand- und Hochwassersicherheit IAA Bielatal: Aktualisierung Standsicherheitsgutachten Hauptdamm & Abschließende Risikobewertung. Übersichtskarte; Projekt-Nr. 30160174, Anlage 1; GEOS Ingenieurgesellschaft mbH: Halsbrücke, Germany, 2017. [Google Scholar]

- Trost, J.J.; Christy, T.M.; Bekins, B.A. A Direct-Push Freezing Core Barrel for Sampling Unconsolidated Subsurface Sediments and Adjacent Pore Fluids; U.S. Geological Survey: Reston, VA, USA, 2018. Available online: https://www.usgs.gov/publications/a-direct-push-freezing-core-barrel-sampling-unconsolidated-subsurface-sediments-and (accessed on 10 April 2025).

- Iorio, M.; Urgeles, R.; Llopart, J.; Canals, M. Evaluation of Disturbance Induced on Soft Offshore Sediments by Two Types of Gravity Piston Coring Techniques. Mar. Pollut. Bull. 2019, 140, 106005. [Google Scholar] [CrossRef]

- Makinson, K.; Smith, A.M.; Hodgson, D.A.; Bentley, M.J. A New Percussion Hammer Mechanism for a Borehole Deployable Subglacial Sediment Corer. Ann. Glaciol. 2021, 62, 71–78. [Google Scholar] [CrossRef]

- Onyeji, J.A.; Okpako, E.T.; Ugochukwu, B.A. Coring Unconsolidated Formations under Challenging Drilling Conditions—A Case Study, Swamp-Niger Delta. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 6–8 August 2018. SPE-193457-MS. [Google Scholar] [CrossRef]

- Konstantinov, E.A. A New Technology of Coring for Bottom Soft Sediments. Oceanology 2019, 59, 781–786. [Google Scholar] [CrossRef]

- Simonsen, A.M.T.; Solismaa, S.; Hansen, H.K.; Jensen, P.E. Evaluation of Mine Tailings’ Potential as Supplementary Cementitious Materials Based on Chemical, Mineralogical and Physical Characteristics. Waste Manag. 2020, 102, 710–721. [Google Scholar] [CrossRef]

- Blowes, D.W.; Jambor, J.L.; Hanton-Fong, C.J.; Lortie, L.; Gould, W.D. Geochemical, mineralogical and microbiological characterization of a sulphide-bearing carbonate-rich gold-mine tailings impoundment, Joutel, Québec. Appl. Geochem. 1998, 13, 687–705. [Google Scholar] [CrossRef]

- Bevandić, S.; Blannin, R.; Vander Auwera, J.; Delmelle, N.; Caterina, D.; Nguyen, F.; Muchez, P. Geochemical and mineralogical characterisation of historic Zn–Pb mine waste, Plombières, East Belgium. Minerals 2020, 11, 28. [Google Scholar] [CrossRef]

- Sracek, O.; Choquette, M.; Gélinas, P.; Lefebvre, R.; Nicholson, R.V. Geochemical Characterization of Acid Mine Drainage from a Waste Rock Pile, Mine Doyon, Quebec, Canada. J. Contam. Hydrol. 2004, 69, 45–71. [Google Scholar] [CrossRef] [PubMed]

- Parviainen, A.; Isosaari, P.; Loukola-Ruskeeniemi, K.; Nieto, J.M.; Gervilla, F. Occurrence and Mobility of As in the Ylöjärvi Cu–W–As Mine Tailings. J. Geochem. Explor. 2012, 114, 36–45. [Google Scholar] [CrossRef]

- Rodríguez-Hernández, A.; Lázaro, I.; Razo, I.; Briones-Gallardo, R. Geochemical and Mineralogical Characterization of Stream Sediments Impacted by Mine Wastes Containing Arsenic, Cadmium and Lead in North-Central Mexico. J. Geochem. Explor. 2021, 221, 106707. [Google Scholar] [CrossRef]

- Verbuyst, B.R.; Jones, A.M.; Kamber, B.S.; Beckett, R. Microbiological and Geochemical Characterization of As-Bearing Tailings and Underlying Sediments. J. Hazard. Mater. 2024, 466, 133554. [Google Scholar] [CrossRef]

