Abstract

Biomass is widely acknowledged as a plentiful and easily accessible source of renewable energy. Unlike many other renewable sources, biomass offers a consistent and predictable power supply without significant concerns about energy and environmental impacts. When used as a fuel in polygeneration systems designed to produce multiple outputs such as electricity, heat, chemicals, and synthetic fuels, biomass greatly enhances overall system efficiency by minimizing energy losses. These systems gain further advantages when integrated in a decentralized manner with energy-intensive applications like buildings. This review article aims to shift the focus of readers from generic biomass-based systems to polygeneration systems tailored for specific applications, such as buildings. The overview will discuss various biomass resources, systematic approaches, technologies, successful case studies, potential benefits, and limitations of such systems integrated into real-life building applications. It also categorizes studies based on different conversion processes such as combustion, gasification, and anaerobic digestion, with combustion-based polygeneration systems being the most prevalent. The review also explores the use of standalone and hybrid biomass-based energy systems. Taking a multidisciplinary approach, the analysis considers energy, exergy, economic, and environmental perspectives. Parameters such as the primary energy savings (PES), exergy efficiency, simple payback (SPB) period, and CO2 emission reductions are commonly used in system analyses. The review underscores how polygeneration systems integrated into the building sector can enhance efficiency, resilience, and environmental sustainability. This synthesis aims to address current gaps, particularly in the domain of polygeneration systems connected with buildings, offering essential insights for researchers and specialists in the field.

1. Introduction

Presently, the global community is confronted with significant challenges in the realms of energy and the environment. The global energy consumption trends and projected demands are steadily rising, posing a substantial environmental threat [1]. In the recent past, the conventional resources and methods used to meet these demands have either depleted or become limited due to transportation challenges and international relations [2,3]. The share of conventional fossil fuel-based power plants in the global energy supply is edging down to reach 73% by 2030 [4]. However, the existing conventional power plants are not very efficient, having an electrical efficiency of around 30%, resulting in wasted energy and environmental pollution [5,6,7].

To address concerns associated with dependence, inefficiency, and emissions of conventional fossil fuel-based power plants, the European Union (EU), under the “2030 Climate and Energy Framework” [8], has set an ambitious target to reduce the greenhouse gas emissions to at least 55% of the 1990 level, ensure up to a 32% share of renewable energy, and collectively reduce energy consumption up to 11.7%.

The building sector alone is responsible for 40% of energy consumption and 36% of CO2 emissions in the EU [9]. This consumption mainly comprises electrical appliance usage, space heating and cooling, and domestic hot water (DHW). Conventionally, the electrical energy demands are fulfilled from the national grid, while the thermal energy demands are fulfilled using conventional onsite natural gas or oil-based boilers [10,11]. The discrete and single production of these energies can result in energy losses and inefficiencies, leading to economic and environmental apprehensions.

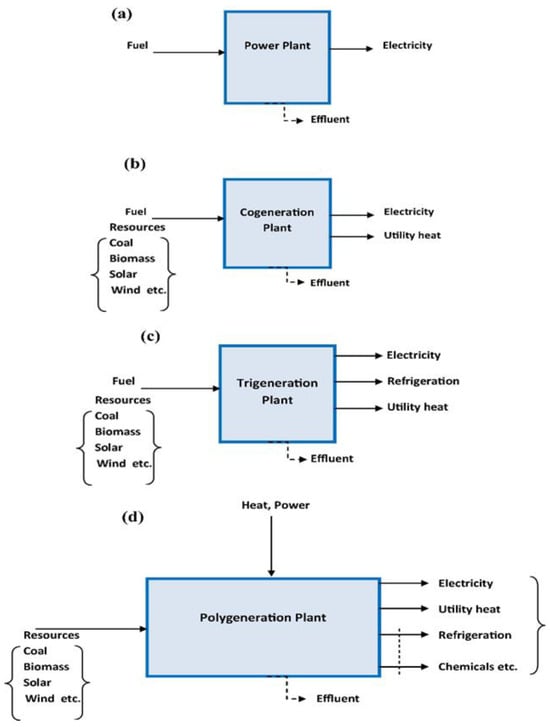

In order to address these concerns, cogeneration systems have been introduced [12]. Cogeneration systems concurrently generate electrical and thermal energy by harnessing low-grade waste heat from the power generation cycle for subsequent heating applications, utilizing a unified energy source. This approach enhances the system’s overall efficiency [13]. When the recovered low-grade heat is employed not only for heating but also for cooling, the system is considered a trigeneration system [14], alternatively known as a combined cooling, heating, and power (CCHP) system [15]. Moreover, if these systems produce additional products, they are classified as multigeneration systems. Following the same line of thought, polygeneration systems have gained significant attention. These systems are purposely designed to produce multiple outputs, typically encompassing electrical power, space heating and cooling, DHW, chemical products, and synthetic fuels [16]. Figure 1 shows the schematic overview of the above-discussed energy conversion systems [17].

Figure 1.

Schematic overview of energy conversion systems [17]: (a) electricity production through conventional power plant, (b) combined production of electrical and thermal energy, (c) combined production of electrical, thermal energy and cooling energy, (d) simultaneous generation of energy vectors and other valuable products.

Polygeneration systems integrated with renewable energy resources have gained significant attention in recent years due to their numerous economic and environmental benefits compared to conventional energy sources [18]. For instance, polygeneration systems can offer better energy security, enable decentralized energy systems, and reduce environmental impacts [17]. Renewable energy resources such as solar, geothermal, wind, hydro, and biomass are considered attractive alternatives to fossil fuels. However, solar and wind energies are highly dependent on weather and environmental factors. Due to their uncertain and intermittent nature, they cannot supply continuous power [19]. However, biomass and geothermal resources can consistently generate power without interruption or dependence on weather conditions. [20].

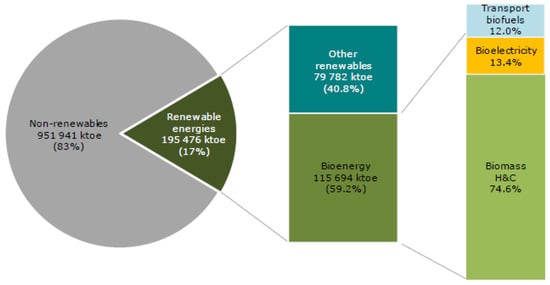

Biomass is considered one of the most abundant and easily available renewable energy resources [21]. Unlike conventional fossil fuel-based systems, the energy obtained from biomass systems does not add CO2 to the environment as it releases the same carbon that biomass had captured before [22,23]. In Europe, a significant amount of biomass is generated annually. Figure 2 shows the breakdown of bioenergy contribution in the EU [24]. One of the attractions of using biomass as an energy source is promoting circular economy and sustainability by recycling bio-waste [25,26].

Figure 2.

Share of bioenergy in EU’s gross final energy consumption [24].

Today’s energy systems are shifting from fossil fuel-based centralized power plants towards local, decentralized, and modular units preferably powered by renewable energy resources [27,28]. When integrated with buildings to fulfil electrical and thermal demands, such systems are considered promising applications so far [29,30]. The concept of integrating biomass-based polygeneration systems with decentralized applications, e.g., buildings, can have the following favourable implications as compared to the conventional systems:

- Higher efficiency [31]: One of the main objectives of such systems is to utilize primary energy resources efficiently. Decentralized systems can significantly improve the system’s overall energy efficiency by generating electrical and thermal power close to the point of use, thereby greatly reducing transmission and distribution losses.

- Resilience and reliability [32]: Such systems have the potential to enhance grid resilience not only by reducing the reliance of individual consumers on the grid but also by potentially offering energy services to the entire network.

- Renewable resource [33]: Biomass-based energy systems have the potential to serve as a renewable energy source, but this is contingent upon the utilization of biomass resources acquired through sustainable management practices. Throughout a designated life cycle, the biomass is expected to regenerate and offset emissions resulting from combustion within the polygeneration system. Consequently, the system could function in a carbon-neutral manner.

- Flexibility and combinability [34,35]: Biomass-based polygeneration systems have great potential to provide various onsite services with great flexibilities. However, for exceptional situations when there is a limitation on biomass availability or economic viability, such systems can be coupled with other energy resources (e.g., solar, geothermal, and wind) and energy storage technologies (e.g., batteries), which can lead to a higher system capacity, with a more stable and reliable system.

- Local resources [33]: Unlike conventional centralized power plants, small-scale biomass-based energy systems can mainly operate on locally grown and harvested biomass resources.

The topic of biomass-based systems is not new, as several papers have previously analyzed it. The majority of the review articles published recently focused on biomass-based CCHP systems and/or renewable energy-based building-integrated systems [4,36,37,38,39,40]. However, to the best of our knowledge, none of these articles has specifically addressed the integration of biomass-based polygeneration systems with building applications. In this situation, the authors of this study have chosen to examine research articles on biomass-based polygeneration systems that are combined with buildings to address the research gap with updated data and studies. The goal of this review article is to shift the focus of readers from generic biomass-based systems to polygeneration systems specifically designed for applications like buildings. This overview will discuss the systematic approach, potential benefits, and limitations of integrating such systems into real-life building applications.

This paper analyses biomass-based building-integrated polygeneration systems from energy, exergy, economic, and environmental perspectives. Since polygeneration systems are usually based on integrating different technologies, increasing their complexity requires a multidisciplinary approach to assess and understand the system’s performance. Some examples of such analysis include:

- I.

- Energy analysis

- II.

- Exergy analysis

- III.

- Economic analysis

- IV.

- Environmental analysis

The outline of the present work is divided into several steps. After this brief introduction section, biomass resources and characteristics that are used in building-integrated energy systems are listed in Section 2. Section 3 includes the generic methodology of the literature study. In Section 4, building-integrated biomass-based polygeneration systems are summarized. Section 5 presents case studies of the successful integration of biomass-based polygeneration systems in building applications. The findings and results are finally discussed in Section 6 of the paper. Lastly, Section 7 presents the conclusions of the paper.

