Machine Learning-Based Tap Temperature Prediction and Control for Optimized Power Consumption in Stainless Electric Arc Furnaces (EAF) of Steel Plants

Abstract

1. Introduction

1.1. Background of Study

1.2. Literature Review

1.2.1. Machine Learning Application in the Steel Industry

1.2.2. Machine Learning Model for Electric Arc Furnace

2. Problem Statements and Model Development

2.1. Problems of Electric Arc Furnace Operation

2.2. Model Development

3. Data Preparation

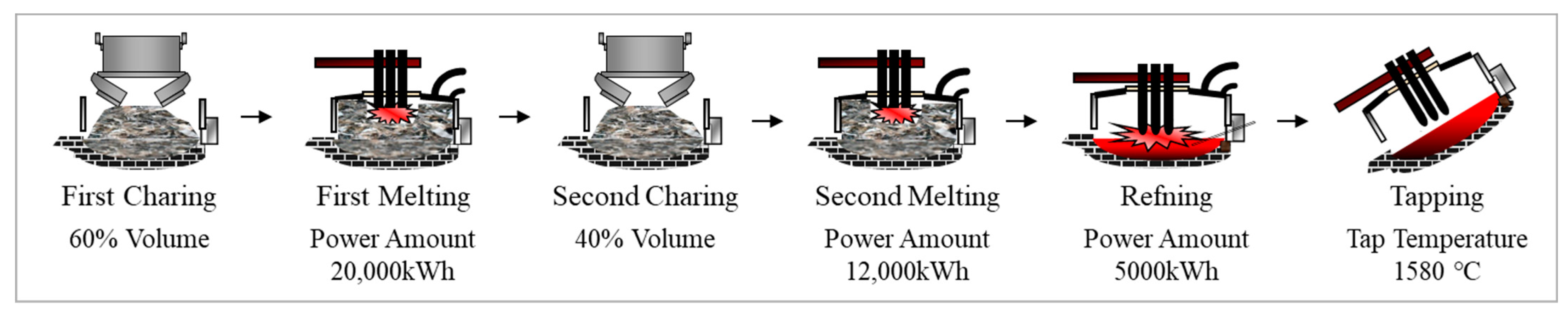

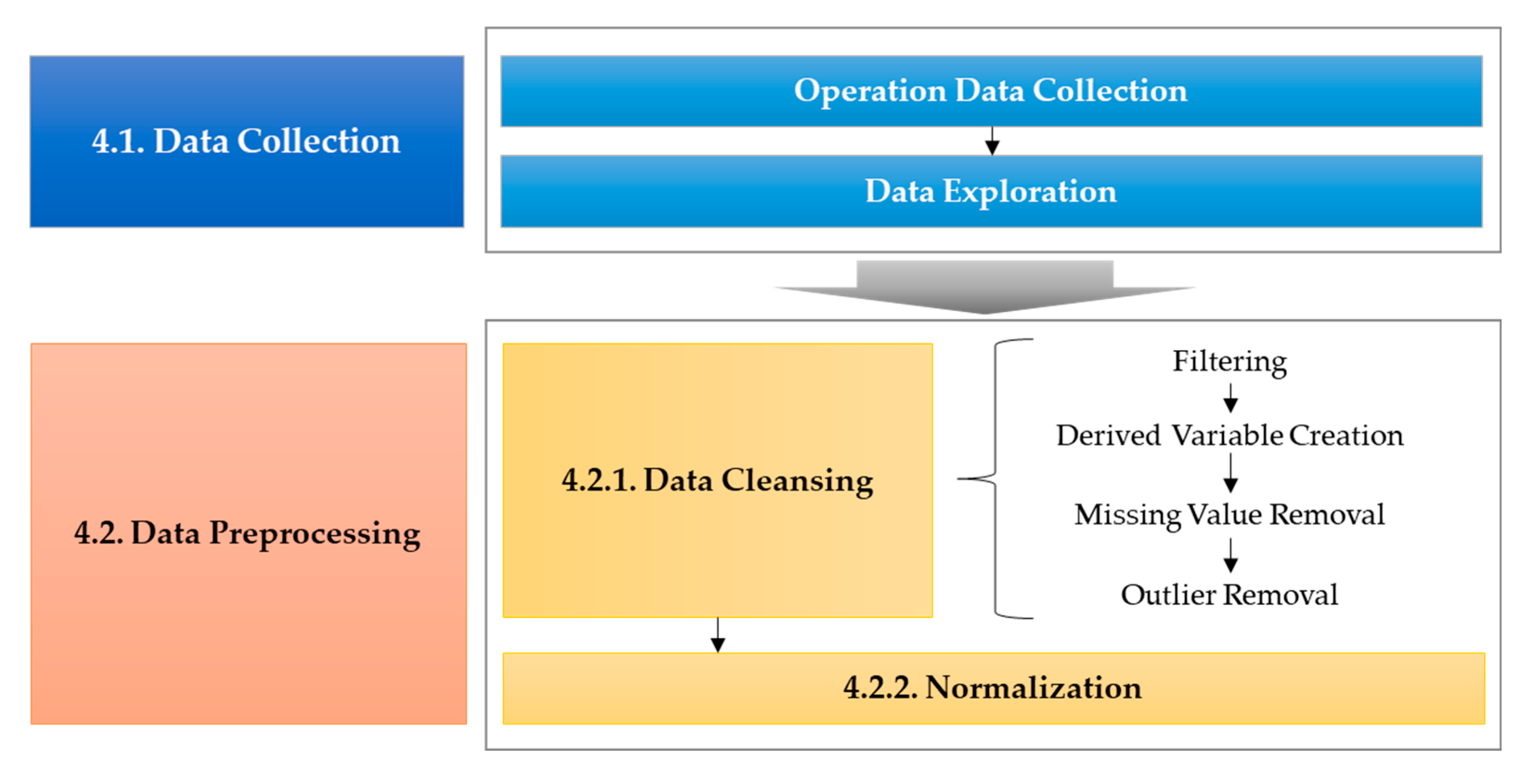

3.1. Data Collection

3.2. Data Preprocessing

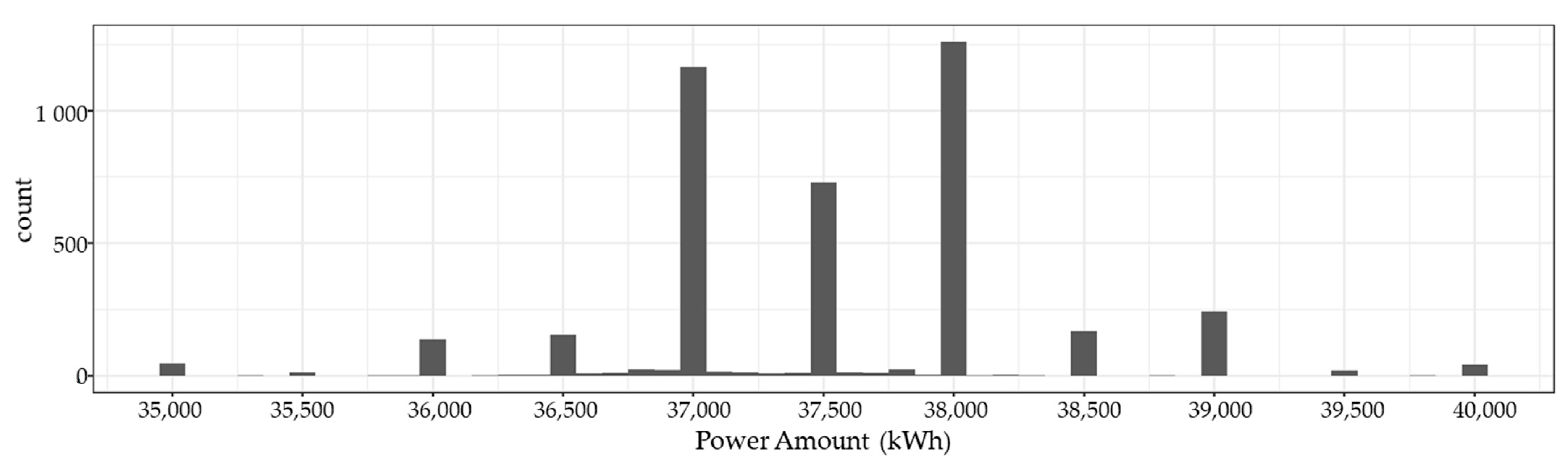

3.2.1. Data Cleansing

3.2.2. Data Normalization

4. Tap Temperature Prediction Model (TTPM)

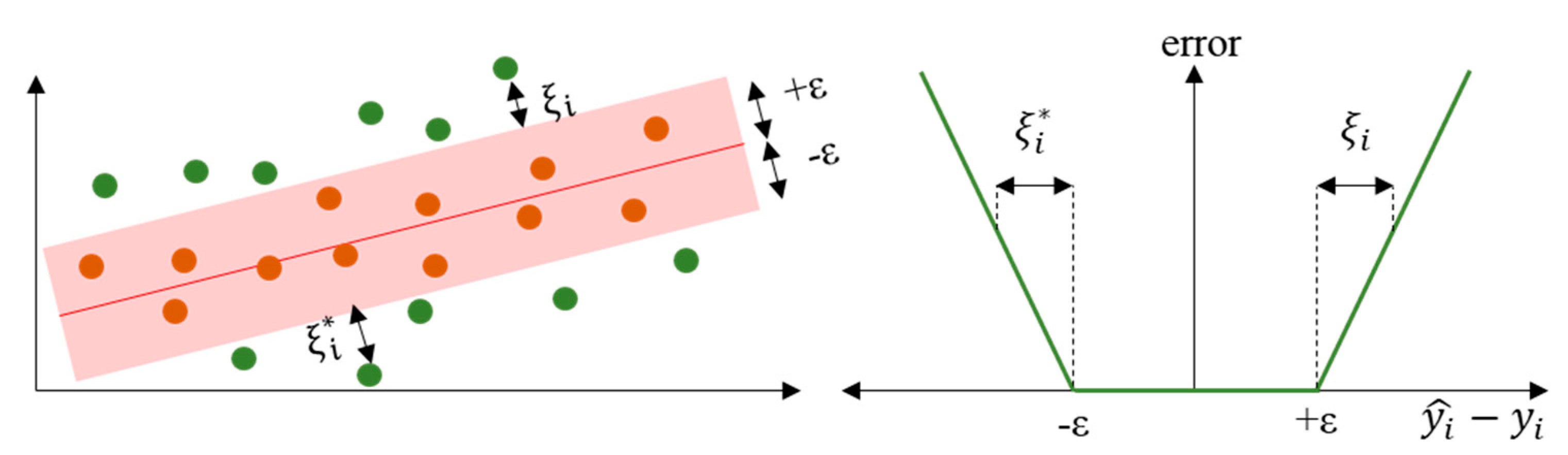

4.1. Modeling

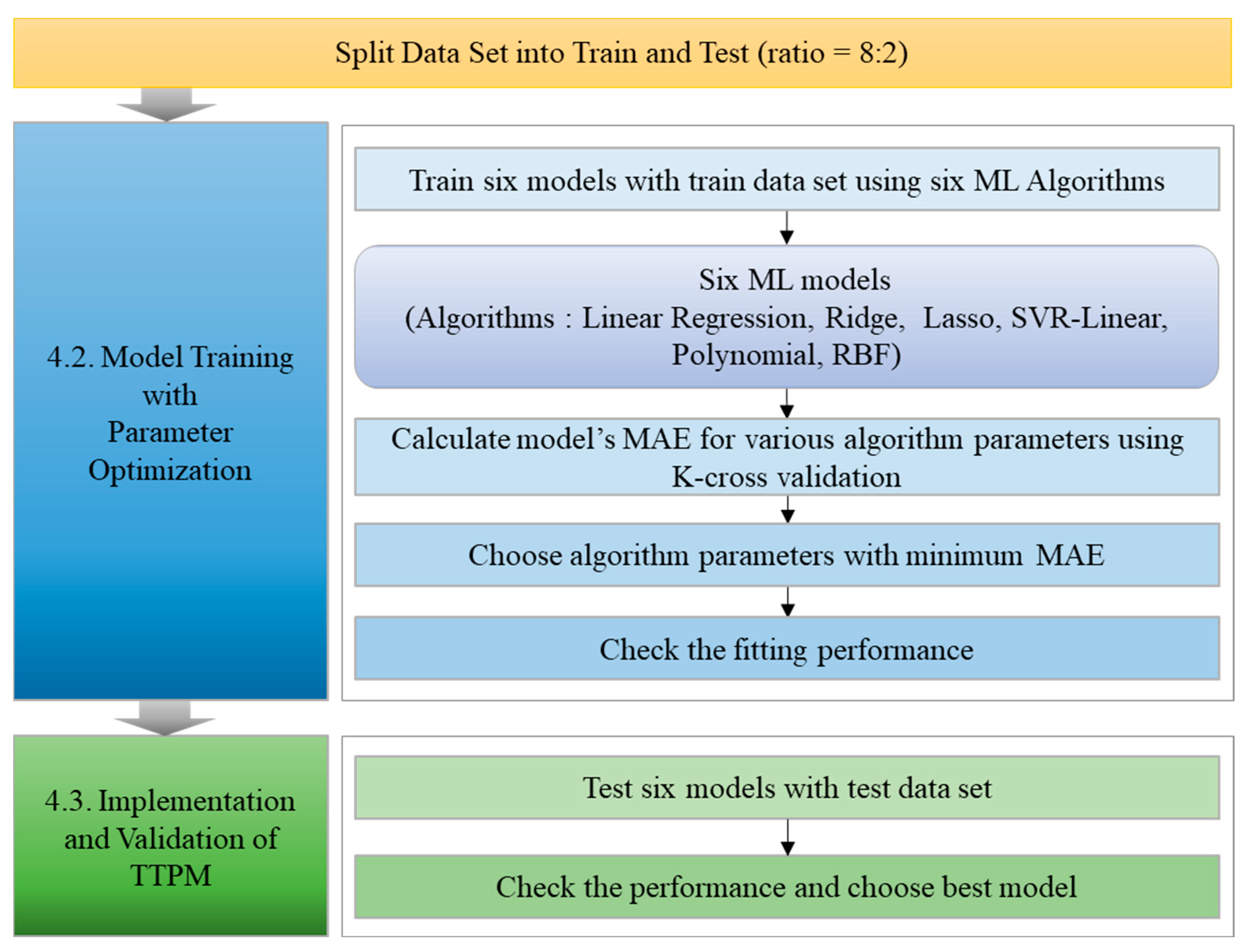

4.2. Model Training with Parameter Optimization

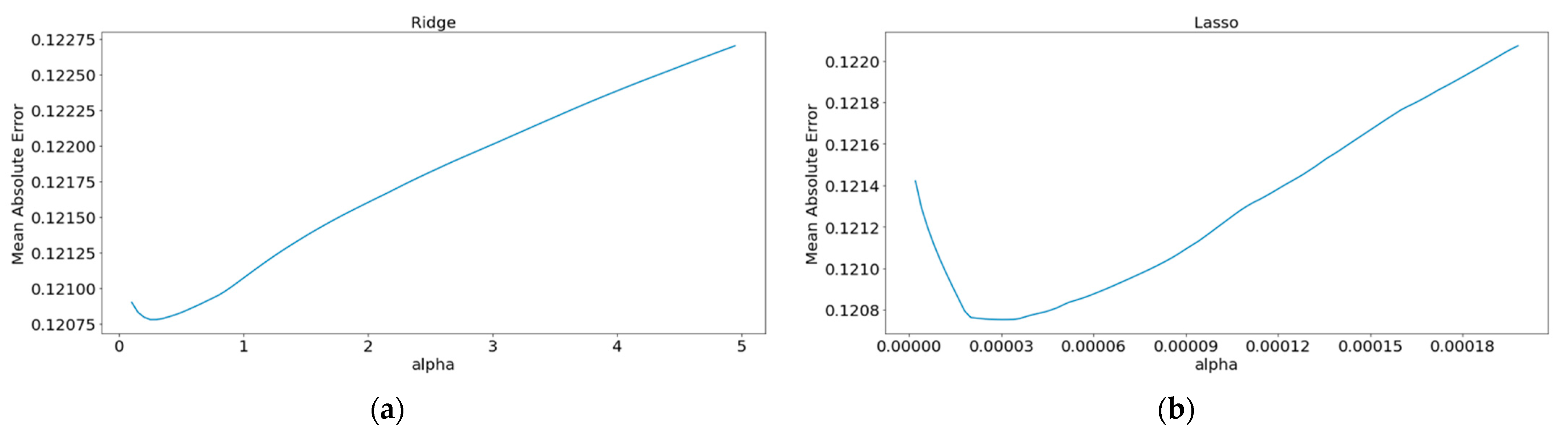

4.2.1. Parameter Optimization

4.2.2. Model Training

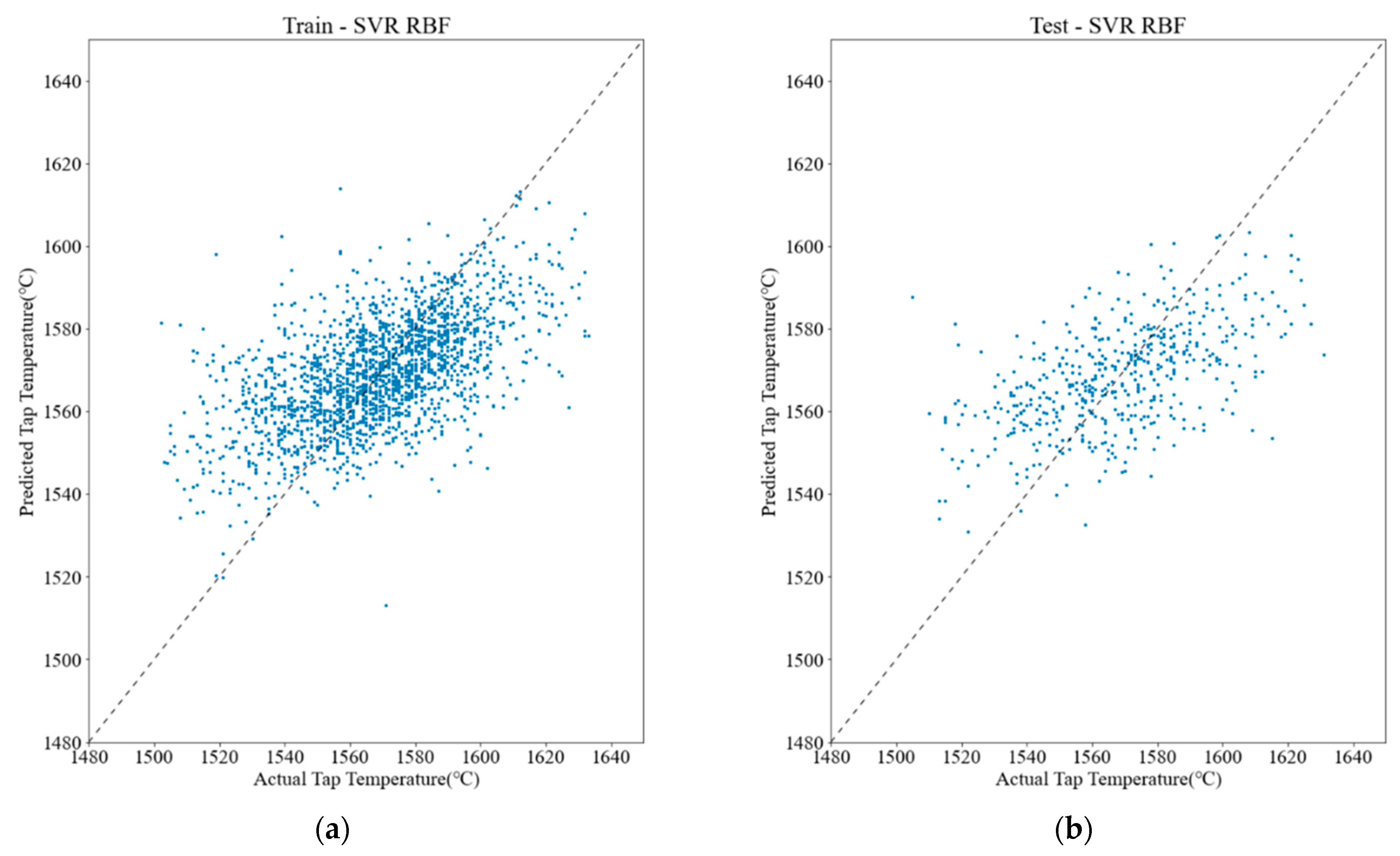