- Ruiz-Roso, J.; García-Lorenzo, M.L.; Castiñeiras, P.; Muñoz-Martín, A.; Crespo-Feo, E. 3D Spatial Distribution of Arsenic in an Abandoned Mining Area: A Combined Geophysical and Geochemical Approach. Minerals 2020, 10, 1130. [Google Scholar] [CrossRef]

- Iqbal, Z. Recovery of Lithium from Kaolin Mining Waste Material. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2015. [Google Scholar]

- Roy, T.; Plante, B.; Benzaazoua, M.; Demers, I.; Coudert, L.; Turcotte, S. Geochemistry of Decades-Old Spodumene Mine Tailings under a Humid Continental Climate. Appl. Geochem. 2022, 146, 105481. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, S.; Cheng, C.; Wang, H.; Liu, R.; Hu, Y.; He, G.; Yu, X.; Fu, W. Recycling Lepidolite from Tantalum–Niobium Mine Tailings by a Combined Magnetic–Flotation Process Using a Novel Gemini Surfactant: From Tailings Dams to the “Bling” Raw Material of Lithium. ACS Sustain. Chem. Eng. 2020, 8, 18206–18214. [Google Scholar] [CrossRef]

- Jandová, J.; Dvořák, P.; Vu, H.N. Processing of Zinnwaldite Waste to Obtain Li2CO3. Hydrometallurgy 2010, 103, 12–18. [Google Scholar] [CrossRef]

- Met-Chem. NI 43-101 Technical Report: Feasibility Study Update on the Whabouchi Lithium Deposit and Hydromet Plant (Revised); DRA Americas Division: Montréal, QC, Canada, 2016; Available online: https://minedocs.com/22/Whabouchi-TR-05312019.pdf (accessed on 10 April 2025).

- Altura Mining Limited. Investor Update: Pilgangoora Lithium—World Class Near Term Production Project; Altura Mining Limited: Pilgangoora, Australia, 2017; Available online: https://www.aspecthuntley.com.au/asxdata/20170804/pdf/01880911.pdf (accessed on 10 April 2025).

- Sweco Industry Oy. Pre-Feasibility Study: Keliber Lithium Project; Keliber Oy: Kaustinen, Finland, 2016; Available online: https://www.scribd.com/document/460023984/keliber-oy-prefeasibility-study-final-2016-14-03-pdf (accessed on 10 April 2025).

- Ausenco Engineering Canada Inc. Technical Report on the Pre-Feasibility Study for the Sonora Lithium Project; Bacanora Minerals Ltd.: Vancouver, BC, Canada, 2016; Available online: https://bacanoralithium.com/_userfiles/pages/files/documents/technicalreportontheprefeasibilitystudyforthesonoralithiumprojectmexico_compressed.pdf (accessed on 10 April 2025).

- Kalnicky, D.J.; Singhvi, R. Field Portable. XRF Analysis of Environmental Samples. J. Hazard. Mater. 2001, 83, 93–122. [Google Scholar] [CrossRef]

- Redwan, M. Geochemical and Mineralogical Characteristics of Some Gold Mine Tailings in the Eastern Desert of Egypt. Front. Earth Sci. 2022, 16, 906–915. [Google Scholar] [CrossRef]

- Zhao, S.; Xia, M.; Yu, L.; Huang, X.; Jiao, B.; Li, D. Optimization for the Preparation of Composite Geopolymer Using Response Surface Methodology and Its Application in Lead-Zinc Tailings Solidification. Constr. Build. Mater. 2021, 266, 120969. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, Green Alkali Activated Cementitious Material: Synthesis, Applications and Challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Luo, Y.; Bao, S.; Zhang, Y. Preparation of One-Part Geopolymeric Precursors Using Vanadium Tailing by Thermal Activation. J. Am. Ceram. Soc. 2020, 103, 779–783. [Google Scholar] [CrossRef]

- Perumal, P.; Piekkari, K.; Sreenivasan, H.; Kinnunen, P.; Illikainen, M. One-Part Geopolymers from Mining Residues–Effect of Thermal Treatment on Three Different Tailings. Min. Eng. 2019, 144, 106026. [Google Scholar] [CrossRef]

