1. Introduction

The construction industry is related to urban development and economic growth; however, this industry involves land deterioration, resource depletion, waste generation, and various forms of pollution to nature. Moreover, the construction industry is responsible for 10% of the total contamination by CO

2 emissions [

1,

2,

3]. According to the European Environment Agency, the construction sector is one of the largest energy consumers in Europe, accounting for about 40% of total energy consumption [

4]; overall construction waste generation has reached billions of tons around the world, and this trend has been increasing constantly [

5,

6,

7]. This extensive resource use underscores the need for sustainable construction practices and efficient material usage to mitigate environmental impacts.

Construction materials significantly impact the environment throughout their life cycle, from extraction to eventual demolition. Among these, one of the most environmentally detrimental aspects is the processing of raw materials, particularly cement production. As the urgency to preserve environmental quality and protect human health increases, the construction industry is progressively focusing on the environmental aspects of their operations, products, and services [

8]. Recent research has increasingly focused on producing sustainable construction materials that either minimize or entirely exclude cement [

9,

10]. Concurrently, studies have explored the incorporation of agricultural wastes, particularly the use of biomass ashes as pozzolanic agents in cement concrete or as alternative activators in geopolymer concrete, while preserving the fundamental properties required for construction materials [

11,

12]. Additionally, several authors have investigated the integration of natural fibers into cement to enhance its mechanical properties [

13,

14,

15]. Recognizing cement’s critical role in construction, substantial efforts have been made to develop more sustainable cements [

16,

17] or alternative materials for replacement. Many researchers are focused on replacing a portion of cement with supplementary cementitious materials to decrease hazardous emissions [

18,

19]. In an effort to mitigate the environmental impact, various studies have proposed sustainable additions to concrete, aiming for eco-friendliness and sustainability. These include alternative concrete recycling methods and green concretes made from agricultural waste materials or compounds that require fewer non-renewable raw materials, such as sugarcane bagasse ash, rice husk ash, and palm oil fuel ash, which can reduce cement consumption while preserving the desired properties of cement [

13,

20,

21,

22,

23,

24,

25]. A significant benefit of these new alternatives in construction materials is the reduction in carbon dioxide emissions, extended durability, and decreased energy consumption [

26].

It is important not only to reduce the environmental impact but also to obtain materials that strike a balance between resistance, appearance, handling, and costs [

27,

28]. Among the most significant advances to obtain construction materials with lesser environmental impact are cement replacement with fly ashes, cement reinforcement with natural fibers and agro-industrial waste, and the recycling of construction waste [

14,

29,

30]; all these options have demonstrated physical characteristics similar to those of conventional materials. The search for new materials to replace traditional raw materials makes the use of wastes an important research area. Any calcium-containing materials are potentially suitable in the production of cement replacements. One type of waste with a high calcium content is animal bones, which could be useful as a biologically and environmentally compatible raw material medium in the construction industry [

31]. Calcined bones have a proportion of 44% calcium oxide, one the raw materials of Portland cement, which is one the most used cements in the construction industry.

There have been some works using waste bones. Naga et al. (2014) evaluated the use of waste fish bones to replace potash feldspar to produce stoneware; they found lower thermal expansion than for conventional tiles [

32]. Onyelowe (2015) studied a bone ash admixture for land stabilization, and he found that the waste bone ash increased the compaction, making it suitable for any construction work including its use as a sub-base material for pavement construction [

33]. Akinyele et al. (2016) used both bone and wood ash wastes for partial replacement of cement in concrete. They found that bone ash was a better pozzolana when compared to the wood ash and can partially replace cement in concrete [

34]. Although the use of animal bone powders as a substitute for cement has been explored, with a predominant focus on cattle bone, the geographical area of our study presents a context characterized by significant pork consumption and pressing concerns about the disposal of pork bones. Therefore, this research aims to investigate and compare the mechanical properties of concrete made with pig or beef bone powder as cement replacement, thereby broadening the research scope within this field. This work evaluates the mechanical response of the cement in a concrete mixture for structural elements of 3000 psi resistance through the implementation of partial replacement with 10%, 15%, and 20% calcinated pig and beef bones.

