Natural Dyeing and Antimicrobial Functionalization of Wool Fabrics Dyed with Chinese Dragon Fruit Extract to Enhance Sustainable Textiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Extraction of Dye

2.2.2. Pre-Mordanting

2.2.3. Dyeing

2.2.4. Color Measurement and Analysis

2.2.5. Scanning Electron Microscopy

2.2.6. FTIR

2.2.7. Color Fastness Assessment

2.2.8. Evaluation of UV Protection Properties

2.2.9. Thermogravimetric Analysis

2.2.10. UV-Visible Spectral Analysis

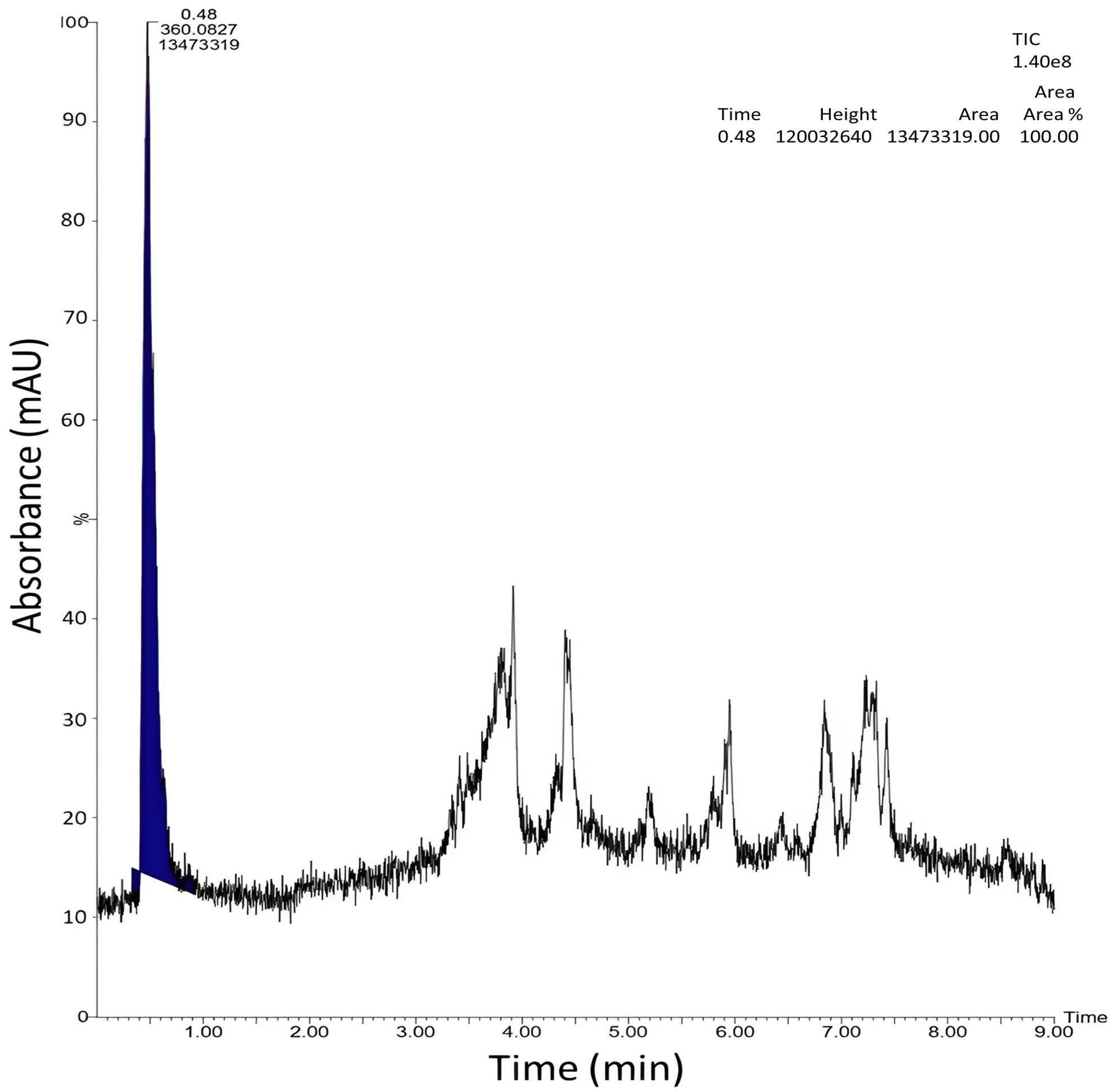

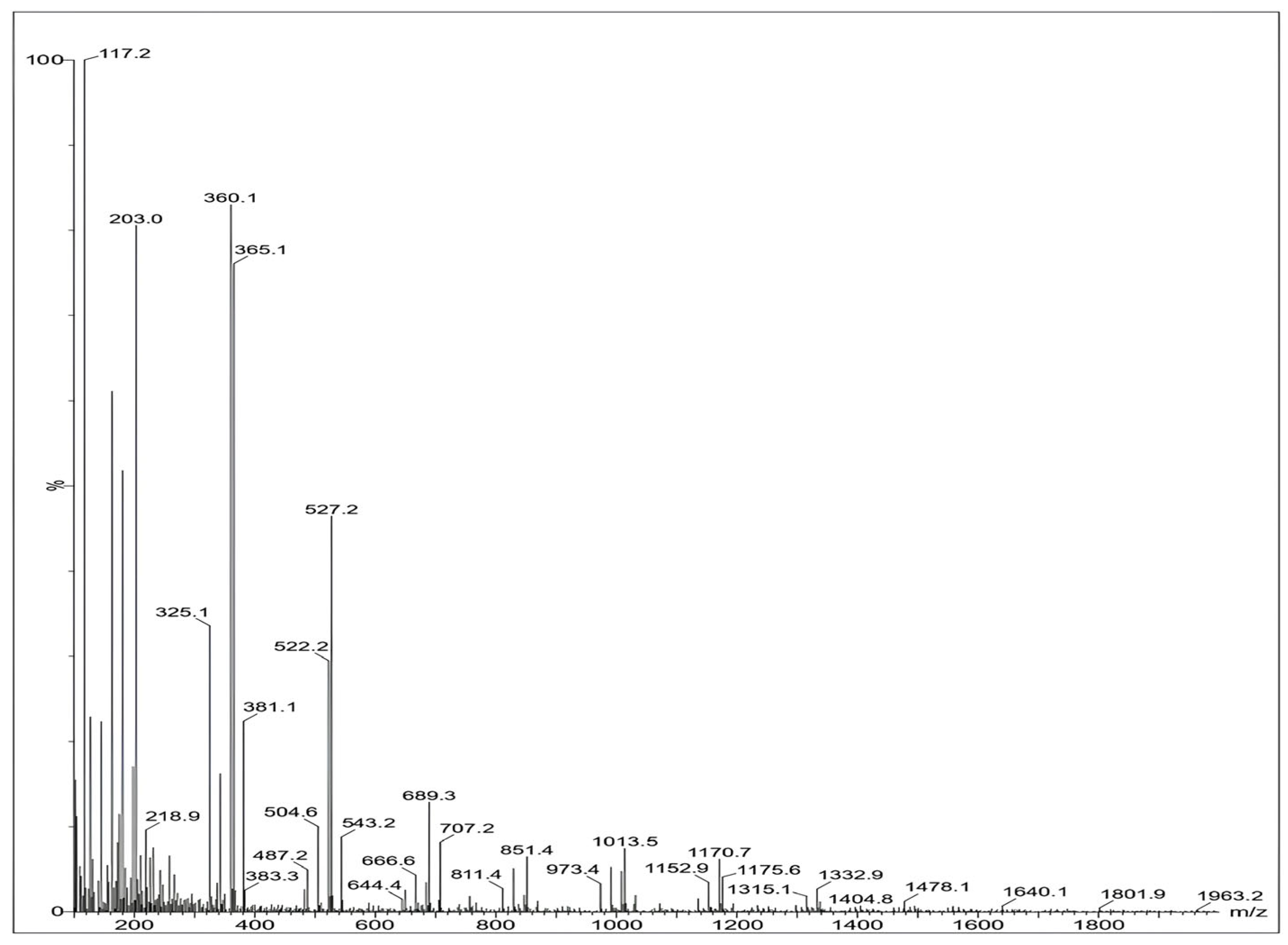

2.2.11. Liquid Chromatography Mass Spectroscopy