2. Biomass Resources and Characteristics

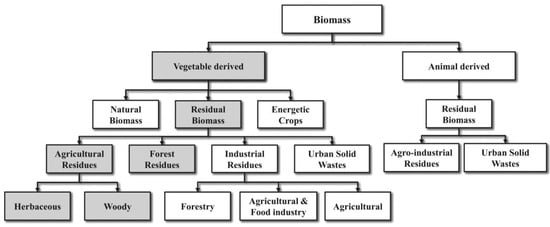

Biomass is considered one of the most prominent and abundant sources of energy after coal and oil, contributing to nearly 10% of the global energy demand [41]. It also accounts for a share of 55% of the global renewable energy resources [42]. Biomass refers to the entirety of organic matter, originating from biological materials derived from living or recently alive organisms. In the context of utilizing biomass for energy, it is often associated with plant-based materials. However, it is essential to note that biomass consists of materials that can be derived from both animals and plants [43]. Figure 3 shows the classification of biomass based on its origin. The process of biomass conversion into energy involves a wide range of different types of biomass sources, conversion technologies, and end-user applications. Therefore, each feedstock of the biomass may need to undergo a pretreatment process to be able to enter the system [44]. In each case, biomass feedstock must be collected, transported, and perhaps stored before being processed to facilitate a continuous conversion process [45]. Furthermore, particular consideration needs to be highlighted before choosing a suitable biomass feedstock such as [46]:

Figure 3.

Classification of biomass [43].

- i.

- Ultimate analysis: It helps in determining the percentage of the constituent elements (e.g., carbon (C), hydrogen (H), oxygen (O), nitrogen (N), chlorine (Cl), and sulphur (S)) of the biomass feedstock and their effects on the conversion process and environmental emissions.

- ii.

- Proximate analysis: It determines the percentage of moisture, volatile matter, fixed carbon, and ash content.

- iii.

- Heating values: Heating values refer to the amount of heat released to the environment when a single unit of biomass fuel is converted into energy measured as (kJ/kg of fuel). In particular, a higher heating value (HHV) value refers to a case when the latent heat of the vaporization of water is included in the total energy released. In contrast, the lower heating value (LHV), is not considered.

Table 1 lists the properties of the biomass used in building-integrated polygeneration systems.

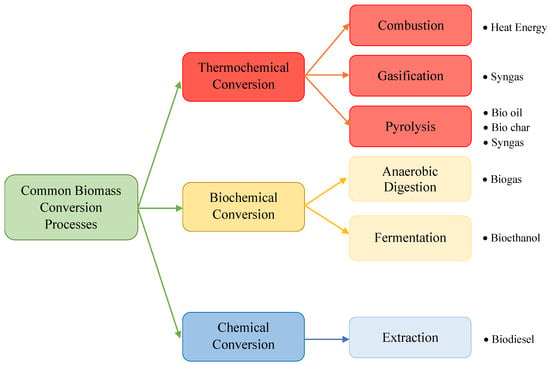

Various technologies have been developed to convert biomass into useful forms of energy (e.g., thermal and/or electrical energy). The transformation can be performed in multiple phases. In the primary conversion phase, biomass is transformed into hot water, steam, gas, liquid, or solid fuels. These products can later be either used directly by the prime movers or stored and transported to respective applications. The most common biomass conversion techniques and their respective bioenergy outcomes are shown in Figure 4 [47].

Table 1.

Properties of biomass types used in the study.

Table 1.

Properties of biomass types used in the study.

| Biomass Type | Ultimate Analysis and Proximate Analysis/Composition (wt%) | Fixed Carbon | Volatile Matter | LHV (kJ/kg) | HHV (kJ/kg) | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | O | N | S | Ash | ||||||

| Bagasse | 48.64 | 5.8 | 37.38 | 0.16 | 8.02 | 7650 | [48] | ||||

| Beech bark | 47.4 | 5.53 | 38.5 | 0.6 | 0.1 | 7.8 | 18.5 | 73.7 | 18,624 | [49] | |

| Christmas trees | 51.7 | 5.6 | 36.7 | 0.5 | 0.4 | 5.1 | 20.7 | 74.2 | 19,973 | [49] | |

| Dairy biomass | 35.3 | 3.1 | 19.1 | 1.9 | 0.42 | 15 | 13 | 46.8 | 17,185 | [50] | |

| Municipal solid waste | 47.6 | 6 | 32.9 | 1.2 | 0.3 | 12 | 19,567 | [51] | |||

| Oak wood | 50.3 | 6.07 | 42.7 | 0.3 | 0.1 | 0.5 | 21.4 | 78.1 | 20,051 | [49] | |

| Olive wood | 47.4 | 5.23 | 43.5 | 0.7 | 0.03 | 3.2 | 17.2 | 79.6 | 18,574 | [49] | |

| Paddy husk | 38.5 | 5.7 | 39.8 | 0.5 | 0 | 15.5 | [52] | ||||

| Paper | 43.4 | 5.8 | 44.3 | 0.3 | 0.2 | 6 | [52] | ||||

| Pine bark | 52.8 | 5.79 | 39.2 | 0.3 | 0.07 | 1.9 | 24.4 | 73.7 | 20,508 | [49] | |

| Pine chips | 49.6 | 5.73 | 38.1 | 0.5 | 0.08 | 6 | 21.6 | 72.4 | 19,451 | [49] | |

| Pine sawdust | 52.53 | 6.08 | 39.04 | 0.09 | 0.55 | 1.7 | 13.15 | 85.15 | 19,853 | [53] | |

| Rice husk | 49.05 | 6.1 | 44.3 | 0.37 | 0.06 | [54] | |||||

| Wood chips | 47.1 | 6.1 | 47.78 | 1.2 | 0.026 | 22.79 | 77.19 | 17,740 | [41] | ||

Figure 4.

Common biomass conversion techniques.

2.1. Thermochemical Conversion

Direct combustion of biomass is the most common and well-known technology for deriving thermal energy from biomass. In this process, biomass is burnt in the presence of excess air to generate heat in the temperature range of 700–1500 °C [55]. One of the prerequisites of this process is the drying of biomass. Biomass drying can reduce the moisture content before combustion occurs and can eventually increase the efficiency by 5–10%. Biomass can be dried by utilizing the radiation heat from the flames, thermal energy recovered from the exhaust stream, or by using direct solar irradiations [56].

Gasification is a thermochemical conversion process involving burning biomass with a limited supply of oxygen/air to produce a synthesis gas (syngas), also referred to as producer gas. Gasification usually occurs in four steps, i.e., drying of biomass, pyrolysis, combustion, and reduction [57]. These series of processes occur at different temperature levels. For instance, the drying of biomass occurs until 120 °C; pyrolysis, where all the volatile constituents of the biomass source are liberated, takes place in the range of 120–700 °C; the combustion process takes place in the temperature range of 700–1500 °C, which oxidizes the fuel constituents and triggers an exothermic reaction; finally, a reduction reaction takes place between 800 and 1100 °C, where the endothermic reaction takes place [58].

Pyrolysis refers to a thermochemical conversion process that occurs in the absence of oxygen. This process typically occurs in the temperature range of 450–600 °C, leading to the production of three main products, namely, biochar, bio-oil, and syngas [59].

2.2. Biochemical Conversion

The predominant method for biochemical conversion is anaerobic digestion. In this process, organic waste, such as food and animal feed, undergoes a disintegration process, resulting in biogas and digestate production, which can be used for energy recovery and as a biofertilizer. The process occurs in closed vessels or digesters in an oxygen-deprived environment. The generated biogas can be used to produce heat, and electricity is upgraded as a substitute for natural gas [60].

Fermentation is a prominent technology for the biochemical conversion of biomass that involves the transformation of biomass into glucose and, subsequently, into alcohols, primarily into bio-ethanol. The feedstock of this process is mainly composed of sugar or starch-based crops; however, lignocellulose biomass can also be utilized after suitable pretreatments aimed at lignin decomposition or with reduced efficiency [61]. It is considered the most widely used method to produce high-quality biofuels on an industrial scale [62].

2.3. Chemical Conversion

Chemical conversion processes of biomass result in high-density biofuel production. Various vegetable oils and animal fats undergo esterification and/or transesterification to be converted into biodiesel [63].

3. Materials and Methods

In this study, the authors conducted a comprehensive review of the literature on biomass-based polygeneration systems integrated within buildings, aiming not only to describe but also to reformulate and introduce a novel perspective to existing studies. Utilizing a set of targeted keywords such as “polygeneration”, “multigeneration”, “building”, “combined cooling, heating, and power (CCHP) system”, “biomass”, and “building-integrated”, the authors curated a collection of pertinent research articles. This effort resulted in the identification of 60 scholarly articles published between 2011 and 2023, which primarily focused on the energy, exergy, economic, and environmental analyses of biomass-based building-integrated polygeneration systems.

The predominant methodology for analyzing polygeneration systems, as derived from the reviewed literature, is a thermodynamic analysis from energy and exergy perspectives. Energy analysis evaluates systems based on the first law of thermodynamics and energy conversion efficiency, whereas exergy analysis assesses the quality of energy and identifies inefficiencies. Common metrics in energy analysis include the system’s energy efficiencies and primary energy savings compared to conventional systems.

In addition to thermodynamic assessments, economic and environmental analyses are crucial. Economic evaluations frequently focus on the payback period, quantifying the timeframe required for the system to recuperate its initial investment costs. From an environmental standpoint, biomass systems, as renewable energy sources, contribute to reducing carbon emissions. This is often quantified by calculating the CO2 emission reductions achieved by substituting biomass for conventional energy sources.

