Abstract

In the building renovation industry, a growing volume of discarded insulation materials, such as stone wool insulation, prematurely finds its way to landfills or incinerators after building demolitions. However, these materials often did not reach their complete service life potential, and the reuse of insulation materials is usually not considered in current building practices. This study provides a comprehensive overview of the potential challenges associated with repurposing stone wool insulation from existing flat roofs. By means of detailed assessments via dismantling and performance evaluations of collected stone wool insulation boards up to 28 years old, this research reveals the unavoidable damages that occur upon dismantling yet emphasizes that this does not impede reuse. While density and thermal performance remain stable over time, water absorption and mechanical stability are affected. In total, 48% of all short-term tests revealed an increase in water absorption, possibly due to hydrophobic substance degradation. Mechanical performances of aged SW insulation from flat roofs depend on various factors, with 43% and 33% of compression and puncture resistance tests, respectively, not meeting current standards. Beyond a durability assessment, this study advocates for a multidisciplinary approach, uniting materials science, construction engineering, and sustainability insights, to creatively repurpose used insulation materials into future projects.

1. Introduction

In recent decades, insulation materials have played a crucial role in improving the energy efficiency of buildings within the construction sector. The development of building codes focusing on thermal performance has stimulated research and production of various insulation materials. For instance, Vienna experienced a significant increase in the use of polystyrene insulation and mineral wool insulation between 1990 and 2015, showing growth factors of 6.5 and 2.5, respectively [1].

In today’s building market, there exists a broad spectrum of insulation materials, each distinguished by its unique properties and manufacturing processes. In this context, prevalent insulation materials such as mineral wool (MW), polyurethane (PUR), polyisocyanurate (PIR), and expanded polystyrene (EPS) are widely employed. However, there is an emerging trend towards the adoption of more environmentally sustainable alternatives. Several studies have already compared different recycled or bio-based insulation materials and composites [2,3], with hemp, cellulose, wood fiber, mycelium [4], reed [5], wheat [6], and straw [5,6] being well-performing insulation options. Moreover, the production of insulation materials is not confined to natural sources alone; there is a growing trend of valorizing waste streams for the creation of new thermal and acoustic insulation materials. In their 2019 review, Massoudinejad et al. [7] delved into the utilization of waste from various streams to manufacture insulation materials for buildings. This spanned from straightforward waste streams such as wood waste [8] and textile waste [9] to more complex waste streams, e.g., plastic waste [10], elastomeric waste residues [11], and even waste products from thermal power plants [12].

The combination of raw material extraction, building component production, construction, and renovation activities, together contribute to 5–12% of total greenhouse gas emissions in Belgium [13]. The environmental impact of insulation materials currently in use plays an important part in this. A critical review of 47 studies compared the environmental impact of different building insulation materials with the use of Life-Cycle Assessment (LCA) [14]. This analysis concluded that EPS, stone wool (SW), and glass wool (GW) have a similar environmental impact, whereas PUR, extruded polystyrene (XPS), and cork exhibit higher impacts. Renewable materials such as cellulose, hemp, and wood fiber insulation have the lowest environmental impact.

The predominant contributor to the environmental impact of insulation materials is the production process. Using inorganic raw materials generates the largest impact for non-renewable insulation materials, whereas binders and additives in production contribute the most to the environmental impact of renewable materials [14,15]. For MW products such as SW and GW, exceptionally high temperatures ranging from 1300 °C to 1500 °C are essential for melting the raw materials [16]. Additionally, processes aiming to achieve higher densities further amplify the environmental impact of production, transportation, construction, and end-of-life scenarios. Considering the fact that SW insulation boards need higher densities for application in flat roofs, their production process is consequently regarded as one of the least environmentally favorable compared to other insulation materials used in this application [17,18]. Various initiatives aim to mitigate the environmental impact of the production process of SW insulation. This includes ongoing studies to optimize the production process itself [19], incorporate circularity in manufacturing processes [20], and repurpose production waste in other products, such as Portland Cement [21].

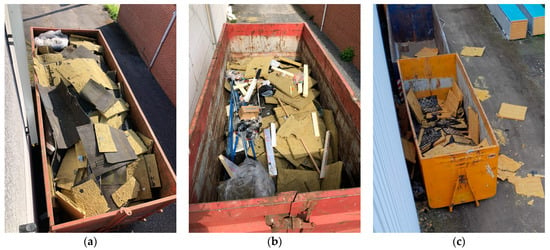

Despite its environmentally intensive production process, stone wool (SW) remains a sustainable material of choice, which is expected to last at least 75 years in a building [22]. Unfortunately, large quantities end up in mixed containers for landfilling or incineration after just 20 years due to degradation of the roof cover, renovation, or demolition (see Figure 1). The annual volume of mineral wool waste will therefore continue to increase year after year [23]. Consequently, the embedded energy of these insulation materials (energy-intensive manufacturing processes, transportation, processing, etc.) is systematically and irreversibly lost.

Figure 1.

(a–c) Pictures of various mixed containers with dismantled SW insulation from different flat roofs located in Flanders, Belgium, observed during standard dismantling processes.

Efforts to tackle this waste stream are already underway, as can be seen in a multifaceted approach highlighted by the use of the R-ladder. This signifies a hierarchy of strategies to transform the current linear model into a new circular model from more to less environmental benefits: R0 refuse, R1 rethink, R2 reduce, R3 reuse, R4 repair, R5 refurbish, R6 remanufacture, R7 repurpose, R8 recycle, and R9 recover [24]. The process always starts with demolition, as research indicates that separating core materials during demolition and recycling and/or reusing them can yield significant environmental benefits [25]. Furthermore, considerable efforts are directed towards the recycling of MW construction and demolition waste (CDW) [23], both within the context of a circular management approach [26] as well as the creation of new materials such as mortars, conglomerates, composites, and more [27,28,29,30]. Given the hierarchy of the R-ladder [24], reuse is consistently preferred over recycling. The recycling of MW insulation requires a considerable amount of energy, as dismantled insulation boards should be shredded, compressed, and melted again. The recycled content of recycled materials is often limited, necessitating a relatively high amount of virgin materials. Additionally, contaminated MW insulation boards consistently impede high-quality recycling, whereas this can be easily taken into account in a reuse scenario.

To initiate the reuse of insulation materials such as MW, knowledge is first acquired about the missing long-term properties of this reused material. Manufacturers and researchers rely on accelerated aging tests to simulate the aging of various insulation materials [31,32,33,34,35,36,37,38]. However, to facilitate the practical reuse of insulation materials, it is essential to understand how these materials perform under real conditions. Regrettably, there is a notable scarcity of specific research in this domain [39,40,41,42,43,44,45], with Langmans et al. [39] being a rare exception, providing a comprehensive overview of the durability of MW insulation. Data of the European Insulation Manufacturers Association for mineral wool insulation (Eurima) [40,41] were compared with existing studies [42,43,44] to assess performance over time. For flat roofs, a case study conducted in Hungary investigated the effect of built-in MW insulation on its thermal and mechanical performance [45]. The findings indicate that the thermal and mechanical performances may degrade in built-in conditions due to moisture, spoiling, and the production mistakes of MW. Consequently, there is a pressing need for research in this domain, not only to assess durability but also to develop theoretical frameworks for efficiently promoting the reuse of insulation materials like MW. Langmans et al. [39] primarily focused on assessing the durability of MW insulation (including glass wool and stone wool) in various applications (walls and roofs) in Lithuania, Switzerland, Denmark, and Germany. By contrast, this paper investigates the disassembly, durability, and reusability of stone wool (SW) insulation from existing flat roofs in Belgium. The outcomes of this research will be consistently interpreted from a circular perspective, ultimately leading to insights into the feasibility of reintegrating this insulation product into current construction practices.