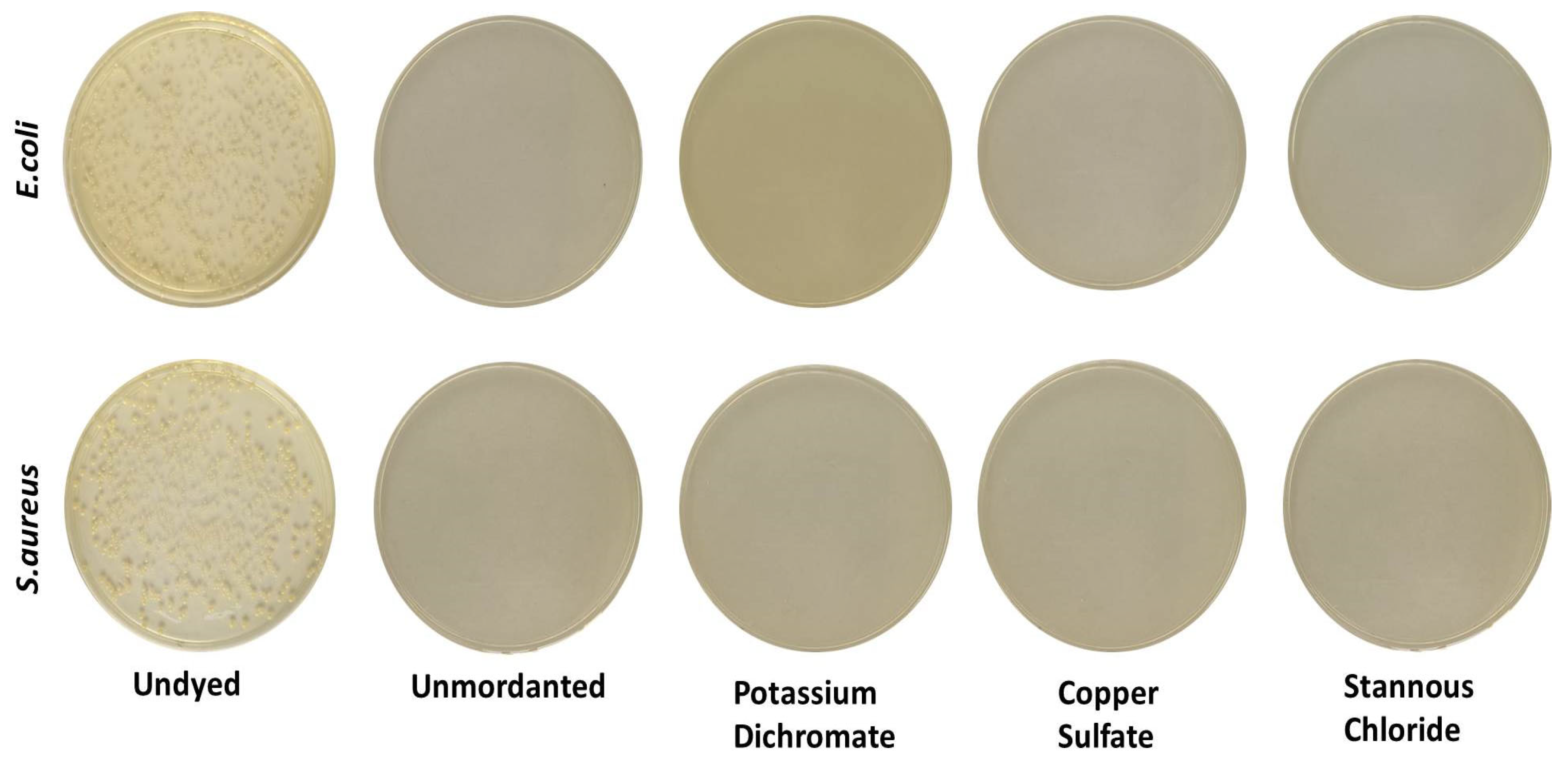

2.2.12. Antibacterial Test

3. Results

3.1. Color Efficiency and Color Values of the Dyed Samples

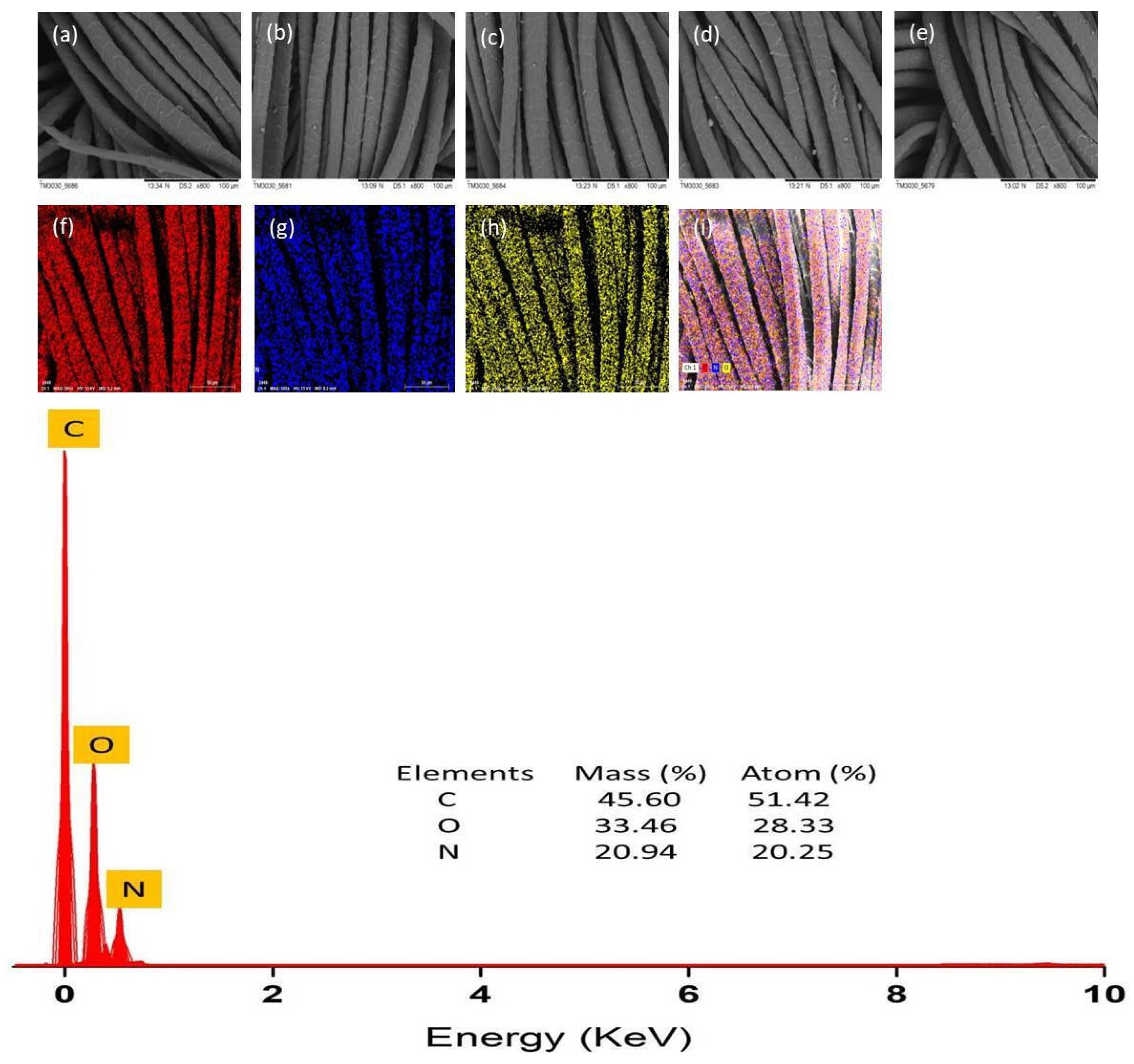

3.2. Surface Morphology of Wool Fabric

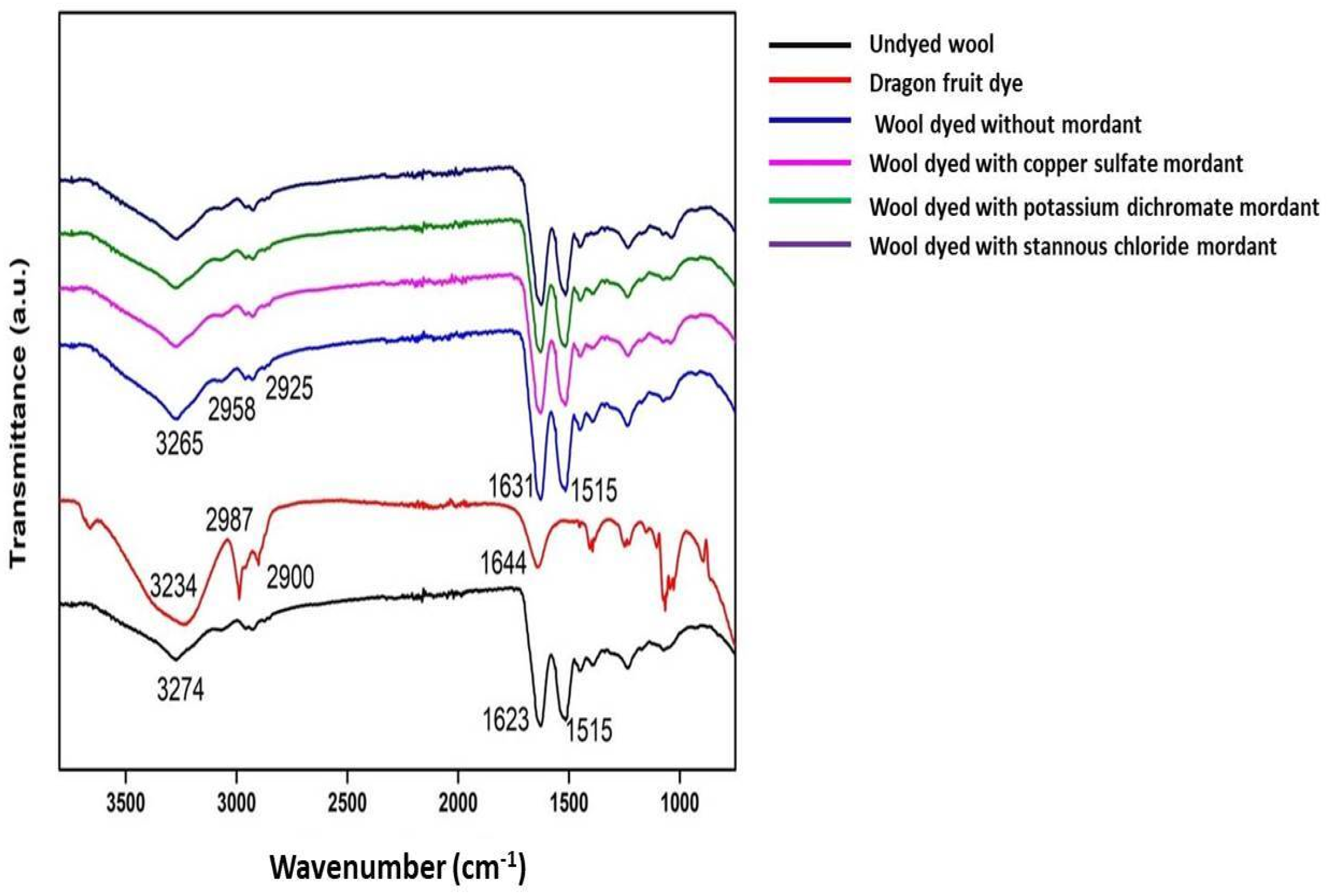

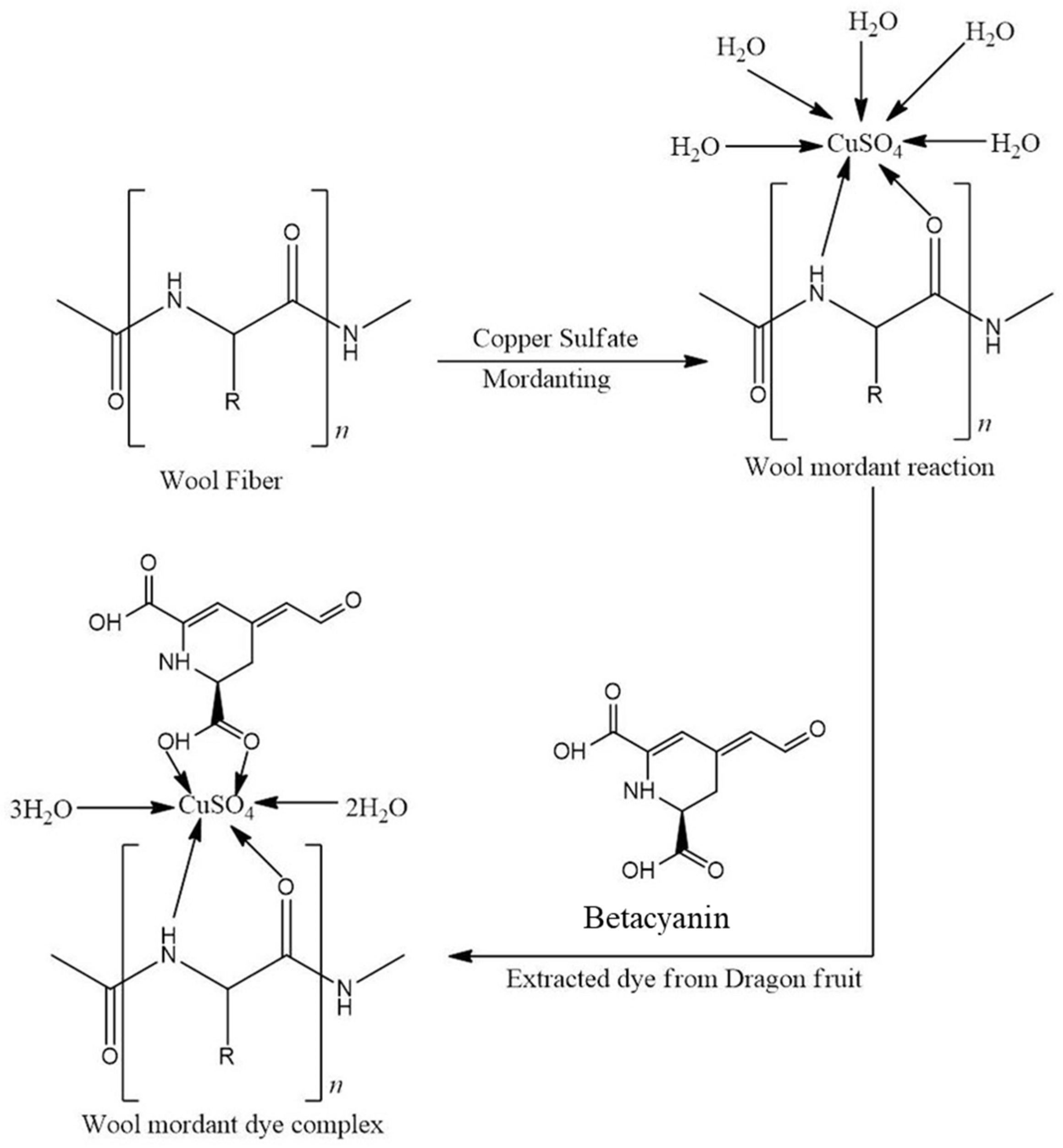

3.3. FTIR

3.4. Color Fastness Properties of Wool Samples Dyed with Dragon Fruit Extract

3.4.1. Light Fastness

3.4.2. Wash Fastness

3.4.3. Perspiration Fastness

3.4.4. Rubbing Fastness

3.5. UV Protection

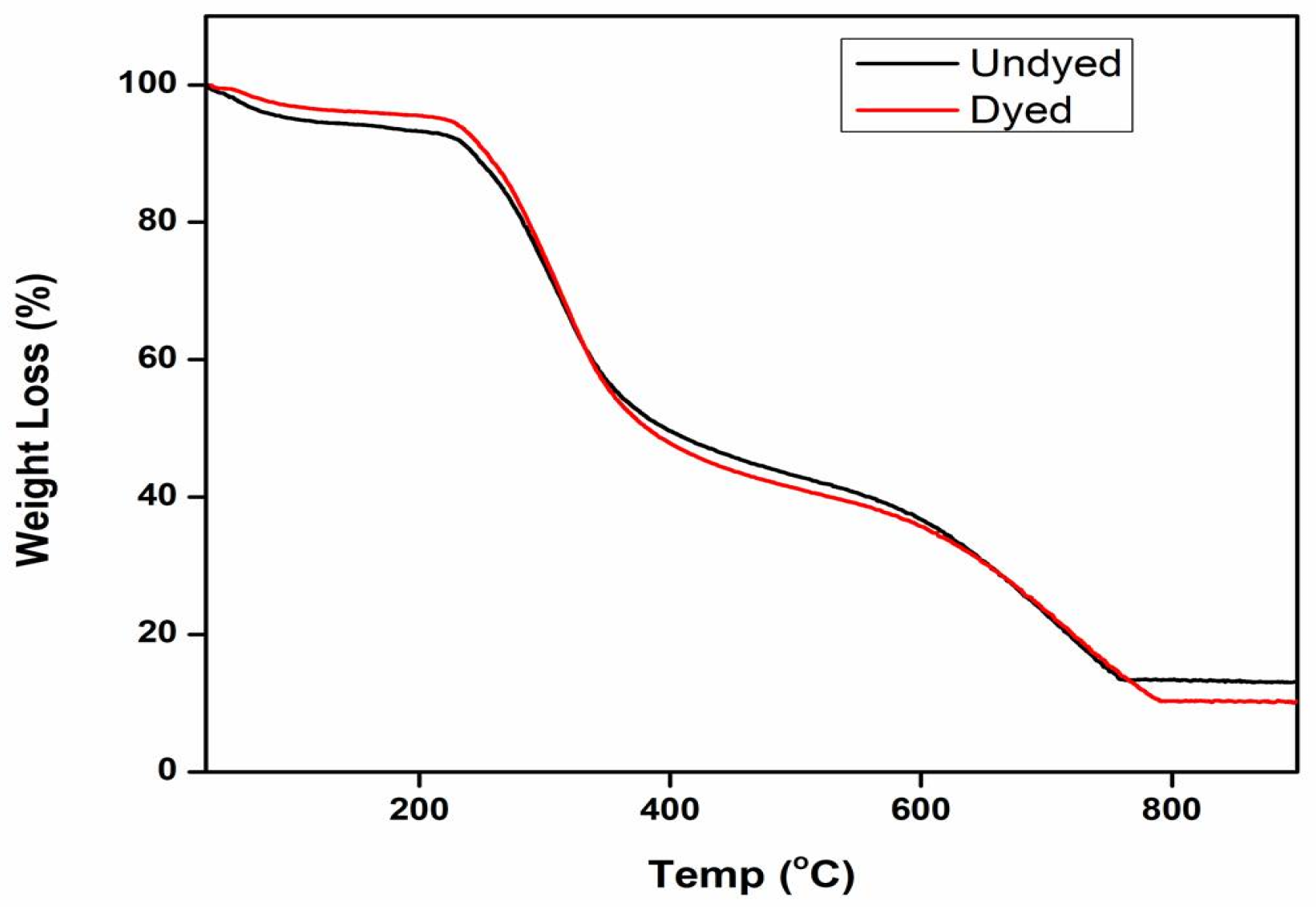

3.6. Thermal Properties

3.7. Absorption Spectra