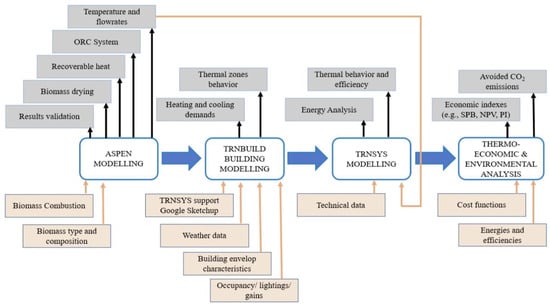

The literature review reveals that biomass-based polygeneration systems are predominantly simulated using various tools. The absence of a single software capable of modelling all system components necessitates the integration of multiple simulation platforms to conduct realistic analyses of both the energy generation (e.g., biomass-based energy generation systems) and energy utilization (e.g., buildings) segments of the polygeneration system. For instance, a case study outlined in Figure 5 employed Aspen Plus V8.8 software for modelling the energy generation part of the system, featuring a biomass combustion-based externally fired gas turbine system, and TRNSYS 18 software for developing a realistic building demand model alongside the remaining CCHP system [41]. Other commonly utilized software tools in the literature include EES, MATLAB, and HOMER.

Figure 5.

The methodological approach of the study [41].

4. Building-Integrated Biomass-Based Polygeneration Systems and Technologies

Polygeneration systems utilizing biomass offer multiple benefits, including increased overall system efficiency and the use of a renewable energy source that is highly available. As a result, they contribute to sustainable development. This study comprehensively investigates research conducted in the field of biomass-based polygeneration systems, with a particular focus on systems that are integrated with buildings and utilize biomass sources to generate energy. Analysis of the recent literature indicates that biomass combustion and gasification are the primary biomass conversion technologies investigated in the assessed studies. The content is divided into several subsections, each one exploring a different method in detail.

Moreover, emphasis is placed on research examining the concurrent utilization of biomass with other energy (e.g., renewable or conventional) resources. Significantly, the debates revolve around conducting research that compares biomass-based standalone systems and biomass hybrid systems, aiming to explore the system’s behaviour in each scenario. In addition, a range of studies with different objectives connected to buildings’ integrated biomass-based polygeneration systems is included. Tables are used to provide a concise summary of important information and significant conclusions from each evaluated paper for ease of reference.

4.1. Biomass Combustion-Based Systems

Biomass combustion-based polygeneration systems have become a potential option for sustainable energy production, providing various advantages when integrated with different building structures. This section offers a detailed analysis of the uses and incorporation of such systems utilizing multiple technological frameworks. A summary of all the studies is shown in Table 2.

4.1.1. Biomass Combustion Integrated as an Auxiliary Boiler in Hybrid Systems

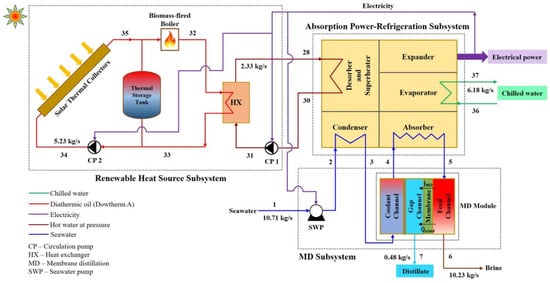

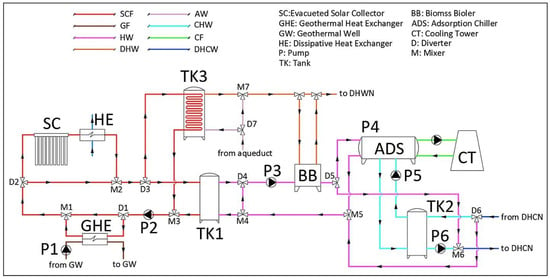

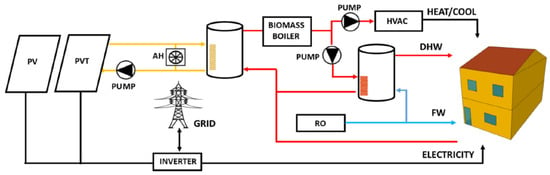

One prominent use of biomass combustion in polygeneration involves using independent boilers or including it as an auxiliary boiler system alongside solar and geothermal energy sources. These systems also include fuels obtained from biomass to produce thermal energy that can be used for space heating and/or DHW, effectively meeting the energy requirements of buildings. Notably, Krarouch et al. conducted a study on a hybrid bath project in order to improve the energy efficiency of traditional Turkish baths and highlighted the energy performance of a biomass boiler system integrated with a three-room (e.g., Hammam or Turkish bath) floor heating system located in Marrakech. The main objective of the study was to design and optimize the performance of the proposed system using the TRNSYS 18 simulation tool. [64]. Multiple investigations have been carried out to showcase the feasibility of employing hybrid energy sources to enhance the ability of systems to withstand seasonal fluctuations and optimize the use of renewable energy. In such cases, biomass boilers can be coupled with other intermittent renewable energy resources as an auxiliary energy source to match the design’s operational conditions. In this context, Uche et al. [65] performed energy, economic, and environmental analyses of innovative configurations employing thermal technologies (PVT and Biomass boiler) capable of generating cold and desalinated water from heat and electricity. The proposed four configurations of the polygeneration system integrated with the residential building were examined for three climatic sites to analyze and compare energy, economic, and environmental perspectives of the layouts. Results revealed that the PES ratio and CO2 emission saving ratio were in the range of 0.640–0.685 and 0.720–0.779, respectively. Similarly, Ayou et al. [66] proposed adopting a thermally integrated absorption refrigeration system and membrane distillation (MD) process to improve the efficiency of converting thermal energy, which is particularly advantageous in areas requiring desalination. The study suggested implementing an independent renewable heat polygeneration system that utilizes permeate/conductive-gap MD modules and an ammonia/water absorption power-refrigeration system, as shown in Figure 6. The system in Almería, Spain, utilizes solar collectors and a biomass-fired boiler to generate heat. It can provide 130 kW of cooling, 6.4 kW of power, and 41.4 m3/day of desalinated water. The system’s resource utilization efficiency is found to be 44.2%. Moreover, Carotenuto et al. [67] created a hybrid model for a low-temperature district heating and cooling system in Pozzuoli, South Italy. The model incorporates solar, geothermal, and an auxiliary wood chip biomass-based boiler, as shown in Figure 7. The proposed model is assessed based on energy and economic criteria. An energy analysis of the system indicates that the combination of geothermal and solar energy resources is sufficient to meet the community’s energy requirements during the winter season. However, using a biomass boiler during the summer months becomes necessary to achieve a higher set-point temperature and fulfil the cooling needs through an adsorption chiller. The proposed system attains solar efficiency exceeding 40% and yields substantial primary energy savings of up to 75%. However, from an economic point of view, the system necessitates public investment to reduce the current SPB period of 20.9 years. Similarly, Calise et al. [68] examined the energy–water nexus, investigating a unique polygeneration system that simultaneously generates electricity and water for two Mediterranean islands (Favignana and Santa Maria di Salina) in Italy. The islands being studied possess sufficient renewable energy resources and access to seawater but have a restricted freshwater supply. Two separate models were suggested for each island. The envisioned polygeneration setup for Favignana Island integrates concentrating photovoltaic–thermal (PVT) solar collectors complemented by a biomass backup boiler. This combination is designed to address the heating and cooling demands of the buildings in the study. Additionally, the system incorporates a multi-effect distillation (MED) unit for the production of potable water. Conversely, the polygeneration system deployed on Salina Island relies on heat pumps for climate control within the conditioned spaces and uses a reverse osmosis unit for a freshwater generation. The performance of these system configurations was thoroughly evaluated through TRNSYS simulation software, with an emphasis on assessing energy efficiency, economic viability, and environmental impact. A comprehensive sensitivity analysis was conducted on the proposed systems by systematically varying the capacity of the PVT system and the number of desalination units. The analytical findings indicate that the suggested polygeneration system for Favignana achieved a primary energy saving ratio of 32.2%, a CO2 emission reduction ratio of 27.8%, and an SPB period of 12 years. The proposed system for Salina achieves 64.4%, 63.9%, and 6.2 years, respectively. In another study, De Lima et al. [69] proposed a renewable energy system for a commercial building (e.g., a hotel) in Northeast Brazil, highlighting the capacity of distributed generation to fulfil energy needs and promote environmental preservation. The system employs mixed-integer linear programming to optimize and minimize the annual economic costs, including capital and operation costs. The optimal solution, despite not relying on cogeneration, exhibited a 70% decrease in total annual expenses compared to a reference system employing traditional energy sources. The system integrated 70 photovoltaic panels and employed biomass (specifically sugarcane bagasse) for a hot water boiler, excluding solar collectors. The system’s resilience was validated by sensitivity assessments conducted on electricity and natural gas pricing and other types of biomasses. Modifying the tariffs or biomass types did not change the best arrangement.

Figure 6.

Schematic diagram of the proposed system [66].

Figure 7.

Simplified district heating and cooling system layout [67].

