Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review

Abstract

1. Introduction

- water sources specifically [7];

2. Generations of Photovoltaic Technology

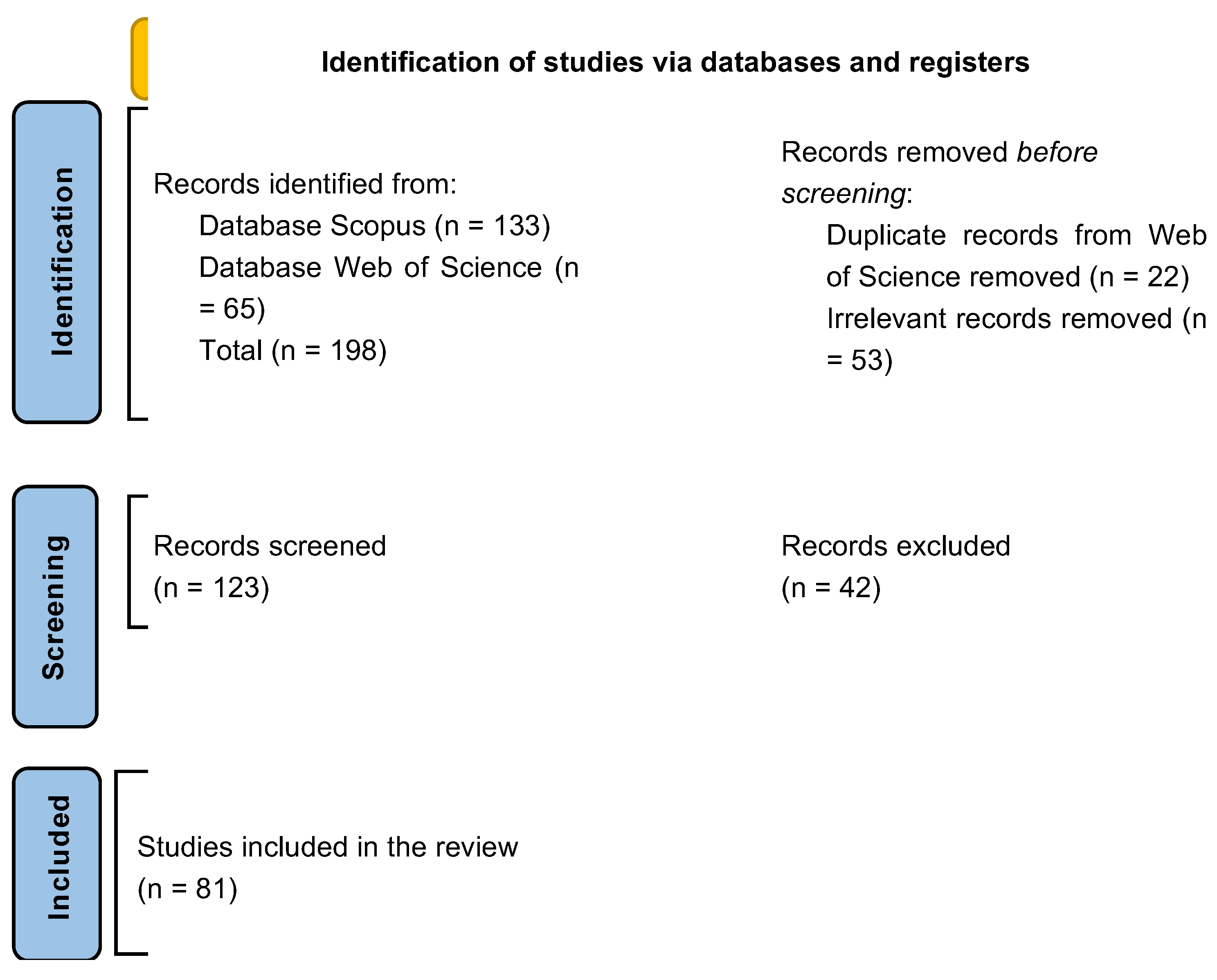

3. Methodology of the Study

4. Bibliometric Distribution of the Selected Paper

5. Thematic Results and Discussion

5.1. Raw Materials

5.2. Manufacturing Technology

5.3. Supply Chain Collaboration

5.4. PV Installation

5.5. Job Market

5.6. Business Models and PV Industry

- Product–service system: Under this model, customers have the advantage of a product–service system (PSS) because they can use products or services without purchasing them directly. The PSS bypasses the upfront costs of installation and maintenance costs, encouraging customer adoption and promoting PV circularity [64] through the reuse, repair and refurbishment of products. Schmidt-Costa et al. [64] identified use-oriented and result-oriented PSS alternatives that may overcome obstacles such as initial costs, a lack of financing options and limited access to appropriate installation sites, even in a region with highly favourable conditions for solar PVs, such as California. A use-oriented PSS includes maintenance and repair services in the rental or lease contracts [65]. In a result-oriented PSS, the consumer pays a predetermined fee for the energy generated, usually measured in kWh. Payment is determined by the results or product performance, such as the amount of energy produced by a PV array. Reim et al. [76] identified three structures for PSS models. A product-oriented PSS holds the provider responsible for the products and services, which the customer pays for. In a use-oriented PSS, the provider is responsible for the usability, which the customer pays for over time. A result-oriented PSS has the provider responsible for results and the customer pays for units of outcome. The PSS model has the advantages of increased solar technology affordability and availability, customers have less financial risk and resource efficiency is increased [64]. On the other hand, the PSS model must address key issues such as active stakeholder engagement and communication, clearly defined value propositions and pricing structures, which can be complex.

- Second-life model. Under this model, PV products are repurposed at the end of their original life to reduce waste, save resources and generate economic benefits [66]. In a second-life cycle, components can be integrated for new use into building materials and furniture, or they can be repaired for reuse in solar panels. Bocken et al. [25] propose that solar panel collection systems be combined with product design strategies to facilitate the reuse, refurbishment and recycling of materials and components to create new products. However, effective second-life models have supportive legislation that puts the responsibility onto producers to manage waste and feed it back into second-life processes [20]. Such product stewardship programs also emphasise consumer education about the challenges of waste associated with solar PV panels and encourage demand for second-life products and services [20].