3.8. Identification of Compounds

3.9. Antimicrobial Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yameen, M.; Adeel, S.; Nasreen, H.; Inayat, A. Sustainable eco-friendly extraction of yellow natural dye from haar singhar (Nyctanthes arbor-tritis) for bio coloration of cotton fabric. Environ. Sci. Pollut. Res. 2022, 29, 83810–83823. [Google Scholar] [CrossRef]

- Bueno, A.; Hoffman, T.; Souza, C.; Carvalho, L.; Gonclaves, M. Optimal process conditions to recycled polyester dyeing using natural annatto dye. J. Clean. Prod. 2022, 370, 133497. [Google Scholar] [CrossRef]

- Farooq, A.; Ashraf, M.; Rasheed, A.; Irshad, F. Development of a novel method for natural dyeing of cotton fabrics using ultrasonic radiations and acacia bark. J. Nat. Fibers 2018, 15, 680–686. [Google Scholar] [CrossRef]

- Eser, F.; Onal, A. Dyeing of wool and cotton with extract of the nettle (Urtica dioica L.) leaves. J. Nat. Fibers 2015, 12, 222–231. [Google Scholar] [CrossRef]

- Motaghi, Z. An economical dyeing process for cotton and wool fabrics and improvement their antibacterial properties and UV protection. J. Nat. Fibers 2018, 15, 777–788. [Google Scholar] [CrossRef]