2. Materials and Methods

2.1. Sampling

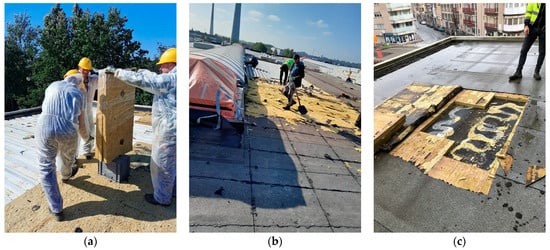

To conduct a thorough analysis of the disassembly process and the damage inflicted on the insulation boards, the disassembly of 14 flat roofs located in Belgium was studied and comprehensively documented (see Figure 2). In these case studies, the existing SW insulation was being replaced due to the demolition, renovation, or repair of the flat roof.

Figure 2.

(a–c) Examples of dismantling SW insulation from flat roofs in Flanders, Belgium.

Subsequently, from six flat roofs where the insulation had been in service for at least 12 years, SW samples were collected for further performance assessment (see Table 1). From each flat roof, at least 2 m2 of SW insulation was collected and transported to the laboratory. An important distinction among these cases is the roof structure, as some SW boards were glued to a concrete roof deck with a vapor barrier (cases C1a,b and C2), while others were mechanically fixed to a steel deck roof without a vapor barrier (cases S1, S2, S3 and S4). Based on the age, the density type, and the identified manufacturer, the appropriate product data sheets and Technical Approval Guidelines (ATGs) that were valid at the time of production were retrieved. To study degradation in aged SW insulation, the results of this experimental study were compared with the corresponding values from historical documents. It should be noted that in one case, two layers of insulation were found in the flat roof assembly (C1 a and b), and among all collected SW insulation boards, three different density types were identified. There are SW insulation boards that consist of only one density layer (Mono Density), some are equipped with a more pressure-resistant integrated top layer of SW (Dual Density) [46,47], and others additionally have a very hard top layer of SW fibers (Triple Density) [48].

Table 1.

Overview of the collected SW samples on a concrete (C) and steel deck (S) roof structure.

2.2. Material Testing

In the context of the durability and reusability of insulation materials like SW, it is important to test the relevant properties for the specific application. Therefore, in this study, a selection was made of specific test standards relevant to mineral wool insulation in flat roofs. Apart from thickness and density, all the specific test standards prescribed in the general product standard for mineral wool insulation (EN 13162 + A1 [51]) were followed, as indicated here:

- Thickness;

- Density;

- Short-term water absorption (acc. to EN ISO 29767 [52]);

- Long-term water absorption (acc. to EN 12087 [53]);

- Compressive strength (acc. to EN ISO 29469 [54]);

- Point load (acc. to EN 12430 [55]);

- Thermal conductivity (acc. to EN 12667 [56]).

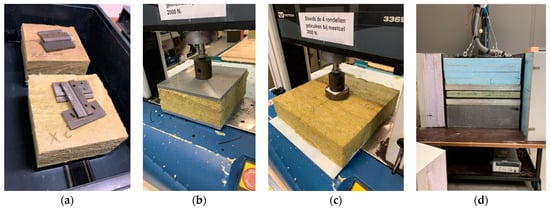

Before the various tests could be conducted, the test samples were first cut to the dimensions as specified in the corresponding test procedure. Subsequently, all test samples were conditioned and dried in the laboratory, after which the tests could be carried out (see Figure 3). To provide a comprehensive assessment of aging, for each case study, a maximum of three tests were conducted on both sides of the insulation board, depending on which parameter was to be tested.

Figure 3.

Pictures of material testing: short- and long-term water absorption (a), compressive stress at 10% deformation (b), point load at 5 mm deformation (c), and thermal conductivity with the heat flow meter method (d).

First, water absorption tests were performed in the Building Physics Laboratory of Ghent University to verify the hydrophobic behavior of SW insulation (see Figure 3a). For this purpose, test samples measuring 200 mm by 200 mm were cut and tested for short-term (24 h) and long-term (28 days) absorption. Subsequently, two mechanical performance tests were conducted at the Textile Science and Engineering Center laboratory (UGent—CTSE). These tests included compressive stress at 10% deformation (see Figure 3b) and point load at 5 mm deformation (see Figure 3c) on test samples measuring 200 mm by 200 mm and 300 mm by 300 mm. The thickness of each sample was measured during thermal conductivity testing performed by the Buildwise Test Centre (Limelette, Belgium), using test samples measuring 300 mm by 300 mm in a heat flow meter (see Figure 3d). These thermal conductivity tests were carried out in the frame of the international ‘Facilitating the circulation of reclaimed building elements in Northwestern Europe’ (FCRBE). Finally, an average density value was calculated based on weight and dimensions per sample. For each case, an average was taken from a minimum of 12 to a maximum of 23 test samples used in all material tests.

3. Results

To facilitate a comprehensive assessment of the reusability of SW insulation extracted from flat roofs, it is imperative to examine its condition after dismantling and its performance after a certain service life. These results will ultimately provide insights and considerations for the future reuse of this insulation material, described in the discussion section of this paper.

3.1. Damage Assessment

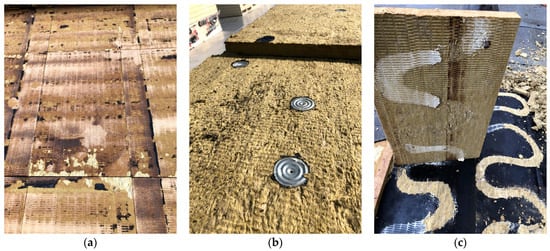

A visual analysis of SW insulation boards after dismantling reveals that damage was inevitable but remained limited, as the product generally remained intact. The predominant damage observed in each insulation board was at the top layer of the insulation. During the removal of the roofing, the bituminous connection to the underlying insulation was torn, partially or sometimes completely removing the top layer of the insulation (see Figure 4a). Additionally, other damage phenomena were visible after dismantling, such as penetrations in the boards due to mechanical fasteners (see Figure 4b). Occasionally, adhesive residues were left on the bottom side, top side, and edges of the insulation boards (see Figure 4c).

Figure 4.

Pictures from the visual damage analysis. (a) Damaged top layer of the SW insulation after the removal of the roofing; (b) perforations of the insulation boards caused by mechanical fasteners; (c) adhesive residues on the bottom side of the insulation board.

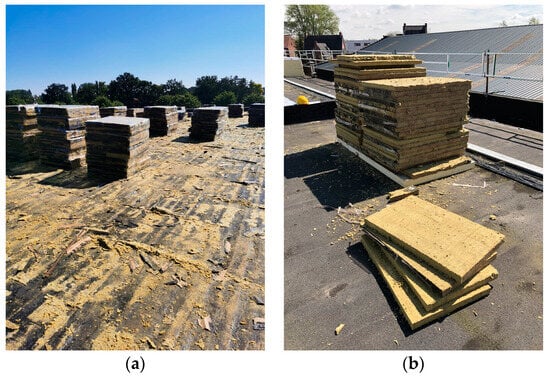

The dismantling process of SW insulation from the examined flat roofs revealed that mechanically fixed SW insulation on a steel deck roof structure was most effectively dismantled in practice. By contrast, SW insulation boards glued to a concrete roof structure suffered damage on the interior side. Nevertheless, the connection to the roofing unavoidably caused damage to the exterior side of the insulation board for every flat roof. Dismantling insulation from flat roofs remains a challenging task, as they are fully encapsulated, making them inseparable without causing damage to surrounding materials or the insulation itself. If the goal is to reuse mineral wool insulation from flat roofs in its entirety, dealing with the inevitable damage caused by detaching various connections during dismantling will always be necessary. Nonetheless, the key is to ensure that the SW remains intact as a rigid board, allowing for easy stacking, transportation, and reuse (see Figure 5).

Figure 5.

Examples of case studies in Flanders, Belgium, where mineral wool can be reused as a rigid board, stacked, and transported. (a) Stacked SW insulation boards after dismantling a flat roof; (b) stacked SW insulation on a construction site with the four samples gathered for this research in front.