- Wan, Q.; Rao, F.; Song, S.; Leon-Patino, C.A.; Ma, Y.; Yin, W. Consolidation of Mine Tailings through Geopolymerization at Ambient Temperature. J. Am. Ceram. Soc. 2019, 102, 2451–2461. [Google Scholar] [CrossRef]

- do Carmo e Silva Defáveri, K.; dos Santos, L.F.; Franco de Carvalho, J.M.; Peixoto, R.A.F.; Brigolini, G.J. Iron Ore Tailing-Based Geopolymer Containing Glass Wool Residue: A Study of Mechanical and Microstructural Properties. Constr. Build. Mater. 2019, 220, 375–385. [Google Scholar] [CrossRef]

- Manjarrez, L.; Nikvar-Hassani, A.; Shadnia, R.; Zhang, L. Experimental Study of Geopolymer Binder Synthesized with Copper Mine Tailings and Low-Calcium Copper Slag. J. Mater. Civ. Eng. 2019, 31, 04019156. [Google Scholar] [CrossRef]

- Falayi, T. A Comparison Between Fly Ash- and Basic Oxygen Furnace Slag-Modified Gold Mine Tailings Geopolymers. Int. J. Energy Environ. Eng. 2020, 11, 207–217. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Shaikh, F.; Krishna, R.S.; Mishra, J. Utilization Potential of Mine Tailings in Geopolymers: Physicochemical and Environmental Aspects. Process Saf. Environ. Prot. 2021, 147, 559–577. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- EN 450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Dinis, M.D.L.; Fiúza, A.; Futuro, A.; Leite, A.; Martins, D.; Figueiredo, J.; Góis, J.; Vila, M.C. Characterization of a mine legacy site: An approach for environmental management and metals recovery. Environ. Sci. Pollut. Res. 2020, 27, 10103–10114. [Google Scholar] [CrossRef]

- Parente, C.E.; Lino, A.S.; Carvalho, G.O.; Pizzochero, A.C.; Azevedo-Silva, C.E.; Freitas, M.O.; Teixeira, C.; Moura, R.L.; Ferreira Filho, V.J.M.; Malm, O. First Year After the Brumadinho Tailings’ Dam Collapse: Spatial and Seasonal Variation of Trace Elements in Sediments, Fishes and Macrophytes from the Paraopeba River, Brazil. Environ. Res. 2021, 193, 110526. [Google Scholar] [CrossRef] [PubMed]

- Zinnerz Altenberg. Vorgänge Bielatal—Zuarbeit, Baumaßnahmen, Berichte; VEB Bergbau- und Hüttenkombinat “Albert Funk”; SächsStA-Bergarchiv Freiberg: Freiberg, Germany, 1970. [Google Scholar]

- Kaulfuss, F. Modellgestützte Betrachtung zur Rückbau-Technologie der Halde Bielatal. Studienarbeit; TU Bergakademie Freiberg: Freiberg, Germany, 2024. [Google Scholar]

- Snellings, R. Assessing, Understanding and Unlocking Supplementary Cementitious Materials. RILEM Tech. Lett. 2016, 1, 50–55. [Google Scholar] [CrossRef]

- Westerholm, M.; Lagerblad, B.; Silfwerbrand, J.; Forssberg, E. Influence of Fine Aggregate Characteristics on the Rheological Properties of Mortars. Cem. Concr. Compos. 2008, 30, 274–282. [Google Scholar] [CrossRef]

Figure 2.

Grain size distribution of tailings samples (Altenberg-RKS1 and Cinovec) and reference samples (basic cement, coal fly ash, and sand).

Figure 2.

Grain size distribution of tailings samples (Altenberg-RKS1 and Cinovec) and reference samples (basic cement, coal fly ash, and sand).

Figure 3.

Milieu parameters of RKS1 with depth: (a) pH (b) Eh and (c) EC.

Figure 3.

Milieu parameters of RKS1 with depth: (a) pH (b) Eh and (c) EC.

Figure 4.

Particle size distribution (d50) and concentration of Rb and Sn of drill core RKS1 by depth on a logarithmic scale.

Figure 4.

Particle size distribution (d50) and concentration of Rb and Sn of drill core RKS1 by depth on a logarithmic scale.

Figure 5.

