Anticipatory Technoeconomic Evaluation of Kentucky Bluegrass-Based Perennial Groundcover Implementations in Large-Scale Midwestern US Corn Production Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Enterprise Budget and Budgeting Assumptions

2.2. Optimistic and Pessimistic PGC Scenarios

2.3. Differences in System Operations

2.3.1. Pre-Harvest Activities

2.3.2. Harvest Activities

2.4. Sensitivity Analysis

3. Results

3.1. Costs

3.2. Revenue and Net Return

3.3. Sensitivity Analysis

4. Discussion

4.1. Groundcover Longevity and Suppression

4.1.1. Groundcover Longevity

4.1.2. Groundcover Suppression

4.2. Machinery Investment and Limitations

4.3. Economic and Labor Demands as They Relate to Federal Policy Framework Compatibility

4.4. Incentives at the Farm Level

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Saavoss, M.; Capehart, T.; McBride, W.; Effland, A. Trends in Production Practices and Costs of the U.S. Corn Sector. ERR-294; U.S. Department of Agriculture, Economic Research Service: Washington, DC, USA, 2021. [Google Scholar]

- Wilhelm, W.W.; Johnson, J.M.F.; Hatfield, J.L.; Voorhees, W.B.; Linden, D.R. Crop and soil productivity response to maize residue removal: A literature review. Agron. J. 2004, 96, 1–17. [Google Scholar] [CrossRef]

- Pribyl, D.W. A critical review of the conventional SOC to SOM conversion factor. Geoderma 2010, 156, 75–83. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.F.; Karlen, D.L.; Lightle, D.T. Corn stover to sustain soil organic carbon further constrains biomass supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Allmaras, R.R.; Reicosky, D.C. Estimating source carbon from crop residues, roots and rhizodeposits using the national grain-yield database. Agron. J. 2006, 98, 622–636. [Google Scholar] [CrossRef]

- Carter, M.R. Soil quality for sustainable land management: Organic matter and aggregation interactions that maintain soil function. Agron. J. 2002, 94, 38–47. [Google Scholar] [CrossRef]

- Pimentel, D.; Harvey, C.; Resosudarmo, P.; Sinclair, K.; Kurz, D.; McNair, M.; Crist, S.; Shpritz, L.; Fitton, L.; Saffouri, R.; et al. Environmental and economic costs of soil erosion and conservation benefits. Science 1995, 267, 1117–1123. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, D.A. Soil erosion and agricultural sustainability. Proc. Natl. Acad. Sci. USA 2007, 104, 13268–13272. [Google Scholar] [CrossRef] [PubMed]

- Rogovska, N.; Laird, D.A.; Karlen, D.L. Corn and soil response to biochar application and stover harvest. Field Crops Res. 2016, 187, 96–106. [Google Scholar] [CrossRef]

- Claassen, R.; Bowman, M.; McFadden, J.; Smith, D.; Wallander, S. Tillage Intensity and Conservation Cropping in the United States, EIB-197; U.S. Department of Agriculture, Economic Research Service: Washington, DC, USA, 2018. [Google Scholar]

- U.S. Department of Energy. Sustainable Aviation Fuel. 2024. Available online: https://afdc.energy.gov/fuels/sustainable-aviation-fuel#:~:text=The%20Sustainable%20Aviation%20Fuel%20Grand,in%20lifecycle%20greenhouse%20gas%20emissions (accessed on 2 May 2024).