3.2. Performance Assessment

3.2.1. Thickness

To assess the damage to the top layer of the insulation, the exact thickness of the insulation boards was measured during the thermal conductivity tests (EN 12667 [56]). This approach allowed for the observation of a specific reduction in thickness by calculating the difference of the original thickness of the SW insulation boards (see Table 2). The SW boards from case C1a were excluded from measurement, as they involved inclined SW insulation.

Table 2.

Overview thickness: original thickness (t0), measured thickness (t), thickness reduction (Δt = t0 − t).

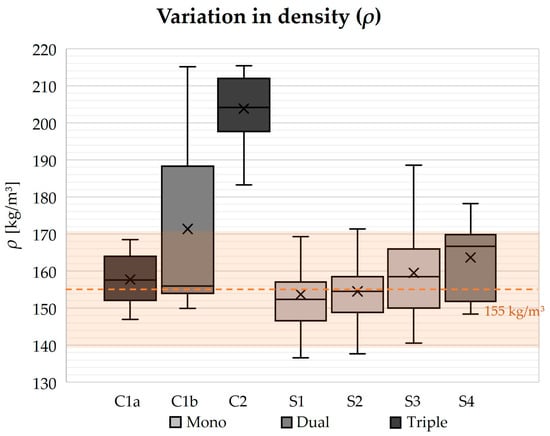

3.2.2. Density

The determination of the average density was based on an outdated test standard (NBN EN 1602 [57]). Despite its withdrawal in 2013 and its exclusion from current product standards, density measurements can still provide valuable information. On the one hand, density may contribute to obtaining deviating results or degradation phenomena after testing the performance of SW insulation. On the other hand, density serves as a reliable indicator for the potential application in which an SW product can be (re)used. In a 1994 technical approval for SW insulation used in warm flat roofs, a reference value of 155 kg/m3 +/− 10% for density was reported [49]. This value served as a reference for comparing the results of the measured densities (see Table 3 and Figure 6).

Table 3.

Overview densities: measured mean density (ρmean), difference with reported reference value 155 kg/m3 (Δρ) both in kg/m3 and in percentage. Values outside the range are indicated in red.

Figure 6.

Variation in the measured densities for every case study, with the indicated range of 155 kg/m3 +/− 10% in orange. Note that the y-axis does not start at zero. The number of density layers (Mono, Dual, or Triple Density) is distinguished by three different shades of gray.

Notably, the samples attached to a concrete structure (C1b and C2) exhibit a higher average density than the indicated range (see Table 3). When weighing the various test samples from C1b, a significant variation was observed (see Figure 6). This can be explained, on the one hand, by the thick layer of insulation on top (C1a), causing prolonged compression of the underlying layer (C1b), and on the other hand, by the ‘Dual Density’ technology used in this type of SW insulation board (C1b and S4) [46,50]. The high density of test sample C2 can be attributed to the ‘Triple Density’ technology, which is not manufactured anymore (C1a and C2) [47]. Since C2 involves a much thinner SW board (60 mm), the presence of these hardened density layers has a more pronounced effect than in the thicker sloping insulation board (110–140 mm) of C1a. All other SW boards are Mono density, and the measured density only deviates in a limited manner from the specified range (S1, S2, and S3).

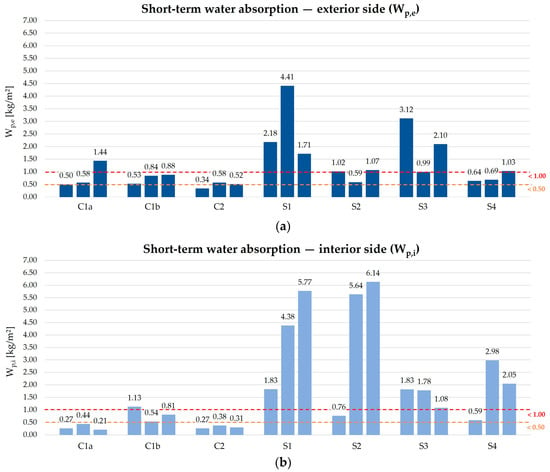

3.2.3. Short-Term Water Absorption (STWA)

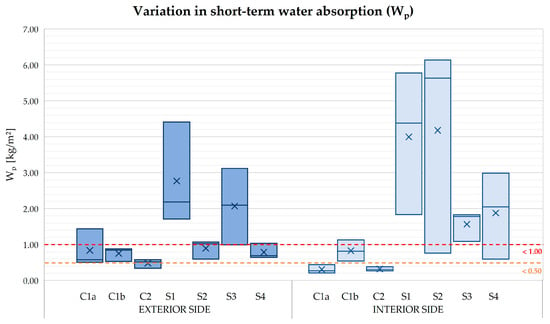

Research has indicated a potential decline in water repellency over time [39,40,41,42,43,44,45], which could impact the performance and reusability of mineral wool products. The graphs below (see Figure 7a,b) depict the results of STWA tests based on EN ISO 29767 [52]. The red line represents the maximum value imposed by the harmonized standard for the production of mineral wool insulation (EN 13162 + A1 [51]) for STWA, set at 1.00 kg/m2 [51]. The yellow line indicates the value specified in the current Technical Approval Guidelines (ATGs) for stone wool roof insulation products, namely 0.50 kg/m2 [46,47,48,49,50].

Figure 7.

STWA measured at the exterior (a) and interior side (b). The red line indicates the maximum value prescribed in the product standard (1.00 kg/m2), and the orange line indicates the maximum value found in the current ATGs (0.50 kg/m2).

Of all test results, 52% comply with the maximum value of 1.00 kg/m2, whereas 48% does not. More specifically, 38% of all the tested SW insulation boards comply regarding both sides—19% only on the exterior side, 10% only on the interior side, and 33% on neither side. Compared with the current ATGs, only 19% meet the reference value of 0.50 kg/m2.

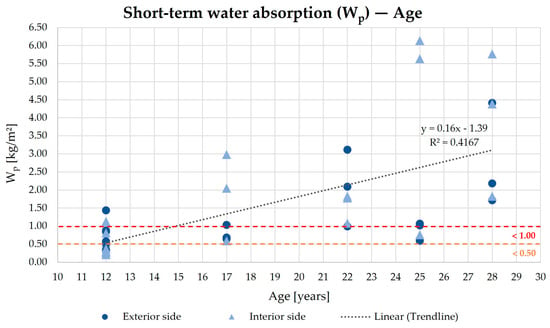

The scatter plot below (see Figure 8) provides a clear illustration of increasing STWA values with insulation age, confirming the loss of water repellency in SW insulation as it ages during its lifetime in the construction of a flat roof. Additionally, there is a difference between the test samples from a concrete roof deck with vapor barrier (C1a, C1b, and C2) and those with a steel deck roof structure without a vapor barrier (S1, S2, S3, and S4). Despite a significant age difference between these two groups, the steel deck group performs notably worse than the concrete roof deck group. More specifically, a significant variation is observed in the results of SW insulation on the steel deck structure. For example, the value on the interior side at 25 years old is higher than in other ages. This phenomenon is further described in the following paragraph and explored in more detail in Section 3.2.4.

Figure 8.

STWA with the increasing age of SW insulation. The red line indicates the maximum value prescribed in the product standard (1.00 kg/m2), and the orange line the maximum value found in the current ATGs (0.50 kg/m2). The linear trendline is based on the results obtained from both the interior and exterior sides.

To further examine the difference between the interior and exterior side in more detail, it is relevant to highlight the variation between the results (see Figure 9). This reveals that the variation in the steel deck group is more pronounced than in the concrete roof deck group. Specifically, there is more variation in the results of the interior side. Therefore, the next section will explore potential causes for this variation (see Section 3.2.4).

Figure 9.

Variation in the STWA on the exterior and interior side. The three horizontal lines indicate the results of the STWA tests, and the cross in the center of each bar represents the mean value. The red line indicates the maximum value prescribed in the product standard (1.00 kg/m2), and the orange line indicates the maximum value found in the current ATGs (0.50 kg/m2).

