4.1. Slope Stability Theory

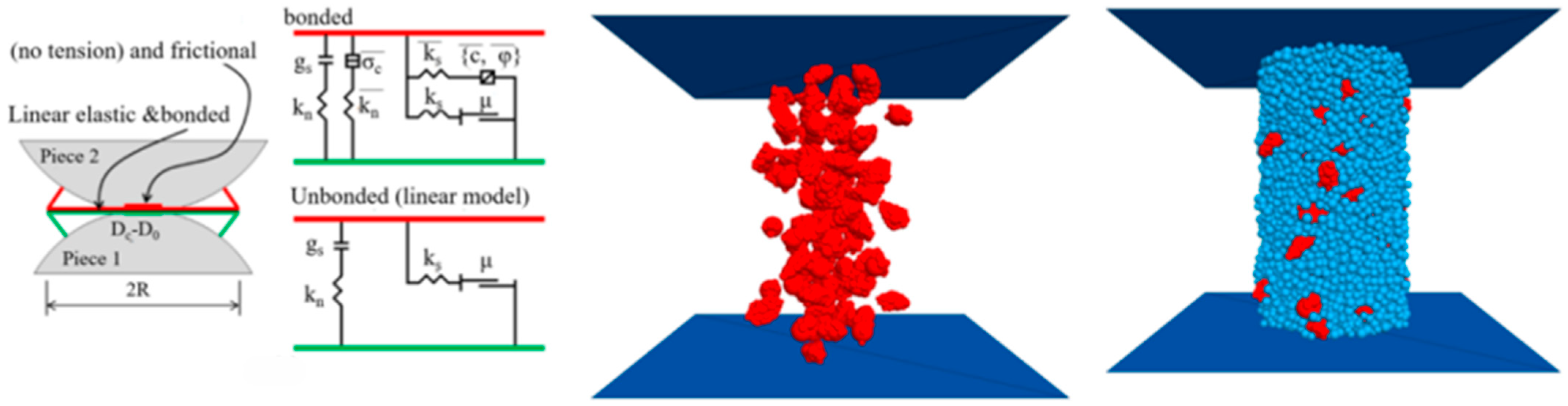

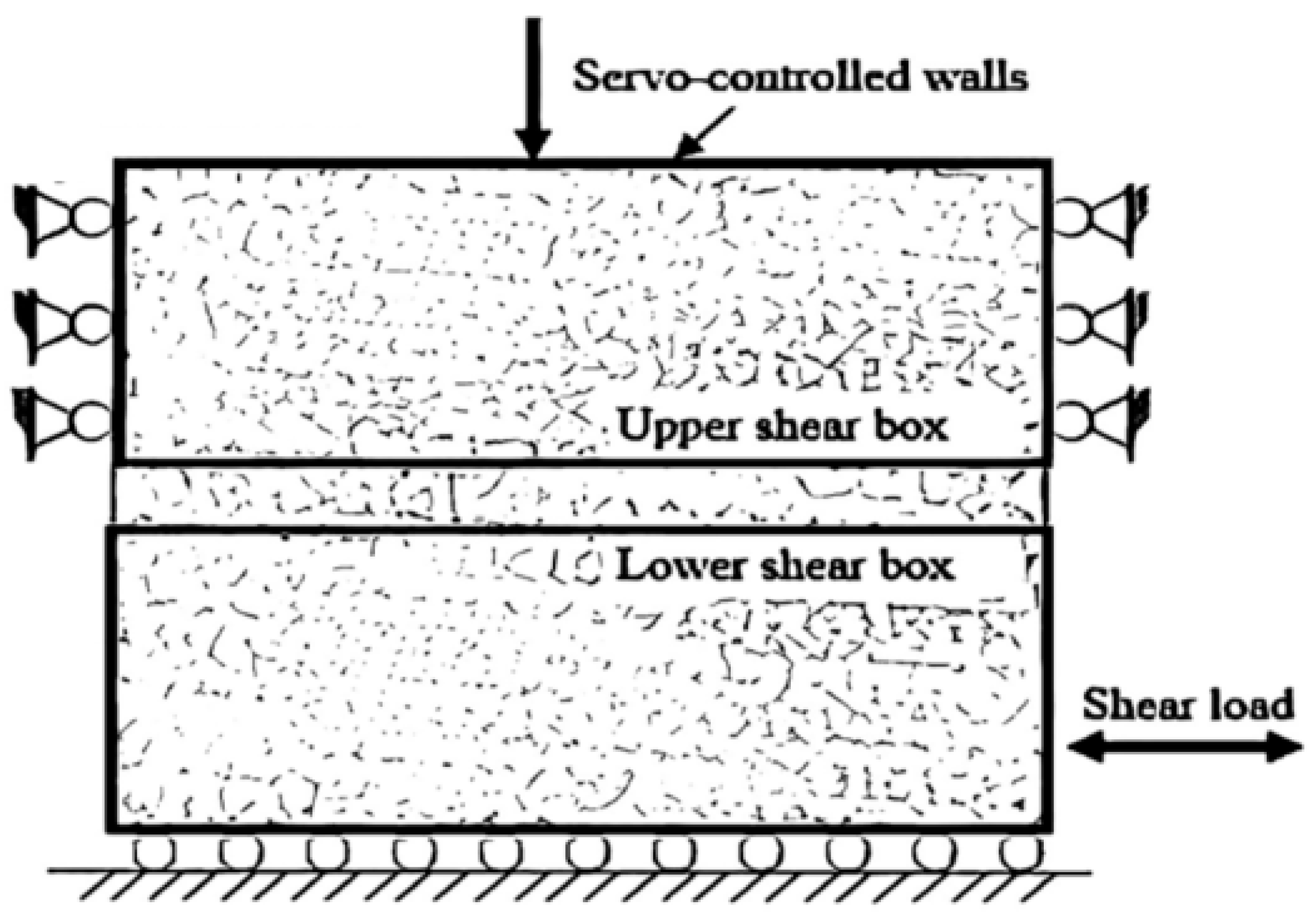

In this paper, advanced numerical calculation methods such as the spring element method (SEM) and discrete element method (DEM) are used, which have been shown to have significant advantages in simulating slope stability and dynamic response. Specifically, the spring element method simulates the deformation of the solid continuum through the particle–spring system, which can analyze the stress distribution and displacement changes in the slope under different types of seismic waves (such as P and S waves) in detail. In this study, the spring element method is used to calculate the dynamic magnification factor of the slope, which is crucial for evaluating the stability of the slope under seismic action.