- Perlack, R.D.; Wright, L.L.; Turhollow, A.F.; Graham, R.L.; Stokes, B.J.; Erbach, D.C. Biomass as Feedstock for a Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billion-Ton Annual Supply; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2005. [Google Scholar]

- Sheehan, J.; Aden, A.; Paustian, K.; Killian, K.; Brenner, J.; Walsh, M.; Nelson, R. Energy and environmental aspects of using maize stover for fuel ethanol. J. Ind. Ecol. 2003, 7, 117–146. [Google Scholar] [CrossRef]

- U.S. Department of Energy. 2023 Billion-Ton Report: An Assessment of U.S. Renewable Carbon Resources; Langholtz, M.H., Ed.; ORNL/SPR-2024/3103; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2024. [Google Scholar] [CrossRef]

- McAloon, A.; Taylor, F.; Yee, W.; Ibsen, K.; Wooley, R. Determining the Cost of Producing Ethanol from Cornstarch and Lignocellulosic Feed Stocks; Technical Report NREL/TP-580-28893; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2000. [Google Scholar]

- U.S. Department of Agriculture National Agriculture Statistics Service. Census of Agriculture, 2022. 2024. Available online: https://www.nass.usda.gov/AgCensus/ (accessed on 10 June 2024).

- Arbuckle, J.G.; Roesch-McNally, G.J. Cover crop adoption in Iowa: The role of perceived practice characteristics. J. Soil Water Conserv. 2015, 70, 418–419. [Google Scholar] [CrossRef]

- Dunn, M.; Ulrich-Schad, J.D.; Prokopy, L.S.; Myers, R.L.; Watts, C.R.; Scanlon, K. Perceptions and use of cover crops among early adopters: Findings from a national survey. J. Soil Water Conserv. 2016, 71, 29–40. [Google Scholar] [CrossRef]

- Gonzalez-Ramirez, M.J.; Kling, C.L.; Arbukle, J.G.; Morton, L.W.; McGuire, J.; Ingels, C.; Benning, J. Cover Crop Adoption Decisions in Iowa: Insights from an In-Person Survey; Agriculture Policy Review; Iowa State University: Ames, IA, USA, 2017. [Google Scholar]

- Myers, R.L.; Wilson, K.R. Farmer perspectives about cover crops by non-adopters. Front. Sustain. Food Syst. 2023, 7, 1011201. [Google Scholar] [CrossRef]

- Ruppert, S.; Coppess, J.; Skidmore, M. A Menace Reconsidered, Part 5: Reviewing Cover Crops. Farmdoc Daily 2024, 14, 84. [Google Scholar]

- Mintert, J.; Langemeier, M. Purdue Center for Commercial Agriculture. Purdue/CME Group Ag Economy Barometer September Results. 2023. Available online: https://ag.purdue.edu/commercialag/ageconomybarometer/weakening-crop-prices-and-high-production-costs-weigh-on-farmer-sentiment/ (accessed on 3 May 2024).

- Deines, J.M.; Guan, K.; Lopez, B.; Zhou, Q.; White, C.S.; Wang, S.; Lobell, D.B. Recent cover crop adoption is associated with small maize and soybean yield losses in the United States. Glob. Chang. Biol. 2023, 29, 794–807. [Google Scholar] [CrossRef]

- Agriculture Improvement Act of 2018, Pub. L. No. 115-334. 2018. Available online: https://www.govinfo.gov/app/details/PLAW-115publ334 (accessed on 3 May 2024).

- U.S. Department of Agriculture. Risk Management Agency. Risk Management Agency Fact Sheet Washington National Office—Washington, DC. Revised June 2019. 2019. Available online: https://www.rma.usda.gov/en/Fact-Sheets/National-Fact-Sheets/Cover-Crops-and-Crop-Insurance (accessed on 14 May 2024).

- U.S. Department of Agriculture. NRCS Cover Crop Termination Guidelines Version 4: June 2019. 2019. Available online: https://www.nrcs.usda.gov/sites/default/files/2022-09/Termination_Guidelines_Designed_6.28_10.24am_%28002%29.pdf (accessed on 3 May 2024).