Correlation of Li with Rb in (a) the bulk sample (all RKS data), (b) different particle size classes, (c) different redox classes, and (d) Altenberg and Cinovec tailings samples (based on sodium peroxide fusion analysis results).

Figure 5.

Correlation of Li with Rb in (a) the bulk sample (all RKS data), (b) different particle size classes, (c) different redox classes, and (d) Altenberg and Cinovec tailings samples (based on sodium peroxide fusion analysis results).

Figure 6.

SEM image of Bielatal tailing sample (RKS1) with marked measuring points (yellow) showing (a) an overview of the tailings sample; (b) quartz; (c) mica phases; (d) cassiterite.

Figure 6.

SEM image of Bielatal tailing sample (RKS1) with marked measuring points (yellow) showing (a) an overview of the tailings sample; (b) quartz; (c) mica phases; (d) cassiterite.

Figure 7.

Ternary phase diagram of CaO-SiO2-Al2O3 + Fe2O3 for screening the cementitious and pozzolanic properties of Altenberg tailings samples (RKS1) and reference samples (basic cement: BC; coal fly ash: CFA; sand: S).

Figure 7.

Ternary phase diagram of CaO-SiO2-Al2O3 + Fe2O3 for screening the cementitious and pozzolanic properties of Altenberg tailings samples (RKS1) and reference samples (basic cement: BC; coal fly ash: CFA; sand: S).

Figure 8.

Annual Sn recovery and average Sn content flushed into the Bielatal tailings dam from 1965 to 1991 (data after [

31]).

Figure 8.

Annual Sn recovery and average Sn content flushed into the Bielatal tailings dam from 1965 to 1991 (data after [

31]).

Figure 9.

(

a) Three-dimensional model of the aerial view of the Bielatal tailings dam. Note: Position of schematic cross-sectional view is indicate by red dotted line (modified after [

71]). (

b) Schematic cross-sectional view of Bielatal tailings dam. Black arrows show the direction of discharge of tailings into the dam and the red shaded area indicates the possible areas of smaller grain sizes (modified after [

72]).

Figure 9.

(

a) Three-dimensional model of the aerial view of the Bielatal tailings dam. Note: Position of schematic cross-sectional view is indicate by red dotted line (modified after [

71]). (

b) Schematic cross-sectional view of Bielatal tailings dam. Black arrows show the direction of discharge of tailings into the dam and the red shaded area indicates the possible areas of smaller grain sizes (modified after [

72]).

Table 1.

Particle size distribution data for the 5 drill core samples (RKS1–5), Cinovec, and reference samples (BC: basic cement; CFA: coal fly ash).

Table 1.

Particle size distribution data for the 5 drill core samples (RKS1–5), Cinovec, and reference samples (BC: basic cement; CFA: coal fly ash).

| Sample | d10 | d50 | d90 | Clay | Silt | Finesand (Sand) |

|---|

| | μm | μm | μm | % | % | % |

|---|

| RKS1 | 8.4 | 45.6 | 137.6 | 8.1 | 59.3 | 32.6 |

| RKS2 | 8.5 | 46.6 | 145.6 | 8.2 | 58.7 | 33.1 |

| RKS3 | 7.3 | 42.7 | 134.8 | 8.5 | 60.7 | 30.8 |

| RKS4 | 6.4 | 42.4 | 131.3 | 9.3 | 60.3 | 30.4 |

| RKS5 | 6.9 | 48.5 | 141.7 | 9.5 | 55.7 | 34.8 |

| Cinovec | 44.2 | 166.2 | 399.5 | 1.7 | 19.7 | (78.6) |

| Sand | 124 | 334 | 977 | | | |

| BC | 2.3 | 14.1 | 53.2 | | | |

| CFA | 3.2 | 14.8 | 73.6 | | | |

Table 2.

Average metal concentration of tailing samples (combined sodium peroxide fusion and lithium borate fusion/XRF data from individual drill holes).

Table 2.