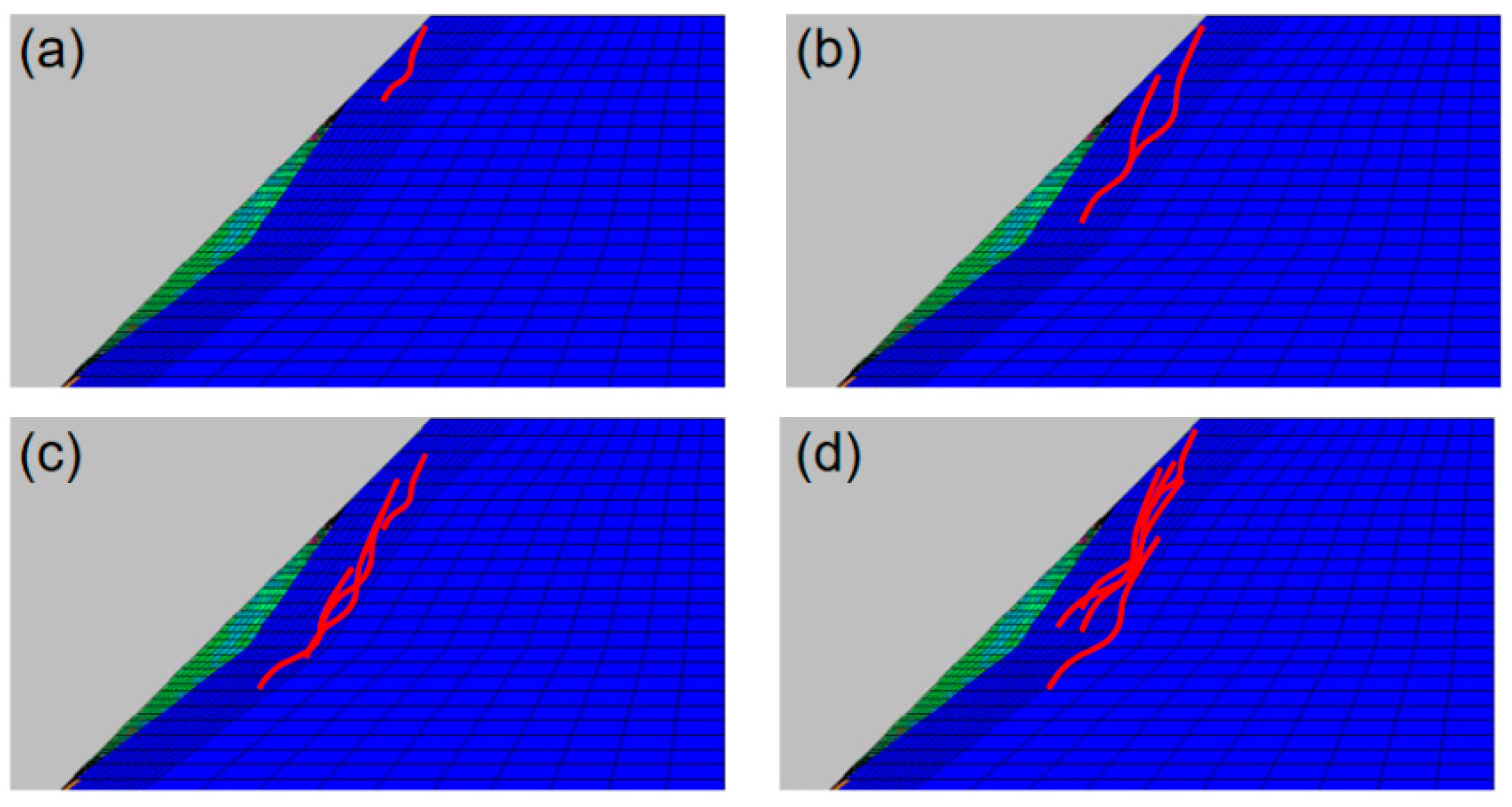

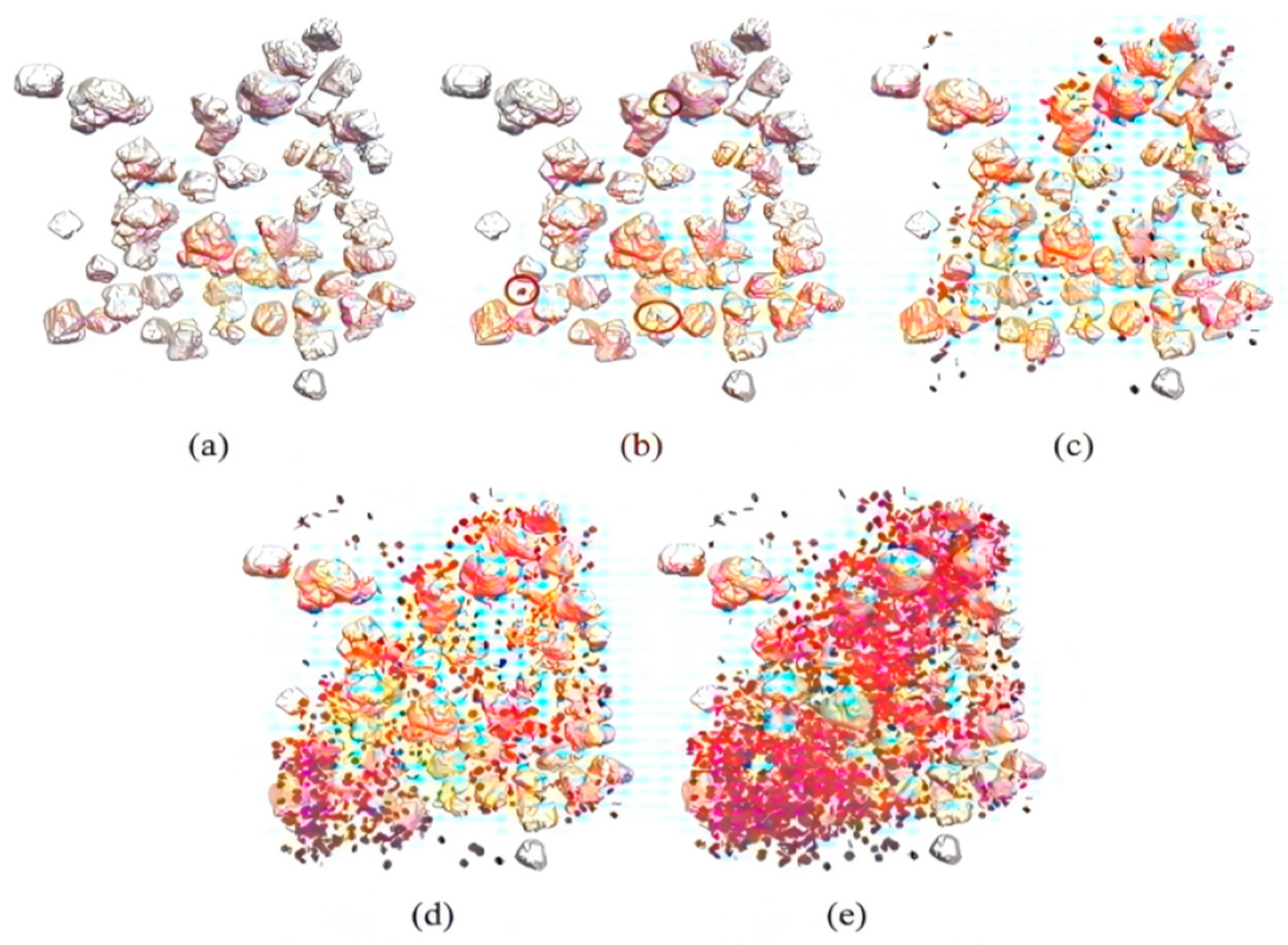

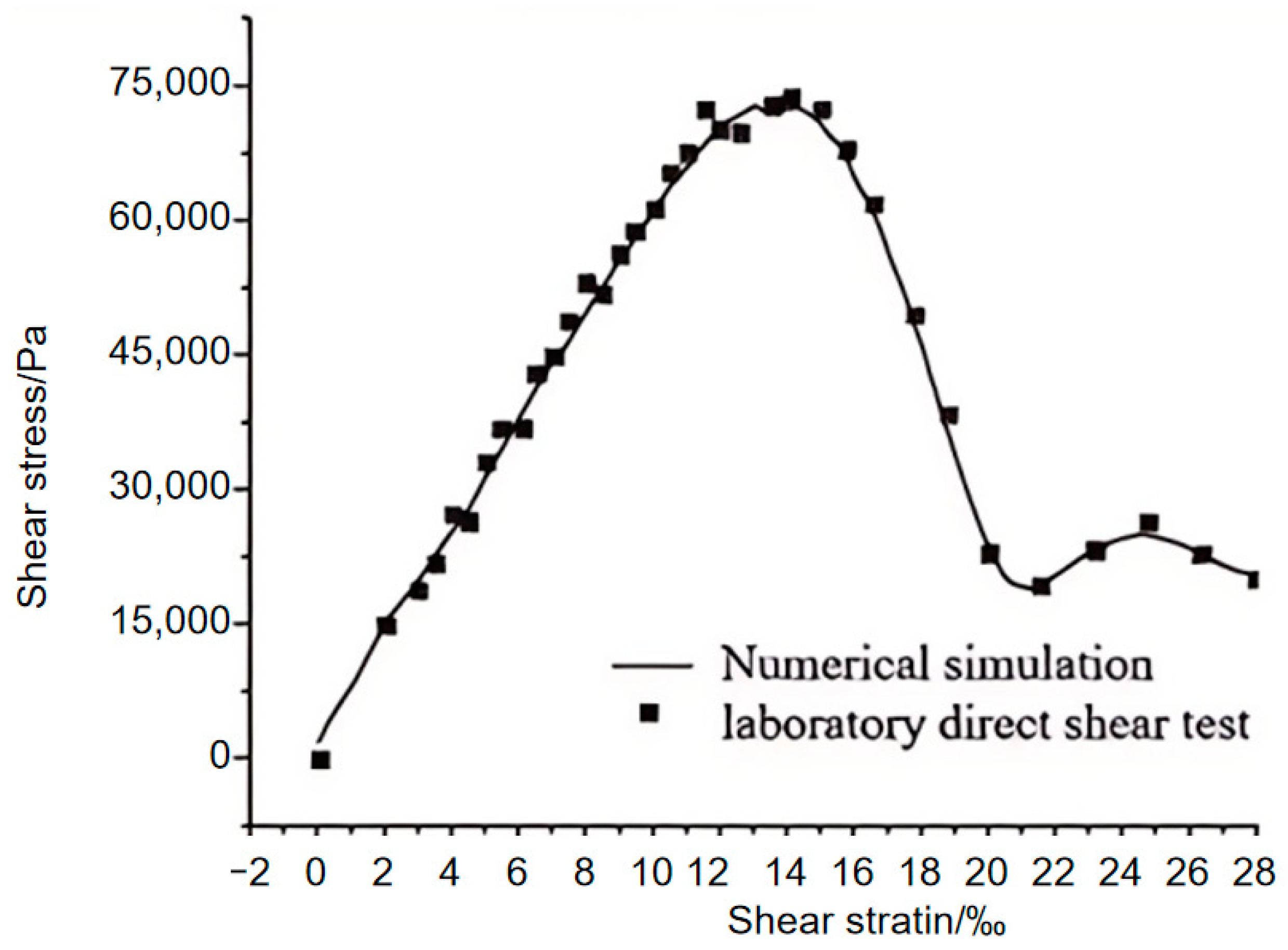

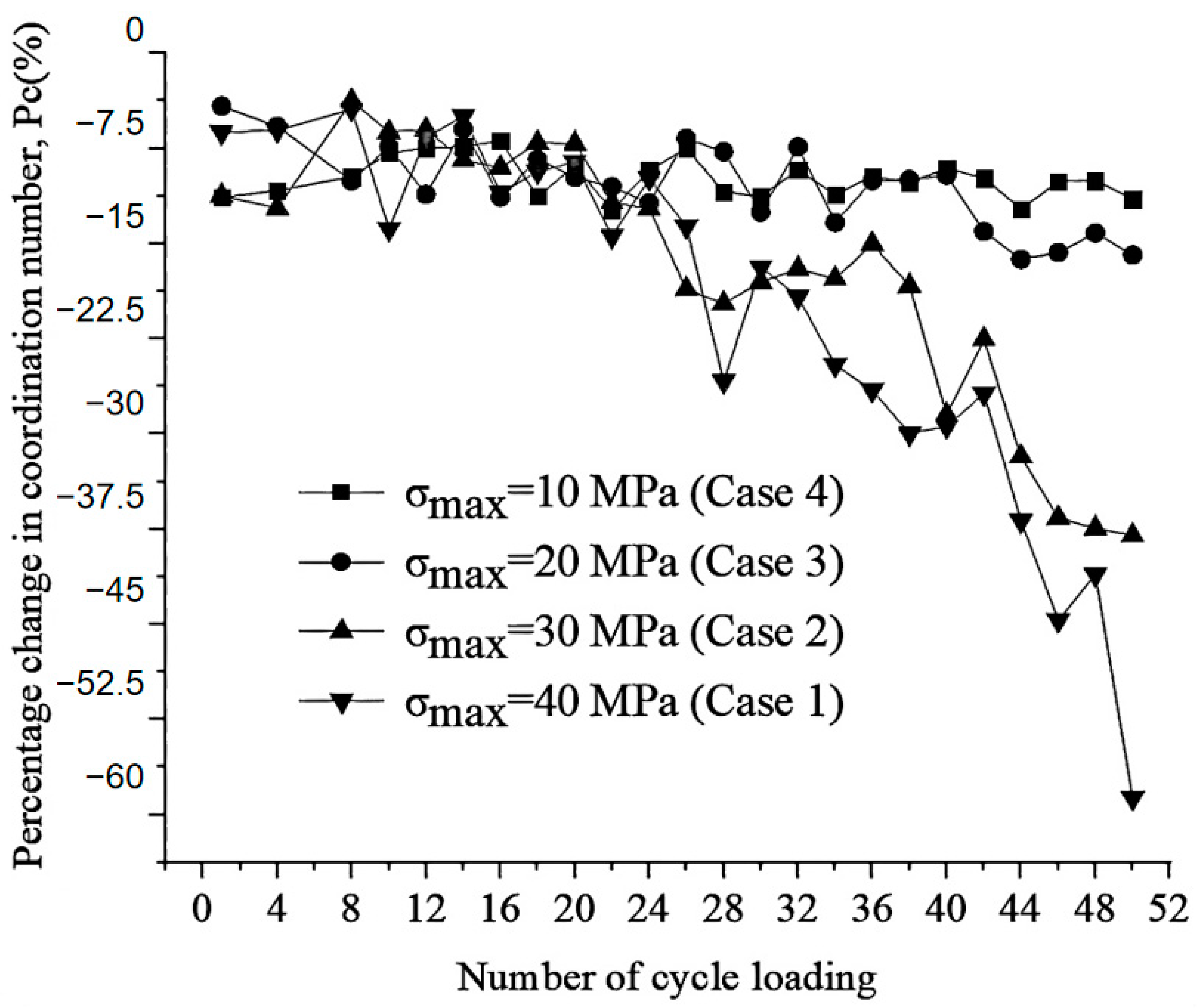

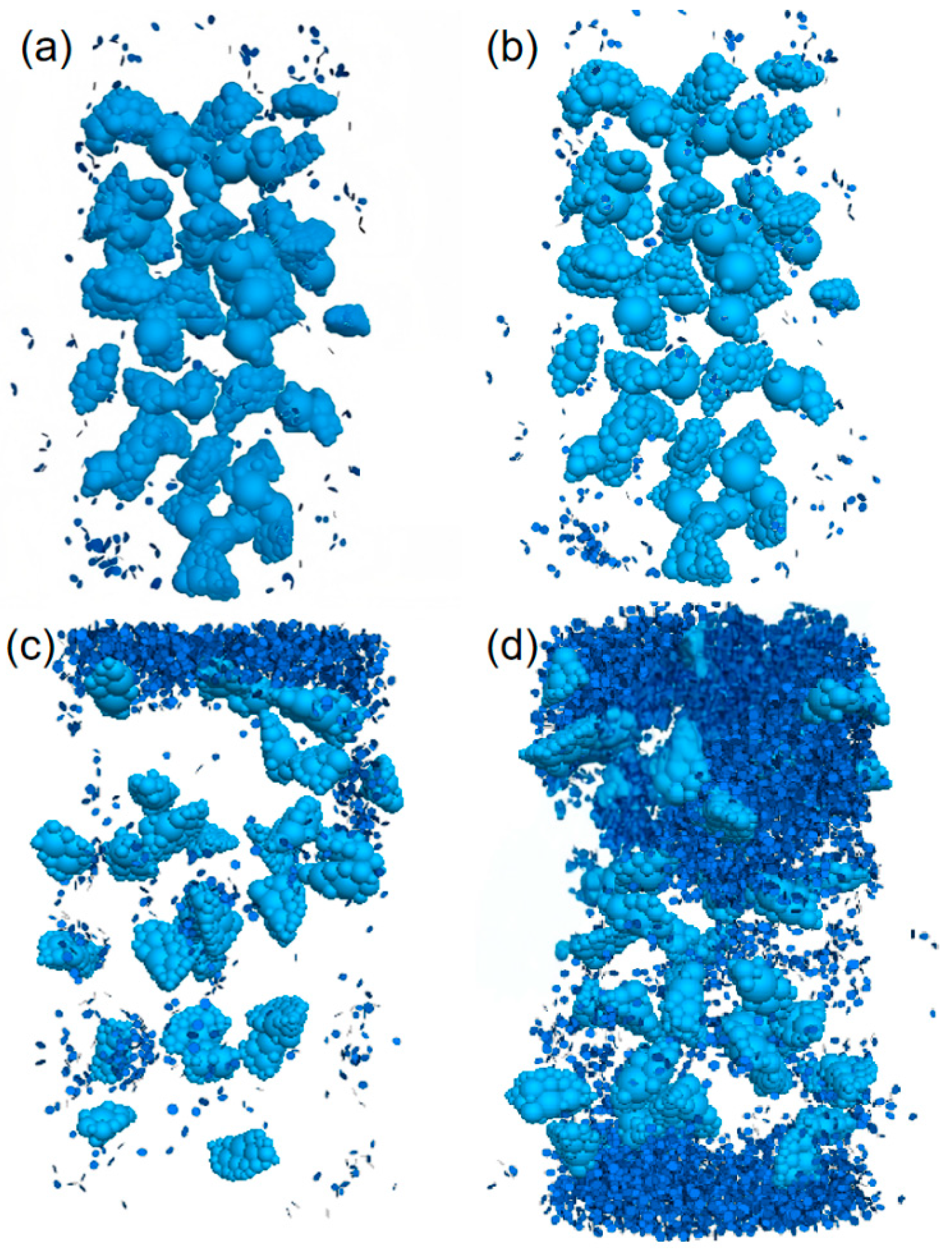

The spring element method (SEM) and discrete element method (DEM) are two core methods for numerical simulation in geotechnical engineering, and the choice depends on the characteristics of the problem. The SEM is based on continuum mechanics and efficiently simulates seismic wave propagation and the overall dynamic response of slopes. It is suitable for homogeneous soil slopes or continuous deformation scenarios. Based on the discrete medium theory, the DEM is good at simulating the discontinuous behavior of particles (such as fragmentation and rotation) and has prominent advantages in the analysis of jointed rock slopes and local instability. The application of both needs to be combined with the problem scale and computing resources: the SEM is used for the overall stability and dynamic parameter evaluation of slopes, while the DEM focuses on the local failure mechanism of slopes with complex structural surfaces (such as faults). In engineering, they are often used in combination. The SEM is used to evaluate the overall