- Moore, K.J.; Anex, R.P.; Elobeid, A.E.; Fei, S.; Flora, C.B.; Goggi, A.S.; Jacobs, K.L.; Jha, P.; Kaleita, A.L.; Karlen, D.L.; et al. Regenerating Agricultural Landscapes with Perennial Groundcover for Intensive Crop Production. Agronomy 2019, 9, 458. [Google Scholar] [CrossRef]

- Bartel, C.A.; Moore, K.J.; Fei, S.; Lenssen, A.W.; Hintz, R.L.; Kling, S.M. Evaluating strip and no-till maintenance of perennial groundcovers for annual grain production. Crops 2022, 2, 268–287. [Google Scholar] [CrossRef]

- Bartel, C.A.; Moore, K.J.; Fei, S.; Lenssen, A.W.; Hintz, R.L.; Kling, S.M. Evaluating chemical suppression treatments to alter the red:far-red ratio in perennial groundcovers for maize production. Agronomy 2022, 12, 1854. [Google Scholar] [CrossRef]

- Chen, A.; Fei, S.; Lenssen, A.W.; Moore, K.J. Evaluating cool-season grass species as potential perennial groundcover for maize production. Agron. J. 2022, 114, 2415–2429. [Google Scholar] [CrossRef]

- Galland, P.; Fei, S.; Moore, K.; Thoms, A. The Effects of Perennial Groundcover on Soil-Water and Nutrient Dynamics in Maize Intercropping Systems. Master’s Thesis, Iowa State University, Ames, IA, USA, 2022. [Google Scholar]

- Wiggans, D.R.; Singer, J.W.; Moore, K.J.; Lamkey, K.R. Response of continuous maize with stover removal to living mulches. Agron. J. 2012, 104, 917–925. [Google Scholar] [CrossRef]

- Wiggans, D.R.; Singer, J.W.; Moore, K.J.; Lamkey, K.R. Maize water use in living mulch systems with stover removal. Crop Sci. 2012, 52, 327–338. [Google Scholar] [CrossRef]

- Flynn, E.S.; Moore, K.J.; Singer, J.W.; Lamkey, K.R. Evaluation of grass and legume species as perennial ground covers in corn production. Crop Sci. 2013, 53, 1–10. [Google Scholar] [CrossRef]

- Perfect, E.; Kay, B.D.; van Loon, W.K.P.; Sheard, R.W.; Posajok, T. Rates of change in soil structural stability under forages compared to corn. Soil Sci. Soc. Am. J. 1990, 54, 179–186. [Google Scholar] [CrossRef]

- Follett, R.F. Soil management concepts and carbon sequestration in cropland soils. Soil Tillage Res. 2001, 71, 77–92. [Google Scholar] [CrossRef]

- Randall, G.W.; Goss, M.J. Chapter 6. Nitrate Losses to Surface Water through Subsurface, Tile Drainage in Nitrogen in the Environment: Sources, Problems, and Management; Hatfield, J.L., Follett, R.F., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Hartwig, N.L.; Ammon, H.U. Cover crops and living mulches. Weed Sci. 2002, 50, 688–699. [Google Scholar] [CrossRef]

- Myers, G. Analysis and Assessment of Novel Food, Bioenergy, and Cropping Systems: Cultured Meat, Anaerobic Digestion, and Perennial Groundcover Analysis and Assessment of Novel Food, Bioenergy, and Cropping Systems: Cultured Meat, Anaerobic Digestion, and Perennial Groundcover. Doctoral Dissertation, Iowa State University, Ames, IA, USA, 2024. [Google Scholar]

- U.S. Department of Agriculture. Crop Technology Readiness Level (TRL). United State Department of Agriculture National Institute of Food and Agriculture Institute of Food Production and Sustainability. 2018. Available online: https://www.nifa.usda.gov/sites/default/files/resources/Crop-Research-Technology-Readiness-Level-2018.pdf (accessed on 14 May 2024).

- Plastina, A.; Magwaba, K. Estimated Costs of Crop Production in Iowa—2024 (File A1-20). Iowa State University Extension and Outreach Ag Decision Maker. 2024. Available online: https://www.extension.iastate.edu/agdm/crops/html/a1-20.html (accessed on 10 June 2024).