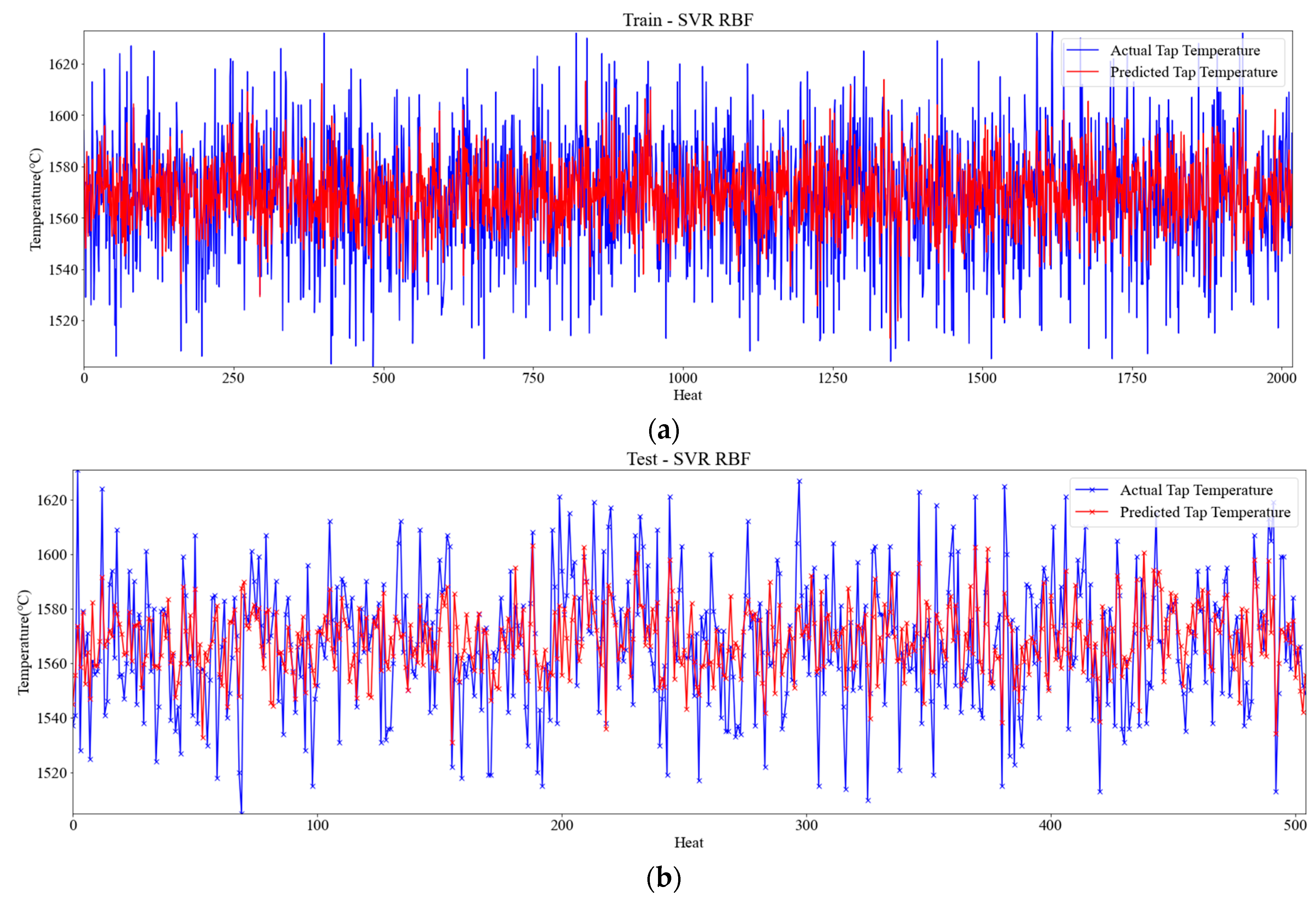

4.3. Implementation and Validation of TTPM

4.3.1. Measurement

4.3.2. Performance Evaluation and Validation

5. System Application and Performance on the Production Site

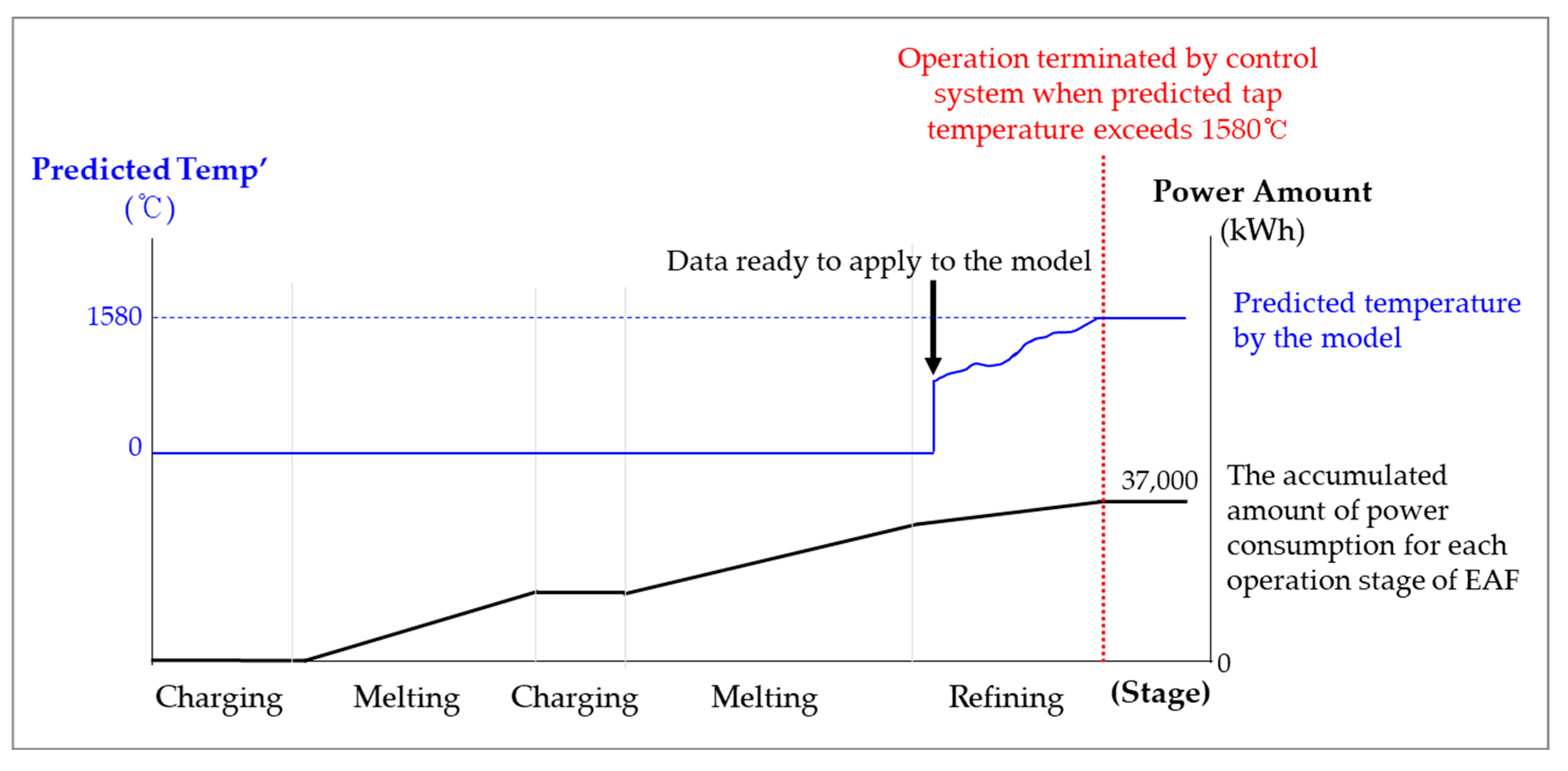

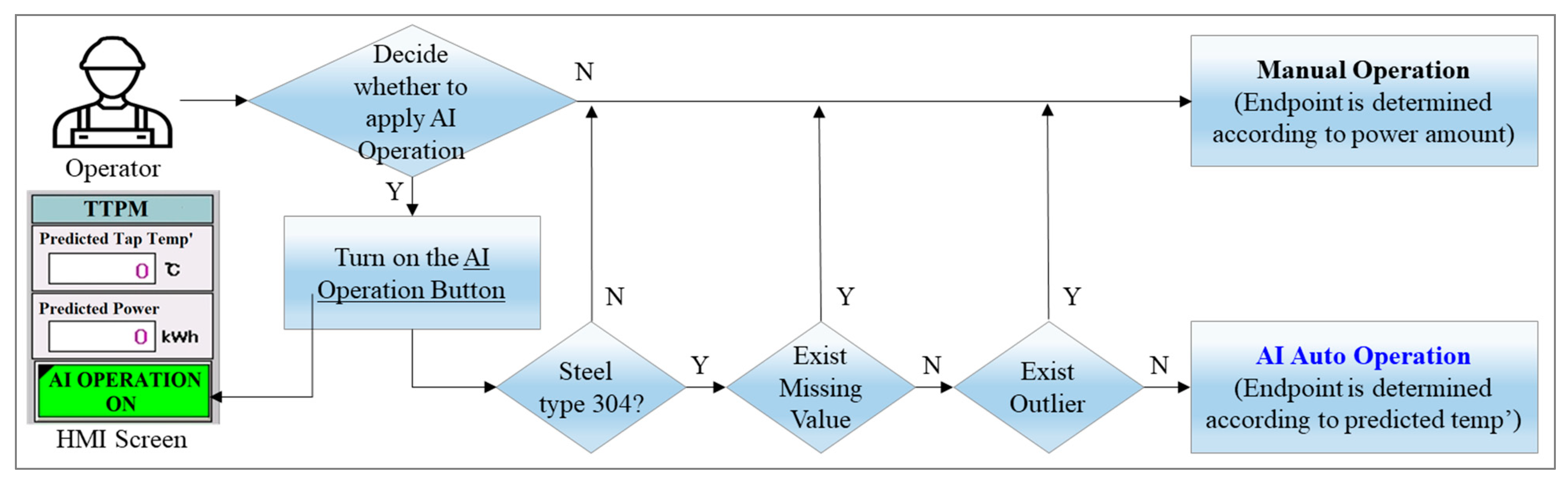

5.1. The Concept of System Application

5.2. Hardware Setup

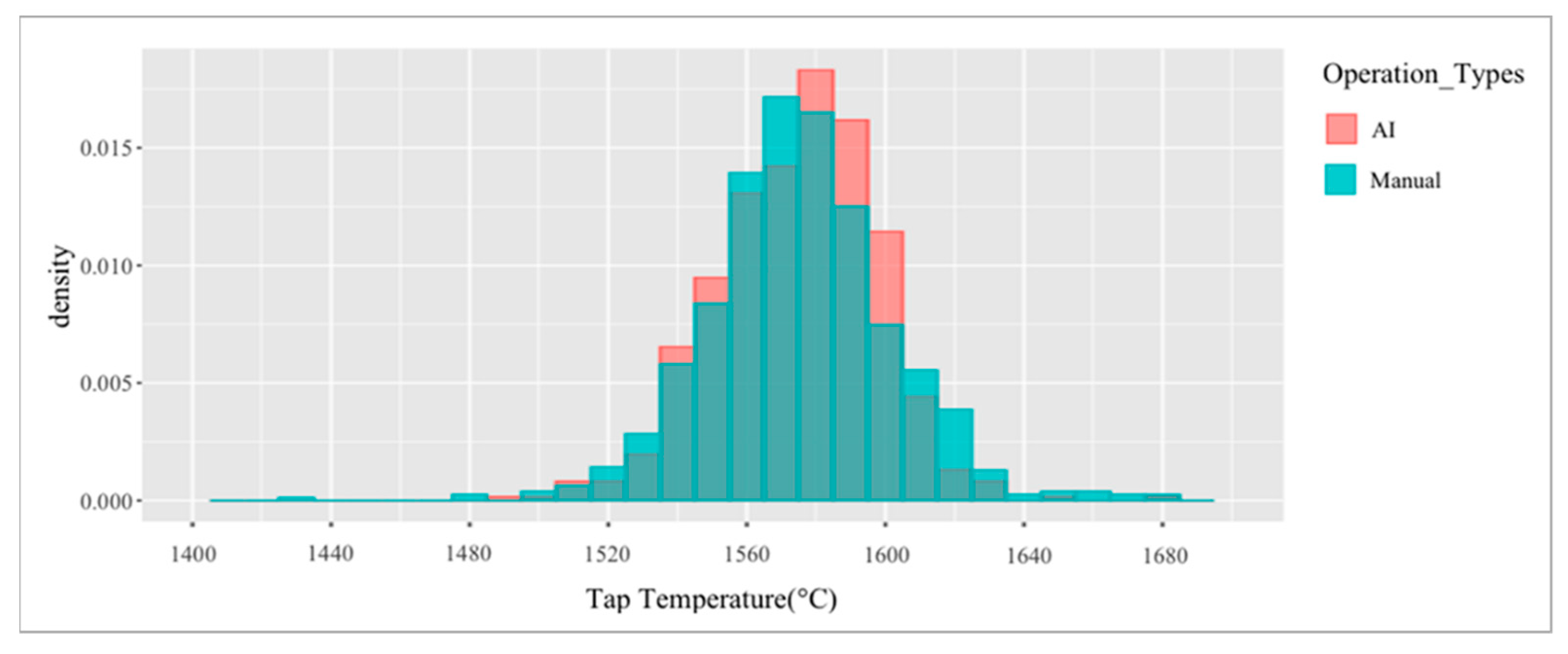

5.3. System Performance on Site

5.4. Economic Effects and Economic Analysis

5.5. Lessons Learned from the On-Site Test

6. Conclusions and Future Works

6.1. Summary and Research Contributions

6.2. Limitations and Further Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| DB | Data Base |

| DL | Deep Learning |

| DRI | Direct Reduced Iron |

| EAF | Electric Arc Furnace |

| GPR | Gaussian Process Regression |

| HMI | Human-Machine Interface |

| IQR | Interquartile Range |

| LiDAR | Light Detection and Ranging |

| LSTM | Long-Short Term Memory |

| MAE | Mean Average Error |

| MAPE | Mean Average Percent Error |