- EOL management. A recycling system to recover materials and components from EOL products is another CBM that can promote circularity in the solar industry. This CBM promotes the creation of new products, a reduction in raw material consumption, and increased resource efficiency. Recycling systems can be designed to recover silver, copper and aluminium from used solar panels [67]. Reduced landfill is another advantage of recycling PV waste.

5.7. Cost

5.8. Government and Other Institutions

- Tax credits, subsidies or feed-in tariffs that encourage the adoption of circular economic practices and ensure the useful recycling of economic resources;

- Extended producer responsibility (EPR) policies that can shift the financial burden of EOL management to manufacturers, encouraging them to use and generate recyclable materials by applying circular economic principles;

- Landfill bans or charges for solar PV waste disposal.

5.9. Health and Environment

5.10. End-of Life (EOF) Closed Loop (Reuse, Recycle)

5.11. EV Batteries/Lithium-Ion Batteries (LIB)

5.12. PV System Benefits

6. Sustainability and PV Management

- RQ1: In the complex value chain of solar PV systems, there are multiple factors that hinder the integration of a circular economy approach. First are conflicting interests, where manufacturers may place cost effectiveness above environmental sustainability and recyclers favour profitability. Second, there is inadequate supportive legal frameworks or enforcement provisions that ensure compliance with proper waste management and recycling practices. Third, there is the absence of an effective communication or education campaign to enhances stakeholder awareness and knowledge on the benefits of implementing circular economy approaches for solar PV systems.

- RQ2: The role of stakeholders in the development of sustainable practices for end-of-life PV panels is essential, and it should be seen in collaboration and partnerships. There are some excellent examples of collaboration from the EU, and such best cases should be seen as models to be adopted across the world given the identified lack of a suitable framework to guide the CBM for the solar PV panel industry. They include extended producer responsibility (EPR) schemes which encourage manufacturers, importers and recyclers to cooperate, such as the Waste Electrical and Electronic Equipment (WEEE) Directive from the European Union [23] and voluntary take-back and recycling program by the PV CYCLE association in Europe [81]. In Australia, the Circular PV Alliance developed circular economy solutions for solar PV waste management as a collaborative initiative involving industry, government and research organisations [82]. Partnerships are a deeper form of collaboration between governments, manufacturers and recyclers to develop recycling infrastructure and promote circular economy practices, which is often also formalised with agreements. They express long-term commitments for finding solutions based on forecasting the scale and persistence of the issue [83]. Cooperation and partnerships can be adopted for stakeholders at different stages of the supply chain to avoid landfill treatment and to procure a green pathway for waste management [32].