3.2.4. Water Absorption Patterns with SW on a Steel Deck Flat Roof Structure

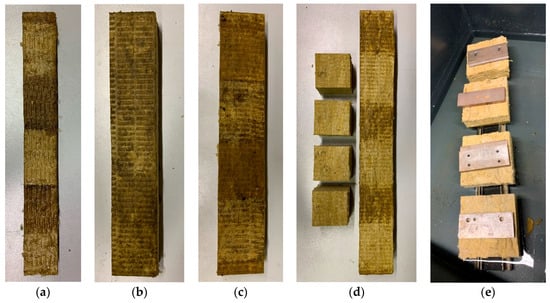

After conducting the STWA test, the test samples were left to dry, and a visual inspection was conducted. In all SW insulation boards originating from roofs with a steel deck structure, a distinct pattern was noticeable after moistening the interior side (see Figure 10a–d). These patterns could potentially be attributed to the profiling of the steel deck on the interior side of the insulation. This might also be the cause of the significant variation in water absorption on the interior side of the SW insulation fixed to a steel deck structure without a vapor barrier. To confirm this hypothesis, additional tests were conducted (see Figure 10d,e).

Figure 10.

Pictures of the water absorption pattern visible at the interior side of case S1 (a), S2 (b), S3 (c), and S4 (d) where additional tests specimens were cut out (d) and tested (e).

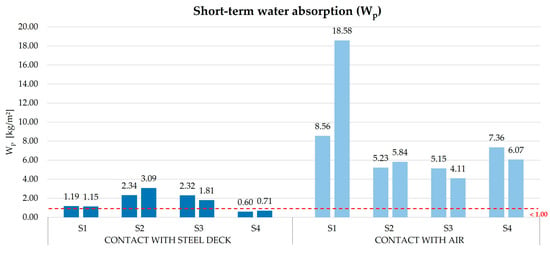

Firstly, two adjacent strips of at least 10 cm were cut from an SW insulation board. By immersing the interior side of one of these two strips in water for a few minutes, the pattern of the steel deck profiling became visible (see Figure 10a–d). Since the visible patterns were not wider than 200 mm, four test samples of 100 mm by 100 mm were cut per strip (see Figure 10d). Two of these came into contact with the steel deck, and the other two came into contact with the air between the steel deck profiling. Subsequently, STWA tests were conducted (see Figure 10e), and the water absorption coefficient was calculated as described in EN ISO 29767 [52]. The results presented below reveal a significant difference (see Figure 11). The average result of the test samples in contact with the steel deck is 1.65 kg/m2, while that of the test samples in contact with the air is 7.61 kg/m2—a remarkable 4.6 times higher, thereby confirming the hypothesis.

Figure 11.

Water absorption coefficients of the interior side of the SW insulation attached to a steel deck structure. A distinction was made between the area that was in contact with the steel deck and that in contact with the air. The red line indicates the maximum value of 1.00 kg/m2 imposed by the product standard.

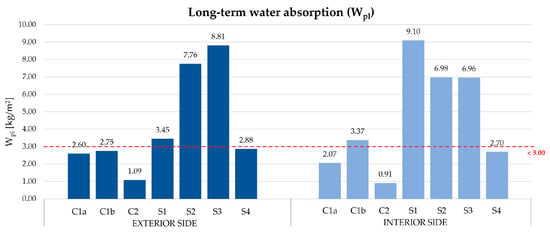

3.2.5. Long-Term Water Absorption (LTWA)

The product standard for mineral wool insulation (EN 13162 + A1 [51]) also comprises a LTWA test. The long-term test is identical to the short-term test, except it spans 28 days instead of 24 h (EN 12087 [53]). In this research, two test samples were examined for every case, one on the interior side and one on the exterior side. The results are reported in the chart below (see Figure 12), where the red line serves as a reference for the maximum value of 3.00 kg/m2 imposed by the product standard (EN 13162 + A1 [51]).

Figure 12.

LTWA test, both on the exterior and interior side. The red line indicates the maximum value of 3.00 kg/m2, as prescribed by the product standard.

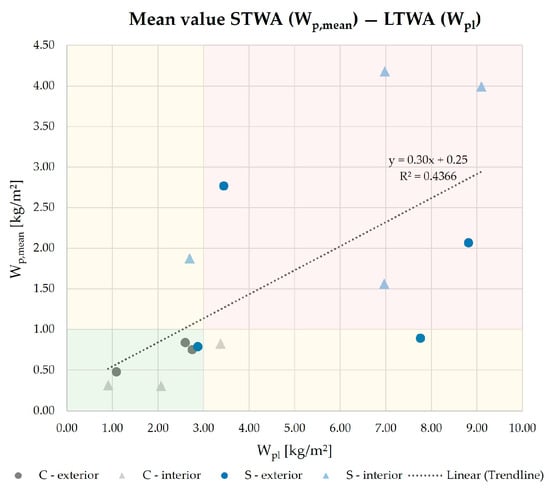

At first glance, similar findings emerge as with the short-term test, where half of the test samples do not meet the prescribed standard. This degradation is mainly found in older SW insulation on the steel deck roof structure. To explore this more precisely, the LTWA was compared with the average value of STWA (see Figure 13). Here, 43% meets both criteria (green zone), 21% only meets one of the criteria (yellow zone), and 36% meets none of the criteria (red zone).

Figure 13.

Mean value of the three results of the short-term water absorption test related to the result of the long-term water absorption test per case study. The green zone indicates the area where both criteria (1.00 and 3.00 kg/m2) are met, the yellow zones indicate where only one of the criteria are met, and the red zone indicates where none of the criteria are met.

An ascending regression line can be observed in the graph, suggesting a correlation between both. Furthermore, the slope of the linear regression line is 0.30, which is nearly equal to the ratio of the two maximum values prescribed in the product standard (NBN EN 13162 + A1 [51]):

3.2.6. Compressive Stress at 10% Deformation

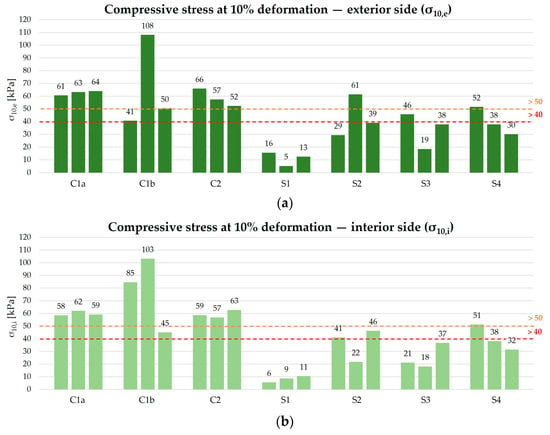

An essential requirement for a flat roof is its walkability for potential maintenance or even prolonged loads (e.g., HVAC or solar panels). To meet this requirement, mineral wool insulation in flat roofs must comply with specific mechanical performance criteria, including compressive stress at 10% deformation (NBN EN ISO 29469 [54]). The results of this test are illustrated below (see Figure 14), indicating two threshold values. Currently, the Belgian Union for Technical Approval in Construction (UBAtc) imposes a minimum value of 40 kPa for mineral wool insulation in flat roofs accessible only for pedestrians for roof maintenance (P2) [58]. On the other hand, in older ATGs, a minimum value of 50 kPa had been stipulated at the time of production [46,47,48,49,50].

Figure 14.

Compressive stress at 10% deformation tested on the exterior (a) and interior side (b). The red line indicates the minimum value prescribed in the UBAtc classification (40 kPa), and the orange line indicates the minimum value found in old ATGs (50 kPa).

