Evaluation of the Effectiveness of Solar Array Simulators in Reproducing the Characteristics of Photovoltaic Modules

Abstract

1. Introduction

2. Solar Array Simulator

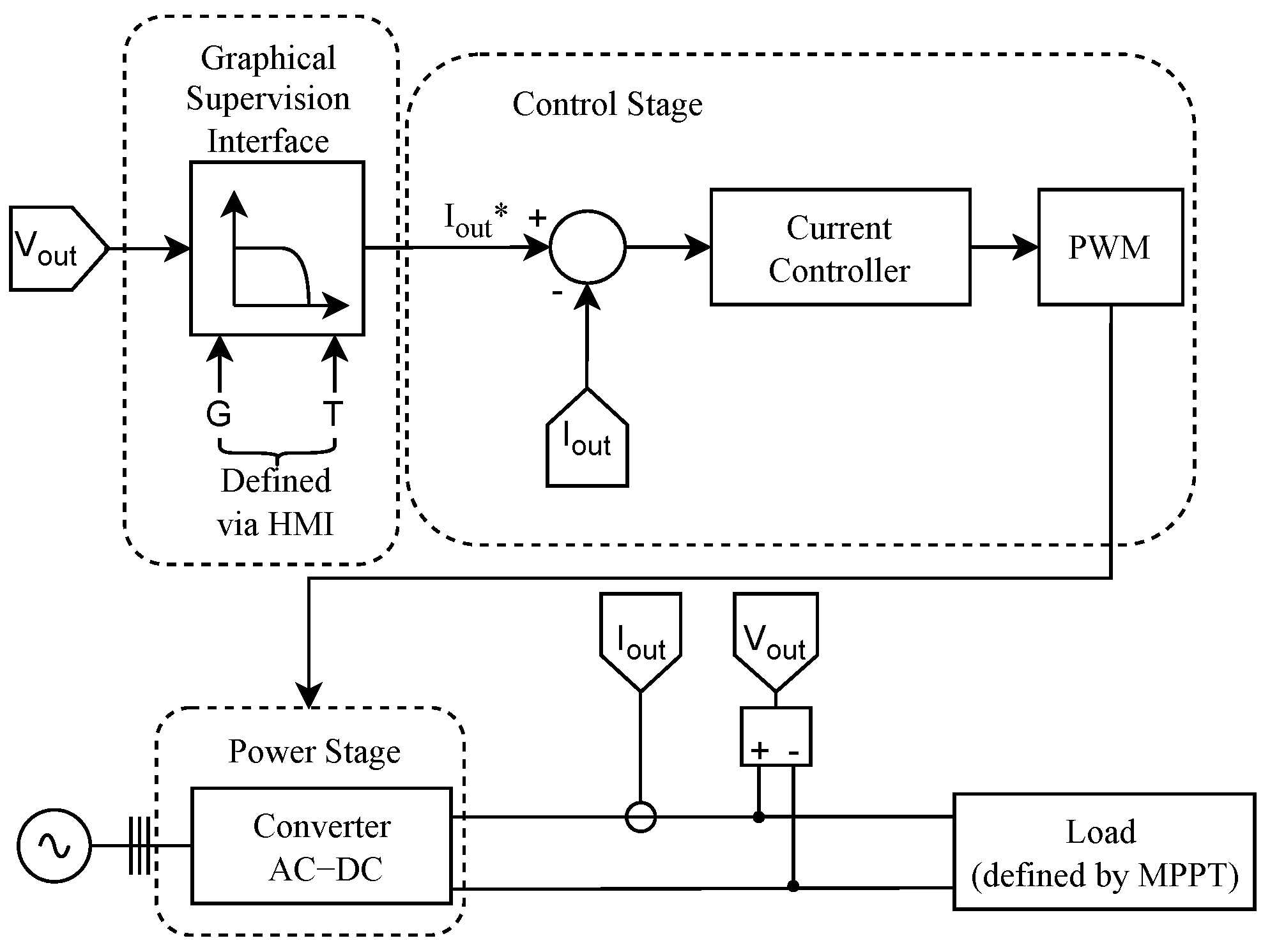

2.1. Power Stage

2.2. Control Stage

2.3. Graphical Supervision Interface

2.4. Common Characteristics of SASs

- An internal algorithm that generates an I–V points table based on input parameters of the PV module, such as open-circuit voltage (), short-circuit current (), current at maximum power point (), and voltage at maximum power point (). This feature allows for a quick and easy approximation of the curve without the need for a computer to perform the simulation;

- An algorithm that allows the user to define a custom table of points to determine the I–V curve (user-defined lookup table). This feature enables users to have full control over the simulation and create specific tables for their project needs. Additionally, custom tables can be stored in the system’s internal memory, making it easy to access and reuse in future simulations;

- A shading mode that allows for simulation of shadow conditions, enabling the evaluation of their impact on the energy production of PV systems. The list mode is used to generate a list of operation points of the I–V curve of a PV module under different conditions, which is essential for determining the module’s efficiency in different situations.

3. Methodology and Characterization of the Evaluated SAS

- Steady-state operation: In this scenario, the SASs are tested under stable operating conditions, considering PV modules subject to constant solar irradiation and a constant temperature. By doing so, it becomes possible to evaluate how the sources respond and follow the global maximum power point (GMPP) in a steady state.