- Bartel, C.A.; Banik, C.; Lenssen, A.W.; Moore, K.J.; Laird, D.A.; Archontoulis, S.V.; Lamkey, K.R. Living mulch for sustainable maize stover biomass harvest. Crop Sci. 2017, 57, 3273–3290. [Google Scholar] [CrossRef]

- Bartel, C.A.; Banik, C.; Lenssen, A.W.; Moore, K.J.; Laird, D.A.; Archontoulis, S.V.; Lamkey, K.R. Establishment of perennial groundcovers for maize-based bioenergy production systems. Agron. J. 2017, 109, 822–835. [Google Scholar] [CrossRef]

- Bartel, C.A.; Archontoulis, S.V.; Lenssen, A.W.; Moore, K.J.; Huber, I.L.; Laird, D.A.; Dixon, P.M. Modeling perennial groundcover effects on annual maize grain crop growth with APSIM. Agron. J. 2020, 112, 1895–1910. [Google Scholar] [CrossRef]

- Nelson, G.C.; van der Mensbrugghe, D.; Ahammad, H.; Blanc, E.; Calvin, K.; Hasegawa, T.; Havlik, P.; Heyhoe, E.; Kyle, P.; Lotze-Campen, H. Agriculture and climate change in global scenarios: Why don’t the models agree. Agric. Econ. 2014, 45, 85–101. [Google Scholar] [CrossRef]

- Johanns, A.; Plastina, A. Historical Costs of Crop Production (File A1-21). Iowa State University Extension and Outreach Ag Decision Maker. 2024. Available online: https://www.extension.iastate.edu/agdm/crops/html/a1-21.html (accessed on 10 June 2024).

- Abendroth, L.J.; Elmore, R.W.; Boyer, M.J.; Marlay, S.K. Corn Growth and Development; North Dakota University: Grand Forks, ND, USA, 2011. [Google Scholar]

- Ruiz, A.; Trifunovic, S.; Eudy, D.M.; Sciarresi, C.S.; SCCm, M.; Danalatos, G.J.N.; Elli, E.F.; Kalogeropoulos, G.; King, K.; dos Santos, C.; et al. Harvest index has increased over the last 50 years of maize breeding. Field Crops Res. 2023, 300, 108991. [Google Scholar] [CrossRef]

- Farooq, M.; Hussain, M.; Wahid, A.; Siddique, K.H.M. Drought Stress in Plants: An Overview. In Plant Responses to Drought Stress; Aroca, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Licht, M. Third Year of Drought Changes Cover Crop Plans. 2 Oct 2023. Ag|Update Iowa Corn Promotion Board. Available online: https://agupdate.com/crops/third-year-of-drought-changes-cover-crop-plans/article_a207a700-5e2e-11ee-a948-cfb4cc551513.html (accessed on 29 May 2024).

- Zumkeller, M.; Yu, R.; Torres, N.; Marigliano, L.E.; Zaccaria, D.; Kurtural, S.K. Site characteristics determine the effectiveness of tillage and cover crops on the net ecosystem carbon balance in California vineyard agroecosystems. Front. Plant Sci. 2022, 13, 1024606. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Hayes, D.; Jacobs, K. The “Stover Availability versus Supply” Puzzle and Contracting Options for Cellulosic Biomass. Agricultural Policy Review. Center for Agricultural and Rural Development, Iowa State University. 2018. Available online: https://agpolicyreview.card.iastate.edu/winter-2018/stover-availability-versus-supply-puzzle-and-contracting-options-cellulosic-biomass (accessed on 29 May 2024).