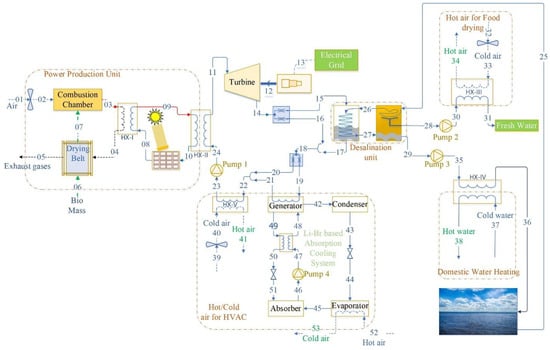

4.1.2. Biomass Combustion Integrated with the Organic Rankine Cycle (ORC)

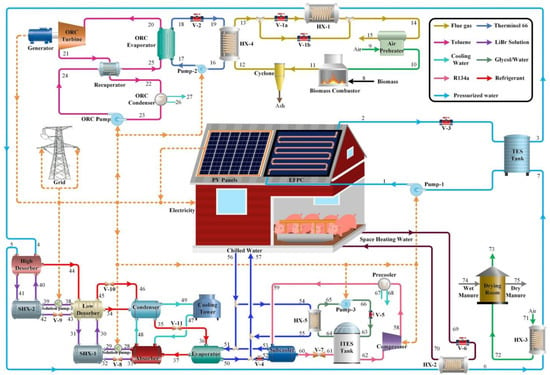

ORC systems bear resemblance to conventional steam power generation systems, with the distinction that they employ organic fluids as the working fluid, rather than water. Possible working fluids for ORC systems encompass hydrocarbons, hydrofluorocarbons, chlorofluorocarbons, and hydrofluoroolefins (HFOs). The ORC, in recent years, has gained recognition as a promising technology for converting low-grade heat energy into power. Typical heat sources encompass residual heat energy from other thermal systems, solar energy, geothermal energy, and biomass products [70]. In the context of biomass combustion-based systems integrated with ORC systems to fulfil the energy requirements of buildings, Luqman et al. [50] highlighted the importance of utilizing a biomass–solar energy system to tackle the interconnected issues of energy, water, and food in coastal regions. The proposed integrated system could generate electricity, provide space heating and cooling (such as for home and food processing purposes), and produce freshwater simultaneously, as shown in Figure 8. The proposed system, when operated at its intended parameters, generated 13.2 MW of electrical power, 4 MW of cooling power, approximately 73 kg/s of hot air for potential food drying purposes, 1687 m3/day of fresh water, and approximately 41 kg/s of domestic hot water. The energy and exergy efficiencies of the system were 55% and 18%, respectively. Similarly, Zhang et al. [54] examined a polygeneration system that utilizes solar and biomass energy sources for a pig farm in Changsha, China (see Figure 9). The primary objective of the work was to decrease dependence on fossil fuels. The system incorporated a biomass combustor, ice thermal storage, absorption chiller, flat plate collectors, photovoltaic panel, and thermal storage tank. The study employed intelligent operational solutions to address the increased cooling requirements and optimize the system using a non-dominated sorted genetic algorithm. The suggested system demonstrates an energy efficiency of 53.59% and an exergy efficiency of 19.05% under ideal circumstances. Additionally, it achieves a CO2 reduction ratio of 70.39% and has a payback period of 5.12 years. These results of the study emphasized its potential as a sustainable energy solution for intensive pig farming. Moreover, Ghasemi et al. [71] proposed an advanced multigeneration energy system that employs biomass and solar energy to generate electricity, cooling capacity, heating capacity, desalinated water, and liquefied natural gas. The thorough examination of the system, which includes sensitivity analysis and optimization, yields a net electric power output of 16.11 kW, a cooling load of 23.41 kW, and a heating load of 28.94 kW. The overall energy and exergy efficiency are 46.8% and 11.2%, respectively. The study highlights the significance of integrating subsystems to optimize efficiency and minimize energy losses. Furthermore, Pina et al. [72] proposed a model to develop and evaluate a combined solar and biomass ORC system for generating energy and cooling a commercial centre in Zaragoza, Spain. The system combines a parabolic trough collector field, thermal energy storage, and a biomass boiler to power an ORC. The thermoeconomic analysis of the system indicates that the current proposed system is not economically feasible since the cost of electricity generated (EUR 279.07/MWh) exceeds the cost of power purchased (EUR 126.70/MWh). Nevertheless, the system exhibits encouraging environmental advantages by reducing 96.1% of CO2 emissions and 85.6% of non-renewable primary energy usage in comparison to conventional grid-based systems. The technical feasibility evaluation confirms the solar system’s 68.4% renewable portion but stresses the ORC’s low efficiency as a cost problem. In another study, Soutullo et al. [73] conducted a comprehensive examination of the operational efficiency of a centralized polygeneration system connected to district networks for distribution in three towns in Spain: Oviedo, Seville, and Zamora. The TRNSYS simulation program was used to integrate various renewable and conventional energy technologies to meet energy requirements. An ORC, a biomass boiler, and solar thermal collectors were all part of the system’s thermal loop. In the event of inadequate renewable energy production, a natural gas-based cogeneration system was used as a backup. The thermal model was examined in two scenarios: Case 1 pertained to optimizing the proportion of solar thermal energy, whereas Case 2 pertained to optimizing the power generated by biomass boilers. Alternatively, the electrical requirements were met by employing three distinct setups incorporating Solar PV, a wind turbine, and polymer electrolyte membrane fuel cells (PEMf). The most favourable results were attained through the simultaneous integration of PV systems, wind turbines, and PEMf. Pina et al. [74] conducted a feasibility analysis of two distinct solar cogeneration plants, namely, Layout A and B. These plants have the capability to meet the electrical and cooling requirements of a commercial building located in Zaragoza, Spain. The system consists of solar parabolic trough collectors, thermal energy storage, an ORC for electricity generation, and mechanical chillers for cooling. The distinction between the two layouts is predicated on the incorporation of a biomass-derived auxiliary backup boiler into the system. There is a biomass boiler in Layout A, whereas Layout B does not employ biomass hybridization and relies solely on a solar-driven ORC system. Layout A incurs electricity costs of 0.2030 EUR/kWh, while Layout B incurs electricity costs of 0.1458 EUR/kWh as per economic evaluation. The findings suggest that Layout B is more economically viable in the near to medium future. The technical viability of these solar-powered cogeneration systems, which fulfil both power and cooling requirements, has been confirmed. These findings highlight their capacity to compete and provide significant environmental benefits within the context of renewable energy-powered systems. Luqman et al. [75] introduced a pioneering polygeneration system that addresses the challenges associated with energy, water, and waste management in dairy production. The system optimally harnesses dairy farm waste, including methane, manure, and wastewater, to fulfil the farm’s needs. The system comprises a combustion chamber, Rankine cycles, an NH3-H2O absorption cooling system, a wastewater evaporator, a water electrolyser, and a fuel cell. Thermodynamic analysis revealed that this system can produce 17 MW of electricity. Moreover, it can also generate 1350 m3/day of purified water and produce other outputs, all while maintaining an overall energy efficiency of 35.2%. The technology efficiently reduces the emission of greenhouse gases, demonstrating its dedication to environmental conservation. The study emphasises the significance of sustainable dairy production, particularly in hot and humid regions, by tackling environmental concerns through a polygeneration strategy. The suggested system efficiently handles trash and minimizes reliance on external networks.

Figure 8.

Schematic diagram of the proposed system [50].

Figure 9.

Schematic diagram of a solar/biomass hybrid multi-generation system [54].

4.1.3. Biomass Combustion Integrated with Gas Turbine

The incorporation of biomass combustion systems with gas turbines presents a dynamic method for polygeneration. In this context, several studies from the literature are presented in this review. The work by Di Fraia et al. [41] investigated the energy, economic, and environmental aspects of a biomass-based CCHP system with a capacity of 169 kWe. The system was implemented in a historical building called Sant’ Apollinare, situated in Perugia, Italy. The study employs Aspen Plus and TRNSYS software to model a wood biomass combustion-based externally fired gas turbine (EFGT) and an ORC system. The CCHP system, which includes a heat exchanger, storage tanks, absorption chiller, and balance of plant elements, specifically caters to the peak thermal energy needs (refer to Figure 10). The economic viability of the system is assessed by employing criteria such as SPB, NPV, and PI to examine different scenarios of biomass supply costs. The results indicate a significant annual decrease of 632 tons in CO2 emissions, highlighting the environmental advantages of the technology.

Figure 10.

Layout of the system [41].

Similarly, Lobo Correia et al. [76] conducted the synthesis and optimization of a polygeneration system designed to meet the energy needs of a dairy facility in Brazil. A mixed-integer linear programming approach was employed to minimize the overall annual expenses in order to optimize two systems: the reference system and the optimal economic system. The reference system, omitting cogeneration and biomass, had an annual expenditure of R$ 2,780,550. On the other hand, the optimization model that was solved without any restrictions showed that the ideal economic system is economically superior, with an annual cost of R$ 2,074,793 (25% lower). The observed decrease in the system’s yearly expenses results from the strategic utilization of diesel and natural gas cogeneration modules during periods of high demand, replacing energy from the grid.

Table 2.

Summary of studies on biomass combustion-based systems.

Table 2.

Summary of studies on biomass combustion-based systems.

| Ref | Biomass Type | Biomass Cost | Other Energy Sources | Conversion Devices | Outputs | Softwares/Tools | Biomass System’s Thermal Capacity [kW] | System’s Electrical Capacity [kW] | Application of the System | Results |

|---|---|---|---|---|---|---|---|---|---|---|

| [77] | Rice straw | - | - |

|

|

|

|

| Residential application (e.g., both electrical and district heating) |

|

| [50] | Dairy biomass | - |

|

|

|

| 4160 | 13,200 | Domestic and food processing application |

|

| [54] | Rice husk | USD 58/Ton |

|

|

|

|

| - | Industry |

|

| [65] | Biomass pellets | EUR 0.2/kWh |

| - |

|

| 100–500 | - | Residential application |

|

| [78] | - | - |

|

|

|

| - | - | Residential building |

|

| [66] | - | - |

|

|

|

| 70.7 | 6.4 | - |

|

| [71] | Bagasse | - |

|

|

|

| 14.7 | 16.11 | - |

|

| [67] | Wood chips | EUR 60/ton |

|

|

|

| - | - | Residential |

|

| [79] | Wood chips | EUR 60/ton |

|

|

|

| Boilers = 53 + 25 |

| Residential |

|

| [72] | Biomass pellets | EUR 0.0444/kWh |

|

|

|

| 2800 | 500 | Commercial centre |

|

| [76] | - | - |

|

|

|

| biomass steam boiler = 321 |

| Dairy industry |

|

| [73] | - | - |

|

|

|

| Boiler = 4.5–119.8 |

| Residential (district heating and cooling) |

|

| [68] | Wood chips | EUR 60/ton |

| - |

|

|

| - | Residential |

|

| [80] | Wood chips | EUR 60/ton |

|

|

|

| 350 | 30 | Residential building |

|

| [69] | Sugarcane bagasse | BRL 51/MWh |

|

|

|

| 149 | - |

| |

| [74] | Biomass pellets | EUR 0.0444/kWh |

|

|

|

| 2800 | Layout A = 500 Layout B = 978 | Comercial |

|

| [75] | Animal manure | - | - |

|

|

| - | 17,000 | Dairy farm |

|

4.2. Biomass Gasification-Based Systems

Biomass gasification systems have garnered considerable interest in comparison to other systems based on biomass conversion methods. These systems have the capability to generate a wide range of products based on their individual subsystems and configurations. Summaries of studies on systems based on biomass gasification are presented in Table 3.