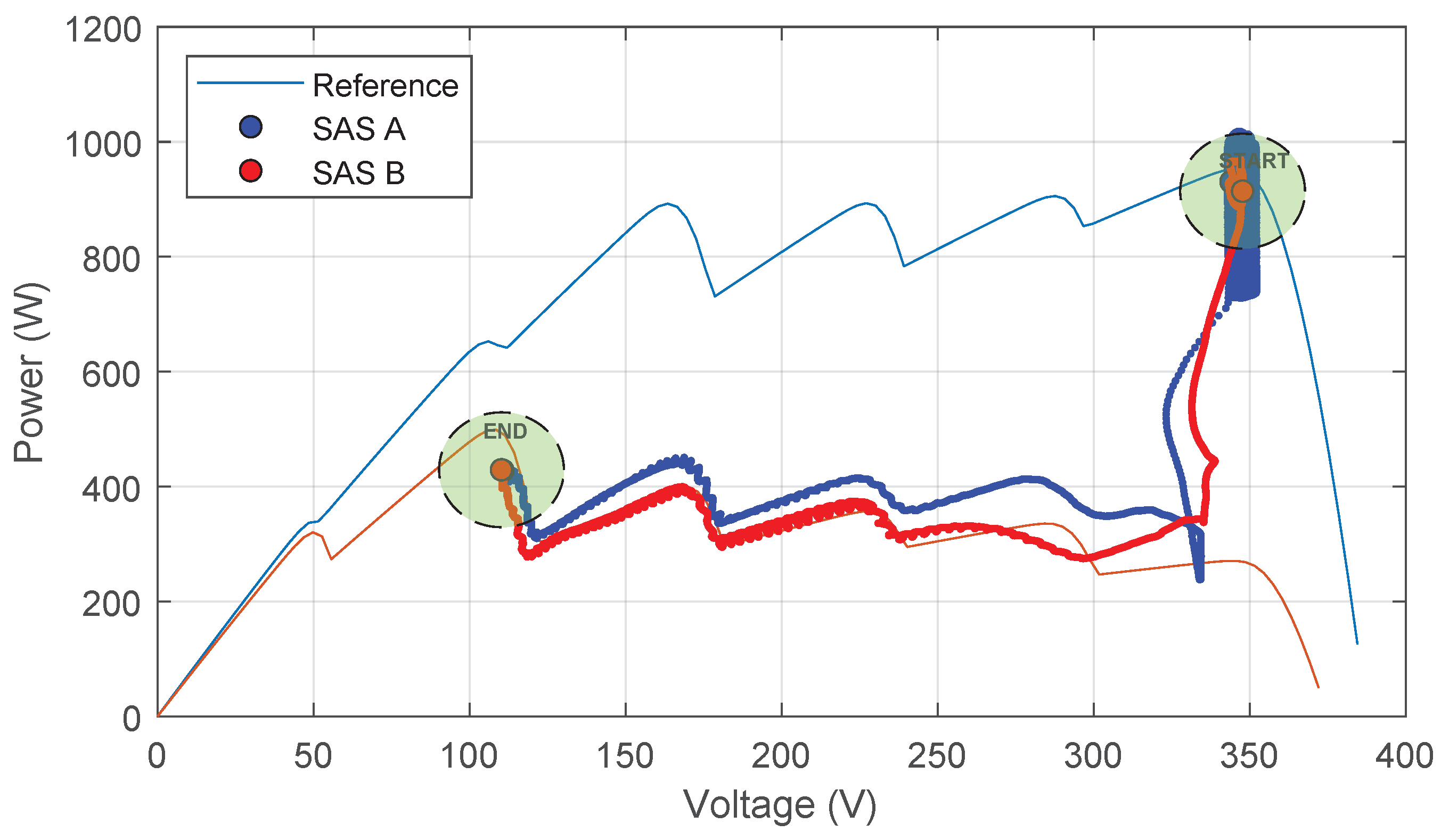

- Shading-induced curve change: This scenario simulates a situation where part of the PV module is shaded, resulting in a change in its characteristic power curve. By doing so, it becomes possible to assess how emulating sources respond to this change and whether they can properly track the new maximum power point.

- Performance during curve transitions: In this scenario, rapid and smooth transitions between different operating points of the PV module are considered. This can occur, for example, due to rapid changes in solar irradiation or ambient temperature. By doing so, it becomes possible to analyze whether emulating sources can accurately follow these transitions and capture variations in the GMPP.