- Adeel, S.; Habib, N.; Saif, M.; Batool, F.; Aftab, M. Environmental friendly pollution free bio-dyeing of wool with haar singhar (Coral Jasmine) flower extract. Environ. Sci. Pollut. Res. Int. 2023, 30, 12453–12465. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.; Zhu, W.; Pervez, M.; Yang, X.; Cai, Y. Adsorption, kinetics, and thermodynamic studies of cacao husk extracts in waterless sustainable dyeing of cotton fabric. Cellulose 2021, 28, 2521–2536. [Google Scholar] [CrossRef]

- Tarte, I.; Singh, A.; Dar, A.; Sharma, A.; Sharma, P. Unfolding the potential of dragon fruit (Hylocereus spp.) for value addition: A review. eFood 2023, 4, 76. [Google Scholar] [CrossRef]

- Kovačević, Z.; Sutlovic, A.; Matin, A.; Bischof, S. Natural dyeing of cellulose and protein fibers with the flower extract of spartium junceum plant. Materials 2021, 14, 4091. [Google Scholar] [CrossRef]

- Shafiq, F.; Siddique, A.; Pervez, M.; Hassan, M.; Hou, A.; Khan, M.; Kim, I. Extraction of natural dye from aerial parts of argy wormwood based on optimized taguchi approach and functional finishing of cotton fabric. Materials 2021, 14, 5850. [Google Scholar] [CrossRef]

- EU standard 13758-2001; Textiles-Solar UV Protective Properties. The European Committee for Standardization: Brussels, Belgium, 2023.