2. Materials and Methods

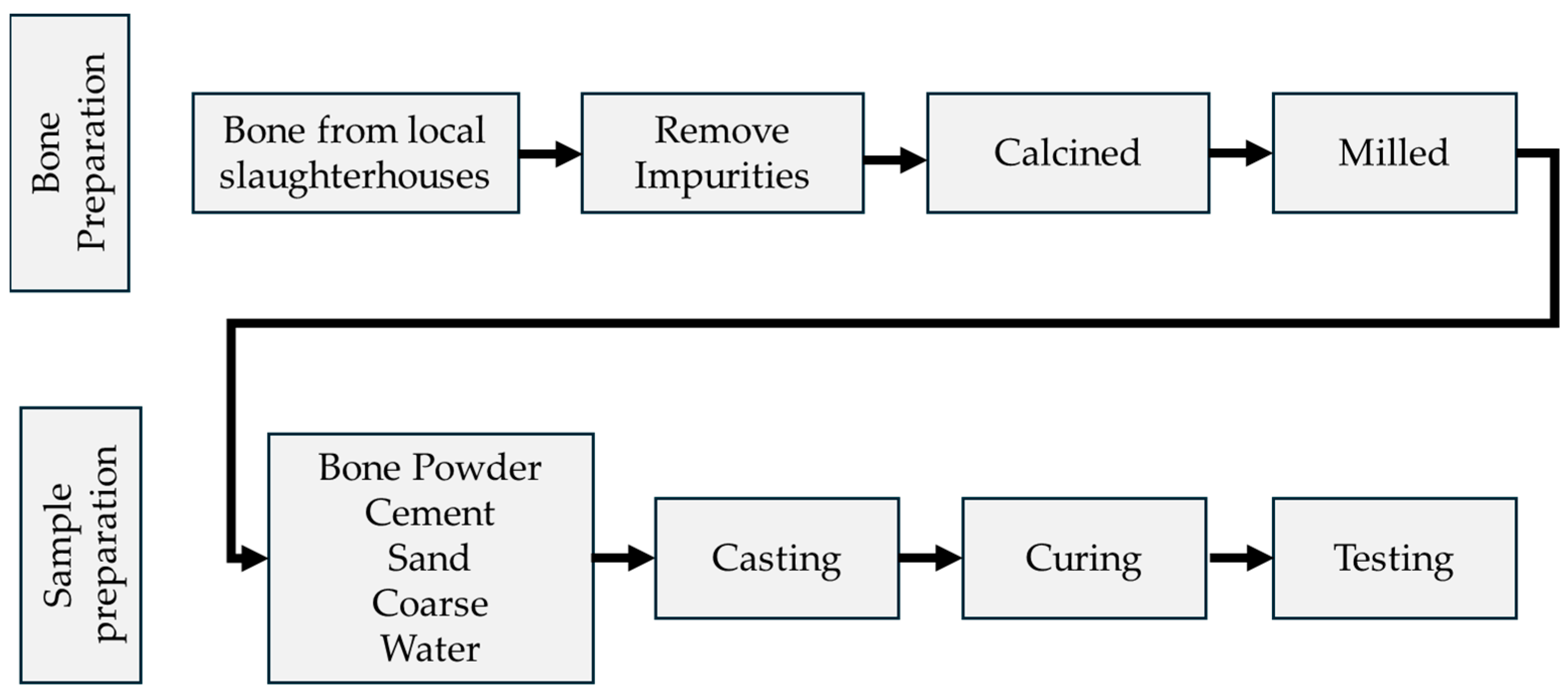

Figure 1 illustrates a general process used for preparing the bone powder and samples. Each step of this preparation process is described in the following sections.

2.1. Materials for Concrete Preparation

Ordinary Portland cement (OPC) from Colombian local company was used in concrete preparation; the OPC was supplied by a local Colombian company and classified as UG (general use) according to NTC 121:2014 (NTC—Norma Técnica Colombiana) [

35]. Sands supplied by a local hardware store were used as fine aggregate in the concrete mix. Coarse crushed stone aggregate, available at the local quarry, was collected as one of the ingredients for the concrete. Tap water free from salts, organic content, and turbidity was used for mixing and during curing.

2.2. Preparation of Pig and Beef Bones

In total, 25 kg of pig and beef bone waste was randomly collected from local slaughterhouses, butchers, and restaurants. The bones were manually cleaned using a scalpel and wire brush to remove residues of muscle, cartilage, and meat [

36]. Subsequently, bones were immersed in 50% sodium hypochlorite solution for 24 h in order to remove impurities and dilute some of the blood and marrow residues (

Figure 2).