- Hoskinson, R.L.; Karlen, D.L.; Birrell, S.J.; Radtke, C.W.; Wilhelm, W.W. Engineering, nutrient removal, and feedstock conversion evaluations of four corn stover harvest scenarios. Biomass Bioenergy 2007, 31, 126–136. [Google Scholar] [CrossRef]

- MacDonald, J.M.; Korb, P.; Hoppe, R.A. Farm Size and the Organization of U.S. Crop Farming, ERR-152; U.S. Department of Agriculture, Economic Research Service: Washington, DC, USA, 2013. [Google Scholar]

- U.S. Department of Agriculture Economic Research Service. Farm Structure and Organization: Farm Structure and Contracting. 2024. Available online: https://www.ers.usda.gov/topics/farm-economy/farm-structure-and-organization/farm-structure-and-contracting/ (accessed on 14 May 2024).

- Marra, M.C.; Carlson, G.A. The Role of Farm Size and Resource Constraints in the Choice between Risky Technologies. West. J. Agric. Econ. 1987, 12, 109–118. Available online: https://www.jstor.org/stable/40987860 (accessed on 14 May 2024).

- Fiechter, C.; Ifft, J. Seed Corn Costs: How Large Are the Discounts? Farmdoc Daily 2019, 9, 190. [Google Scholar]

- US Department of Agriculture Risk Management Agency, The Risk Management Safety Net: Market Penetration and Market Potential, September 2017. Available online: https://www.rma.usda.gov/about-crop-insurance/highlighted-initiatives-plans/beginners-guide-crop-insurance (accessed on 29 May 2024).

- U.S. Department of Agriculture. Federal Crop Insurance Corporation Crop Insurance Handbook: 2023 and Succeeding Years FCIC-18010 (06-2022); United States Department of Agriculture Farm Production and Conservation Risk Management Agency: Kansas City, MO, USA, 2023. [Google Scholar]

- U.S. Department of Agriculture Federal Crop Insurance Corporation. Summary of Changes for the Common Crop Insurance Policy Basic Provisions—Reinsured Version (24.1-br) (Released November 2023). Available online: https://www.rma.usda.gov/policy-procedure/general-policies (accessed on 9 May 2024).

- Stubbs, M. Agricultural Conservation and the Next Farm Bill. Report R47478. Congressional Research Service 20 March 2023. Available online: https://crsreports.congress.gov (accessed on 29 May 2024).

| Year 1 | Year 2+ | ||

|---|---|---|---|

| Expected Yields | Corn (bu/ac) | Identical assumptions * | Approx 15% yield drag |

| Stover harvest (Ton/acre, T/ac) | Identical assumptions | Approx 16% yield drag | |

| Costs: Spring Activities | Pre-harvest machinery | Identical assumptions | Identical assumptions |

| Seed, Chemical, inputs per acre | Identical assumptions | Identical assumptions | |

| Grass establishment (Year 1) | Pessimistic requires more seed and greater seed bed preparation (field operations) | - | |

| Grass suppression (Year 2+) | - | More intense strip tilling and suppressant application | |

| Costs: Fall andPost-Harvest Activities | Corn harvest | Identical assumptions | Reduced hauling, drying, and handling due to lower yield |

| Corn stover removal per acre | Identical assumptions | Reduced hauling due to lower removal rate | |

| Costs: Other | Land (cash rent equivalent) | Identical assumptions | Identical assumptions |

| Labor | Increased due to greater spring field operations | Increased due to greater suppression needs | |

| Revenue (per acre) | Corn sales | Identical assumptions | Lower due to yield drag |