Characterization of the Evaluated Emulating Sources

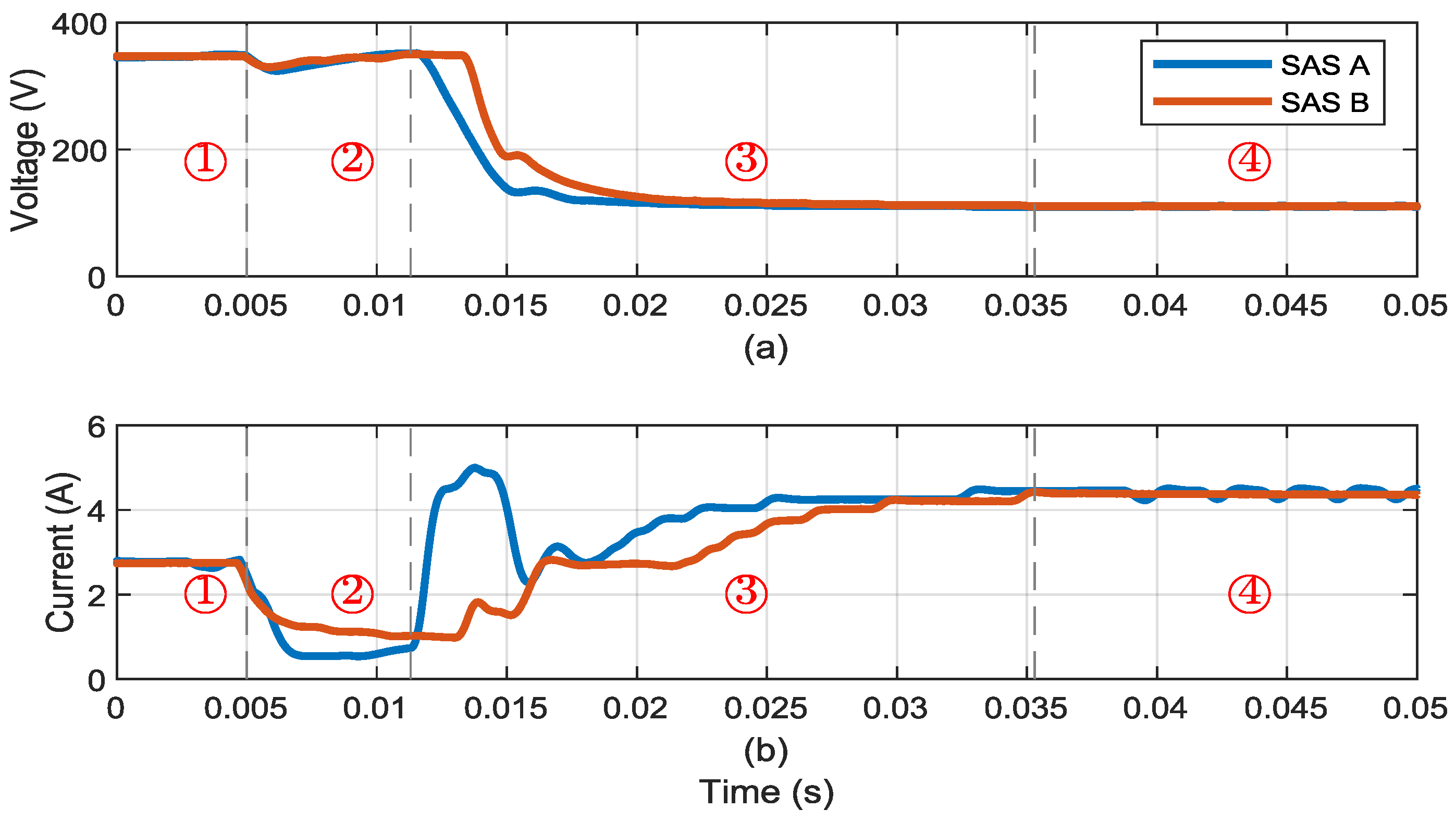

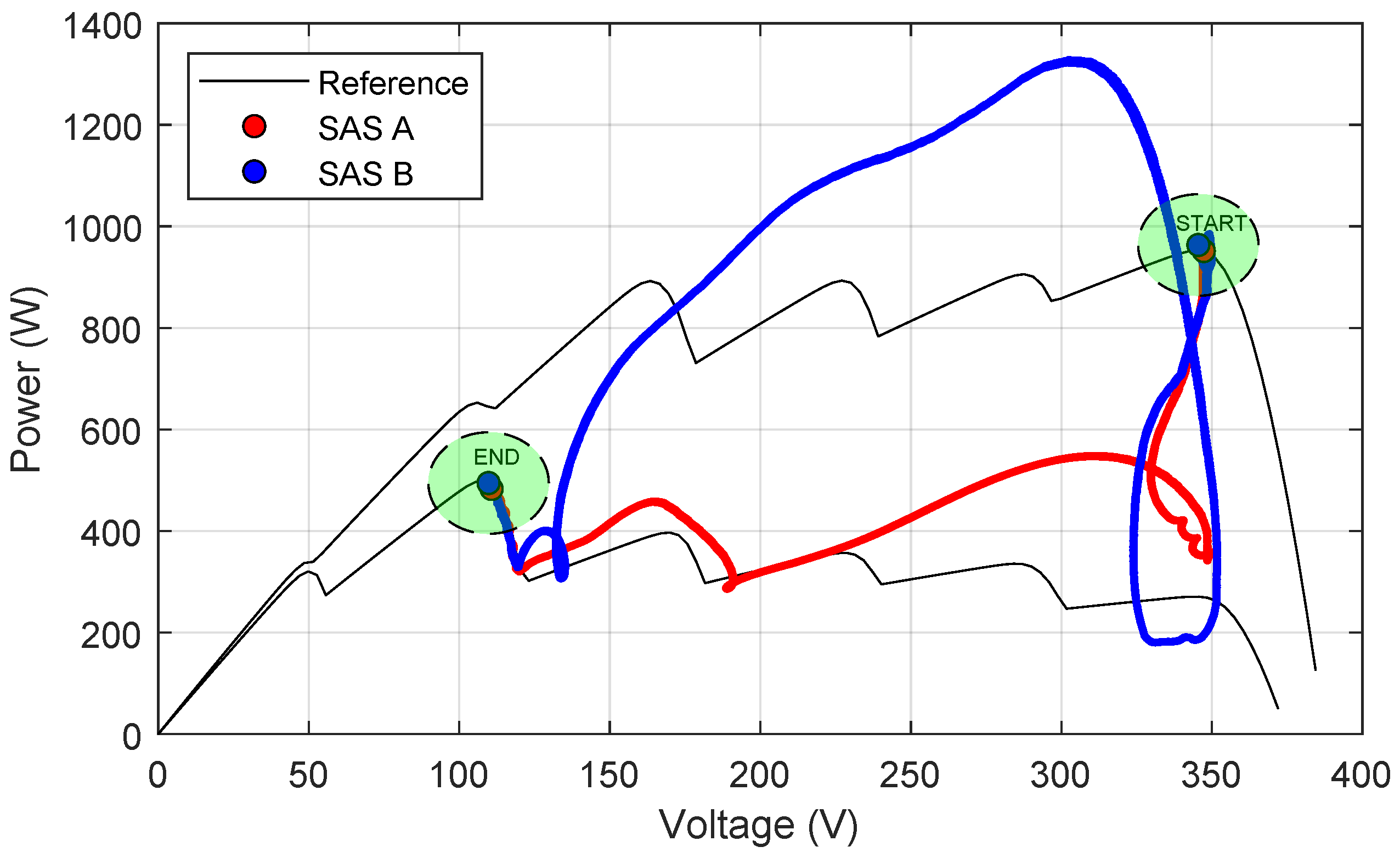

- SAS A is an emulating source equipped with a built-in 16-bit digital control, along with voltage and current measurement circuits. According to the manufacturer, this source is particularly suitable for real-time analysis of maximum power point tracking (MPPT) and for the monitoring of inverter tracking. However, this source does not allow the user to modify the internal control gains. The results obtained with SAS A are graphically represented in blue in the following sections of this work.

- SAS B is a fully programmable emulating source. Its dynamics are determined by the control gains imposed by the user in the graphical supervision interface, allowing for the digital adjustment of properties such as voltage, current, and power. Additionally, this source offers adjustable simulation of internal resistance. The multiprocessing architecture of SAS B enables not only the combination of different control profiles but also real-time data processing. The results obtained with SAS B are graphically represented in red in the following sections of this work.