Of all the test results, 57% meet the current minimum standard of 40 kPa, and 45% meet the minimum of 50 kPa. Furthermore, there is again a significant difference between the two groups related to different roof structures. Of all the test samples fixed to a concrete structure, 100% meet the minimum of 40 kPa, and 89% meet the minimum of 50 kPa, whereas for the test samples from a steel deck roof structure, these percentages are 25% and 13%, respectively.

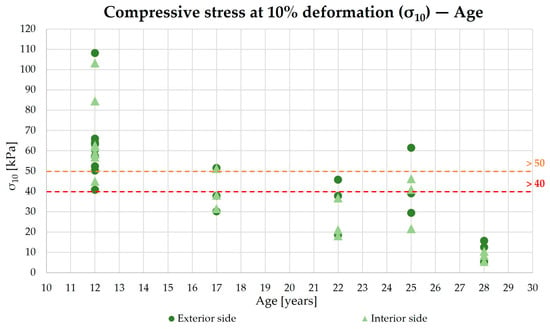

To assess the possible degradation of this mechanical performance, compressibility was plotted as a function of the age of the SW insulation (see Figure 15). Some degradation can be observed as the SW insulation ages. The main reason for this degradation lies in the prolonged loads in the original flat roof application. For example, in case studies S2, S3, and S4, solar panels were installed on these flat roofs. Not only their weight but also the wind loads that these solar panels absorbed could have caused continuous compressive or tensile stress on the existing SW insulation. Moreover, degradation can also be attributed to the age of the insulation. This is not only due to material relaxation but also due to the older production technology of these aged SW insulation boards.

Figure 15.

Compressive stress at 10% deformation with the increasing age of SW insulation. The red line indicates the minimum value prescribed in the UBAtc classification (40 kPa), and the orange line indicates the minimum value found in old ATGs (50 kPa).

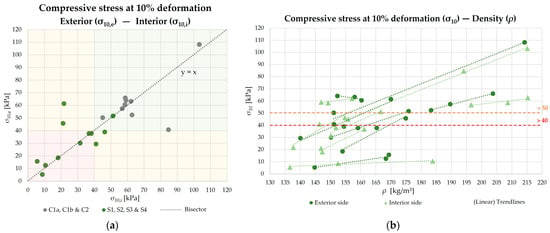

To assess the disparity in compressibility between the exterior and interior sides, their correlation is illustrated in the scatter plot (see Figure 16a). The bisector (y = x) was included to examine whether the values from this test exhibited any discernible relationship. With the exception of a few outliers, it is evident that the data points in this scatter plot cluster around this linear trend. This suggests that the compressive stress at 10% deformation, as tested on the exterior side, is directly proportional to that on the interior side, indicating consistent mechanical performance on both sides.

Figure 16.

Compressive stress at 10% deformation on both sides (a). Here, the green zone indicates the area where the minimum criteria of UBAtc (40 kPa) is met on both sides, the yellow zones indicate the area where it is met only on one side, and the red zone indicates where it is met on neither side. Compressive stress at 10% deformation in function of the density (b). Here, the red line indicates the minimum value prescribed in the UBAtc classification (40 kPa), and the orange line indicates the minimum value found in old ATGs (50 kPa).

Finally, each outcome of the compression test was plotted against the corresponding density of the respective test sample (see Figure 16b). A linear trendline was applied based on the three results per tested side of each case to discern a correlation between these two properties. It can be inferred that these three points consistently align closely with the trendline, indicating a direct proportional relationship. The higher the density of SW insulation, the greater the compressive stress at 10% deformation.

3.2.7. Point Load at 5 mm Deformation

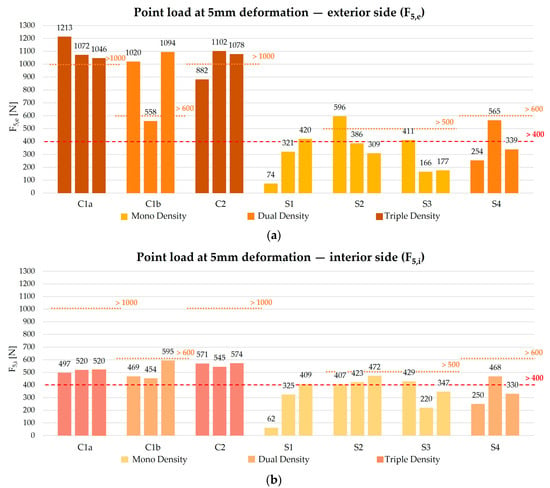

Another crucial mechanical performance specified in the product standard and vital for insulation in flat roofs is the point load at 5 mm deformation, commonly known as puncture resistance. To assess this, pressure tests were conducted following the corresponding standard (NBN EN 12430 [55]), and the outcomes are depicted in the bar charts below (see Figure 17). Here, the UBAtc imposes a minimum requirement of 400 N [58]. However, the minimum values from old ATGs vary significantly based on the type of SW insulation board. For ‘Triple density’, it is 1000 N [48]; for ‘Dual density’, it is 600 N [46,47]; and for ‘Mono density’, it is 500 N [50]. Only for the oldest insulation boards (S1) was no exact reference value found in the corresponding ATG; therefore, comparisons were made with the minimum of 400 N.

Figure 17.

Point load at 5 mm deformation tested on the exterior (a) and interior side (b). The red line indicates the minimum value prescribed in the UBAtc classification (400 N), and the orange lines indicate the minimum value found in old ATGs (500, 600, and 1000 N). The number of density layers (Mono, Dual, or Triple Density) is distinguished by three different colors.

Among all test results, 67% meet the current minimum standard of 400 N, and merely 24% meet the respective minimum prescribed in the old ATGs. Interestingly, none of the tests on the interior side meet the minimum value set in the old ATGs. The minimum limit established in the old ATGs was based on tests conducted on the exterior side of these insulation products, evidently resulting in a lower puncture resistance when tested on the interior side. This trend will be consistently observed in all subsequent graphs.

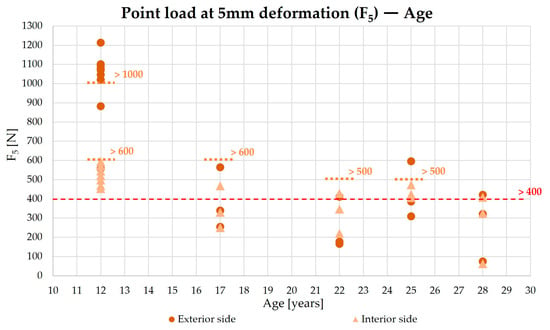

To assess the influence of aging on puncture resistance, the results are plotted as a function of the age of the SW insulation (see Figure 18). Given the differing minimum limits imposed in the old ATGs, it is logical that a declining trendline can be observed. Nevertheless, it can be inferred that puncture resistance somewhat degrades over time. This is primarily attributed to the aged and damaged top layer, reducing resistance to local indentation. Additionally, exposure to local loads from, e.g., maintenance, technical installations, and solar panels may also play a significant role. Moreover, these loads will have a less pronounced effect on SW insulation attached to a concrete roof deck than on a steel deck roof deck since the load distribution on the insulation is less favorable in a steel deck profile due to partial cantilevering.

Figure 18.

Point load at 5 mm deformation with the increasing age of SW insulation. The red line indicates the minimum value prescribed in the UBAtc classification (400 N), and the orange lines indicate the minimum value found in old ATGs (500, 600, and 1000 N).

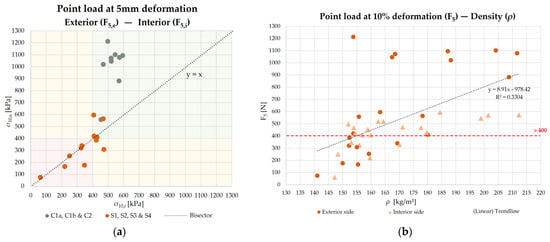

To illustrate the difference in puncture resistance tested on both sides of the insulation boards, both values are presented in relation to each other (see Figure 19a). Once again, a bisector (y = x) was drawn to assess whether puncture resistance on both sides was directly proportional. In the results of case studies with a steel roof deck (S1-4), the points lie approximately on this line, explained by the fact that these insulation boards consist of one, or at most two, density layers without an additional hardened top layer. For the test samples installed to a concrete roof deck (C1a, C1b and C2), however, there was a significant difference between the exterior and interior sides, as these SW boards had a hard top layer that was hardly damaged in the dismantling process.