| ML | Machine Learning |

| NDC | Nationally Determined Contribution |

| PC | Process Computer |

| PLC | Programmable Logic Controller |

| RMSE | Root Mean Squared Error |

| SD | Standard Deviation |

| SSE | Sum of Squared Error |

| TSS | Total Sum of Squares |

| SVM | Support Vector Machine |

| SVR | Support Vector Regression |

| TCP/IP | Transmission Control Protocol/Internet Protocol |

| T-T | Tap to tap time |

| TTPM | Tap Temperature Prediction Model |

| TTPS | Tap Temperature Prediction System |

| WCP | Water Cooled Panel |

References

- Tanaka, K.; O’Neill, B.C. The Paris Agreement zero-emissions goal is not always consistent with the 1.5 °C and 2 °C temperature targets. Nat. Clim. Change 2018, 8, 319–324. [Google Scholar] [CrossRef]

- Ministry of Foreign Affairs, Republic of Korea. Climate Change Negotiations. Available online: https://www.mofa.go.kr/www/wpge/m_20150/contents.do (accessed on 23 December 2022).

- Bae, S.C.; Nam, J.S.; Moon, J.H. Current status of cement-concrete carbon neutrality in countries around the world. J. Concr. Soc. 2022, 34, 50–57. [Google Scholar]

- Zhang, S.; Yi, B.; Guo, F.; Zhu, P. Exploring selected pathways to low and zero CO2 emissions in China’s iron and steel industry and their impacts on resources and energy. J. Clean. Prod. 2022, 340, 130813. [Google Scholar] [CrossRef]

- Yi, S.H.; Lee, U.J.; Lee, Y.S.; Kim, W.H. Hydrogen-based reduction ironmaking process and conversion technology. Korean J. Met. Mater. 2021, 59, 41–53. [Google Scholar] [CrossRef]

- POSCO. Stainless Steel Features & Application. Available online: http://product.posco.com/homepage/product/eng/jsp/process/s91p2000810s.jsp (accessed on 22 December 2022).

- Lee, W.C.; Kim, Y.S.; Kim, J.M.; Lee, C.K. Forecasting of Iron Ore Prices using Machine Learning. J. Korea Ind. Inf. Syst. Res. 2020, 25, 57–72. [Google Scholar] [CrossRef]