4. Equipment and Settings Used to Evaluate Emulating Sources

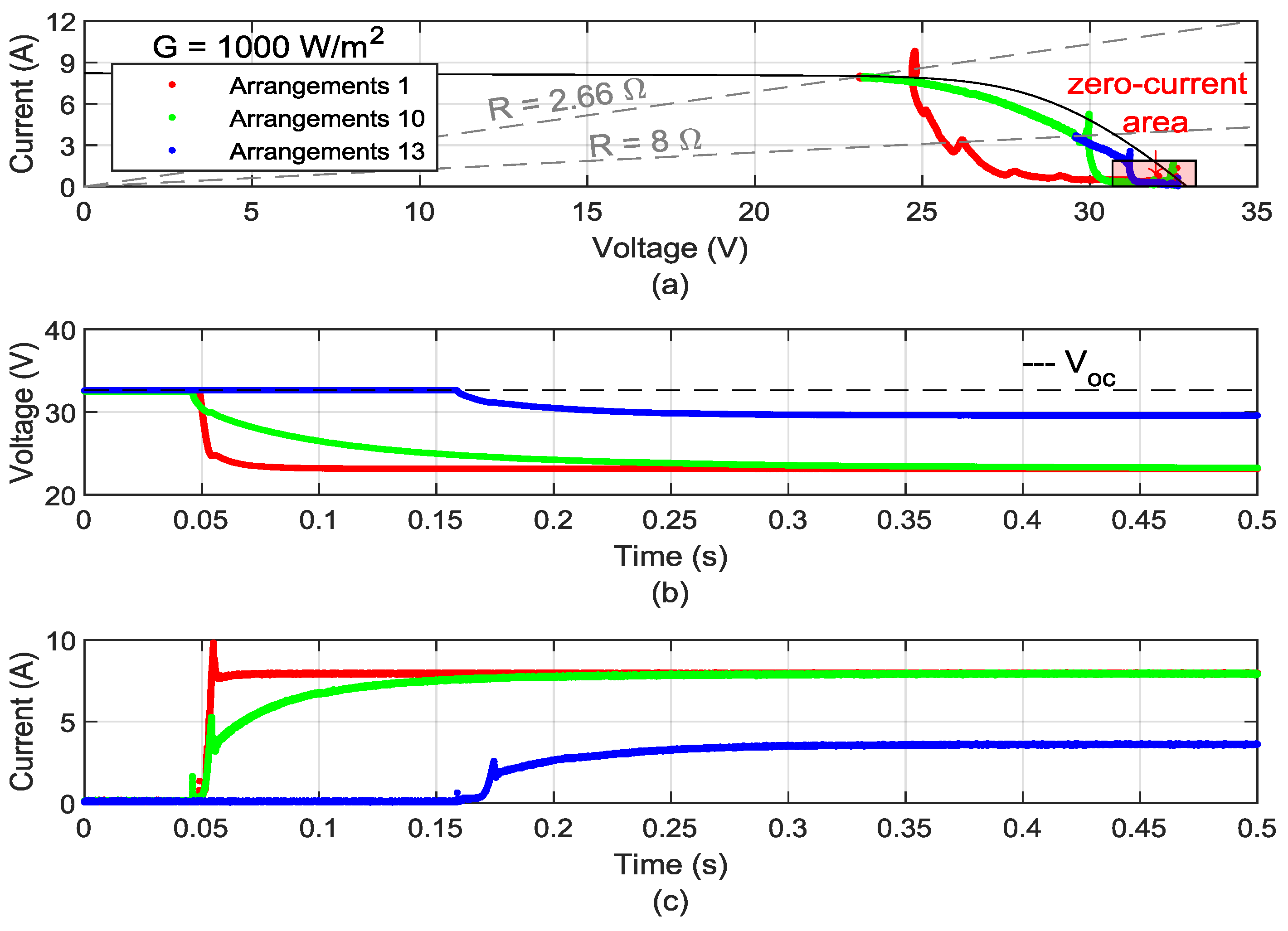

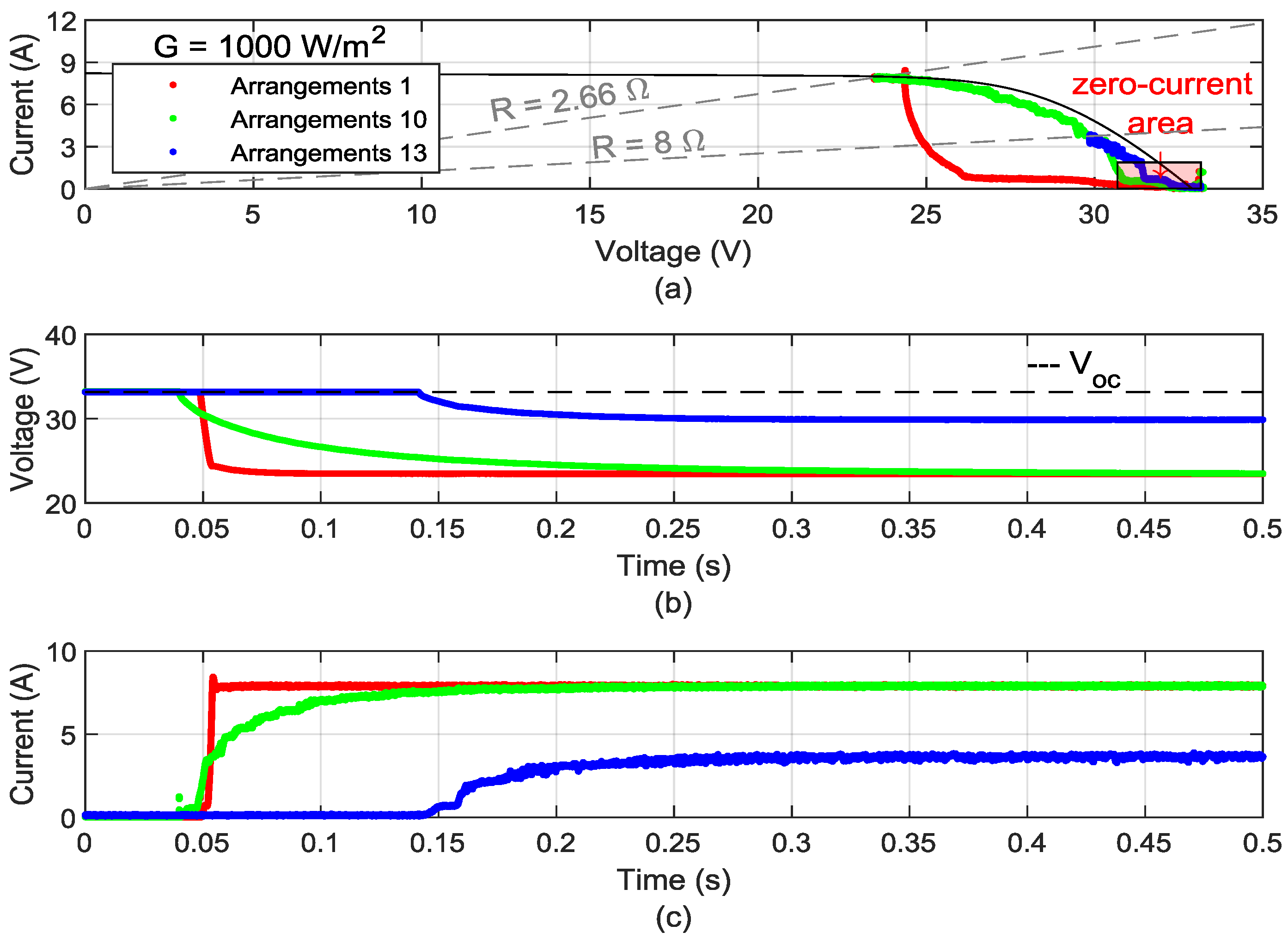

4.1. Configuration 1: RC Load

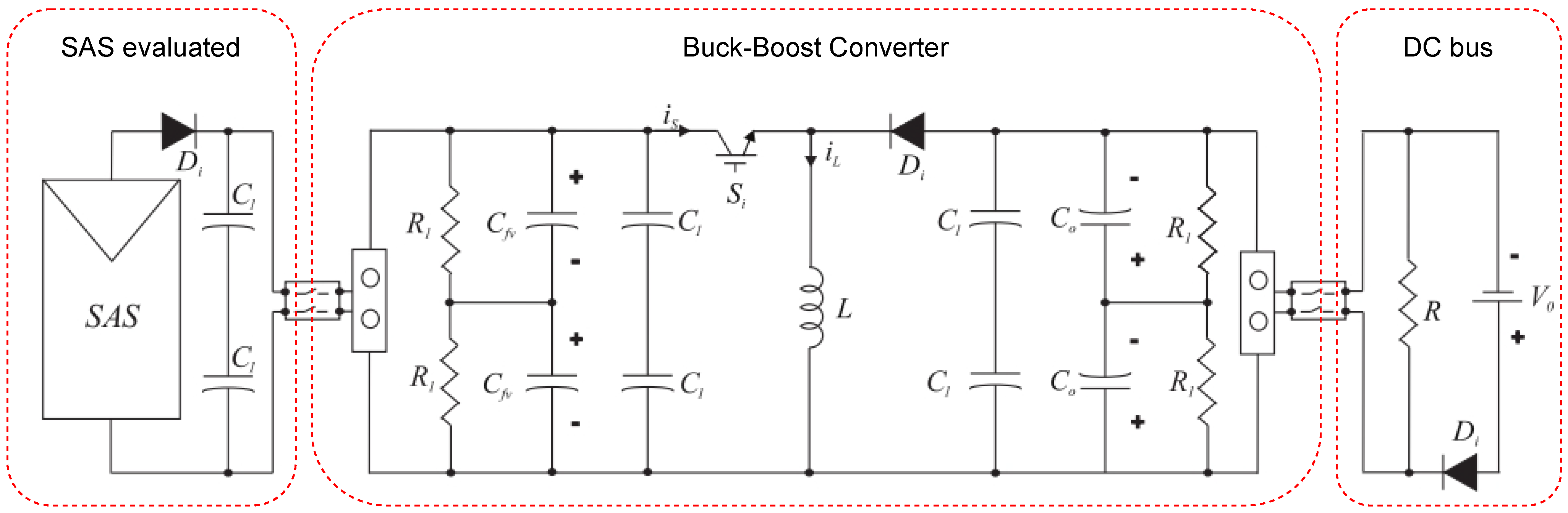

4.2. Configuration 2: Buck–Boost Converter

5. Results

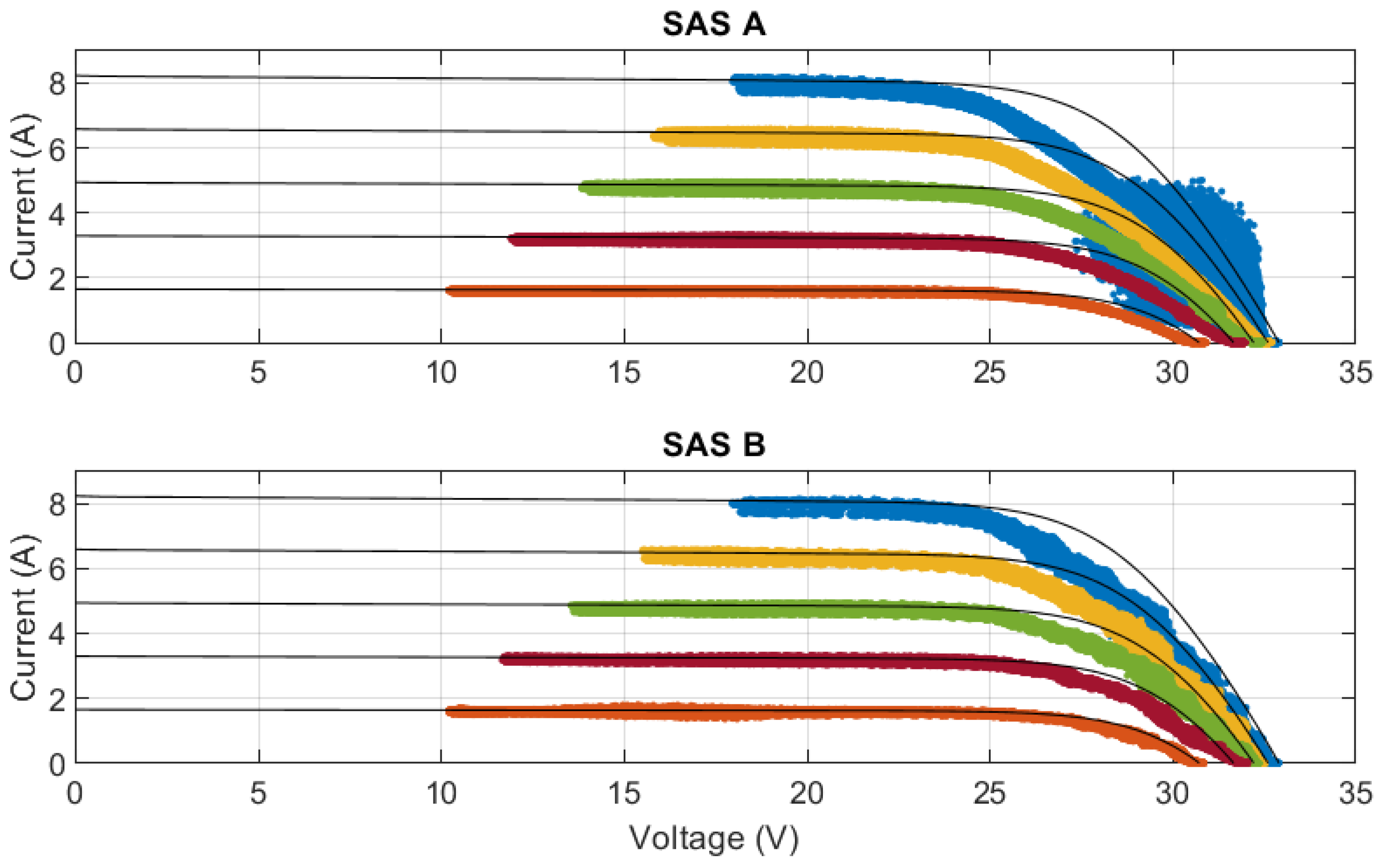

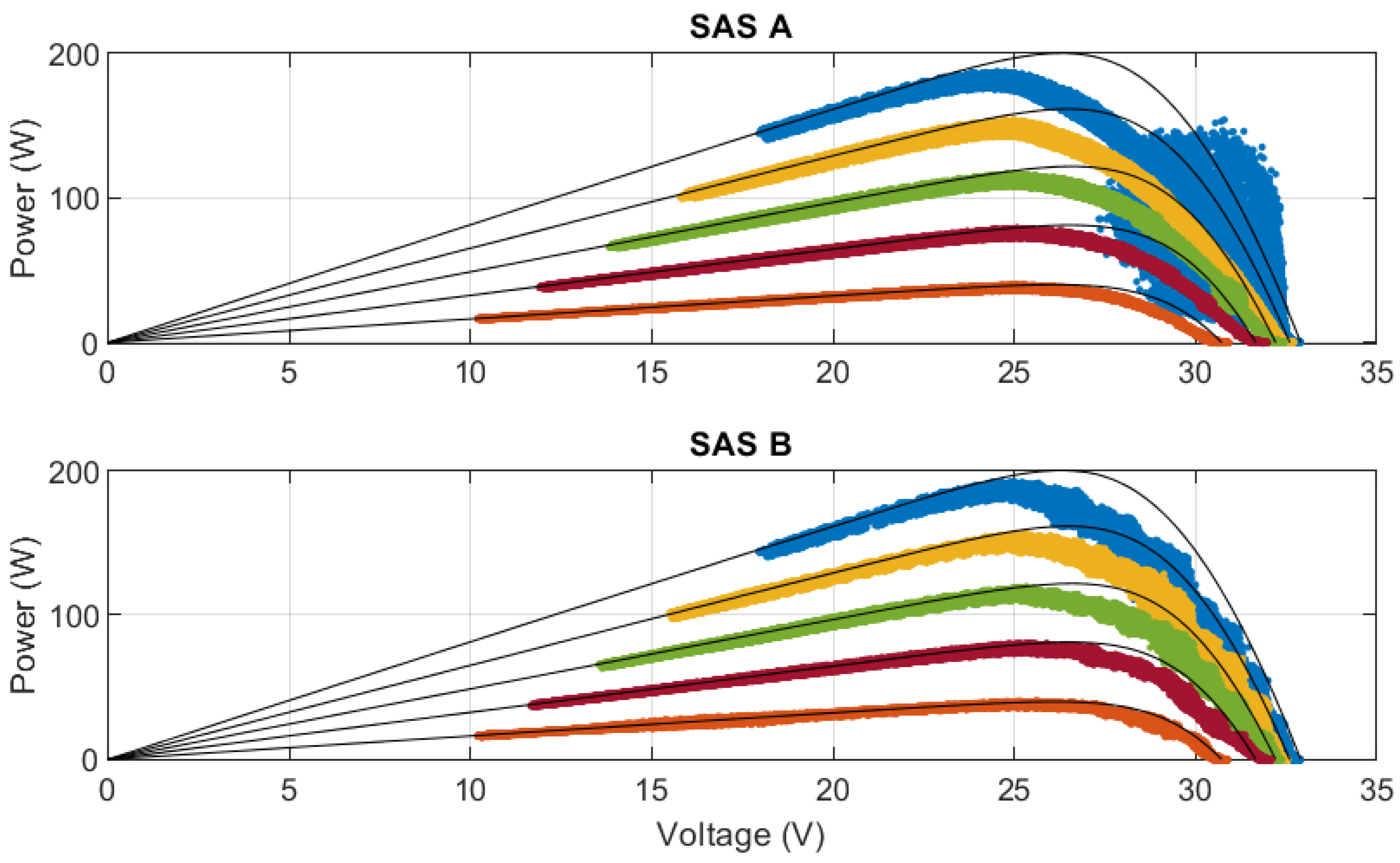

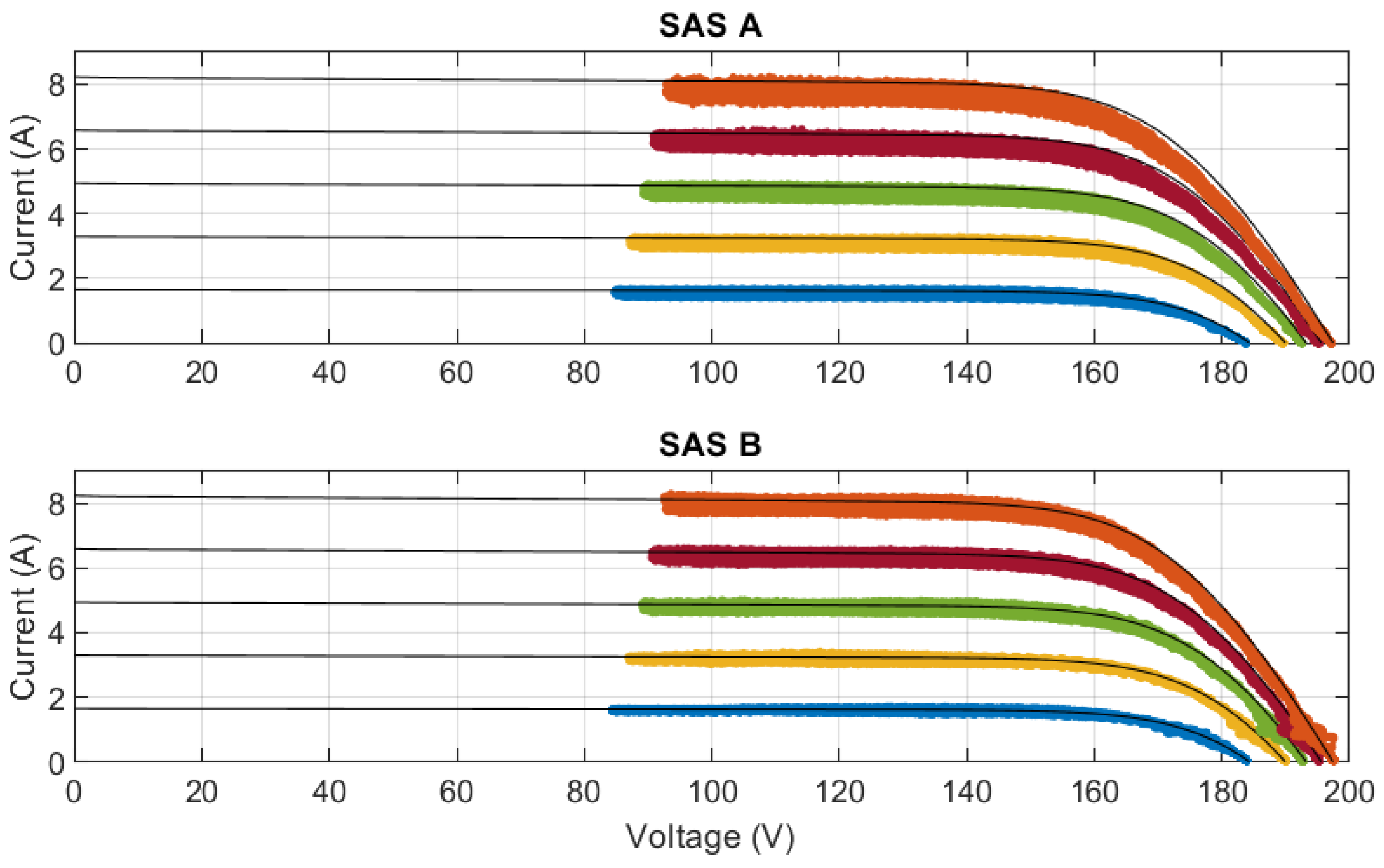

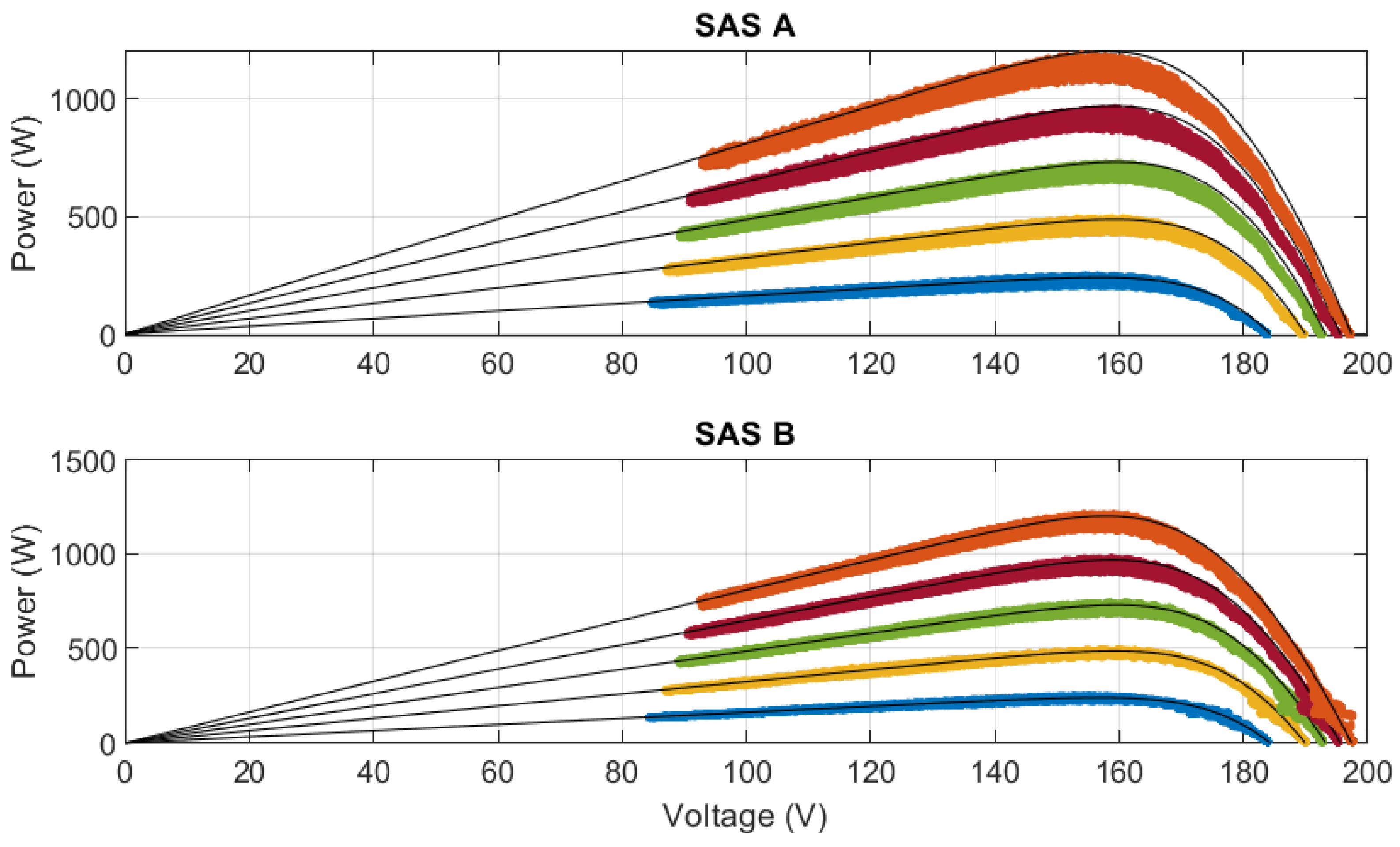

5.1. Steady-State Behavior of SAS