- Eyupoglu, C.; Eyupoglu, S.; Merdan, N.; Basyigit, Z. Natural dyeing of air plasma-treated wool fabric with Rubia tinctorum L. and prediction of dyeing properties using an artificial neural network. Color. Technol. 2024, 140, 91–102. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, L.; Luo, L.; King, M. Natural dye extracted from Chinese gall–the application of color and antibacterial activity to wool fabric. J. Clean. Prod. 2014, 80, 204–210. [Google Scholar] [CrossRef]

- Rahman, M.; Kim, M.; Youm, K.; Hopng, K. Sustainable one-bath natural dyeing of cotton fabric using turmeric root extract and chitosan biomordant. J. Clean. Prod. 2022, 382, 135303. [Google Scholar] [CrossRef]

- Silva, F.; Fiaschitello, T.; Queiroz, R.; Freeman, H.; Leo, P.; Costa, S. Natural dye from Croton urucurana Baill. bark: Extraction, physicochemical characterization, textile dyeing and color fastness properties. Dyes Pigm. 2019, 173, 107953. [Google Scholar] [CrossRef]

- Ali, R.; Naryan, N. Fabrication and analysis of dye-sensitized solar cell using natural dye extracted from dragon fruit. Int. J. Integr. 2010, 2, 55–62. [Google Scholar]

- Zhu, L.; Ding, X.; Wu, X. A novel method for improving the anti-pilling property of knitted wool fabric with engineered water nanostructures. J. Mater. Res. Technol. 2020, 9, 3649–3658. [Google Scholar] [CrossRef]

- Syafinar, R.; Gomesh, N.; Irwanto, M.; Fareq, M.; Irwan, Y. FT-IR and UV-Vis spectroscopy phtochemical analysis of dragon fruit. ARPN J. Eng. Appl. Sci. 2015, 10, 6354–6358. [Google Scholar]

- Mirjalili, M.; Nazarpoor, K.; Karimi, L. Extraction and characterization of natural dyes from Green Walnut shells and its use in dyeing polyamide: Focus on antibacterial properties. J. Chem. 2013, 1, 375352. [Google Scholar] [CrossRef]

- Khan, A.; Hussain, M.; Jian, H.; Gul, S. Development of functional wool fabric by treatment with aqueous and alkaline extracts of Cinnamomum camphora plant leaves. J. Nat. Fibers 2018, 17, 472–481. [Google Scholar] [CrossRef]

- Aulia, S.; Setiawati, Y.; Koendhori, K. Antibacterial Activity of Methanol Extract of Red Dragon Fruit Peel (Hylocereus polyrhizus) against Methicillin-Susceptible Staphylococcus aureus (MSSA) ATCC 25923 and Methicillin Resistant Staphylococcus aureus (MRSA) In Vitro. Inidan J. Med. Forensic. Med. Toxicol. 2021, 15, 4269–4273. [Google Scholar] [CrossRef]

- Ghaheh, F.; Mortazavi, S.; Nateri, A.; Abedi, D. Assessment of antibacterial activity of wool fabrics dyed with natural dyes. J. Clean. Prod. 2014, 72, 139–145. [Google Scholar] [CrossRef]

- Silva, M.; Barros, M.; Almeida, R.; Pilau, E.; Pinto, E.; Santos, J. Cleaner production of antimicrobial and anti-UV cotton materials through dyeing with eucalptus leaves extract. J. Clean. Prod. 2018, 199, 807–816. [Google Scholar] [CrossRef]

- Karabulut, K.; Atav, R. Dyeing of cotton fabric with natural dyes without mordant usage Part 1: Determining the most suitable dye plants for dyeing and UV protective functionalization. Fibers Polym. 2019, 21, 1773–1782. [Google Scholar] [CrossRef]

- Tummino, M.; Peila, R.; Tonetti, C.; Velic, N.; Stjepanovic, M. Towards zero-waste processes: Waste wool derivatives phosphate adsorbents and auxiliaries for textiles’ natural dyeing. Environ. Sci. Pollut. Res. 2024, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Uren, N.; Kutlu, B. Natural dyeing of plasma treated wool with avocado seed extract and use of tartaric acid as bio-mordant. Color. Technol. 2024, 1–15. [Google Scholar] [CrossRef]

- Tegegne, W.; Haile, A.; Zeleke, Y.; Temesgen, Y.; Bantie, H.; Biyable, S. Natural dyeing and antibacterial finishing of cotton fabric with extracts from Justicia schimperiana leaf extract: A step towards sustainable dyeing and finishing. Int. J. Sustain. Eng. 2024, 17, 1–10. [Google Scholar] [CrossRef]