- RQ3: We could not find an explicit answer to the question about how a country such as Australia should manage future solar PV panel waste, including through existing policies. The practical relevance and impact on current environmental and economic challenges are yet to be fully and properly addressed in the available literature. Only a few studies bridge the gap between research and real-world applications, including policy development, industry best practices and technological innovations for recycling and waste management. The review shows there is need for more interdisciplinary studies that combine technological solutions with the economic, environmental and social dimensions of the problem.

7. Future Research

- What will be the effects of the lack of raw materials for making solar panels or the effect of toxic substances released during the recovery of failed panels? Is the risk of recycling panels superior to the risk of causing negative health impacts?

- What is the estimated recovery rate and cost of reusing or recycling waste?

- If the recovery of solar panels creates jobs, would the increase in jobs created be significant?

- Given the lack of raw materials and the inability of some countries to produce or recover solar cells, when could solar PV technology be considered as a main method of energy production in the majority of countries?

- What are the circular policies, economic programs and circular technologies of advanced countries for solar PV systems?

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Oteng, D.; Zuo, J.; Sharifi, E. An expert-based evaluation on end-of-life solar photovoltaic management: An application of Fuzzy Delphi Technique. Sustain. Horiz. 2022, 4, 100036. [Google Scholar] [CrossRef]

- AL-Zoubi, O.H.; Shawaqfah, M.; Almomani, F.; Damash, R.A.; Al-Zboon, K. Photovoltaic Solar Cells and Panels Waste in Jordan: Figures, Facts, and Concerns. Sustainability 2022, 14, 13313. [Google Scholar] [CrossRef]

- Kiwan, S.; Al-Gharibeh, E. Jordan toward a 100% renewable electricity system. Renew. Energy 2019, 147, 423–436. [Google Scholar] [CrossRef]

- Herceg, S.; Pinto Bautista, S.; Weiß, K.-A. Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems. Energies 2020, 13, 2146. [Google Scholar] [CrossRef]

- Vargas, C.; Chesney, M. End of life decommissioning and recycling of solar panels in the United States. A real options analysis. J. Sustain. Financ. Invest. 2021, 11, 82–102. [Google Scholar] [CrossRef]

- Bang, Y.-Y.; Hong, N.-J.; Lee, D.S.; Lim, S.-R. Comparative assessment of solar photovoltaic panels based on metal-derived hazardous waste, resource depletion, and toxicity potentials. Int. J. Green Energy 2018, 15, 550–557. [Google Scholar] [CrossRef]

- Nain, P.; Kumar, A. Initial metal contents and leaching rate constants of metals leached from end-of-life solar photovoltaic waste: An integrative literature review and analysis. Renew. Sustain. Energy Rev. 2020, 119, 109592. [Google Scholar] [CrossRef]

- Kwak, J.I.; Nam, S.-H.; Kim, L.; An, Y.-J. Potential environmental risk of solar cells: Current knowledge and future challenges. J. Hazard. Mater. 2020, 392, 122297. [Google Scholar] [CrossRef] [PubMed]

- Stamford, L.; Azapagic, A. Environmental impacts of photovoltaics: The effects of technological improvements and transfer of manufacturing from Europe to China. Energy Technol. 2018, 6, 1148–1160. [Google Scholar] [CrossRef]

- D’Adamo, I.; Miliacca, M.; Rosa, P. Economic Feasibility for Recycling of Waste Crystalline Silicon Photovoltaic Modules. Int. J. Photoenergy 2017, 2017, 4184676. [Google Scholar] [CrossRef]

- Yu, M.; Halog, A. Solar Photovoltaic Development in Australia—A Life Cycle Sustainability Assessment Study. Sustainability 2015, 7, 1213–1247. [Google Scholar] [CrossRef]

- Australian Government. Office of Northern Australia. Available online: https://www.infrastructure.gov.au/territories-regions-cities/regional-australia/office-northern-australia (accessed on 8 August 2024).