5.1.1. Results of SASs in Measurements with the Buck–Boost Converter Duty Cycle Varied Linearly

5.1.2. Steady-State Performance Evaluation

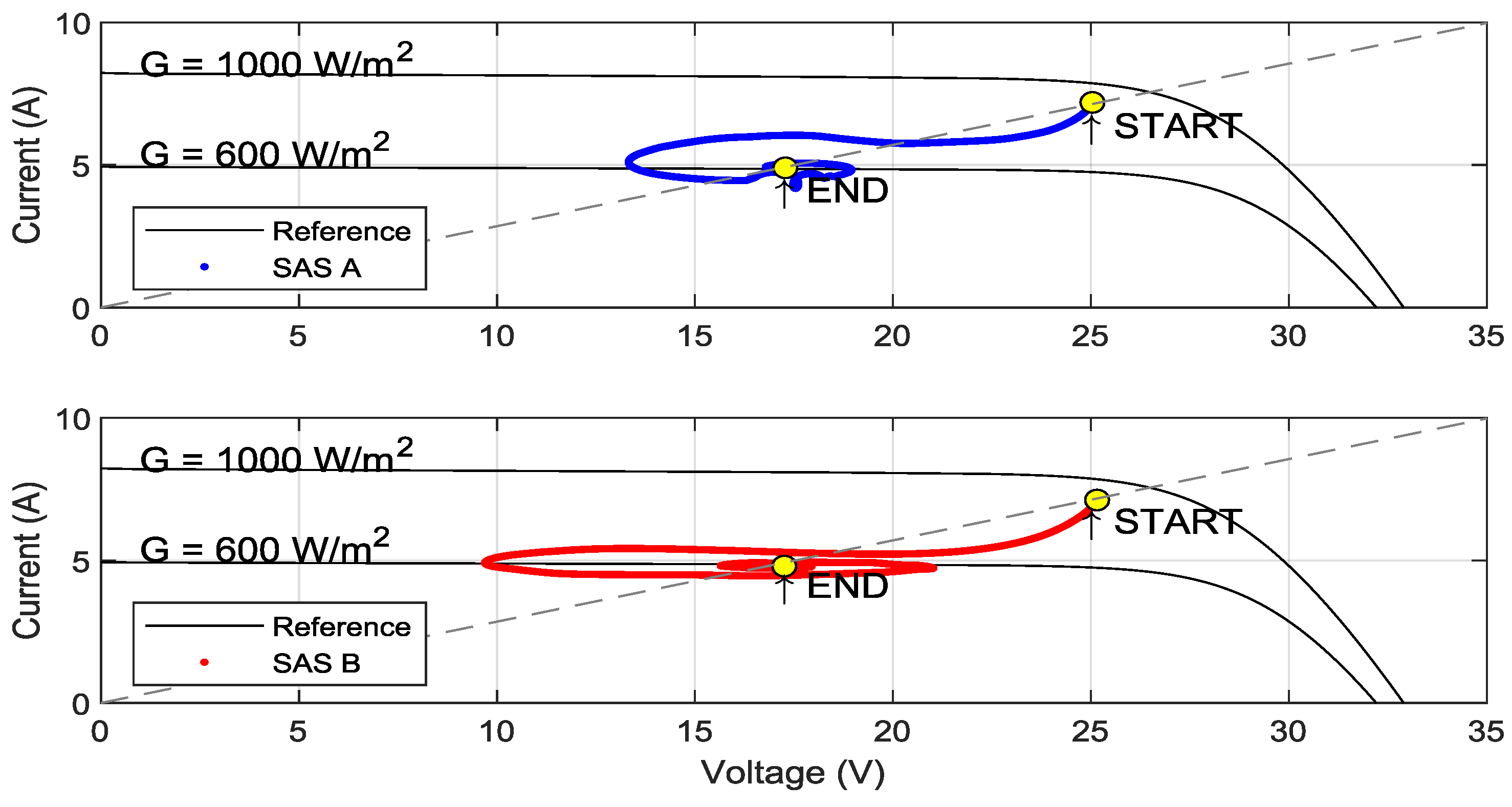

5.2. Transient Behavior of SASs

5.2.1. Transient Behavior for Source Connected in Buck–Boost Converter with Fixed Duty Cycle

5.2.2. Transient for Source Connected to RC Load

5.2.3. Transient with GMPPT

- CASE 1—Converter control with regular response time: In this application, the the control loop for the converter input voltage (voltage at the output of the emulated source) was designed that the system had zero error in a steady state, a crossover frequency of 3 kHz, a phase margin of 67.1°, and infinite gain margin. For this purpose, a PI controller with gains of = and = was used. The crossover frequency was selected to be ten times lower than the switching frequency, a common practice in static converters with only one control loop.