- Ismal, O. Insight into Low-Temperature One-Step Biopreparation and Natural Dyeing of Cotton as an Environmentally Benign Route. Fibers Polym. 2024, 25, 2185–2202. [Google Scholar] [CrossRef]

- Nadeem, T.; Javed, K.; Anwar, F.; Malik, M.; Khan, A. Sustainable Dyeing of Wool and Silk with Conocarpus erectus L. Leaf Extract for the Development of Functional Textiles. Sustainability 2024, 16, 811. [Google Scholar] [CrossRef]

- Naqvi, S.; Wara, K.; Adeel, S.; Mia, R.; Hosseinnezhad, M.; Rather, L.; Imran, M. Modern ecofriendly approach for extraction of luteolin natural dye from weld for silk fabric and wool yarn dyeing. Sustain. Chem. Pharm. 2024, 39, 101554. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, L.; Wang, P.; Ran, R.; Zhang, T. Silk textile finished with natural dyes and UV resistance agents from agricultural waste Aloe vera rinds. J. Text. Inst. 2023, 115, 632–638. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, Z.; Zhao, L.; Li, X.; Cai, H.; Yang, S.; Yin, M.; Xing, J. Environmental Dyeing and Functionalization of Silk Fabrics with Natural Dye Extracted from Lac. Molecules 2024, 29, 2358. [Google Scholar] [CrossRef] [PubMed]

| Mordant | K/S | L* | a* | b* | C* | h |

|---|---|---|---|---|---|---|

| Without mordant | 8.17 | 43.66 | 45.62 | 5.26 | 45.93 | 6.57 |

| K2Cr2O7 | 5.75 | 46.88 | 27.68 | 6.24 | 28.38 | 12.71 |

| CuSO4·5H2O | 9.93 | 38.12 | 28.98 | 17.30 | 33.75 | 30.84 |

| SnCl2·2H2O | 13.29 | 39.11 | 31.36 | 5.12 | 31.77 | 9.27 |

| Mordants | Light Fastness ISO 105-B02 | Washing Fastness ISO 105-C10 | Perspiration Fastness | Rubbing Fastness | ||

|---|---|---|---|---|---|---|

| ISO 105-E04 | ISO 105-X12 | |||||

| Acidic | Alkali | Dry | Wet | |||

| Without mordant | 4 | 5–6 | 4–5 | 4–5 | 4–5 | 4 |

| K2Cr2O7 | 4–5 | 4–5 | 4–5 | 4–5 | 4 | 4 |

| CuSO4·5H2O | 4 | 4–5 | 4–5 | 4–5 | 4–5 | 4 |

| SnCl2·2H2O | 5–6 | 5–6 | 4–5 | 5 | 4–5 | 4 |

| Sample | UPF (Mean) | UV (A %) | UV (B %) |

|---|---|---|---|

| Undyed wool | 298 | 2.87 | 0.08 |

| Dyed without mordant | 363 | 0.05 | 0.05 |

| K2Cr2O7 | 517 | 0.10 | 0.05 |

| CuSO4·5H2O | 680 | 0.05 | 0.08 |

| SnCl2·2H2O | 1058 | 0.58 | 0.05 |

| Sample | Microbial Growth | Bacterial Reduction (%) | |

|---|---|---|---|

| E. coli | S. aureus | ||

| Undyed wool | Completely Present | - | - |

| Dyed without mordant | Partially present | 91 | 92 |

| Potassium Dichromate | Partially present | 94 | 96 |

| Copper Sulfate | Partially present | 95 | 93 |

| Stannous Chloride | Partially present | 94 | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadannavar, M.K.; Periyasamy, A.; Islam, S.R.; Shafiq, F.; Dong, X.; Zhao, T. Natural Dyeing and Antimicrobial Functionalization of Wool Fabrics Dyed with Chinese Dragon Fruit Extract to Enhance Sustainable Textiles. Sustainability 2024, 16, 6832. https://doi.org/10.3390/su16166832

Sadannavar MK, Periyasamy A, Islam SR, Shafiq F, Dong X, Zhao T. Natural Dyeing and Antimicrobial Functionalization of Wool Fabrics Dyed with Chinese Dragon Fruit Extract to Enhance Sustainable Textiles. Sustainability. 2024; 16(16):6832. https://doi.org/10.3390/su16166832

Chicago/Turabian StyleSadannavar, Mohmadarslan Kutubuddin, Aravin Periyasamy, Syed Rashedul Islam, Faizan Shafiq, Xue Dong, and Tao Zhao. 2024. "Natural Dyeing and Antimicrobial Functionalization of Wool Fabrics Dyed with Chinese Dragon Fruit Extract to Enhance Sustainable Textiles" Sustainability 16, no. 16: 6832. https://doi.org/10.3390/su16166832

APA StyleSadannavar, M. K., Periyasamy, A., Islam, S. R., Shafiq, F., Dong, X., & Zhao, T. (2024). Natural Dyeing and Antimicrobial Functionalization of Wool Fabrics Dyed with Chinese Dragon Fruit Extract to Enhance Sustainable Textiles. Sustainability, 16(16), 6832. https://doi.org/10.3390/su16166832