- Parkinson, G. Households to Be “Driving Force” of Energy Transition with Solar, Batteries and EVs. 2024. Available online: https://reneweconomy.com.au/households-to-be-driving-force-of-energy-transition-with-solar-batteries-and-evs/ (accessed on 8 August 2024).

- Barbosa, R.R.; Schultz, H.S.; Garcia, L.d.C.; Martins, D.D.; Carvalho, M. Economic and greenhouse gas assessments for two hot water industrial systems: Solar vs. natural gas. Clean. Eng. Technol. 2022, 6, 100365. [Google Scholar] [CrossRef]

- Lassio, J.G.; Branco, D.C.; Magrini, A.; Matos, D. Environmental life cycle-based analysis of fixed and single-axis tracking systems for photovoltaic power plants: A case study in Brazil. Clean. Eng. Technol. 2022, 11, 100586. [Google Scholar] [CrossRef]

- Gautam, A.; Shankar, R.; Vrat, P. End-of-life solar photovoltaic e-waste assessment in India: A step towards a circular economy. Sustain. Prod. Consum. 2021, 26, 65–77. [Google Scholar] [CrossRef]

- Irena, I.-p. End-of-Life Management: Solar Photovoltaic Panels; International Renewable Energy Agency and International Energy Agency Photovoltaic Power Systems: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Van Opstal, W.; Smeets, A. Circular economy strategies as enablers for solar PV adoption in organizational market segments. Sustain. Prod. Consum. 2023, 35, 40–54. [Google Scholar] [CrossRef]

- Ndzibah, E.; La Cruz, G.A.P.-D.; Shamsuzzoha, A. End of life analysis of solar photovoltaic panel: Roadmap for developing economies. Int. J. Energy Sect. Manag. 2022, 16, 112–128. [Google Scholar] [CrossRef]

- Majewski, P.; Al-shammari, W.; Dudley, M.; Jit, J.; Lee, S.-H.; Myoung-Kug, K.; Sung-Jim, K. Recycling of solar PV panels-product stewardship and regulatory approaches. Energy Policy 2021, 149, 112062. [Google Scholar] [CrossRef]

- Baldwin, S.; Bindewald, G.; Brown, A.; Chen, C.; Cheung, K.; Clark, C.; Cresko, J.; Crozat, M.; Daniels, J.; Edmonds, J. Quadrennial Technology Review: An Assessment of Energy Technologies and Research Opportunities; US Department of Energy: Washington, DC, USA, 2015.

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on life cycle assessment of solar photovoltaic panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef]

- Radavičius, T.; van der Heide, A.; Palitzsch, W.; Rommens, T.; Denafas, J.; Tvaronavičienė, M. Circular solar industry supply chain through product technological design changes. Insights Reg. Dev. 2021, 3, 10–30. [Google Scholar] [CrossRef] [PubMed]

- Atasu, A.; Duran, S.; Van Wassenhove, L.N. The dark side of solar power. Harv. Bus. Rev. 2021. Available online: https://hbr.org/2021/06/the-dark-side-of-solar-power (accessed on 8 August 2024).

- Bocken, N.M.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Bocken, N.M.; Antikainen, M. Circular business model experimentation: Concept and approaches. In Proceedings of the Sustainable Design and Manufacturing 2018: Proceedings of the 5th International Conference on Sustainable Design and Manufacturing (KES-SDM-18) 5, Gold Coast, Australia, 24–26 June 2018. [Google Scholar]

- Moro, S.R.; Cauchick-Miguel, P.A.; Mendes, G.H.d.S. Adding sustainable value in product-service systems business models design: A conceptual review towards a framework proposal. Sustain. Prod. Consum. 2022, 32, 492–504. [Google Scholar] [CrossRef]