situation, while the DEM is used to refine key areas. The SEM has an advantage in efficiency in seismic wave field simulation, and the DEM has better accuracy in the destructive stage of strong earthquakes (such as liquefaction). Both have obvious limitations: the SEM is difficult to capture discontinuous deformation, and the computational complexity of the DEM increases exponentially with the number of particles, relying on parallel computing optimization. In the future, it is necessary to develop multi-scale coupling algorithms, improve the constitutive model of materials, and combine high-performance computing to break through the bottleneck of the particle number, providing a better solution for the dynamic stability of complex geological slopes. Our results show that the platform width, load type, and frequency of multi-stage slope have different degrees of influence on the dynamic magnification factor. In addition, the discrete element rule is more suitable for simulating rock slopes with many discontinuities. These discontinuities (such as joints) are often the key parts of landslides under cyclic micro-seismic action. By using the discrete element method, we can simulate the permanent displacement of the slope under the action of seismic waves and further study the law of the influence of the combination of slope height, seismic intensity, slope angle, and joint angle on the permanent displacement of the jointed rock slope. This method enables us to know more deeply the deformation and failure mechanism of the slope under the action of a micro-earthquake. In the numerical simulation, we also take into account the incidence of seismic waves, including both vertical and horizontal vibrations. By breaking down the vibration mode into these two basic forms, we can analyze the effect of ground motion on the slope more comprehensively. In addition, to simulate the real situation, we use a geometric model close to the actual slope scale and consider the influence of material parameters (such as elastic modulus, Poisson’s ratio, etc.) on the dynamic loading response results. Through the numerical simulation analysis, we not only obtained the stress distribution and displacement changes in the slope under the action of repeated micro-earthquakes but also further revealed the mechanical mechanism of landslide occurrence. These research results provide an important theoretical basis and practical guidance for slope seismic design and geological hazard protection.