Figure 19.

Point load at 5 mm deformation on both sides (a). Here, the green zone indicates the area where the minimum criteria of UBAtc (400 N) is met on both sides, the yellow zones indicate the area where it is met only on one side, and the red zone indicates where it is met on neither side. Point load at 5 mm deformation in function of the density (b). Here, the red line indicates the minimum value prescribed in the UBAtc classification (400 N).

Finally, the correlation with density was analyzed (see Figure 19b). Again, it can be deduced that there was a significant difference in puncture resistance tested on the exterior side of the SW boards attached to a concrete roof deck compared to the rest of the results. Subsequently, an increasing trend is observed in this graph based on the regression line. Higher density entails a higher puncture resistance, but this strongly depends on the number of density layers present in the SW insulation boards.

3.2.8. Thermal Conductivity

Mineral wool is known for its excellent thermal stability, and to assess the reusability of collected SW insulation, tests on its thermal performance are indispensable. Thermal conductivity measurements, conducted using the heat flow meter method, are outlined in the standard NBN EN 12667. The results are presented in the table below (see Table 4), including all measured values, both exclusive and inclusive of the maximum measured error prescribed in the heat flow meter test setup used (+2%). These values were then compared with the declared lambda value for SW insulation in flat roofs, set at 0.040 W/m.K, as found in all old ATGs [46,47,48,49,50]. The SW boards from case C1a were excluded from measurement, as they involved inclined SW insulation.

Table 4.

Overview of the thermal conductivity for every case: declared lambda value (ld), measured lambda value (lm), measured lambda value including the maximum measured error (lm+2%), and percentage of the lambda value difference (Δl = (lm − ld) * 100/ld). If the measured value is lower than the declared value, then the lambda value difference will be negative and indicated in green.

It can be observed that none of the measured lambda values exceed the declared value of 0.040 W/m.K, even when the maximum measured error is included. This indicates no noticeable degradation in thermal performances for SW insulation up to 28 years old. Furthermore, the thermal conductivity of old SW insulation is significantly lower than the value of 0.050 W/m.K stipulated by Flemish EPBD regulations in the absence of specific values [59]. Therefore, thermal conductivity tests on old insulation products prevent unnecessarily oversized reused insulation in the thermal envelope.

4. Discussion

From the case studies, it can be confirmed that damage to dismantled SW insulation boards from flat roofs is inevitable, especially at the top layer of the insulation. When removing the roofing, the bituminous connection with the underlying insulation was torn, consistently either partially or entirely removing the top layer of the insulation. Additionally, other damage phenomena were observed after dismantling the insulation, such as perforations through the boards caused by mechanical fasteners and residual adhesives on the upper and lateral sides of the insulation boards. Nevertheless, these boards can still be dismantled as intact rigid panels, allowing for their reuse. Therefore, the overarching objective should be, in a circular future, to design insulation materials in flat roof constructions that allow for easy dismantling. Simultaneously, efforts should be made to explore methods for the careful dismantling of existing insulation materials in pursuit of a more sustainable approach.

During the performance assessment, the first notable finding was the minimal shift in the thickness and density of aged SW insulation. The notably high values in these density measurements are primarily attributed to the number of density layers in the specific type of stone wool insulation (Triple Density) and potential deviations during production or built-in effects, as also hypothesized in other research [45]. Despite a reduction in panel thickness by 1 to 6 mm during dismantling, mainly due to top layer removal, the density remained nearly constant. This stability can have positive implications for both mechanical and thermal performances, given their dependency on density. Additionally, density will play a crucial role in potential reuse applications, as SW boards for flat roofs, along with those for floating screeds in floors, have the highest densities compared to SW for other applications such as pitched roofs, walls, intermediate floors, etc.

The investigation into short- and long-term water absorption reveals diverse outcomes linked to various factors, with aging playing a pivotal role. Older SW insulation exhibits decreased water repellency over time, possibly due to prolonged exposure to moisture during its lifespan in roof structures. Moreover, significant differences were found between water absorption on the interior and exterior sides. The presence of a vapor barrier and the specific structure to which the SW insulation is attached are determining factors. This research demonstrates that SW insulation attached to a steel deck substrate displays a remarkable degradation pattern in water absorption. Areas where the insulation was exposed to air between the steel deck profiling had an absorption 4,6 times higher than the zones directly on the steel deck profiling. The absence of a vapor barrier or the corrosion-resistant treatment of the steel deck could, hypothetically, be potential causes. The exact reason as to why the hydrophobic behavior of SW insulation decreases as it ages can be linked to existing research [39,40,41,42,43,44,45]. During the production process of SW insulation, a specific mineral oil or resin is added to the SW fibers to create a water-repellent layer. If SW boards are left uncovered without foil and exposed to the outdoor environment for an extended period of time, the oil may be washed out through prolonged exposure to moisture. This decline in water repellency in aged SW insulation significantly influences its reuse, necessitating careful consideration of potential increased moisture uptake in new applications. Furthermore, the degradation phenomena observed in long-term water absorption align with those in short-term water absorption, implying the short-term test accurately assesses water repellency. Consequently, potentially reusable SW insulation may only need a short-term test, enhancing efficiency in practical implementation.

The mechanical performance of aged SW insulation from flat roofs is contingent on various factors. Compressibility degradation is primarily attributed to the age of the insulation, and the loads it bears over its lifespan have a significant impact in particular. A lower resin content in old SW insulation due to older production technologies and material relaxation can lead to a loss of mechanical performance [45]. Additionally, the type of roof structure is relevant, especially for SW insulation boards fixed to a steel deck structure, as these are partially in a cantilever formation due to the profiling. Density is another crucial factor, with an increasing compressive stress at 10% deformation as insulation density rises. Furthermore, this study demonstrates that compressibility remains consistent when tested on both sides of the insulation board. This implies that, when considering the reusability of old SW insulation from flat roofs, placing the insulation board upside down in a new construction project may be feasible without any loss of compressibility. Puncture resistance, on the other hand, is primarily dependent on the type of SW insulation board, specifically the presence of different density layers and, more importantly, the additional hard top layer that may or may not be damaged. Additionally, there is some degradation observable, possibly caused by exposure to local loads throughout the first life cycle. If puncture resistance is a crucial aspect in the new application for these insulation boards, consideration must be given to the type of SW insulation, the degradation along the exterior side, and the lower puncture resistance along the interior side. Therefore, considering additional tests for mechanical performances will always be crucial for potential reuse applications.

In terms of thermal performance, it is encouraging to observe that the thermal conductivity of old SW insulation does not degrade after a maximum of 28 years, as confirmed in existing research [39,40,41,42,43,44]. This not only underscores the durability and potential reuse value of aged SW insulation in flat roofs but also emphasizes the importance of thermal performance assessments. It provides assurance regarding the thermal performance of recovered insulation in new projects, and it minimizes the oversizing of reused insulation in the thermal envelope, contributing to more efficient material usage.

5. Conclusions

To promote a more sustainable construction sector, it is imperative to ensure that building materials, such as SW insulation, do not end up in landfills or incinerators after a single life cycle. Therefore, this research focuses on the most ambitious option to avoid such disposal—the potential reuse of SW insulation from flat roofs. Since old SW insulation remains mainly intact as a panel after dismantling, reusing it is a viable option. Performance assessments reveal that after 28 years, old SW insulation from flat roofs maintains its density and its thermal conductivity. Consequently, if old SW insulation from flat roofs stays dry after dismantling, it still exhibits the same thermal performance as new SW insulation. However, these SW insulation panels can absorb more water as they age, with 48% of all samples tested in the short term failing to meet today’s standards. This degradation may be caused by the hydrophobic substance applied to SW fibers during production breaking down over time. Additionally, mechanical performance depends on various factors (age, density, type, loads during the lifespan, and post-dismantling damage), with 43% and 33%, respectively, of all compression and puncture resistance tests not meeting current minimum standards. Therefore, to repurpose old SW insulation, creative thinking is required to explore new reuse applications where this degradation has minimal to no impact on its functionality.