After sodium hypochlorite immersion, the bones were subjected to two heating processes with the aim being to eliminate biological, fat, and water residues. When bones are exposed to a high temperature, they can exhibit morphological and color changes, turning from ivory white to brown and black, to different shades of gray and chalky white. These changes are related with the maximum temperature and time of exposure [

37]. The first process was to place bones in a grill in direct contact with the fire (

Figure 3a) in order to eliminate fat residues; in this step, bones were dried and obtained a brown hue (

Figure 3b). After that, the cleaned and dried bones were oven-calcined for 30 h at an average temperature of 450 ± 5 °C. The temperature used in the oven was based on preliminary studies of calcined bones [

34]; the time of exposure and temperature used allowed the bones to be easily crushed, obtaining a gray color like that of cement (

Figure 3c).

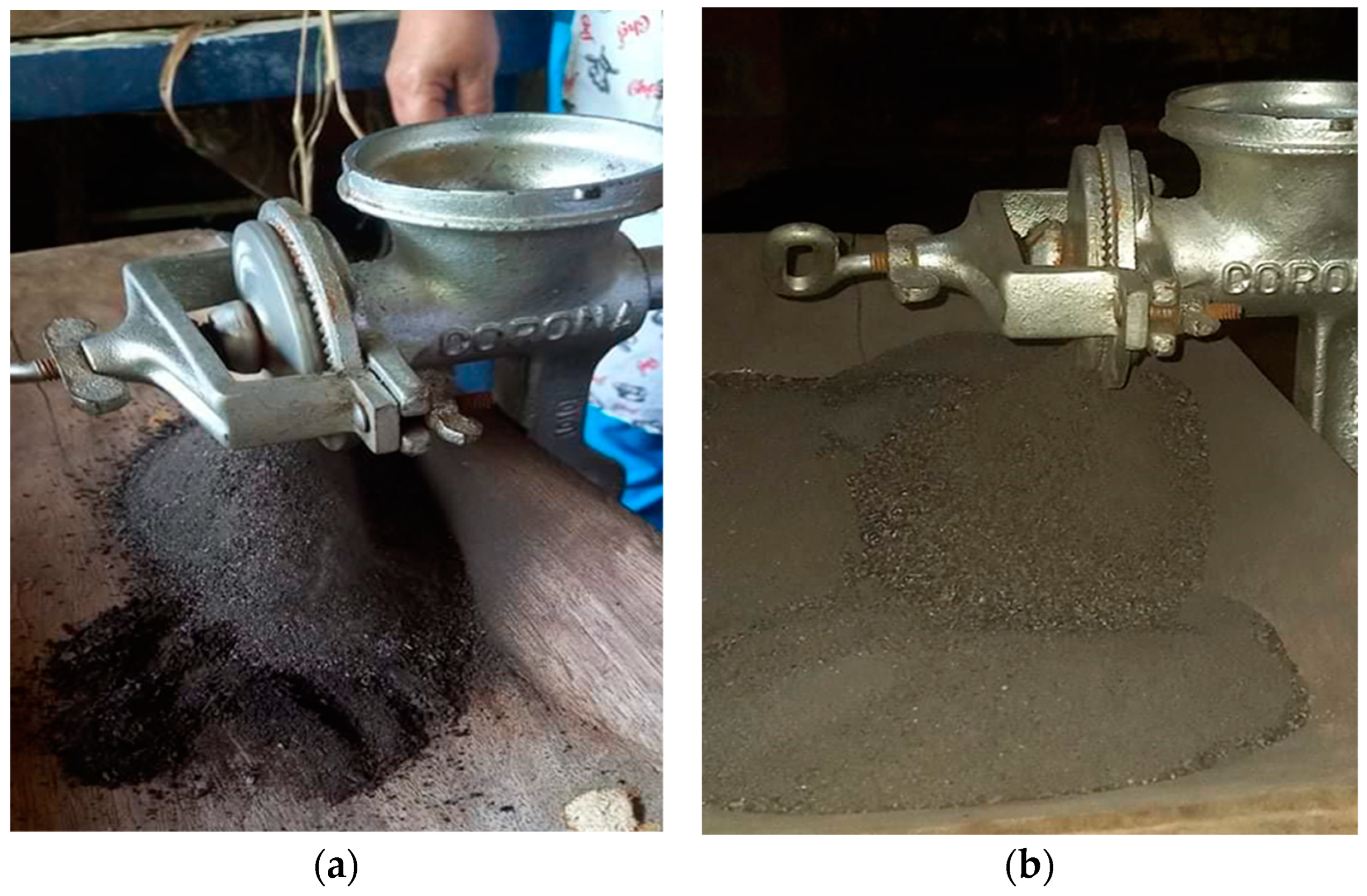

Finally, the bones were crushed, milled in a conventional mill, and sieved to a particle size of 100

to obtain the powder that was used as a cement replacement (

Figure 4).