4.2.1. Biomass Gasification Integrated with ORC

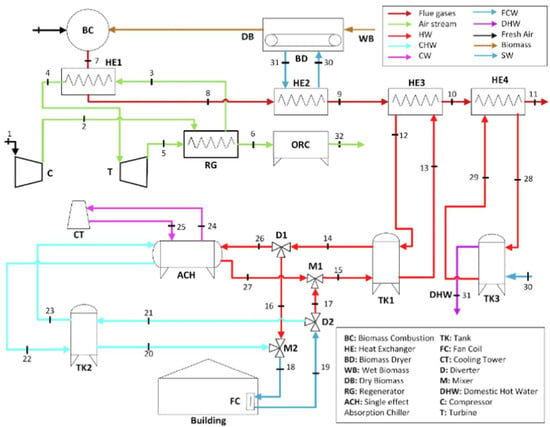

An effective approach to incorporating biomass gasification is by integrating it with an ORC. The combination of biomass-derived gases and the ORC process improves energy efficiency and enables the generation of electricity and useful heat. In this context, Xu et al. [52] investigated a biomass-powered polygeneration system that combines a solid oxide electrolyser cell, multi-effect desalination, and the Rankine cycle to generate electricity, freshwater, and hydrogen. The biomass gasification chamber produces syngas, while the waste heat from the Rankine cycle is used to operate the desalination and electrolyser units. The layout of the reviewed article is shown in Figure 11. The system underwent thermodynamic and exergoeconomic analysis using NSGA-II optimization and TOPSIS decision-making methodologies using MATLAB. The parametric study investigated the effects of varying the flow rate of biomass fuel, the pressure at the turbine inlet, the temperature at the combustion chamber exit, and the temperature difference at the pinch point of the steam generator. The optimal parameters obtained by multi-criteria optimization are as follows: an exergy efficiency of 17.64%, a net electricity output of 7658.5 kW, and a total unit exergy cost of products of USD 26/GJ.

Figure 11.

Layout of the proposed system for electricity, freshwater, and hydrogen production [52].

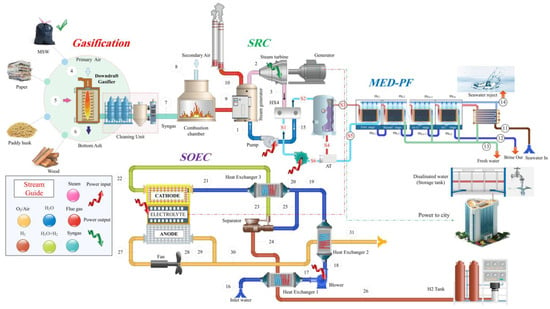

Similarly, Li et al. [81] proposed a polygeneration system utilizing biomass to produce power and methanol simultaneously in their work. The system is compared to two biomass-based systems that produce power and methanol separately. The proposed polygeneration system achieves a reduction in energy consumption of up to 10% compared to the individual reference systems. Finally, Taheri et al. [22] conducted a multi-objective optimization of a biomass-based multigeneration system in their study. The system comprised a gas/steam turbine system, an ORC system, an absorption chiller, a PEM electrolyser, and a liquid natural gas subsystem, as shown in Figure 12. System optimization was carried out for two objective function parameters: the total product cost rate and exergy efficiency. An exergy efficiency of 39.02% and an hourly total product cost rate of USD 1107 were the outcomes of the final optimisation.

Figure 12.

Schematic diagram of the proposed integrated multigeneration system [22].

4.2.2. Biomass Gasification Integrated with an Internal Combustion Engine (ICE)

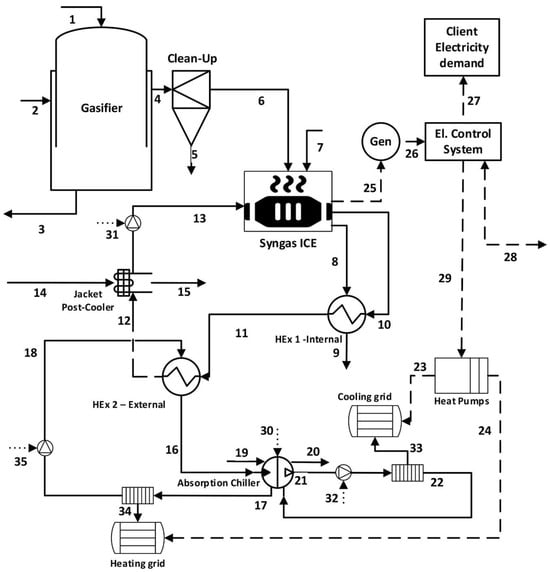

Regarding biomass gasification-based systems that are combined with internal combustion engines to produce polygeneration, Wegener et al. [49] assessed the exergy efficiency of a compact biomass-powered CCHP system that is incorporated into the Montjuic Castle, a historical edifice in Barcelona. The layout of the system is shown in Figure 13. A sensitivity study was conducted on the system, varying the sizes of its components. The analysis indicates that larger system components, such as those with a capacity of 100 kWe, have lower exergy efficiencies, namely, approximately 11.8%. On the other hand, a smaller CCHP system with a capacity of 25 kWe, which operates continuously for a longer period, achieves the maximum efficiency, approximately 13.3%. The study also determined that the selection of biomass had a limited impact on the exergy efficiency of the system, therefore making it a secondary consideration in the design of an energy system.

Figure 13.

Layout of the system [49].

Moreover, Puig-Amavat et al. [82] outlined a systematic method for creating a simulation model and optimizing a biomass gasification-based polygeneration system specifically designed for small to medium size applications ranging from 250 kWe to 2 MWe. The model provided five specific setups to generate heating, cooling, and electricity concurrently for a case study conducted in Cerdanyola del Valles (Barcelona, Spain). Natural biomass, such as wood chips and almond shells, was utilized as an energy source. The suggested energy system configurations consist of a gasifier, an internal combustion engine, and multiple absorption chillers, including single- and double-effect chillers. The analytical results indicate that all layouts exhibit an equivalent electricity efficiency above the minimal level of 27% mandated by Spanish regulations.

Furthermore, all the configurations exhibit primary energy savings that surpass 7.8%. Additionally, the energy and exergy efficiencies are greater than 53.2% and 18.9%, respectively, thereby confirming the system’s classification as a high-efficiency system. Caliano et al. [83] presented a strategic, operational approach for a biomass-fired CCHP system in another study. The proposed system included a cogeneration unit, an absorption chiller, and a thermal energy storage system. The aim was to efficiently meet the dynamic energy demands of a cluster of residential multi-apartment buildings in Italy. The operational plan was implemented to achieve economic optimization of two crucial elements: the absorption chiller and the storage system. A comprehensive sensitivity analysis examined the influence of electricity generation incentives on optimized results. It independently evaluated the impacts of different sizes of absorption chillers and thermal energy storage systems on system performance. In addition, the possibility of including a cold thermal energy storage system was examined under various pricing scenarios. Findings underline the impact of electricity-producing incentives and absorption chiller power in selecting the appropriate sizes. The study demonstrates that changes in the size of thermal energy storage have a negligible effect on economic factors. In contrast, adjustments to the size of the absorption chiller have a considerable influence on the economic and energetic components of the CCHP system. Moreover, implementing a cold thermal energy storage system appears to be a potentially feasible and economical option in the hot season, provided that there are favorable cost differences compared to the main thermal energy storage.

4.2.3. Biomass Gasification Integrated with a Gas/Steam Turbine

Investigation of combining biomass gasification with gas/steam turbines reveals more possibilities for polygeneration capabilities. In this context, Wegener et al. [84] studied the feasibility of a local agricultural waste-based CCHP system from energy, economic, and environmental perspectives. The study investigated four distinct energy system configurations to meet the energy requirements of a resort hotel on Neil Island, India, utilizing HOMER simulation software. The analysis determines that the local biomass-based CCHP system, with solar assistance, has the most favorable economic and environmental outcomes.

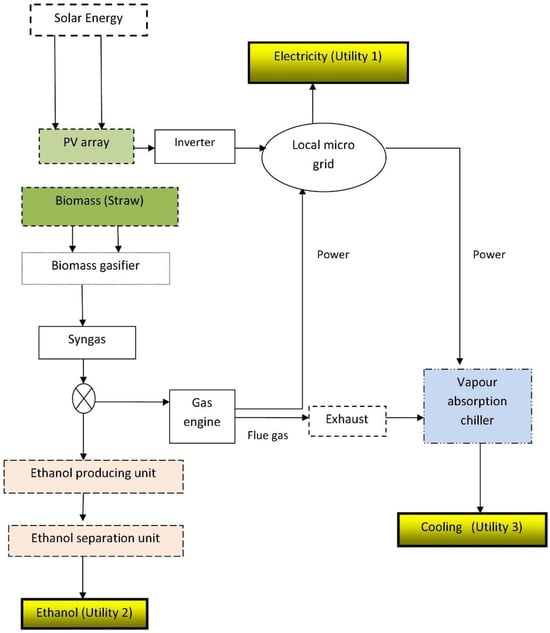

In another study, Ray et al. [85] aimed to address the energy requirements of remote Indian communities that lack access to the main power grid and depend on extensive coal-fired power stations. The study presented a decentralized polygeneration system integrating solar PV, biomass power, ethanol manufacturing, and cooling. Figure 14 shows the flow chart of the proposed system. To maximise the annualised profit and optimise the system size, a MATLAB-based economic model that uses linear programming was used. The findings demonstrate the practicality of supplying various energy services using decentralized polygeneration, resulting in decreased CO2 emissions compared to diesel generators. The system’s economic feasibility is evidenced by a simple payback period of 2.5 years and a substantial decrease of 96% in CO2 emissions. The study highlights the significance of cost-effectiveness and the utilization of local resources for the economic sustainability of distributed energy systems.