When the rock and soil mass is in the stage of elastic deformation, its stress–strain relationship conforms to the elastic constitutive equation. For the plane stress problem, its elastic matrix is

In the above equation, [o] is the elastic matrix, and E is the elastic modulus of the material µ and Poisson’s ratio. If the material yields, its constitutive relation also changes accordingly. For the element of compressive (shear) failure, the total strain increment d {ε} is the sum of the elastic strain increment d {εe} and the plastic strain increment d {εp}, according to the increment theory:

The second equation is the flow law; if the associated flow law is used, then the plastic potential function can be used as the yield function f using the Drucke -Prager yield criterion, and

Under the action of a micro-earthquake, the cracks and joints inside the slope gradually expand and connect, which provides favorable conditions for the occurrence of landslides. The propagation of seismic waves leads to a change in the pore water pressure inside the rock and soil mass, especially at the moment when the seismic waves arrive; the sharp increase in pore water pressure will further reduce the shear strength of the rock and soil mass, thus accelerating the start of the landslide. In addition, the reflection and superposition effect of seismic waves inside the slope makes the stress concentration phenomenon more obvious in some areas, further aggravating the instability risk of the slope. First, according to the Piot theory, the saturated soil is first assumed to be a linear elastic medium, and the equilibrium equations in the consolidation and deformation process are derived by taking any differential element in the soil for analysis:

where σ is the effective stress, p is the residual pore water pressure (including vibration pore water pressure), σ + p = σ is the total stress, and X, Y, and Z are the unit physical forces in the x-, y-, and z-directions. The geometric equation is then listed, where the compressive stress is positive, and the tensile stress is negative:

where εx, εy, and εz are the positive strains of the soil skeleton in the x-, y-, and z-directions. Yx, yy, y, and z are the shear strains in the three directions. u, v, and W are the displacements of the soil skeleton in the x-, y-, and z-directions. Before the constitutive relation is proposed, the total strain {ε} is divided into two parts: one is the normal strain {ε-ε0}; another is the vibration strain {epsilon zero}, so {sigma} = {epsilon − epsilon zero} [D] = [D] {it} − {epsilon zero} [D].

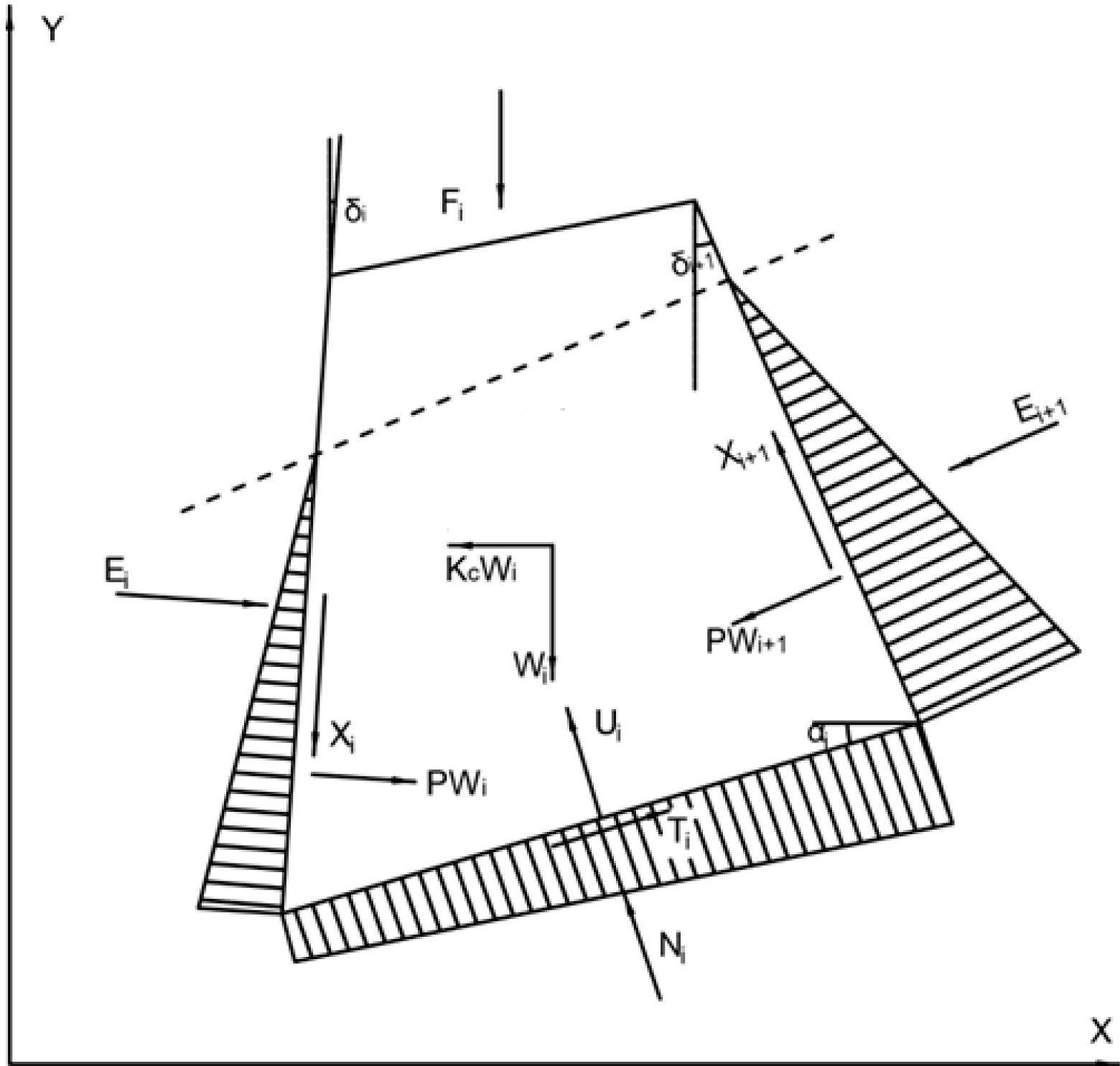

The Sarma method of slope limit equilibrium analysis is used to calculate the stability of a high and steep slope with faults, as shown in

Figure 15. Taking any strip I in the slope body as an example, the working principle of the Sarma method is that, at any time, the transient stability coefficient of the sliding surface is F = 1, after the horizontal seismic inertia force term KW

c acting on the strip.

From the principle of static equilibrium, i.e., ΣX = 0 and ΣY = 0,

Ti and Ni are, respectively, the shear force and normal force acting on the bottom surface of strip I; Wi is the weight of strip I; Xi and Xi+1 are the shear forces acting on the I side and i+1 side, respectively; Ei and Ei+1 are the normal forces acting on the I side and i+1 side, respectively; Fi is the external load acting on the top of the slope; δi and δi+1 are the angles between the I side and the i+1 side and the vertical direction, respectively; αi is the angle between the sliding plane of the I block and the horizontal direction.