- CASE 2—Converter control with slow response time: In this application, the gains of the PI controller were decreased to reduce the system’s crossover frequency, making its dynamics slower. For this purpose, a PI controller with gains of = and = was used.

5.2.4. Evaluation of Transient Results

6. Conclusions

- Regarding static analysis, the analyzed SAS showed inaccuracies in the knee region and in the nonlinear region of the I–V curve, especially when configured to emulate only one module. However, it was observed that increasing the number of modules tended to significantly reduce inaccuracies.

- Regarding dynamic analysis, the analyzed SASs faced difficulties in following the reference curves during transitions. Their dynamic characteristics (resulting from the control system) and their slew-rate limitations ended up generating behaviors divergent from what is expected for PV modules. This limitation is especially critical when evaluating model-based MPPT algorithms, since the ability to quickly identify the maximum power point after a change in the I–V curve is crucial for the efficiency of this class of algorithms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azharuddin, S.M.; Vysakh, M.; Thakur, H.V.; Nishant, B.; Babu, T.S.; Muralidhar, K.; Paul, D.; Jacob, B.; Balasubramanian, K.; Rajasekar, N. A Near Accurate Solar PV Emulator Using dSPACE Controller for Real-time Control. Energy Procedia 2014, 61, 2640–2648. [Google Scholar] [CrossRef]

- Alghamdi, H.; Alviz-Meza, A. Techno-Environmental Evaluation and Optimization of a Hybrid System: Application of Numerical Simulation and Gray Wolf Algorithm in Saudi Arabia. Sustainability 2023, 15, 3284. [Google Scholar] [CrossRef]

- Yilmaz, M. Comparative Analysis of Hybrid Maximum Power Point Tracking Algorithms Using Voltage Scanning and Perturb and Observe Methods for Photovoltaic Systems under Partial Shading Conditions. Sustainability 2024, 16, 4199. [Google Scholar] [CrossRef]

- Subbulakshmy, R.; Palanisamy, R.; Alshahrani, S.; Saleel, C.A. Implementation of Non-Isolated High Gain Interleaved DC-DC Converter for Fuel Cell Electric Vehicle Using ANN-Based MPPT Controller. Sustainability 2024, 16, 1335. [Google Scholar] [CrossRef]

- Farhangi, S.; Nazer, A.; Moradi, G.R.; Asadi, E. Improved Performance of Solar Array Simulator Based on Constant Voltage/Constant Current Full-Bridge Converter. In Proceedings of the 2020 11th Power Electronics, Drive Systems, and Technologies Conference (PEDSTC), Tehran, Iran, 4–6 February 2020; pp. 1–5. [Google Scholar]

- Nagadurga, T.; Narasimham, P.V.R.L.; Vakula, V.S. Global Maximum Power Point Tracking of Solar Photovoltaic Strings under Partial Shading Conditions Using Cat Swarm Optimization Technique. Sustainability 2021, 13, 11106. [Google Scholar] [CrossRef]

- Ram, J.P.; Manghani, H.; Pillai, D.S.; Babu, T.S.; Miyatake, M.; Rajasekar, N. Analysis on solar PV emulators: A review. Renew. Sustain. Energy Rev. 2018, 81, 149–160. [Google Scholar] [CrossRef]

- Dawahdeh, A.; Sharadga, H.; Kumar, S. Novel MPPT Controller Augmented with Neural Network for Use with Photovoltaic Systems Experiencing Rapid Solar Radiation Changes. Sustainability 2024, 16, 1021. [Google Scholar] [CrossRef]

- Cupertino, A.F.; Santos, G.Y.; Cardoso, E.N.; Pereira, H.A.; Mendes, V.F. Modeling and design of a flexible solar array simulator topology. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference (COBEP/SPEC), Fortaleza, Brazil, 29 November–2 December 2015; pp. 1–6. [Google Scholar]

- Punitha, K.; Rahman, A.; Radhamani, A.S.; Nuvvula, R.S.S.; Shezan, S.A.; Ahammed, S.R.; Kumar, P.P.; Ishraque, M.F. An Optimization Algorithm for Embedded Raspberry Pi Pico Controllers for Solar Tree Systems. Sustainability 2024, 16, 3788. [Google Scholar] [CrossRef]

- Ayop, R.; Tan, C.W. A comprehensive review on photovoltaic emulator. Renew. Sustain. Energy Rev. 2017, 80, 430–452. [Google Scholar] [CrossRef]

- Barbosa, E.J.; Cavalcanti, M.C.; de Souza Azevedo, G.M.; Barbosa, E.A.; Bradaschia, F.; Limongi, L.R. Global Hybrid Maximum Power Point Tracking for PV Modules Based on a Double-Diode Model. IEEE Access 2021, 9, 158440–158455. [Google Scholar] [CrossRef]

- Ye, S.P.; Liu, Y.H.; Pai, H.Y.; Sangwongwanich, A.; Blaabjerg, F. A Novel ANN-Based GMPPT Method for PV Systems under Complex Partial Shading Conditions. IEEE Trans. Sustain. Energy 2024, 15, 328–338. [Google Scholar] [CrossRef]

- Kumaresan, A.; Tafti, H.D.; Beniwal, N.; Gorla, N.B.Y.; Farivar, G.G.; Pou, J.; Konstantinou, G. Improved Secant-Based Global Flexible Power Point Tracking in Photovoltaic Systems Under Partial Shading Conditions. IEEE Trans. Power Electron. 2023, 38, 10383–10395. [Google Scholar] [CrossRef]

- Jassim, B.; Jasim, H. Modelling of a solar array simulator based on multiple DC-DC converters. Int. J. Renew. Energy Res. 2018, 8, 1038–1044. [Google Scholar]

- Norman, K.; Ren, B.; Zhong, Q.C. Learning-by-Doing: Design and Implementation of a Solar Array Simulator with a SYNDEM Smart Grid Research and Educational Kit. IEEE Power Electron. Mag. 2024, 11, 47–54. [Google Scholar] [CrossRef]

- Zhou, H.; Sun, Y.; Zhang, M.; Ni, Y.; Zhang, F.; Young Jeong, S.; Huang, T.; Li, X.; Woo, H.Y.; Zhang, J.; et al. Over 18.2% efficiency of layer–by–layer all–polymer solar cells enabled by homoleptic iridium(III) carbene complex as solid additive. Sci. Bull. 2024; in press. [Google Scholar]

- Xia, H.; Zhang, M.; Wang, H.; Sun, Y.; Li, Z.; Ma, R.; Liu, H.; Dela Peña, T.A.; Chandran, H.T.; Li, M.; et al. Leveraging Compatible Iridium(III) Complexes to Boost Performance of Green Solvent-Processed Non-Fullerene Organic Solar Cells. Adv. Funct. Mater. 2024, 2411058. [Google Scholar] [CrossRef]

- Seo, Y.T.; Park, J.Y.; Choi, S.J. A rapid I-V curve generation for PV model-based solar array simulators. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–5. [Google Scholar]

- Coelho, R.F.; Concer, F.; Martins, D.C. A Study of the Basic DC-DC Converters Applied in Maximum Power Point Tracking. In Proceedings of the 2009 Brazilian Power Electronics Conference, Bonito-Mato Grosso do Sul, Brazil, 27 September–1 October 2009; pp. 673–678. [Google Scholar]

- Chroma. Solar Array Simulation Soft Panel. Available online: https://www.chromausa.com/62000h-s-solar-array-simulation-video/ (accessed on 23 July 2024).