Figure 14.

Schematic of the polygeneration system [85].

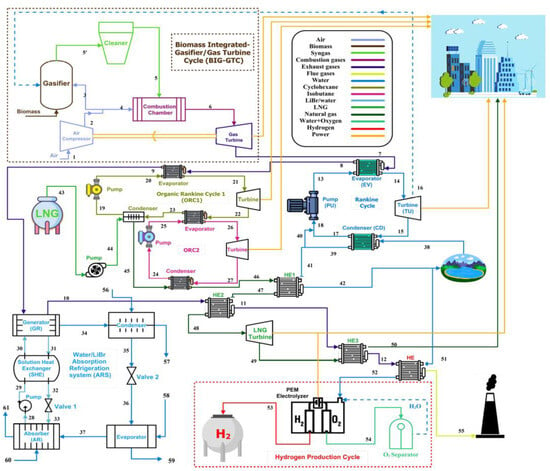

Similarly, Wu et al. [86] presented a universal approach for modeling and optimizing biomass-based polygeneration systems in metropolitan environments. These systems provide power, heating, cooling, and chemical products like bio-methanol. The case studies examined the practicality of implementing this combined system in various areas of China, such as Dalian, Shanghai, Guangzhou, and Kunming. These studies utilize a mixed-integer nonlinear programming method within the general algebraic modelling system. The approach encompasses crucial elements such as technology choice, equipment arrangement, strategic planning, and process design, considering economic and environmental viewpoints. The biomass polygeneration integrated energy system’s operational strategies are developed with the time-dependent process and boundary conditions taken into account. A comparative analysis compares the proposed system with a standard combined cooling, heating, and power system that relies on natural gas. The optimization results indicate that the city of Dalian has the shortest payback period of 3.403 years and the largest CO2 emission reduction rate of 63.59%. On the other hand, Shanghai ranks first in terms of the primary energy saving rate with a value of 29.65%.

In their study, Ubando and Chen [87] focused on addressing global challenges related to carbon emissions and energy-intensive industries by explicitly targeting the advancement of sustainable iron and steel manufacturing techniques. The proposed strategy involves incorporating a biomass polygeneration system to supply the required electricity and mitigate carbon dioxide emissions. This system combines various existing technologies to enhance thermodynamic efficiency by recovering and reusing lost energy and repurposing by-products. Prior research in the domain of polygeneration systems for the iron and steel sector typically concentrates on a single objective, neglecting the possible compromises between multiple objectives. The current research suggests a multi-objective approach that utilizes fuzzy linear programming (FLP) to create a biomass-based polygeneration system to address this limitation. The case study examines biochar production by torrefaction, pyrolysis, gasification techniques, and the generation of power and heat. An optimal polygeneration process network includes a gas turbine, heat recovery steam generator, gasifier for syngas synthesis, and torrefaction for biochar production. The model aims to assist engineers and managers in the cost-effective and efficient installation of a biomass-based polygeneration system in the iron production industry.

4.3. Biomass Anaerobic Digestion-Based Systems

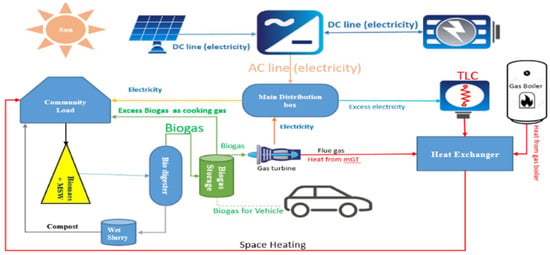

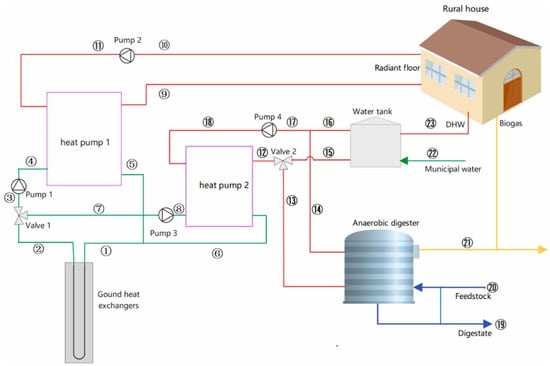

Biomass anaerobic digestion is the predominant technique used in biochemical conversion processes. There is a substantial body of research relative to other biochemical conversion techniques. However, in comparison to thermochemical conversion, there is a scarcity of scientific articles exploring this technology. Kumar et al. [88] suggested a waste-to-energy polygeneration system to achieve the most efficient production of renewable energy, cost-effectiveness, and environmental sustainability. The HOMER@ Pro software enables the system to produce 59,330 kWh/year of electricity, 17,842 kWh/year of heat, 57.51 kg/day of cooking gas, 269.31 kg/day of biogas for transport fuel, and 1395 kg/day of compost. The energy cost is Rs. 5.49 per kilowatt-hour (kWh), resulting in a net current cost of Rs. 38.87 lakh. The emission study indicates a low level of CO2 generation (5469 kg/year) and a substantial reduction (40,772 kg/year), resulting in an annual carbon credit of 40.7 units. Sensitivity analysis reveals concerns over the reliability of the capacity shortage while also reinforcing the positive impact of renewable energy variables. The schematic diagram of the proposed system is shown in Figure 15. Similarly, Luo et al. [89] developed a polygeneration system that combines ground source heat pumps with anaerobic digestion units to simultaneously generate heating, cooling, and biogas for residential use in the rural area of Chongqing, China (see Figure 16). The anaerobic digester model was implemented using C++ programming, while the rest of the system was simulated using TRNSYS. The method utilized rice straw and animal manure as feedstock. The system’s performance was assessed by comparing key performance metrics between a separate generation and current systems. The suggested system demonstrates substantial reductions of 21.6% and 32.2% in primary energy and 35.6% and 34.4% in annual expenditures, respectively, when compared to a separate generation and the current system. The exergy analysis determined that the overall efficiency is 32.2%. The anaerobic digester and heat pump units were recognized as crucial components. Table 4 provides a concise overview of the articles discussed in this section.

Table 3.

Summary of studies on biomass gasification-based systems.

Table 3.

Summary of studies on biomass gasification-based systems.

| Ref | Biomass Type | Biomass Cost | Other Energy Sources | Conversion Devices | Outputs | Softwares/Tools | Biomass System’s Thermal Capacity [kW] | System’s Electrical Capacity [kW] | Application of the System | Results |

|---|---|---|---|---|---|---|---|---|---|---|

| [81] | Pine chips | - | - |

|

|

| 1897 | 252 |

| |

| [22] | Solid waste biomass | - | - |

|

|

| - | - |

|

|

| [87] | - | - |

|

| - | 1070 | Iron and steel industry | capital cost = USD 2.49 Million | ||

| [52] |

| - | - |

|

|

| - | 1356 | Residential application |

|

| [49] | Woody biomass (Christmas trees, pine chips, pine bark, oak wood, olive wood, beech bark) |

|

|

| 25 | Tourist museum and residential building | Exergy efficiency = 13.3% | |||

| [90] | - | USD 72/ton | Grid power | - |

| - | 2693 | 735 |

| |

| [84] | Agricultural waste (e.g., crop residue, rice husk, coconut shells, etc.) | USD 0.032/kWh | Solar PV |

|

|

| 75 | 40 | Commercial (e.g., Hotel) |

|

| [82] | Wood chips and almond shells | - | - |

|

|

| 2057–5217 | 250–2000 |

| |

| [86] | Agricultural straw | RMB 250–420/ton | Solar PV |

|

|

| 112–512 | 1000–3000 | Multiple building loads (e.g., office, supermarket, hotel, school, and hospital) |

|

| [83] | Wood chip | EUR 160/ton | - |

|

|

| 120 | 50 | Residential |

|

| [85] | Straw | INR 0.081/ton | Solar PV |

|

|

| 316 | Gas engine = 79.85Solar PV = 1 | Domestic |

|

| [91] | Solar thermal |

|

|

|

|

Figure 15.

Schematic diagram of the proposed model [88].

Figure 16.

Schematic layout of the polygeneration system [89].

Table 4.

Summary of studies on biomass anaerobic digestion-based systems.