| Stover sales | Identical assumptions | Lower due to yield drag | |

| USDA payments | Identical assumptions | Identical assumptions | |

| Crop insurance rebate | Identical assumptions | Identical assumptions |

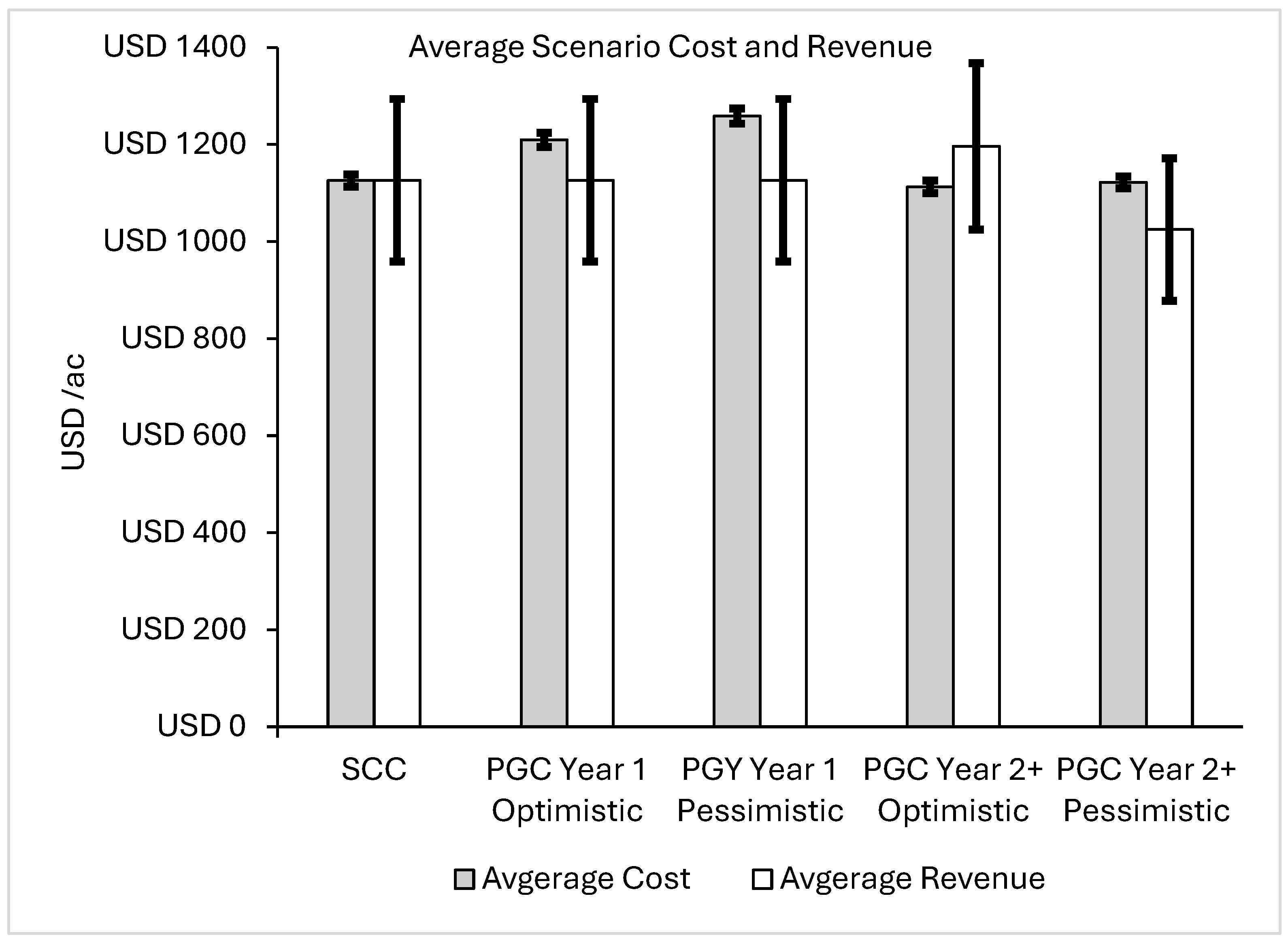

| SCC | PGC—Year 1|Optimistic | PGC—Year 1|Pessimistic | PGC—Year 2+|Optimistic | PGC—Year 2+|Pessimistic | |