- Geels, F.W.; Sovacool, B.K.; Schwanen, T.; Sorrell, S. The socio-technical dynamics of low-carbon transitions. Joule 2017, 1, 463–479. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. A scientometric review of trends in solar photovoltaic waste management research. Sol. Energy 2021, 224, 545–562. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Ali, A.; Koch, T.W.; Volk, T.A.; Malmsheimer, R.W.; Eisenbies, M.H.; Kloster, D.; Brown, T.R.; Naim, N.; Therasme, O. The Environmental Life Cycle Assessment of Electricity Production in New York State from Distributed Solar Photovoltaic Systems. Energies 2022, 15, 7278. [Google Scholar] [CrossRef]

- Sheoran, M.; Kumar, P.; Sharma, S.; Bukya, M. Current situation analysis of solar PV waste management in India. Mater. Today Proc. 2022, 58, 773–782. [Google Scholar] [CrossRef]

- Pastuszak, J.; Węgierek, P. Photovoltaic cell generations and current research directions for their development. Materials 2022, 15, 5542. [Google Scholar] [CrossRef] [PubMed]

- Alami, A.H.; Alasad, S.; Aljaghoub, H.; Ayoub, M.; Alashkar, A.; Mdallal, A.; Hasan, R. First-Generation Photovoltaics: History and Conventional Manufacturing. In PV Technology and Manufacturing; Alami, A.H., Ed.; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1–17. [Google Scholar] [CrossRef]

- Aamir Iqbal, M.; Malik, M.; Shahid, W.; Zaheer Ud Din, S.; Anwar, N.; Ikram, M.; Idrees, F. Materials for Photovoltaics: Overview, Generations, Recent Advancements and Future Prospects; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Conibeer, G. Third-generation photovoltaics. Mater. Today 2007, 10, 42–50. [Google Scholar] [CrossRef]

- Battaglia, C.; Cuevas, A.; De Wolf, S. High-efficiency crystalline silicon solar cells: Status and perspectives. Energy Environ. Sci. 2016, 9, 1552–1576. [Google Scholar] [CrossRef]

- Gao, J.; Tang, L.; Shen, Z.; Dong, Y.; Wang, Z.; Lyu, J.; Li, J.; Yu, H. Efficient solar-light conversion for optimizing the catalytic ozonation of gaseous toluene with PdOx-LaFeO3. Appl. Catal. B Environ. 2021, 288, 120004. [Google Scholar] [CrossRef]

- Heath, G.A.; Silverman, T.J.; Kempe, M.; Deceglie, M.; Ravikumar, D.; Remo, T.; Cui, H.; Sinha, P.; Libby, C.; Shaw, S.; et al. Research and development priorities for silicon photovoltaic module recycling to support a circular economy. Nat. Energy 2020, 5, 502–510. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Chai, J.; Xue, B.; Zhao, F.; Wang, X. Environmental influence assessment of China’s multi-crystalline silicon (multi-Si) photovoltaic modules considering recycling process. Sol. Energy 2017, 143, 132–141. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. An evaluation of the impact framework for product stewardship on end-of-life solar photovoltaic modules: An environmental lifecycle assessment. J. Clean. Prod. 2023, 411, 137357. [Google Scholar] [CrossRef]

- Tasnim, S.S.; Rahman, M.M.; Hasan, M.M.; Shammi, M.; Tareq, S.M. Current challenges and future perspectives of solar-PV cell waste in Bangladesh. Heliyon 2022, 8, e08970. [Google Scholar] [CrossRef] [PubMed]

- Ndzibah, E.; Pinilla-De La Cruz, G.A.; Shamsuzzoha, A. Collaboration towards value creation for end-of-life solar photovoltaic panel in Ghana. J. Clean. Prod. 2022, 333, 129969. [Google Scholar] [CrossRef]

- Cherrington, R.; Goodship, V.; Longfield, A.; Kirwan, K. The feed-in tariff in the UK: A case study focus on domestic photovoltaic systems. Renew. Energy 2013, 50, 421–426. [Google Scholar] [CrossRef]

- Priyadarshini, P.; Abhilash, P.C. Circular economy practices within energy and waste management sectors of India: A meta-analysis. Bioresour. Technol. 2020, 304, 123018. [Google Scholar] [CrossRef] [PubMed]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-analysis of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, S.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Scimago Journal & Country Rank. Sustainability. Available online: https://www.scimagojr.com/journalsearch.php?q=21100240100&tip=sid&clean=0 (accessed on 8 August 2024).