5. Case Studies

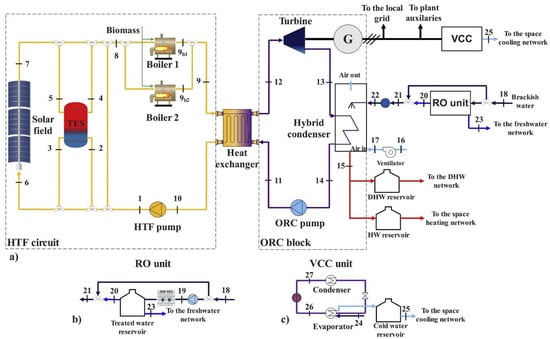

When exploring the complex relationship between biomass-based polygeneration systems and their integration into buildings, it is crucial to analyze case study examples thoroughly. The subsequent case studies thoroughly examine effective implementations, illuminating the intricate dynamics and diverse benefits of these integrated systems. For example, a case study building in Almeria, Spain, integrated with a solar PV/thermal and biomass boiler hybrid system was evaluated. The study conducted a term economic analysis of a polygeneration system that generates electrical and thermal energy by utilizing solar PV/thermal collectors in conjunction with a biomass boiler, as shown in Figure 17. The system can provide a residential structure’s energy requirements (including electricity, heating, cooling, DHW, and freshwater). The suggested system produced a primary energy savings of 12.9 megawatt-hours with a simple payback period of 20.69 years [92]. Figaj et al. [93] conducted a thorough examination of a hybrid polygeneration system. The system combines biomass, wind, and solar energy to generate electricity, heating, cooling, DHW, and freshwater for a small community of 10 families on Pantelleria Island, Italy. The key components were a biomass-fired steam cycle, a wind turbine, and a PV field, all interconnected with electrical and thermal energy storage systems. The system integrates an adsorption chiller for the purpose of cooling and a desalination system utilising reverse osmosis for the generation of freshwater. The system was simulated and assessed against a reference scenario using TRNSYS simulation software. The system analysis revealed a significant reduction in primary energy consumption of more than 94% and a payback period ranging from 7 to 12 years. Moreover, Calise et al. [94] performed a thermoeconomic analysis on two solar energy technologies: photovoltaic panels and evacuated flat-plate solar collectors. These technologies are incorporated into renewable polygeneration facilities. These systems attempt to provide power, heat, and cooling using a 6 kWe ORC, a 17 kW single-stage H2O/LiBr absorption chiller, a geothermal well, a biomass auxiliary heater, a lithium-ion battery, and a 25 m2 solar field. Both setups include electric and thermal storage systems to reduce the impact of fluctuations in solar radiation. The ORC is predominantly powered by geothermal energy, with additional support from solar thermal collectors and a biomass boiler. A different secondary arrangement substitutes solar thermal collectors with photovoltaic panels, hence augmenting power generation. The analysis conducted in TRNSYS for a commercial area in Campi Flegrei demonstrates that the configuration with photovoltaic panels has a shorter payback period of 13 years, in contrast to the configuration with evacuated flat-plate solar collectors, which has a payback period of 15 years. In addition, the integration of an electric energy storage system enhances energy self-sufficiency by 42% and 47% for the two respective systems. Furthermore, Mouaky et al. [95] proposed a hybrid polygeneration system that included vapour compression cycles, biomass boilers, compound parabolic collectors, thermocline thermal storage, ORC, reverse osmosis, and a hybrid condenser (as illustrated in Figure 18), and it was tested in a semi-arid area (Benguerir, Morocco). Evaluating energetic, exergetic, and exergoeconomic indicators for a 40-household community with robust solar potential, the system demonstrated potential, meeting a substantial portion of energy needs with 342 tons of annual biomass consumption and a 20% average solar contribution. Energy efficiency ranged from 15% to 44%, with exergy efficiency between 5% and 2.9%. Notably, the ORC cycle working fluid significantly affected the thermo-economic performance of the system. For instance, employing R1336mzz(Z) reduced biomass consumption by 13.4%, while R1234ze(Z) increased it by 8.94%. A parametric study emphasized the need for cost reductions at the solar field level.

Figure 17.

Layout of the polygeneration system [92].

Figure 18.

Systems layout: (a) general layout, (b) RO unit’s layout, (c) VCC unit’s layout [95].

Similarly, Rubio-Maya et al. [96] presented an innovative and methodical strategy for choosing and determining the appropriate size of a polygeneration plant that is powered by natural gas, solar energy, and gasified biomass. The study investigates different arrangements for a polygeneration system that produces electricity, heat, cold, and fresh water, using a detailed and inclusive specification of the system’s structure. Using a mathematical programming model, the technique is implemented in a Spanish tourist resort to optimize energy savings, reduce greenhouse gas emissions, and ensure economic feasibility. The results demonstrate the dependability of concurrently generating various utilities based on stated assumptions. At present, natural gas-based technologies are more economically profitable, even though incorporating renewable energy sources gradually would result in greater energy savings and reductions in greenhouse gas emissions.

Finally, Wegener et al. [97] present an optimization technique for determining the optimal capacities of biogas and battery storage in a polygeneration system. The system was engineered to generate power, purify water, and produce bio-sludge, which can be utilized as a fertilizer, for a case study conducted in a remote off-grid area in Bolivia. The system was evaluated using energy, economic, and environmental parameters and compared to a reference case scenario. The suggested polygeneration system exhibits a reduction of 22% in lifetime cost and a decrease of over 98% in CO2 emissions. Table 5 provides a concise overview of the articles discussed in this section.

Table 5.

Summary of biomass-based case studies systems.

6. Discussion

In this study, we conducted a comprehensive review of existing research articles focusing on biomass-based polygeneration systems integrated with buildings, presented in Section 4 and Section 5. The findings demonstrate the integration of these systems into various types of buildings, including residential, commercial, and industrial applications. The primary objective of these systems is to meet the electrical, heating, and cooling requirements of the integrated buildings [67,79]. Additionally, some systems also yield supplementary outputs such as freshwater [66,68,91,92] and byproducts like biogas [88,89] and cooling gas.

The reviewed literature is organized into sub-sections based on biomass conversion processes, such as combustion, gasification, and anaerobic digestion. Our analysis reveals that combustion-based systems are more prevalent in building integration projects, with the highest number of research articles compared to gasification and anaerobic digestion processes. This preference may be attributed to the simpler layout of combustion systems as well as to the lower space requirements.

The most commonly employed conversion devices for electrical power generation in biomass systems are ORC systems, followed by ICE systems, while gas cycles are less frequently utilized. Absorption chillers have emerged as the predominant technology for meeting cooling demands, typically harnessing thermal energy recovered from primary electrical generation devices. Additionally, some cases employ heat pumps for heating and cooling purposes.

Approximately 70% of the studied biomass systems incorporate solar assistance (e.g., both solar PV and thermal), highlighting the advantages of hybrid systems. However, it is noted that most articles rely on simulation tools for analysis, lacking experimental calibration and validation [98]. This absence of experimental data may impact the accuracy of the system performance assessment, as crucial onsite parameters are overlooked.

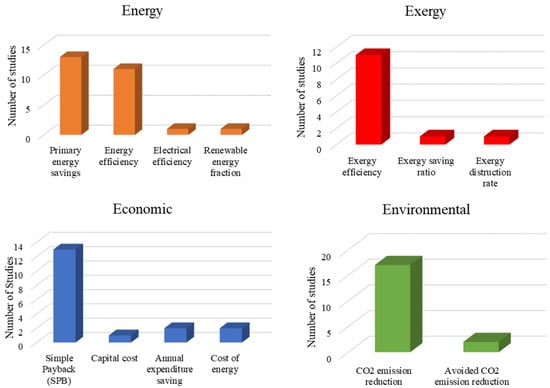

Our study underscores the importance of analyzing biomass systems from energy, exergy, economic, and environmental perspectives to obtain a comprehensive viewpoint of the system performance. Figure 19 shows the metadata results of the studied literature. PES and energy efficiencies are commonly used parameters for energy analysis, while the SPB period is a key economic indicator. However, caution is advised when comparing systems based on these parameters due to variations in subsidy assumptions across studies [99,100]. CO2 emission reduction serves as a crucial environmental metric, calculated by comparing CO2 savings from biomass systems to conventional energy sources [41]. Some studies also consider the production rates of various outputs to evaluate system performance.

Figure 19.

Metadata results of the studied literature.

In conclusion, the integration of biomass-based polygeneration systems, both standalone and hybrid, is witnessing significant growth. Nevertheless, there remains a paucity of scientific literature on integrating these systems with buildings to fulfill their energy needs. Given the abundance of biomass resources worldwide, legislative and policy initiatives are needed to address issues related to biomass supply, management, and disposal, particularly concerning residual biomass.

7. Conclusions

Biomass, the most abundant renewable energy source, plays a crucial part in sustainable development by providing energy for systems. This study explored recent progress in biomass-based polygeneration systems, particularly their integration with various types of buildings, including residential, commercial, and industrial structures. The objective of this review article was to redirect the attention of readers from general biomass-based systems to polygeneration systems that are specifically designed for applications such as buildings. This article examined different types of biomasses and the methodical approaches, possible advantages, and constraints of incorporating these technologies into practical construction applications. The studied literature was classified on the basis of biomass conversion methods, emphasizing combustion, gasification, and anaerobic digestion, which are extensively studied and widely applied in building contexts. The details of each conversion method, along with different prime movers, were thoroughly explained, and the results were organized in tables for the benefit of the readers. ORC systems were the most frequently used conversion devices for generating electrical power in biomass systems, followed by ICE systems. Gas cycles, on the other hand, were employed less. Absorption chillers emerged as a main component for fulfilling cooling needs, usually utilizing thermal energy obtained from primary electrical production devices.

Although there is a growing interest in incorporating biomass-based polygeneration systems into buildings in a decentralized fashion, a significant observation from the present study is that most research predominantly focuses on computer models based on simulations rather than real data. This dependence creates a discrepancy between theoretical and practical feasibility, as models frequently depict very cost-effective solutions, while investors display reluctance due to inherent uncertainties.

Furthermore, in areas with well-established electric infrastructures, these compact systems can contribute substantially to decentralization goals, thereby improving the energy resilience of communities and individuals. A notable observation is the widespread utilization of biomass energy as a supplementary rather than a primary source despite its consistent accessibility as a renewable resource. These factors give rise to apprehensions regarding the autonomy, functioning, and upkeep of such systems and the management and accessibility of biomass feedstock.

Ultimately, the incorporation of biomass-based polygeneration systems, whether operating independently or in a hybrid manner, is experiencing substantial growth. However, there is still a lack of scholarly literature regarding the integration of these systems into buildings to meet their energy requirements. Considering the ample availability of biomass resources globally, it is imperative to implement legal and policy measures to tackle concerns pertaining to the supply, management, and disposal of biomass, especially residual biomass. In order to deal with these difficulties, it is crucial to encourage the implementation of independent biomass-based polygeneration systems and specific case study building applications in different sectors. Implementing this proactive strategy will enhance the dependability and autonomy of these systems while also facilitating the development of a more resilient and enduring energy landscape.