|---|---|---|---|---|---|

| Pre-harvest total | USD 556 | USD 637 | USD 676 | USD 533 | USD 554 |

| Harvest total | USD 129 | USD 129 | USD 129 | USD 129 | USD 117 |

| Stover operations total | USD 56 | USD 56 | USD 56 | USD 66 | USD 62 |

| Total costs per acre | USD 1126 | USD 1210 | USD 1258 | USD 1113 | USD 1122 |

| Cost comparison to SCC | USD 84 | USD 133 | -USD 13 | -USD 4 |

| SCC | PGC—Year 1|Optimistic | PGC—Year 1|Pessimistic | PGC—Year 2+|Optimistic | PGC—Year 2+|Pessimistic | |

|---|---|---|---|---|---|

| Expected corn yield, bu/ac | 204 | 204 | 204 | 204 | 175 |

| Expected corn stover harvest, T/ac | 1.9 | 1.9 | 1.9 | 3.3 | 2.8 |

| Return per acre | |||||

| Expected selling price, corn bu/ac @ USD 5.05/bu | USD 1030 | USD 1030 | USD 1030 | USD 1030 | USD 884 |

| Expected selling price, stover T/ac @ USD 50.00/T | USD 95 | USD 95 | USD 95 | USD 165 | USD 140 |

| Revenue/ac | USD 1125 | USD 1125 | USD 1125 | USD 1195 | USD 1024 |

| Net return/ac | USD 0 | −USD 84 | −USD 133 | USD 83 | −USD 98 |

| Differences in Costs and Revenue for PGC from SCC (USD /ac/yr) | ||||

|---|---|---|---|---|

| PGC Year and Scenario | PGC Y1 Optimistic | PGY Y1 Pessimistic | PGC Y2+ Optimistic | PGC Y2+ Pessimistic |

| Average cost | USD 84 | USD 133 | −USD 13 | −USD 4 |

| Standard deviation cost | USD 8 | USD 10 | USD 1 | USD 0 |

| Average revenue | USD 0 | USD 0 | USD 70 | −USD 101 |

| Standard deviation revenue | USD 0 | USD 0 | USD 11 | USD 23 |

| Differences in Net Return (USD /ac/yr) of PGC and SCC | |||||

|---|---|---|---|---|---|

| PGC Life Expectancy | 1 Year | 3 Years | 5 Years | 7 Years | 9 Years |

| Average difference | −USD 84 | USD 28 | USD 50 | USD 60 | USD 65 |

| Standard Deviation | USD 8 | USD 8 | USD 9 | USD 9 | USD 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartel, C.A.; Jacobs, K.L.; Moore, K.J.; Raman, D.R. Anticipatory Technoeconomic Evaluation of Kentucky Bluegrass-Based Perennial Groundcover Implementations in Large-Scale Midwestern US Corn Production Systems. Sustainability 2024, 16, 7112. https://doi.org/10.3390/su16167112

Bartel CA, Jacobs KL, Moore KJ, Raman DR. Anticipatory Technoeconomic Evaluation of Kentucky Bluegrass-Based Perennial Groundcover Implementations in Large-Scale Midwestern US Corn Production Systems. Sustainability. 2024; 16(16):7112. https://doi.org/10.3390/su16167112

Chicago/Turabian StyleBartel, Cynthia A., Keri L. Jacobs, Kenneth J. Moore, and D. Raj Raman. 2024. "Anticipatory Technoeconomic Evaluation of Kentucky Bluegrass-Based Perennial Groundcover Implementations in Large-Scale Midwestern US Corn Production Systems" Sustainability 16, no. 16: 7112. https://doi.org/10.3390/su16167112

APA StyleBartel, C. A., Jacobs, K. L., Moore, K. J., & Raman, D. R. (2024). Anticipatory Technoeconomic Evaluation of Kentucky Bluegrass-Based Perennial Groundcover Implementations in Large-Scale Midwestern US Corn Production Systems. Sustainability, 16(16), 7112. https://doi.org/10.3390/su16167112