- Liu, L.; Wang, A.; Sha, M.; Sun, X.; Li, Y. Optional SVM for Fault Diagnosis of Blast Furnace with Imbalanced Data. ISIJ Int. 2011, 51, 1474–1479. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, Y.; Li, X.; Liu, X.; Lyu, Q.; Hao, L. An Online Sintering Batching System Based on Machine Learning and Intelligent Algorithm. ISIJ Int. 2021, 61, 2237–2248. [Google Scholar] [CrossRef]

- Jo, H.; Hwang, H.J.; Phan, D.; Lee, Y.; Jang, H. Endpoint Temperature Prediction model for LD Converters Using Machine-Learning Techniques. In Proceedings of the 2019 IEEE 6th International Conference on Industrial Engineering and Applications (ICIEA), Tokyo, Japan, 12–15 April 2019; pp. 22–26. [Google Scholar]

- Schlueter, J.; Odenthal, H.-J.; Uebber, N.; Blom, H.; Morik, K. A novel data-driven prediction model for BOF endpoint. In Proceedings of the the Iron & Steel Technology Conference, Pittsburgh, PA, USA, 6–9 May 2013; pp. 923–928. [Google Scholar]

- Bae, J.; Li, Y.; Ståhl, N.; Mathiason, G.; Kojola, N. Using Machine Learning for Robust Target Prediction in a Basic Oxygen Furnace System. Metall. Mater. Trans. B 2020, 51, 1632–1645. [Google Scholar] [CrossRef]