Author Contributions

Conceptualization, L.V. and S.D.F.; methodology, M.S.; formal analysis, M.S.; writing—original draft preparation, M.S.; writing—review and editing, M.S and S.D.F.; visualization, M.S and S.D.F.; supervision, L.V and S.D.F. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out in the framework of the Italian Research Program PRIN (Progetti di ricerca di Rilevante Interesse Nazionale) 2017: “BIOmasses Circular Holistic Economy APproach to EneRgy equipments (BIO-CHEAPER)”—Project code: U-GOV PRJ-0207.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ORC | Organic Rankine cycle |

| CCHP | Combined cooling, heating, and power |

| CPVT | Concentrating photovoltaic thermal |

| DHW | Domestic hot water |

| EES | Engineering equation solver |

| EFGT | Externally fired gas turbine |

| FLP | Fuzzy linear programming |

| HHV | Higher heating value |

| ICE | Internal combustion engine |

| LHV | Lower heating value |

| MD | Membrane distillation |

| MED | Multi-effect distillation |

| NPV | Net present value |

| PB | Payback |

| PEM | Proton exchange membrane electrolyser |

| PEMf | Polymer electrolyte membrane fuel cells |

| PES | Primary energy saving |

| PI | Profitability index |

| PV | Photovoltaic |

| PVT | Photovoltaic thermal |

| RO | Reverse osmosis |

| SPB | Simple payback |

References

- Cook, M. Trends in global energy supply and demand. Dev. Pet. Sci. 2021, 71, 15–42. [Google Scholar] [CrossRef]

- Adebayo, T.S.; Awosusi, A.A.; Rjoub, H.; Agyekum, E.B.; Kirikkaleli, D. The influence of renewable energy usage on consumption-based carbon emissions in MINT economies. Heliyon 2022, 8, e08941. [Google Scholar] [CrossRef] [PubMed]

- Subedi, S.; Bhattarai, N.; Paudel, R. Impact of hydropower construction delay in energy banking opportunities between Nepal and India. J. Innov. Eng. Educ. 2024, 6, 1–4. [Google Scholar] [CrossRef]

- Tabriz, Z.H.; Khani, L.; Mohammadpourfard, M.; Akkurt, G.G. Biomass driven polygeneration systems: A review of recent progress and future prospects. Process Saf. Environ. Prot. 2023, 169, 363–397. [Google Scholar] [CrossRef]

- Köse, Ö.; Koç, Y.; Yağlı, H. Is Kalina cycle or organic Rankine cycle for industrial waste heat recovery applications? A detailed performance, economic and environment based comprehensive analysis. Process Saf. Environ. Prot. 2022, 163, 421–437. [Google Scholar] [CrossRef]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, Z.; Mazlan, M. A review of industrial waste heat recovery system for power generation with Organic Rankine Cycle: Recent challenges and future outlook. J. Clean. Prod. 2021, 287, 125070. [Google Scholar] [CrossRef]

- Poudyal, R.; Loskot, P.; Nepal, R.; Parajuli, R.; Krishna Khadka, S. Mitigating the current energy crisis in Nepal with renewable energy sources. Renew. Sustain. Energy Rev. 2019, 116, 109388. [Google Scholar] [CrossRef]

- Wright, V.P. World Energy Outlook. In Energy Systems for the 21st Century; ASCE: Reston, VA, USA, 1986; pp. 23–28. [Google Scholar]

- Ahmad, A.S.; Hassan, M.Y.; Abdullah, M.P.; Rahman, H.A.; Hussin, F.; Abdullah, H.; Saidur, R. A review on applications of ANN and SVM for building electrical energy consumption forecasting. Renew. Sustain. Energy Rev. 2014, 33, 102–109. [Google Scholar] [CrossRef]

- Martínez-Lera, S.; Ballester, J. A novel method for the design of CHCP (combined heat, cooling and power) systems for buildings. Energy 2010, 35, 2972–2984. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Energy analysis of a trigeneration plant based on solid oxide fuel cell and organic Rankine cycle. Int. J. Hydrogen Energy 2010, 35, 5104–5113. [Google Scholar] [CrossRef]

- Wu, D.W.; Wang, R.Z. Combined cooling, heating and power: A review. Prog. Energy Combust. Sci. 2006, 32, 459–495. [Google Scholar] [CrossRef]

- Mago, P.J.; Chamra, L.M. Analysis and optimization of CCHP systems based on energy, economical, and environmental considerations. Energy Build. 2009, 41, 1099–1106. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Hamdullahpur, F.; Dincer, I. Trigeneration: A comprehensive review based on prime movers. Int. J. Energy Res. 2011, 35, 233–258. [Google Scholar] [CrossRef]

- Alanne, K.; Saari, A. Sustainable small-scale CHP technologies for buildings: The basis for multi-perspective decision-making. Renew. Sustain. Energy Rev. 2004, 8, 401–431. [Google Scholar] [CrossRef]

- Calise, F.; Vicidomini, M.; Cappiello, F.L.; Dentice D’Accadia, M. Polygeneration. In Polygeneration Systems; Academic Press: Cambridge, MA, USA, 2022; pp. 1–33. [Google Scholar] [CrossRef]

- Jana, K.; Ray, A.; Majoumerd, M.M.; Assadi, M.; De, S. Polygeneration as a future sustainable energy solution—A comprehensive review. Appl. Energy 2017, 202, 88–111. [Google Scholar] [CrossRef]

- Calise, F.; de Notaristefani di Vastogirardi, G.; Dentice d’Accadia, M.; Vicidomini, M. Simulation of polygeneration systems. Energy 2018, 163, 290–337. [Google Scholar] [CrossRef]

- Shivarama Krishna, K.; Sathish Kumar, K. A review on hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2015, 52, 907–916. [Google Scholar] [CrossRef]

- Passey, R.; Spooner, T.; MacGill, I.; Watt, M.; Syngellakis, K. The potential impacts of grid-connected distributed generation and how to address them: A review of technical and non-technical factors. Energy Policy 2011, 39, 6280–6290. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Low-grade heat conversion into power using organic Rankine cycles – A review of various applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979. [Google Scholar] [CrossRef]

- Taheri, M.H.; Khani, L.; Mohammadpourfard, M.; Aminfar, H. Multi-objective optimization of a novel biomass-based multigeneration system consisting of liquid natural gas open cycle and proton exchange membrane electrolyzer. Int. J. Energy Res. 2021, 45, 16806–16823. [Google Scholar] [CrossRef]

- Poudyal, R.; Regmi, S. Review of Future of Bio-Mass Energy: A Case of Nepal. In Proceedings of the Society of Nepalese Engineers in UK (SONEUK) With the Guidance of the 8th SONEUK Conference Committee and Collaboration with the Nepal Engineers, London, UK, 6 December 2023. [Google Scholar]

- Joint Research Centre—European Commission. Brief on Biomass for Energy in the European Union; Joint Research Centre—European Commission: Brussels, Belgium, 2019; pp. 1–8. Available online: https://ec.europa.eu/knowledge4policy/bioeconomy%0AContact:%0Ahttps://ec.europa.eu/jrc/en/publication/brochures-leaflets/brief-bio-mass-energy-european-union%0Ahttps://op.europa.eu/en/publication-detail/-/publication/7931acc2-1ec5-11e9-8d04-01aa75ed71a1/la (accessed on 1 January 2024).

- Banu, J.R.; Sharmila, V.G. A systematic review on plastic waste conversion for a circular economy: Recent trends and emerging technologies. Catal. Sci. Technol. 2023, 13, 2291–2302. [Google Scholar] [CrossRef]

- Villarini, M.; Marcantonio, V.; Colantoni, A.; Bocci, E. Sensitivity Analysis of Different Parameters on the Performance of a CHP Internal Combustion Engine System Fed by a Biomass Waste Gasifier. Energies 2019, 12, 688. [Google Scholar] [CrossRef]

- Alanne, K.; Saari, A. Distributed energy generation and sustainable development. Renew. Sustain. Energy Rev. 2006, 10, 539–558. [Google Scholar] [CrossRef]

- Ikram, H.; Javed, A.; Mehmood, M.; Shah, M.; Ali, M.; Waqas, A. Techno-economic evaluation of a solar PV integrated refrigeration system for a cold storage facility. Sustain. Energy Technol. Assess. 2021, 44, 101063. [Google Scholar] [CrossRef]

- Battaglia, V.; Massarotti, N.; Vanoli, L. Urban regeneration plans: Bridging the gap between planning and design energy districts. Energy 2022, 254, 124239. [Google Scholar] [CrossRef]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Jradi, M.; Riffat, S. Tri-generation systems: Energy policies, prime movers, cooling technologies, configurations and operation strategies. Renew. Sustain. Energy Rev. 2014, 32, 396–415. [Google Scholar] [CrossRef]

- Carvalho, M.; Lozano, M.A.; Ramos, J.; Serra, L.M. Synthesis of trigeneration systems: Sensitivity analyses and resilience. Sci. World J. 2013, 2013, 604852. [Google Scholar] [CrossRef]

- Rong, A.; Lahdelma, R. Role of polygeneration in sustainable energy system development challenges and opportunities from optimization viewpoints. Renew. Sustain. Energy Rev. 2016, 53, 363–372. [Google Scholar] [CrossRef]

- Farhat, K.; Reichelstein, S. Economic value of flexible hydrogen-based polygeneration energy systems. Appl. Energy 2016, 164, 857–870. [Google Scholar] [CrossRef]

- Mavromatidis, G.; Orehounig, K.; Bollinger, L.A.; Hohmann, M.; Marquant, J.F.; Miglani, S.; Morvaj, B.; Murray, P.; Waibel, C.; Wang, D.; et al. Ten questions concerning modeling of distributed multi-energy systems. Build. Environ. 2019, 165, 106372. [Google Scholar] [CrossRef]

- Rezaei, M.; Sameti, M.; Nasiri, F. Biomass-fuelled combined heat and power: Integration in district heating and thermal-energy storage. Clean Energy 2021, 5, 44–56. [Google Scholar] [CrossRef]

- Wegener, M.; Malmquist, A.; Isalgué, A.; Martin, A. Biomass-fired combined cooling, heating and power for small scale applications—A review. Renew. Sustain. Energy Rev. 2018, 96, 392–410. [Google Scholar] [CrossRef]

- Murugan, S.; Horák, B. A review of micro combined heat and power systems for residential applications. Renew. Sustain. Energy Rev. 2016, 64, 144–162. [Google Scholar] [CrossRef]

- Raj, N.T.; Iniyan, S.; Goic, R. A review of renewable energy based cogeneration technologies. Renew. Sustain. Energy Rev. 2011, 15, 3640–3648. [Google Scholar] [CrossRef]