Average metal concentration of tailing samples (combined sodium peroxide fusion and lithium borate fusion/XRF data from individual drill holes).

| Element | Concentration (wt%) |

|---|

| | RKS1 | RKS2 | RKS3 | RKS4 | RKS5 |

|---|

| Al | 8.13 | 8.23 | 7.73 | 7.59 | 8.50 |

| As | 0.04 | 0.06 | 0.04 | 0.05 | 0.05 |

| Bi | 0.01 | 0.02 | 0.02 | 0.01 | 0.02 |

| Ca | 0.47 | 0.50 | 0.49 | 0.39 | 0.45 |

| Fe | 5.06 | 5.25 | 4.83 | 4.71 | 5.51 |

| K | 2.16 | 2.12 | 2.04 | 1.94 | 2.11 |

| Li | 0.10 | 0.10 | 0.10 | 0.09 | 0.10 |

| Mg | 0.06 | 0.06 | 0.05 | 0.05 | 0.06 |

| Mn | 0.07 | 0.08 | 0.07 | 0.07 | 0.07 |

| Mo | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Na * | | | | | 0.06 |

| Rb | 0.13 | 0.14 | 0.13 | 0.12 | 0.13 |

| S | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 |

| Si * | 32.32 | 32.60 | 33.25 | 32.85 | 31.91 |

| Sn | 0.11 | 0.12 | 0.11 | 0.14 | 0.14 |

| Ti | 0.05 | 0.05 | 0.04 | 0.05 | 0.05 |

| W | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Zn | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

Table 3.

Comparative summary of the chemical composition of selected tailings around the world explored for Li extraction.

Table 3.

Comparative summary of the chemical composition of selected tailings around the world explored for Li extraction.

| | | Chemical Composition (wt%) | |

|---|

| Source | Type of Tailings | Al | As | Bi | Ca | Fe | K | Li | Mg | Mn | Mo | Na | Nb | Rb | S | Si | Sn | Ta | Ti | W | Zn | Ref. |

|---|

| La Corne, Quebec, Canada | Li | 6.8 | - | 0.003 | 0.26 | 0.47 | 2.4 | 0.20 | 0.08 | 0.032 | - | 3.25 | 0.003 | 0.25 | - | >30 | 0.001 | 0.004 | <0.05 | - | - | [49] |

| Jiangxi, China | Ta-Nb | 10.5 | - | - | - | 0.53 | 2.48 | 0.29 | - | - | - | 3.98 | 0.005 | 0.16 | - | 32.83 | 0.061 | 0.01 | - | - | - | [50] |

| Guiyang, China | Bauxite | 23.9 | - | - | - | 0.35 | 0.27 | 0.098 | 0.09 | - | - | - | - | - | - | 17.58 | - | | 1.43 | - | - | [29] |

| Cinovec, Czech Republic | Sn–W | 13.3 | - | - | 0.63 | 5.86 | 10.9 | 0.21 | - | - | - | 0.3 | - | 0.18 | | 30.5 | - | - | - | - | - | [51] |

| St Austell, Cornwall, UK | kaolinite | 4.4 | - | - | - | 2.67 | - | 0.04 | - | - | - | - | - | 0.09 | - | 37.9 | - | - | 0.31 | - | - | [48] |

| Altenberg, Germany | Sn | 8.04 | 0.05 | 0.016 | 0.46 | 5.072 | 2.07 | 0.098 | 0.06 | 0.072 | 0.01 | 0.06 | - | 0.13 | 0.022 | 32.6 | 0.12 | | 0.05 | 0.02 | 0.01 | This work |

Table 4.

Overview of selected global lithium projects: ore type, resources, recovery, and mine life.

Table 4.

Overview of selected global lithium projects: ore type, resources, recovery, and mine life.

| Project Name | Country | Li Ore Type | Life of Mine | Tonnage | Li Grade | Li Cut-Off Grade | Recovery | Ref. |

|---|

| | | | y | Mt | % | % | % | |

|---|

| Whabouchi | Canada | Spodumene (Hard rock) | 26 | 27.3 | 0.68 | 0.20 (OP) 1, 0.37 (UG) 2 | 86.5 (Li2CO3),

77 (Li2O) | [52] |

| Pilgangoora | Australia | Spodumene (Pegmatite) | 13.2 | 34.2 | 0.48 | 0.2 | 83 (Li2O) | [53] |

| Keliber | Finland | Spodumene (Pegmatite) | 16.2 | 4.49 kt | 0.52 | 0.23 | 90 (Li2CO3),

80 (Li2O) | [54] |

| Sonora | Mexico | Lithium-bearing clays | 20 | 129.7 | 0.30 | 0.12 | 69.8 (Li) | [55] |

| Zinnwald Lithium | Germany | Zinnwaldite (Greisen-hosted) | >40 | 128.1 | 0.21 | 0.17 | 68.1–73.2 (Li) | [33] |

Table 5.