- Tian, H.; Mao, Z.; Wang, Y. Hybrid Modeling of Molten Steel Temperature Prediction in LF. ISIJ Int. 2008, 48, 58–62. [Google Scholar] [CrossRef]

- Laha, D.; Ren, Y.; Suganthan, P.N. Modeling of steelmaking process with effective machine learning techniques. Expert Syst. Appl. 2015, 42, 4687–4696. [Google Scholar] [CrossRef]

- Santos, I.; Nieves, J.; Ugarte-Pedrero, X.; Bringas, P.G. Anomaly Detection for the Prediction of Ultimate Tensile Strength in Iron Casting Production. In Proceedings of the 22nd International Conference on Database and Expert Systems Applications (DEXA 2011), Toulouse, France, 29 August–2 September 2011; pp. 519–526. [Google Scholar]

- Wang, R.; Li, H.; Guerra, F.; Cathcart, C.; Chattopadhyay, K. Development of Quantitative Indices and Machine Learning-Based Predictive Models for SEN Clogging. In Proceedings of the Iron & Steel Technology Conference (AISTech 2021), Nashville, TN, USA, 29 June–1 July 2021; pp. 1892–1901. [Google Scholar]

- Ghorai, S.; Mukherjee, A.; Gangadaran, M.; Dutta, P.K. Automatic Defect Detection on Hot-Rolled Flat Steel Products. IEEE Trans. Instrum. Meas. 2013, 62, 612–621. [Google Scholar] [CrossRef]

- Ding, J.G.; He, Y.H.C.; Kong, L.P.; Peng, W. Camber Prediction Based on Fusion Method with Mechanism Model and Machine Learning in Plate Rolling. ISIJ Int. 2021, 61, 2540–2551. [Google Scholar] [CrossRef]

- Colla, V.; Pietrosanti, C.; Malfa, E.; Peters, K. Environment 4.0: How digitalization and machine learning can improve the environmental footprint of the steel production processes. Matériaux Tech. 2020, 108, 507. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Panagiotopoulou, V.C.; Papacharalampopoulos, A.; Aivaliotis, P.; Georgopoulos, D.; Smyrniotakis, K. A Framework for CO2 Emission Reduction in Manufacturing Industries: A Steel Industry Case. Designs 2022, 6, 22. [Google Scholar] [CrossRef]

- Zhou, C.; Moreland, J.; Silaen, A.; Okosun, T.; Walla, N.; Toth, K. Digitalization for Advanced Manufacturing Through Simulation, Visualization, and Machine Learning. In REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I); Springer: Berlin/Heidelberg, Germany, 2022; pp. 497–502. [Google Scholar]

- Reimann, A.; Hay, T.; Echterhof, T.; Kirschen, M.; Pfeifer, H. Application and Evaluation of Mathematical Models for Prediction of the Electric Energy Demand Using Plant Data of Five Industrial-Size EAFs. Metals 2021, 11, 1348. [Google Scholar] [CrossRef]

- Kovačič, M.; Stopar, K.; Vertnik, R.; Šarler, B. Comprehensive Electric Arc Furnace Electric Energy Consumption Modeling: A Pilot Study. Energies 2019, 12, 2142. [Google Scholar] [CrossRef]

- Carlsson, L.S.; Samuelsson, P.B.; Jönsson, P.G. Using Statistical Modeling to Predict the Electrical Energy Consumption of an Electric Arc Furnace Producing Stainless Steel. Metals 2019, 10, 36. [Google Scholar] [CrossRef]

- Li, C.; Mao, Z.; Yuan, P. Long Short-Term Memory Network Based Tapping Temperature Prediction Model for Electric Arc Furnace. In Proceedings of the 33rd Chinese Control and Decision Conference (CCDC 2021), Kunming, China, 22–24 May 2021; pp. 5017–5022. [Google Scholar]

- Blažič, A.; Škrjanc, I.; Logar, V. Soft sensor of bath temperature in an electric arc furnace based on a data-driven Takagi–Sugeno fuzzy model. Appl. Soft Comput. 2021, 113, 107949. [Google Scholar] [CrossRef]

- Ave, G.D.; Hernandez, J.; Harjunkoski, I.; Onofri, L.; Engell, S. Demand Side Management Scheduling Formulation for a Steel Plant Considering Electrode Degradation. IFAC-Pap. OnLine 2019, 52, 691–696. [Google Scholar] [CrossRef]

- Risonarta, V.Y.; Kirschen, M.; Echterhof, T.; Jung, H.P.; Lenz, S.; Beiler, C.; Pfeifer, H. Higher cost and resource efficiencies during stainless steelmaking in an EAF. Stahl Und Eisen 2011, 131, S63–S72. [Google Scholar]

- Vazdirvanidis, A.; Pantazopoulos, G.; Louvaris, A. Overheat induced failure of a steel tube in an electric arc furnace (EAF) cooling system. Eng. Fail. Anal. 2008, 15, 931–937. [Google Scholar] [CrossRef]

- Teng, L.; Meador, M.; Ljungqvist, P. Application of new generation electromagnetic stirring in electric arc furnace. Steel Res. Int. 2017, 88, 1600202. [Google Scholar] [CrossRef]

- Staib, W.E.; Staib, R.B. The intelligent arc furnace controller: A neural network electrode position optimization system for the electric arc furnace. In Proceedings of the International Joint Conference on Neural Networks (IJCNN 1992), Baltimore, MD, USA, 7–11 June 1992; pp. 1–9. [Google Scholar]

- Choi, S.-W.; Lee, E.-B.; Kim, J.-H. The Engineering Machine-Learning Automation Platform (EMAP): A Big-Data-Driven AI Tool for Contractors’ Sustainable Management Solutions for Plant Projects. Sustainability 2021, 13, 10384. [Google Scholar] [CrossRef]

- Numpy. Available online: https://numpy.org (accessed on 22 December 2022).

- Pandas. Available online: https://pandas.pydata.org (accessed on 22 December 2022).

- Scikit-Learn. Available online: https://scikit-learn.org/stable (accessed on 22 December 2022).

- Lin, J.; Bhattacharyya, D.; Kecman, V. Multiple regression and neural networks analyses in composites machining. Compos. Sci. Technol. 2003, 63, 539–548. [Google Scholar] [CrossRef]

- Acaps. Data Cleaning. Available online: https://www.acaps.org/node/893 (accessed on 26 March 2023).

- Adams, W.; Alameddine, S.; Bowman, B.; Lugo, N.; Paege, S.; Stafford, P. Total energy consumption in arc furnaces. Metall. Plant Technol. Int. MPT 2002, 25, 44–50. [Google Scholar]

- Kleimt, B.; Köhle, S.; Kühn, R.; Zisser, S. Application of Models for Electrical Energy Consumption to Improve the EAF Operation and Dynamic Control. 2005. Available online: https://www.researchgate.net/profile/Bernd-Kleimt-2/publication/239615624_APPLICATION_OF_MODELS_FOR_ELECTRICAL_ENERGY_CONSUMPTION_TO_IMPROVE_EAF_OPERATION_AND_DYNAMIC_CONTROL/links/02e7e53689424f1626000000/APPLICATION-OF-MODELS-FOR-ELECTRICAL-ENERGY-CONSUMPTION-TO-IMPROVE-EAF-OPERATION-AND-DYNAMIC-CONTROL.pdf (accessed on 23 November 2022).