It is crucial to acknowledge certain limitations in this study, as certain pivotal performance aspects, such as reaction to fire and the presence of hazardous substances, remained beyond the scope of this investigation. Additionally, this research only concentrated on a limited number of case studies, specifically addressing SW insulation in flat roofs. To comprehensively assess the durability of insulation materials on a larger scale, future studies should generate more test results of other relevant properties and for various insulation materials (PUR, PIR, XPS, EPS, glass wool, etc.) in different applications (walls, floors, pitched roofs, etc.). This approach can unveil new degradation phenomena, not only shedding light on reusability but also contributing to the sustainability of existing production processes. Several steps must be explored to effectively deploy reused insulation materials in practice. This includes the development of more efficient dismantling tools and streamlined accessible testing methods to facilitate the practical performance measurement of reused insulation. Once these performances are known, the exploration of all possible reuse applications can ensue, providing a sustainable second life for old insulation materials in buildings. However, this also implies the need to explore alternatives when insulation materials are no longer reusable as whole panels. Developing new recycling processes is, therefore, equally crucial, as this can exclude raw materials from the production process to lower its environmental impact.

Author Contributions

Conceptualization, G.A.; methodology, G.A.; validation, G.A.; formal analysis, G.A.; investigation, G.A.; resources, G.A.; data curation, G.A.; writing—original draft preparation, G.A., M.S. and N.V.D.B.; writing—review and editing, G.A.; visualization, G.A.; supervision, M.S. and N.V.D.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data supporting the results reported can be requested through the email address of the first author.

Acknowledgments

We extend our gratitude to the companies and contractors who collaborated in collecting case studies and gathering old stone wool insulation boards. Additionally, we acknowledge the efforts of the staff at all testing facilities for their support in performance assessments (UGent, CTSE and Buidwise). Lastly, we offer special recognition to the stone wool manufacturer involved for providing the essential information for this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lederer, J.; Gassner, A.; Keringer, F.; Mollay, U.; Schremmer, C.; Fellner, J. Material Flows and Stocks in the Urban Building Sector: A Case Study from Vienna for the Years 1990–2015. Sustainability 2019, 12, 300. [Google Scholar] [CrossRef]

- Hoxha, D.; Ismail, B.; Rotaru, A.; Izabel, D.; Renaux, T. Assessment of the Usability of Some Bio-Based Insulation Materials in Double-Skin Steel Envelopes. Sustainability 2022, 14, 10797. [Google Scholar] [CrossRef]

- Zoure, A.N.; Genovese, P.V. Comparative Study of the Impact of Bio-Sourced and Recycled Insulation Materials on Energy Efficiency in Office Buildings in Burkina Faso. Sustainability 2023, 15, 1466. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered Mycelium Composite Construction Materials from Fungal Biorefineries: A Critical Review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Bakatovich, A.; Gaspar, F.; Boltrushevich, N. Thermal Insulation Material Based on Reed and Straw Fibres Bonded with Sodium Silicate and Rosin. Constr. Build. Mater. 2022, 352, 129055. [Google Scholar] [CrossRef]

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Upcycling Wheat and Barley Straws into Sustainable Thermal Insulation: Assessment and Treatment for Durability. Resour. Conserv. Recycl. 2023, 198, 107161. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of Municipal, Agricultural, Industrial, Construction and Demolition Waste in Thermal and Sound Building Insulation Materials: A Review Article. J. Env. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef] [PubMed]

- Cetiner, I.; Shea, A.D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile Waste as an Alternative Thermal Insulation Building Material Solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Malet-Damour, B.; Habas, J.-P.; Bigot, D. Is Loose-Fill Plastic Waste an Opportunity for Thermal Insulation in Cold and Humid Tropical Climates? Sustainability 2023, 15, 9483. [Google Scholar] [CrossRef]

- Benkreira, H.; Khan, A.; Horoshenkov, K.V. Sustainable Acoustic and Thermal Insulation Materials from Elastomeric Waste Residues. Chem. Eng. Sci. 2011, 66, 4157–4171. [Google Scholar] [CrossRef]

- Duong, H.M.; Ling, N.R.B.; Thai, Q.B.; Le, D.K.; Nguyen, P.T.T.; Goh, X.Y.; Phan-Thien, N. A Novel Aerogel from Thermal Power Plant Waste for Thermal and Acoustic Insulation Applications. Waste Manag. 2021, 124, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Debacker, W.; Vrijders, J.; Voorter, J.; Vergauwen, A.; Bergmans, J.; Stouthuysen, P.; OVAM. Urban Mining van Gebouwen; Vlaanderen Circulair: Mechelen, Belgium, 2021; Available online: https://vlaanderen-circulair.be/src/Frontend/Files/userfiles/files/FINAL%20Eindrapport%20Deelopdracht%201_versie%2020210329_hoge%20resolutie.pdf (accessed on 16 October 2023).

- Füchsl, S.; Rheude, F.; Röder, H. Life Cycle Assessment (LCA) of Thermal Insulation Materials: A Critical Review. Clean. Mater. 2022, 5, 100119. [Google Scholar] [CrossRef]

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A Framework for Sustainable and Circular System Design: Development and Application on Thermal Insulation Materials. Resour. Conserv. Recycl. 2020, 154, 104631. [Google Scholar] [CrossRef]

- Eurima: How is Mineral Wool Insulation Made? Available online: https://www.eurima.org/how-is-mineral-wool-insulation-made (accessed on 19 December 2023).

- NIBE. Milieuclassificaties. Available online: https://www.nibe.info/nl (accessed on 19 December 2023).

- Milieubewust Isoleren. Platdak Isolatie—Massiefbouw. Available online: https://www.milieubewustisoleren.be/milieu-impact/platdak-isolatie-massiefbouw (accessed on 19 December 2023).

- De La Hera, G.; Muñoz-Díaz, I.; Cifrian, E.; Vitorica, R.; Gutierrez San Martin, O.; Viguri, J.R. Comparative Environmental Life Cycle Analysis of Stone Wool Production Using Traditional and Alternative Materials. Waste Biomass Valor. 2017, 8, 1505–1520. [Google Scholar] [CrossRef]

- Giama, E.; Mamaloukakis, M.; Papadopoulos, A.M. Circularity in Production Process as a Tool to Reduce Energy, Environmental Impacts and Operational Cost: The Case of Insulation Materials. In 2019 4th International Conference on Smart and Sustainable Technologies (SpliTech); IEEE: Split, Croatia, 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Kubiliute, R.; Kaminskas, R.; Kazlauskaite, A. Mineral Wool Production Waste as an Additive for Portland Cement. Cem. Concr. Compos. 2018, 88, 130–138. [Google Scholar] [CrossRef]

- Straub, A.; van Nunen, H.; Janssen, R.; Liebregts, M.A.A.M. Levensduur van Bouwproducten: Methode voor Referentiewaarden; Stichting Bouwresearch: Rotterdam, The Netherlands, 2011. [Google Scholar]

- Väntsi, O.; Kärki, T. Mineral Wool Waste in Europe: A Review of Mineral Wool Waste Quantity, Quality, and Current Recycling Methods. Mater. Cycles Waste Manag. 2014, 16, 62–72. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017; Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 19 December 2023).