From the Mohr–Coulomb criterion,

Bi is the width acting on the bottom surface of block i; U

i is the water pressure acting on the bottom surface of block i;

is the strength parameter of the bottom surface of block i.

cBi.

d

i and d

i+1 are the length of the i side and i + 1 side; PW

i and PW

i+1 are, respectively, the water pressure acting on the i and i+1 side, and

and

are the strength parameters of the i side. Through iterative calculation, different values can be calculated by using a different F value, and the F value at that time is the safety factor of the slope stability under the action of the natural earthquake inertia force. Previous models mostly simplified ground motion to a single frequency or static load, ignoring the propagation characteristics of the seismic spectrum (such as the energy distribution and phase difference in different frequency components) in rock and soil masses and their dynamic interaction with mesoscopic damage. For example, the synergistic effect between the local stress concentration effect caused by high-frequency waves and the cumulative effect of pore water pressure caused by low-frequency waves was not considered, nor was the influence of spectral characteristics (such as the main frequency and spectral width) on the crack propagation path quantified. The theories in Reference [

24] are compared with the theoretical data and numerical simulation results of this paper, as shown in

Table 9. By comparing

Table 9, it can be seen that the theory in this paper is closer to the numerical simulation calculation results. The slope stability coefficient obtained by the theoretical calculation in this paper is closer to the numerical simulation, while the results of the traditional theory and numerical simulation calculation are relatively larger, indicating that the theoretical research results in this paper are more accurate.