- Davy, E.; Hansen, U.E.; Nygaard, I. Localizing the solar value chain in Kenya? Innov. Dev. 2024, 14, 217–240. [Google Scholar] [CrossRef]

- Sah, D.; Chitra; Kumar, S. Investigation and recovery of copper from waste silicon solar module. Mater. Chem. Phys. 2023, 296, 127205. [Google Scholar] [CrossRef]

- Kolathur, S.; Khatiwada, D.; Khan, E.U. Life cycle assessment and life cycle costing of a building-scale, solar-driven water purification system. Energy Nexus 2023, 10, 100208. [Google Scholar] [CrossRef]

- Senthil, R. A technical note on integrating thermal energy systems into solar photovoltaic panels toward a circular economy. Renew. Energy Focus 2022, 42, 97–100. [Google Scholar] [CrossRef]

- Sinha, P. Life cycle materials and water management for CdTe photovoltaics. Sol. Energy Mater. Sol. Cells 2013, 119, 271–275. [Google Scholar] [CrossRef]

- Venkatachary, S.K.; Samikannu, R.; Murugesan, S.; Dasari, N.R.; Subramaniyam, R.U. Economics and im-pact of recycling solar waste materials on the environment and health care. Environ. Technol. Innov. 2020, 20, 101130. [Google Scholar] [CrossRef]

- Bonilla-Alicea, R.J.; Fu, K. Social life-cycle assessment (S-LCA) of residential rooftop solar panels using challenge-derived framework. Energy Sustain. Soc. 2022, 12, 7. [Google Scholar] [CrossRef]

- Maani, T.; Celik, I.; Heben, M.J.; Ellingson, R.J.; Apul, D. Environmental impacts of recycling crystalline silicon (c-SI) and cadmium telluride (CDTE) solar panels. Sci. Total Environ. 2020, 735, 138827. [Google Scholar] [CrossRef] [PubMed]

- Perkins, G. Techno-economic comparison of the levelised cost of electricity generation from solar PV and battery storage with solar PV and combustion of bio-crude using fast pyrolysis of biomass. Energy Convers. Manag. 2018, 171, 1573–1588. [Google Scholar] [CrossRef]

- Tannous, S.; Manneh, R.; Harajli, H.; El Zakhem, H. Comparative cradle-to-grave life cycle assessment of traditional grid connected and solar stand-alone street light systems: A case study for rural areas in Lebanon. J. Clean. Prod. 2018, 186, 963–977. [Google Scholar] [CrossRef]

- Farrell, C.; Osman, A.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.; Kumaravel, V.; Al-Muhtaseb, A.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Rao, R.R.; Priyadarshani, S.; Mani, M. Examining the use of End-of-Life (EoL) PV panels in housing and sustainability. Sol. Energy 2023, 257, 210–220. [Google Scholar] [CrossRef]

- Lema, R.; Bhamidipati, P.L.; Gregersen, C.; Hansen, U.E.; Kirchherr, J. China’s investments in renewable energy in Africa: Creating co-benefits or just cashing-in? World Dev. 2021, 141, 105365. [Google Scholar] [CrossRef]

- Mkhwebane, E.; Ntuli, N. Alternatives for small, medium and micro scale enterprises participation in the renewable energy industry-small scale embedded generation review. J. Energy S. Afr. 2019, 30, 144–151. [Google Scholar] [CrossRef]

- Schmidt-Costa, J.R.; Uriona-Maldonado, M.; Possamai, O. Product-service systems in solar PV deployment programs: What can we learn from the California Solar Initiative? Resour. Conserv. Recy. 2018, 140, 145. [Google Scholar] [CrossRef]

- Borg, D.; Mont, O.; Schoonover, H. Consumer acceptance and value in use-oriented product-service systems: Lessons from Swedish consumer goods companies. Sustainability 2020, 12, 8079. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strat. Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Guerin, T.F. Using integrated risk assessment to enable on-site re-purposing of construction wastes from renewable energy projects to confirm highest value re-use. Environ. Sci. Pollut. Res. 2022, 29, 8909–8920. [Google Scholar] [CrossRef] [PubMed]