- Aggarwal, C.C.; Yu, P.S. Outlier detection for high dimensional data. In Proceedings of the 2001 ACM SIGMOD International Conference on Management of Data, Santa Barbara, CA, USA, 21–24 May 2001; pp. 37–46. [Google Scholar]

- Buxton, P.; Tabor, P. Outlier detection for dppm reduction. In Proceedings of the International Test Conference (ITC 2003), Charlotte, NC, USA, 30 September–2 October 2003; pp. 818–827. [Google Scholar]

- Scikit-Learn Developers. Scikit-Learn Preprocessing. Available online: https://scikit-learn.org/stable/modules/preprocessing.html (accessed on 6 November 2022).

- Ahsan, M.M.; Mahmud, M.A.P.; Saha, P.K.; Gupta, K.D.; Siddique, Z. Effect of Data Scaling Methods on Machine Learning Algorithms and Model Performance. Technologies 2021, 9, 52. [Google Scholar] [CrossRef]

- Acosta, S.M.; Amoroso, A.L.; Sant’Anna, Â.M.O.; Junior, O.C. Predictive modeling in a steelmaking process using optimized relevance vector regression and support vector regression. Ann. Oper. Res. 2021, 52, 1081–1086. [Google Scholar] [CrossRef]

- Omar, I.; Khan, M.; Starr, A. Suitability Analysis of Machine Learning Algorithms for Crack Growth Prediction Based on Dynamic Response Data. Sensors 2023, 23, 1074. [Google Scholar] [CrossRef]

- Bansal, N.; Defo, M.; Lacasse, M.A. Application of Support Vector Regression to the Prediction of the Long-Term Impacts of Climate Change on the Moisture Performance of Wood Frame and Massive Timber Walls. Buildings 2021, 11, 188. [Google Scholar] [CrossRef]

- Sandhu, A.; Sahu, K.M. Role of Artificial Intelligence in Forecast Analysis of COVID-19 Outbreak. In Impact of AI and Data Science in Response to Coronavirus Pandemic; Mishra, S., Mallick, P.K., Tripathy, H.K., Chae, G.-S., Mishra, B.S.P., Eds.; Springer Nature: Singapore, 2021; pp. 37–52. [Google Scholar]

- Bansal, A.; Singh, S. Implication of Machine Learning Models Toward Education Loan Repayment Rate Analysis. In Proceedings of the 2nd International Conference on Computing, Communications, and Cyber-Security (IC4S 2020), Delhi, India, 3–4 October 2020; pp. 423–433. [Google Scholar]

- Melkumova, L.; Shatskikh, S.Y. Comparing Ridge and LASSO estimators for data analysis. In Proceedings of the 3rd International Conference of Information Technology and Nanotechnology (ITNT-2017), Samara, Russia, 25–27 April 2017; pp. 746–755. [Google Scholar]

- Ye, Y.; Gao, J.; Shao, Y.; Li, C.; Jin, Y.; Hua, X. Robust support vector regression with generic quadratic nonconvex ε-insensitive loss. Appl. Math. Model. 2020, 82, 235–251. [Google Scholar] [CrossRef]

- Xu, P.; Ji, X.; Li, M.; Lu, W. Small data machine learning in materials science. npj Comput. Mater. 2023, 9, 42. [Google Scholar] [CrossRef]

- Khalil, A.; Almasri, M.N.; McKee, M.; Kaluarachchi, J.J. Applicability of statistical learning algorithms in groundwater quality modeling. Water Resour. Res. 2005, 41. [Google Scholar] [CrossRef]

- Wisnowski, J.W.; Simpson, J.R.; Montgomery, D.C.; Runger, G.C. Resampling methods for variable selection in robust regression. Comput. Stat. Data Anal. 2003, 43, 341–355. [Google Scholar] [CrossRef]

- Owen, A.B. A robust hybrid of lasso and ridge regression. Contemp. Math. 2007, 443, 59–72. [Google Scholar]

- Smola, A.J.; Schölkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Hong, C.-S.; Lee, E.-B. Power Plant Economic Analysis: Maximizing Lifecycle Profitability by Simulating Preliminary Design Solutions of Steam-Cycle Conditions. Energies 2018, 11, 2245. [Google Scholar] [CrossRef]

- Gato-Trinidad, S.; Gan, K. Rainwater tank rebate scheme in Greater Melbourne, Australia. J. Water Supply Res. Technol. AQUA 2014, 63, 601–610. [Google Scholar] [CrossRef]

- Le, S. The Applications of NPV in Different Types of Markets. In Proceedings of the 3rd International Conference on Economic Management and Cultural Industry (ICEMCI 2021), Guangzhou, China, 22–24 October 2021; pp. 1054–1059. [Google Scholar]

- Ebrahimi-Moghadam, A.; Moghadam, A.J.; Farzaneh-Gord, M.; Aliakbari, K. Proposal and assessment of a novel combined heat and power system: Energy, exergy, environmental and economic analysis. Energy Convers. Manag. 2020, 204, 112307. [Google Scholar] [CrossRef]

- Steel Statistical Yearbook 2017; World Steel Association Economics Committee: Belgium, Brussels, 2017.

- Budinis, S.; Levi, P.; Mandová, H.; Vass, T. Iron and Steel Technology Roadmap: Towards More Sustainable Steelmaking; IEA Publications: Paris, France, 2020. [Google Scholar]

| Deviation of Tap Temp. | Count (Heats) | Rate (%) |

|---|---|---|

| ±0~20 °C | 1715 | 55.2 |

| ±21~40 °C | 871 | 28.0 |

| ±41 °C~ | 519 | 16.8 |

| Total | 3105 | 100 |

| Stage | Attributes | |||||

|---|---|---|---|---|---|---|

| Weight | Volume | Power | Temperature | Time | Etc. | |

| Charging (32 Variables) | Total weight, weight by element, weight by scrap type | Steel type, scrap ratio | ||||

| Melting (12 Variables) | Oxygen injection amount | Power amount, power factor | WCP temp’, bottom temp’ | Wait time | ||

| Refining (2 Variables) | Oxygen injection amount | Power amount | ||||

| Tapping (1 Variable) | Tap temperature (Y Feature) | |||||

| AOD charging (6 Variables) | (Previous Ch’) Remain weight, tap weight, slag weight | (Previous Ch’) Tap temperature | (Previous Ch’) Basicity, yield of tapping | |||

| Filter Condition | Number of Heats | Data Loss (%) | |

|---|---|---|---|

| Raw Data | 4598 | - | |

| Filtering | Steel type = 304 | 3230 | 29.8 |

| Number of charing = 2 | 3003 | 7.0 | |

| Missing Value Removal | 2937 | 2.2 | |

| Outlierremoval | Tap temperature (before heat) | 2795 | 4.8 |

| Power per weight | 2666 | 4.6 | |

| Water cooled panel (WCP) temperature | 2654 | 0.5 | |

| tap temperature (Y feature) | 2523 | 4.9 | |

| Total data loss (%) | 45.1 | ||

| Stage | Variable | Min | Max | Range | Stage | Variable | Min | Max | Range |

|---|---|---|---|---|---|---|---|---|---|

| First charge and melt | AvgTempBot | 34 | 244 | 210 | Second charge and melt | Oxygen_per_Weight | 0.57 | 7.81 | 7.24 |

| AvgTempWCP | 27 | 40 | 13 | CConsCon | 1.34 | 2.64 | 1.30 | ||

| MaxTempBot | 55 | 280 | 225 | CrConsCon | 14.70 | 21.77 | 7.07 | ||

| MaxTempWCP | 34 | 84 | 50 | CuConsCon | 0.11 | 0.32 | 0.21 | ||

| Power_per_Weight | 149.49 | 260.50 | 111.01 | FeCr_Conscon | 0.00 | 0.55 | 0.55 | ||