2.3. Preparation of Test Samples

Samples were cast as per the mix design for 21 MPa (3000 psi) concrete with different dosages of bone powder as a cement replacement; this concrete was designed to meet the requirements of technical standard NSR10 [

38]. According to the theory of concrete mix design [

39], it is important to define the final use of the specimen; once the use is defined, it is necessary to consider the mix characteristics [

40]. For this work, the mix characteristics were defined for concrete to be used in reinforced retaining walls, foundations, compacted pavements, lightly reinforced slabs, beams, and columns.

Table 1 shows the characteristics for concrete design.

The water/cement ratio is one of the most important parameters in the concrete design and is a crucial factor influencing various aspects of concrete, including performance, workability, serviceability, durability, and crack control; it is also strongly related with the final properties of the concrete [

41,

42]. The water/cement ratio is calculated according to Equation (1):

where

K1 and

K2 are related with the compressive strength: for 20 MPa,

MPa and

, and for 25 MPa,

MPa and

. By extrapolation, we defined

MPa and

for a compressive strength of 21 MPa.

is obtained from Abram’s equation (Equation (2)):

With , , and defined, the water/cement ratio was established using Equation (1), and it was obtained as 0.49.

2.3.1. Mix Proportions

The theoretical quantity of cement in the mix is defined following Equation (3), where

s indicates settlement and

TM is the maximum size of the aggregate. Once the water quantity is defined, the quantity of cement is established considering the water/cement ratio; however, the theoretical water and cement quantities need to be approached by mean correlations of humidity, settlement, and unitary mass according to the requirements of NTC396 and NTC1926 in order to obtain a mix with a better workability.

A 3000 psi resistance concrete was designed; the material proportions and quantities are shown in

Table 2. From these values, the corrected water/cement ratio was established as 0.51; this is above the calculated value, demonstrating better mix workability in practice. The final design considered safety factors according to the use of the designed concrete [

43].