- Franco, M.A.; Groesser, S.N. A systematic literature review of the solar photovoltaic value chain for a circular economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, C.; Zheng, S. Investment and pricing in solar photovoltaic waste recycling with government intervention: A supply chain perspective. Comput. Ind. Eng. 2023, 177, 109044. [Google Scholar] [CrossRef]

- Le LUU, Q.; Binh, V.; Nguyen, N.Q.; Nguyen, N.H. Life Cycle Assessment (LCA) of an Integrated Solar PV and Wind Power System in Vietnam. J. Asian Energy Stud. 2020, 4, 36–47. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. Environmental emissions influencing solar photovoltaic waste management in Australia: An optimised system network of waste collection facilities. J. Environ. Manag. 2022, 314, 115007. [Google Scholar] [CrossRef] [PubMed]

- Volan, T.; Vaz, C.R.; Uriona-Maldonado, M. Scenarios for end-of-life (EOL) electric vehicle batteries in China. Rev. Gestão 2021, 28, 335–357. [Google Scholar] [CrossRef]

- Amiryar, M.E.; Pullen, K.R. Assessment of the Carbon and Cost Savings of a Combined Diesel Generator, Solar Photovoltaic, and Flywheel Energy Storage Islanded Grid System. Energies 2019, 12, 3356. [Google Scholar] [CrossRef]

- Maso, M.D.; Olsen, K.H.; Dong, Y.; Pedersen, M.B.; Hauschild, M.Z. Sustainable development impacts of nationally determined contributions: Assessing the case of mini-grids in Kenya. Clim. Policy 2020, 20, 815–831. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Maqbool, R.; Akubo, S.A.; Rashid, Y.; Ashfaq, S.; Saiba, M.R. Solar energy and the circular economy policies for sustainable management. In Solar Energy Harvesting, Conversion, and Storage: Materials, Technologies, and Applications; Khalid, M., Walvekar, R., Panchal, H., Vaka, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 363–376. [Google Scholar] [CrossRef]

- Gerbinet, S.; Belboom, S.; Léonard, A. Life Cycle Analysis (LCA) of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2014, 38, 747–753. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Ostrowski, P. Chemical treatment of crystalline silicon solar cells as a method of recovering pure silicon from photovoltaic modules. Renew. Energy 2010, 35, 1751–1759. [Google Scholar] [CrossRef]

- Institute for Energy Economics and Financial Analysis [IEEFA]. Role of Recycling for Resilient Solar Photovoltaic Supply Chains. (2 April 2024). Available online: https://ieefa.org/resources/role-recycling-resilient-solar-photovoltaic-supply-chains (accessed on 8 August 2024).

- Circular PV Alliance. Research|Circular PV Alliance. Available online: https://www.circularpv.com.au/research (accessed on 8 August 2024).

- Mahmoudi, S.; Huda, N.; Behnia, M. Photovoltaic waste assessment: Forecasting and screening of emerging waste in Australia. Resour. Conserv. Recycl. 2019, 146, 192–205. [Google Scholar] [CrossRef]

| Themes | ||||

|---|---|---|---|---|

| Solar Technology | Policies and Regulations | Monitoring, Tracking and Logistics | Infrastructure | Treatment Pathways |

| First generation | Policies and regulations in place | Collection, monitoring and tracking | Optimised recovery and recycling | Recycling and recovery |

| Second generation | No policies and regulations in place | No monitoring and tracking | Current/available infrastructure | Landfilling and disposal |

| Third generation | No infrastructure | Exportation (interstate and overseas) | ||

| Reuse or reconditioning | ||||

| Incineration | ||||

| Timeframe | 2013–2023 |

|---|---|

| Data source | Journal articles and conference papers published in English |

| Search keywords and terms | (“solar system” OR “solar PV” OR “rooftop solar”) AND (“circular business model” OR “end-of-life” OR “value chain”) |