| CConsCon | 0.00 | 3.11 | 3.11 | MnConsCon | 0.31 | 1.10 | 0.79 | ||

| CrConsCon | 0.00 | 25.83 | 25.83 | MoConsCon | 0.05 | 0.18 | 0.13 | ||

| CuConsCon | 0.00 | 0.34 | 0.34 | NiConsCon | 4.21 | 8.05 | 3.84 | ||

| FeCr_Conscon | 0.04 | 0.29 | 0.25 | PConsCon | 0.02 | 0.03 | 0.01 | ||

| MnConsCon | 0.00 | 1.10 | 1.10 | SConsCon | 0.02 | 0.51 | 0.49 | ||

| MoConsCon | 0.00 | 0.22 | 0.22 | SiConsCon | 0.68 | 1.78 | 1.10 | ||

| NiConsCon | 0.00 | 9.88 | 9.88 | SI300WGT | 0 | 30,250 | 30,250 | ||

| PConsCon | 0.00 | 0.03 | 0.03 | SK300WGT | 0 | 28,050 | 28,050 | ||

| SConsCon | 0.00 | 0.83 | 0.83 | SP300WGT | 0 | 11,893 | 11,893 | ||

| SiConsCon | 0.00 | 1.80 | 1.80 | SP400WGT | 0 | 2678 | 2678 | ||

| SI300WGT | 0 | 29,960 | 29,960 | SPGENWGT | 0 | 7880 | 7880 | ||

| SK300WGT | 0 | 27,740 | 27,740 | Waittime | 147 | 2964 | 2817 | ||

| SK400WGT | 0 | 6390 | 6390 | Refine | Oxygen_per_Weight | 0.68 | 5.94 | 5.25 | |

| SP300WGT | 0 | 19,265 | 19,265 | Power_per_Weight | 34.92 | 93.03 | 58.11 | ||

| SP400WGT | 0 | 6580 | 6800 | Tapping | Tap_Temperature | 1501 | 1633 | 132 | |

| SPGENWGT | 0 | 9560 | 9560 | ||||||

| Waittime | 157 | 2501 | 2344 | AOD charging (previous ch’) | Basicity | 1.1 | 2.5 | 1.4 | |

| Second charge and melt | AvgTempBot | 34 | 242 | 208 | Remain_Weight | 0 | 13,300 | 13,300 | |

| AvgTempWCP | 26 | 39 | 13 | Slag Weight | 0 | 19,300 | 19,300 | ||

| MaxTempBot | 56 | 277 | 221 | Tap_Weight Rate | 76.6 | 145.2 | 68.6 | ||

| MaxTempWCP | 33 | 88 | 55 | Tap_Temperature | 1432 | 1663 | 231 | ||

| Power_per_Weight | 67.96 | 191.98 | 124.02 | Tap_Weight | 70,200 | 104,800 | 34,600 |

| Variable | Definition |

|---|---|

| AvgTempBot | Average temperature (°C) measured with a thermometer installed on the floor of the EAF |

| AvgTempWCP | Average temperature (°C) measured in water cooled panel (installed on the EAF side) |

| Power_per_Weight | Electricity input per ton of scrap (kWh) |

| * ConsCon | * Ratio (%) of elements included in scrap (calculated by scrap sampling) |

| SI300WGT | 300 series imported scrap weight (kg) |

| SK300WGT | 300 series domestic scrap weight (kg) |

| SK400WGT | 400 series domestic scrap weight (kg) |

| SP300WGT | 300 Series Company P recycled scrap weight (kg) |

| SP400WGT | 400 Series Company P recycled scrap weight (kg) |

| SPGENWGT | Other types of recycled scrap weight (kg) by P Company |

| Waittime | Waiting time before operation (sec) |

| Oxygen_per_Weight | Oxygen input per ton of scrap (Nm3) |

| Basicity | slag basicity |

| Remain_Weight | Remaining weight of hot water (kg) |

| Slag Weight | Amount of slag (kg) |

| Tap_Weight Rate | Tapping error rate = tapping amount/scrap weight (%) |

| Tap_Weight | Tap amount (kg) |

| k-Fold | Ridge | Lasso | SVR Linear | SVR Polynomial | SVR RBF |

|---|---|---|---|---|---|

| k = 5 | 0.120789 | 0.120765 | 0.122903 | 0.120078 | 0.119452 |

| k = 10 | 0.120892 | 0.120812 | 0.123187 | 0.120125 | 0.119812 |

| k = 20 | 0.121354 | 0.121265 | 0.123843 | 0.120228 | 0.120013 |

| Error Functions | Linear | Ridge | Lasso | SVR | ||

|---|---|---|---|---|---|---|

| Linear | Polynomial | RBF | ||||

| RMSE | 19.55 | 19.57 | 19.57 | 19.74 | 19.16 | 18.99 |

| MAE | 15.37 | 15.41 | 15.41 | 15.27 | 14.68 | 14.46 |

| R2 | 0.294 | 0.292 | 0.293 | 0.280 | 0.322 | 0.334 |

| Section | Metric | Formula |

|---|---|---|

| Tap temperature prediction model (TTPM) | MAE | |

| RMSE | ||

| R2 | ||

| System development and application on production site | SD |

| Error Functions | Linear | Ridge | Lasso | SVR | ||

|---|---|---|---|---|---|---|

| Linear | Polynomial | RBF | ||||

| RMSE | 20.57 | 20.62 | 20.59 | 20.73 | 20.35 | 20.14 |

| MAE | 16.51 | 16.62 | 16.60 | 16.66 | 16.27 | 16.05 |

| R2 | 0.278 | 0.275 | 0.277 | 0.267 | 0.293 | 0.308 |

| PLC | Model Server | Data Analyzer Server | Software |

|---|---|---|---|

| Siemens S7 416-2 CPU Work memory 8 MB 1st interface MPI/DP 2nd interface PROFIBUS DP | CPU: Intel Core i7 3.0 GHz RAM: 8 GB HDD: 1TB + 4 TB OS: Linux (Redhat) | CPU: Intel Core i7 3.2 GHz RAM: 16 GB HDD: 1 TB GPU: GeForce GTX 1070 OS: Windows 10 | Language: Python 3.8.1 Libraries: pandas 1.3.4, matplotlib 3.4.3, numpy 1.20.3, scikit-learn 0.24.2, seaborn 0.11.2 Jupyter Lab 3.2.1 Jupyter Notebook 6.5.1 |

| process control | model execution (new installation) | model development | |

| Metrics | Total | Operation Types | |

|---|---|---|---|

| Manual | AI | ||

| Heats (Ch’) | 1388 | 775 | 613 |

| Average Tap Temperature | 1575.6 | 1575.9 | 1575.2 |

| MAE | 19.9 | 21.1 | 18.4 (△13%) |

| SD (σ) | 25.9 | 27.9 | 23.1 (△17%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-W.; Seo, B.-G.; Lee, E.-B. Machine Learning-Based Tap Temperature Prediction and Control for Optimized Power Consumption in Stainless Electric Arc Furnaces (EAF) of Steel Plants. Sustainability 2023, 15, 6393. https://doi.org/10.3390/su15086393

Choi S-W, Seo B-G, Lee E-B. Machine Learning-Based Tap Temperature Prediction and Control for Optimized Power Consumption in Stainless Electric Arc Furnaces (EAF) of Steel Plants. Sustainability. 2023; 15(8):6393. https://doi.org/10.3390/su15086393

Chicago/Turabian StyleChoi, So-Won, Bo-Guk Seo, and Eul-Bum Lee. 2023. "Machine Learning-Based Tap Temperature Prediction and Control for Optimized Power Consumption in Stainless Electric Arc Furnaces (EAF) of Steel Plants" Sustainability 15, no. 8: 6393. https://doi.org/10.3390/su15086393

APA StyleChoi, S.-W., Seo, B.-G., & Lee, E.-B. (2023). Machine Learning-Based Tap Temperature Prediction and Control for Optimized Power Consumption in Stainless Electric Arc Furnaces (EAF) of Steel Plants. Sustainability, 15(8), 6393. https://doi.org/10.3390/su15086393