2.3.2. Casting of Specimens

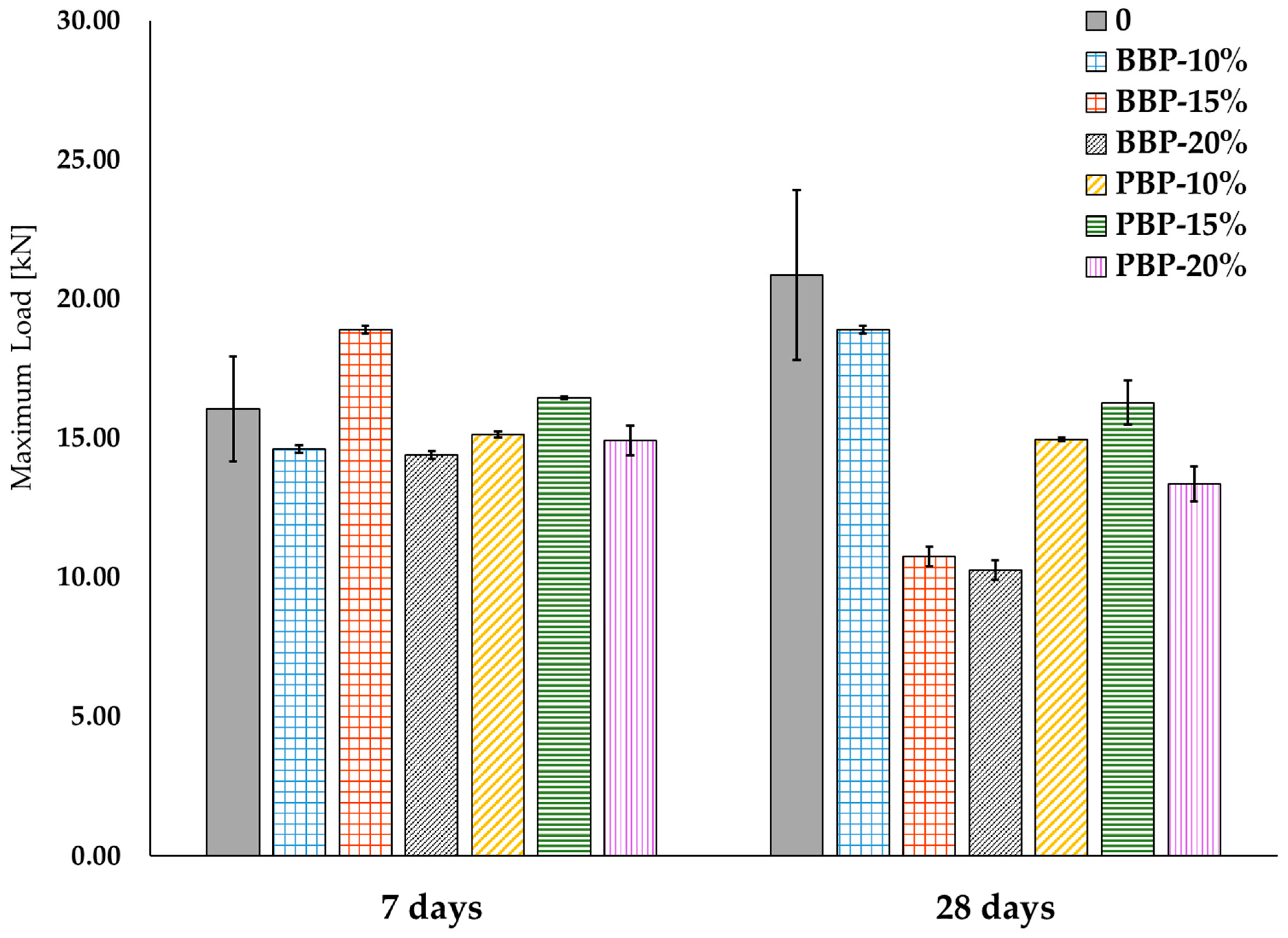

Pig and beef bone powder in proportions of 10%, 15%, and 20% were used as a cement replacement in the mix; a control specimen without bone powder was also cast in order to provide a comparison of the properties.

Table 3 shows the mix proportions for each specimen. The specimens were cast in two types. The first group was cast as cylinders 150 mm in diameter and 300 mm in height; the second group was cast as beams with a size of

mm. The specimens were labeled as BBP for those that contained beef bone powder as a replacement and PBP for those that contained pig bone powder; also, the control specimen was labeled as C-0.

Table 3 and

Table 4 show the specimen names and the proportions of compounds used in the mix for the cylinders and beams, respectively.