| Searched database | Scopus, Web of Science |

| Journals | Number of Published Papers per Journal | Total Papers |

|---|---|---|

| Sustainability | 6 | 6 |

| Energy Policy | 4 | 4 |

| Energy Conversion and Management; Journal of Cleaner Production; Resources, Conservation and Recycling Advances; Sustainable Production and Consumption; Applied Energy; Renewable and Sustainable Energy Reviews | 3 | 18 |

| Climate Policy; Energies; Energy, Sustainability and Society | 2 | 6 |

| Acta Astronautica; Aerospace; Australian Planner; Clean Technologies and Environmental Policy; Cleaner Engineering and Technology; Computers and Industrial Engineering; Development Policy Review; Energy Nexus; Energy Research and Social Science; Energy Sources, Part B: Economics, Planning and Policy; Environment, Development and Sustainability; Environmental Progress and Sustainable Energy; Environmental Science and Pollution Research; Environmental Technology and Innovation; European Planning Studies; GCB Bioenergy; Heliyon; IEEE Transactions on Power Electronics; Industry and Innovation; Innovation and Development; International Journal of Energy Sector Management; International Journal of Green Economics; International Journal of Scientific and Technology Research; International Journal of Sustainable Energy; Journal of Asian Energy Studies; Journal of Business Research; Journal of Energy in Southern Africa; Journal of Environmental Management; Materials Chemistry and Physics; Materials Today: Proceedings; Metallurgical Research and Technology; Proceedings of the Institution of Civil Engineers: Engineering Sustainability; Renewable Energy; Renewable Energy Focus; Revista de Gestao; Science of the Total Environment; Solar Energy; Solar Energy; Solar Energy Materials and Solar Cells; Solar Energy Materials and Solar Cells; Sustainable Energy Technologies and Assessments; Sustainable Horizons; Sustainable Materials and Technologies; Waste Management; Waste Management and Research; Water, Air, and Soil Pollution; World Development | 1 | 47 |

| Category | Description | References |

|---|---|---|

| Raw materials | Initial access to knowledge of raw material to manufacturing end-of-life (EOL) panels | [2,33,42,50,51] |

| Manufacturing technology | Improving solar cells for high efficiency | [20,42,50,52,53,54,55] |

| Supply chain collaboration | Collaboration within the supply chain to access EOL scenarios for PV models | [32,42,52,56,57,58,59,60] |

| PV system installation | Appropriate framework that helps to create options for dealing with EOL PV panels installation | [18,19,61] |

| Job market | Job market in the PV industry | [1,11,20,32,42,62,63] |

| Business model & PV industry | Business models used in the PV industry | [18,20,25,32,64,65,66,67] |

| Cost | Economic viability and low cost of PV panels’ end of life | [16,20,42,51,61,68] |

| Government and other institutions | Government and other institutions policy on formal PV development | [18,20,69,70] |

| Health and environment | Determining the risk to human health or environment | [1,41,55,68,71] |

| End-of Life (EOL) close loop (reuse, recycle) | Promotion related to efficient management for EOL solar PV panels | [16,42,44,53,61,68,72,73] |

| Electric vehicle (EV) batteries Lithium-ion Batteries (LIB) | Benefits of lithium-ion to supplement solar PV system | [73,74] |

| PV system benefits | Increasing the benefits from the circular economy concept for PV panels | [18,20,75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amrollahi Biyouki, Z.; Zaman, A.; Marinova, D.; Minunno, R.; Askari Shayegan, M. Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review. Sustainability 2024, 16, 7038. https://doi.org/10.3390/su16167038

Amrollahi Biyouki Z, Zaman A, Marinova D, Minunno R, Askari Shayegan M. Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review. Sustainability. 2024; 16(16):7038. https://doi.org/10.3390/su16167038

Chicago/Turabian StyleAmrollahi Biyouki, Zahra, Atiq Zaman, Dora Marinova, Roberto Minunno, and Maryam Askari Shayegan. 2024. "Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review" Sustainability 16, no. 16: 7038. https://doi.org/10.3390/su16167038

APA StyleAmrollahi Biyouki, Z., Zaman, A., Marinova, D., Minunno, R., & Askari Shayegan, M. (2024). Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review. Sustainability, 16(16), 7038. https://doi.org/10.3390/su16167038