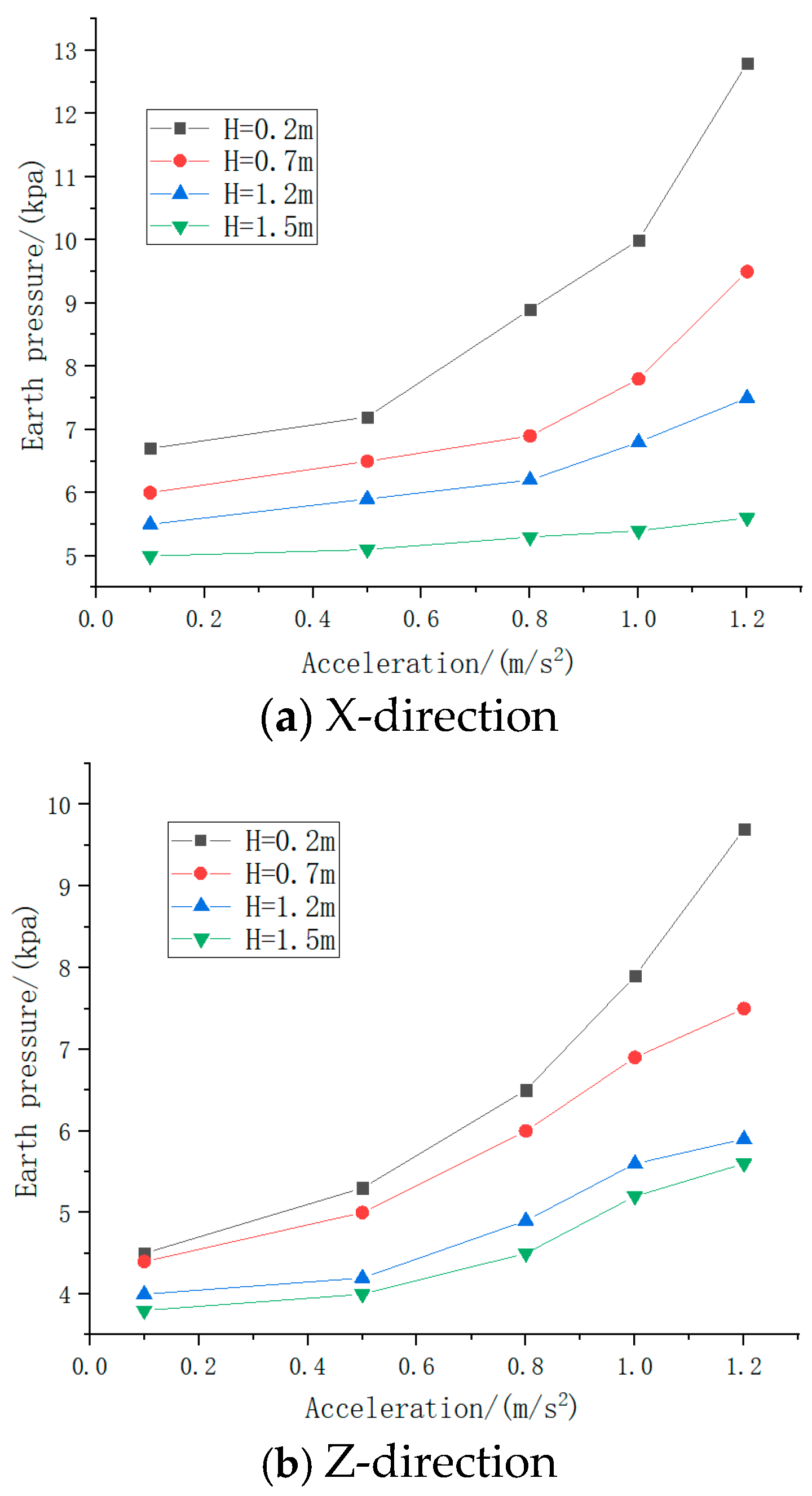

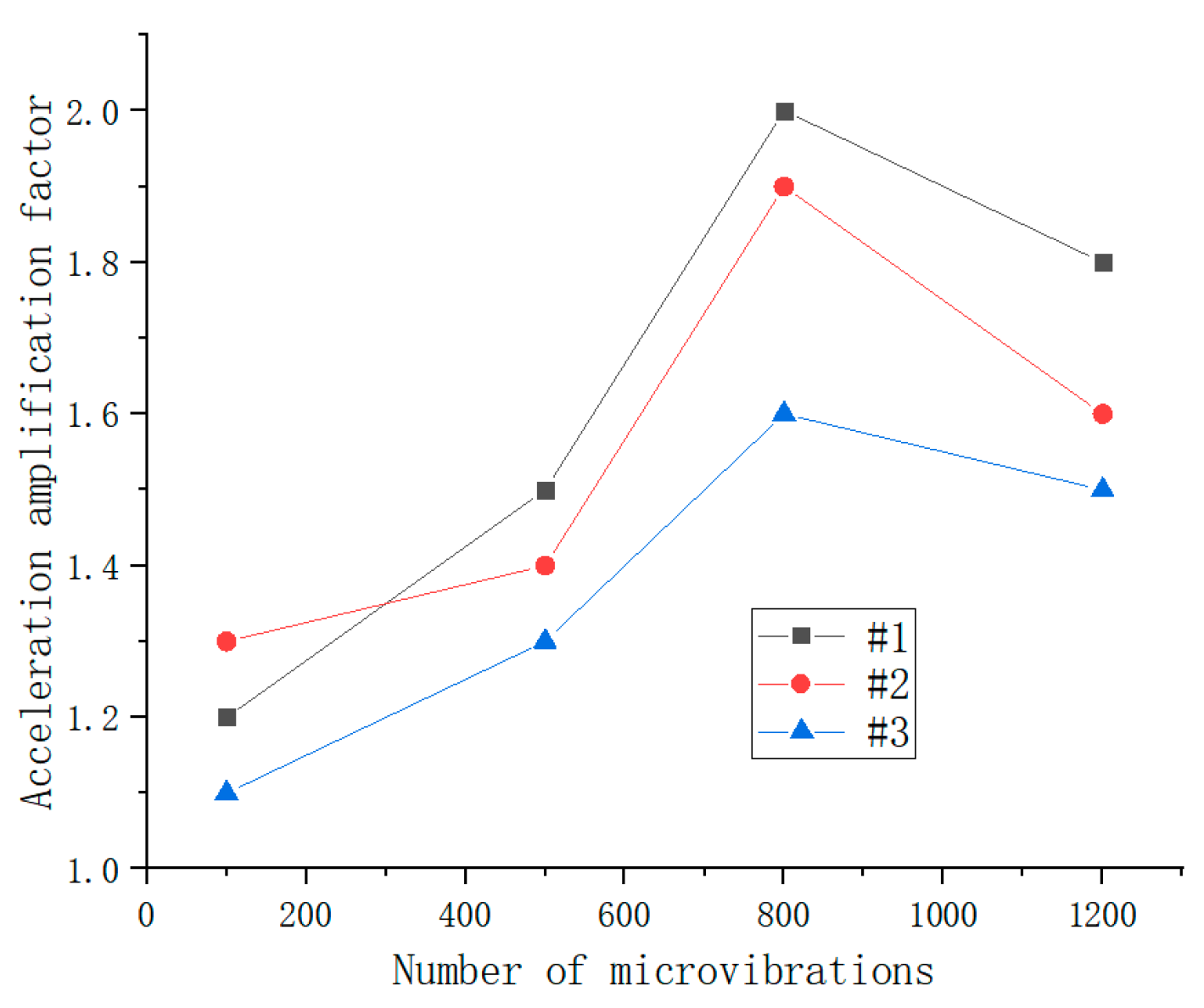

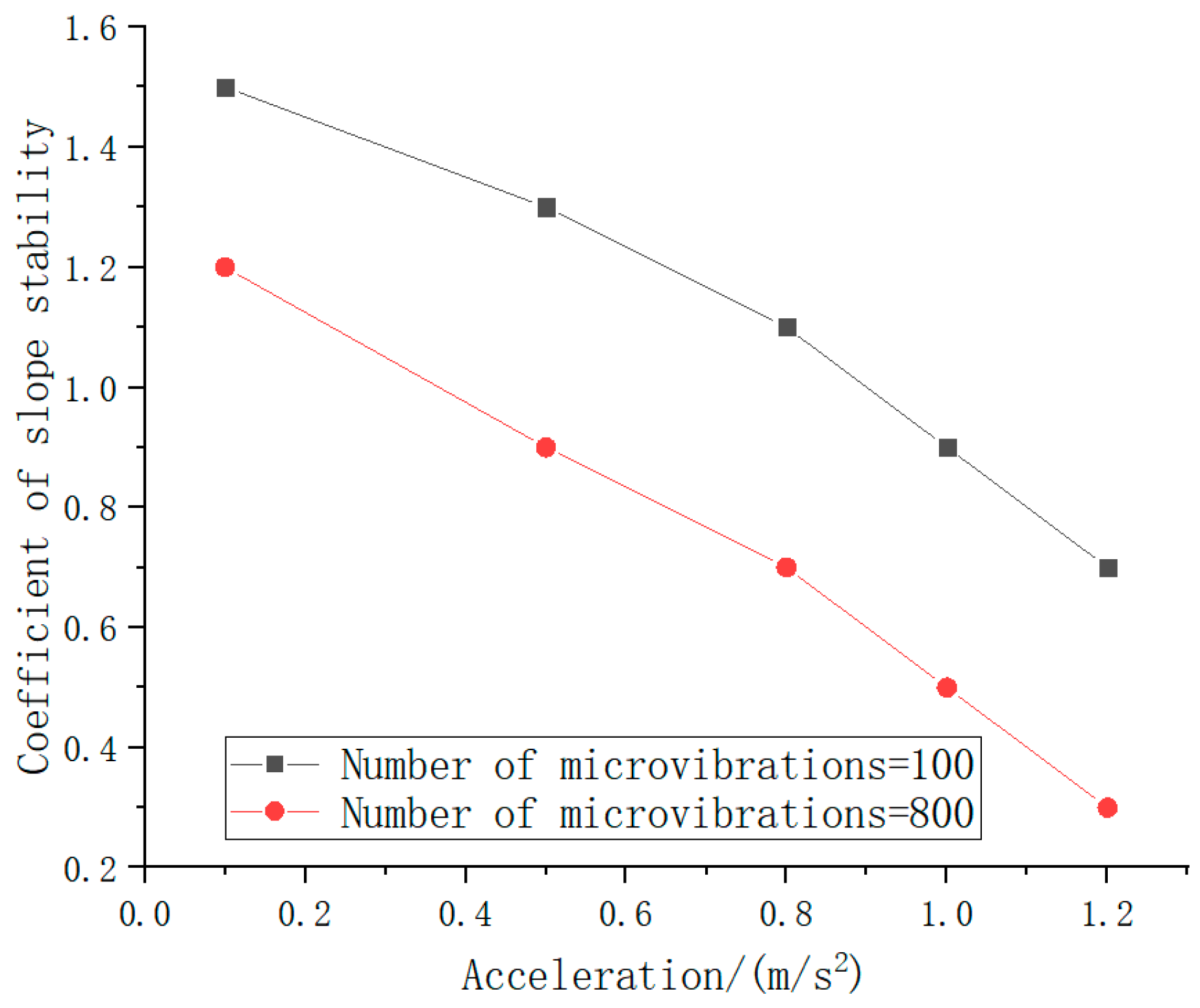

4.2. Change the Rule of Slope Stability

With the increase in seismic action times, the damage to the model slope continues to accumulate, the slope stability coefficient decreases with the vibration test, and the stability of the slope increases with the vibration times (100 times, 200 times, 300 times, 400 times, 500 times, 600 times, 700 times, and 800 times) and the vibration load strength (0.1 g, 0.5 g, 0.5 g, 0.5 g). 0.8 g, 1.0 g, and 1.2 g); the data change trend is shown in

Figure 16.

The test data show that, with the increase in vibration times and load strength, the stability coefficient of the model slope presents a significant decreasing trend. And the higher the load strength, the greater the decline.