2.4. Testing of Specimens

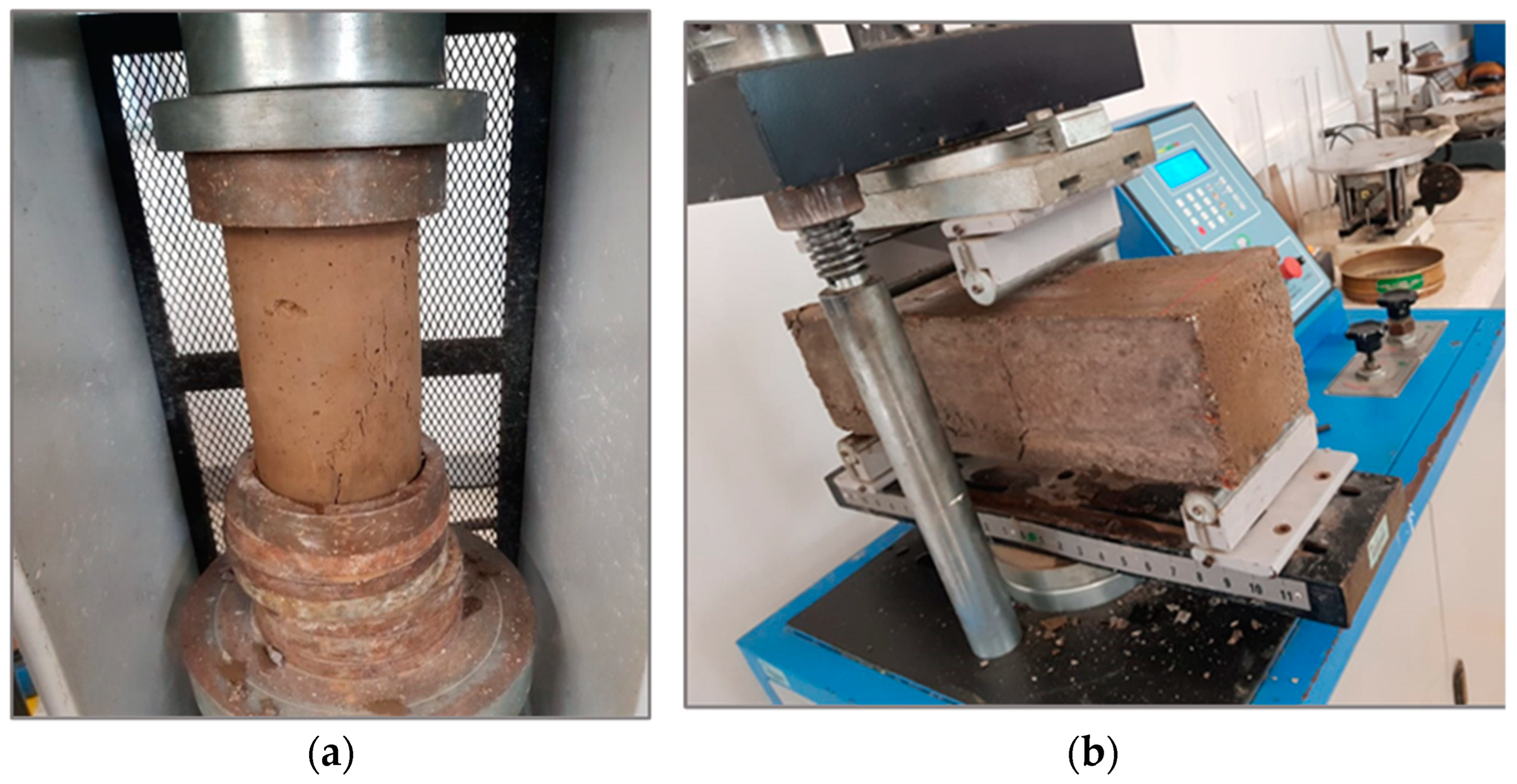

All specimens were placed in a curing tank and were soaked in tap water. Specimens were removed after 7 and 28 days for different mechanical tests.

The beam specimens were used to determine the flexural strength of the concretes; specimens were placed in between two jaws for a three-point test, as shown in

Figure 5b. For flexural strength, load was applied at a rate of 190 kg/cm

2/min until complete failure of the specimen. The flexural strength testing was carried out following the specifications of the ASTM C78 standard [

44].