- Coelho, A.; De Brito, J. Influence of Construction and Demolition Waste Management on the Environmental Impact of Buildings. Waste Manag. 2012, 32, 532–541. [Google Scholar] [CrossRef]

- Superti, V.; Forman, T.V.; Houmani, C. Recycling Thermal Insulation Materials: A Case Study on More Circular Management of Expanded Polystyrene and Stonewool in Switzerland and Research Agenda. Resources 2021, 10, 104. [Google Scholar] [CrossRef]

- Piña Ramírez, C.; Del Río Merino, M.; Viñas Arrebola, C.; Vidales Barriguete, A.; Kosior-Kazberuk, M. Analysis of the Mechanical Behaviour of the Cement Mortars with Additives of Mineral Wool Fibres from Recycling of CDW. Constr. Build. Mater. 2019, 210, 56–62. [Google Scholar] [CrossRef]

- Piña Ramírez, C.; Atanes Sánchez, E.; Del Río Merino, M.; Viñas Arrebola, C.; Vidales Barriguete, A. Feasibility of the Use of Mineral Wool Fibres Recovered from CDW for the Reinforcement of Conglomerates by Study of Their Porosity. Constr. Build. Mater. 2018, 191, 460–468. [Google Scholar] [CrossRef]

- Väntsi, O.; Kärki, T. Utilization of Recycled Mineral Wool as Filler in Wood–Polypropylene Composites. Constr. Build. Mater. 2014, 55, 220–226. [Google Scholar] [CrossRef]

- Ji, R.; Zheng, Y.; Zou, Z.; Chen, Z.; Wei, S.; Jin, X.; Zhang, M. Utilization of Mineral Wool Waste and Waste Glass for Synthesis of Foam Glass at Low Temperature. Constr. Build. Mater. 2019, 215, 623–632. [Google Scholar] [CrossRef]

- Pontinha, A.D.R.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings’ Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241. [Google Scholar] [CrossRef] [PubMed]

- Landolfi, R.; Nicolella, M. Durability Assessment of ETICS: Comparative Evaluation of Different Insulating Materials. Sustainability 2022, 14, 980. [Google Scholar] [CrossRef]

- Belayachi, N.; Hoxha, D.; Slaimia, M. Impact of Accelerated Climatic Aging on the Behavior of Gypsum Plaster-Straw Material for Building Thermal Insulation. Constr. Build. Mater. 2016, 125, 912–918. [Google Scholar] [CrossRef]

- Bomberg, M.T.; Kumaran, M.K. Progress Report on Long-Term Thermal Performance of Polyisocyanurate Boardstock Materials; National Research Council of Canada: Ottawa, ON, Canada, 1991; p. 28. [Google Scholar] [CrossRef]

- Montanari, G.C.; Mazzanti, G. Ageing of Polymeric Insulating Materials and Insulation System Design. Polym. Int. 2002, 51, 1151–1158. [Google Scholar] [CrossRef]

- Murphy, J. Long-Term Aging of Closed-Celled Foam Insulation. Cell. Polym. 2010, 29, 313–326. [Google Scholar] [CrossRef]

- Berardi, U. The Impact of Aging and Environmental Conditions on the Effective Thermal Conductivity of Several Foam Materials. Energy 2019, 182, 777–794. [Google Scholar] [CrossRef]

- Wilkes, K.E.; Yarbrough, D.W.; Gabbard, W.A.; Nelson, G.E.; Booth, J.R. Aging of Polyurethane Foam Insulation in Simulated Refrigerator Panels–Three-Year Results with Third-Generation Blowing Agents. J. Cell. Plast. 2002, 38, 317–339. [Google Scholar] [CrossRef]

- Langmans, J.; Roels, S. Durability Assessment of Mineral Wool Insulation: What Are the Thermal Properties after 20 Years? 2017. In Proceedings of the 14th International Conference on Durability of Building Materials and Components, Ghent, Belgium, 29–31 May 2017. [Google Scholar]

- The Durability of Mineral Wool Products. 2016. Available online: https://www.eurima.org/uploads/files/modules/articles/1669726579_2017-02-21%20Eurima%20Position%20Paper_Durability%20MW_Nov%202016.pdf (accessed on 16 October 2023).

- E3.3-2016/01; Durability Project Mineral Wool. FIW München: Gräfelfing, Germany, 2016; p. 49. Available online: https://fivra.it/images/documenti/approfondimenti/durabilita-lane/2016-04-27%20FIW%20-%20E3%203-2016_01%20EURIMA%20Brussels%20-%20Durability%20Project%20Miner....pdf (accessed on 16 October 2023).

- Stazi, F.; Di Perna, C.; Munafò, P. Durability of 20-Year-Old External Insulation and Assessment of Various Types of Retrofitting to Meet New Energy Regulations. Energy Build. 2009, 41, 721–731. [Google Scholar] [CrossRef]

- Stazi, F.; Tittarelli, F.; Politi, G.; Di Perna, C.; Munafò, P. Assessment of the Actual Hygrothermal Performance of Glass Mineral Wool Insulation Applied 25 Years Ago in Masonry Cavity Walls. Energy Build. 2014, 68, 292–304. [Google Scholar] [CrossRef]

- Tittarelli, F.; Stazi, F.; Politi, G.; di Perna, C.; Munafò, P. Degradation of Glass Mineral Wool Insulation after 25 Years in Masonry Cavity Walls. In Proceedings of the International Journal Conference on Humanities, Bio-Science, Chemical and Environmental Engineering (HBCEE’2014), Dubai, United Arab Emirates, 6–7 January 2014; pp. 9–13. [Google Scholar]

- Nagy, B.; Simon, T.K.; Nemes, R. Effect of Built-in Mineral Wool Insulations Durability on Its Thermal and Mechanical Performance. Therm. Anal. Calorim. 2020, 139, 169–181. [Google Scholar] [CrossRef]

- ATG 11/2413; Technische Goedkeuring ATG met Certificatie: Isolatiesysteem voor Warm Dak Taurox DUO NP, Taurox DUO NP Bitufilm, Taurox DUO Bitumen. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2011.

- ATG 04/2413; Technische Goedkeuring met Certificatie: Isolatiesysteem voor Warm Dak Taurox DUO NP, Taurox DUO NP Bitufilm, Taurox DUO Bitumen. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2004.

- ATG 11/2601; Technische Goedkeuring ATG met Certificatie: Isolatiesysteem voor Warm Dak Rhinox, Rhinox Film, Rhinox Afschot en Rhinox Afschot Film. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2011.

- ATG 94/1685; Technische Goedkeuring met Certificaat: Isolatiesysteem voor Warm Dak Rockwool Serie 340 Type 341, 345, 348 en 349. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 1994.

- ATG 03/H577-2; Productgoedkeuring met Certificatie: Minerale Wol—Rotswol (MW). BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2003.

- EN 13162+A1; Thermal Insulation Products for Buildings–Factory Made Mineral Wool (MW) Products. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2015.

- EN ISO 29767; Thermal Insulating Products for Building Applications—Determination of Short-Term Water Absorption by Partial Immersion. International Organization for Standardization: Geneva, Switzerland, 2019.

- EN 12087; Thermal Insulating Products for Building Applications—Determination of Long Term Water Absorption by Immersion. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2013.

- EN ISO 29469; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. International Organization for Standardization: Geneva, Switzerland, 2022.

- Thermal Insulating Products for Building Applications—Determination of Behaviour under Point Load. EN 12430. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2013.

- EN 12667; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. British Standard: London, UK, 2001.

- EN 1602; Thermal Insulating Products for Building Applications—Determination of the Apparent Density. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2013.

- Noirfalisse, E. Het Platte Dak; Technische Voorlichting 280; Buildwise: Ottignies-Louvain-la-Neuve, Belgium, 2022; p. 160. [Google Scholar]

- Transmissie Referentie Document. 2018. Available online: https://assets.vlaanderen.be/image/upload/v1675177215/MB_van_28_december_2018_Bijlage_4_voor_bouwaanvragen_vanaf_1_januari_2023_draft_wogkau.pdf (accessed on 1 March 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).