- Ecosense. Solar PV Emulator System (SPVE). Available online: https://www.ecosenseworld.com/sites/default/files/spve.pdf (accessed on 23 July 2024).

- Technologies, K. Keysight E4360 Modular Solar Array Simulators. Available online: https://www.axiomtest.com/documents/models/Keysight%20N8937APV%20DATASHEET.pdf (accessed on 23 July 2024).

- Regatron. SASControl Software Solar Array Simulation Program Manual. Available online: https://ohmini.com.br/downloads/catalogos/simulador-fotovoltaico/Catalogo-SASControl.pdf (accessed on 23 July 2024).

- Treter, M.E.; Michels, L. Métodos de aquisição experimental de curvas I-V de arranjos fotovoltaicos: Uma revisão. In Proceedings of the 1th Seminar on Power Electronics and Control-SEPOC, Santa Maria, Brazil, 21–24 October 2018. [Google Scholar]

- Cavalcante, V.M.; Fernandes, T.A.; Freitas, R.A.; Bradaschia, F.; Cavalcanti, M.C.; Limongi, L.R. A Global Nonlinear Model for Photovoltaic Modules Based on 3-D Surface Fitting. IEEE J. Photovolt. 2024, 1–9. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, D.; Bao, Z.; Liu, X. High Dynamic Performance Solar Array Simulator Based on a SiC MOSFET Linear Power Stage. IEEE Trans. Power Electron. 2018, 33, 1682–1695. [Google Scholar] [CrossRef]

- Cupertino, A.F.; Pereira, H.A.; Mendes, V.F. Modeling, Design and Control of a Solar Array Simulator Based on Two-Stage Converters. J. Control. Autom. Electr. Syst. 2017, 28, 585–596. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, D.; Wang, C. UI-RI Hybrid Lookup Table Method with High Linearity and High-Speed Convergence Performance for FPGA-Based Space Solar Array Simulator. IEEE Trans. Power Electron. 2018, 33, 7178–7192. [Google Scholar] [CrossRef]

- Orts, C.; Garrigós, A.; Marroquí, D.; Franke, A. Sequential Switching Shunt Regulation Using DC Transformers for Solar Array Power Processing in High Voltage Satellites. IEEE Trans. Aerosp. Electron. Syst. 2024, 60, 421–429. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, D.; Wang, C.; Gu, Y. Optimized Design of Space Solar Array Simulator with Novel Three-Port Linear Power Composite Transistor Based on Multiple Cascaded SiC-JFETs. IEEE Trans. Ind. Electron. 2018, 65, 4691–4701. [Google Scholar] [CrossRef]

| Parameter | SAS A | SAS B |

|---|---|---|

| Power | 0–5 kW | 0–10 kW |

| Current | 0–8.5 A | 0–13 A |

| Maximum output voltage | 600 V | 1000 V |

| Curve storage | 100 * | 1000 |

| Point capacity | 128 | 64 |

| Voltage rms ripple | 0.11% ** | 0.40% ** |

| Peak voltage noise | 1.50 V | 1.50 V |

| Parameter | Description | Value |

|---|---|---|

| Maximum output power | 4000 W | |

| Maximum input voltage | 500 V | |

| Maximum output voltage | 500 V | |

| Input current ripple | 0.2% | |

| Output current ripple | 0.04% | |

| Switching frequency | 20 kHz |

| Parameter | Description | Value |

|---|---|---|

| L | Inductance | 6 mH |

| Maximum current through inductor | 25 A | |

| Electrolytic capacitors (input) | 470 μF | |

| Electrolytic capacitors (output) | 330 μF | |

| to | Polyester capacitors (high-frequency decoupling) | 4.7 μF |

| to | Bus discharge resistors | 20 k |

| Curve | Curve 1 200 W/m2 | Curve 2 400 W/m2 | Curve 3 600 W/m2 | Curve 4 800 W/m2 | Curve 5 1 kW/m2 |

|---|---|---|---|---|---|

| SAS A | 7.1760 | 7.9615 | 8.1349 | 9.8986 | 12.9918 |

| SAS B | 4.4700 | 8.4491 | 5.5101 | 9.4378 | 9.8855 |

| Curve | Curve 1 200 W/m2 | Curve 2 400 W/m2 | Curve 3 600 W/m2 | Curve 4 800 W/m2 | Curve 5 1 kW/m2 |

|---|---|---|---|---|---|

| SAS A | 0.0027 | 0.0028 | 0.0029 | 0.0035 | 0.0045 |

| SAS B | 0.0017 | 0.0027 | 0.0022 | 0.0029 | 0.0031 |

| Curve | Curve 1 200 W/m2 | Curve 2 400 W/m2 | Curve 3 600 W/m2 | Curve 4 800 W/m2 | Curve 5 1 kW/m2 |

|---|---|---|---|---|---|

| SAS A | 5.3046 | 4.3502 | 5.0178 | 3.9010 | 3.0319 |

| SAS B | 1.3504 | 1.6747 | 2.1754 | 1.5903 | 1.5471 |

| Curve | Curve 1 200 W/m2 | Curve 2 400 W/m2 | Curve 3 600 W/m2 | Curve 4 800 W/m2 | Curve 5 1 kW/m2 |

|---|---|---|---|---|---|

| SAS A | 0.0016 | 0.0013 | 0.0014 | 0.0012 | 0.0010 |

| SAS B | 0.0006 | 0.0006 | 0.0007 | 0.0006 | 0.0006 |

| # | Resistance () | Capacitance (mF) | Time Constant (ms) |

|---|---|---|---|

| 1 | 2.66 | 4.70 | 12.50 |

| 2 | 2.66 | 9.40 | 25.06 |

| 3 | 2.66 | 14.10 | 37.59 |

| 4 | 2.66 | 18.80 | 50.12 |

| 5 | 2.66 | 23.50 | 62.65 |

| 6 | 2.66 | 28.20 | 75.18 |

| 7 | 2.66 | 32.90 | 87.71 |

| 8 | 2.66 | 37.60 | 100.24 |

| 9 | 2.66 | 42.30 | 112.77 |

| 10 | 2.66 | 47.00 | 125.30 |

| 11 | 3.43 | 47.00 | 161.11 |

| 12 | 4.80 | 47.00 | 225.60 |

| 13 | 8.00 | 47.00 | 376.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavalcante Junior, V.M.; Neto, R.C.; Barbosa, E.J.; Bradaschia, F.; Cavalcanti, M.C.; Azevedo, G.M.d.S. Evaluation of the Effectiveness of Solar Array Simulators in Reproducing the Characteristics of Photovoltaic Modules. Sustainability 2024, 16, 6932. https://doi.org/10.3390/su16166932

Cavalcante Junior VM, Neto RC, Barbosa EJ, Bradaschia F, Cavalcanti MC, Azevedo GMdS. Evaluation of the Effectiveness of Solar Array Simulators in Reproducing the Characteristics of Photovoltaic Modules. Sustainability. 2024; 16(16):6932. https://doi.org/10.3390/su16166932

Chicago/Turabian StyleCavalcante Junior, Valdemar Moreira, Rafael C. Neto, Eduardo José Barbosa, Fabrício Bradaschia, Marcelo Cabral Cavalcanti, and Gustavo Medeiros de Souza Azevedo. 2024. "Evaluation of the Effectiveness of Solar Array Simulators in Reproducing the Characteristics of Photovoltaic Modules" Sustainability 16, no. 16: 6932. https://doi.org/10.3390/su16166932

APA StyleCavalcante Junior, V. M., Neto, R. C., Barbosa, E. J., Bradaschia, F., Cavalcanti, M. C., & Azevedo, G. M. d. S. (2024). Evaluation of the Effectiveness of Solar Array Simulators in Reproducing the Characteristics of Photovoltaic Modules. Sustainability, 16(16), 6932. https://doi.org/10.3390/su16166932