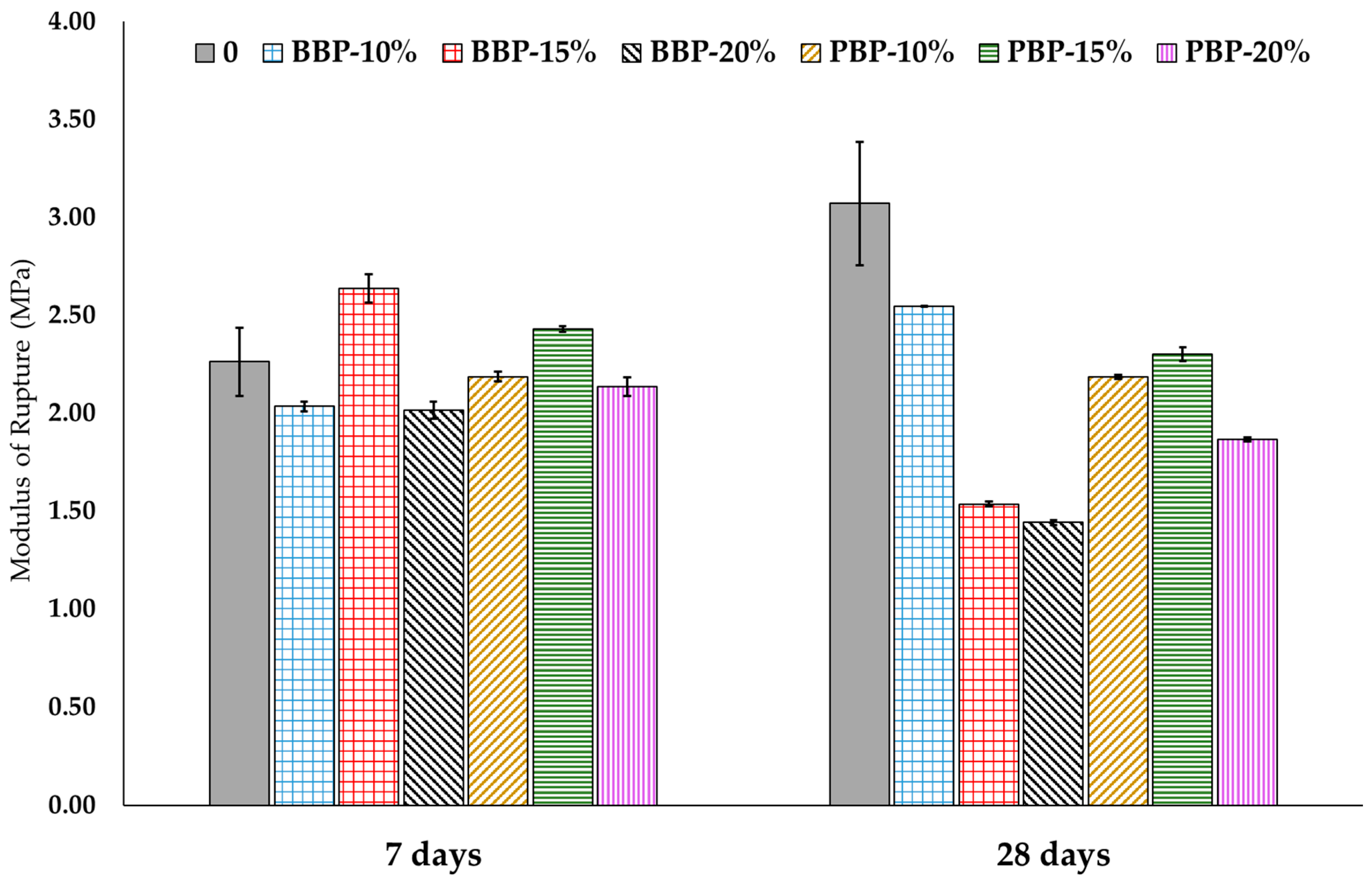

The load that produced rupture of the beam was employed to calculate the modulus of rupture (MPa) following Equation (4):

where

F = load (force) at the fracture point (N);

= length of the support (outer) span (mm);

= width (mm);

= thickness (mm).

The cylinder specimens were tested for compressive loading on the compression testing machine, as shown in

Figure 4a. Specimens were placed between the two jaws of the compression testing machine, and the load was applied increasingly at a rate of 190 kg/cm

2/min until complete failure of the specimen. The compressive testing was carried out following the specifications of the ASTM C39 standard [

45]. The ultimate compressive load for each test specimen was recorded to find the compressive strength values of the concretes following Equation (5):

where

F = ultimate compressive load (N);

= area of each specimen (mm2).

Finally, the

value was used to calculate the cracking stress; this value allows for correlation of the results with the modulus of rupture using Equation (6).

2.5. Statistical Analysis

To compare the results on flexural strength and compressive strength between different samples, an analysis of variance (ANOVA) was carried out; the intervals were calculated to determine whether there were significant differences. Then, the Games–Howell test, which is a single-step multiple comparison, was performed using SPSS® v.25 software (25, IBM Corp.©, Armonk, NY, USA) to locate these differences.