Classification groups and description of RKS samples based on different grain sizes and redox states.

Table 5.

Classification groups and description of RKS samples based on different grain sizes and redox states.

| Particle Size Boundary | Class | Description | Redox State Boundary | Class | Description |

|---|

| µm | | | | | |

|---|

| d10 | d50 | d90 | | | rH Value Range | | |

|---|

| <2 | <20 | <90 | 1 | Finer | >25 | A | Oxidized |

| <12 | <70 | <225 | 2 | Fine | 17–25 | B | Moderately reduced |

| >4 | >70 | >225 | 3 | “Coarse” | <15–17 | C | Reduced |

Table 6.

Quantitative mineral composition of Bielatal tailings material [

31].

Table 6.

Quantitative mineral composition of Bielatal tailings material [

31].

| Mineral Phase | Concentration (wt%) |

|---|

| Quartz | 50–55 |

| Feldspar | 5–7 |

| Mica | 20–30 |

| Topaz | 8–15 |

| Clay minerals | 2 |

| Hematite | 5 |

Table 7.

EDX measurements of the marked measuring points (yellow) of the tailing sample (RKS1). (a) Overview of the tailings sample. (b) Quartz. (c) Mica phases. (d) Cassiterite. Note that EDX element results are unnormalized.

Table 7.

EDX measurements of the marked measuring points (yellow) of the tailing sample (RKS1). (a) Overview of the tailings sample. (b) Quartz. (c) Mica phases. (d) Cassiterite. Note that EDX element results are unnormalized.

| Measured Spot | Element Content (wt%) | Probable Mineral Phase |

|---|

| | O | F | Na | Mg | Al | Si | S | K | Ca | Ti | Fe | As | Sn | |

|---|

| a | 56.31 | 7.58 | 0.37 | 0.24 | 12.20 | 27.76 | 0.03 | 2.38 | 0.57 | 0.07 | 6.91 | 0.06 | 0.19 | overview |

| b | 58.83 | | | | 1.22 | 40.81 | | | | | 0.90 | | | quartz |

| c | 43.18 | 7.69 | | 0.02 | 11.49 | 19.25 | | 6.94 | | | 11.79 | | | mica |

| d | 33.99 | | | | 0.46 | 1.14 | | | | | | | 70.84 | cassiterite |

Table 8.

Comparative summary of mineralogical composition of selected tailings around the world explored for Li extraction.

Table 8.

Comparative summary of mineralogical composition of selected tailings around the world explored for Li extraction.

| Source | Type of Tailings | Mineral Composition | Ref. |

|---|

| La Corne, Quebec, Canada | Li | Quartz, albite, spodumene, muscovite, biotite, lepidolite, amphiboles | [49] |

| Jiangxi, China | Ta-Nb | Quartz, feldspar, sericite, kaolinite, lepidolite | [50] |

| Guiyang, China | Bauxite | Quartz, kaolinite, diaspore, boehmite, anatase, illite | [29] |

| Cínovec, Czech Republic | Sn–W | Quartz orthoclase, calcite, plagioclase, albite, topaz, zinnwaldite | [51] |

| St Austell, Cornwall, UK | kaolinite | Quartz, alkali feldspar, biotite, muscovite, tourmaline, topaz, zinnwaldite, kaolinite (China clay), lepidolite | [48] |

| Altenberg, Germany | Sn | Quartz, topaz, zinnwaldite, biotite, muscovite, kaolinite, alkali feldspars, hematite, cassiterite | This work |

Table 9.

Chemical composition of various tailings used for geopolymers, modified according to [

66], as compared to the Altenberg tailings (RKS).

Table 9.