The decrease in the slope stability coefficient is mainly related to the influence of the vibration frequency and load strength on the accumulation of internal damage and the stress distribution of the slope. Under low load strength (e.g., 0.1 g), vibration mainly causes a slight expansion of the initial damage (e.g., plane, secondary joint, etc.) inside the slope and a small reduction in the stability coefficient (20%). With the increase in the load strength (e.g., 0.5 g~1.2 g), the expansion and penetration effect of vibration on the internal damage of the slope is significantly enhanced, resulting in a significant increase in the reduction in the stability coefficient (30.8~57.1%). In addition, the increase in vibration frequency further intensifies the cumulative effect of the internal damage of the slope, resulting in a continuous decline of the stability coefficient. At low load strength, the damage accumulation speed is slow, and the stability coefficient is relatively gentle. However, under high load strength, the damage accumulation speed is accelerated, and the decline of the stability coefficient is significantly increased. This changing trend reflects the synergistic influence of the vibration frequency and load intensity on the slope dynamic stability: the load intensity determines the degree of slope damage from a single vibration, while the vibration frequency determines the total effect of damage accumulation. The test results show that the slope stability coefficient has a non-linear decreasing trend with the increase in vibration times and load strength, which provides an important basis for the study of slope dynamic stability.

4.3. Deep Neural Network Model Training

A total of 200 sets of finite element calculation results were selected as the sample data set, which was divided into a 70% training set and a 30% test set by random allocation to ensure the uniformity of data distribution and avoid potential bias. To improve the efficiency and performance of the model training, the sample data were normalized, and all the data were scaled to the interval [0, 1] to monitor gradient changes and avoid overfitting or insufficient training during the model training process. After the training, the model’s performance was analyzed by a regression graph, and the following key indicators were obtained:

The training regression coefficient is as high as 0.99607, indicating that the predicted value of the model has a high degree of fit with the actual value and can accurately capture the law of data change.

The mean square error is only 0.00054, which is far lower than the preset error range, indicating that the model has a very high prediction accuracy.

Analysis of training process: MSE is high in the initial stage, but with the increase in training times, MSE gradually decreases and tends to be stable by adjusting the weight and bias, while the value continues to rise, reflecting the gradual improvement of model prediction ability. To sum up, this study successfully constructed a neural network model with excellent performance through reasonable parameter settings and sufficient data training. The training results not only verify the reliability of the model but also reveal its strong potential in the evaluation of pipeline residual strength, which provides an important reference for the application of deep learning in the engineering field.

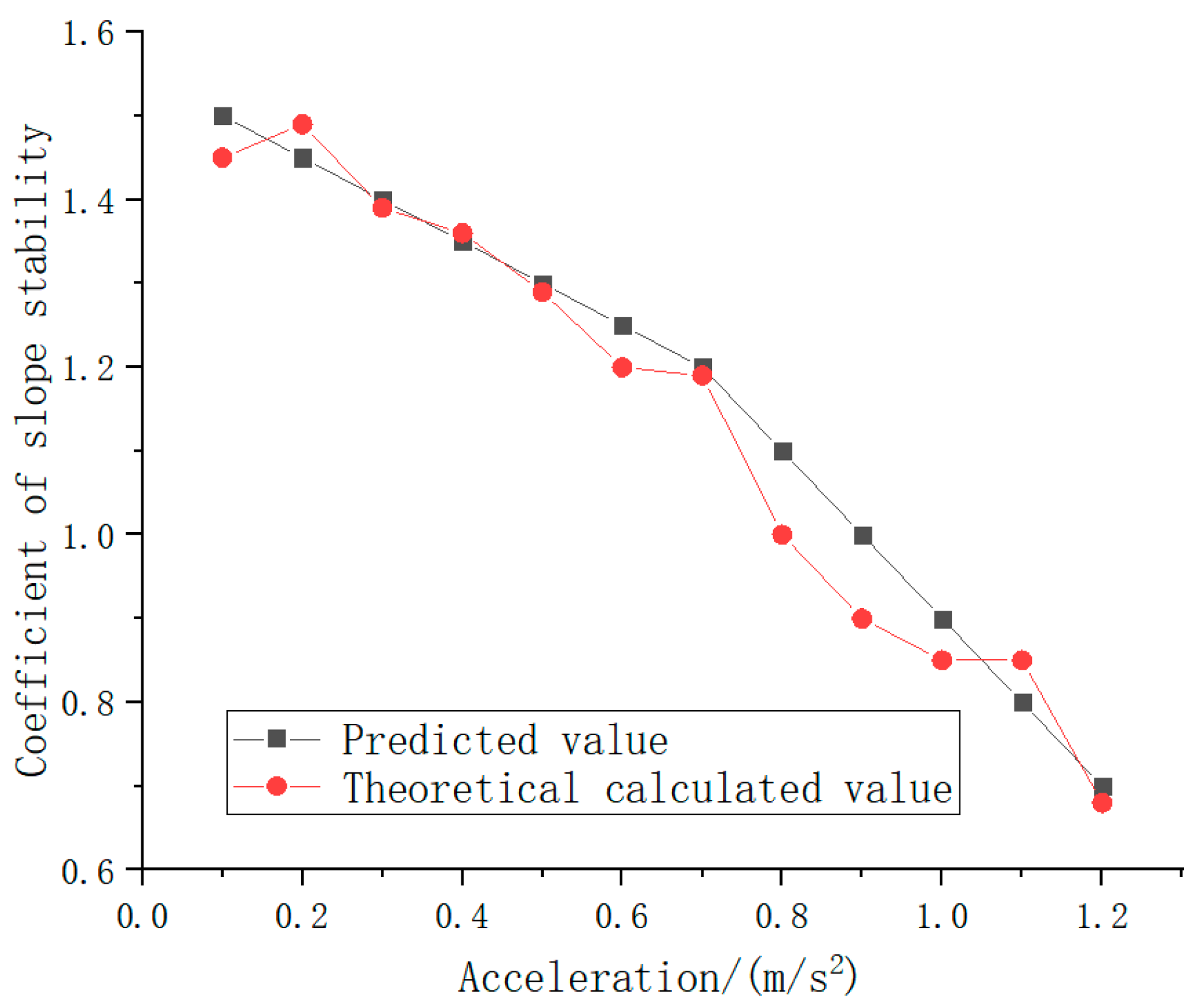

Although slope stability, as the only parameter to evaluate slope safety, has some limitations, based on its extensive engineering application background and a lot of research support, we believe that this index is reasonable and effective in the current study. To further verify the reliability of the deep learning-based neural network model in slope stability prediction, an independent test set was used in this study. This test set consists of the slope stability coefficient obtained from the test analysis, as shown in

Figure 17. It covers a variety of corrosion patterns and severity. The independence and difference from the training set data are guaranteed, to comprehensively evaluate the generalization ability of the model. The verification results show that the neural network model not only performs well on specific data sets but also maintains highly accurate prediction ability in the face of unknown and diverse slope stability judgments, which reflects its strong generalization and robustness. Specifically, the prediction error of the model on the test set is significantly lower than the preset threshold, and the predicted results have a high degree of fitting to the actual values, which further confirms its reliability.

Based on the above verification results, this study indicates that the BP neural network model has high reliability and practicability in evaluating slope stability. The predicted results can provide an important reference for engineering practice and help to provide more accurate slope maintenance, repair, or replacement strategies, to ensure the safety and stability of the slope. These research results not only deepen the application of deep learning in slope stability assessment but also provide new technical support for related engineering fields.