4. Conclusions

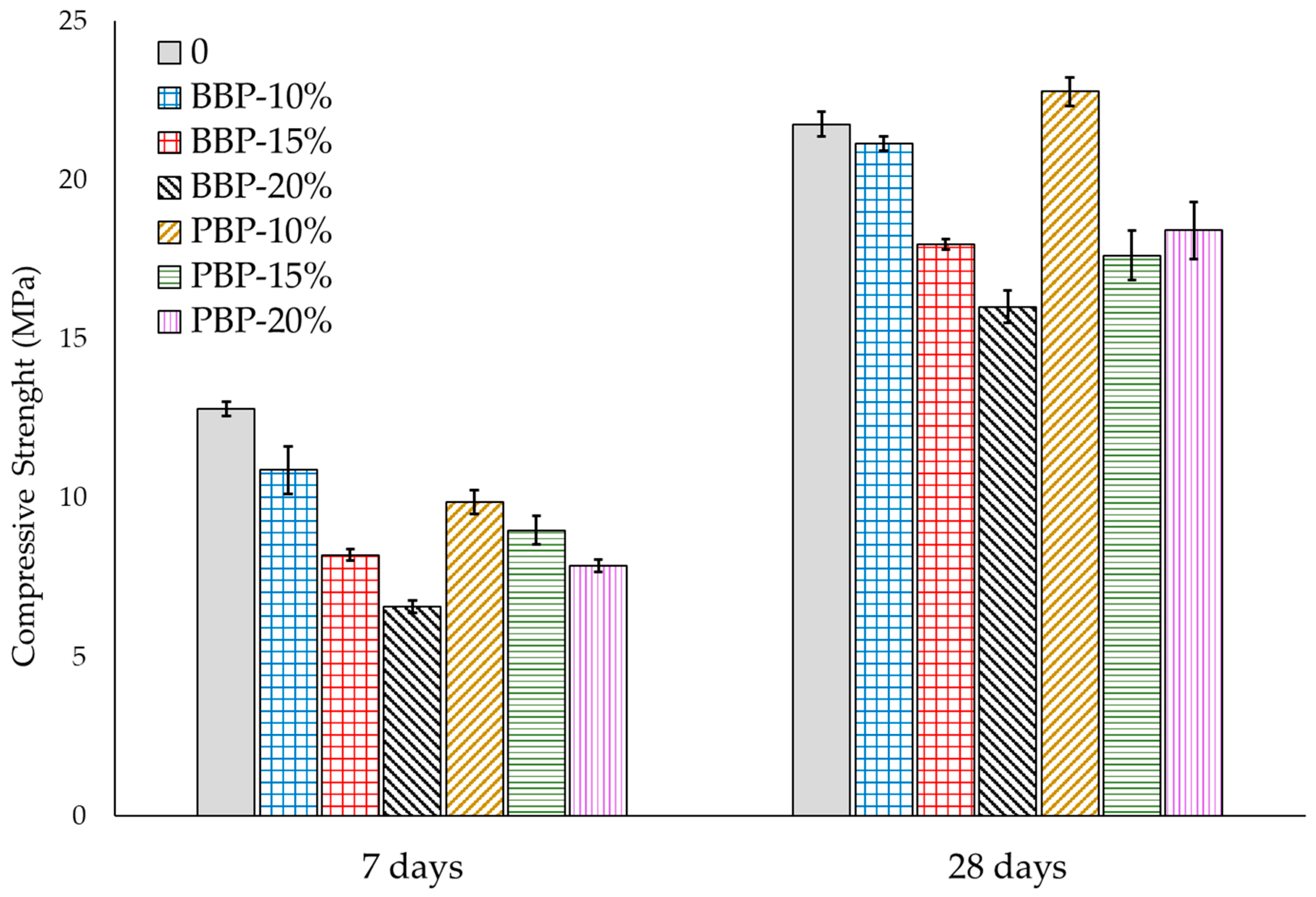

This study demonstrated that both beef and pig bone powders hold significant potential as cement replacements. Despite a slight reduction in mechanical properties beyond a 10% replacement level compared to those of the control mix, statistical tests revealed no significant differences, suggesting that the mechanical integrity of concrete incorporating bone powder remains within acceptable design resistance parameters. While the compressive response of these materials is promising for structural applications, expanded research into their long-term durability is necessary to fully understand and utilize their potential in construction.

The optimal performance In terms of mechanical properties for both pig and beef bone powder replacements was observed at a 10% substitution level, with pig bone powder demonstrating superior efficacy. The results indicate that an increase in the replacement percentage leads to a decrease in mechanical properties after 28 days of curing. Given the potential of using bone powder as a cement replacement, it is crucial to conduct an economic study to determine the associated costs of producing this novel material.

The modulus of rupture results for concretes modified with PBP and BBP yielded values of 2.18 mPa and 2.54 mPa, respectively. These figures fall within the recommended minimum tensile stress range of 10% to 15% of the compressive strength, suggesting the material’s suitability for use in structures subject to bending. However, future research should aim to further explore the flexural and tensile properties of concrete with partial BBP and PBP replacements. Methods like indirect tension tests on cylinders and beam bending experiments will be invaluable in confirming the findings of this study, particularly regarding the material’s performance in pavement slabs, sidewalks, and other structures where resistance to bending stresses is important.

The production of concrete or cement requires a large amount of energy for its manufacturing and handling. Opting for alternative construction materials such as bone powder allows us to reduce the amount of cement used, guaranteeing quality and generating sustainable options. Determining the exact energy required to produce and process bone powder varies depending on the method. Therefore, it is necessary to conduct new research to verify and compare whether using bone powder as a cement replacement results in energy consumption savings.