Chemical composition of various tailings used for geopolymers, modified according to [

66], as compared to the Altenberg tailings (RKS).

| Source | Type of Tailings | Chemical Component (wt%) | |

|---|

| SiO2 | Al2O3 | Fe2O3 | MgO | CaO | K2O | Na2O | P2O5 | V2O3 | V2O5 | TiO2 | SO3 | MnO | ZnO | CuO | PbO | BaO | LOI | Others | Ref. |

|---|

| China | Pb-Zn | 62.09 | 4.34 | 2.72 | 0.56 | 20.44 | 0.54 | - | - | - | - | 0.2 | 3.62 | - | - | - | - | - | - | - | [58] |

| China | Cu | 28.19 | 4.24 | 57.83 | 1.1 | 1.91 | 0.81 | 0.52 | - | - | - | 0.3 | - | - | - | - | - | - | - | - | [59] |

| China | V | 83.47 | 5.09 | 2.4 | 0.65 | 0.95 | 0.66 | 3.2 | - | 0.23 | - | - | - | - | - | - | - | - | 1.25 | - | [60] |

| Finland | Li | 78.44 | 12.57 | 0.51 | 0.14 | 0.3 | 2.8 | 4.44 | - | - | - | - | - | - | - | - | - | - | 0.2 | 0.59 | [61] |

| China | Zn | 38.4 | 12.65 | 11.9 | - | 29.9 | 1.67 | - | 0.85 | - | - | 0.6 | 0.53 | 0.62 | 2.96 | 0.21 | 0.24 | - | - | 0.11 | [62] |

| Brazil | Fe | 40 | 8.7 | 48.9 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 6 | 1.9 | [63] |

| USA | Cu | 55.9 | 14.1 | 3.07 | 1.78 | 2.27 | 3.89 | 3.02 | 0.19 | - | - | 0.49 | - | 0.06 | - | - | - | - | - | - | [64] |

| South Africa | Au | 74.5 | 6.98 | 7.03 | 5.16 | 0.53 | 1.26 | 0.27 | 0.08 | - | 0.03 | 0.44 | 3.05 | 0.06 | 0.02 | 0.01 | 0.02 | 0.08 | - | 0.41 | [65] |

| Altenberg, Germany | Sn | 70.92 | 14.73 | 7.08 | 0.11 | 0.61 | 2.33 | 0.12 | 0.04 | - | - | 0.09 | 0.02 | 0.09 | 0.009 | 0.008 | 0.002 | 0.015 | 3.01 | 0.83 | This work |

Table 10.

Chemical composition of reference samples (BC: basic cement; CFA: coal fly ash; S: sand [

40]) and requirements for the use of CFA [

67] and cement [

68] in comparison with the Altenberg tailings samples (RKS samples).

Table 10.

Chemical composition of reference samples (BC: basic cement; CFA: coal fly ash; S: sand [

40]) and requirements for the use of CFA [

67] and cement [

68] in comparison with the Altenberg tailings samples (RKS samples).

| | Al2O3 | CaO | CaCO3 | Fe2O3 | K2O | LOI550 | MgO | Na2O | Na2OEq | pH | SiO2 | SO3 | Σ(Al2O3, Fe2O3, SiO2) | Σ(SiO2, CaO) | Σ

(Oxides) |

|---|

| | % | % | % | % | % | % | % | - | % | - | % | % | % | % | % |

|---|

| Reference Samples | |

| BC | 5.48 | 56 | 15.2 | 5.86 | 1.07 | 0.5 | 0.95 | 0.93 | 1.63 | 12.5 | 21.4 | 4.74 | 32.7 | 77.4 | 96.4 |

| CFA | 22.3 | 4.06 | 1.47 | 6.43 | 2.41 | 2.69 | 1.16 | 0.67 | 2.26 | 9.58 | 53.5 | 1.25 | 57 | 57.5 | 91.8 |

| Sand | 2.83 | 0.97 | 7.7 | 0.66 | 1.33 | 0.2 | 0.17 | 0.67 | 1.55 | 9.8 | 53.5 | 0.21 | 82.2 | 54.4 | 60.3 |

| Altenberg Samples | |

| RKS | 14.73 | 0.61 | - | 7.08 | 2.33 | 3.01 * | 0.11 | 0.12 | 1.65 | 5.80 | 70.92 | 0.02 | 92.73 | 71.52 | 95.92 |